Patents

Literature

65results about How to "Guaranteed stirring efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

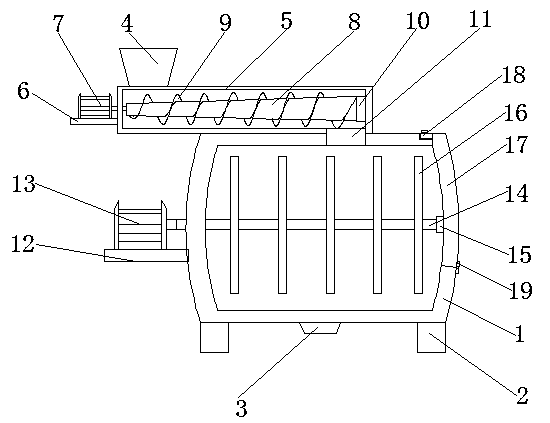

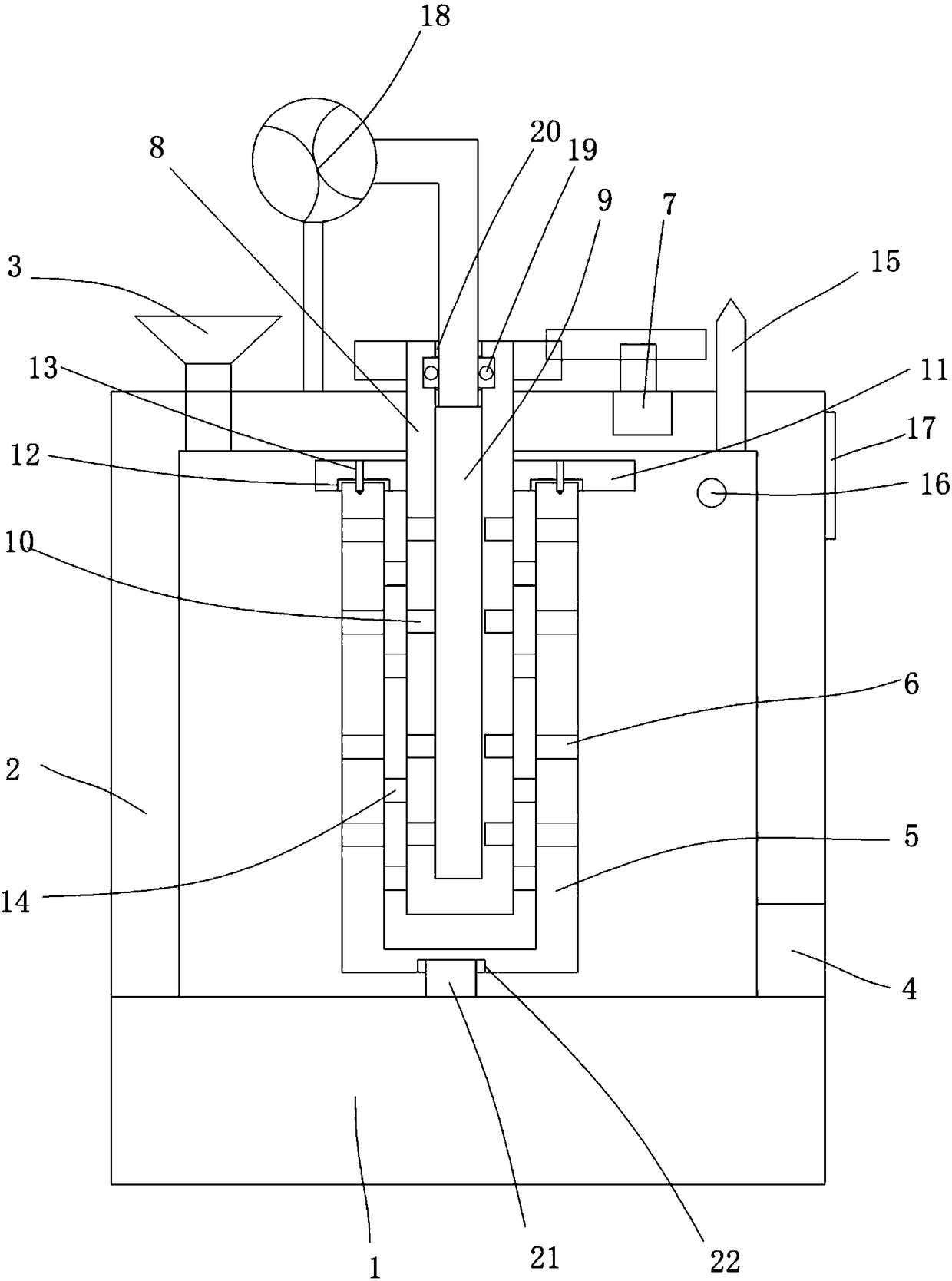

High-efficiency agitation device for chemical production

InactiveCN106378029AQuality assuranceQuality improvementTransportation and packagingRotary stirring mixersHelical bladeIron removal

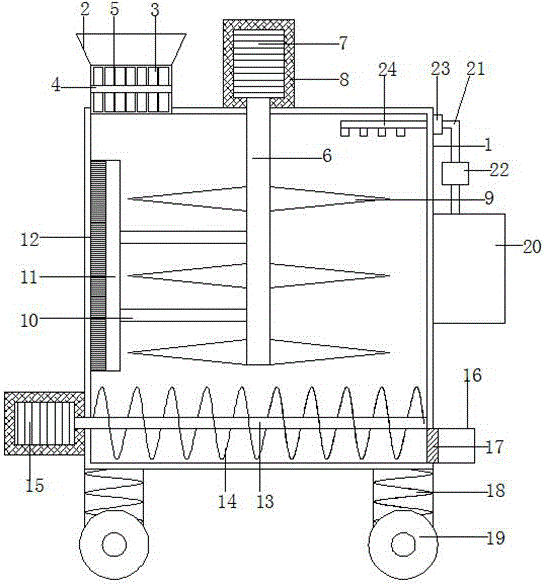

The invention discloses a high-efficiency agitation device for chemical production. The high-efficiency agitation device comprises an agitation barrel, wherein the left end of the upper side of the agitation barrel is provided with a material feeding hopper; the lower side of the material feeding hopper is connected with an iron removal cavity; an iron removal rotating shaft is horizontally arranged in the center of the interior of the iron removal cavity; the outer wall of the iron removal rotating shaft is provided with permanent magnet sheets in a longitudinal symmetry manner. By using a high-efficiency pre-crushed chemical material agitator, the iron removal can be carried out on a raw material of a chemical material; in an agitation process, the scraping and the washing can be carried out on the chemical material, which is adhered to an inner wall, by a scraping and washing hairbrush; the waste which is caused as the chemical material is adhered to the inner wall is avoided; the material discharge can be carried out when a helical blade positively rotates; the agitation and the mixing can be carried out on the chemical material at a bottom when the helical blade negatively rotates; the agitation effect and efficiency are improved; the automatic and quantitative water addition can be realized; the quality of the material is guaranteed; the effective shock absorption can be realized by a spring pillar; further, the movement is more convenient and quicker; the practicability and the convenience are high.

