High-strength water-based automobile coating, preparation method thereof and preparation equipment thereof

A high-strength, water-based technology, applied in the direction of mixing methods, epoxy resin coatings, chemical instruments and methods, etc., can solve the problems of insufficient strength of the coating film, lower performance, and uneven mixing, etc., to achieve strong connection strength and improved The effect of using performance and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

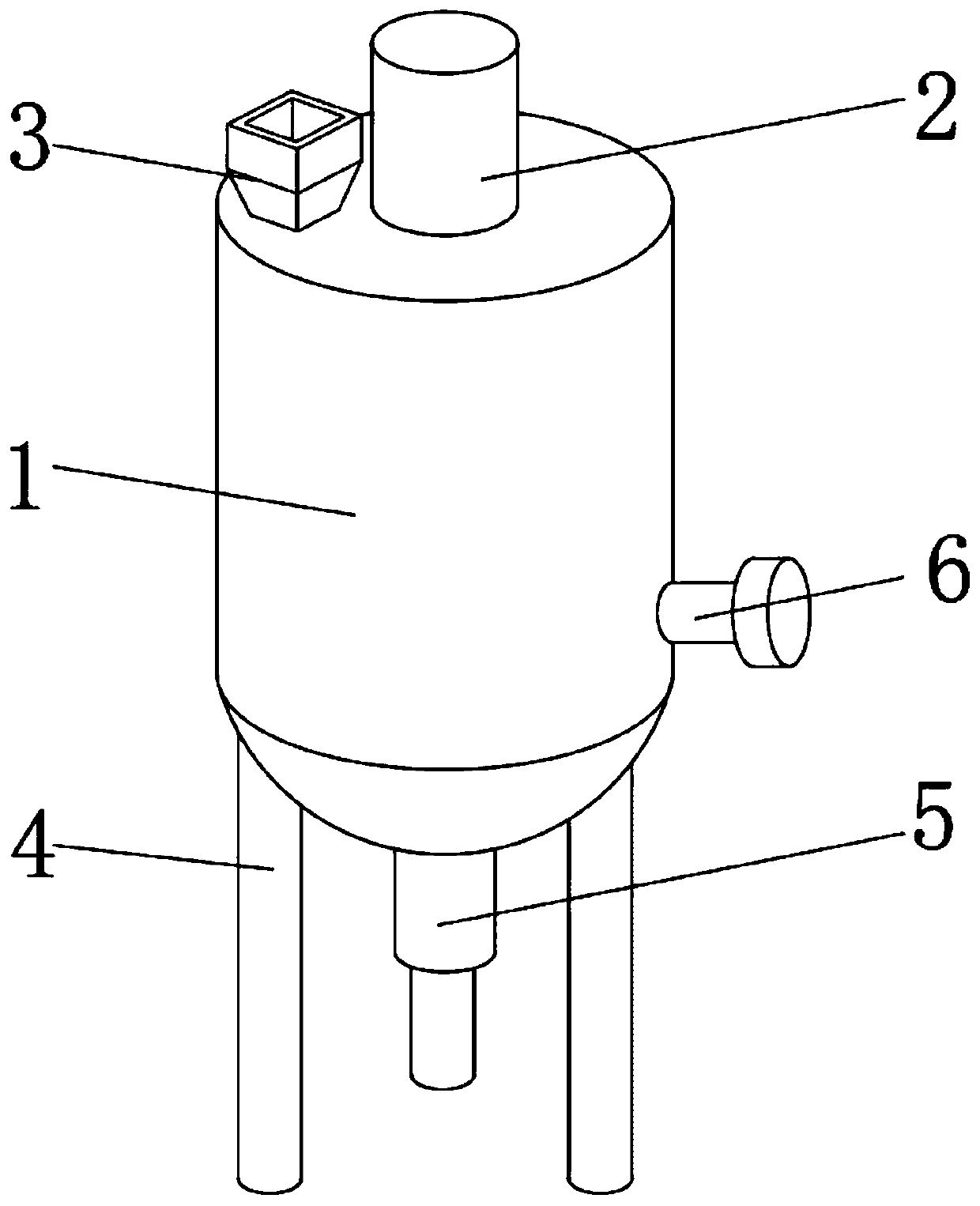

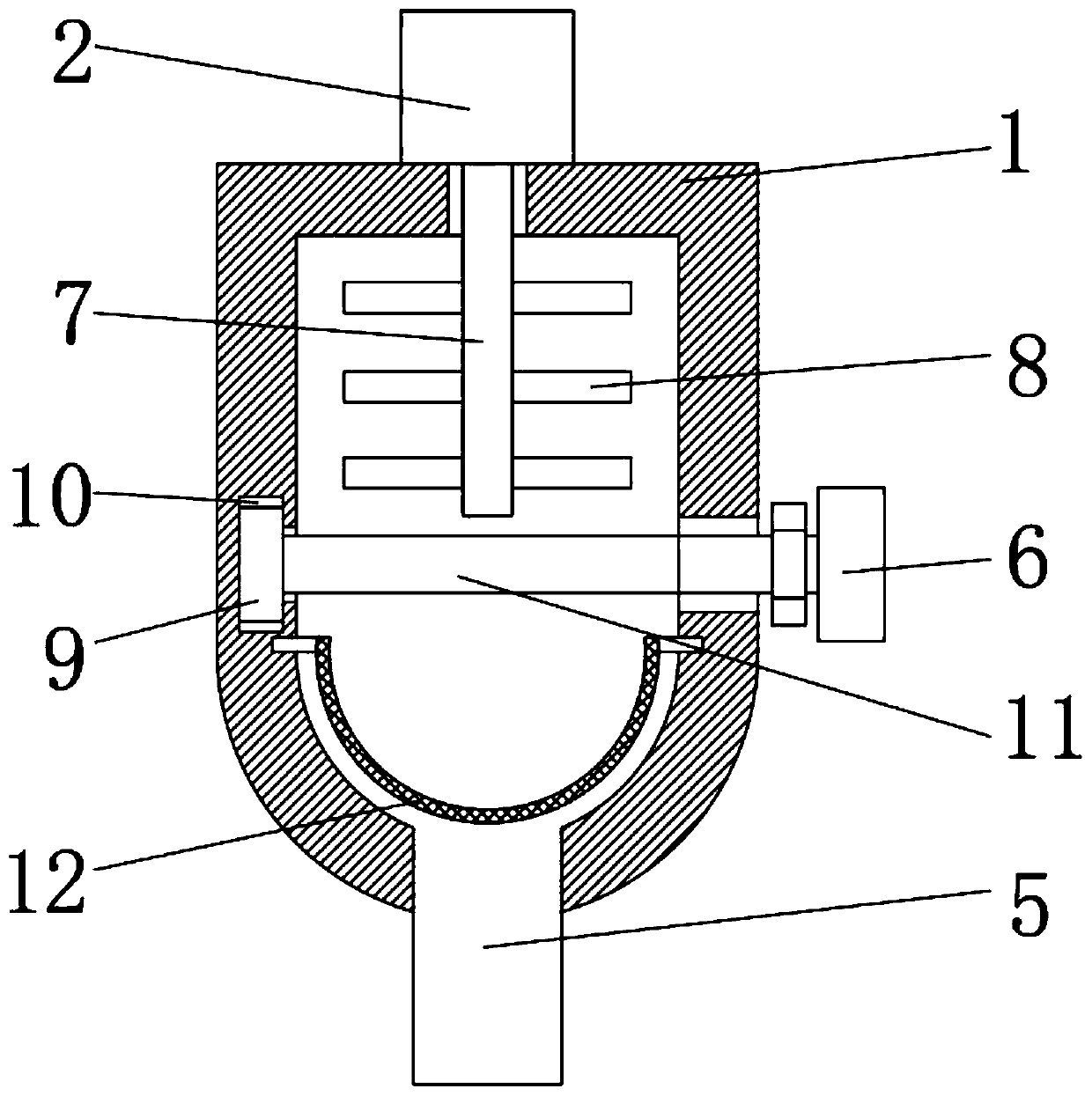

[0034] see Figure 1-4 , the high-strength water-based automotive coating provided by the present invention is prepared from the following components in parts by weight: 30 parts of curable epoxy material, 50 parts of deionized water, 0.01 part of graphene oxide, and 22 parts of biuret , 14 parts of isophorone diisocyanate, 9 parts of tetrahydrofuran, 5 parts of ethylene glycol, 5 parts of thickener, 5 parts of graphite powder, 5 parts of wetting agent, 9 parts of dispersant, 10 parts of defoamer, 6 parts of plasticizer, 15-25 parts of emulsion; wherein, the curable epoxy material is one of water-soluble anion resin, water-soluble cationic resin or water-emulsion epoxy resin.

