Multifunctional coating type foam magnesium alloy casting device

A foamed magnesium alloy and cladding technology, which is applied in the field of magnesium alloy casting, can solve the problems of molten metal without exhaust protection function, inability to automatically open and close molds, and the influence of impurities, so as to ensure separation stability and convenience. Maintenance and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

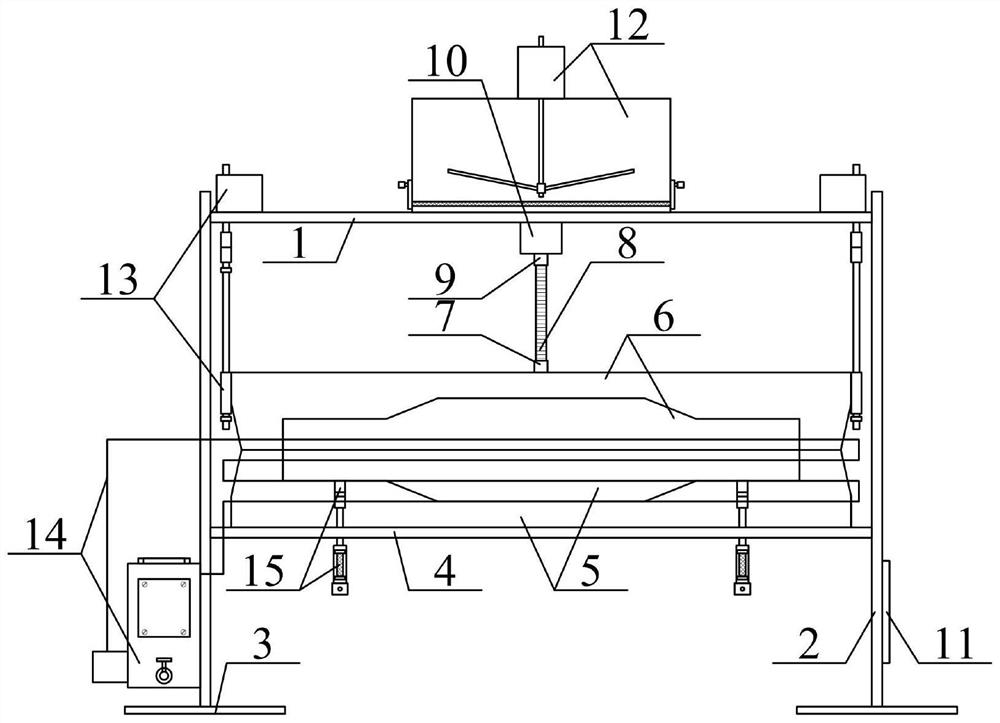

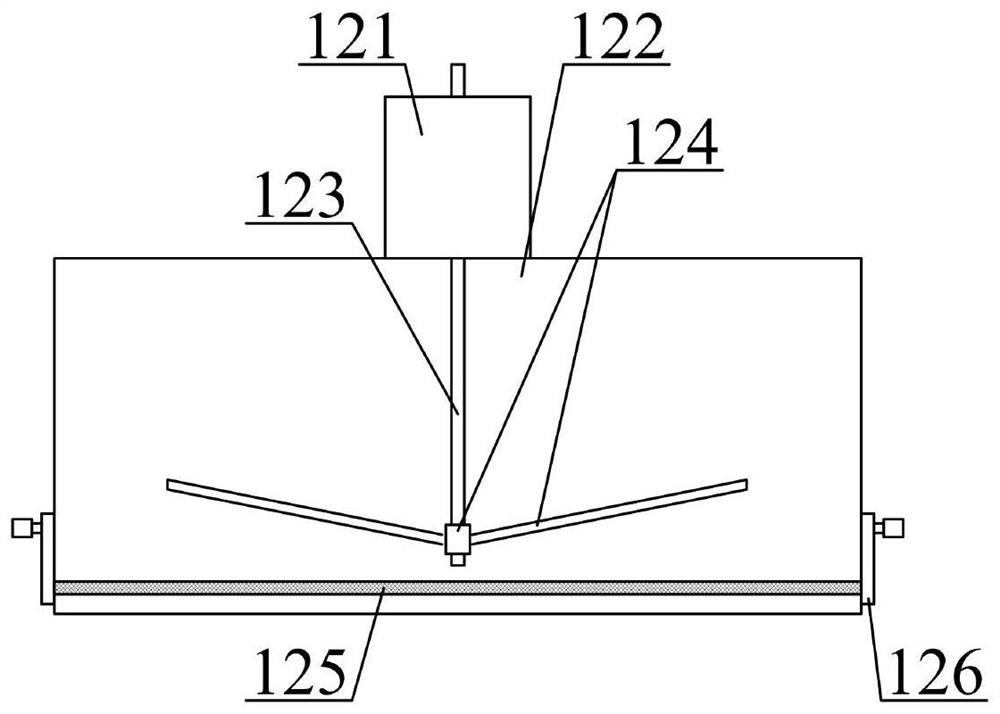

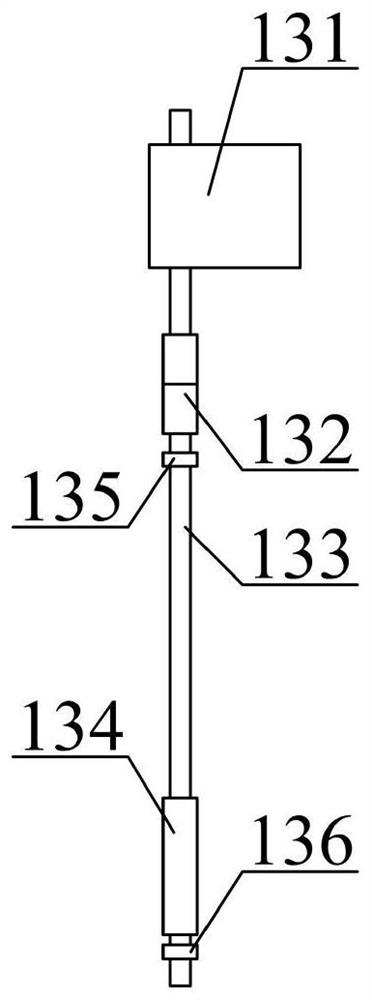

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a multifunctional coated foam magnesium alloy casting casting device includes a beam 1, a stand 2, a floor stand 3, a frame 4, a lower mold 5, an upper mold 6, a connecting pipe head 7, a metal Hose 8, connecting pipe head 2 9, buffer cylinder 10, control panel 11, metal liquid anti-impurity filter mixing box structure 12, free lifting opening and closing mold rod structure 13, circulating cooling box structure 14 and exhaust antifouling treatment Pipe structure 15, the crossbeam 1 is connected to the upper part between the uprights 2 by horizontal bolts; the lower end of the uprights 2 is bolted to the floor stand 3; the inner middle and lower parts between the uprights 2 are connected by bolts There is a frame 4, a lower mold 5 is connected with bolts at the middle part of the upper part of the frame 4, and an upper mold 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com