Owner:GUANGXI UNIV

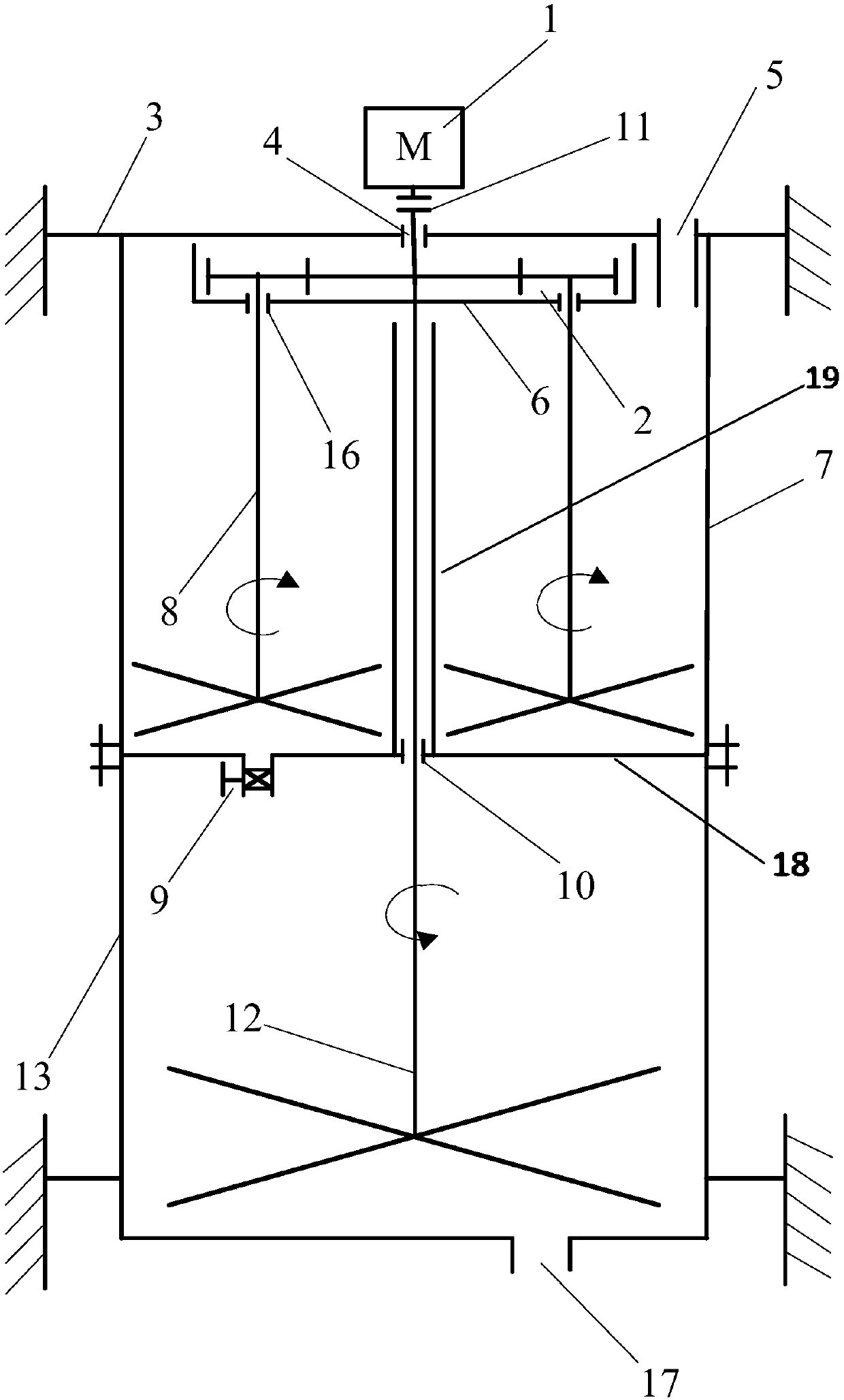

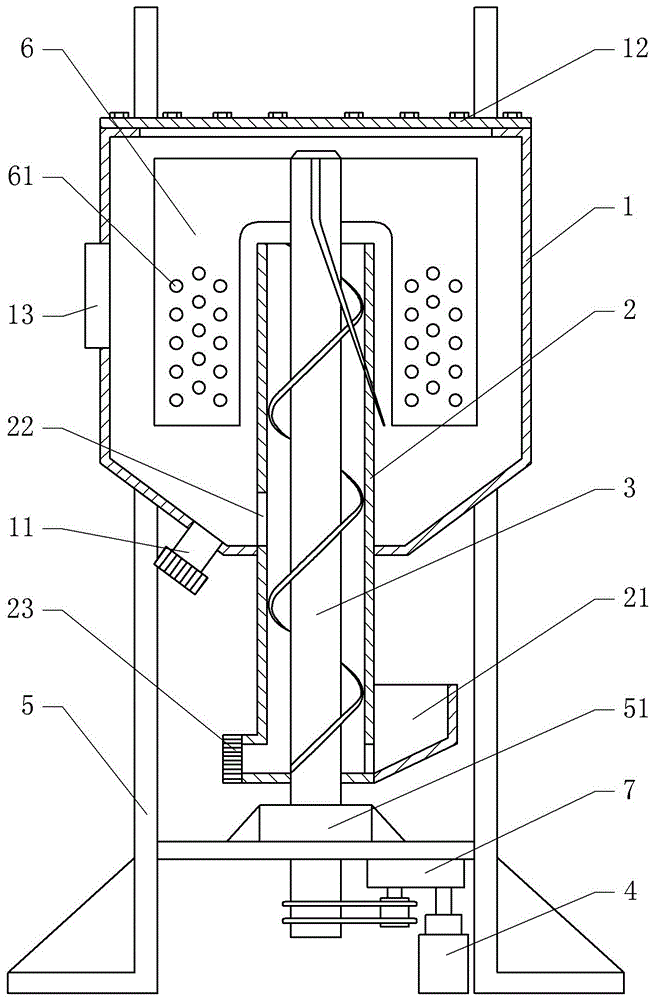

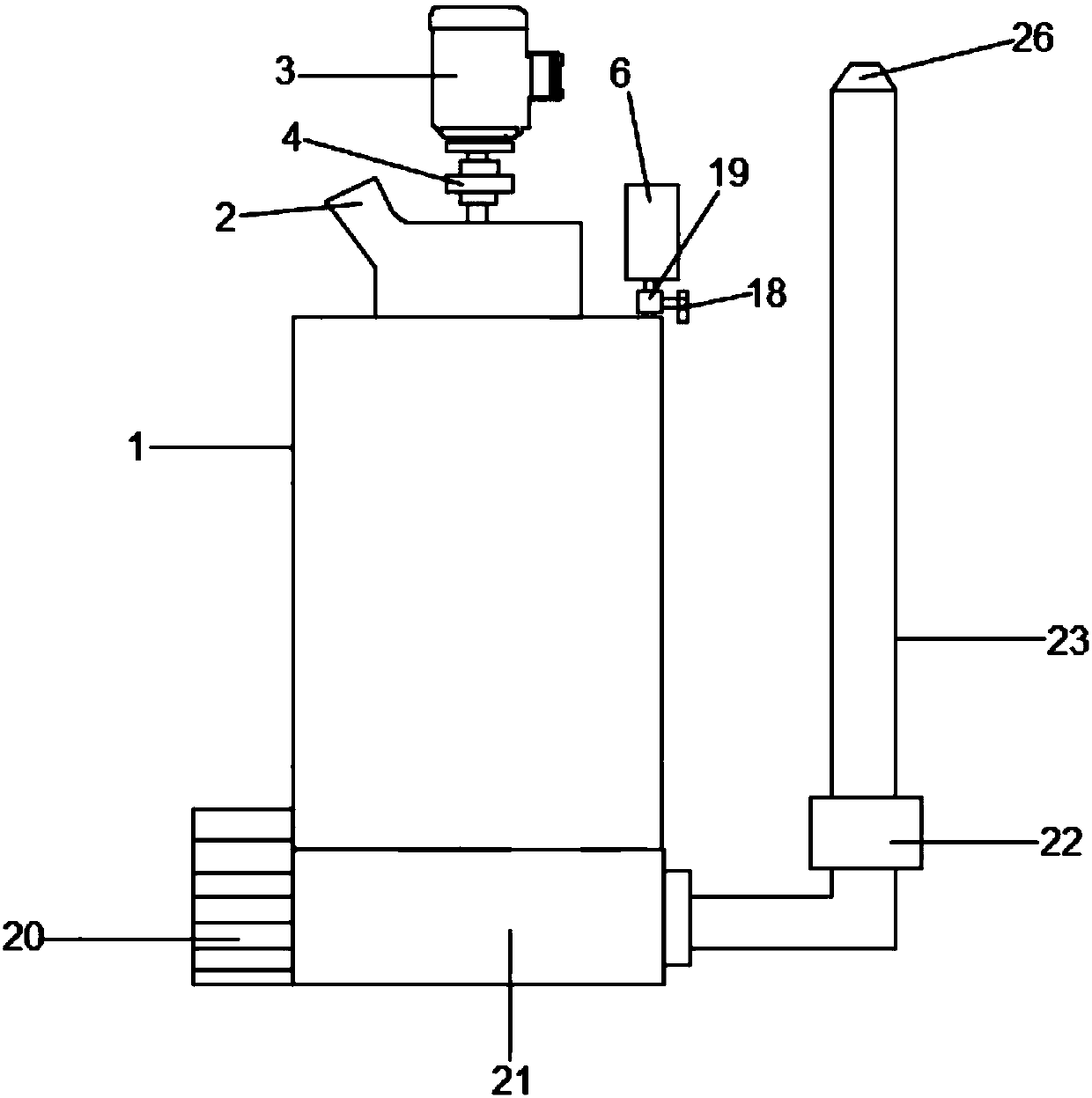

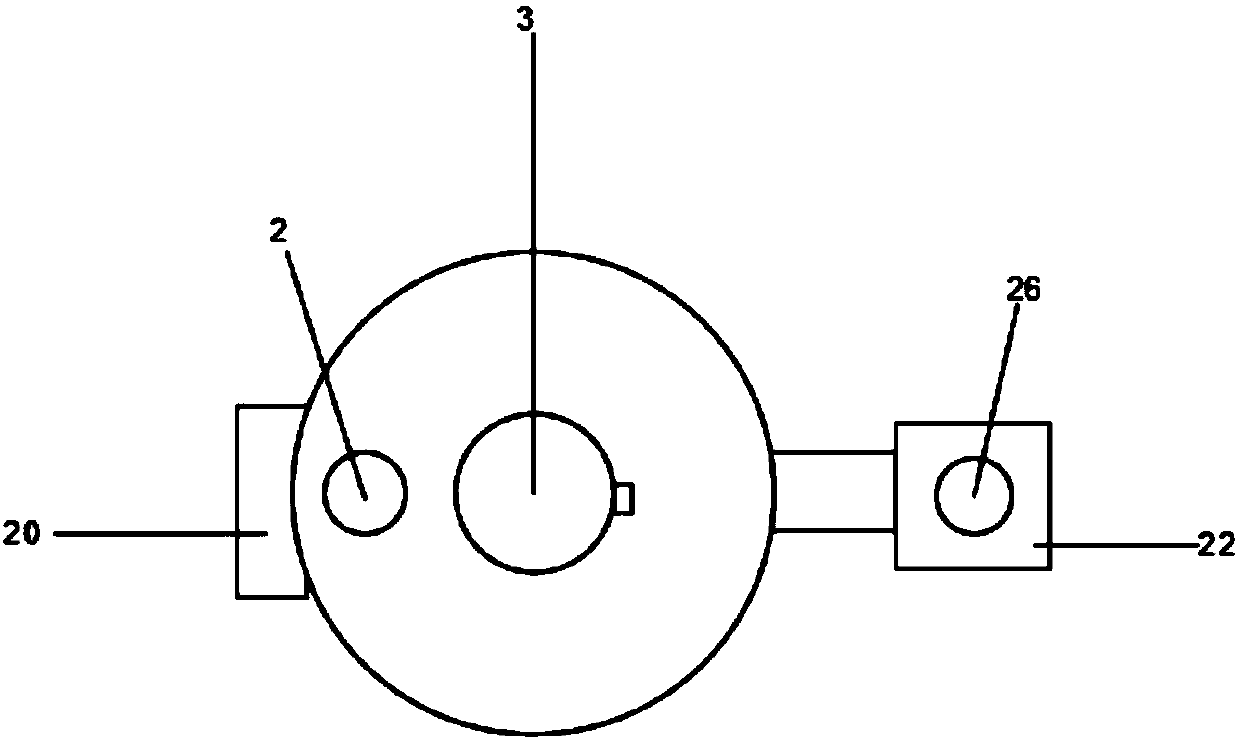

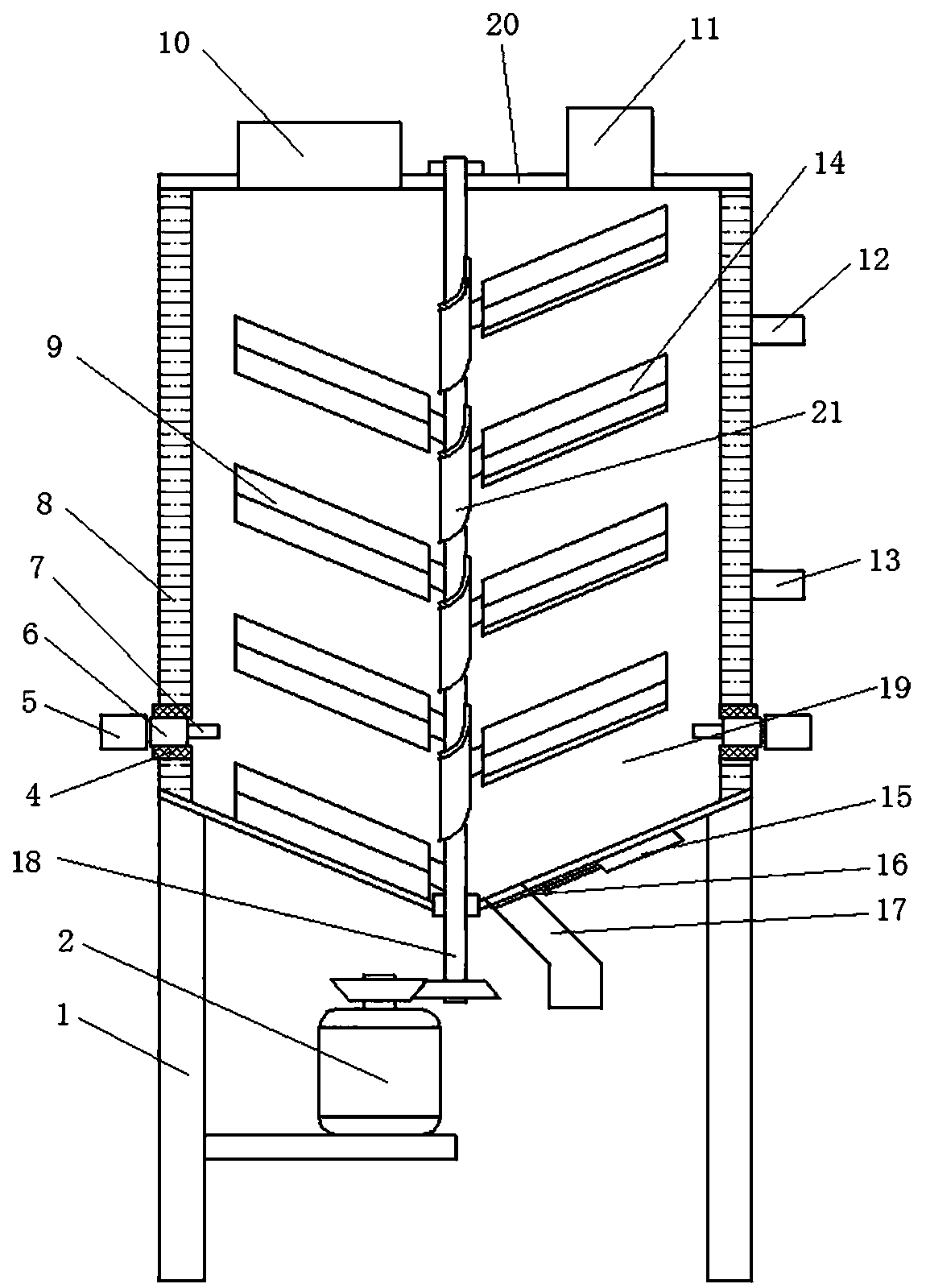

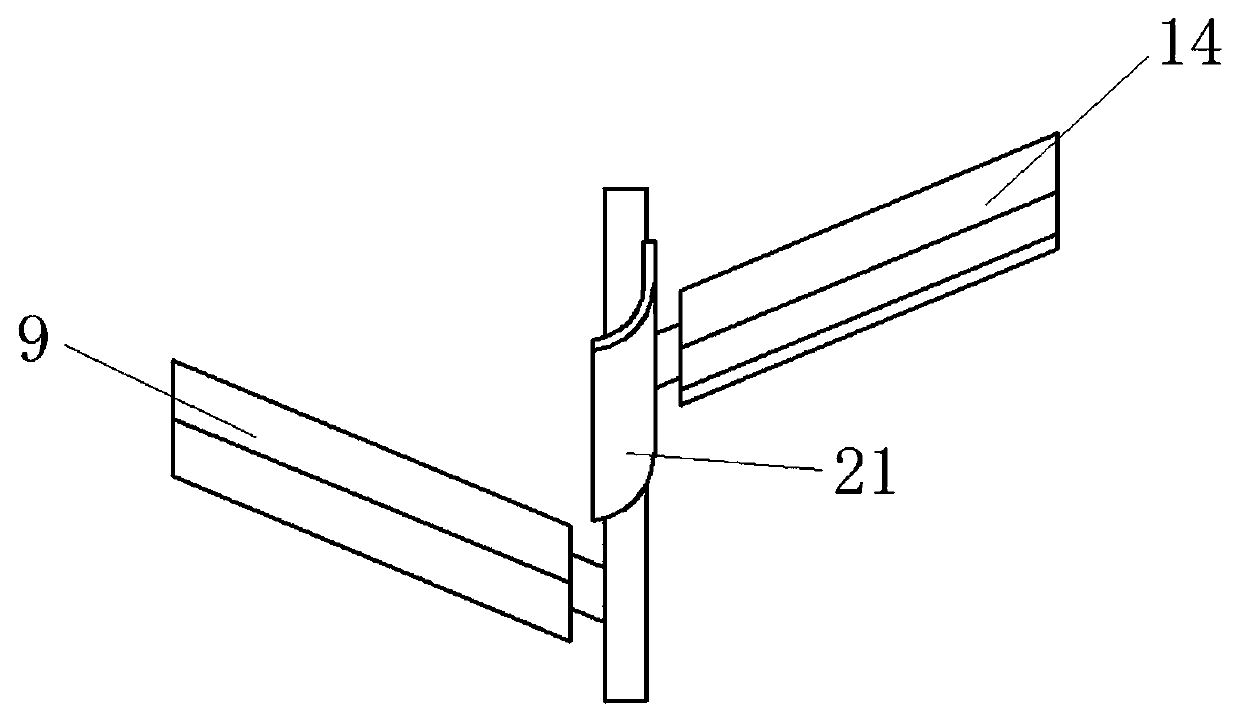

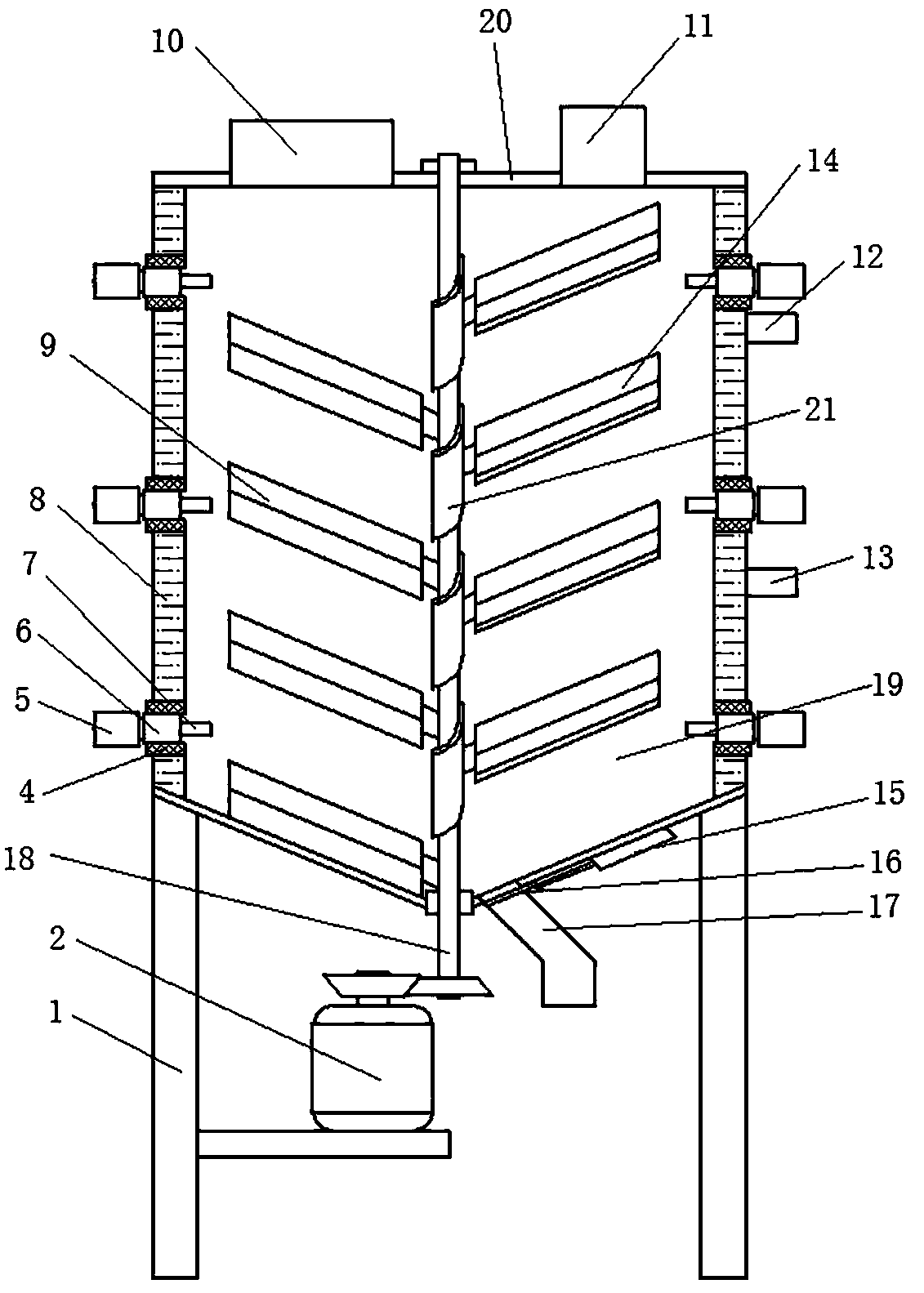

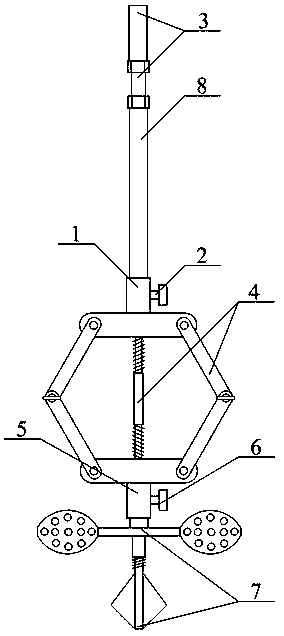

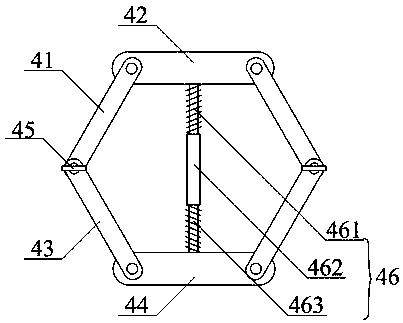

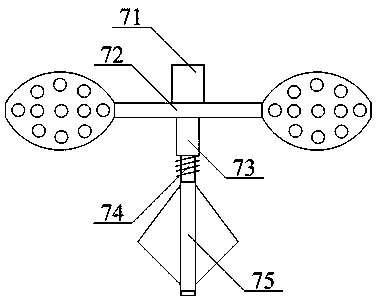

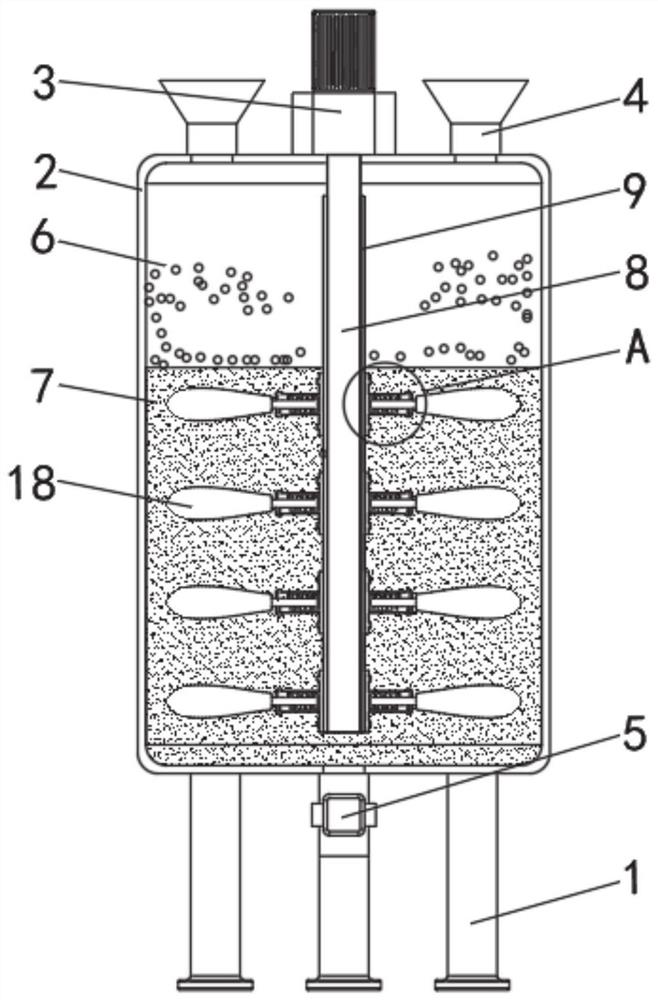

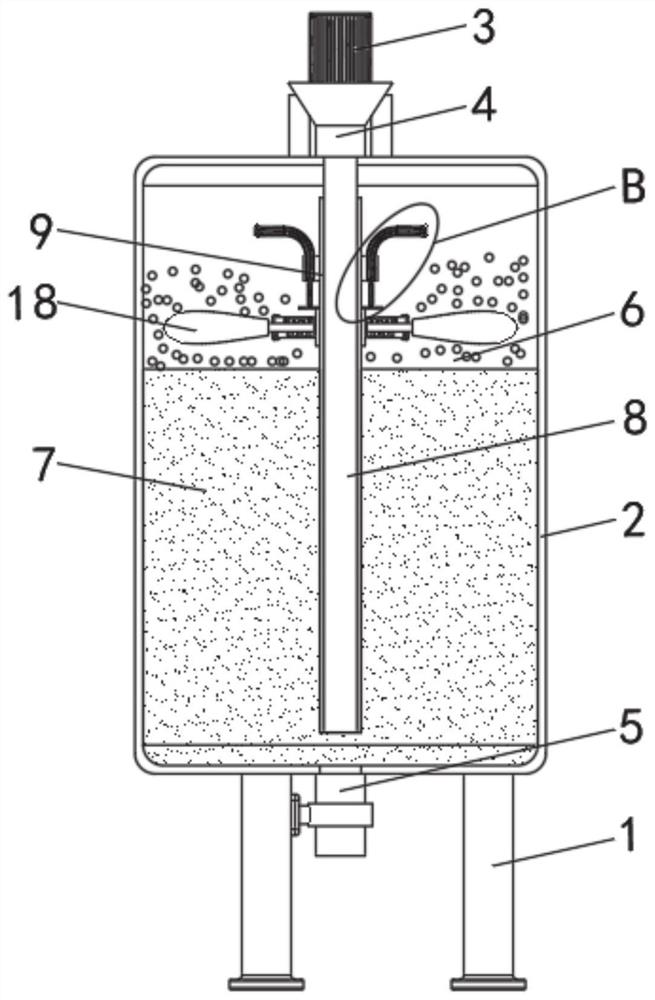

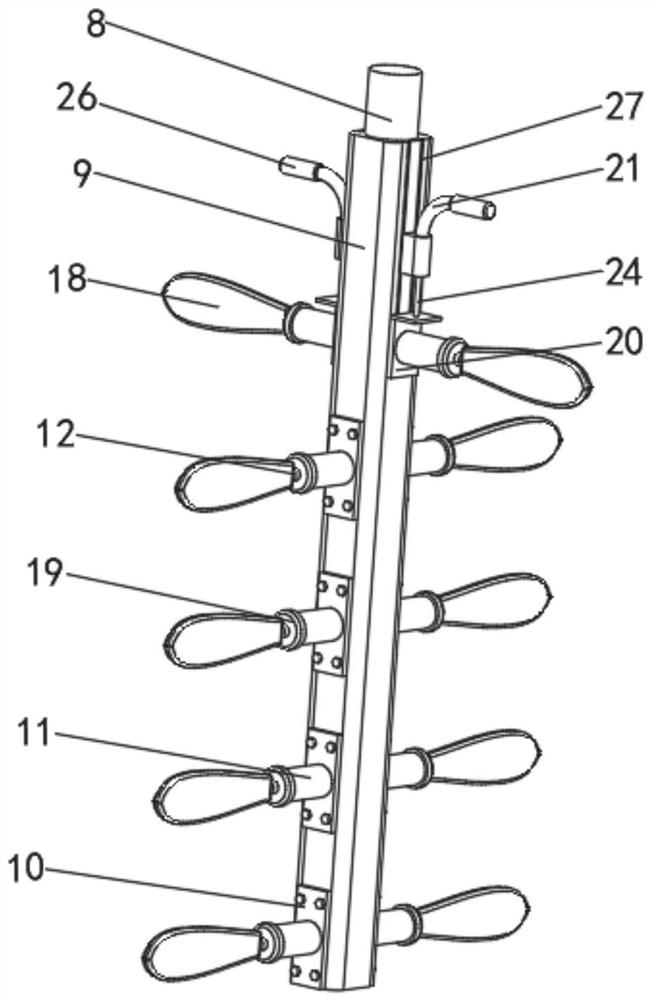

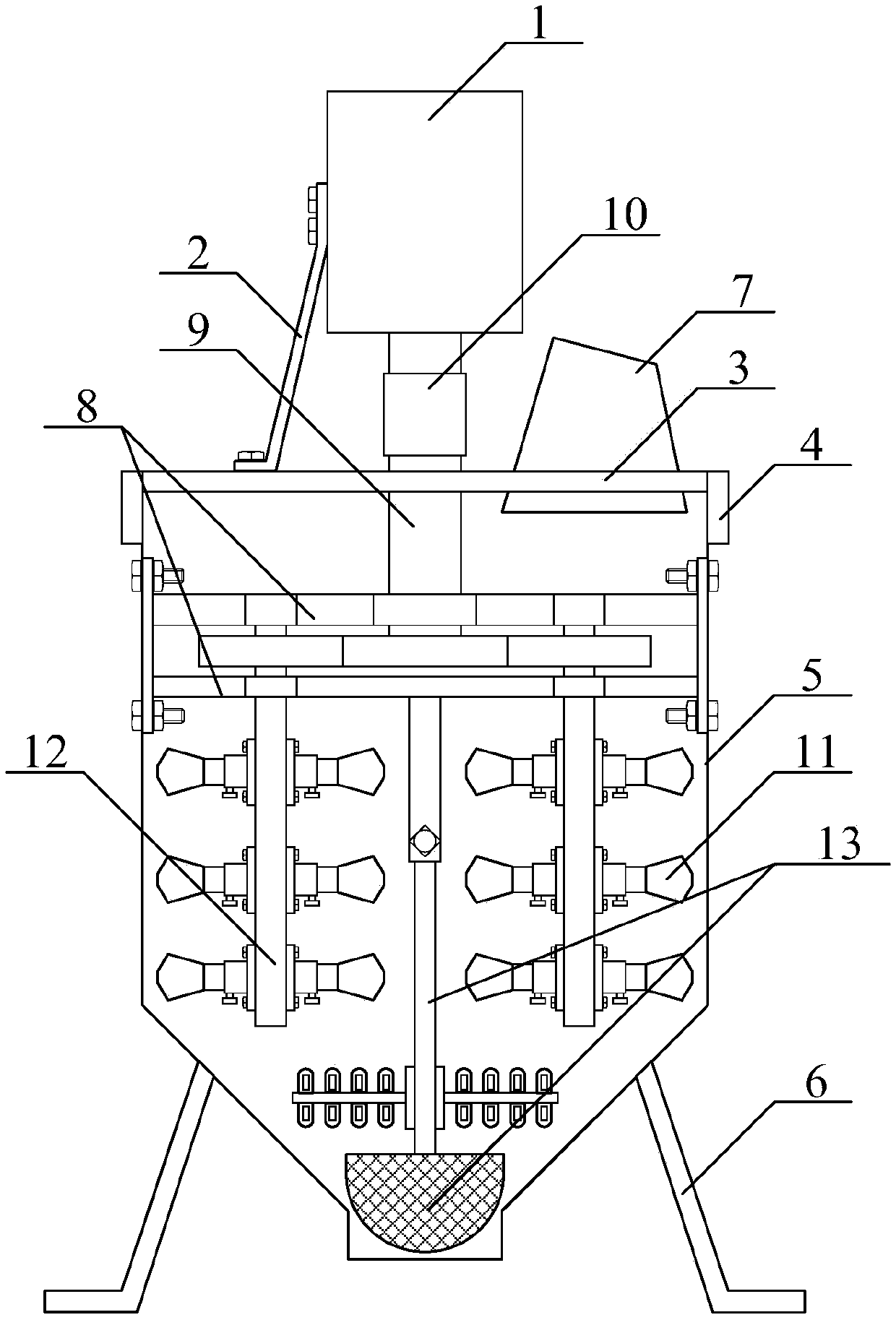

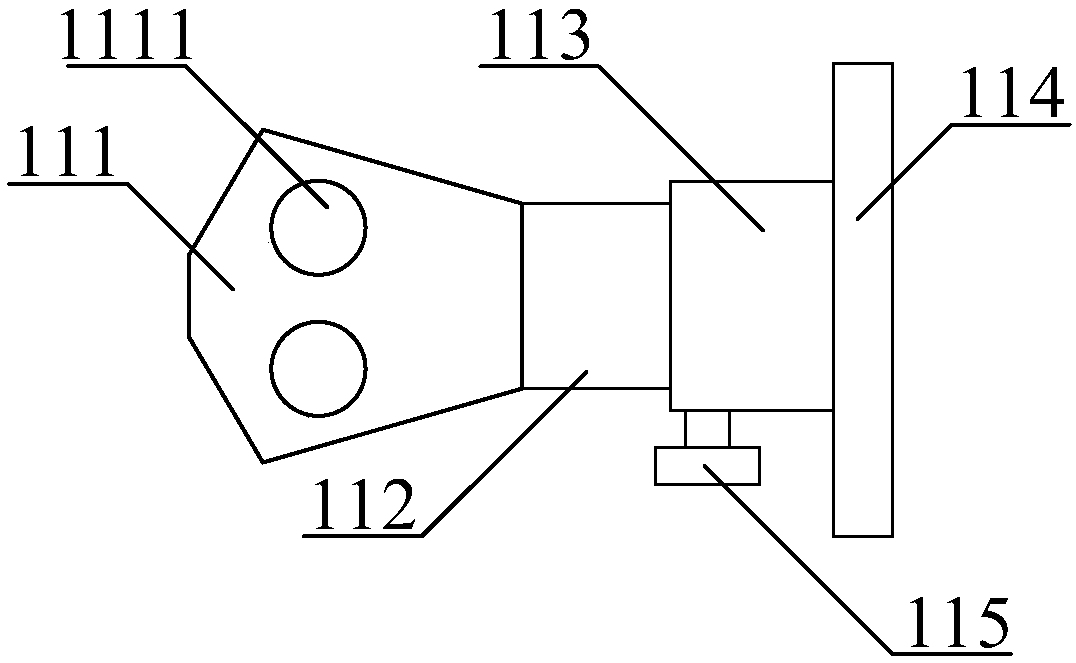

Vertical multi-component high viscosity material continuous-feeding stirrer and using method thereof

ActiveCN110280176ARealize continuous output feedingAchieve segregationTransportation and packagingRotary stirring mixersEngineeringTruck

The invention provides a vertical multi-component high viscosity material continuous-feeding stirrer and a using method thereof. The stirrer comprises a stirring tank, a stirring device is arranged in the stirring tank, a power system for driving the stirring device is arranged outside the stirring tank, a material inlet is arranged at the upper part of the stirring tank, a material outlet is arranged at the bottom of the stirring tank, the stirring tank comprises a premixing tank and a material feeding tank, a stirring device is arranged in each of the premixing tank and the material feeding tank, and the premixing tank is communicated with the material feeding tank through an openable / closable material hole. The stirrer realizes double stirring and continuous feeding of a multi-component high viscosity material, can ensure the stirring quality and the stirring efficiency of the multi-component high viscosity material to prevent the stirred material from being separated, also can improve the labor productivity, save the use space and save the manpower and time cost, and is especially suitable for being used on construction sites and mixer trucks.

Owner:重庆市智翔铺道技术工程有限公司

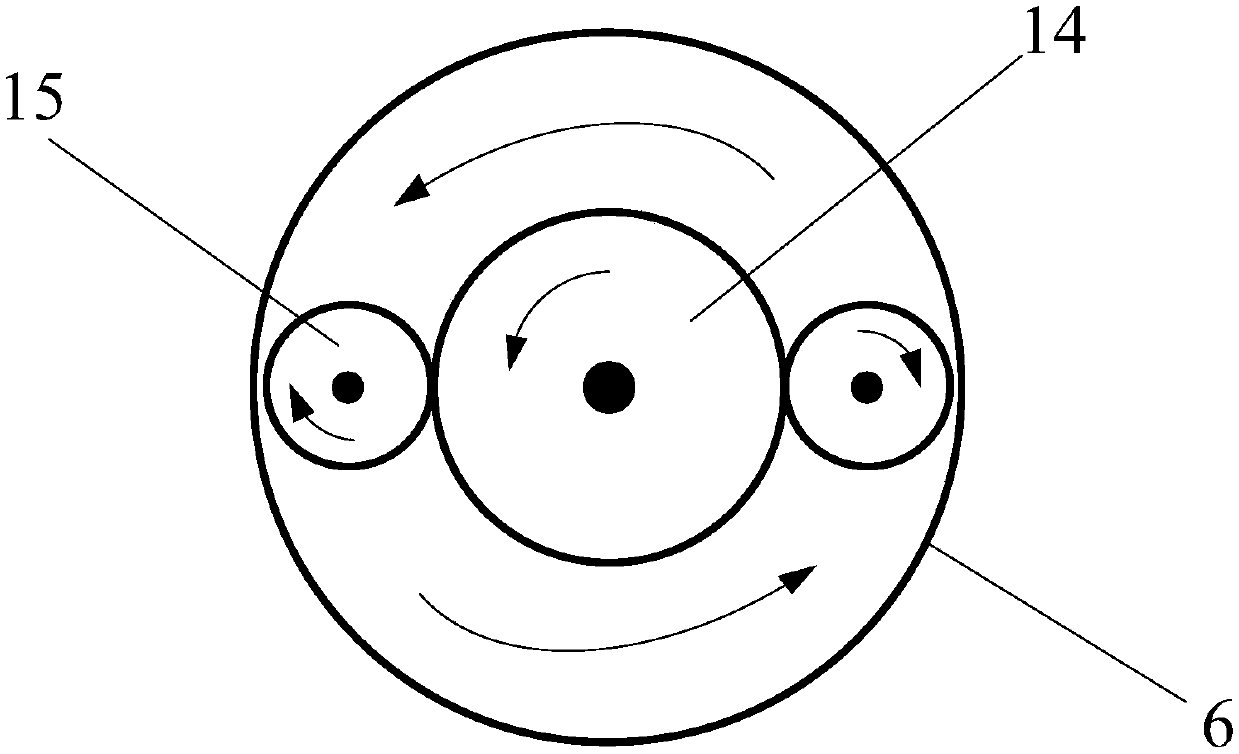

Plastic particle mixing device

This patent discloses a plastic particle mixing device, which relates to the technical field of plastic machinery; the plastic particle mixing device includes a frame, a motor, an inner cylinder, an outer cylinder and a screw push rod; the outer cylinder is fixed on the frame, and the inner cylinder The body is fixed in the outer cylinder, and the upper end of the inner cylinder is open, the screw push rod is set in the inner cylinder, and the motor can drive the screw push rod to rotate in the inner cylinder; Hopper, the middle part of the inner cylinder is provided with a circulation port connecting the inner cylinder and the outer cylinder, and the bottom of the outer cylinder is provided with a discharge port; the upper end of the screw push rod is fixedly connected with a stirring paddle; when the device is working, the screw The push rod can make the material circulate between the inner cylinder and the outer cylinder, and the stirring paddle can stir the material between the inner cylinder and the outer cylinder, so the device can circulate the material, and the efficiency is also improved. improve.

