Method for preparing two-dimensional nanosheet crystal Ti3C2 alkene

A two-dimensional nano and lamella technology, applied in the direction of carbide, titanium carbide, etc., can solve the problems of long reaction time, time and energy consumption, and low efficiency, and achieve the goal of improving reaction efficiency, shortening corrosion time, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

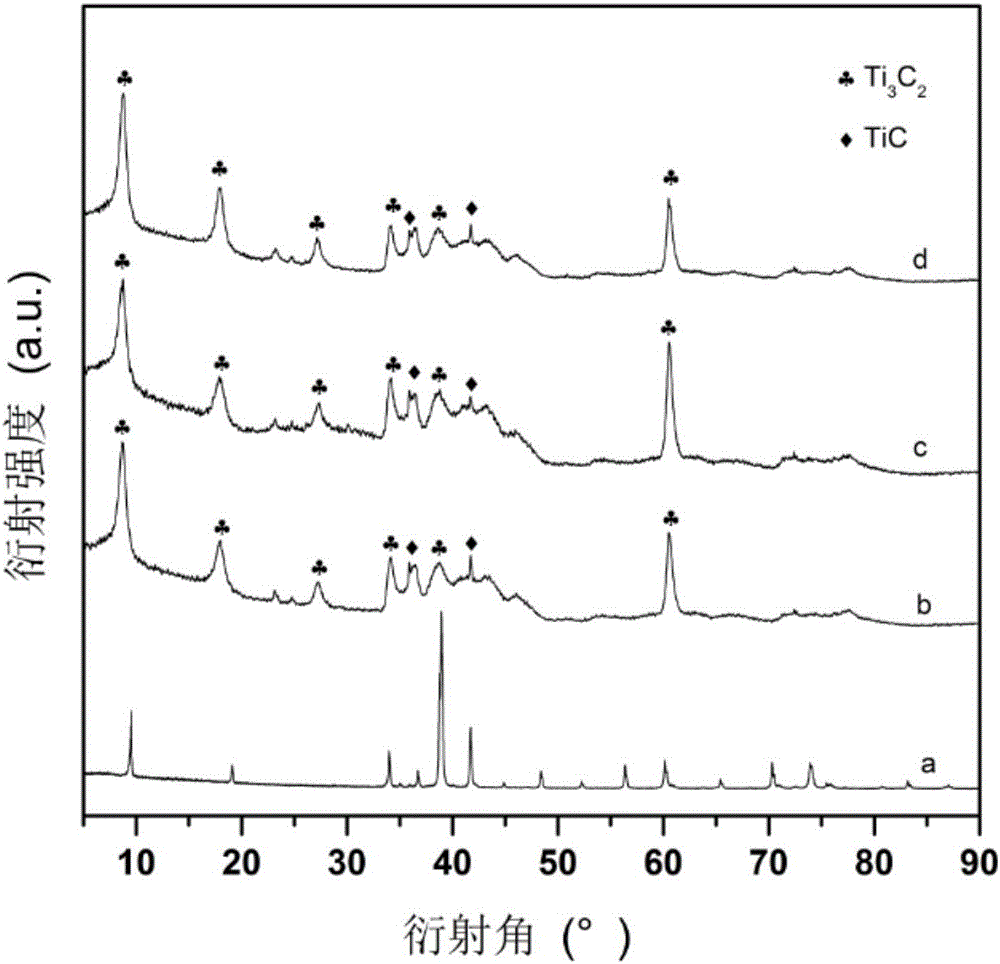

Embodiment 1

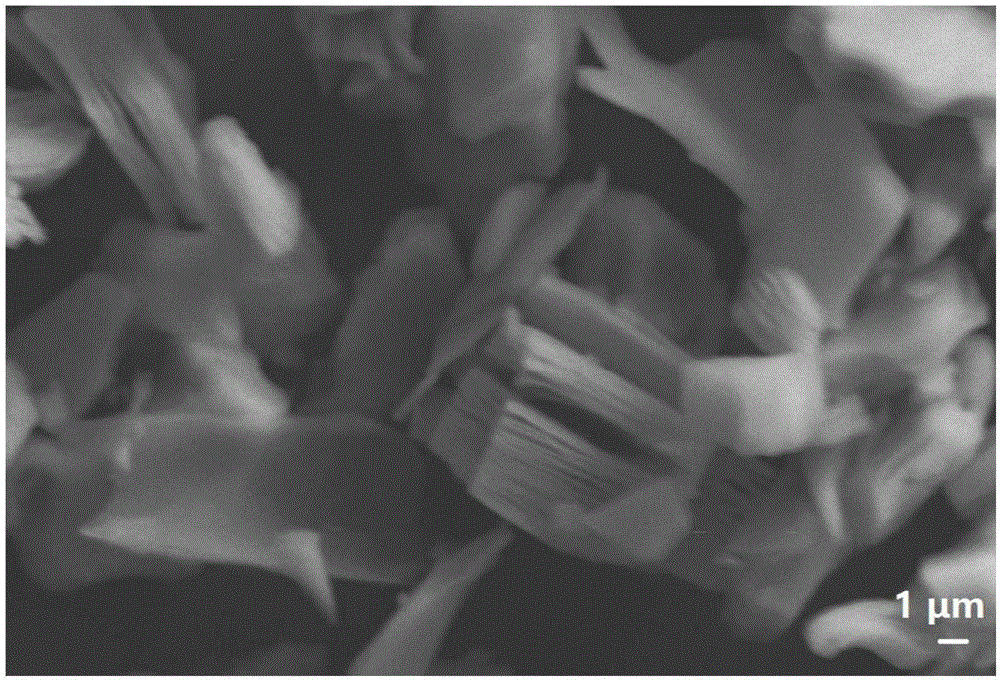

[0036] A two-dimensional nanosheet Ti 3 C 2 The preparation method of alkenes, comprises the steps:

