Full-automatic water injector in shaft kiln

A water spray device and fully automatic technology, which is applied in the field of cement shaft kiln production, can solve the problems of inability to achieve rapid cooling, affect clinker transportation and grinding, and slow cooling speed, so as to contribute to environmental protection and save burning coal consumption , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

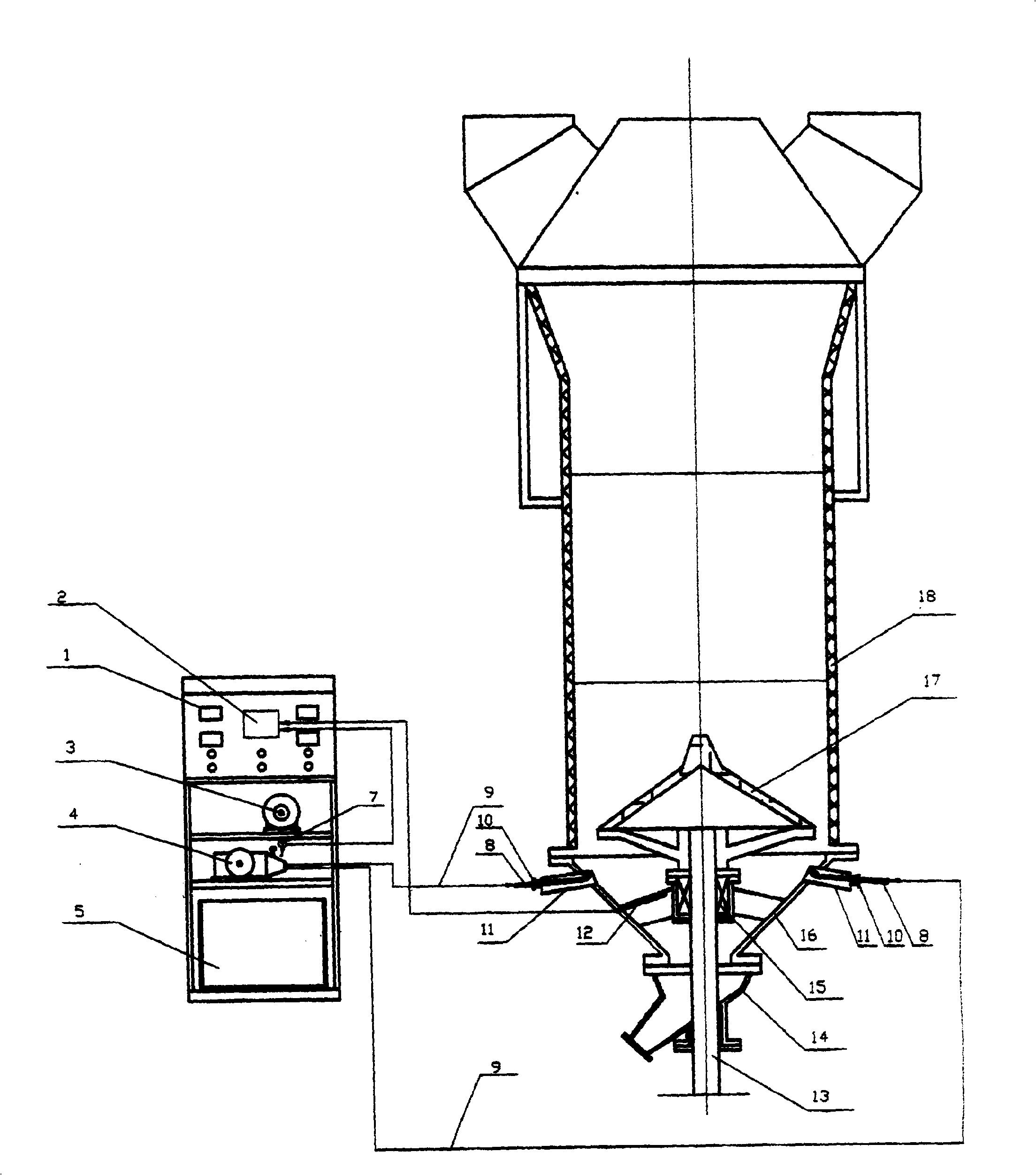

