Material conveying method for horizontal reactor of potassium manganate

A technology of horizontal reactors and reactors, applied in chemical/physical/physicochemical fixed reactors, manganate/permanganate, etc., can solve the problem of increasing residence time, preventing overflow, and sinking in the reaction problems such as the bottom of objects, to achieve the effects of saving investment, reducing operating costs, and reducing equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

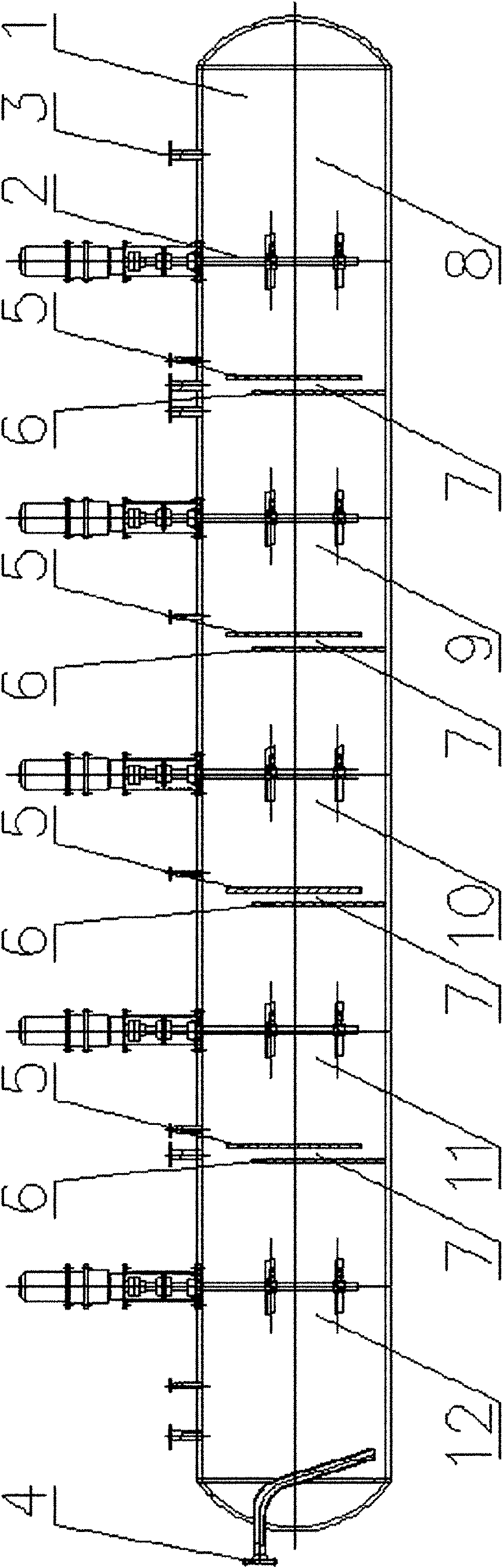

[0021] see figure 1 , the material enters the first reaction chamber 8 in the horizontal reactor 1 from the material inlet 3, and after being agitated by the agitator 2 to fully react, the potassium manganate product with a larger specific gravity enters the material from the gap at the bottom of the upper baffle plate 5 The channel 7 enters the second reaction chamber 9 from the upper part of the lower baffle plate 6 . After being agitated by the agitator 2 for sufficient reaction, it enters the material channel 7 from the gap at the bottom of the upper baffle 5 and enters the third reaction chamber 10 from the top of the lower baffle 6 . By analogy, the final reacted material is discharged from the reactor through the material outlet 4, and the entire reaction process is completed.

[0022] This example has been successfully applied to Yunnan Jianshui Manganese Industry Co., Ltd. The diameter of the industrial test horizontal reactor is φ800mm, and the reaction pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com