Heatproof magnesium alloy

A magnesium alloy, heat-resistant technology, applied in the field of magnesium alloy, can solve the problems that magnesium alloy cannot meet, achieve excellent mechanical properties, improve high temperature resistance, fluidity and good die-casting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Heat-resistant magnesium alloys are prepared according to the steps described in the above-mentioned process one, and the castings are cast by metal molds. The weight percentages of the magnesium alloys are composed of Zn 0.2%, Zr 0.1%, Y 0.0002%, Nb 0.0002%, Al 0.001%, and the rest are Mg.

[0029] Castings are heat treated.

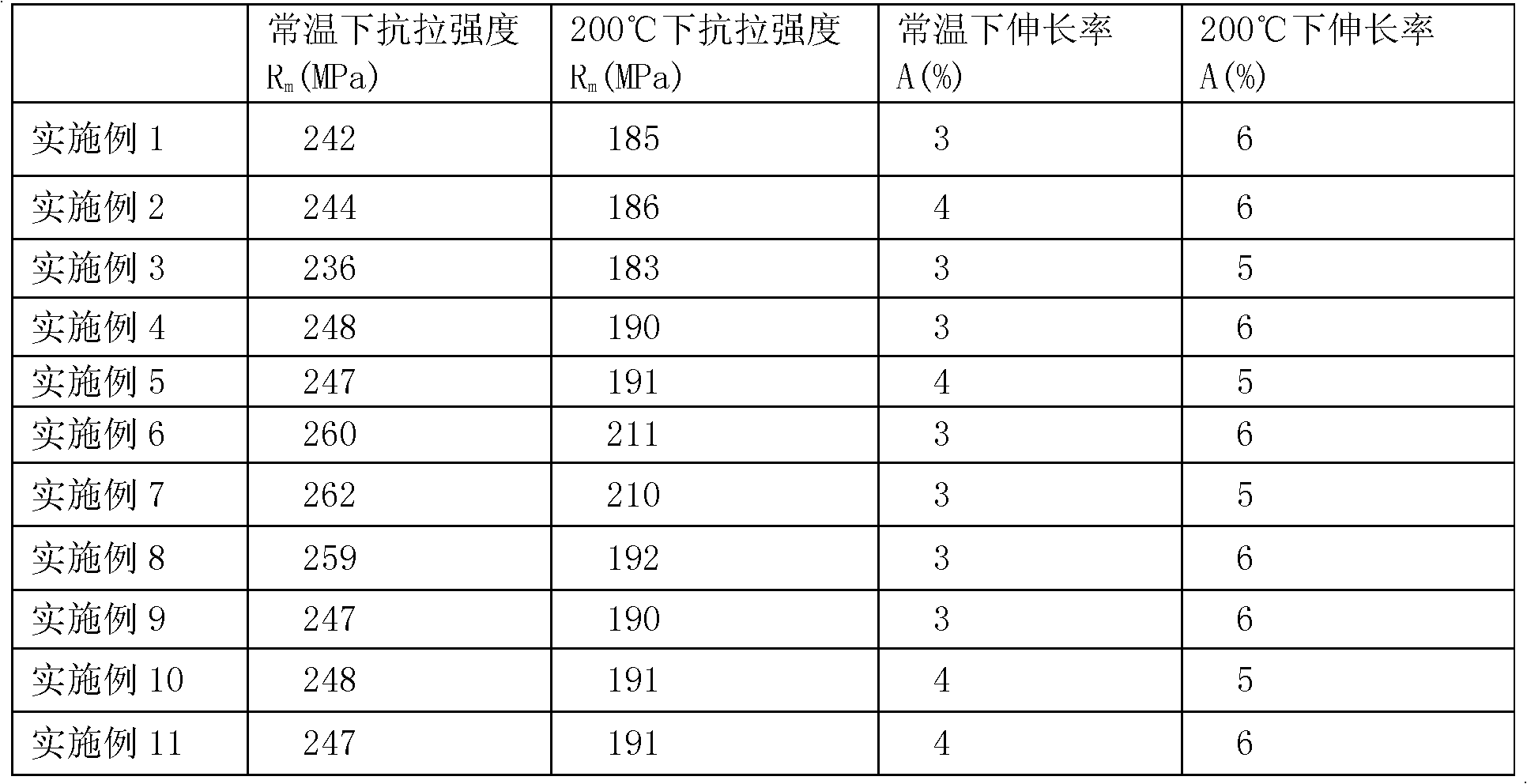

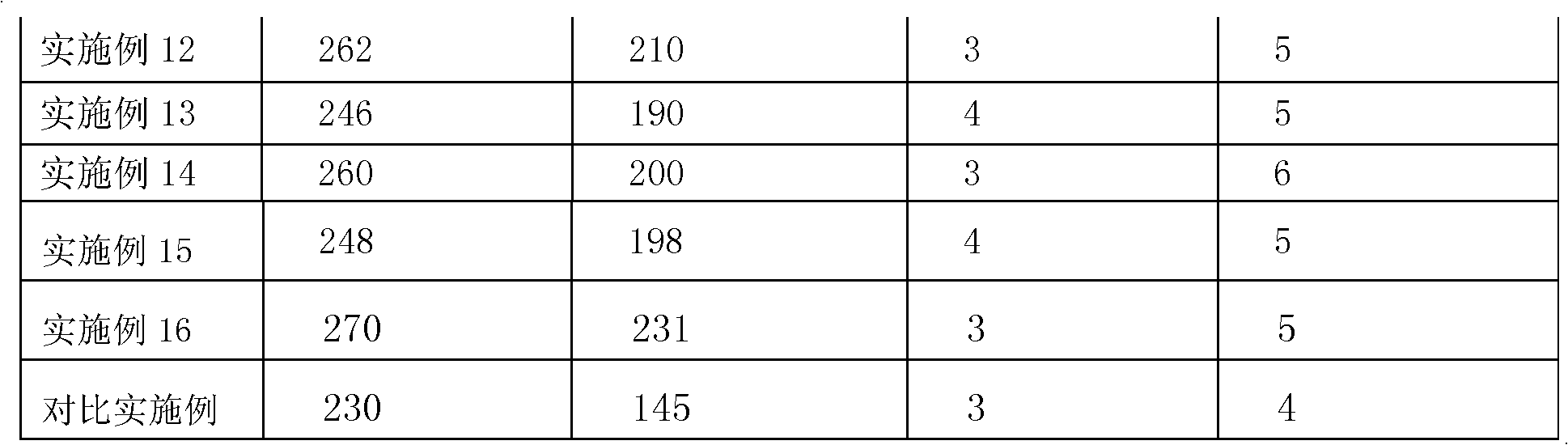

[0030] See Table 1 for the properties of the magnesium alloy castings provided in this example.

Embodiment 2

[0032] Prepare the heat-resistant magnesium alloy according to the steps described in the above process two, the casting adopts semi-solid casting, and the weight percentage of the magnesium alloy is composed of Zn 2%, Zr 1.5%, Sc 8%, Nb 3%, Al 1%, and the rest is Mg.

[0033] Castings are heat treated.

[0034] See Table 1 for the properties of the magnesium alloy castings provided in this example.

Embodiment 3

[0036] The heat-resistant magnesium alloy is prepared according to the steps described in the above-mentioned process. The casting adopts high-pressure die-casting. The weight percentage of the heat-resistant magnesium alloy is composed of Zn 9%, Zr 2%, Sm 16%, Nb 4%, Al 1.49%, and the rest is Mg .

[0037] See Table 1 for the properties of the magnesium alloy castings provided in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com