Owner:重庆敏驰塑胶有限公司

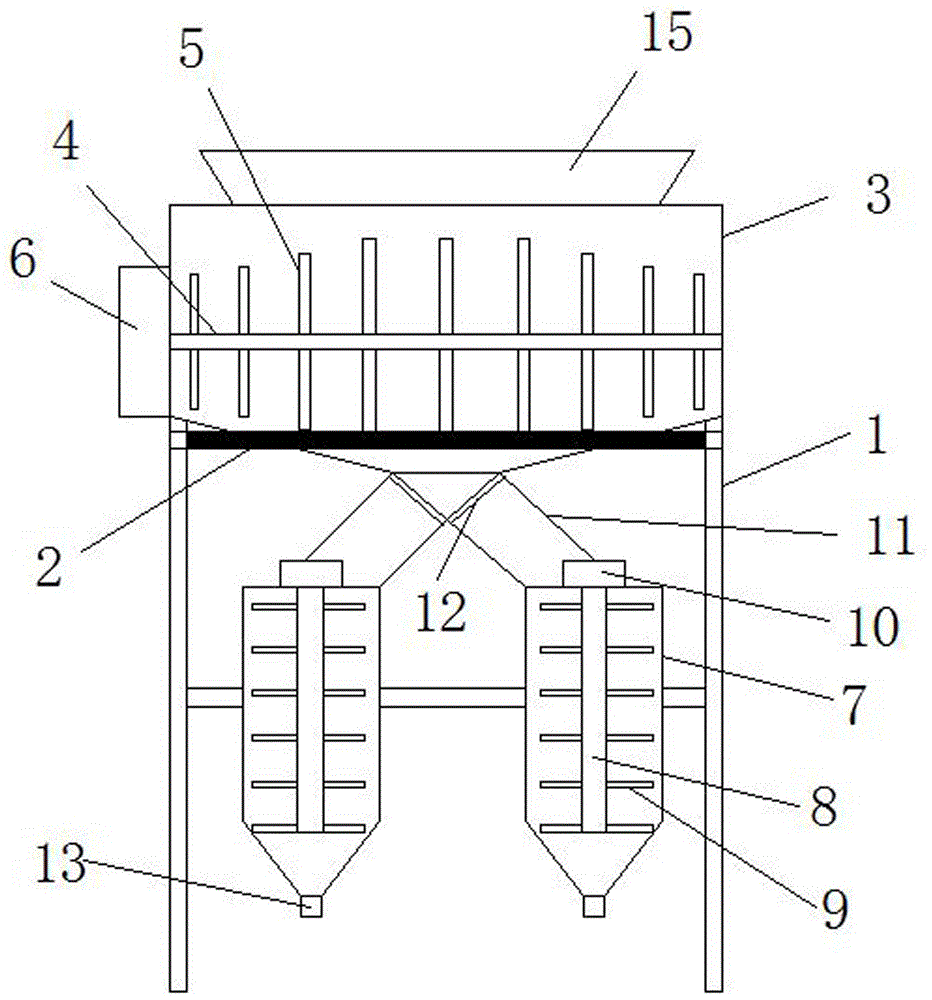

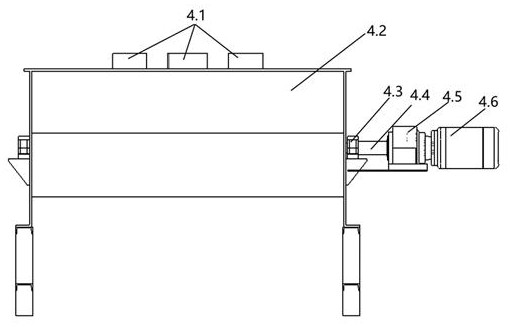

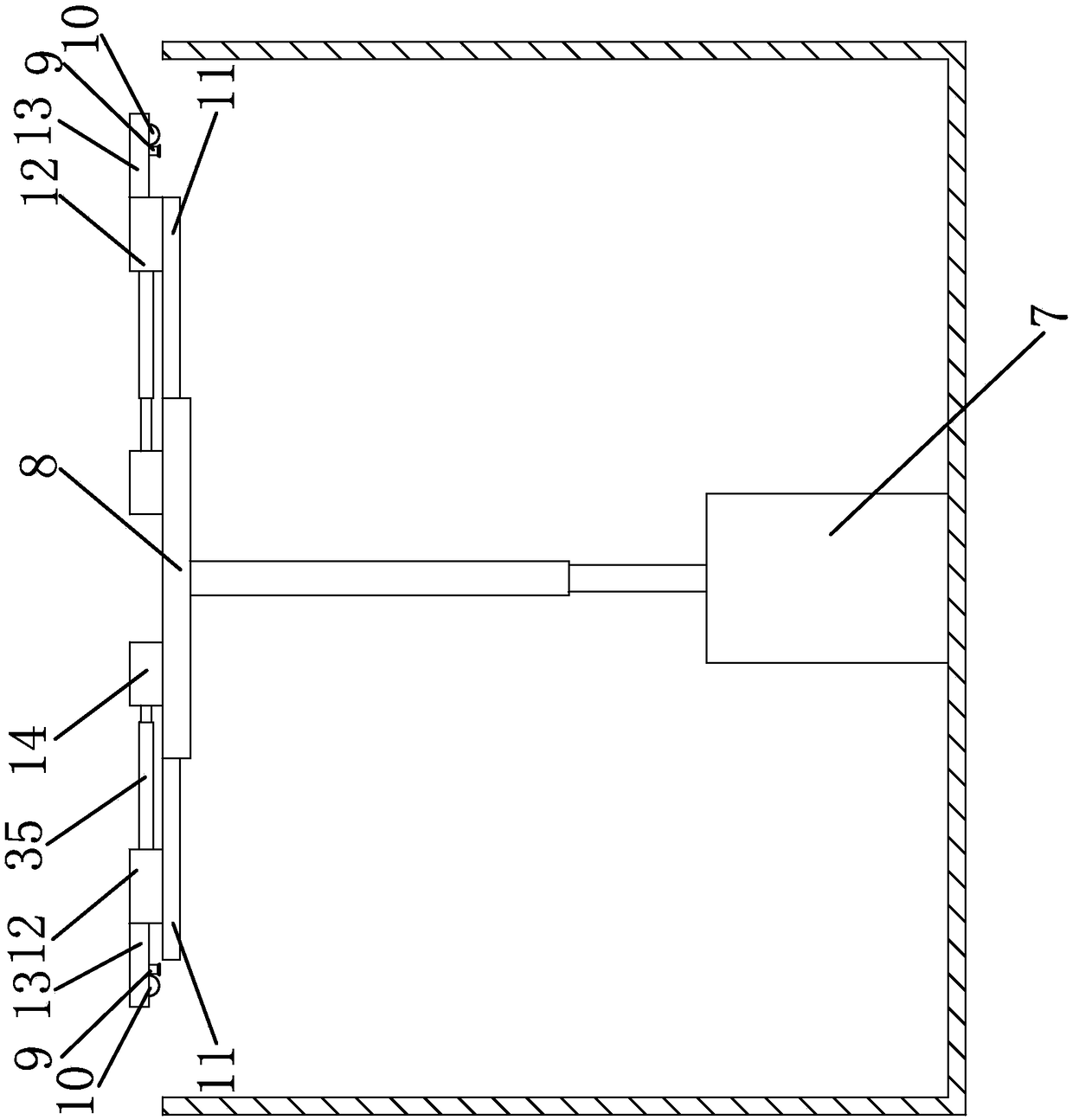

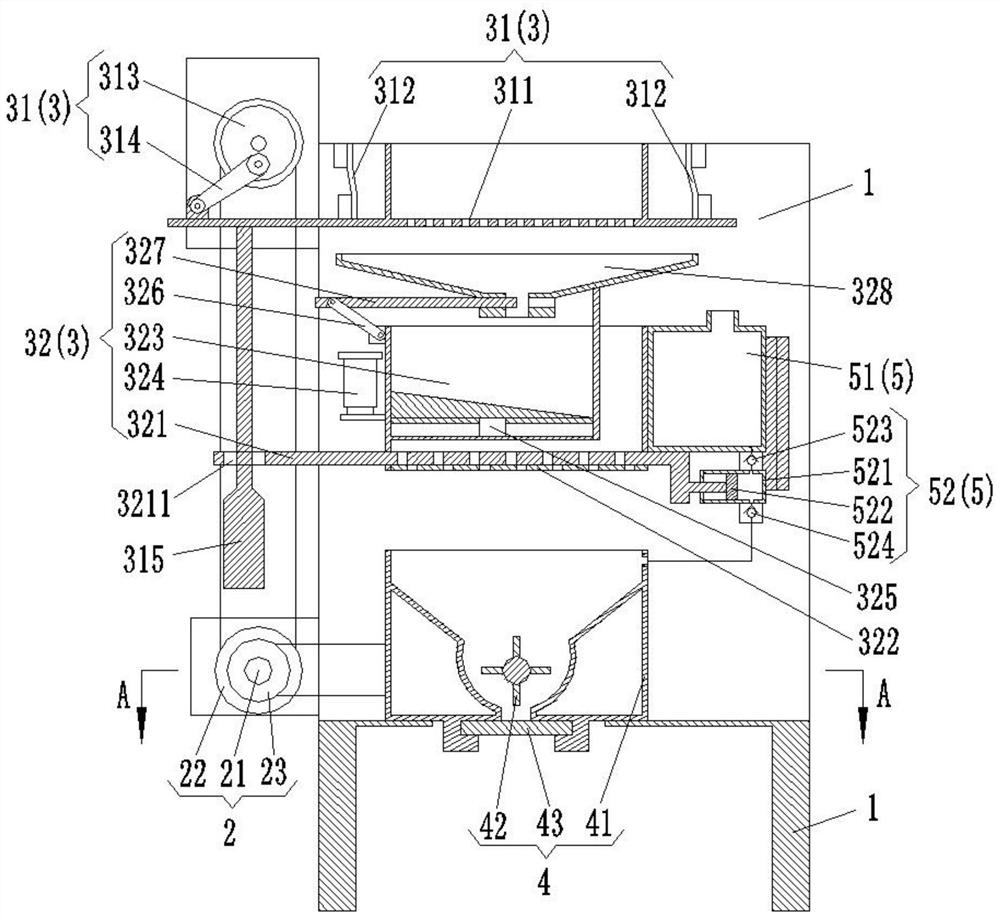

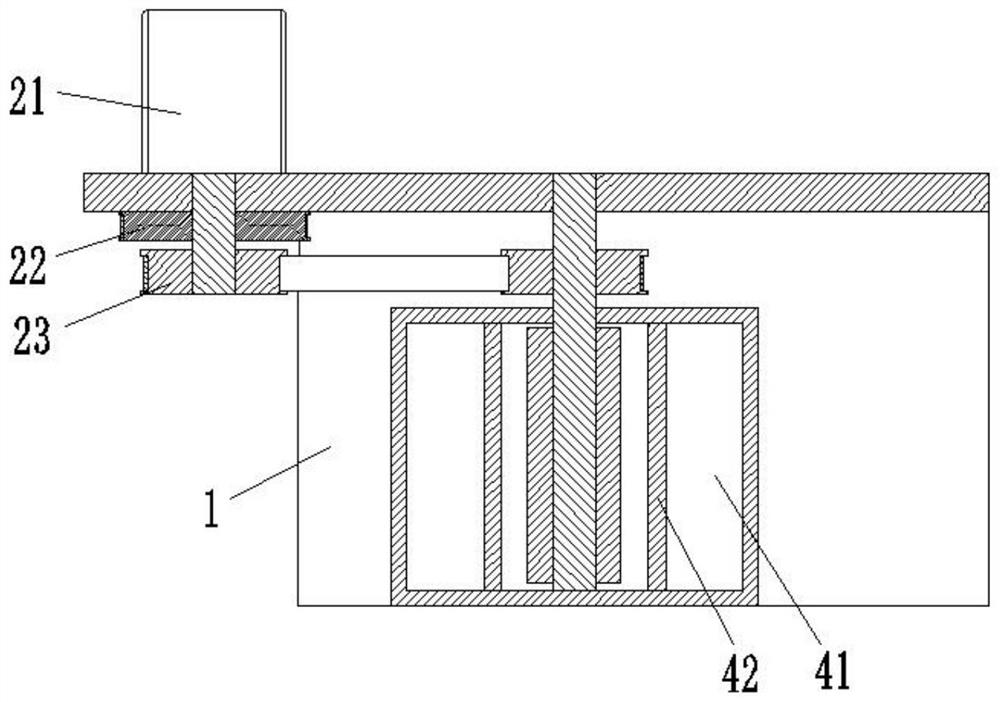

Double-barrel stirring machine

InactiveCN106139997AEvenly mixedGuaranteed stirring efficiencyRotary stirring mixersTransportation and packagingDischarge efficiencyEngineering

The invention discloses a double-barrel stirring machine which comprises a machine frame. An operation platform is fixedly connected to the top of the machine frame. A premixing stock bin is installed on the operation platform. A rotary shaft is installed in an inner cavity of the premixing stock bin and evenly provided with peddles, a first motor is installed on one side of the premixing stock bin and drives the rotary shaft, two stirring barrels are arranged below the operation platform and fixedly connected with the machine frame, stirring shafts are vertically arranged in inner cavities of the stirring barrels and evenly provided with stirring blades, and second motors are arranged on the tops of the stirring barrels and drive the stirring shafts. The two stirring barrels are connected with the bottom of the premixing bin through connection pipelines respectively. The connection pipelines are provided with gate valves. Discharge openings are formed in the bottoms of the stirring barrels. The stirring machine is uniform in mixing, can achieve continuous production, and guarantees stirring and discharging efficiency.

Owner:桂林健威科技发展有限公司

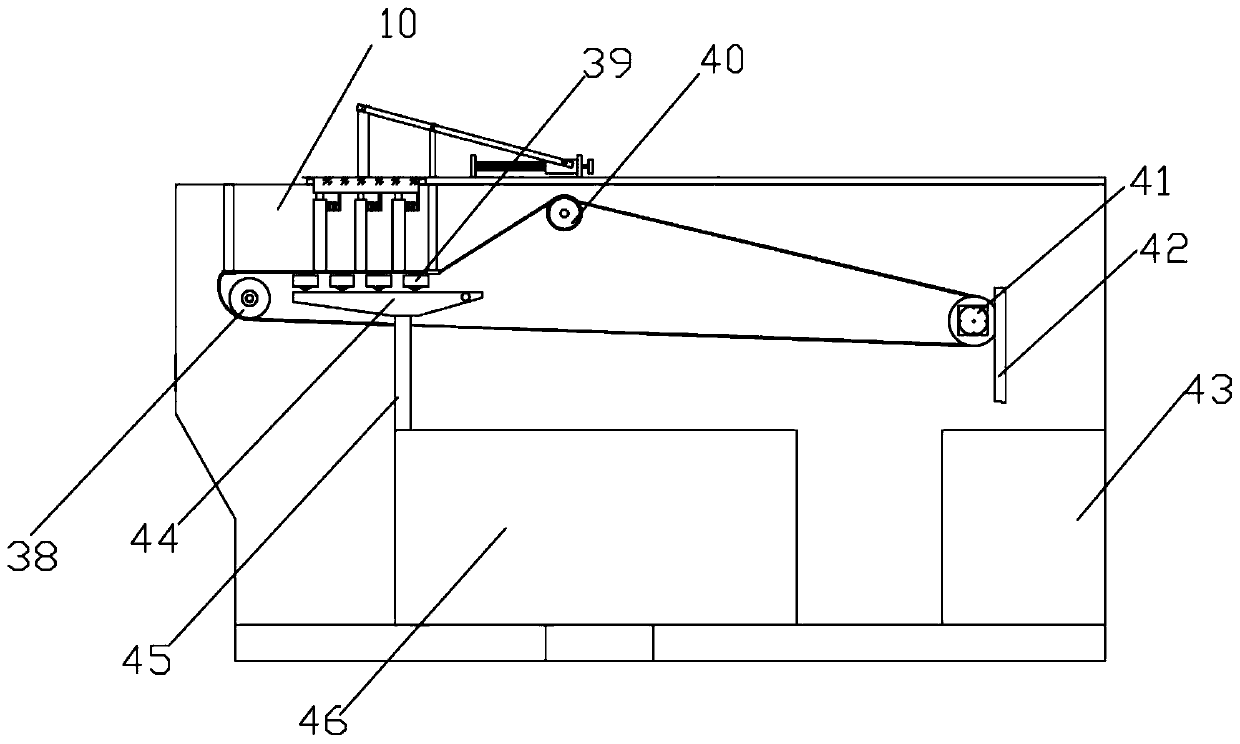

Watercourse sludge desilting treatment equipment

ActiveCN110318436ALow manufacturing costImprove mud scraping efficiencySludge treatmentMechanical machines/dredgersSludgeWater filter

The invention discloses watercourse sludge desilting treatment equipment. The device comprises an equipment main body, wherein a first steel channel and a second steel channel are correspondingly fixed on the same side outer wall of the equipment main body from bottom to top, and a mud scraping cavity is fixedly arranged at the top of an inner cavity of the equipment main body; and the mud scraping cavity comprises a front mudguard and a rear mudguard, a movable top cover is arranged on the top of one side of the mud scraping cavity, a first connecting rod which is longitudinally arranged is fixedly connected to the upper end surface of the movable top cover, and a second connecting rod is hinged to one end, far away from the movable top cover, of the first connecting rod. According to thewatercourse sludge desilting treatment equipment, the mud scraping cavity and a filtering belt can be cleaned without dismounting the equipment, so that the cleaning of the equipment is more convenient, and meanwhile, the time cost for cleaning the equipment is saved; and sludge in a sludge inlet pipe is optimized and stirred through a bidirectional motor, the stirring efficiency of the sludge isensured while the use number of stirring blades is reduced, the manufacturing cost of the equipment is saved, and fine sand in the sludge can be effectively prevented from being adsorbed on the surface of the filtering belt so as to affect the water filtering efficiency of the filtering belt.

