An all-position welding method for stainless steel pipelines for oil and gas transportation

A welding method, stainless steel technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor penetration of welding forming effect, affecting the crystal shape of welding materials, increasing welding current, etc., to achieve excellent protection effect, the gas pressure stress is small, and the effect of shortening the welder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

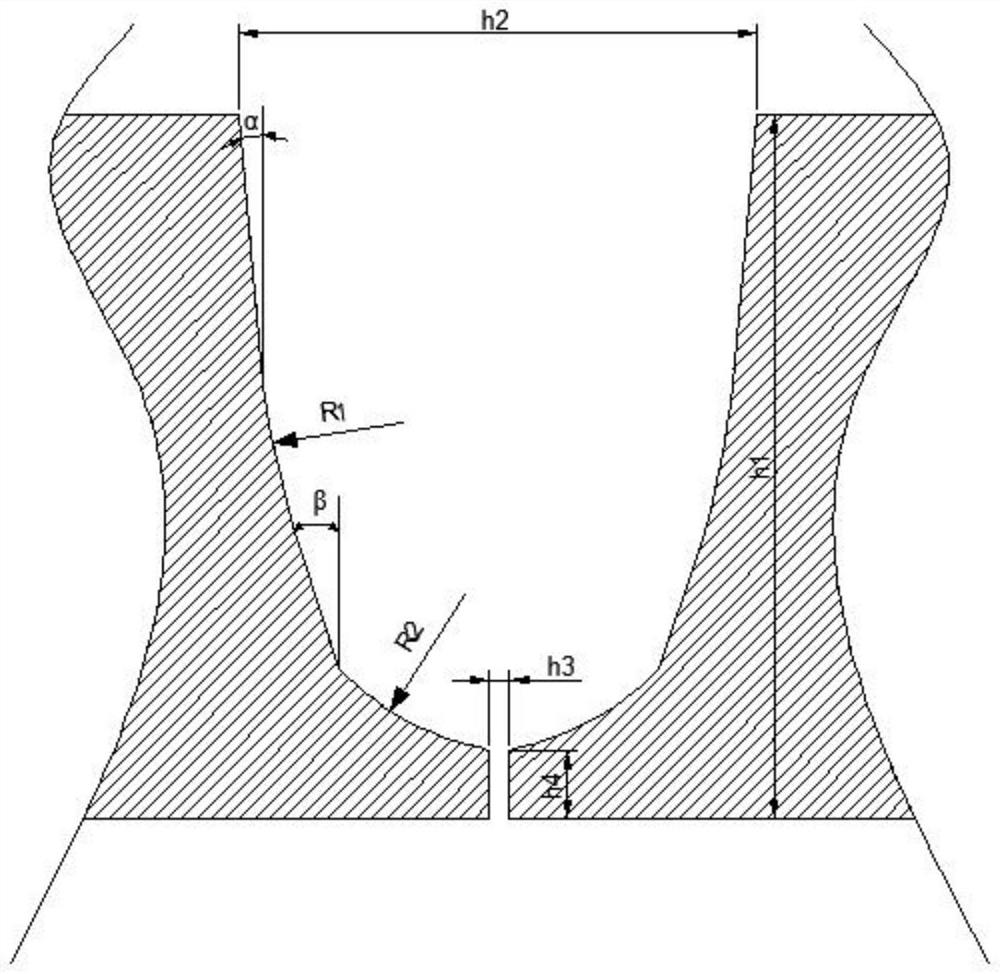

[0024] 304 stainless steel pipe is selected, the diameter of the stainless steel pipe is 700mm≤Φ≤1100mm, the wall thickness of the pipe is 10mm≤h1≤15mm, the opening width between the grooves of two stainless steel pipes is 8mm≤h2≤12mm, and the width of the root gap between the grooves is 0.2mm≤h3≤ 0.5mm, blunt edge thickness 1.3mm≤h4≤2.0mm, two stainless steel pipe welding seam port reinforcement ≤1mm, double U-shaped bevel including slope one, arc one, slope two, arc two from outside to inside Section, the slope of the first section of the slope is greater than the slope of the second section of the slope, and the curvature of the first section of the arc surface is smaller than the curvature of the second section of the arc surface.

[0025] Specifically, the inclination angle of the first section of the inclined surface is 6°≤α≤12°, the inclination angle of the second section of the inclined surface is 15°≤β≤20°, the radius of the first section of the arc surface is 1 / 3h1≤R1...

