Scandium-containing oxidable die-casting aluminium alloy, preparation method and structural part

A technology for casting aluminum alloys and structural parts, which is applied in the field of aluminum alloys, and can solve problems such as limited application, failure to meet the requirements of mechanical properties of thin-walled parts, and inability to realize oxidation of other colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

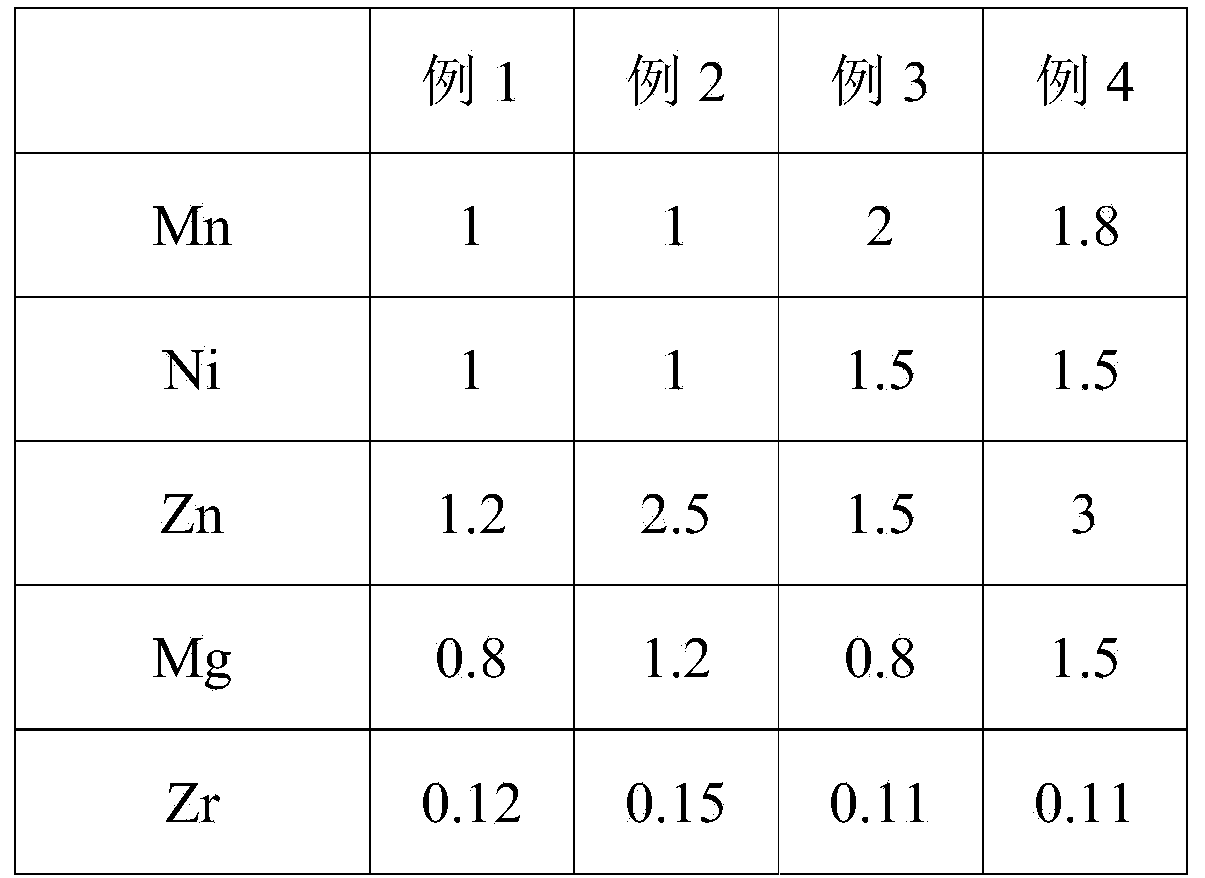

[0022] According to an embodiment of the present invention, a scandium-containing oxidizable die-casting aluminum alloy comprises 1% to 2% of Mn, 1% to 2% of Ni, 1% to 3% of Zn, 0.8% to 2% of Mg, 0.05 %-0.3% Sc, 0.05%-0.2% Zr, and 90%-95% Al. The content of other individual impurities is less than 0.5%. Zn, Mg, Ni, Mn, Sc, and Zr elements are added as aluminum alloy elements at the same time, and formulated according to the above ratio, the prepared alloy can simultaneously realize the comprehensive properties of high strength, anodic oxidation, and die-casting. Zn and Mg are strengthening elements in the alloy composition, mainly forming MgZn2, which can improve the strength of the aluminum alloy. The hot cracking tendency that Zn and Mg exist easil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com