Multifunctional epoxypropane separation device

A propylene oxide and multifunctional technology, applied in the field of multifunctional separation propylene oxide devices, can solve the problem that odor gas easily pollutes the environment, propylene oxide and the discharged solution are inconvenient for filtration and drainage treatment, and the propylene oxide solution cannot be filtered to affect separation. effect and other issues, to achieve the effect of convenient operation, ensuring the effect of cooling and preservation, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

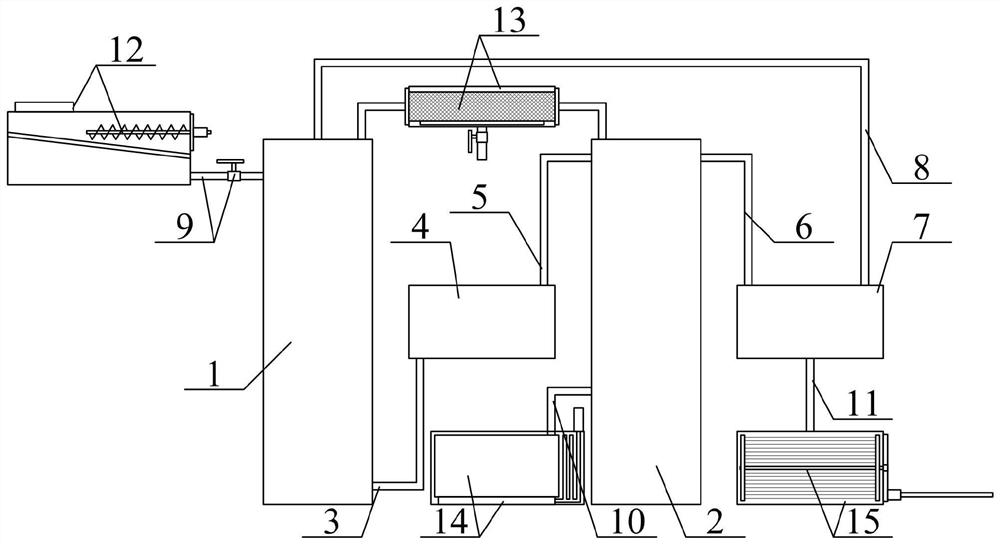

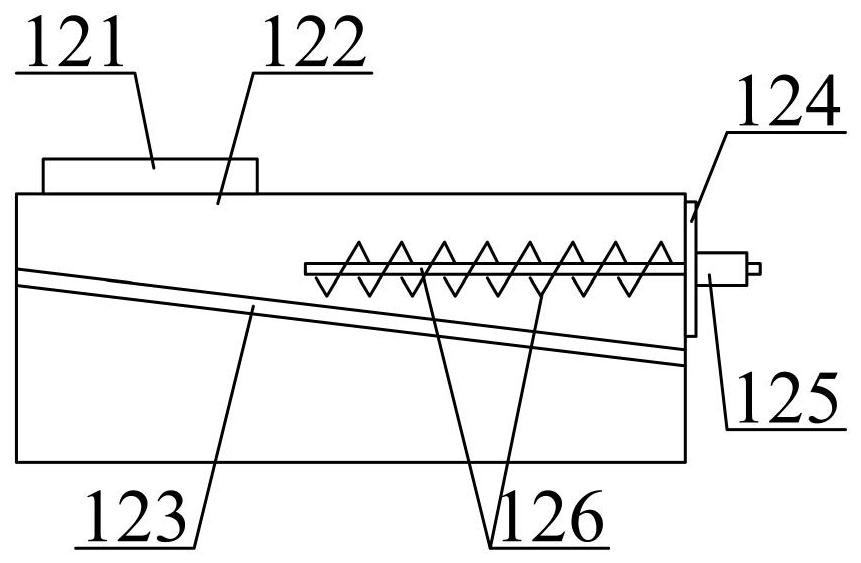

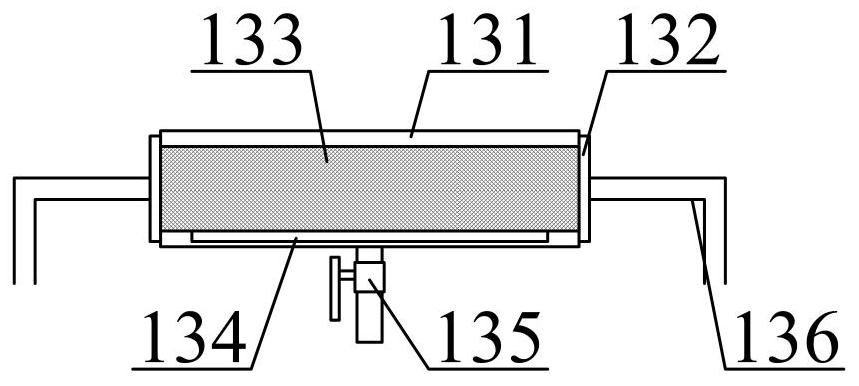

[0033] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 Shown, a kind of multifunctional separation propylene oxide device comprises propylene oxide separation tower 1, propylene oxide separation tower 2 again, separation conduit 3, first heat exchanger 4, condensation pipe 5, row pipe 6, the second Heat exchanger 7, return pipe 8, drainage pipe with valve 9, discharge pipe 10 and liquid discharge pipe 11, one end of the separation conduit 3 is threaded to the outlet on the lower right side of the propylene oxide separation tower 1, and the other end is threaded to The inlet of the lower left side of the first heat exchanger 4; one end of the condensation pipe 5 is threaded to the upper right outlet of the first heat exchanger 4, and the other end is threaded to the upper left inlet of the propylene oxide re-separation tower 2; One end of the row pipe 6 is threaded to the upper left inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com