Metallographic corrosion method for high-carbon martensitic stainless steel grain boundary

A carbon martensitic and metallographic corrosion technology, applied in the field of stainless steel metallographic analysis and detection, can solve the problems of complicated operation, no high-carbon martensitic stainless steel grain boundary metallographic corrosion method, high cost, short corrosion time, high cost and high cost. Effective grain boundary corrosion method, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

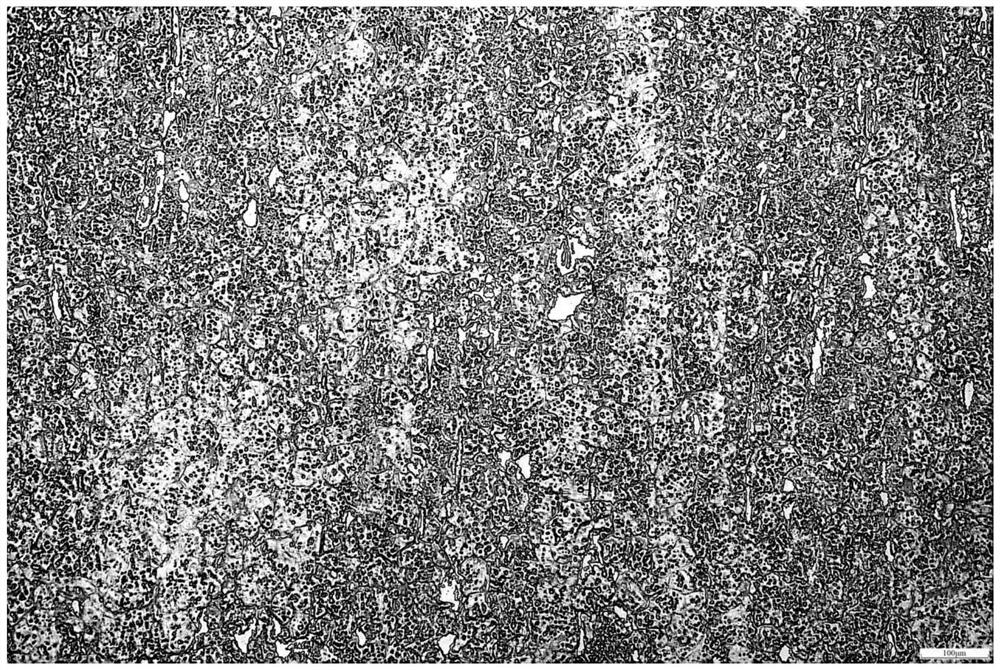

[0044] Embodiment 1 adopts the inventive method to corrode 9Cr18Mo high-carbon martensitic stainless steel

[0045] (1) Sample treatment: 9Cr18Mo high-carbon martensitic stainless steel metallography is coarsely ground with water sandpaper (400 mesh), finely ground with 600 / 800 / 1000 mesh metallographic sandpaper, polished with diamond abrasive paste, and cleaned with ultrasonic cleaning agent + alcohol After rinsing, dry with a hair dryer to obtain a bright polished surface without scratches.

[0046] (2) Use a 200ml beaker to weigh 4g of picric acid on an electronic balance, use a measuring cylinder to take 100ml of analytically pure grade alcohol and pour it into the beaker, and then remove the measuring cylinder to take 5ml of concentrated hydrochloric acid with a mass fraction of 30% and drop it into the beaker. After the rod is stirred, add 5ml of detergent to the solution after the dissolution, and continue to stir evenly. Pour the prepared reagent into the volumetric fl...

Embodiment 2

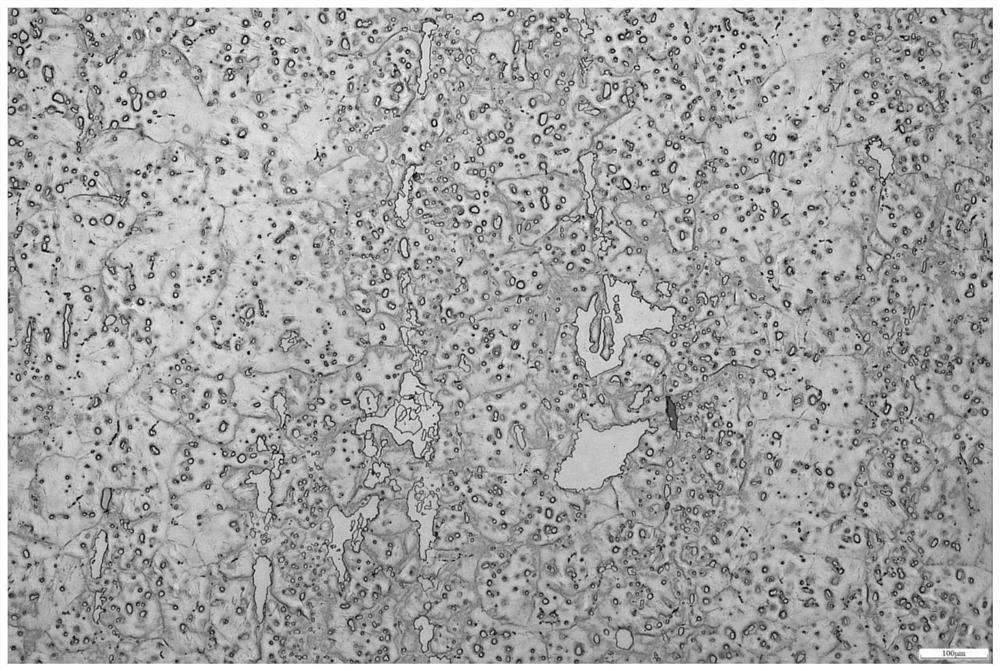

[0050] Embodiment 2 adopts the inventive method to corrode 6Cr18Mo high-carbon martensitic stainless steel

[0051] (1) Sample treatment: 6Cr18Mo high-carbon martensitic stainless steel metallography is rough ground with water sandpaper (400 mesh), finely ground with 600 / 800 / 1000 mesh metallographic sandpaper, polished with diamond abrasive paste, cleaned with ultrasonic cleaning agent + alcohol After rinsing, dry with a hair dryer to obtain a bright polished surface without scratches.

[0052] (2) Use a 200ml beaker to weigh 1g of picric acid on an electronic balance, use a measuring cylinder to take 100ml of analytically pure grade alcohol and pour it into the beaker, and then remove the measuring cylinder to take 5ml of concentrated hydrochloric acid with a mass fraction of 30% and drop it into the beaker. After the rod is stirred, add 2ml of detergent to the solution after the dissolution, and continue to stir evenly. Pour the prepared reagent into the volumetric flask and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com