A rapid prototyping mold for pe pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments.

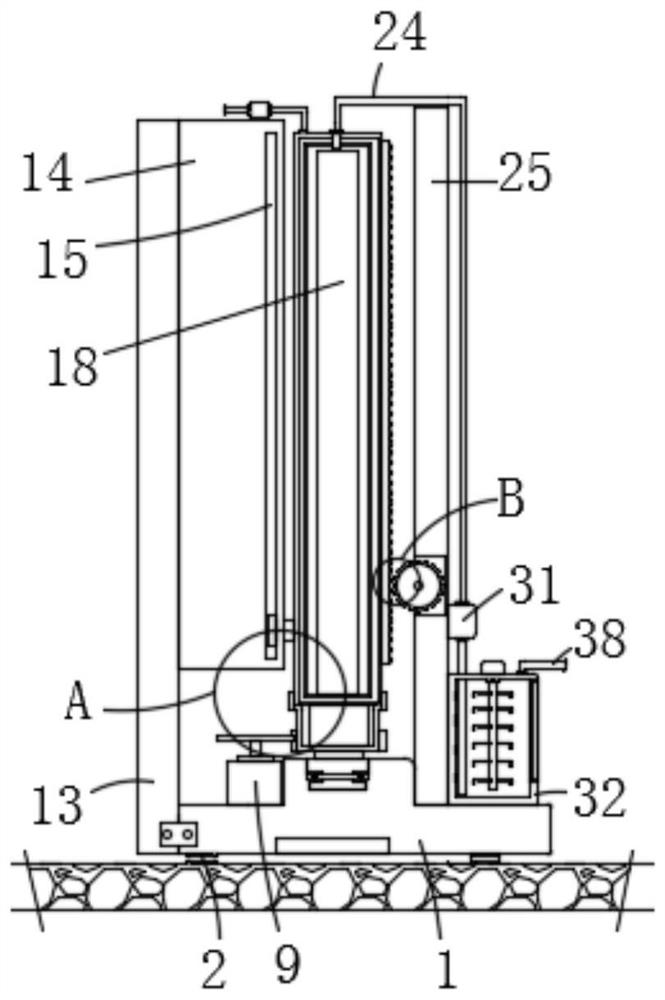

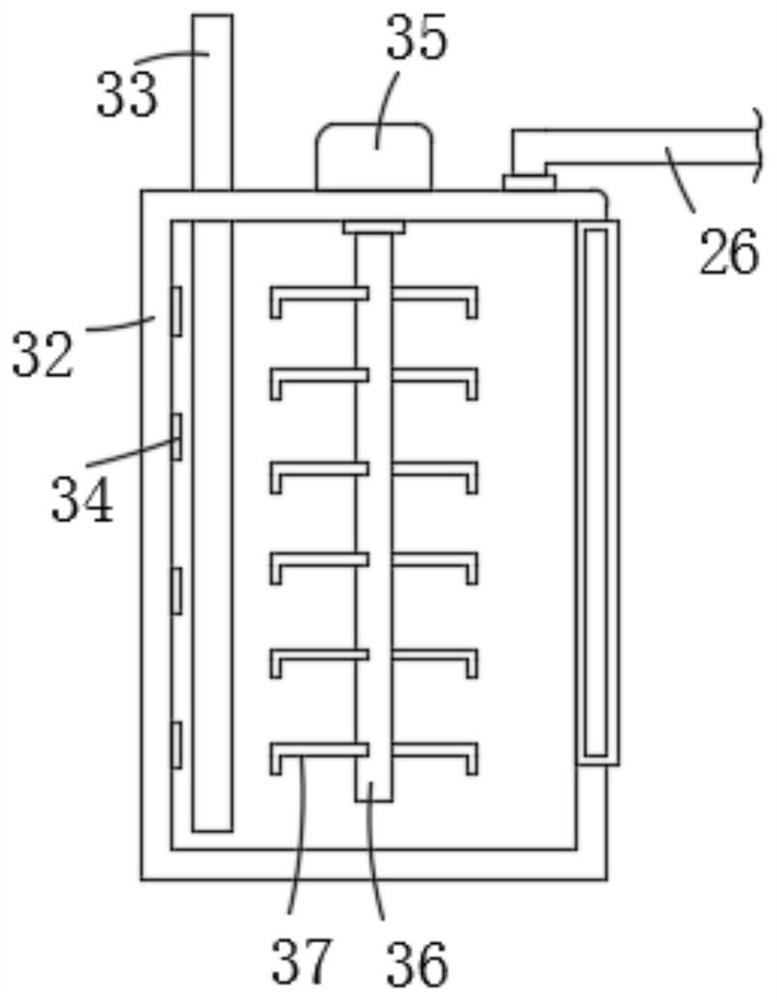

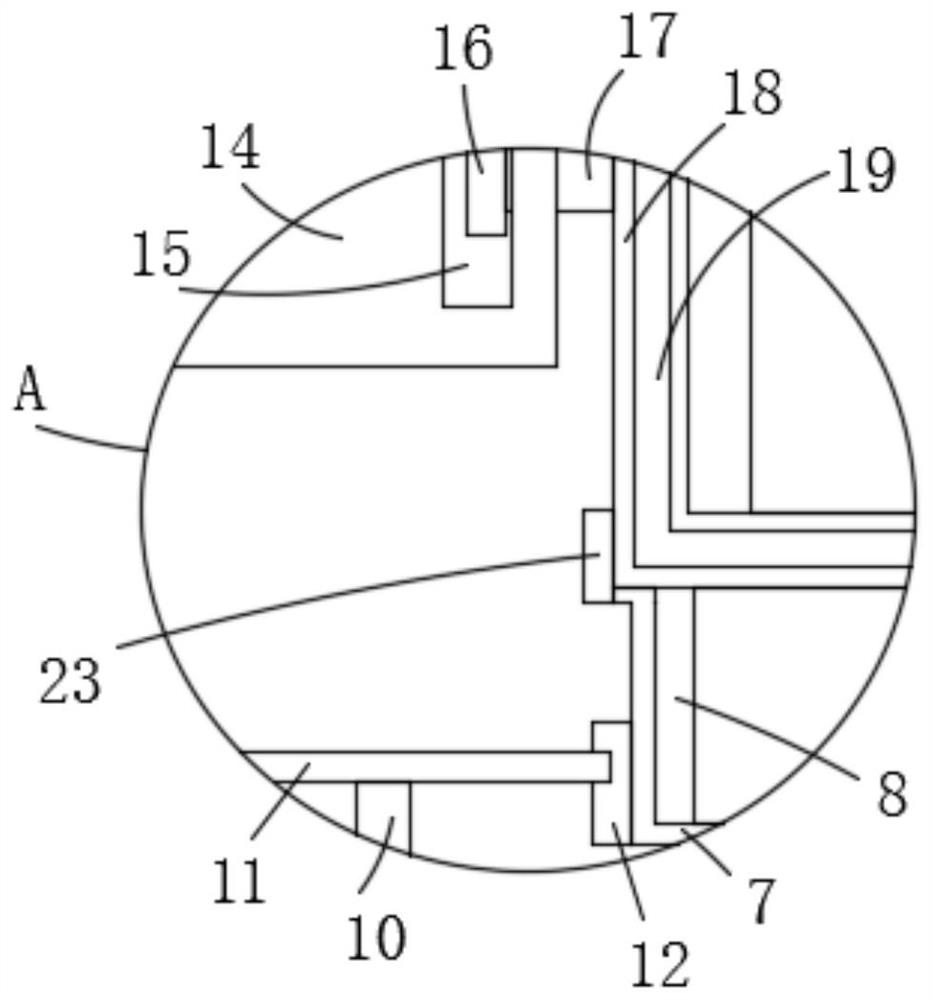

[0021] Reference Figure 1-6

[0022] In the present invention, when using the molding mold, after starting the operation of motor one 9, after meshing through the first tooth disc 11 and the first ring of gear 12, the injection mold 7 is promoted to rotate, during the control of the motor two 27 operation, after meshing through the second tooth plate 28 and the rack one 30 phase, the injection molding top mold 18 is pressed down, so as to promote the injection mold 7 and the injection molding top mold 18 after closing, using the injection pump 31, the PE resin material in the storage box 32 is injected into the injection molding cavity 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com