Automatic rice-steaming, spreading-cooling and automatic-stirring integrated machine for brewing wine and rice-steaming, spreading-cooling and stirring process

An automatic stirring and integrated machine technology, which is applied in the field of brewing equipment and technology, can solve the problems of high labor intensity, low production efficiency, poor stirring effect, etc., and achieve the effect of improving stirring efficiency, improving work efficiency, and efficient operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

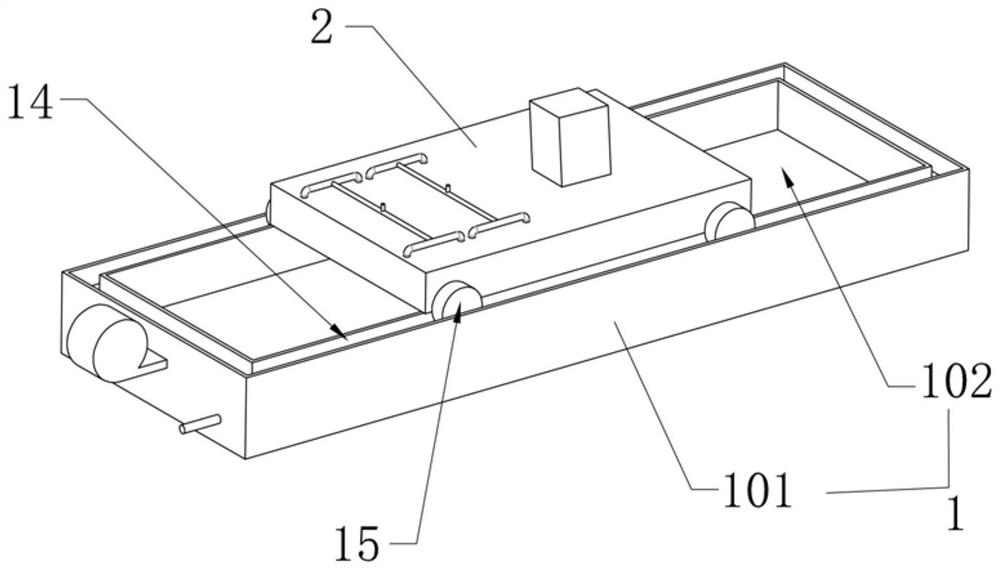

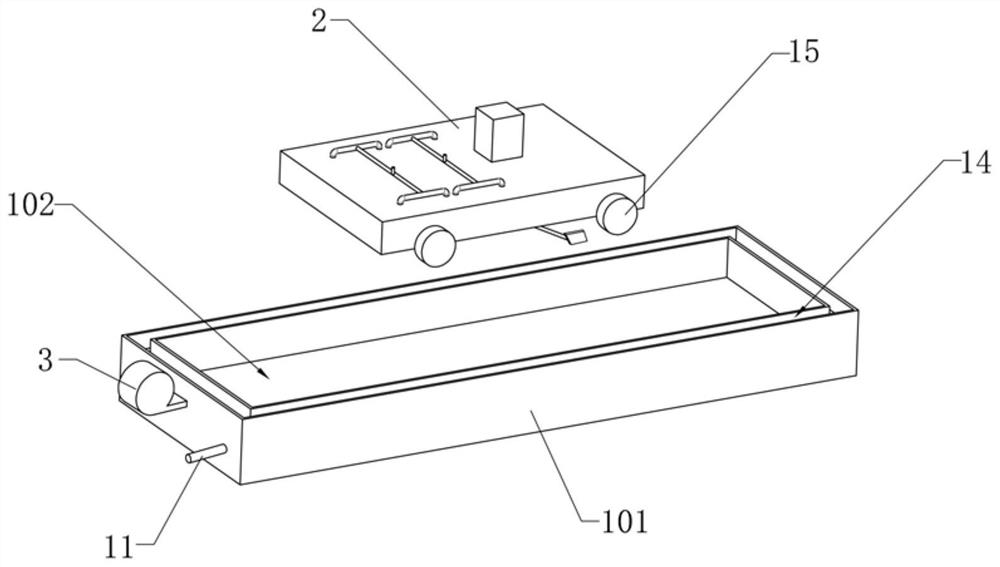

[0046] The invention provides an automatic mixing machine for steaming and cooling rice for brewing, which includes a rice steaming chamber 1, a lid 2 arranged on the rice steaming chamber 1 and used to cover the rice steaming chamber 1, and a lid 2 arranged on the rice steaming chamber 1. The bin 1 is also used for a cooling device 3 for cooling the temperature in the rice steaming bin 1 , and the bin cover 2 is provided with a stirring device 4 .