Owner:SHANGHAI RUIHUI ENVIRONMENTAL PROTECTION TECH

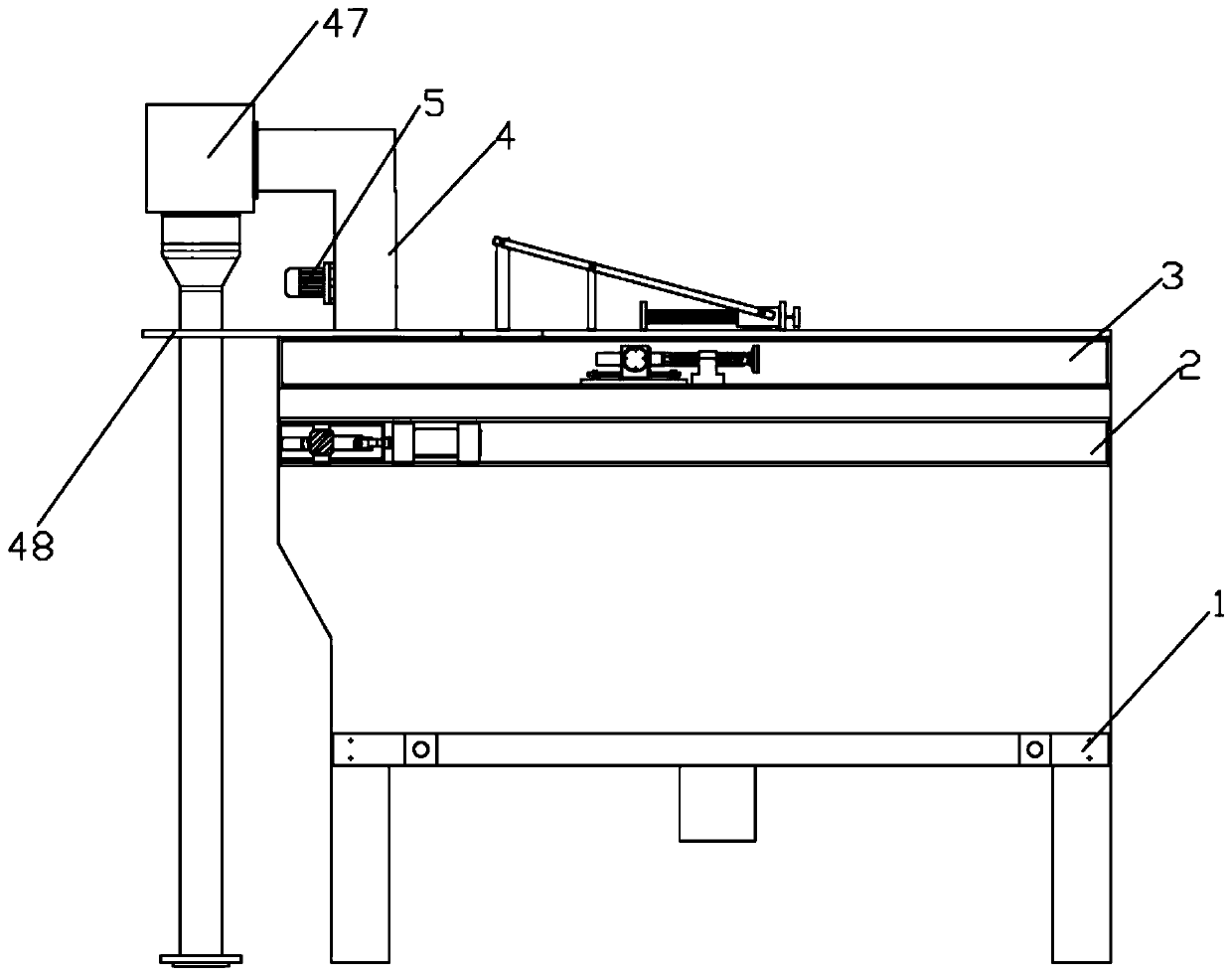

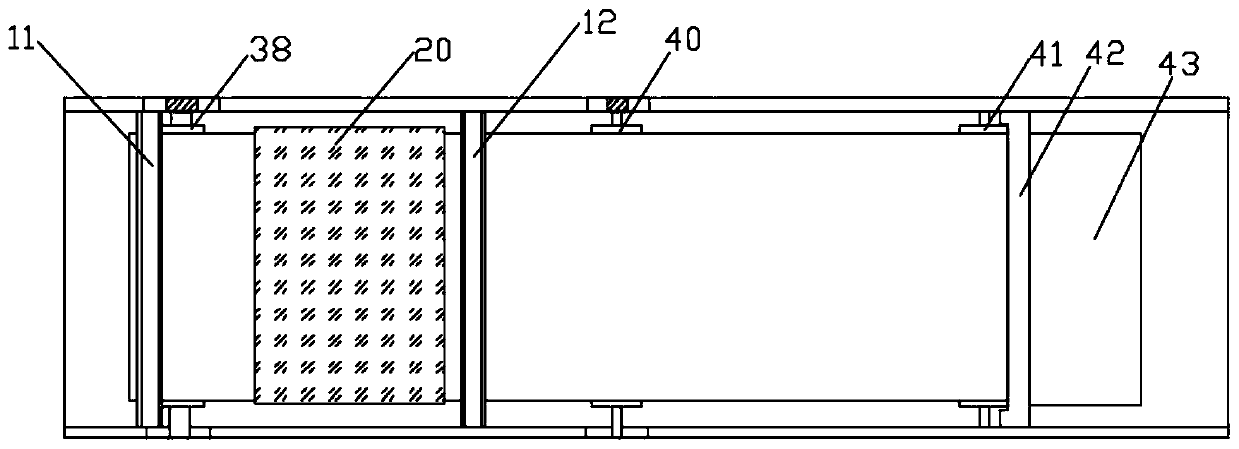

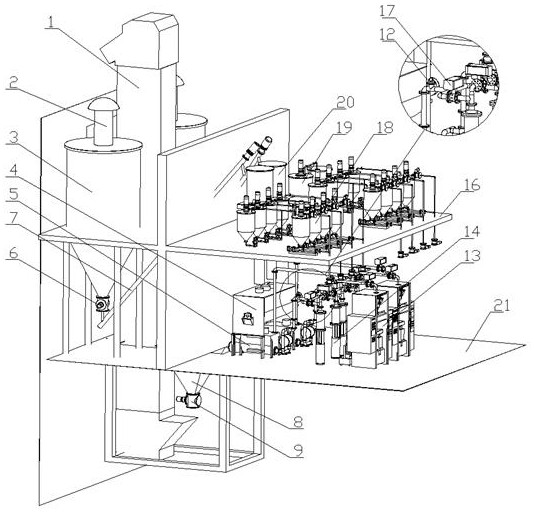

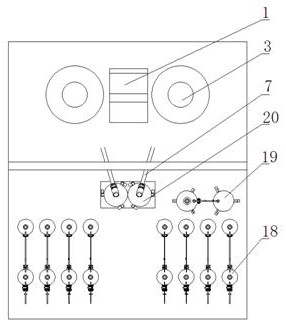

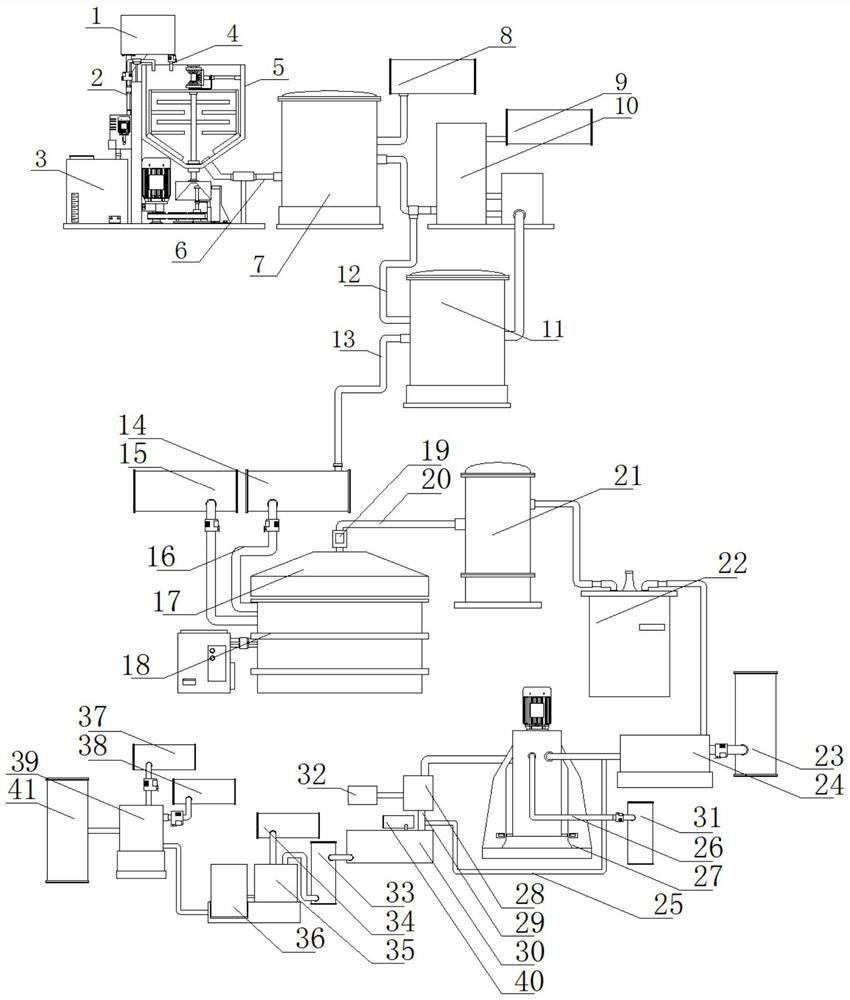

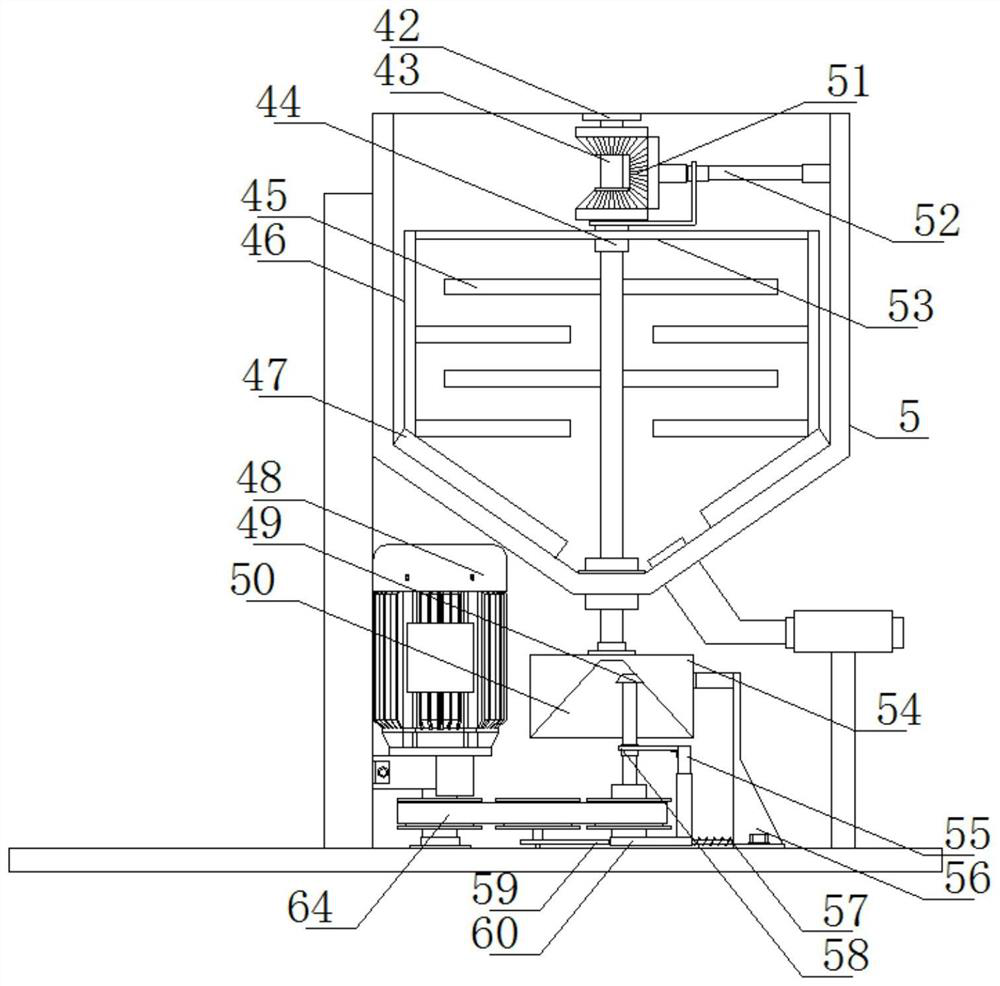

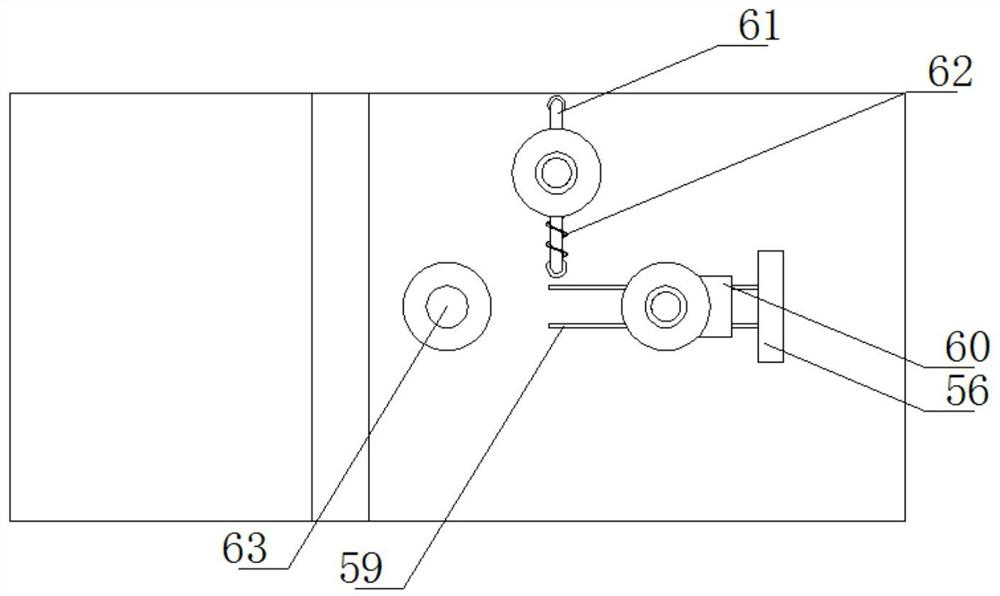

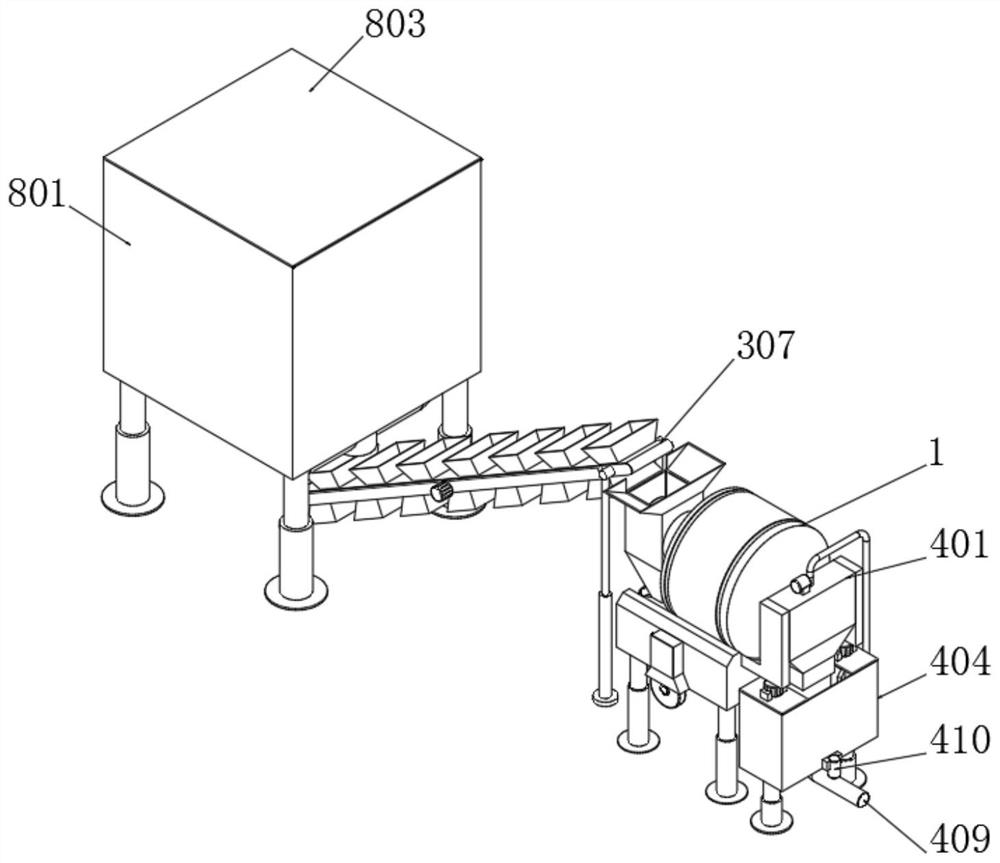

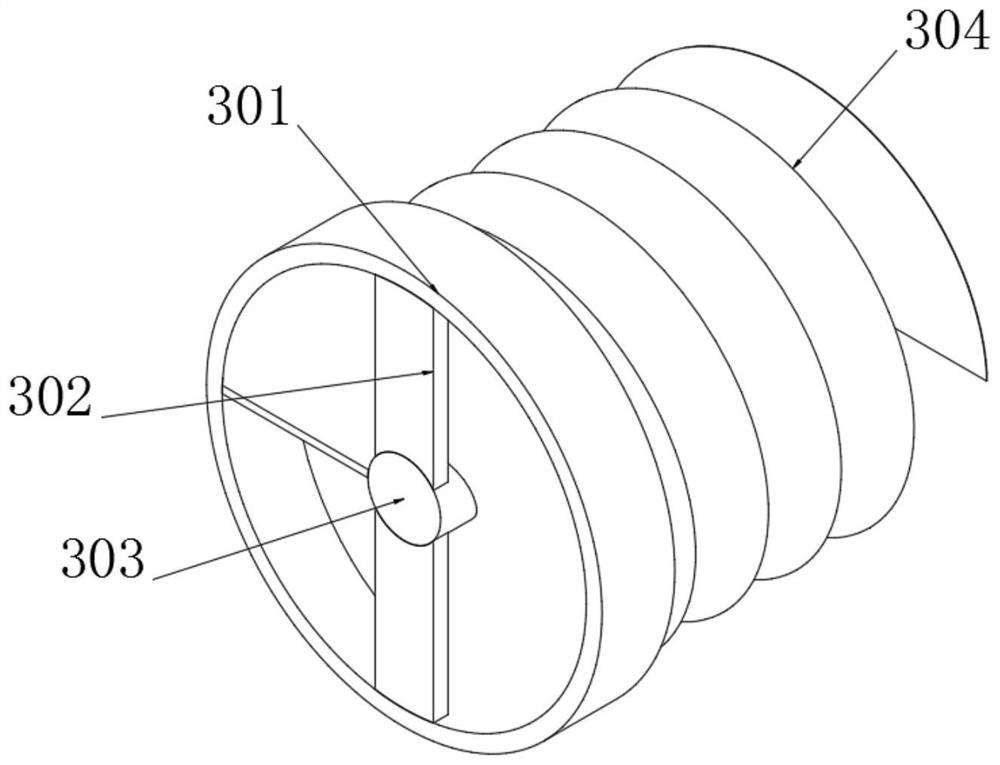

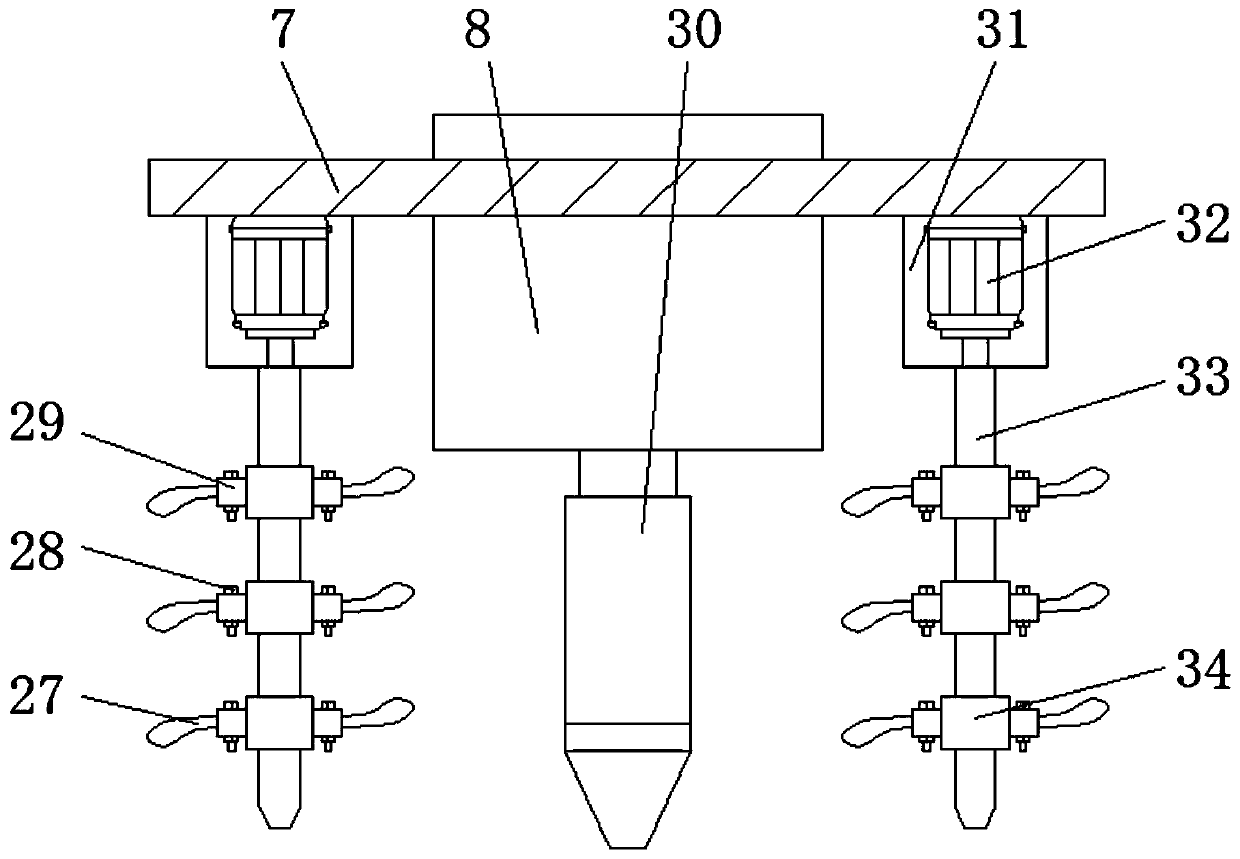

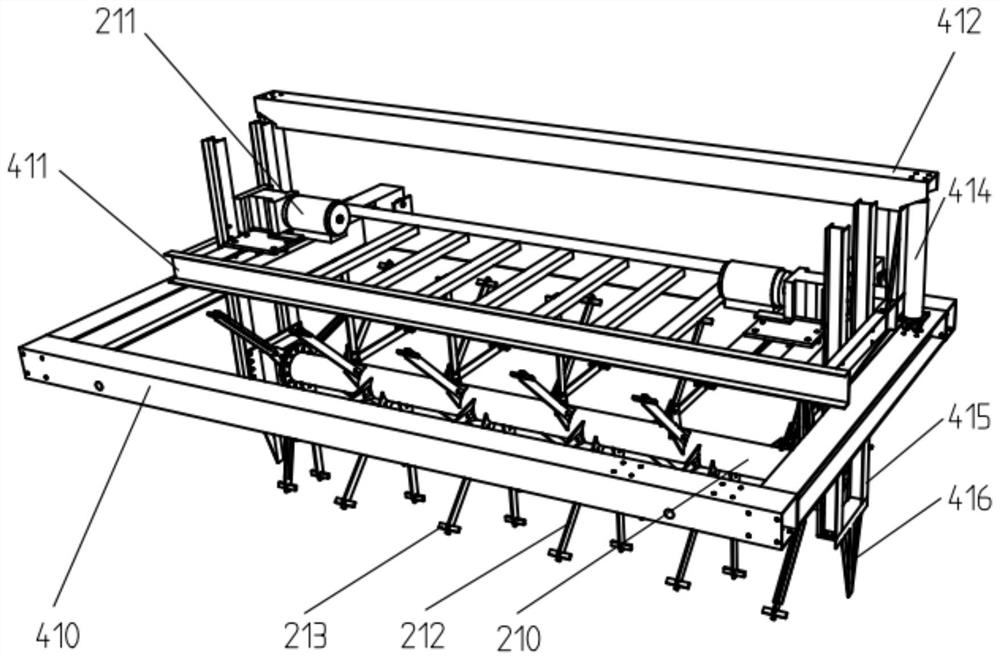

Unmanned production equipment for anchoring agent for anchor net supporting

PendingCN113859602AThe overall structure is simpleCompact layoutMixer accessoriesLiquid materialProcess engineeringPotential energy

The invention belongs to the field of anchoring agent production, and particularly relates to unmanned production equipment for an anchoring agent for anchor net supporting. The unmanned production equipment comprises a stock bin, a stock bin feeding system, a resin stirring system, a curing agent stirring system, a plaster cylinder, a weighing stock bin, a stirring system and a machine head control cabinet, wherein the resin stirring system, the curing agent stirring system, the plaster cylinder, the weighing stock bin, the stirring system and the machine head control cabinet are connected according to the working procedures and arranged in a layered mode in the material flow direction. The stock bin supplies anchoring agent raw materials to the weighing stock bin, the weighing stock bin quantitatively feeds materials to the stirring system, the stirring system uniformly mixes the anchoring agent raw materials and resin to prepare plaster, and the plaster enters the plaster cylinder and then is pushed into the machine head control cabinet. The curing agent stirring system is connected with the machine head control cabinet, a curing agent is conveyed to the machine head control cabinet, and the plaster and the curing agent are quantitatively canned through the machine head control cabinet. The whole production line is arranged in a layered mode, the gravitational potential energy of the raw materials is fully utilized, the system integration is high, and a large number of conveying pipelines and connectors are saved. Compared with existing anchoring agent production equipment in China, the scheme has the advantages that the plant space is reasonably utilized, the occupied space is reduced, and the arrangement is more compact.

Owner:TAIYUAN UNIV OF TECH

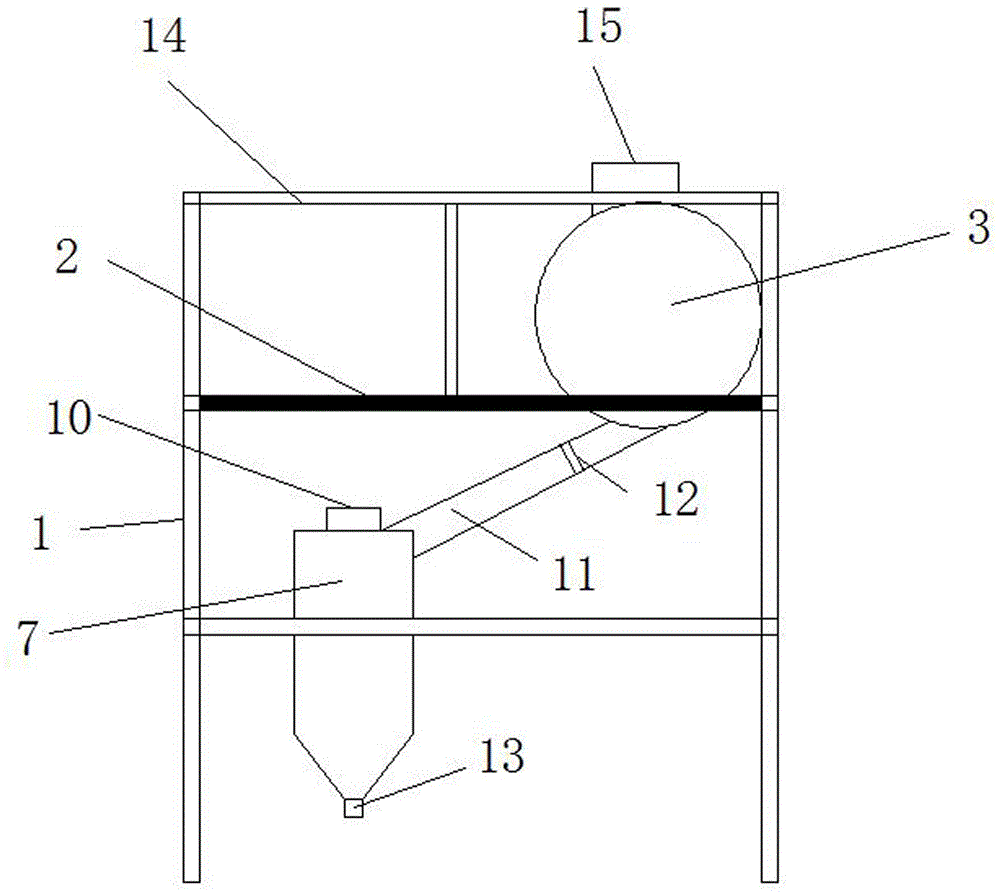

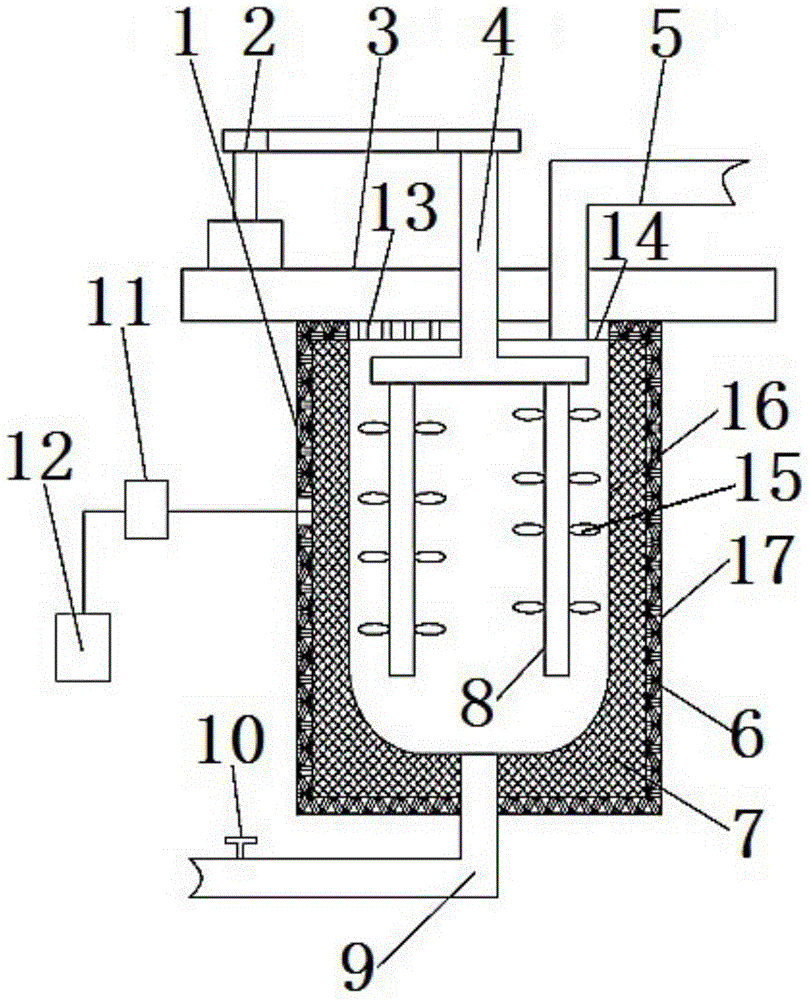

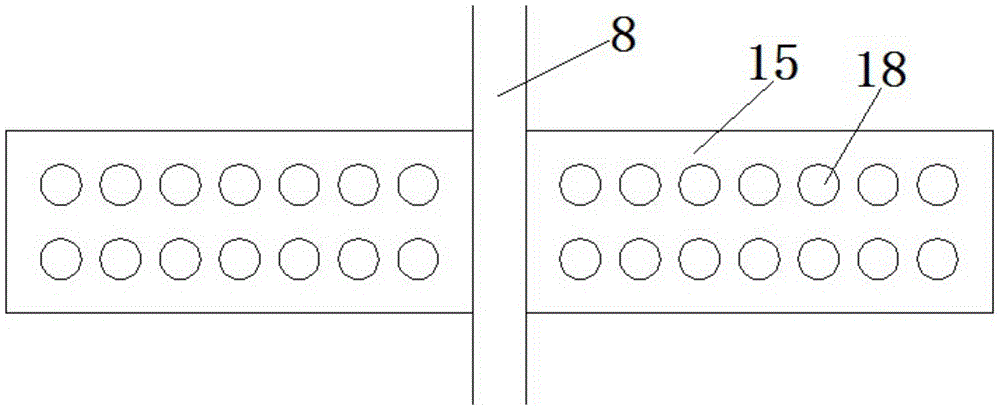

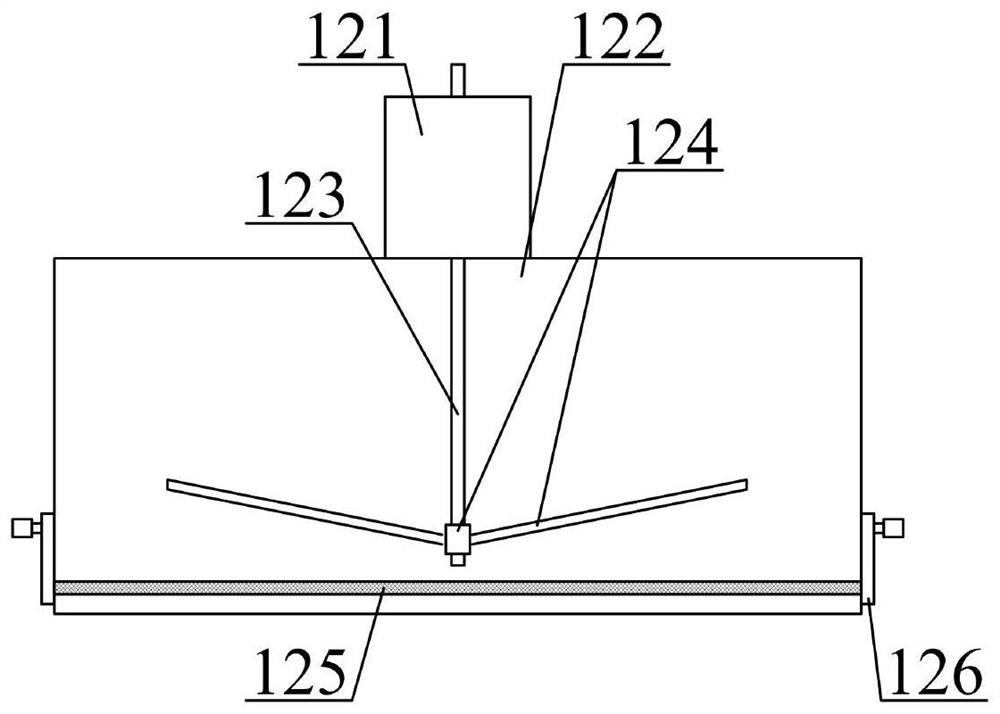

Sealant production stirring apparatus

InactiveCN104984678APrevent solidificationGuaranteed stirring efficiencyRotary stirring mixersMixer accessoriesElectric heatingEngineering

A sealant production stirring apparatus comprises a stirring barrel and a crossbeam arranged on the stirring barrel, the upper end of the stirring barrel is provided with a barrel cover, the barrel cover is provided with a feeding pipeline, the lower end of the stirring barrel is provided with a discharging pipeline, the crossbeam is provided with a stirring motor, the apparatus also comprises a rotating shaft cooperating with the crossbeam in a rotary manner, the electric shaft of the motor is in transmission connection with the rotating shaft through a belt, the rotating shaft is provided with a plurality of stirring rods, and the stirring rods are provided with blades; and each of the blades is provided with a plurality of through holes, the stirring barrel comprises an inner cylinder and a shell, an electric heating wire is wound on the cylinder wall of the inner cylinder, the electric heating wire is electrically connected with a power supply, and a heat insulation layer is arranged between the shell and the electric heating wire.

