Material organization predict device, product fabrication method, and material organization predict method

一种预测装置、预测方法的技术,应用在材料检验品、使用数字装置的温度控制、制造工具等方向,能够解决难以利用多相场法、难定量评价、预测精度不够等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

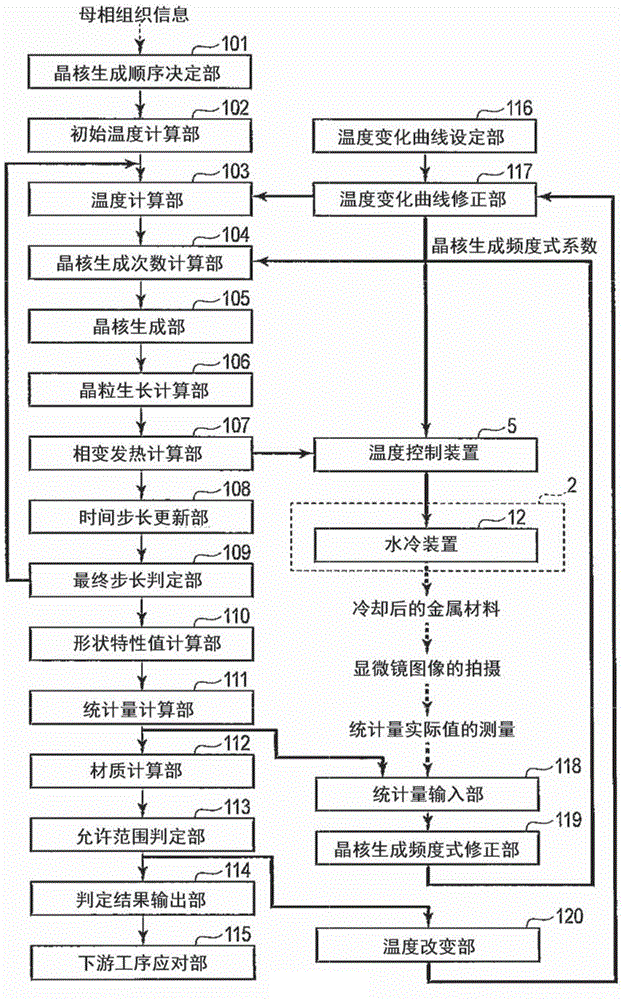

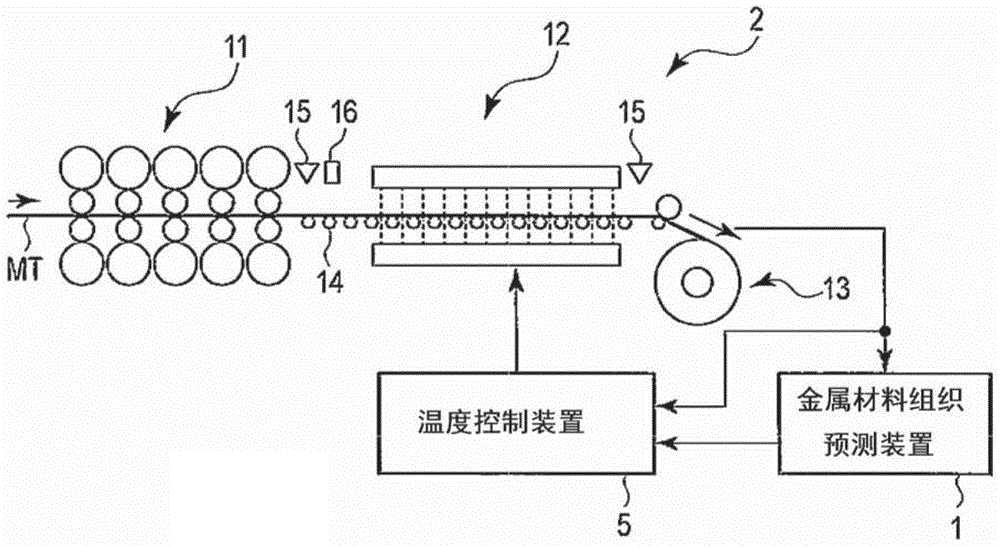

[0026] figure 1 It is a configuration diagram showing the configuration of the texture prediction device 1 according to the embodiment of the present invention. In addition, the same reference numerals are assigned to the same parts in the drawings and their detailed descriptions are omitted, and the explanations are mainly focused on different parts.