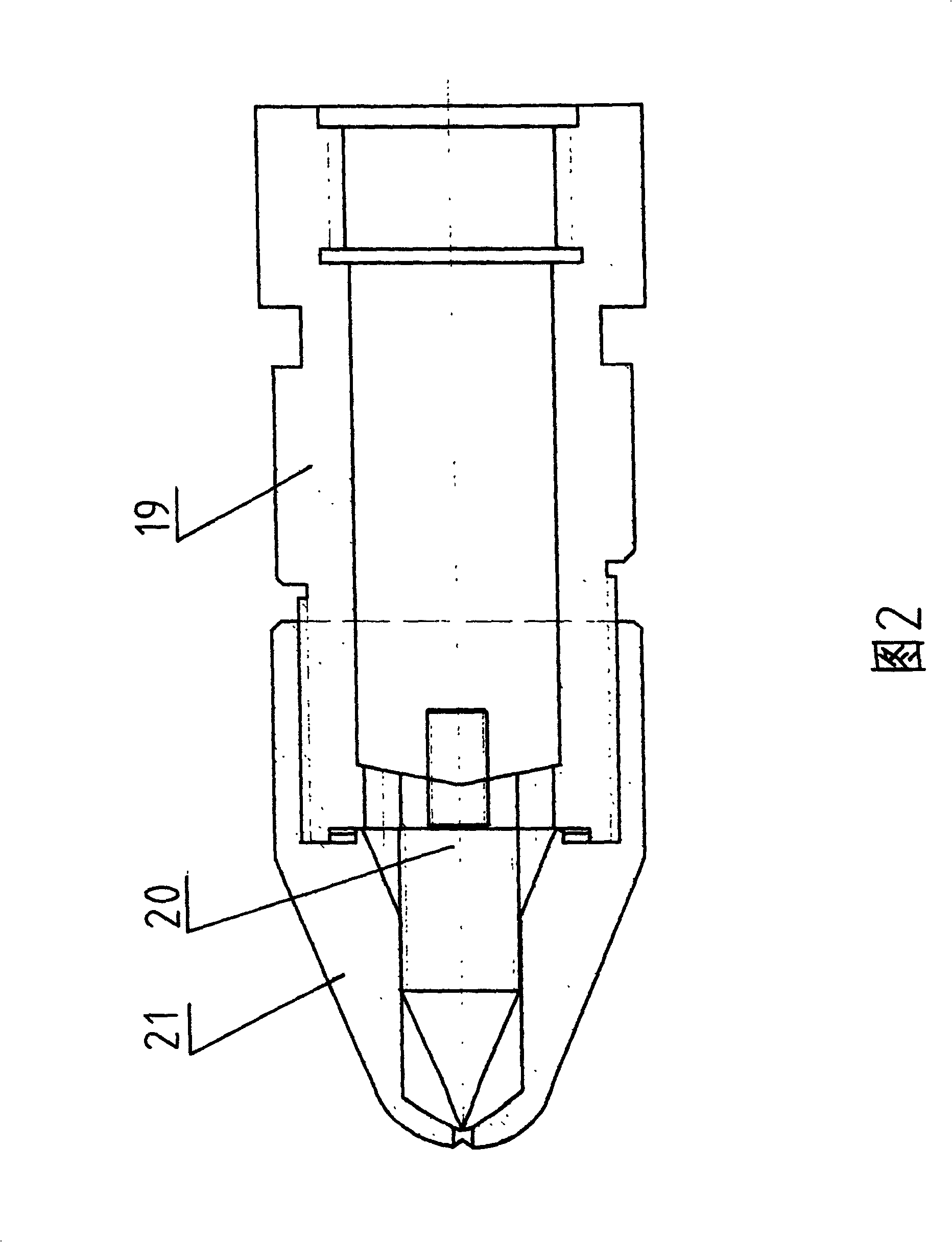

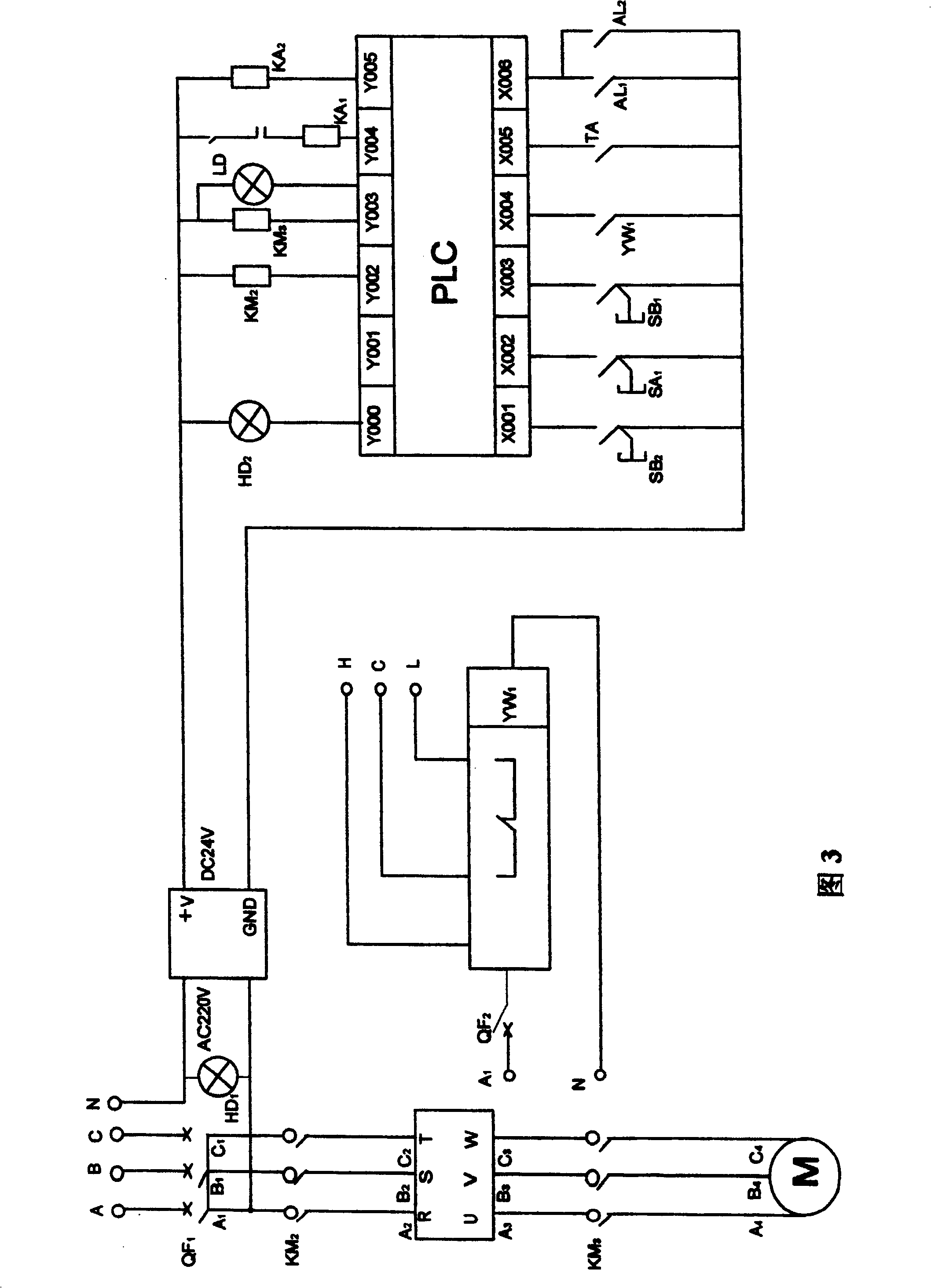

[0024] like figure 1 As shown, among the figure 13 is the large vertical shaft of the vertical kiln 18, 14 is the blanking slide, 15 is the bearing, and 16 is the lower cone bucket; on the lower cone bucket 16 of the vertical kiln 18, a thermometer 12 and a spray gun 8 are installed, The spray gun 8 is symmetrically installed on both sides of the lower cone 16, the spray gun 8 passes through the installation holes on the two circular air inlet pipes 11 on the lower cone 16, and is welded here with the mounting flange interface 10, and the spray gun 8 passes through the holes extend into the appropriate position in the kiln, weld it on the flange, and fix it on the flange interface through threads; the spray gun 8 is connected to the water outlet of the high-pressure pump 4 through the high-pressure water pipe 9; the thermometer 12 can be a the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com