Owner:ANHUI HUAYUN LIGHT IND MFG CO LTD

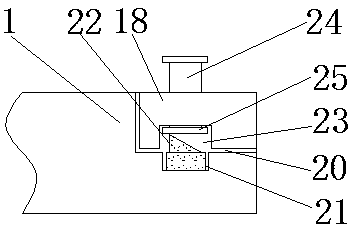

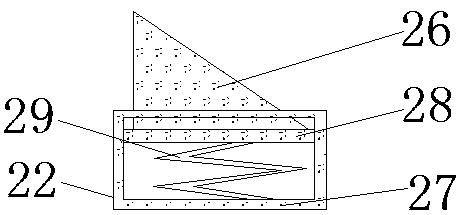

Anti-blocking gypsum mortar spraying machine

InactiveCN107584664AStir wellImprove fluencyDischarging apparatusCement mixing apparatusPulp and paper industryAir compressor

The invention discloses an anti-blocking gypsum mortar spraying machine. The machine comprises a rack, a motor, a stirring device and a discharging device, wherein the motor is located above the rack;a primary stirring device and a secondary stirring device are correspondingly mounted at the upper part and the lower part of the rack respectively; the primary stirring device comprises a primary stirring barrel, a primary stirring shaft and primary stirring bars, the primary stirring barrel is fixedly mounted at the upper part of the rack, a feeding port is formed in the upper left part of theprimary stirring barrel, and a control valve is arranged at the bottom of a secondary stirring barrel; a spraying mechanism comprises an air compressor, an extruding mechanism, a screw conveyor, a mortar spraying pipe, a spiral steel wire, a two-way water ring and a mortar spraying head. The anti-blocking gypsum mortar spraying machine is convenient to use, low in construction cost, safe and efficient; the raw materials are subjected to coarse stirring and fine stirring, all stages of stirring are non-interfering, not only can the raw materials be sufficiently stirred, but also stirring efficiency and stirring quality are guaranteed; smoothness of mortar spraying is improved, blockage is reduced, and work efficiency is improved.

Owner:金晶

Trifluoromethanesulfonic acid production device and method

PendingCN112679392APut an end toImprove efficiencyCellsOrganic compound preparationPotassium fluorideTriflic acid

The invention relates to a trifluoromethanesulfonic acid production device and method, and belongs to the technical field of organic chemical engineering. The method comprises the following steps: reacting a methanesulfonyl chloride aqueous solution with potassium fluoride to obtain a methanesulfonyl fluoride crude product, carrying out reduced pressure distillation and phase separation, carrying out reduced pressure distillation again, electrolyzing the obtained methanesulfonyl fluoride pure product and anhydrous hydrogen fluoride in an electrolyzer, cooling the electrolyzed gas, introducing the cooled gas into a sodium fluoride tower, collecting the cooled gas by using a cold trap device, carrying out hydrolysis reaction on the obtained trifluoromethanesulfonyl fluoride and a potassium hydroxide solution, carrying out extraction separation on a reaction product, and recrystallizing to obtain potassium trifluoromethanesulfonate; and carrying out acidolysis reaction on potassium trifluoromethanesulfonate and excessive concentrated sulfuric acid to obtain a trifluoromethanesulfonic acid crude product, and distilling the trifluoromethanesulfonic acid crude product to obtain purified trifluoromethanesulfonic acid. Methylsulfonyl fluoride can be rapidly prepared and purified, unqualified products generated in the preparation process can be fluorinated again, and the production efficiency and quality are effectively improved.

Owner:PERIC SPECIAL GASES CO LTD

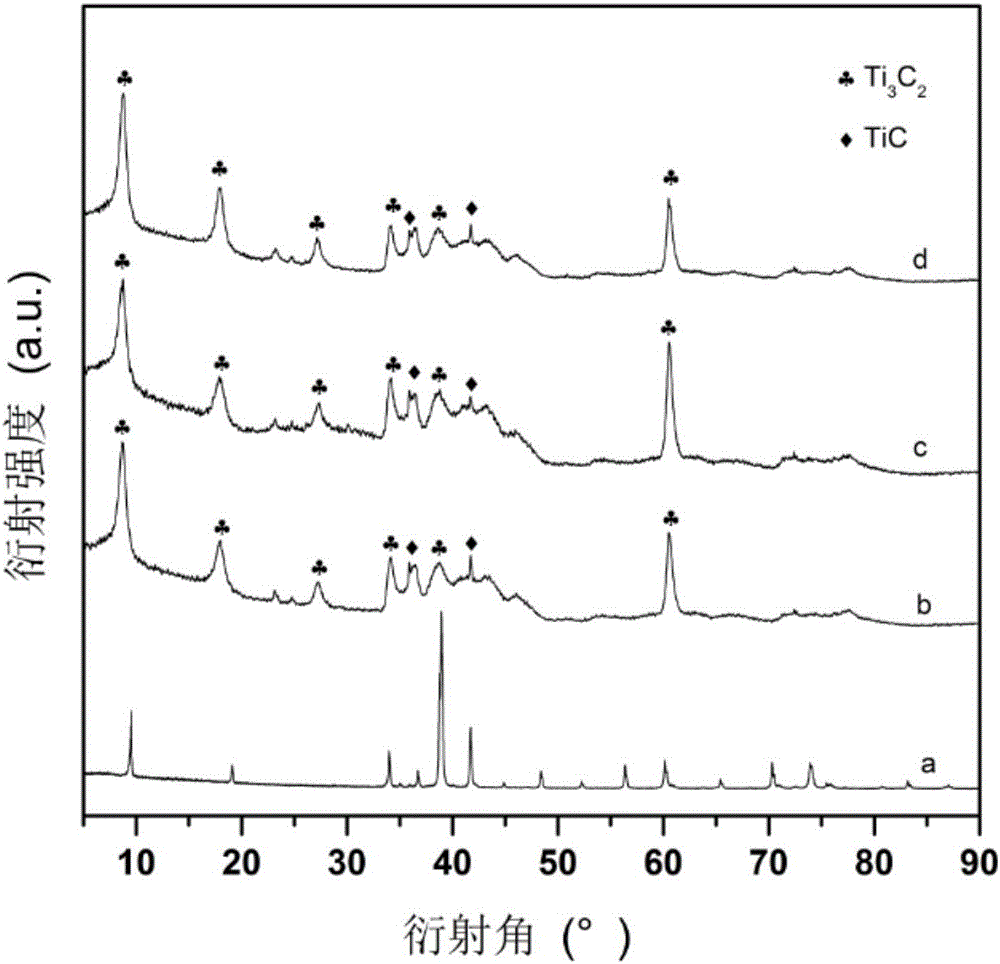

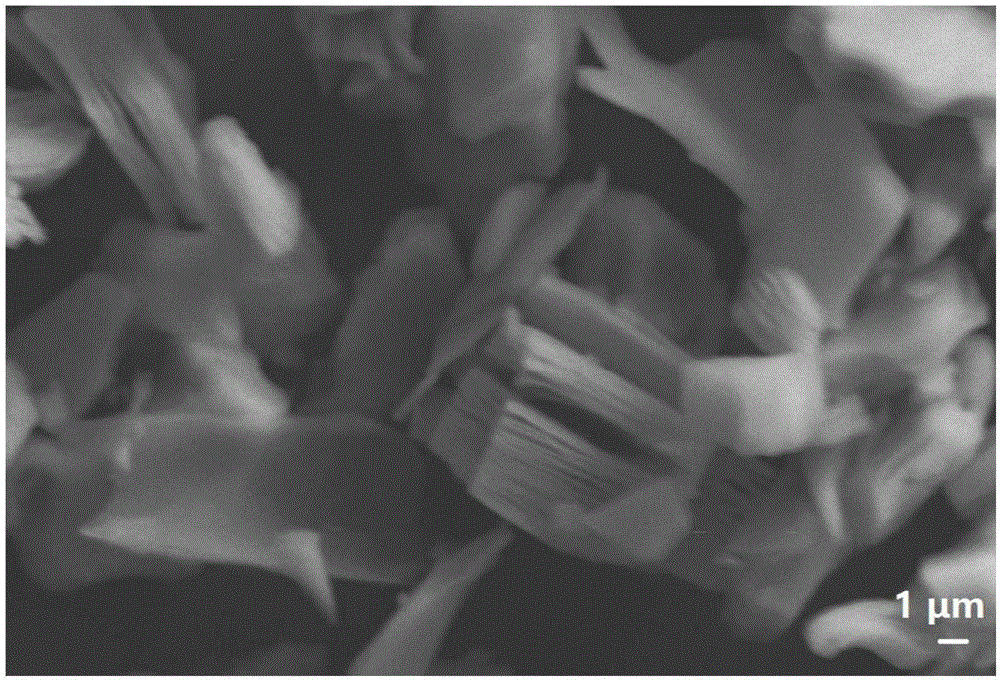

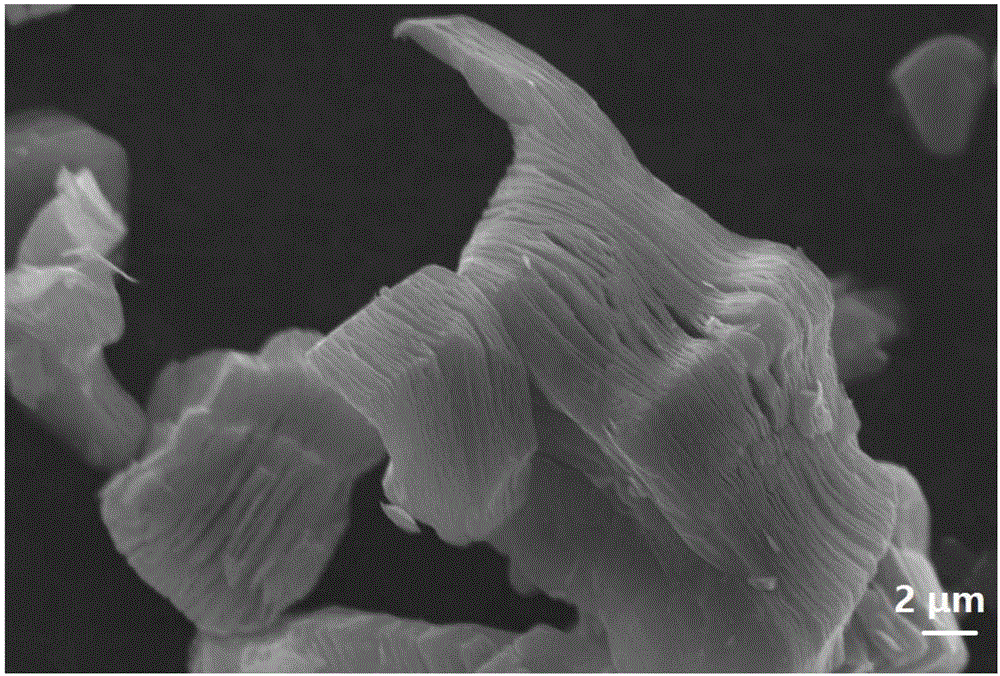

Method for preparing two-dimensional nanosheet crystal Ti3C2 alkene

InactiveCN106744961AWell mixedReduce the binding forceTitanium carbideHydrogen fluorideMechanical crushing

The invention discloses a method for preparing two-dimensional nanosheet crystal Ti3C2 alkene. The method specifically comprises the following steps: performing mechanical crushing and grinding on a high-purity Ti3AlC2 block, and screening by using a sieve of 200 meshes so as to obtain Ti3AlC2 raw material powder of which the particle size is smaller than 75[mu] m; mixing the Ti3AlC2 raw material powder and 10-40wt% HF (Hydrogen Fluoride) acid, sealing, stirring, heating to 25-60 DEG C, and further stirring to react for 0.5-10 hours at 25-60 DEG C so as to obtain a liquid mixture; performing multiple times of centrifugal treatment on the liquid mixture till the pH value of supernate obtained after centrifugal treatment is 5-7 so as to obtain a crude product; performing vacuum drying on the crude product, thereby obtaining the two-dimensional nanosheet crystal Ti3C2 alkene. Compared with other documents and patents, the method aims to prepare raw material powder with low-concentration acid corrosion and a relatively wide particle size range from the Ti3AlC2 raw material powder of which the particle size is smaller than 75[mu] m by using a low-concentration acid solution in modes of continuous stirring and heating heat preservation, not only is the particle size range of the raw material powder increased, but also the corrosion time is greatly shortened, and great significances for promoting industrial production and actual application of MXene can be achieved.

Owner:BEIJING JIAOTONG UNIV

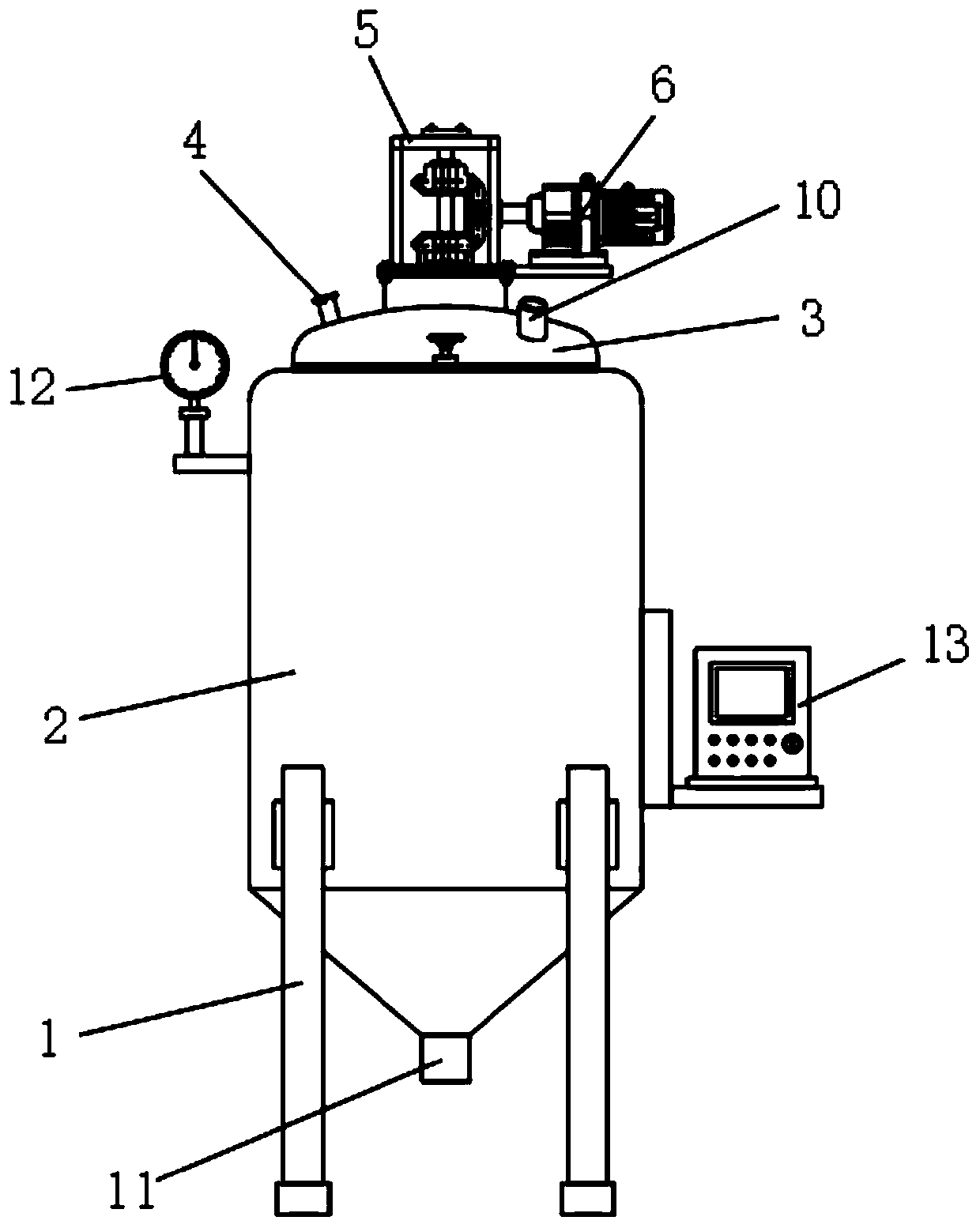

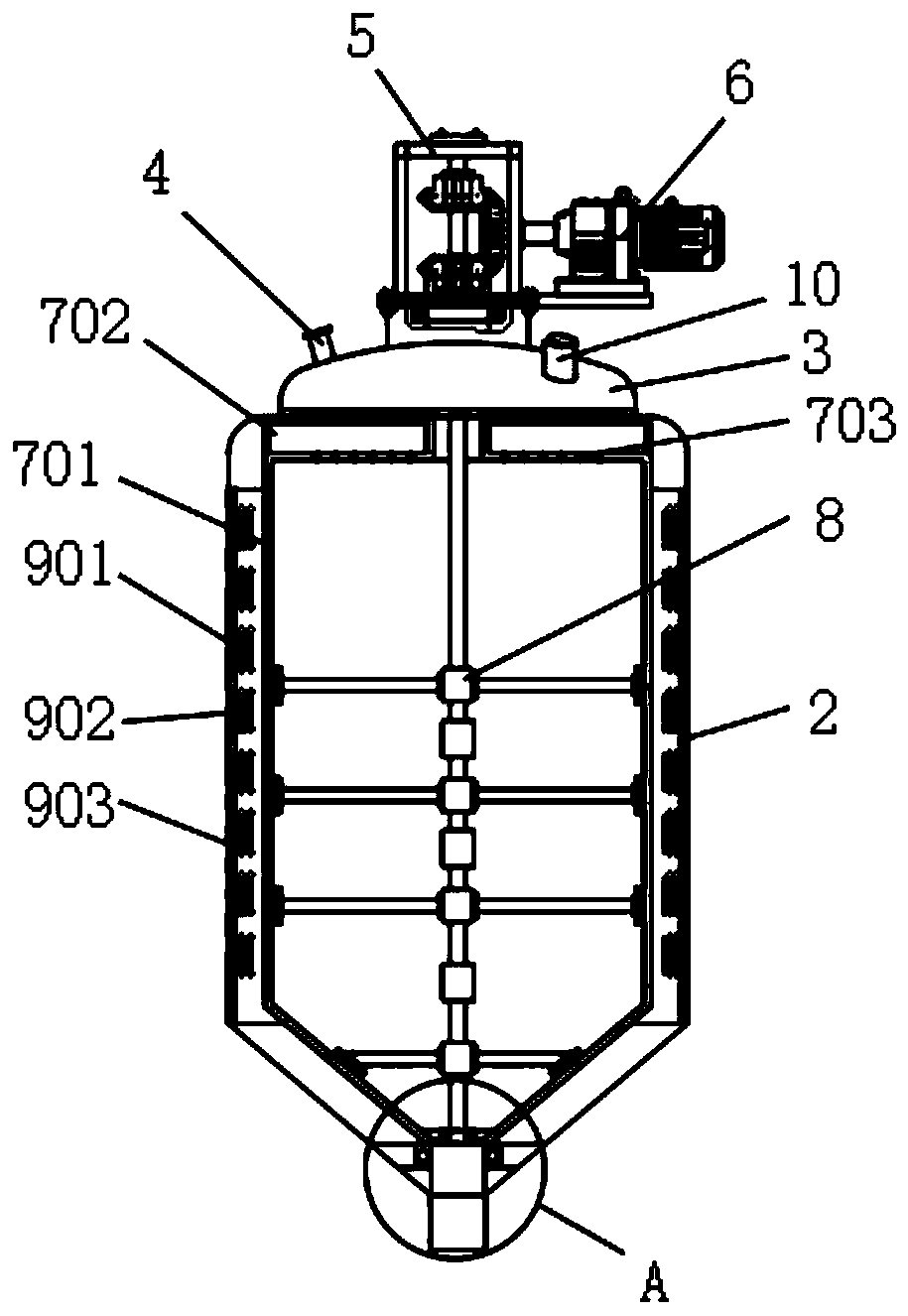

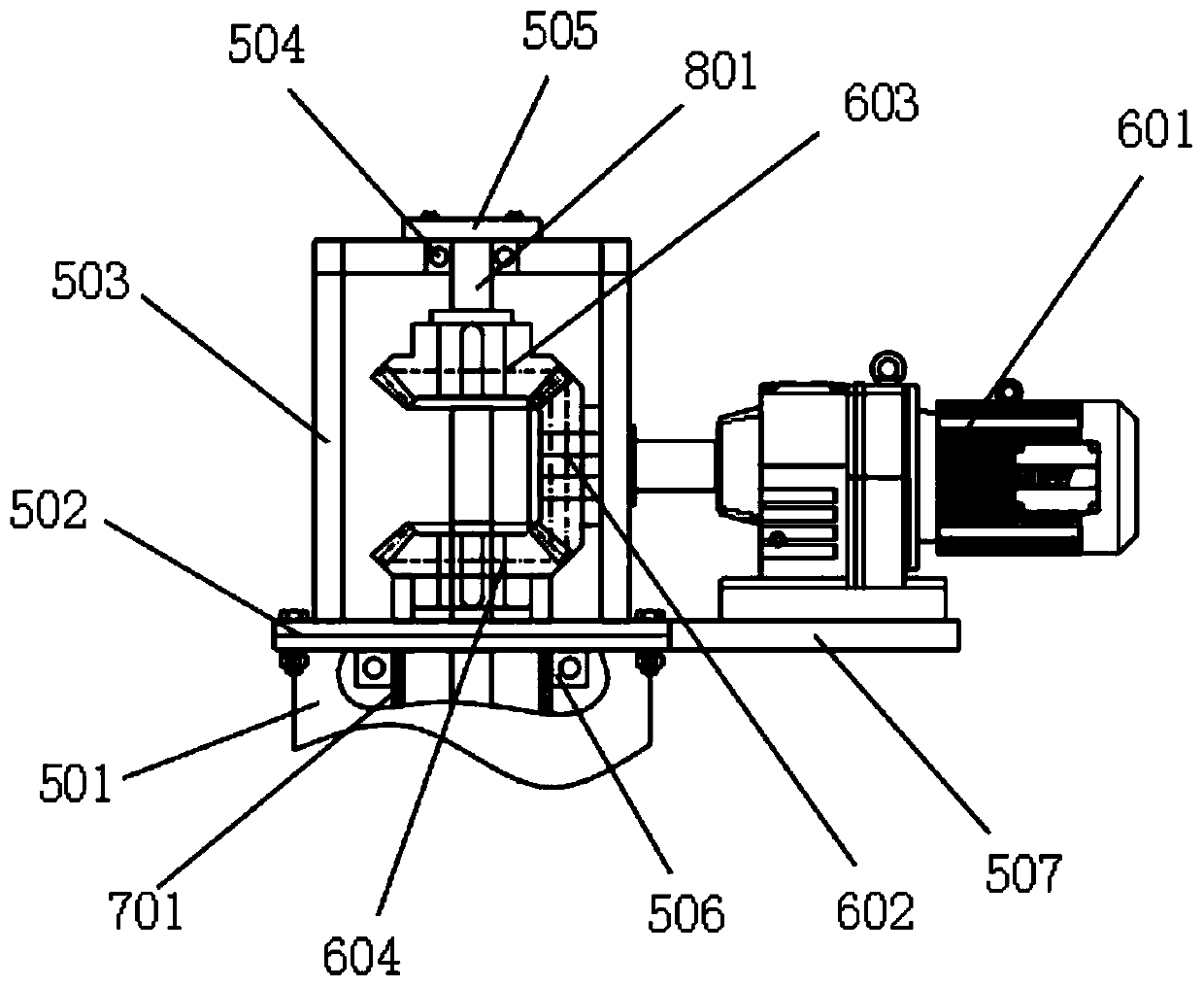

Novel crystallization kettle capable of improving evaporative crystallization efficiency

PendingCN111097187AImprove evaporation and crystallization efficiencyRealize automatic cleaningSolution crystallizationCrystallization by component evaporationEngineeringMaterials science

The invention provides a novel crystallization kettle capable of improving evaporative crystallization efficiency, and relates to the technical field of crystallization kettles. The novel crystallization kettle capable of improving evaporative crystallization efficiency comprises a support frame, the center of the support frame is fixedly connected with a crystallizing tank, and a tank cover is arranged at the top of the crystallizing tank. A supporting mechanism is arranged at the top of the tank cover. A transmission mechanism is arranged on one side of the supporting mechanism. A centrifugal stirring mechanism is arranged in the center of the crystallizing tank. A rotary stirring mechanism is mounted in the center of the centrifugal stirring mechanism. A heating mechanism is arranged between the crystallizing tank and the centrifugal stirring mechanism. An air outlet is formed in one side of the outer surface of the top of the tank cover. A control panel is arranged at the bottom ofone side of the outer wall of the crystallizing tank. Through mutual cooperation of the transmission mechanism, the centrifugal stirring mechanism, the rotary stirring mechanism and the automatic heating mechanism, the evaporative crystallization efficiency of the stock solution can be greatly improved, a large amount of energy is saved, and meanwhile the processing efficiency is guaranteed.

