Device and method of detecting magnetic characteristic change for long material

a technology of magnetic characteristic change and long material, applied in the direction of magnetic property measurement, hysteresis curve measurement, testing metal structures, etc., can solve the problem of difficult detection of poorly quenched portion generated in a part of a cross-section, pipe after cutting cannot be treated as products, and all pipes cannot be inspected, so as to achieve accurate detection of portions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

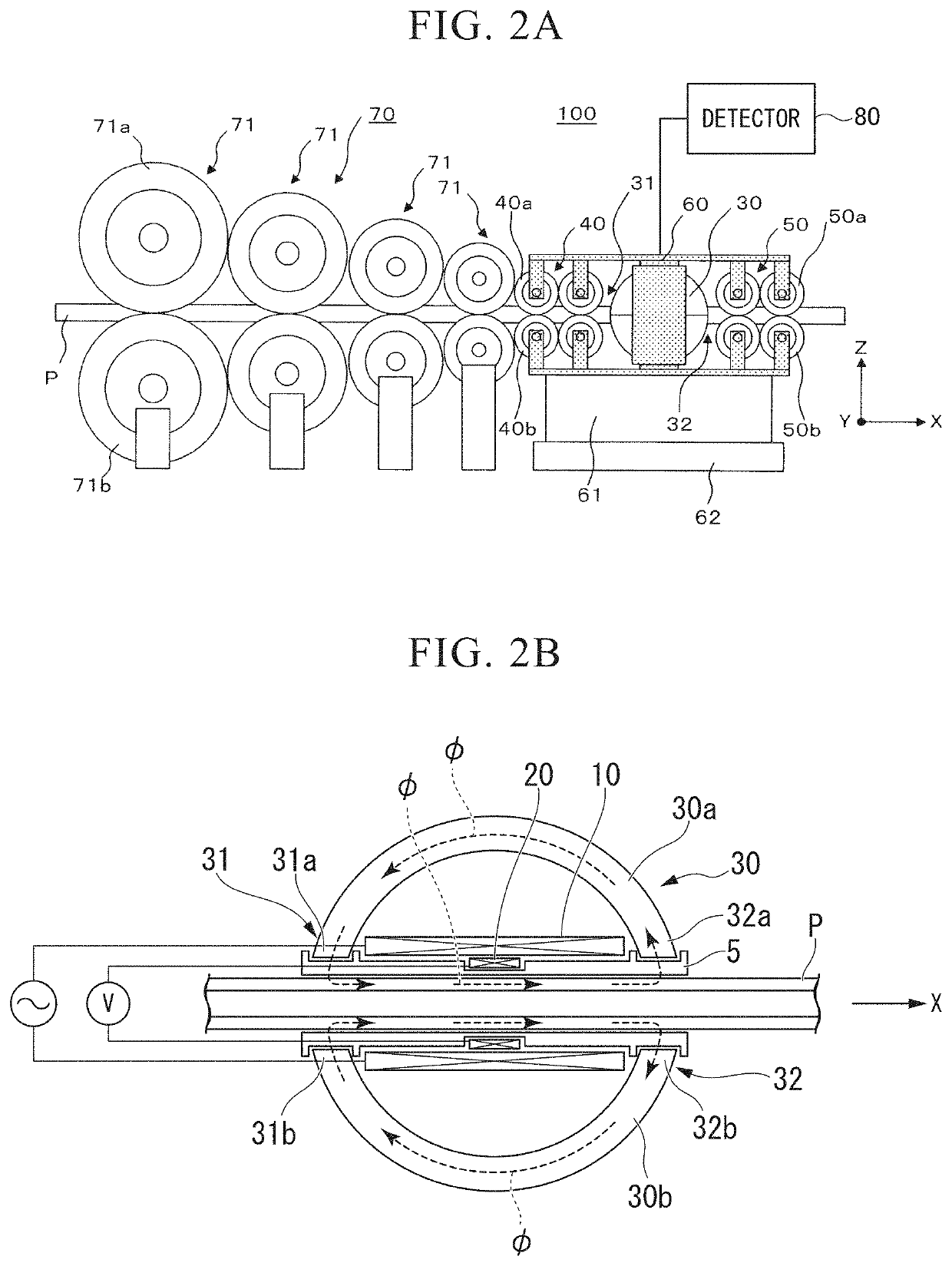

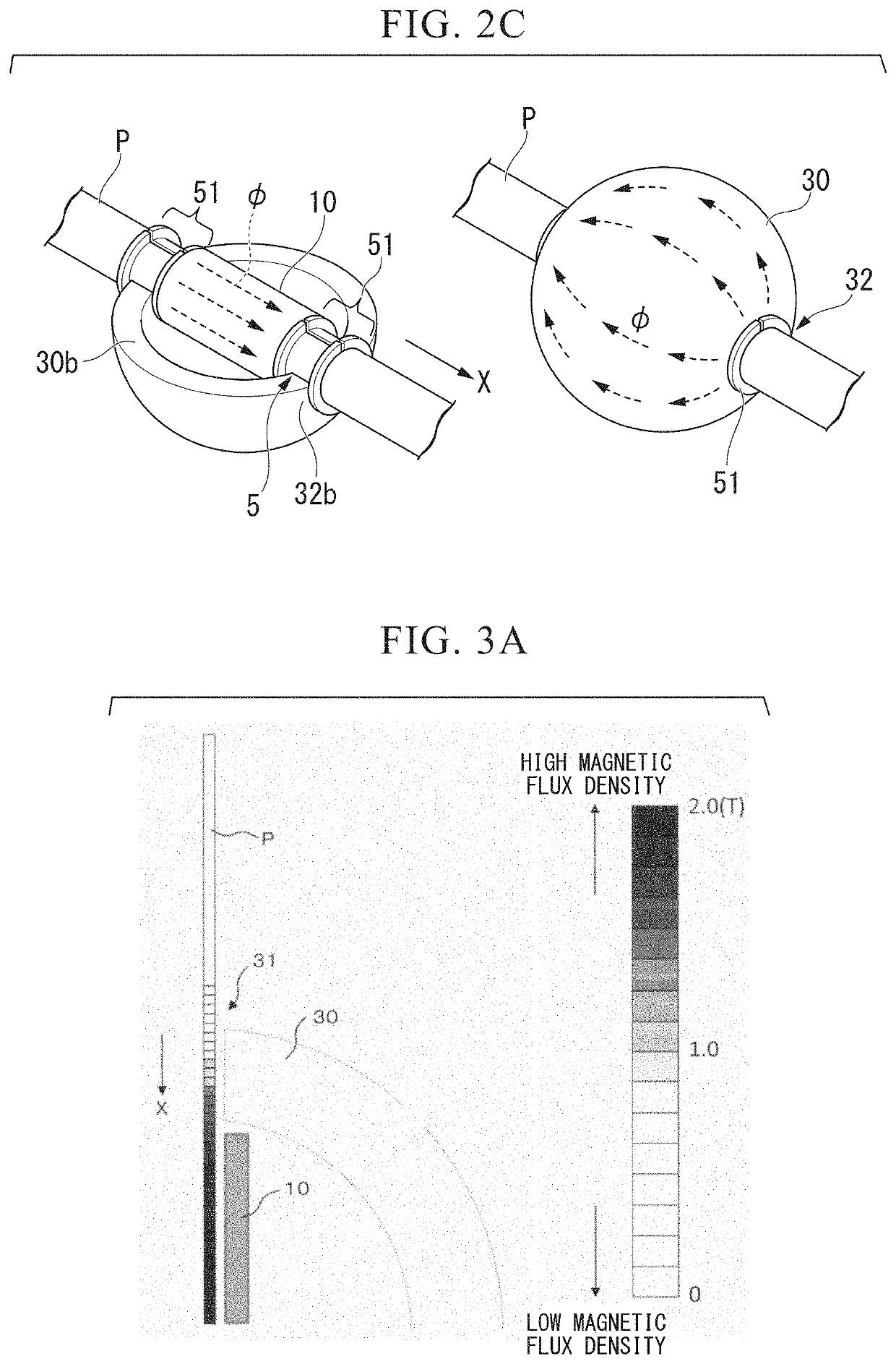

[0158]Hereinafter, an example of results obtained by inspecting a normal pipe and a pipe having portions where magnetic characteristics change using the device of detecting magnetic characteristic change 100 according to this embodiment under the following conditions (1) to (11) will be described.

[0159]Pipes P as inspection targets are eight pipes made of 0.15% carbon steel. In one of them, magnetic characteristic was changed by forcibly forming a poorly quenched portion by partially changing a cooling condition.

[0160](1) Pipe Size: outer diameter 35 mm, thickness 3.5 mm

[0161](2) Pipe Conveyance Speed: 300 mm / sec

[0162](3) Material of Yoke Member 30: ultralow carbon steel having carbon concentration of 0.05%

[0163](4) Size of Yoke Member 30: spherical shape having outer diameter of 160 mm and thickness of 30 mm

[0164](5) Minimum Gap between Yoke Member 30 and Outer Surface of Pipe: 10 mm

[0165](6) Size of Exciting Coil 10: inner diameter 58 mm, length 95 mm

[0166](7) Size of Detecting Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| magnetic characteristic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com