[0047] In practical application, the rice steaming bin 1 is used to carry the grain used for brewing, and the grain can be soaked in the rice steaming bin 1. After the grain is soaked, the water body in the rice steaming bin 1 is discharged, and then the grain is distilled; When the grain is subjected to high-pressure distillation, the lid 2 of the rice steamer 1 is combined and sealed, and then high-pressure steam is introduced into the rice steamer 1 to distill the grain; The cooked grain is stirred and cooled. At this time, the...

Embodiment 2

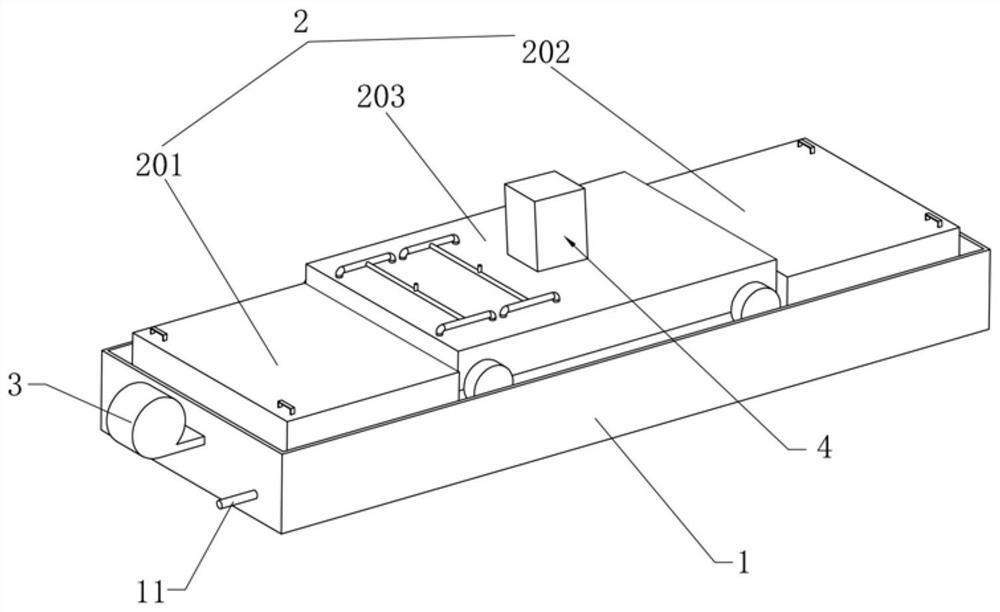

[0070] The difference between this embodiment and Embodiment 1 is that the compartment cover 2 includes a first sealed and spliced compartment cover 201, a second sealed and spliced compartment cover 202 and a central compartment cover 203, and the first sealed and spliced compartment cover 201 and the second sealed and spliced compartment cover 201 The two sealed and spliced compartment covers 202 are respectively arranged on the left and right sides of the central compartment cover 203, and are all movable and sealed with the central compartment cover 203; the first sealed and spliced compartment cover 201, the second sealed and spliced compartment cover 202 and the central compartment cover 203 are all slidably arranged on the rice steaming bin 1. Preferably, the water spraying device, the song spraying device and the stirring device 4 are all arranged on the central bin cover 203, and the specific structures of the water spraying device, the song spraying devi...

Embodiment 3

[0074] see Figure 11 , The difference between this embodiment and Embodiment 1 and Embodiment 2 is: an automatic mixing machine for steaming and cooling rice for brewing, comprising a rice steaming chamber 1, which is movable and arranged on the rice steaming chamber 1 and used to adjust the rice steaming chamber 1. The first sealing cover 5 for sealing and sealing, the cooling device 3 arranged on the rice steaming chamber 1 and used to cool the temperature in the rice steaming chamber 1, and the stirring chamber cover 6 that can be placed on the rice steaming chamber for sliding , the stirring chamber cover 6 is provided with a stirring device 4 .

[0075] Preferably, the water spraying device, the song spraying device and the stirring device 4 are all arranged on the mixing chamber cover 6, and the specific structure and working principle of the water spraying device, the song spraying device and the stirring device 4 are the same as those in Embodiment 1 or Embodiment 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com