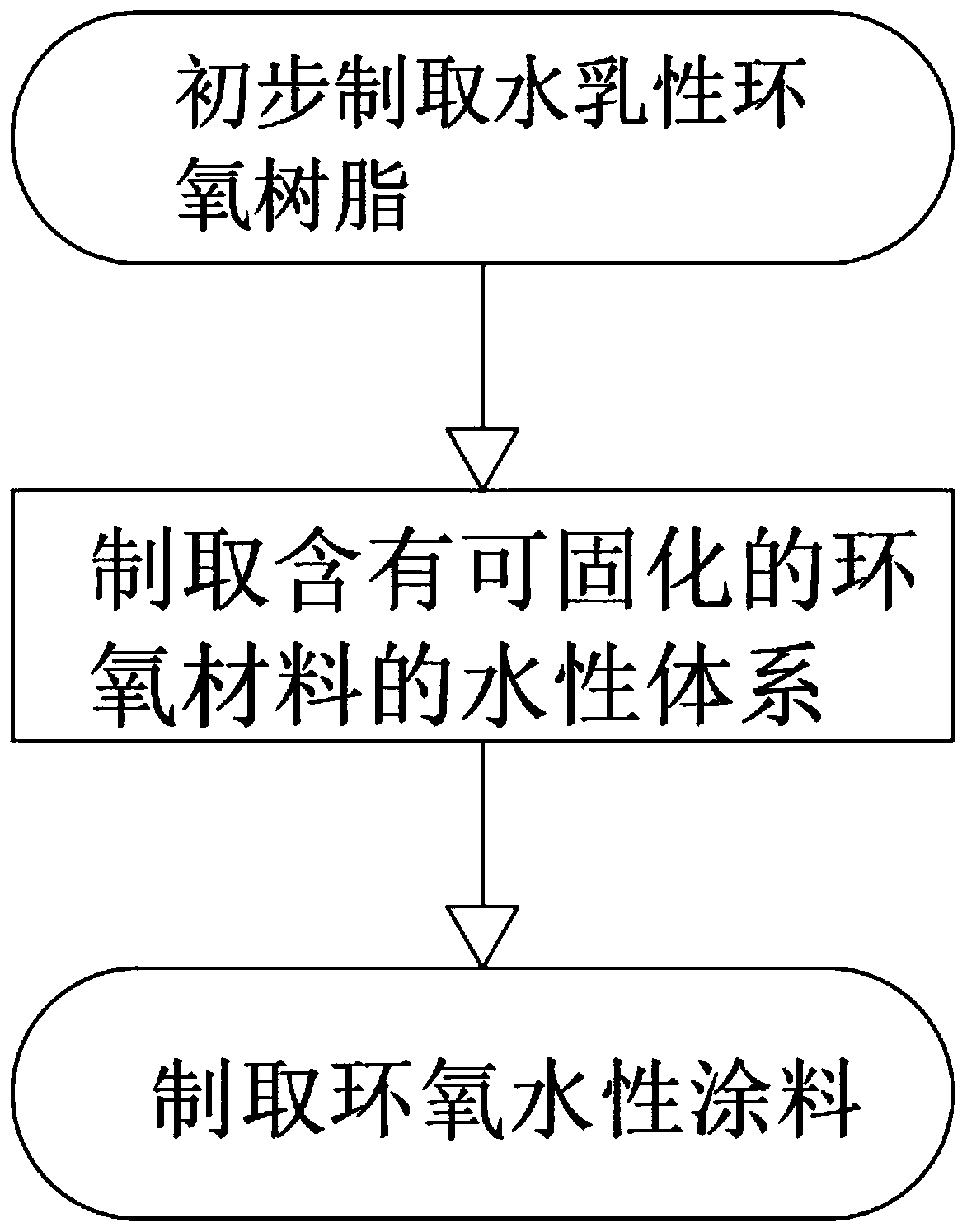

[0035] A preparation method of the aforementioned high-strength water-based automotive paint, comprising the following steps:

[0036] S1: Preliminary preparation of water-emulsion epoxy resin emulsion: Add deionized water into the dispersion container, then add the curable epoxy material and latex int...

Embodiment 2

[0043] Embodiment The high-strength water-based automotive paint provided by the present invention, preparation method and preparation equipment are basically the same as embodiment one, and its difference is:

[0044] Described high-strength water-based automotive paint is made of the following specific components in parts by weight:

[0045] 40 parts of curable epoxy material, 60 parts of deionized water, 2.25 parts of graphene oxide, 28.5 parts of biuret, 21 parts of isophorone diisocyanate, 17 parts of tetrahydrofuran, 8.5 parts of ethylene glycol, 8.5 parts of thickener, 10 parts of graphite powder, 10.5 parts of wetting agent, 18.5 parts of dispersant, 16 parts of defoamer, 7.5 parts of plasticizer, 15-25 parts of emulsion.

Embodiment 3

[0047] Embodiment The high-strength water-based automotive paint provided by the present invention, preparation method and preparation equipment are all substantially the same as embodiment one and two, and its difference is:

[0048] Described high-strength water-based automotive paint is made of the following specific components in parts by weight:

[0049] 50 parts of curable epoxy material, 70 parts of deionized water, 5 parts of graphene oxide, 35 parts of biuret, 28 parts of isophorone diisocyanate, 25 parts of tetrahydrofuran, 5-12 parts of ethylene glycol, 12 parts of thickener, 15 parts of graphite powder, 16 parts of wetting agent, 28 parts of dispersant, 22 parts of defoamer, 9 parts of plasticizer, 15-25 parts of emulsion.

[0050] The present invention can find through above-mentioned three groups of embodiments, through the added biuret and isophorone diisocyanate, it combines with epoxy resin first, can produce relatively complete emulsification reaction with ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com