Concrete preparation method

A technology for concrete and preparation device, which is applied in clay preparation device, chemical instrument and method, filter screen, etc., can solve the problems of insufficient mixing, poor homogeneity, and reduced screening efficiency of concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

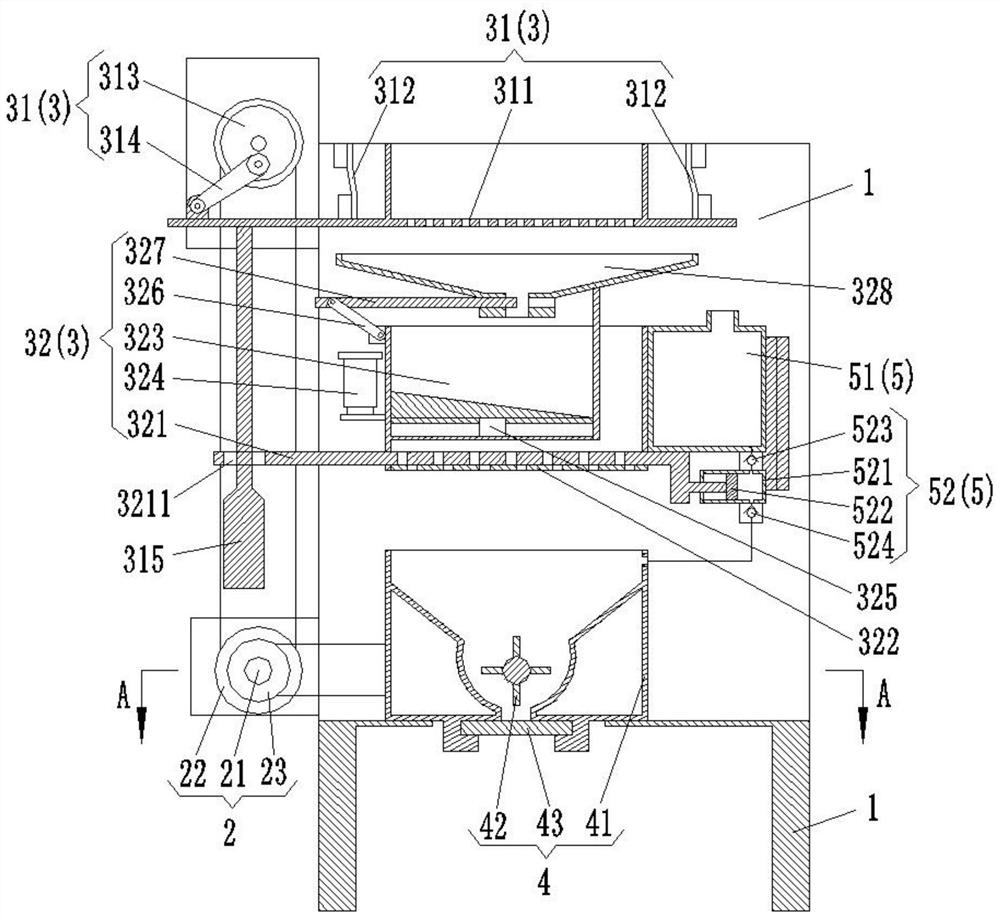

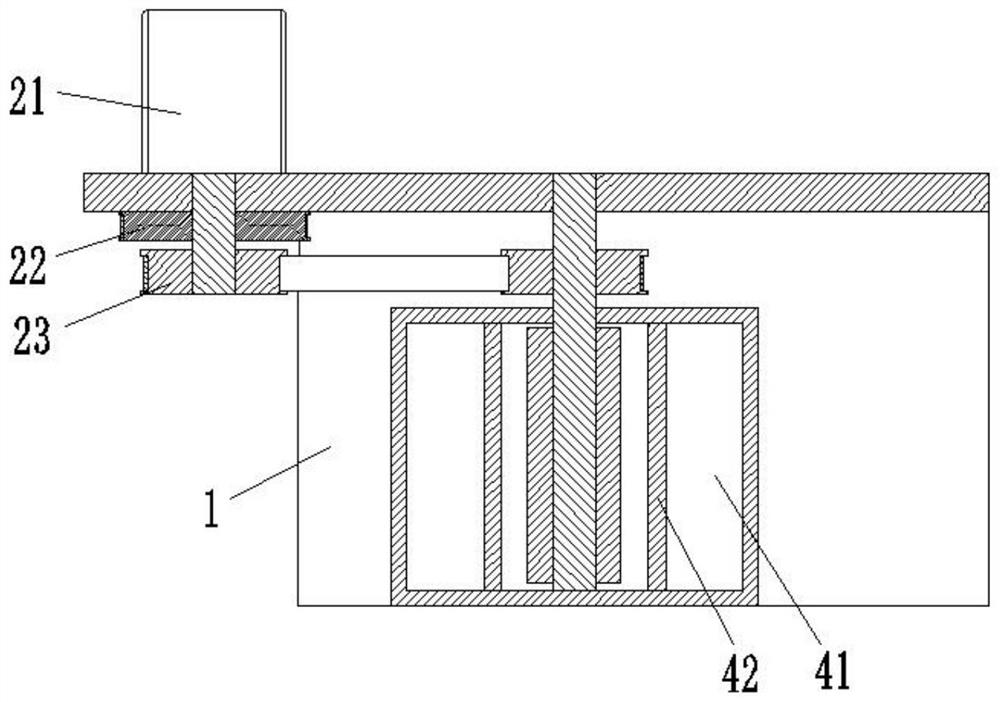

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] The concrete preparation method of the present embodiment specifically comprises the following steps:

[0030] Step S1, weighing the cement, water, admixture solution, and externally mixed material according to the mixing ratio.

[0031] Step S2, add part of the weighed water into the water tank of the concrete preparation device, put the remaining water, cement, admixture solution, and externally mixed materials into the mixing mechanism of the concrete preparation device, and put the materials to be added into the concrete preparation In the screening mechanism of the device.

[0032] Step S3, start the concrete preparation device to prepare concrete.

[0033] combine figure 1 with figure 2 As shown, the concrete preparation device of this embodiment includes a driving mechanism 2 fixed on a mounting fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com