Refining method and application of polyoxyethylated castor oil

A technology of polyoxyethylene castor and refining method, which is applied in the directions of medical preparations containing active ingredients, pharmaceutical formulas, non-active ingredients of oil/fat/wax, etc. High problems, to achieve the effect of easy stirring and filtration, shortening the filtration process, and reducing oxidized impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

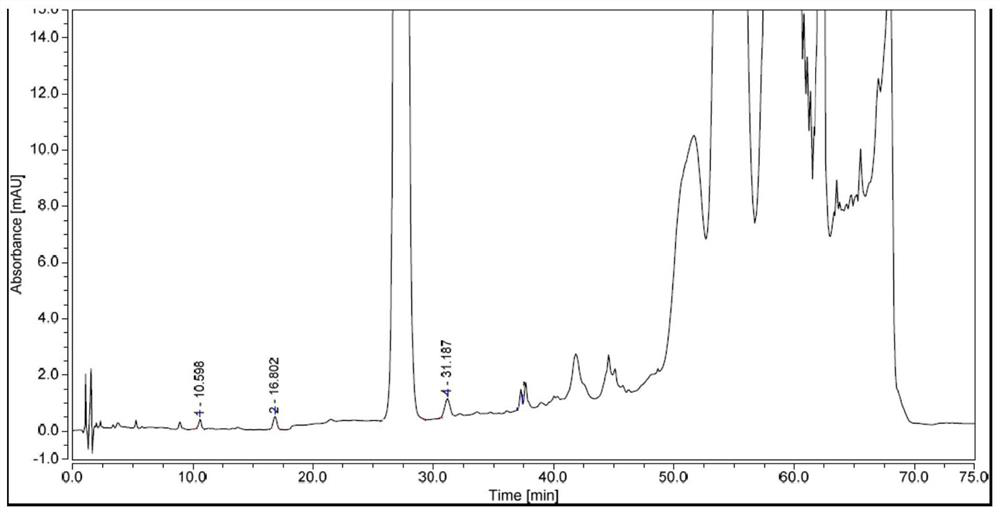

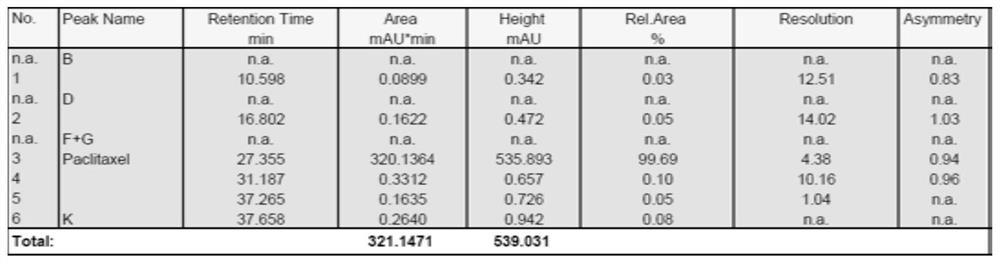

Image

Examples

Embodiment 1

[0053] Example 1 : present embodiment provides a kind of refining method of polyoxyethylene castor oil, and it comprises the steps:

[0054] (1) 3kg of polyoxyethylene (35) castor oil (BASF production) is placed in a 10L reaction flask, then 0.3kg of acidic alumina (SIGMA) is added, and 0.15kg of silicon-magnesium adsorbent (magnesium silicate, Sinopharm ), the absolute ethanol of 6L;

[0055] (2) Replace the air in the bottle with nitrogen, protect it with nitrogen, stir at 40°C for 4 hours, and then filter out the solid matter to obtain the filtrate;

[0056] (3) The filtrate was mixed with 7320 cation exchange resin and stirred at room temperature for 2 hours, and then the cation exchange resin was filtered off to obtain filtrate 2;

[0057] (4) The filtrate two was concentrated under reduced pressure at 45° C. to remove ethanol to obtain refined polyoxyethylene (35) castor oil.

Embodiment 2

[0058] Example 2 : present embodiment provides a kind of refining method of polyoxyethylene castor oil, and it comprises the steps:

[0059] (1) 3kg of polyoxyethylene (35) castor oil (BASF production) is placed in a 10L reaction flask, then 0.3kg of acidic alumina (SIGMA) is added, and 0.15kg of silicon-magnesium adsorbent (magnesium silicate, Sinopharm ), the absolute ethanol of 2L;

[0060] (2) Replace the air in the bottle with nitrogen, protect it with nitrogen, stir at 40°C for 4 hours, and then filter out the solid matter to obtain the filtrate;

[0061] (3) The filtrate was mixed with 7320 cation exchange resin and stirred at room temperature for 2 hours, and then the cation exchange resin was filtered off to obtain filtrate 2;

[0062] (4) The filtrate two was concentrated under reduced pressure at 45° C. to remove ethanol to obtain refined polyoxyethylene (35) castor oil.

Embodiment 3

[0063] Example 3 : present embodiment provides a kind of refining method of polyoxyethylene castor oil, and it comprises the steps:

[0064] (1) 3kg of polyoxyethylene (35) castor oil (produced by BASF) is placed in a 10L reaction flask, and then 0.15kg of silicon-magnesium-type adsorbent (magnesium silicate, Chinese medicine) and 6L of absolute ethanol are added;

[0065] (2) Replace the air in the bottle with nitrogen, protect it with nitrogen, stir at 40°C for 4 hours, and then filter out the solid matter to obtain the filtrate;

[0066] (3) The filtrate was mixed with 732 cation exchange resin and stirred at room temperature for 2 hours, and then the cation exchange resin was filtered off to obtain filtrate 2;

[0067] (4) The filtrate two was concentrated under reduced pressure at 45° C. to remove ethanol to obtain refined polyoxyethylene (35) castor oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com