Owner:南京紫晶藤节能科技有限公司

Livestock feed stirring device for animal husbandry

InactiveCN108607378AKeep healthyFacilitates thorough cleaningFeeding-stuffRotary stirring mixersClamp connectionSpiral blade

The invention provides a livestock feed stirring device for animal husbandry, and relates to the technical field of feed stirring. The stirring device comprises a stirring box. Support legs are fixedly installed on the bottom of the stirring box. The bottom of the stirring box is provided with an outlet. The top of the outlet penetrates the bottom of the stirring box and extends into the stirringbox. A grinding box is fixedly arranged on the top of the stirring box. One side of the top of the grinding box is communicated with the bottom of a feed inlet. An installation board is fixedly installed on the left side of the grinding box. A top motor is fixedly installed on the top of the installation board. The stirring device has the advantages that one side of a side door is movably connected to the lateral wall of the stirring box, the other side of the side door is fixed on the lateral wall of the stirring box through clamp connection between a clamping member and a clamping plate, thus the side door can be opened, the stirring device can be more conveniently and radically cleaned; large caked feed particles are grinded into fine particles by spiral blades, and the stirring efficiency is improved therefore.

Owner:朱德仲

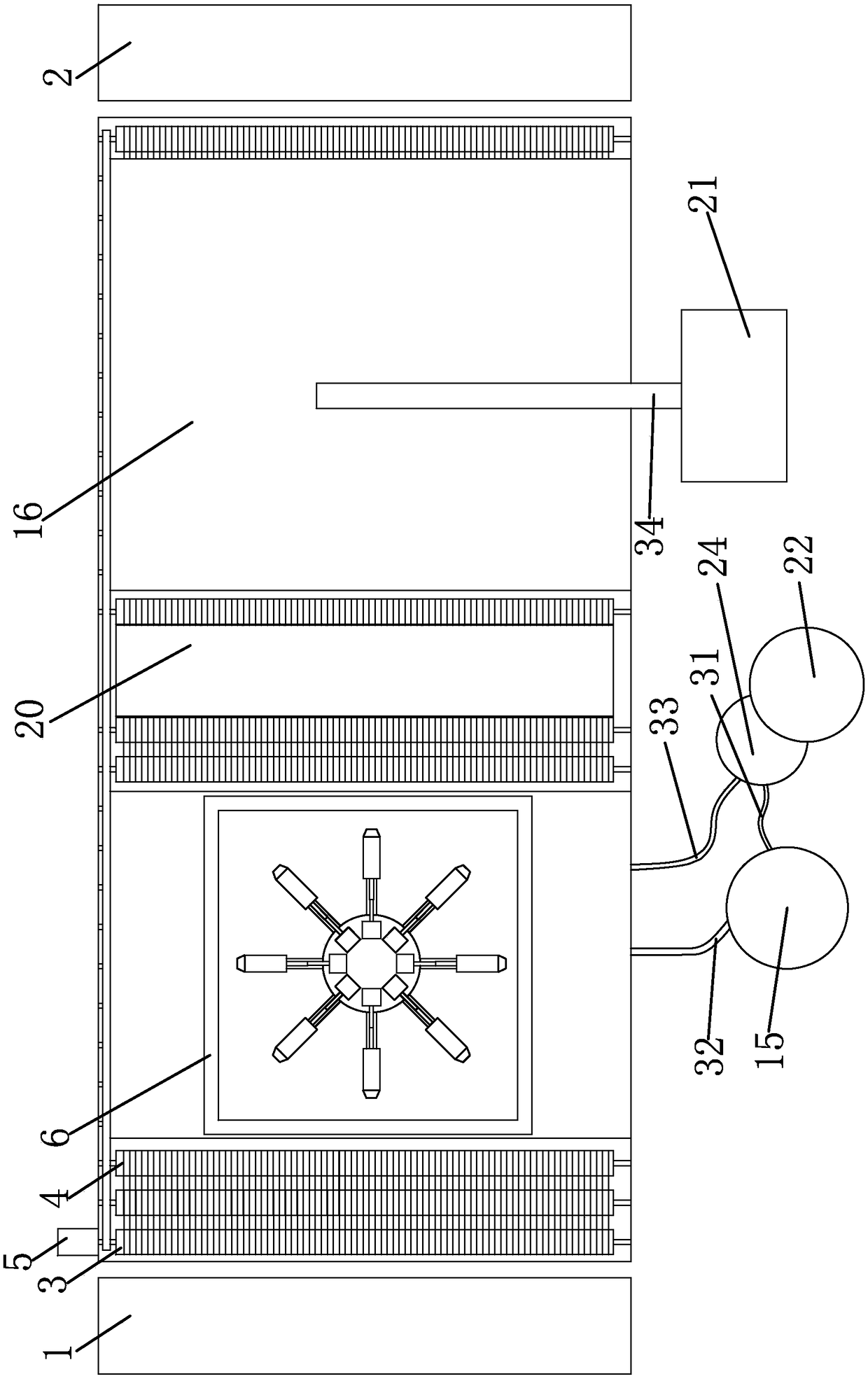

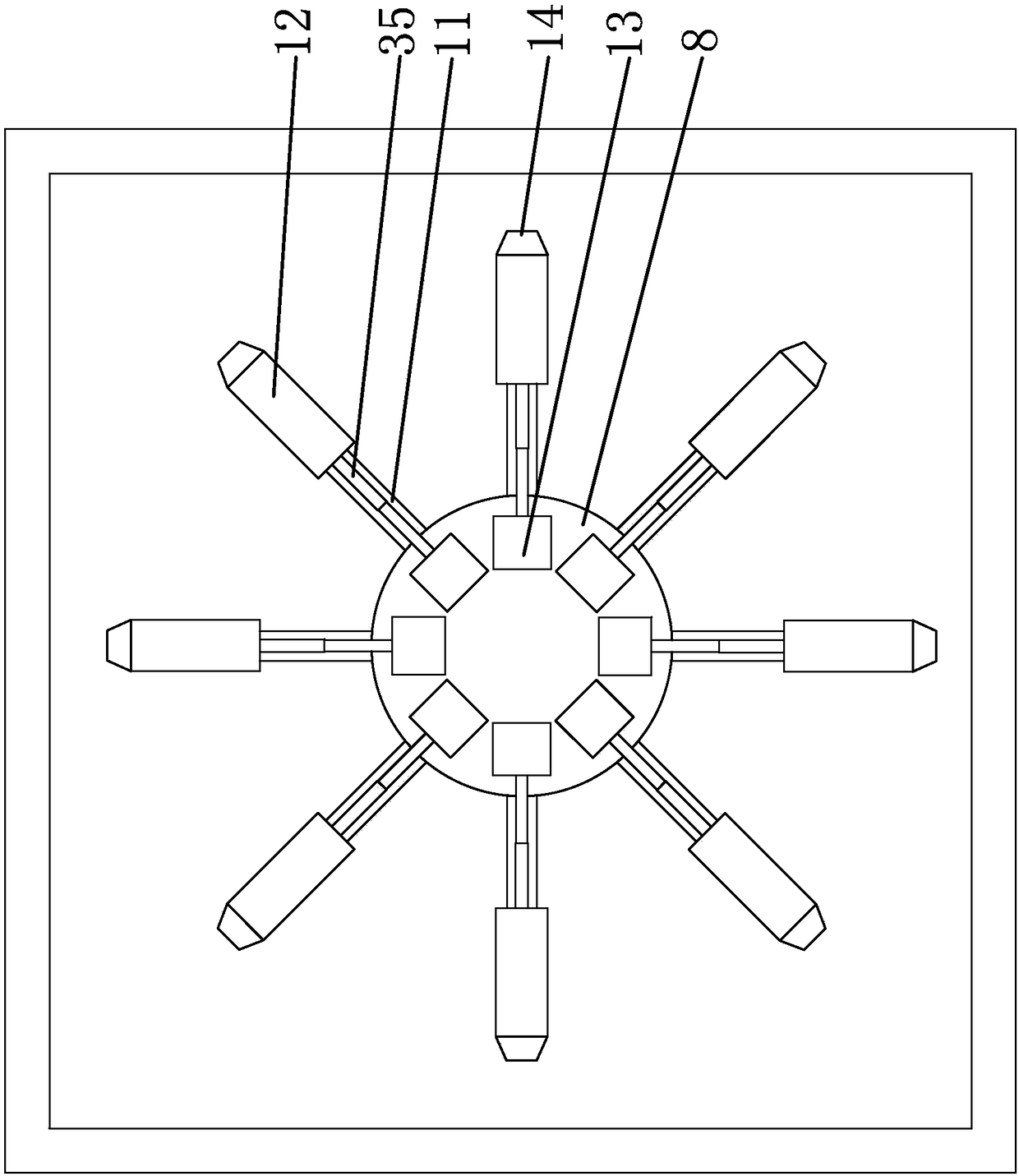

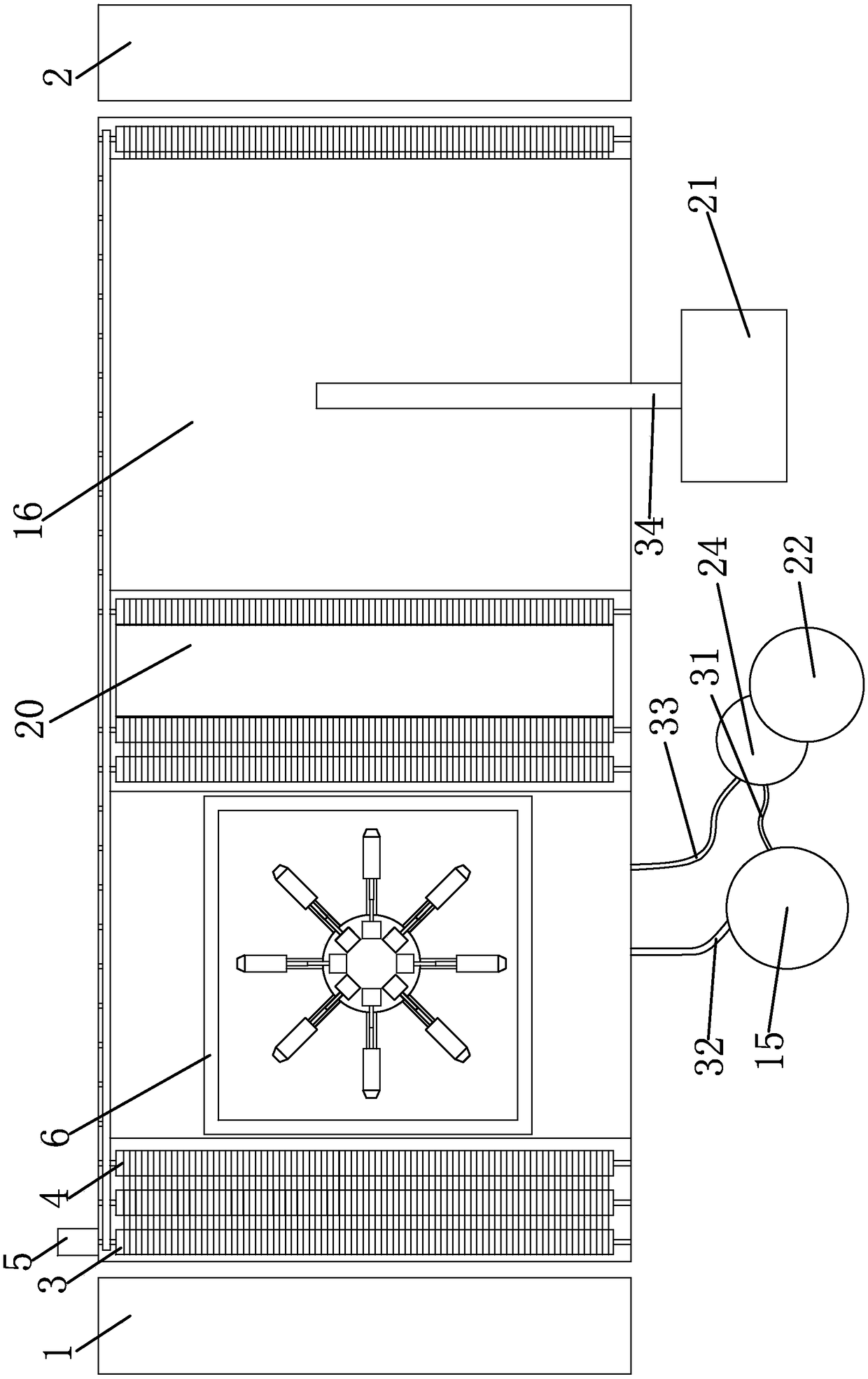

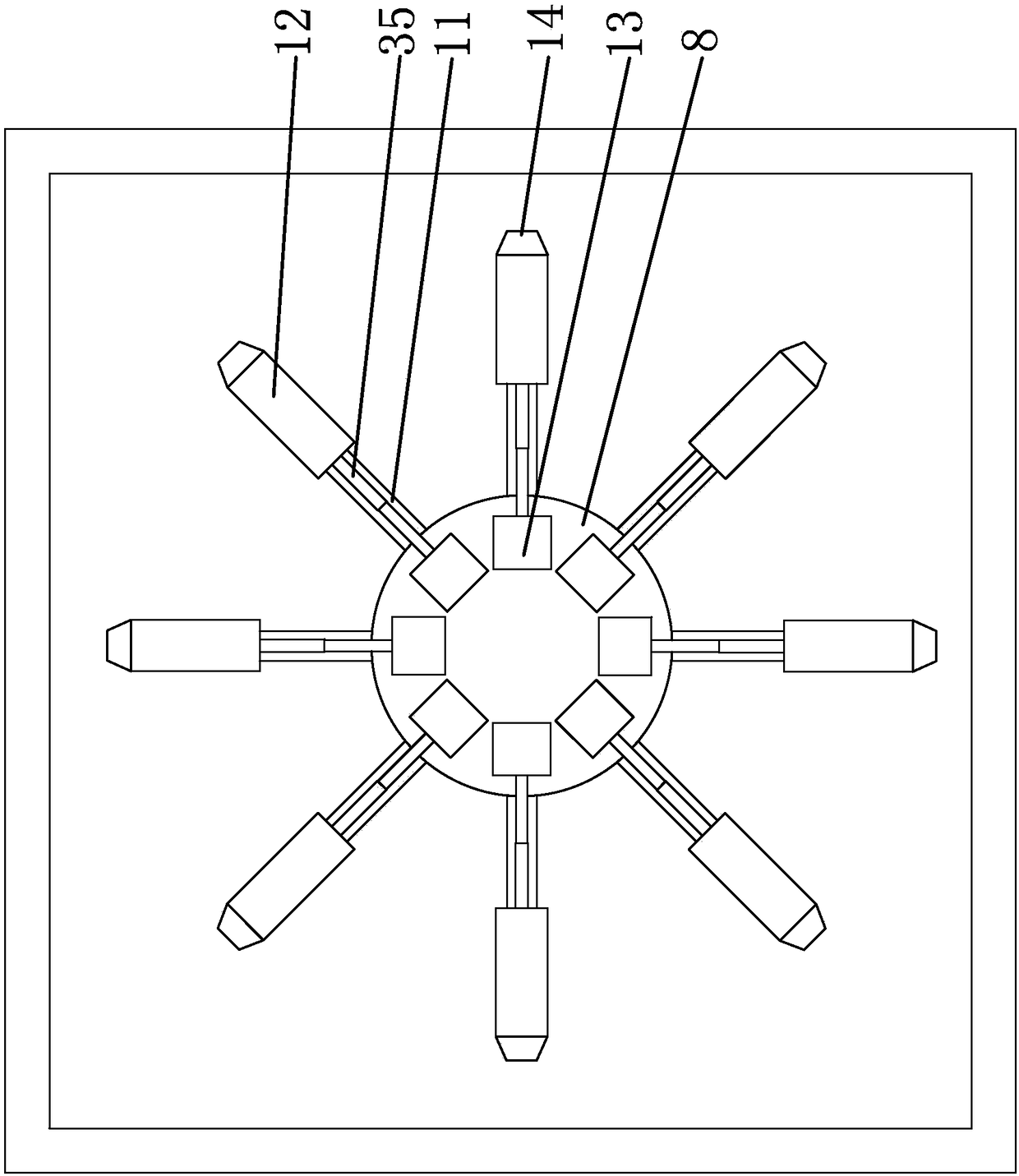

Spraying device for spraying vehicle leathers

PendingCN108273683AAvoid wastingReduce manufacturing costLeather/skins/hides/pelt chemical treatment apparatusSpray boothsProduction lineElectric machine

The invention provides a spraying device for spraying vehicle leathers, belongs to the technical field of spraying machines, and solves the problem of bad waste in the prior art. In the spraying device for spraying the vehicle leathers, a production line for machining the vehicle leathers comprises a base and a frame fixed on the base; the spraying device comprises a working base, a rotating motor, a rotating frame, multiple nozzles and multiple induction probes; the working base is fixed on the base; the rotating motor is fixed above the working base through a bracket, and an output shaft isvertical upwards; the rotating frame comprises a rotating shaft; a mounting base is fixed at the top of the rotating shaft; multiple slide rails are horizontally and annularly arranged on the mountingbase; slide bars are slidingly arranged on the slide rails; mounting blocks are fixed on the slide bars; the nozzles and the induction probes are fixed on the mounting blocks; multiple first push rodmotors are arranged on the mounting bases; and output shafts of the first push rod motors are coaxially connected with the slide bars through connecting bars. The spraying device for spraying the vehicle leathers has the advantage of decelerating wastes of spraying liquid.

Owner:浙江富邦汽车内饰科技有限公司

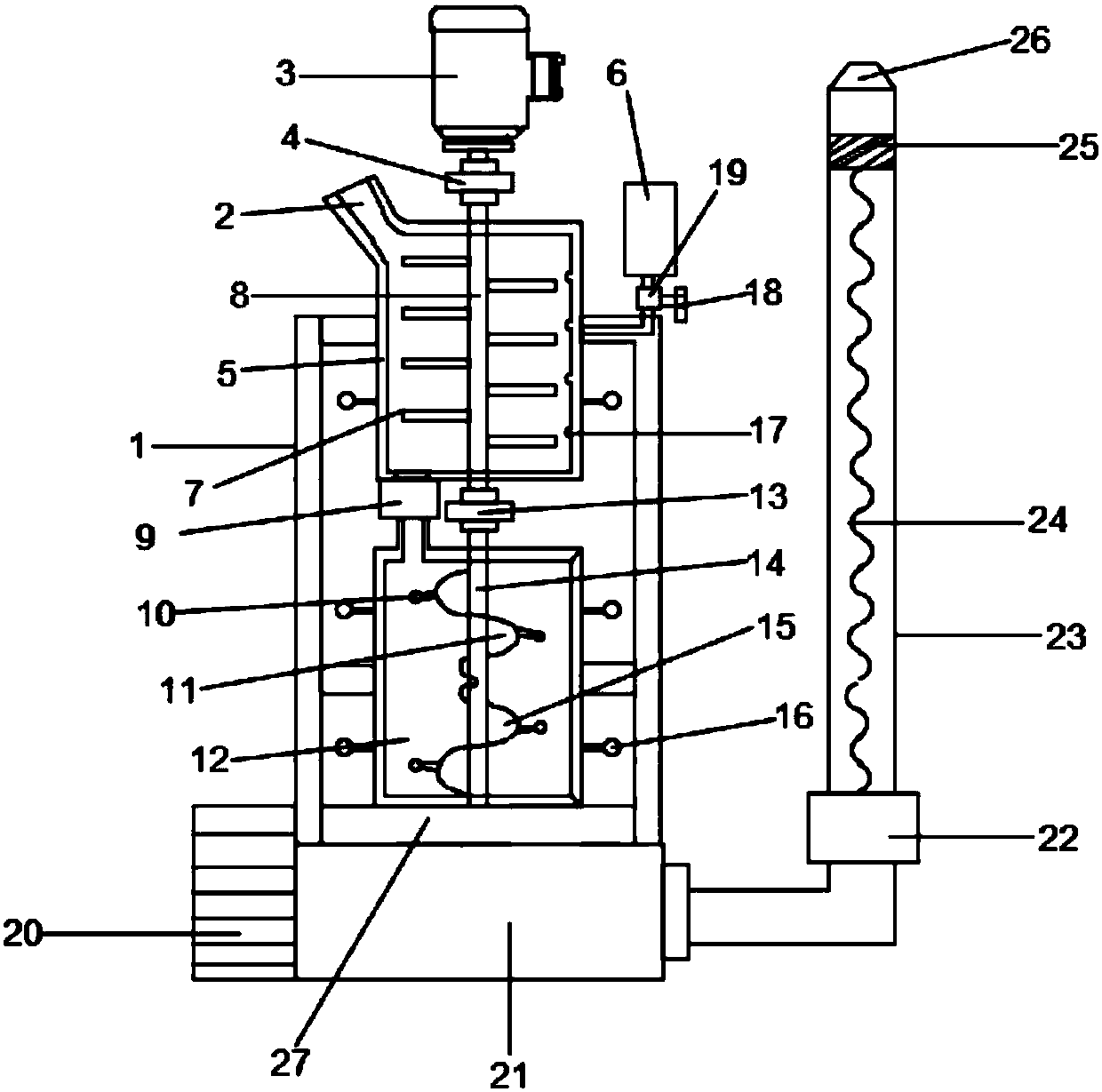

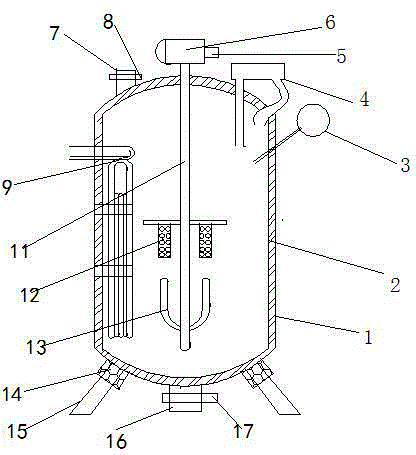

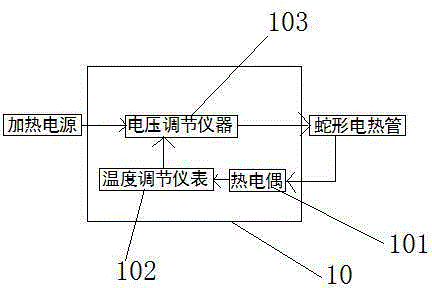

Chemical reactor

InactiveCN105727865AIncrease contact areaImprove heating efficiencyRotary stirring mixersMixer accessoriesAutomatic controlVoltage regulation

The invention discloses a chemical reactor. The chemical reactor comprises a tank, an electric motor and a temperature control system; the temperature control system comprises a thermocouple, a temperature control instrument and a voltage regulator; a mixing shaft is vertically arranged in the tank; a U-shaped mixer and a plate are connected to the mixing shaft; the mixing shaft is connected to the electric motor; a frequency converter is connected to the electric motor; a serpentine heating tube is arranged in the tank; the serpentine heating tube is connected to the temperature control system; an anti-corrosion layer is arranged on an inner wall of the tank; a material inlet and a material outlet are respectively arranged at a top and a bottom of the tank; a condenser reflux is further arranged at the top of the tank; a barometer is arranged on one outer side of the tank; support legs are arranged under the bottom of the tank; and vibration absorbers are arranged on the support legs at the joints of the support legs and the tank. The invention has the following beneficial effects: the chemical reactor is simple and compact in structure and practical in functions; and the chemical reactor is capable of heating rapidly and controlling heating temperature automatically; moreover, the chemical reactor is capable of adjusting rotation speed of the electric motor by itself, so that operation time of the chemical reactor is reduced and work efficiency and quality of the chemical reactor are improved.

