Metallographic corrosive agent and metallographic display method for primary banded structure of steel

A technology of strip structure and display method, applied in the field of metallographic inspection, can solve the problems of inability to corrode and display clear primary strip structure, primary strip structure corrosion and difficult display, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Preparation of metallographic etchant for primary banded structure of steel according to the present invention: 25 ml of water, 25 ml of methanol, 20 g of copper chloride and 1 ml of hydrochloric acid with a mass percentage concentration of 36w% are uniformly mixed to obtain the metallographic etchant for primary banded structure of steel, and put into Reserve in container.

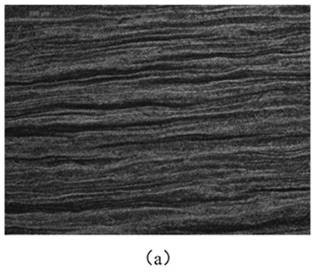

[0074] (1) Take 20CrMnTi steel (after heat treatment: heat to 930 degrees in the austenite zone, keep warm for 30 minutes, and then carry out water cooling treatment), obtain a longitudinal section along the direction parallel to the rolling direction of the steel, and obtain a 20CrMnTi steel sample. After inlaying, grinding and polishing, until the polished surface is smooth and free of obvious scratches and stains;

[0075] (2) adopt the metallographic etchant of the primary strip structure of the steel prepared above, the polished surface of the steel sample obtained in step (1) is rubbed for 10...

Embodiment 2

[0079] Preparation of metallographic etchant for primary banded structure of steel according to the present invention: 35 ml of water, 35 ml of methanol, 30 g of copper chloride and 3 ml of hydrochloric acid with a mass percent concentration of 38w% are uniformly mixed to obtain the metallographic etchant for primary banded structure of steel, and put into Reserve in container.

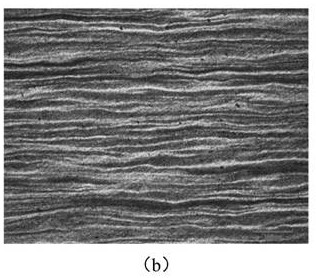

[0080] (1) Take Q420 steel, obtain a longitudinal section parallel to the rolling direction of the steel, and obtain a Q420 steel sample, which is inlaid, ground and polished until the polished surface is smooth and free of obvious scratches and stains;

[0081] (2) adopt the metallographic etchant of steel material primary strip structure of above-mentioned preparation, the polishing surface of the steel sample that step (1) obtains is carried out drop etching treatment 8 seconds, and polishing surface appears red, obtains metallographic corrosion sample;

[0082] (3) the metallographic corrosion sam...

Embodiment 3

[0085] Preparation of metallographic etchant for primary banded structure of steel according to the present invention: 30ml of water, 30ml of methanol, 25g of copper chloride and 2ml of hydrochloric acid with a mass percentage concentration of 36w% are uniformly mixed to obtain the metallographic etchant for primary banded structure of steel, and put into Reserve in container.

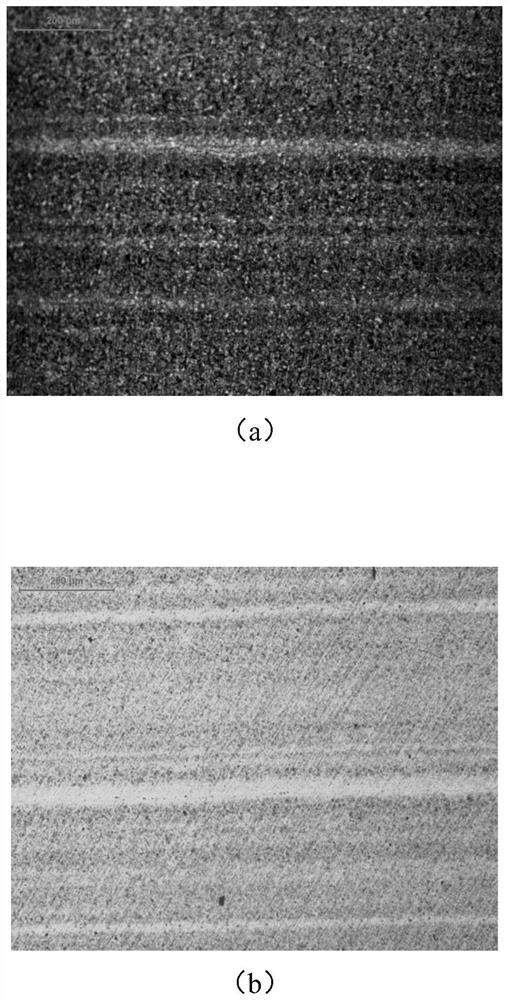

[0086] (1) Take Q420 steel, obtain a longitudinal section parallel to the rolling direction of the steel, and obtain a Q420 steel sample, which is inlaid, ground and polished until the polished surface is smooth and free of obvious scratches and stains;

[0087] (2) The polished surface of the steel sample that step (1) obtains is immersed in the metallographic etchant of the primary banded structure of the above-mentioned steel, and the polished surface of the steel sample is perpendicular to the liquid level of the metallographic etchant of the primary banded structure of the steel, and is carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com