[0037] 1) High-purity Ti 3 AlC 2 The block is mechanically crushed and ground and passed through a 200-mesh sieve to obtain Ti with a particle size of less than 75 μm 3 AlC 2 raw material powder;

[0038] 2) Add 2g of Ti 3 AlC 2The raw material powder and 60 mL of HF acid with a mass fraction of 35% were added to a tetrafluoroethylene beaker and sealed, then magnetically stirred, and heated to 50°C in a water bath, and the magnetic stirring reaction was continued at 50°C for 0.5h; get a liquid mixture;

[0039] 3) The liquid mixture is centrifuged several times with a centrifuge with a rotating speed of 4000rpm, and after each centrifugation, the sediment and water are mixed and ultrasonicated for 3-5min, and after centrifugation until the pH value of the supernatant is 5-7, Then wash twice with absolute ethanol to obtain the crude product.

[0040] 4) Dry the crude ...

Embodiment 2

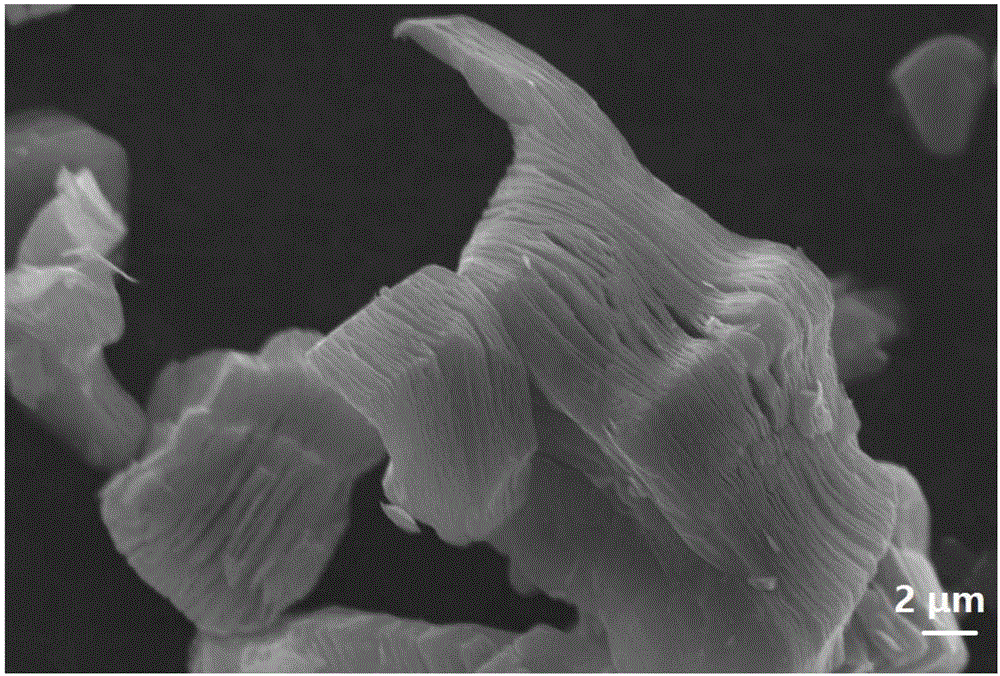

[0044] A two-dimensional nanosheet Ti 3 C 2 The preparation method of alkenes, comprises the steps:

[0045] 1) High-purity Ti 3 AlC 2 The block is mechanically crushed and ground and passed through a 200-mesh sieve to obtain Ti with a particle size of less than 75 μm. 3 AlC 2 raw material powder;

[0046] 2) Add 0.5g of Ti 3 AlC 2 The raw material powder and 60mL of HF acid with a mass fraction of 30% were added to a tetrafluoroethylene beaker and sealed, then magnetically stirred, and heated to 40°C in a water bath, and the magnetic stirring reaction was continued at 40°C for 2h; liquid mixture;

[0047] 3) The liquid mixture is centrifuged several times with a centrifuge with a rotating speed of 4000rpm, and after each centrifugation, the sediment and water are mixed and ultrasonicated for 3-5min, and after centrifugation until the pH value of the supernatant is 5-7, Then wash twice with absolute ethanol to obtain the crude product.

[0048] 4) Dry the crude produ...

Embodiment 3

[0052] A two-dimensional nanosheet Ti 3 C 2 The preparation method of alkenes, comprises the steps:

[0053] 1) High-purity Ti 3 AlC 2 The block is mechanically crushed and ground and passed through a 200-mesh sieve to obtain Ti with a particle size of less than 75 μm. 3 AlC 2 raw material powder;

[0054] 2) Add 2.5g of Ti 3 AlC 2 The raw material powder and 60mL of HF acid with a mass fraction of 30% were added to a tetrafluoroethylene beaker and sealed, then magnetically stirred, and heated to 50°C in a water bath, and the magnetic stirring reaction was continued for 1h under the condition of 50°C; liquid mixture;

[0055] 3) The liquid mixture is centrifuged several times with a centrifuge with a rotating speed of 4000rpm, and after each centrifugation, the sediment and water are mixed and ultrasonicated for 3-5min, and after centrifugation until the pH value of the supernatant is 5-7, Then wash twice with absolute ethanol to obtain the crude product.

[0056] 4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com