[0027] First, a general metal material processing line to which the material structure predicting device 1 is applied will be described.

[0028] At least one of heating and cooling of the metal material is performed on the metal material processing line.

[0029] The heating device includes an induction heating device, a gas heating device, and the like. The cooling device has a water cooling device, an oil cooling device or a forced air cooling device and the like. There may be a plurality of the above-mentioned means. The arrangement order of the heating means and the cooling means is arbitrary.

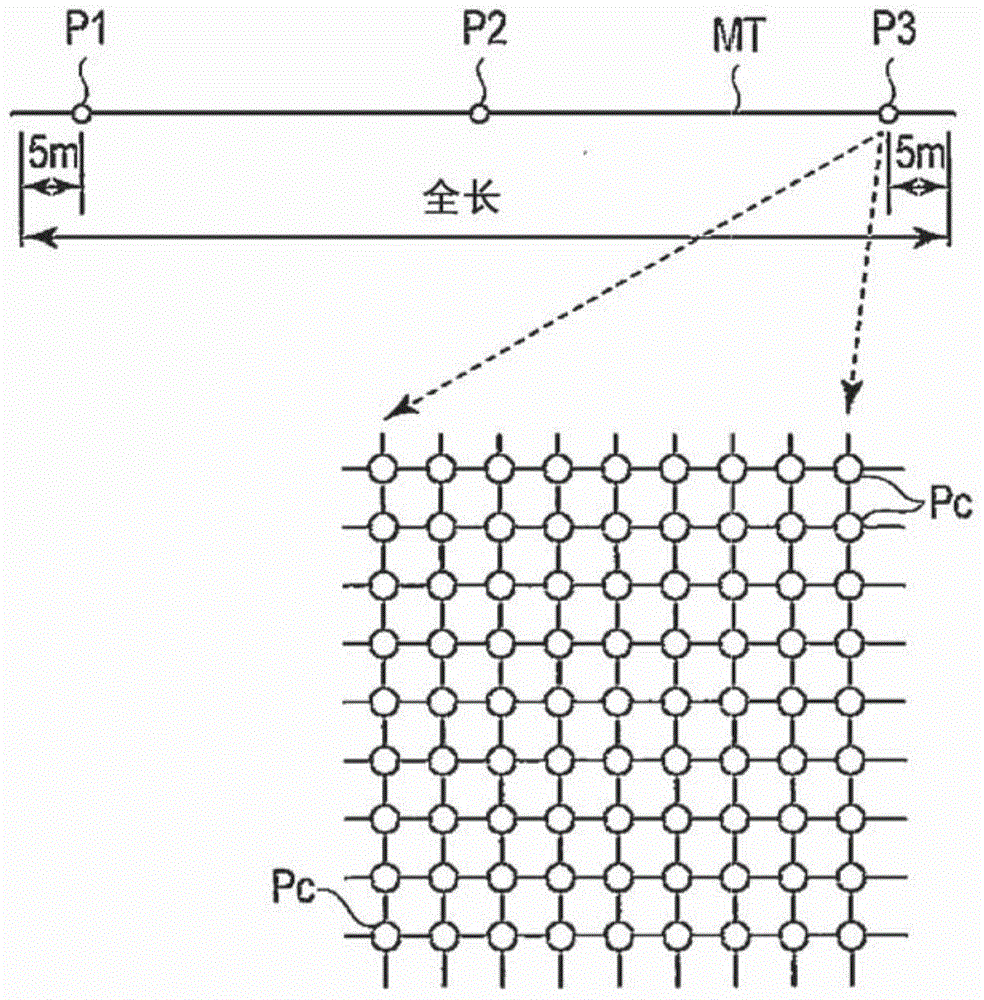

[0030] Here, a configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com