Owner:天津天成昇科技有限公司

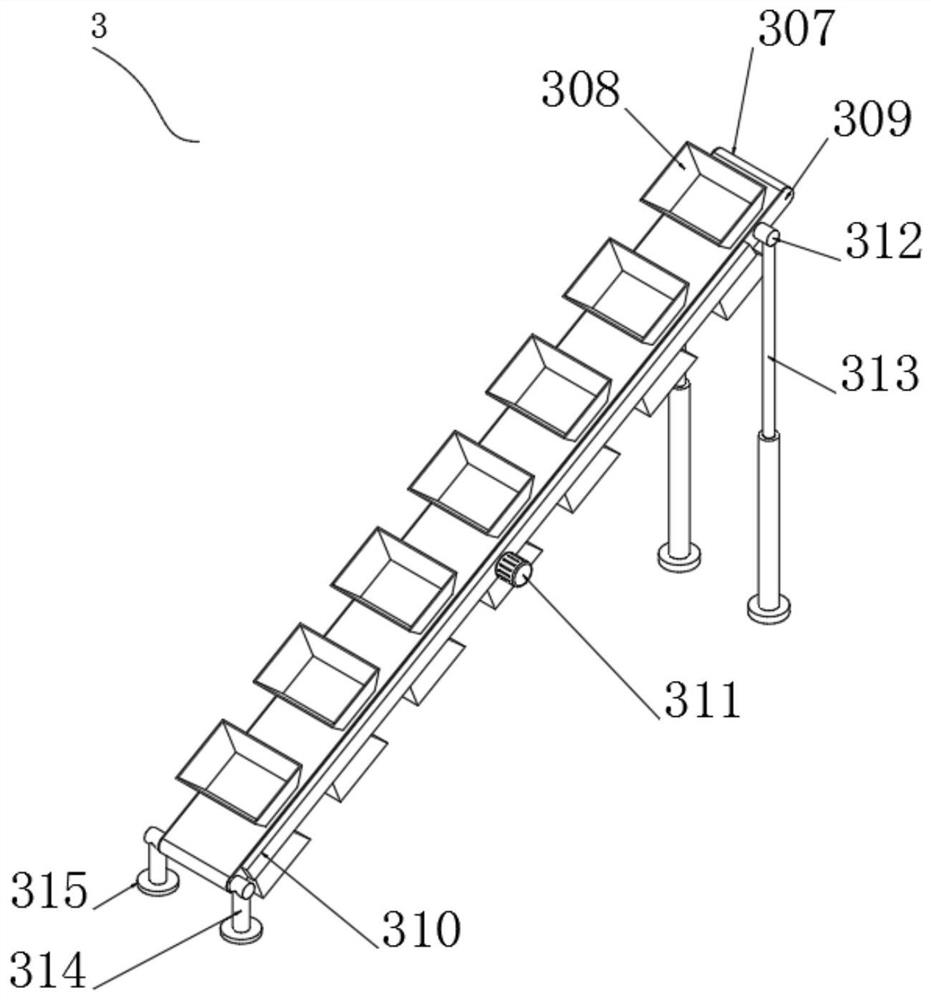

Concrete mixing equipment convenient for feeding and discharging materials

InactiveCN111702958AScientific and reasonable structureEasy to useDischarging apparatusCement mixing apparatusElectric machineryFan blade

The invention discloses concrete mixing equipment convenient for feeding and discharging materials. The bottom side of a mixing tank is installed with the top side with a support frame in a rotated manner; the feeding end of the mixing tank is installed with a feeding component; the feeding end of the mixing tank is welded with a connecting pipe; a fixed rod is welded on the inside of the connecting pipe; a linkage rod is welded on one side of the fixed rod; a rotating fan blade is welded on one side of the linkage rod; a conveyor belt is placed on one side of an inlet hopper; a number of feeding hoppers are installed on the outside of the conveyor belt; a reduction box is installed on one side of the conveyor belt; and a transmission motor is installed on one side of the reduction box. According to the invention, the feeding component is arranged, and through the connecting pipe, the fixed rod, the linkage rod, the rotating fan blade and the inlet hopper, the material conveyed into the inlet hopper is driven into the mixing tank through the rotating fan blade, therefore, the operations of the staff is reduced; and through the conveyor belt, the inlet hopper, the reduction box andthe transmission motor, the workers can easily send the materials into the inlet hopper, therefore, the labor intensity of workers is reduced, and the conveying speed is accelerated.

Owner:李彦红

Pyrolysis stirring apparatus for treating contaminated soil

InactiveCN110142288AImprove stirring efficiencyFully heatedContaminated soil reclamationAgricultural engineeringUltrasonic vibration

The invention discloses a pyrolysis stirring apparatus for treating the contaminated soil. The apparatus comprises a machine frame and a pyrolysis tank welded on the machine frame, wherein the top ofthe pyrolysis tank is connected with a top cover by bolts, the top cover is provided with a material inlet and a gas discharge port, a jacket is disposed at the outer side of the side wall of the pyrolysis tank, the jacket is provided with an oil inlet and an oil outlet, the side wall of the pyrolysis tank is provided with at least one set of ultrasonic vibration components, the bottom of the pyrolysis tank has a funnel shape, a stirring component is arranged at the center of the bottom of the pyrolysis tank, and a material discharge component is further arranged at the bottom of the pyrolysistank. The apparatus can fully stir the soil to ensure that the soil can be uniformly heated.

Owner:HUNAN CITY UNIV

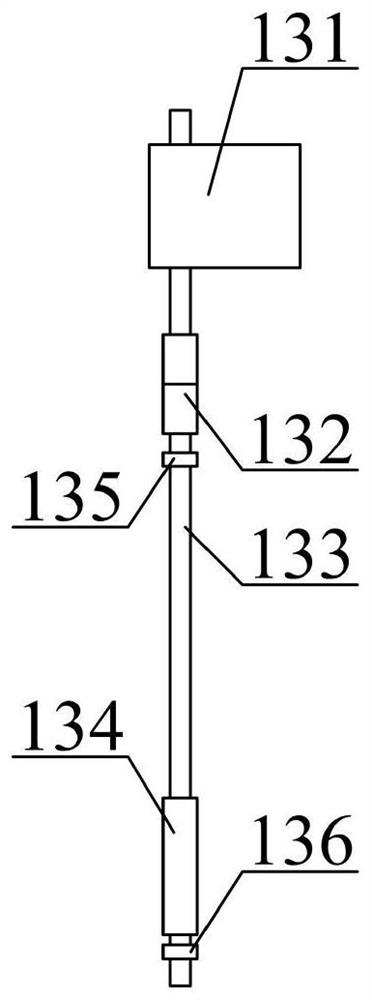

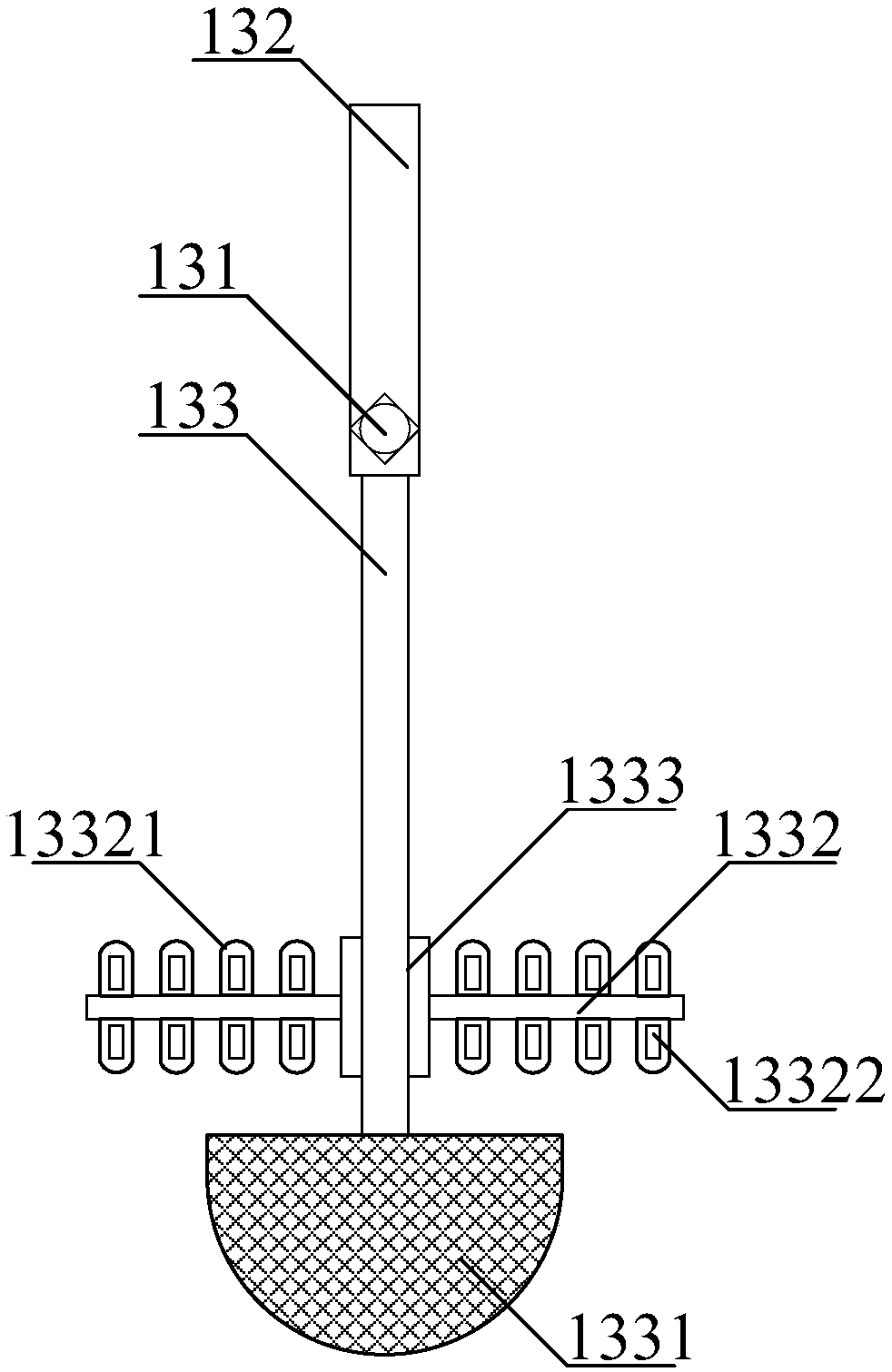

Combined fertilizer stirring rod

ActiveCN108014671ASpacing is easy to adjustStir wellRotary stirring mixersTransportation and packagingArchitectural engineeringSteel tube

The invention provides a combined fertilizer stirring rod. The stirring rod comprises a primary connecting sleeve, a primary fastening bolt, a combined detachable rod, an adjustable stirring rod, a secondary connecting sleeve, a secondary fastening bolt, a detachable and replaceable breaking rod and a protective steel tube, wherein the primary connecting sleeve is longitudinally welded to the upper middle position of the adjustable stirring rod; the protective steel tube is longitudinally inserted and connected at the inner upper part of the primary connecting sleeve; the combined detachable rod is longitudinally fixed at the inner upper part of the protective steel tube; the primary fastening bolt is in threaded connection with the right middle position of the primary connecting sleeve; the second connecting sleeve is longitudinally welded in the lower middle position of the adjustable stirring rod. The stirring rod can be replaced according to use requirements, can be combined with other use tools and realizes functions of replacement convenience and quick detachment.

Owner:博兴中嘉汇信息技术服务有限公司

Material transportation device for building concrete construction

ActiveCN111775315BSupport stabilityPrevent dumpingCement mixing apparatusHand cart accessoriesRubber materialArchitectural engineering

The invention relates to the technical field of building construction, and discloses a material transport device for building concrete construction, which includes a concrete transport box and a lift box, and the lift box is located below the concrete transport box. The material transport device for building concrete construction can quickly and stably support the concrete transport box through the rubber support pad when the ground is uneven during the moving process, effectively avoiding the concrete transport box from dumping when the ground is uneven When the situation occurs, the flexibility of the lifting device and the stability of the lifting device can be effectively improved. During the transportation process, the motor can be started to make the rotating rod rotate, so that the mixing plate can stir the concrete inside the concrete transport box to prevent condensation and collapse. It solves the problem of concrete hardening while ensuring mixing efficiency, and because the mixing plate and the rotating rod are threaded through bolts, the mixing plate can be replaced quickly, shortening the repair time and ensuring work efficiency.

Owner:至赢建设有限公司

Multifunctional coating type foam magnesium alloy casting device

InactiveCN113333733AEasy to stir and filterGuarantee casting qualityCasting cleaning apparatusMould handling equipmentsElectric machineryMolten metal

The invention provides a multifunctional coating type foam magnesium alloy casting device. The multifunctional coating type foam magnesium alloy casting device comprises a cross beam, vertical bases, landing foot bases, a rack, a lower die, an upper die, a first connecting pipe head, a metal hose, a second connecting pipe head, a buffer barrel and a control panel; the cross beam is connected to the upper portion between the vertical bases through transverse bolts; the lower ends of the vertical bases are connected with the landing foot bases through bolts; the middle lower portion of the inner side between the vertical bases is connected with the rack through bolts; and the middle portion of the upper portion of the rack is connected with the lower die through bolts. According to the multifunctional coating type foam magnesium alloy casting device, a stirring motor, a molten metal stirring box, a stirring shaft, stirring blades, an impurity filtering net and a cleaning plate are arranged, molten metal is stored through the molten metal stirring box, then the stirring motor drives the stirring shaft and the stirring blades to rotate at a high speed, the molten metal can be stirred, accordingly, the stirring efficiency is guaranteed, and the situation that the casting effect is influenced due to uneven mixing is avoided; and the impurity filtering net assists in filtering large particles for casting, and the quality of a cast casting is guaranteed.

Owner:滨州鲁德曲轴有限责任公司

Cell disruption device for biological gene detection

InactiveCN109971644AImprove crushing efficiencyEasy to disassembleBioreactor/fermenter combinationsBiological substance pretreatmentsWater bathsUltrasonic sensor

The invention discloses a cell disruption device for biological gene detection. The cell disruption device comprises a tank, a water bath drum, a bottom plate and a base, the tank is mounted at the top end of the base, a control box is mounted at one end of the tank, a door is hinged to one side of the tank, an electromagnetic sliding rail is mounted at the inner top end of the tank, an electromagnetic slider is mounted at the bottom end of the electromagnetic sliding rail, an electric cylinder is mounted at the bottom end of the electromagnetic slider, a crushing box is mounted at the bottomend of the electric cylinder, an ultrasonic transducer is mounted at the inner top end of the crushing box, an amplitude transformer is mounted at the bottom end of the ultrasonic transducer and vertically penetrates the bottom end of the crushing box, a fixed plate sleeves the outer side of the crushing box, and driving boxes are mounted at the bottom ends of two sides of the fixed plate. By theaid of a first limit groove, a first limit block and a handle, a bearing block is conveniently drawn from the inside of the tank, so that a treatment cup is conveniently taken out.

Owner:魏绘

Negative ion air purification liquid, preparation method and special production equipment

PendingCN113828134ARealize automatic angle adjustment functionImplementing Angle ChangesGas treatmentLiquid degasificationElectric machineIonic crystal

The invention belongs to the technical field of air purification liquid, and discloses negative ion air purification liquid, a preparation method and special production equipment. The negative ion air purification liquid comprises the following components in parts by weight: 100-120 parts of negative ion crystals (powdery), 1-3 parts of a dispersing agent, 3-15 parts of a pH regulator, 10-20 parts of a natural hydrolat extracting solution and 50-60 parts of calcium carbonate (powdery). An adjusting column is driven to move, and rotation of the moving column in the moving process is completed through path guidance in an angle adjusting cavity, so that angle change of stirring blades during rotation is achieved, the contact area with materials is reduced at a high rotating speed, resistance is reduced, electric power used by a motor is saved, meanwhile, by arranging a first limiting ring, a reset spring and a second limiting ring, under the condition of low rotating speed, outward tension generated by the stirring blades on the moving column due to the centrifugal phenomenon is smaller than counter-acting force of the reset spring, low rotating speed causes low resistance, at the moment, the angle of the stirring blades is not changed in time, too large resistance cannot be caused, and the stirring efficiency is kept.

Owner:施凯西(广东)生物技术有限公司

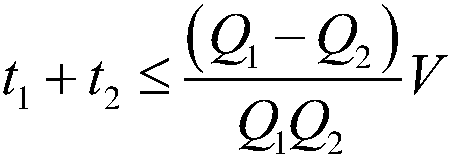

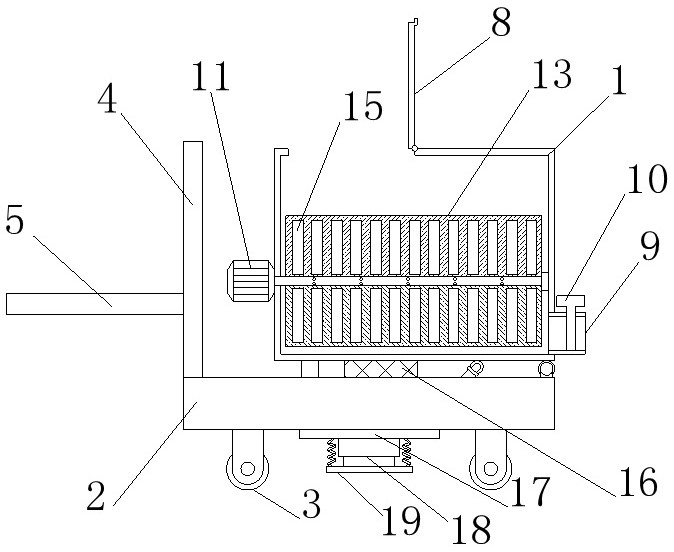

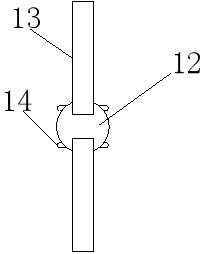

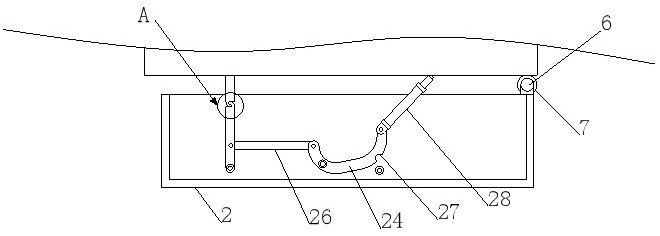

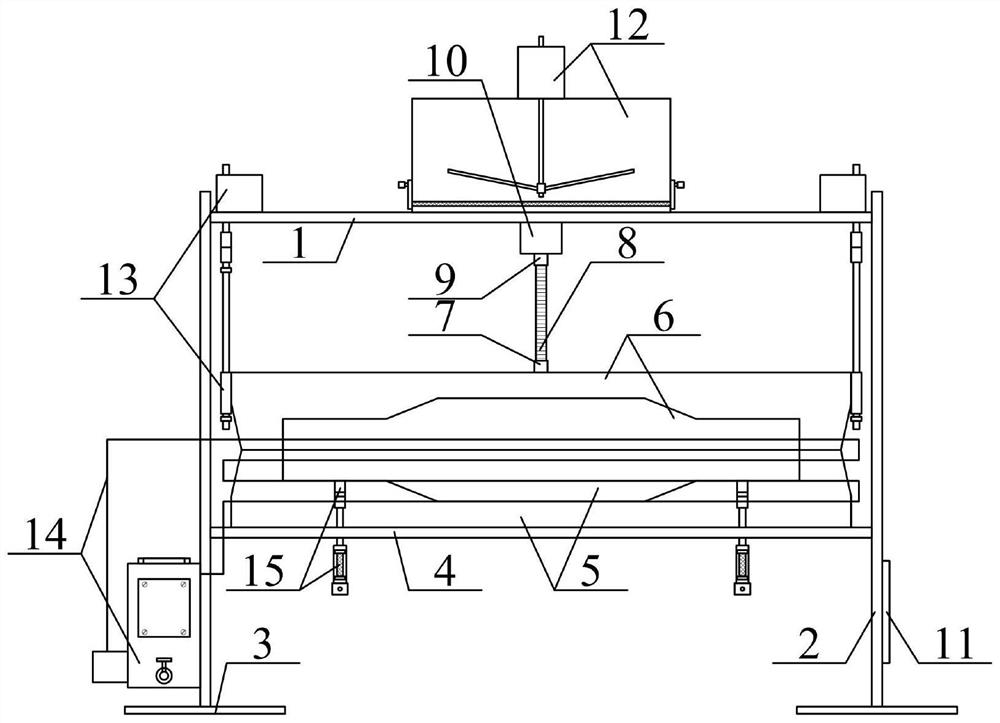

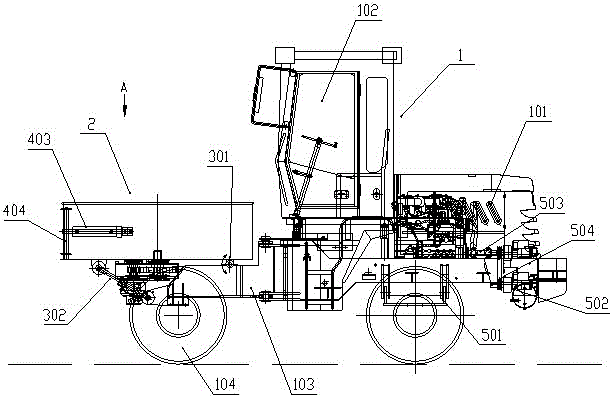

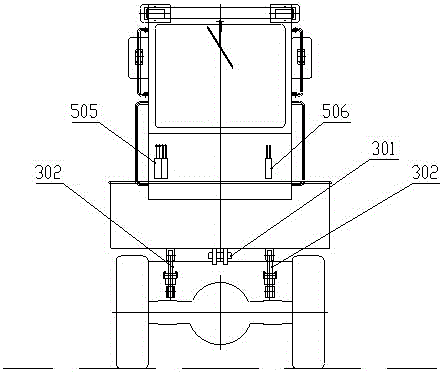

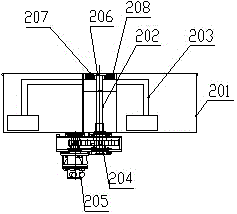

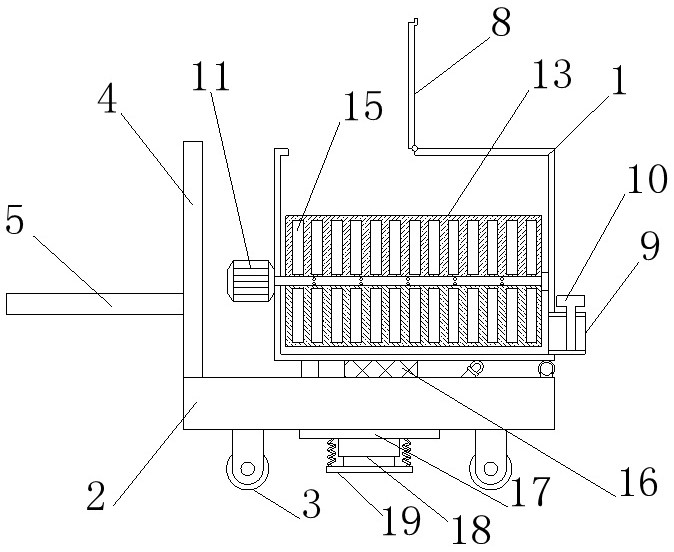

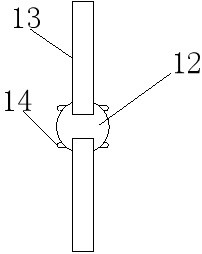

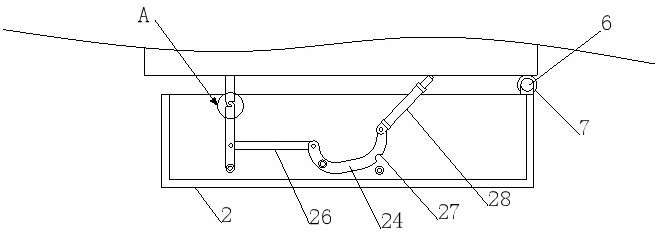

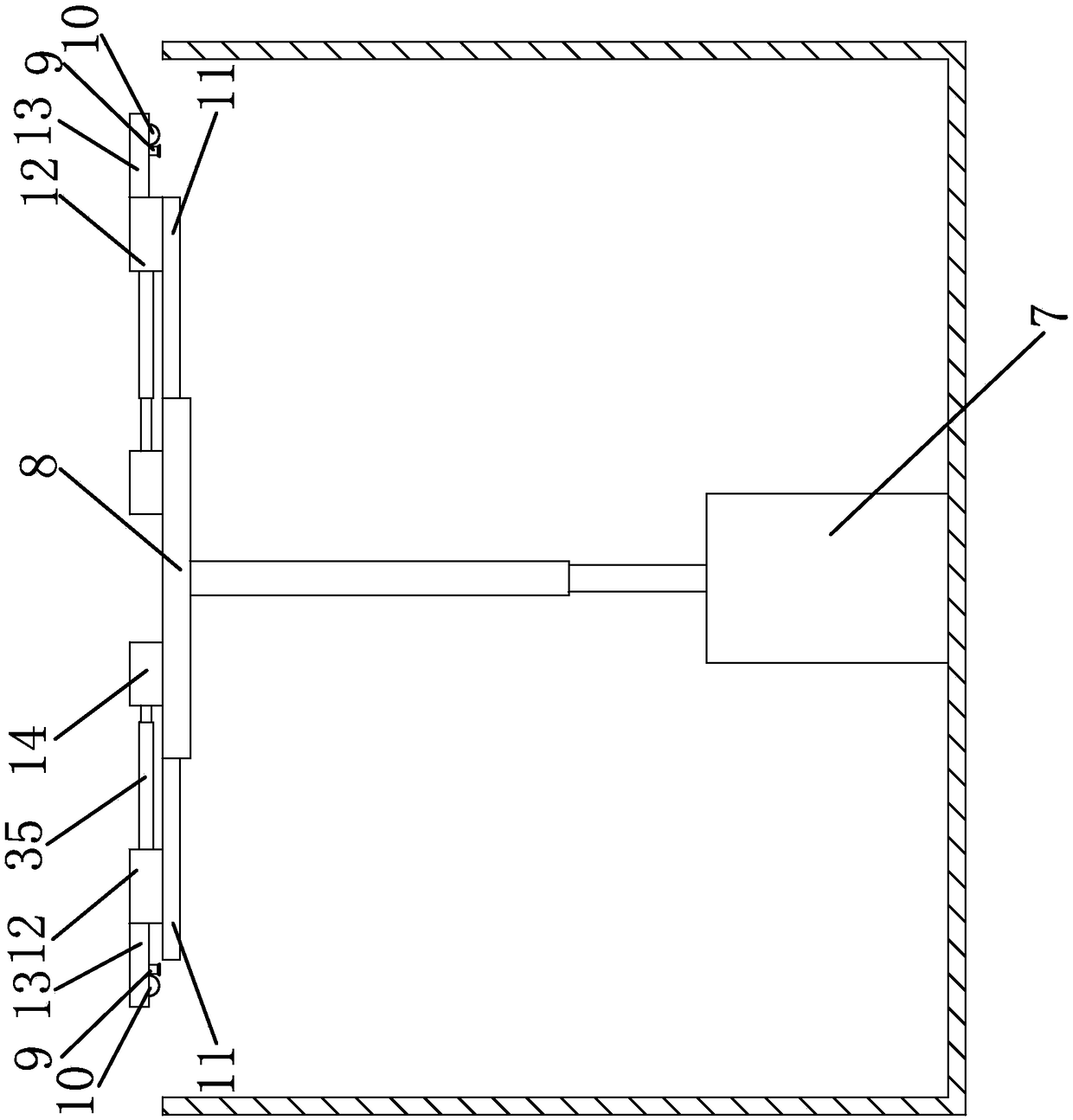

self-propelled hydraulic mixer

ActiveCN104760137BGuaranteed stirring efficiencyDischarging apparatusCement mixing apparatusTransverse axisAutomotive engineering

A self-propelled hydraulic agitator is disclosed. The hydraulic agitator comprises a movable vehicle body and an agitator mounted on the vehicle body. The agitator can rotate around a horizontal shaft parallel to the vehicle shaft of the vehicle body, and is driven to swing around the horizontal shaft by first swing cylinders on the vehicle body. When the vehicle body works on a slope, the agitator is driven to swing by the first swing cylinders, and the axial position of the agitator can be adjusted to ensure that the agitator is not inclined at the axial direction, thus effectively ensuring the agitating efficiency of the agitator.