Embodiment 2

[0033] After the groove of the stainless steel pipe is polished, the cut surface of the groove is pretreated. The specific operation is to clean the groove with 10wt% propanol aqueous solution, and then apply the pre-preparation and welding activator on the cut surface in turn. Pre-formulation coating amount is 0.4-0.7g / cm 3 , Welding activator adopts commercially available rosin flux for stainless steel, solid content is 4.3wt%.

[0034] Wherein, the pre-preparation is a pure acetone solution mixture containing carbon dioxide, wherein the carbon dioxide content is 3-5ml / g. The pure acetone solution adopts the grade of analytical grade, the carbon dioxide is mixed in a liquid state, and the pre-preparation mixing and application temperature is 20-30°C.

Embodiment 3

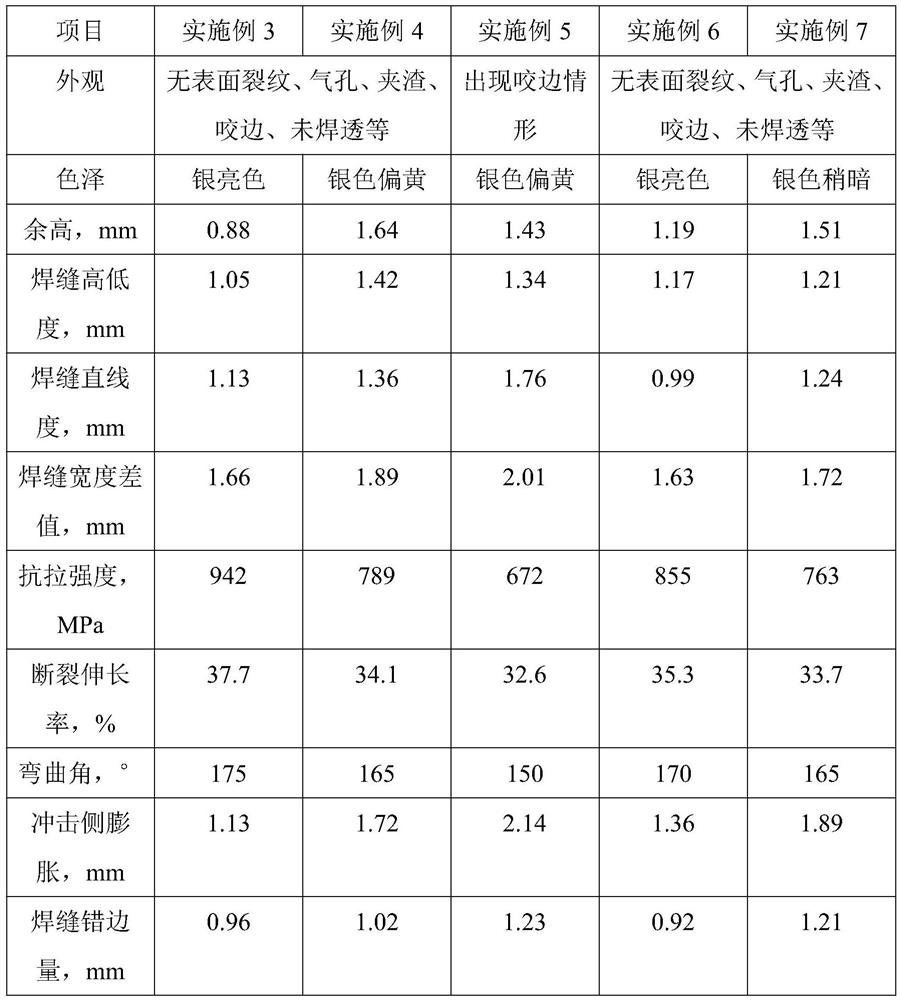

[0036] The stainless steel pipe adopts Φ800×12.4mm, with double U-shaped grooves, and the fixed-point weld distance is determined to be 8.5 ±0.5mm. The opening width between the grooves of two stainless steel pipes is 9.8mm, the width of the root gap between the grooves is 0.3mm, the thickness of the blunt edge is 1.8mm, the reinforcement height of the weld ports of the two stainless steel pipes is 0.88mm, and the first-stage inclination angle of the double U-shaped groove is α10°. The inclination angle of the second section of the inclined surface is β20°, the radius of the first section of the arc surface is 6.20mm, and the radius of the second section of the arc surface is 4.12mm (such as figure 1 ). Through the pretreatment operation of embodiment 2, then carry out welding, and concrete process is as follows:

[0037] Root welding parameters: the welding wire used is Φ1.2mm, the welding speed is 20±1cm / min, the wire feeding speed is 250±20cm / min, the welding voltage is 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com