Component-based special steel performance evaluation method and system

A technology for performance and special steel, applied in the field of composition-based performance evaluation of special steel, which can solve the problem of difficulty in ensuring the combination of special steel preparation process parameters and application scenarios.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

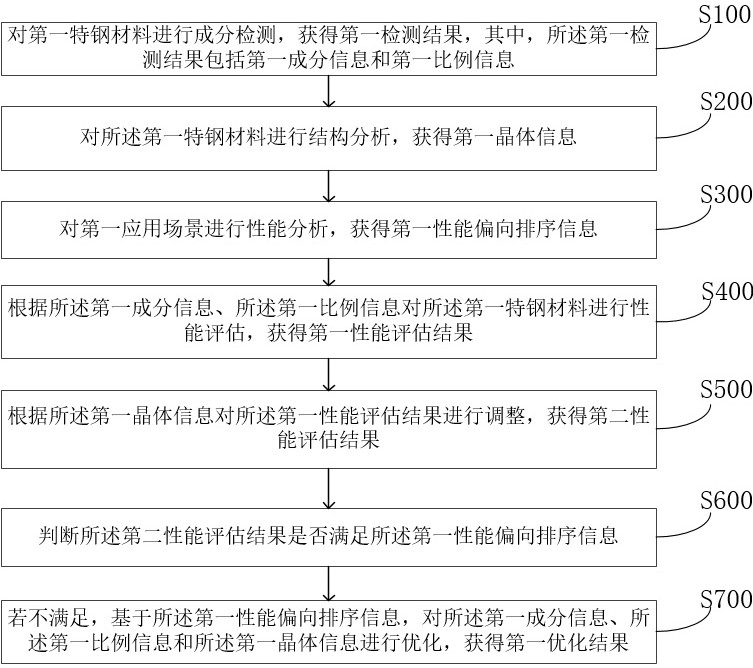

[0026] like figure 1 As shown, the embodiment of the present application provides a composition-based performance evaluation method for special steel, wherein the method includes:

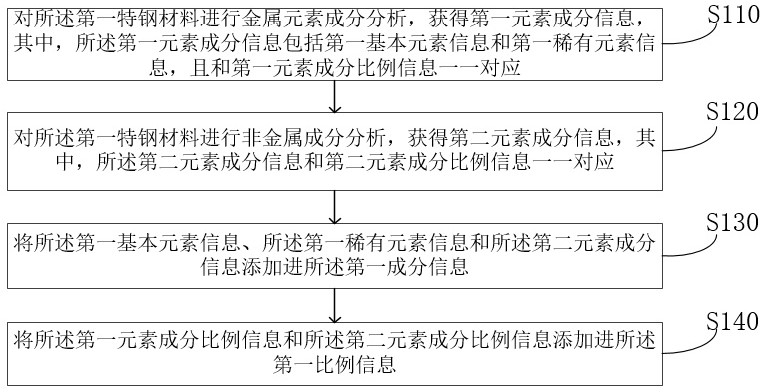

[0027] S100: Perform component detection on the first special steel material to obtain a first detection result, wherein the first detection result includes first component information and first ratio information;

[0028] Specifically, the first special steel material refers to the special steel used in various fields and scenarios, including but not limited to: machinery, automobile, military industry, chemical industry, home appliances, ships, transportation, railways, and emerging industries. Steel; low-end special steel products mainly composed of high-quality carbon structural steel; mid-end special steel products represented by alloy steel; high-end special steel products represented by stainless steel, tool steel, die steel and high-speed steel, etc. Material.

[0029] The first detection...

Embodiment 2

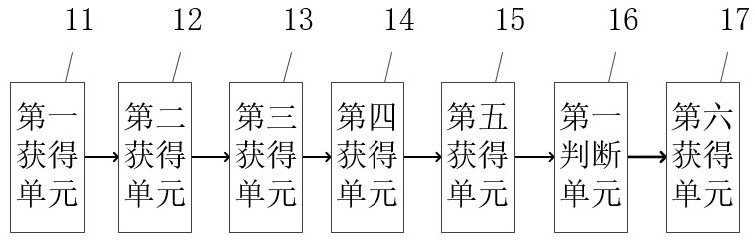

[0094] Based on the same inventive concept as a composition-based performance evaluation method for special steel in the foregoing embodiment, such as image 3 As shown, the embodiment of the present application provides a composition-based special steel performance evaluation system, wherein the system includes:

[0095] The first obtaining unit 11 is used to perform component detection on the first special steel material, and obtain a first detection result, wherein the first detection result includes first component information and first ratio information;

[0096] The second obtaining unit 12 is used to perform structural analysis on the first special steel material to obtain first crystal information;

[0097] A third obtaining unit 13, configured to perform performance analysis on the first application scenario, and obtain first performance preference ranking information;

[0098]a fourth obtaining unit 14, configured to perform performance evaluation on the first speci...

Embodiment 3

[0135] Based on the same inventive concept as the composition-based performance evaluation method for special steel in the foregoing embodiment, the embodiment of the present application provides a computer-readable storage medium, where a computer program is stored on the storage medium, and the computer program is When executed by the processor, the method described in any one of the embodiments is implemented.

[0136] Exemplary Electronics

[0137] Reference below Figure 4 to describe the electronic device of the embodiments of the present application.

[0138] Based on the same inventive concept as the composition-based performance evaluation method for special steel in the foregoing embodiment, the embodiment of the present application further provides an electronic device, including: a processor, wherein the processor is coupled with a memory, and the memory is used for A program is stored, and when the program is executed by the processor, the system is made to exec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com