Owner:CHONGQING HONGGONG INSTRUCTIONAL MACHINE

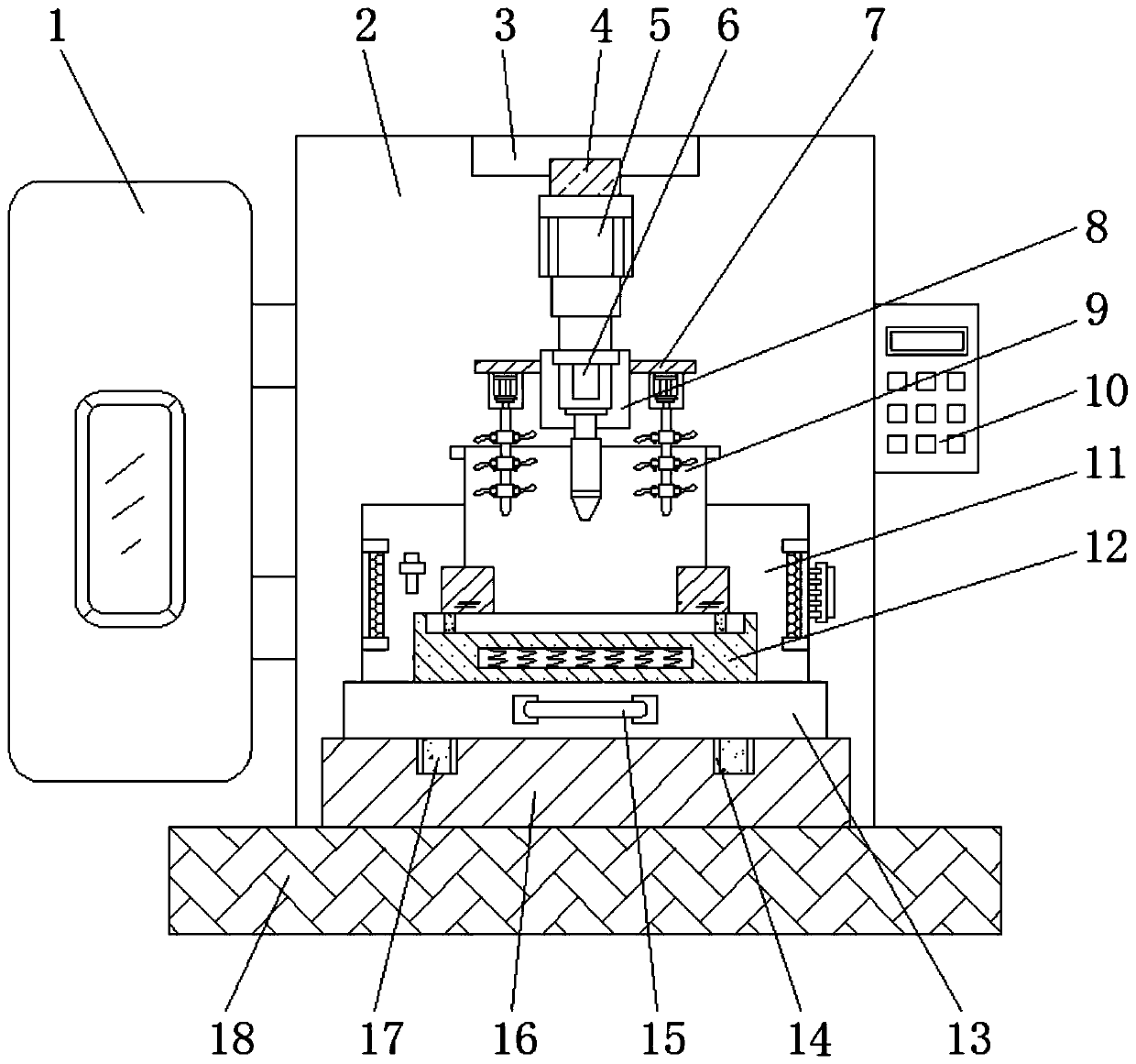

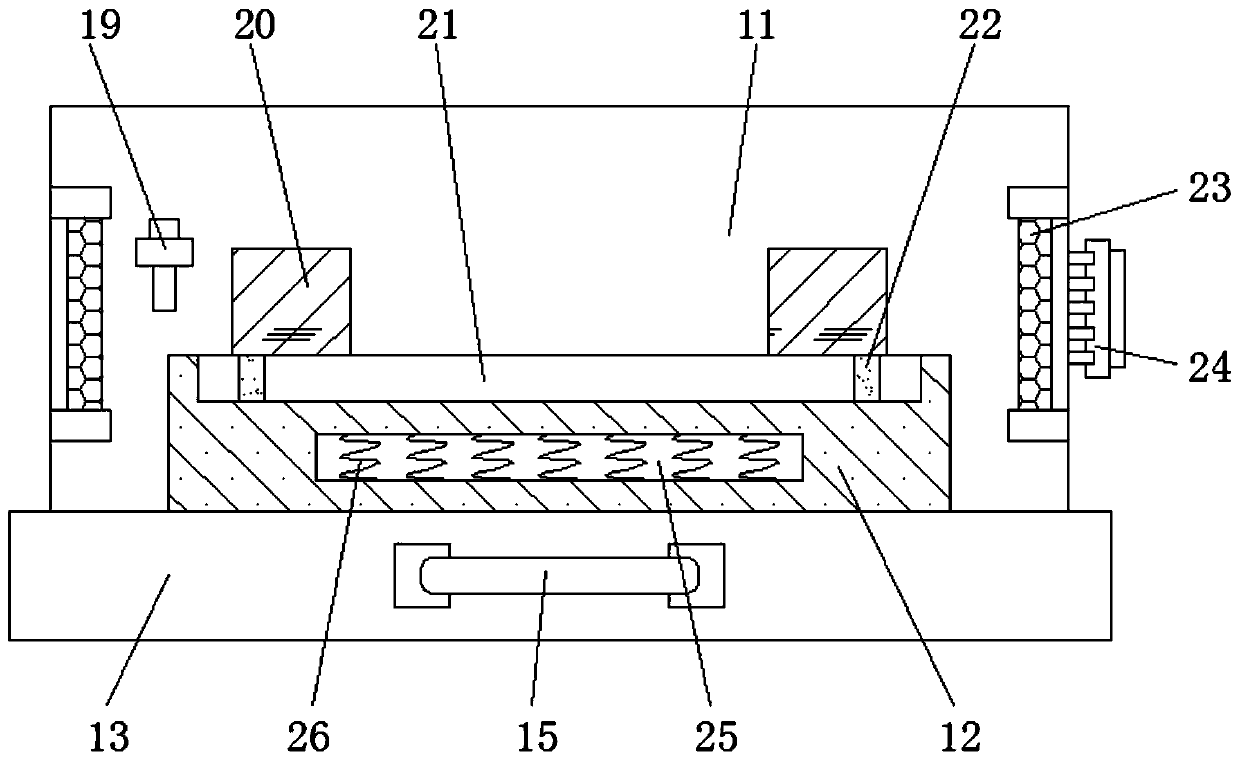

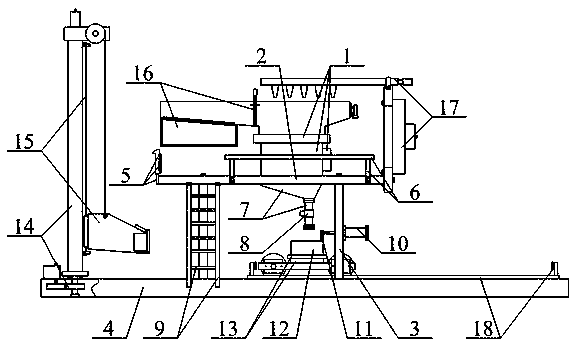

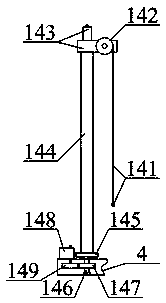

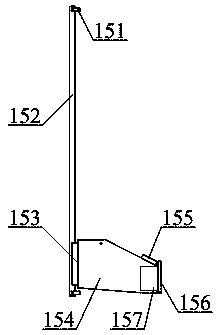

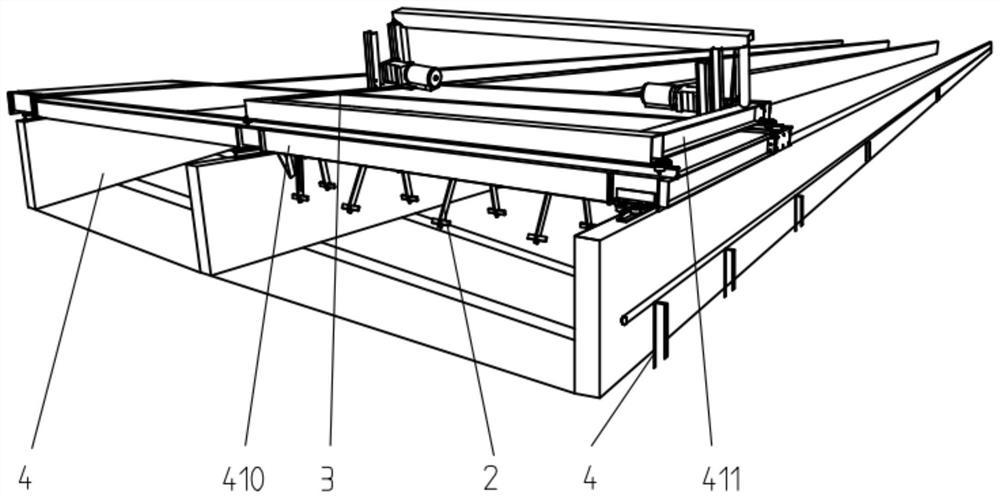

Intelligent brick-making system equipment

ActiveCN110605775AChange the cumbersome wayImprove securityFeeding arrangmentsAuxillary shaping apparatusBrickSelf locking

The invention provides intelligent brick-making system equipment. The equipment comprises a brick-making raw material mixer, a mixing operation platform, a platform building pillar, a supporting base,an intelligent main control integrated machine, a platform operation protective fence, a pipe for discharging the mixed brick-making raw material, a discharge electromagnetic control valve, a mobileclimbing ladder, an auxiliary flattening cylinder, a flattening slab, a brick-making mold, a brick-making shaking table, a rotatable self-lifting self-locking machine structure, a slidable self-controlling raw material lifting bucket structure, a quantity controllable type raw material filtering and vibrating bucket structure, a heat-dissipative dust-proof spraying branch pipe structure and a self-moving brick lead-out wheel structure, wherein the brick-making raw material mixer is bolted at the upper right middle position of the mixing operation platform. Through the arrangement of a liftingrope, an I-shaped storage wheel and a self-locking reduction motor, the cumbersome way of lifting raw materials of an original crane is changed. The self-locking reduction motor is used for lifting the rope, so that good self-locking effect can be achieved, and the security is improved.

Owner:DEZHOU TIANYUAN GRP

Multifunctional stirring device for aluminum alloy production

PendingCN108043280APrevent stirring efficiency from being affectedGuaranteed stirring efficiencyTransportation and packagingRotary stirring mixersCouplingImpurity

The invention provides a multifunctional stirring device for aluminum alloy production. The stirring device comprises a stirring motor, a support plate, an upper cover, quick locking devices, a stirring casing, foot stands, a feeding hopper, detachable stirring frames, a main shaft, a sleeve coupler, replaceable stirring blades, stirring shafts and a fishing filter screen structure, wherein the stirring motor is arranged in the middle of the upper part of the upper cover through the support plate by bolts; the upper cover is mounted at the upper part of the stirring casing through the quick locking devices; the foot stands are mounted at the bottom of the stirring casing through bolts at an angle of 120 degrees. The hemispherical filter screen specifically adopts a hemispherical stainlesssteel mesh, and impurities in an aluminum alloy solution can be effectively filtered, so that a discharged aluminum alloy solution is cleaner; overflow holes are circular through holes with diameter being 3-5 cm, and two overflow holes are formed in each stirring blade body, stirring efficiency can be ensured, and the influence on the stirring efficiency due to blockage of the overflow holes by the aluminum alloy solution is prevented.

Owner:无锡新区鸿声铝品有限公司

Material transporting device for building concrete construction

ActiveCN111775315ASupport stabilityPrevent dumpingCement mixing apparatusHand cart accessoriesElectric machineArchitectural engineering

The invention relates to the technical field of building construction, and discloses a material transporting device for building concrete construction. The material transporting device for building concrete construction comprises a concrete transporting box and a lifting box, and the lifting box is located below the concrete transporting box. According to the material transporting device for building concrete construction, when the ground is uneven in the moving process, rapidly and stably supporting can be carried out on the concrete transporting box through a supporting pad made of rubber, so that the situation that the concrete transporting box topples over when the ground is uneven is effectively avoided, and the stability of the device is effectively improved while the flexibility ofthe device is improved; in the transportation process, a motor can be started to enable a rotating rod to rotate, so that a stirring plate stirs concrete in the inner part of the concrete transportation box to prevent coagulation and collapse, and the problem of concrete hardening is solved while the stirring efficiency is guaranteed; and the stirring plate is in threaded connection with the rotating rod through a bolt, so that the stirring plate is quickly replaced, the repairing time is shortened, and the working efficiency is ensured.

Owner:至赢建设有限公司

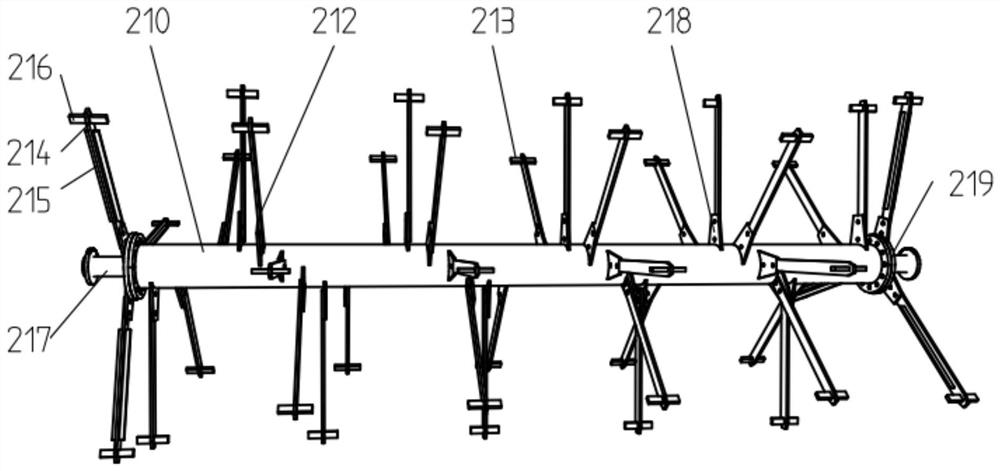

Organic fertilizer stirring and aeration equipment

PendingCN111871252AStir wellFully breathableBio-organic fraction processingRotary stirring mixersAgricultural scienceAgricultural engineering

The invention relates to the technical field of organic fertilizer stirring equipment, and discloses organic fertilizer stirring and aeration equipment, which comprises a stirring tank, a stirring device and an aerating device; the stirring tank is composed of a plurality of stirring channels arranged side by side, the stirring device is arranged on the stirring tank and used for stirring organicfertilizer in the stirring tank, and the aerating device is arranged on the lower portion of the stirring tank in order to supply gas to the organic fertilizer in the stirring tank. Through the stirring blades arranged at one end of the first stirring rod, it can be guaranteed that the stirring shaft can fully stir organic fertilizer in the stirring process and can also push the organic fertilizerin the stirring direction, and it is avoided that due to the fact that the first stirring rod pushes the organic fertilizer to the two ends in the rotating stirring process, stirring is uneven, and the stirring efficiency is low. In addition, the aeration device ensures that the organic fertilizer can fully ventilate in the stirring tank, thereby avoiding the decay of the organic fertilizer.

Owner:诺日布斯仁

Stirring processing device and working method thereof

InactiveCN108435010AReduce usageReduce exposureRotary stirring mixersTransportation and packagingCircular discInlet channel

The invention discloses a stirring processing device. The stirring processing device comprises a support and a device casing arranged on the support, wherein a feed port is formed in the top of the device casing, a discharge port is formed in the bottom of the device casing, a cylinder with open top surface is arranged in the device casing, air nozzles are uniformly fixed on the side wall of the cylinder, a stirring motor is fixed on the top wall of the device casing, a stirring shaft lever is connected to a spindle of the stirring motor, an air inlet channel with open top surface is formed inthe stirring shaft lever, air blowing ports communicated with the air inlet channel are formed fixedly in the side wall of the stirring shaft lever, a mounting disc is fixed at the upper part of thestirring shaft lever, clamp grooves are formed in the bottom surface of the mounting disc, and the top end of the cylinder is propped in the clamp grooves in the bottom surface of the mounting disc and fixed through screws. The stirring processing device is reasonable in structure arrangement, convenient to operate, good in use stability and high in practicability, service life of a stirring shaftcan be prolonged, and the stirring shaft is convenient to replace.

Owner:李正梅

Concrete preparation method

ActiveCN112720843AEnsure mixing qualityAchieve differentiated deliverySievingSolid waste managementArchitectural engineeringStructural engineering

The invention belongs to the technical field of concrete preparation, and discloses a concrete preparation method. According to the concrete preparation method, a used concrete preparation device comprises a driving mechanism, a screening mechanism, a stirring mechanism and a water supply mechanism which are fixed to a mounting frame; the driving mechanism is connected with the screening mechanism, the stirring mechanism and the water supply mechanism and drives the screening mechanism, the stirring mechanism and the water supply mechanism to work. The screening mechanism comprises a first screening mechanism and a second screening mechanism, and the second screening mechanism is located between the first screening mechanism and the stirring mechanism and used for directly feeding the stirring mechanism; the second screening mechanism is connected with the water supply mechanism and is used for synchronously feeding and injecting water into the stirring mechanism. When the concrete preparation method is used for concrete preparation operation, the production quality of concrete can be improved.

Owner:湖南省云传供应链管理有限公司

Production line for processing automobile leather

PendingCN108300821AAvoid wastingReduce manufacturing costLeather/skins/hides/pelt chemical treatment apparatusProduction lineDrive motor

The invention provides a production line for processing automobile leather, and belongs to the technical field of leather processing. The problem that the processing efficiency is low in the prior artis solved. The production line for processing the automobile leather comprises a base and a machine frame fixed to the base, one end of the machine frame is provided with a feeding frame, the other end of the machine frame is provided with a discharge frame, a first conveying roller and a plurality of second conveying rollers are rotationally arranged on the machine frame, one end of the first conveying roller is connected with a driving motor capable of enabling the first conveying roller to rotate, a first chain wheel is coaxially fixed to the other end of the first conveying roller, the second conveying rollers are arranged parallel to the first conveying roller, a second chain wheel is fixed to the ends of the second conveying rollers, a first chain is arranged between the first chainwheel and the second chain wheels in a sleeving mode, a spraying device capable of achieving spraying for the automobile leather is arranged above the second conveying rollers, a drying device capable of drying the automobile leather is arranged at the end close to the discharge frame, and the machine frame is further provided with a preparation mechanism capable of preparing coating liquid. Theproduction line has the advantage of improving processing efficiency.

Owner:浙江富邦汽车内饰科技有限公司

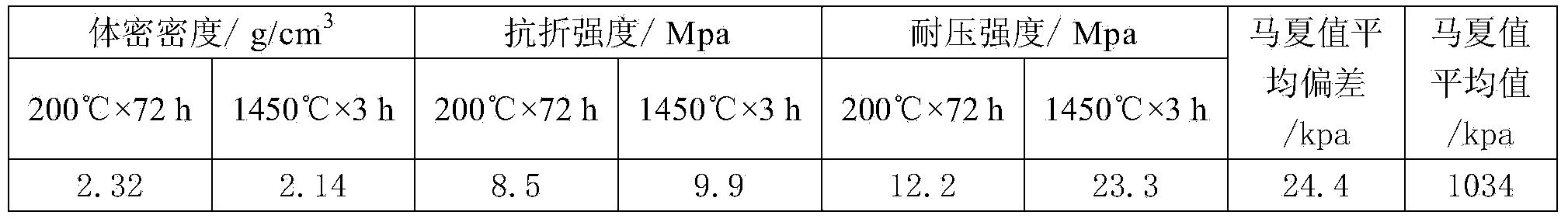

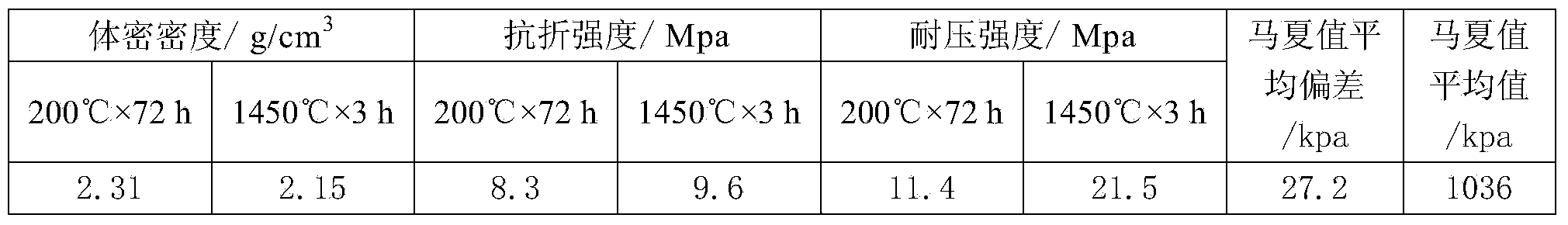

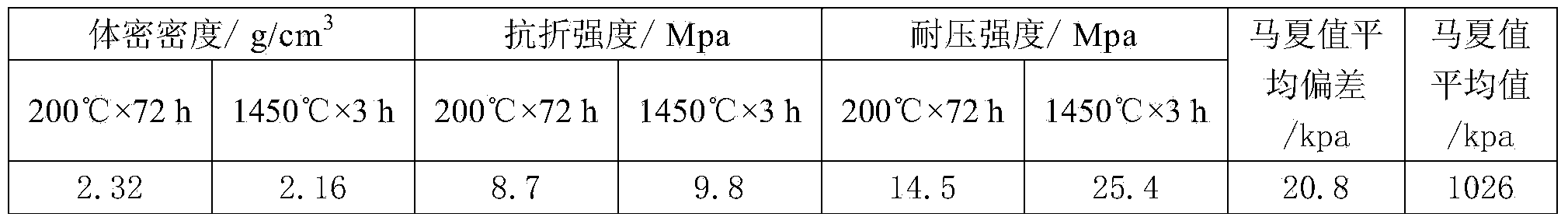

Stirring process for water-free taphole clay production process

InactiveCN104139458AImprove stirring efficiencyImprove stabilityClay mixing apparatusTime rangeMaterials science

The invention discloses a stirring process for the water-free taphole clay production process. The stirring process has the advantages that efficiency is high, bonding agents can fully wet aggregates and powder, the uniformity is good, and the stability is high. The stirring process comprises the steps of (1) conducting dry-blending, wherein various kinds of aggregates and powder weighed according to a formula are placed into a mixer for stirring, the stirring speed of a rotor ranges from 72 r / m to 108 r / m, and the stirring time ranges from 60 s to 120 s, (2) adding the bonding agents, wherein the bonding agents weighed according to the formula are placed into the mixer, the adding speed of the bonding agents ranges from 1.2 Kg / s to 2.2 Kg / s, and the stirring speed of the rotor ranges from 72 r / m to 108 r / m, and (3) conducting wet-blending. The stirring process can be widely applied to the water-free taphole clay production field.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com