Method for preparing laurolactam through extraction rearrangement reaction of cyclododecanone oxime

A technology of cyclododecanone oxime and laurolactam is applied in the field of preparation of laurolactam by extraction and rearrangement reaction of cyclododecanone oxime, and can solve the problem of affecting product quality, increasing material viscosity, high exothermic power, etc. problems, to enhance the anti-fluctuation ability, prevent impurity pollution, and eliminate the effect of material carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

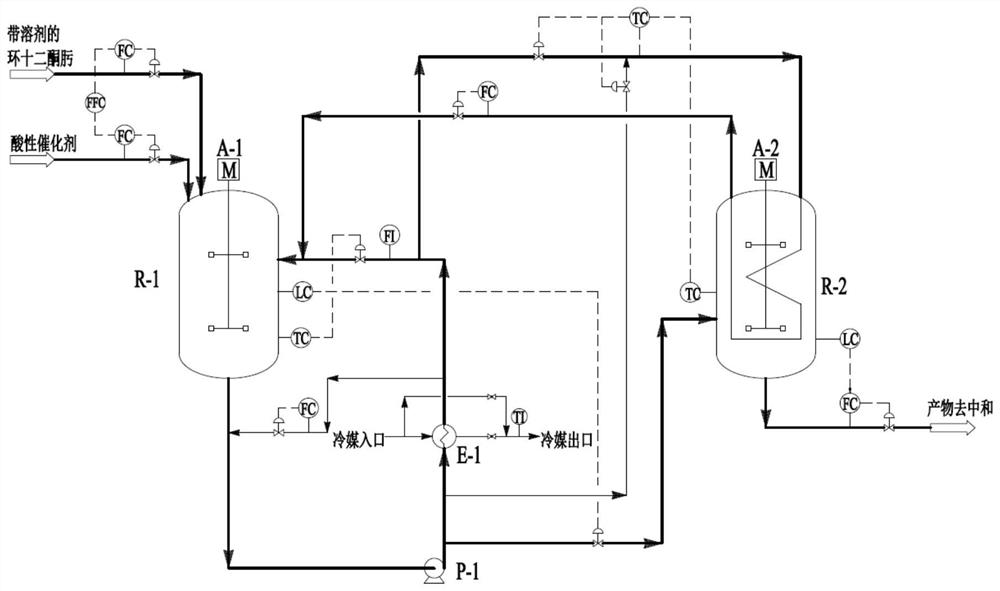

Method used

Image

Examples

Embodiment 1

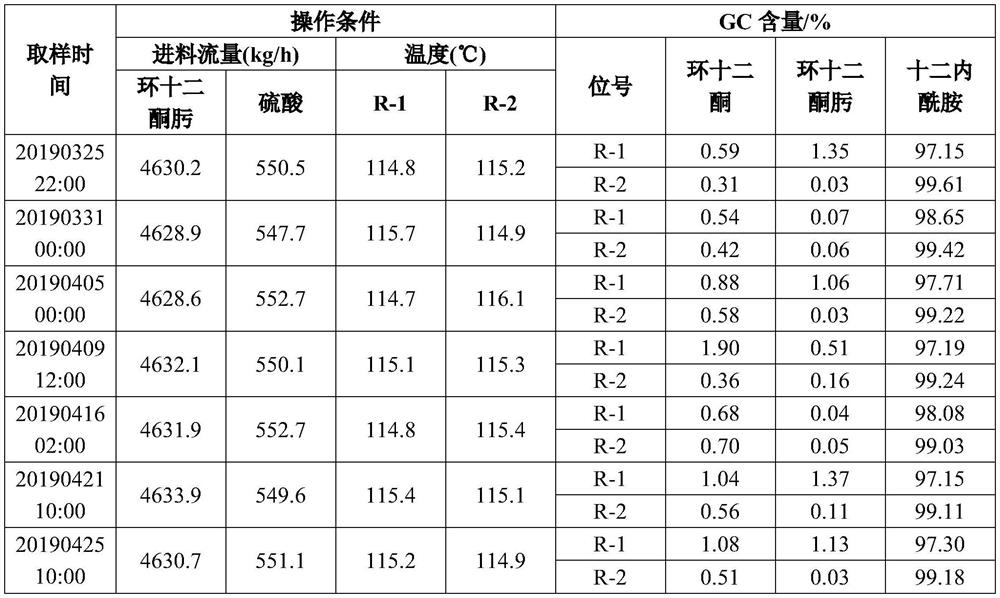

[0024] Cyclododecanone oxime with solvent and sulfuric acid are fed in proportion, the amount of cyclododecanone oxime with solvent is 4630kg / hr, and the amount of sulfuric acid is 550kg / hr. The internal temperature of R-1 is 115℃, the material residence time is 10min; the inlet flow rate of E-1 process is 11700kg / hr, the heat load is 150kW, the outlet temperature of E-1 process side is 105℃; the flow rate of the inner coil of R-2 is 4680kg / hr, R -2 The outlet temperature of the inner coil is 106°C. The temperature inside R-2 is 115°C, and the material residence time is 10 minutes. Under this operating condition, the device has been running stably for more than one month. Table 1 lists some of the operating and sampling test results.

[0025] Table 1 Operating conditions and GC analysis results of R-1 and R-2 samples

[0026]

Embodiment 2

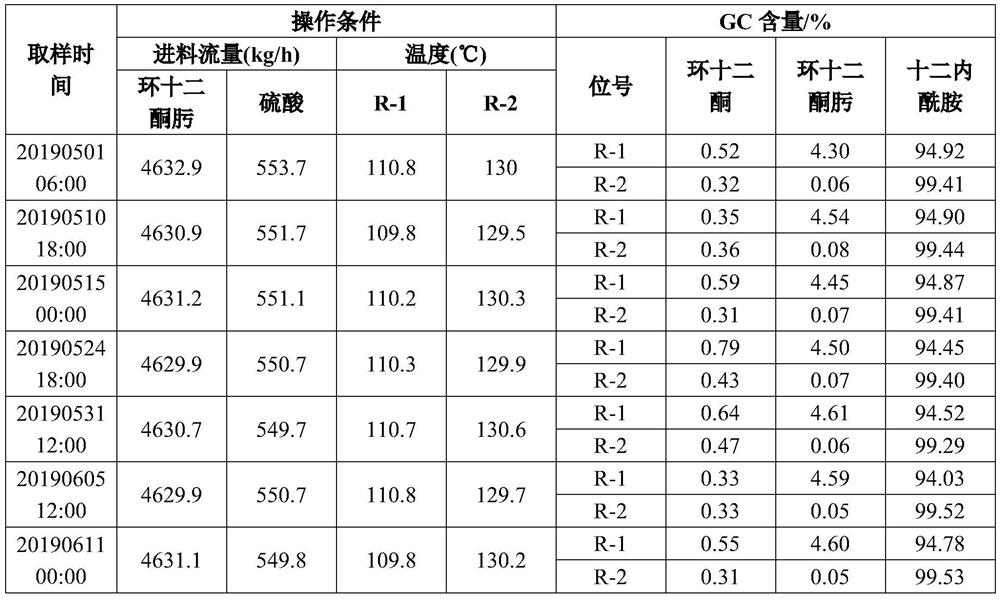

[0028] Change the operating conditions in each reactor, the temperature in R-1 is 110°C, and the temperature in R-2 is 130°C. Under this operating condition, the device has been running stably for more than one month. Table 2 lists some of the operating and sampling test results.

[0029] Table 2 Operating conditions and GC analysis results of R-1 and R-2 samples

[0030]

Embodiment 3

[0032] Change the operating conditions in each reactor, the temperature in R-1 is 140°C, and the temperature in R-2 is 100°C. Under this operating condition, the device has been running stably for more than one month. Table 3 lists some of the operating and sampling test results.

[0033] Table 3 Operating conditions and GC analysis results of R-1 and R-2 samples

[0034]

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com