Patents

Literature

51results about How to "Improve the detection pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

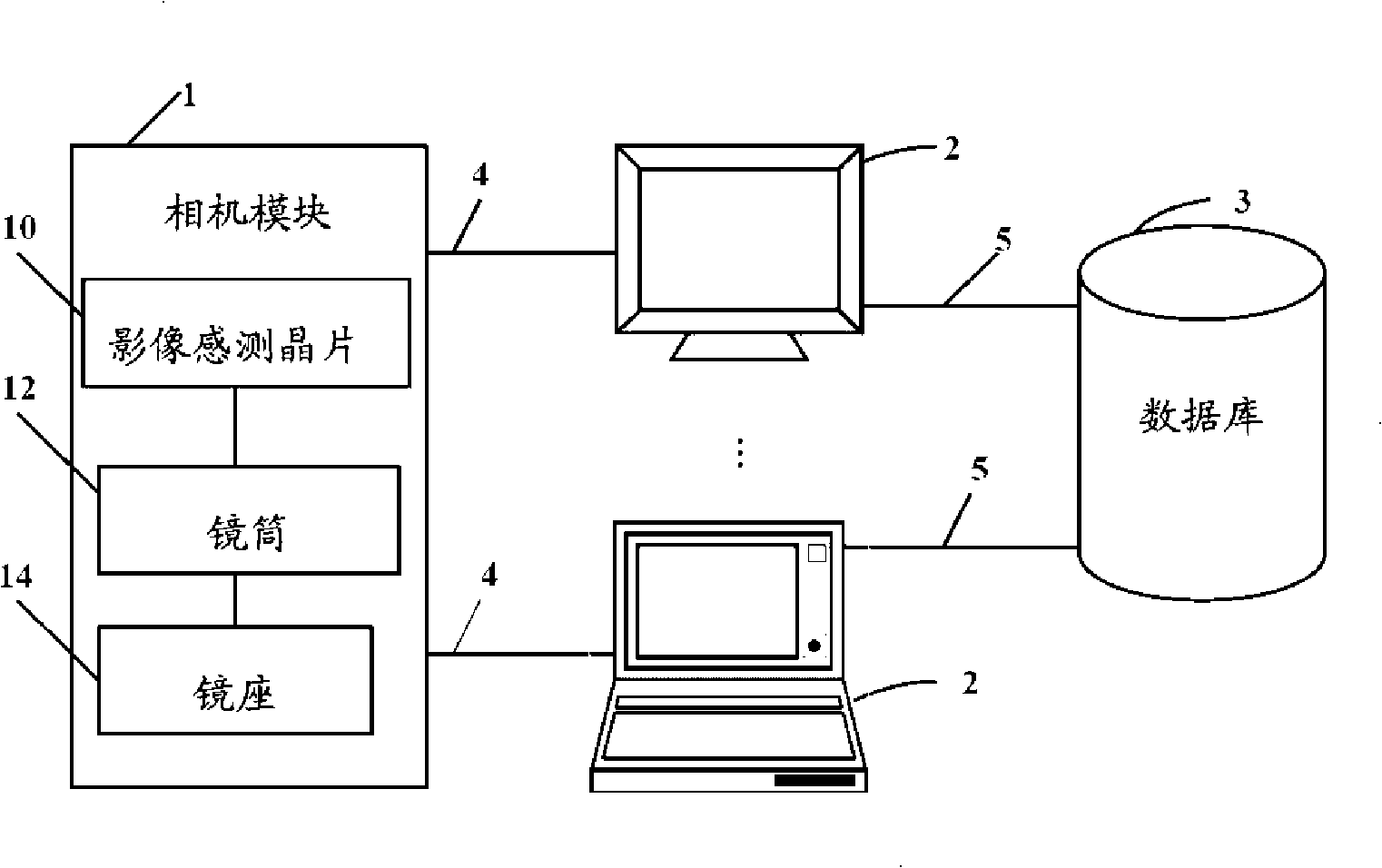

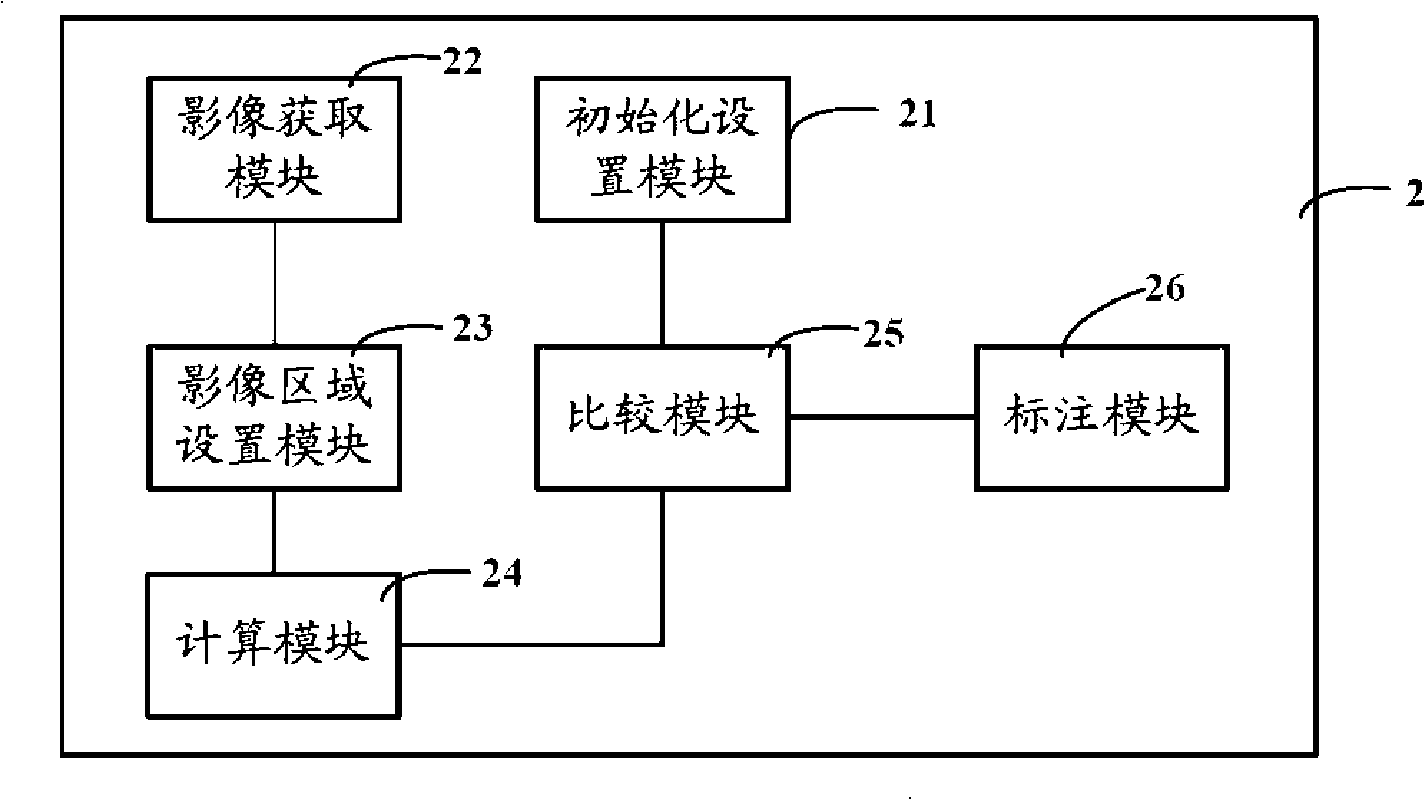

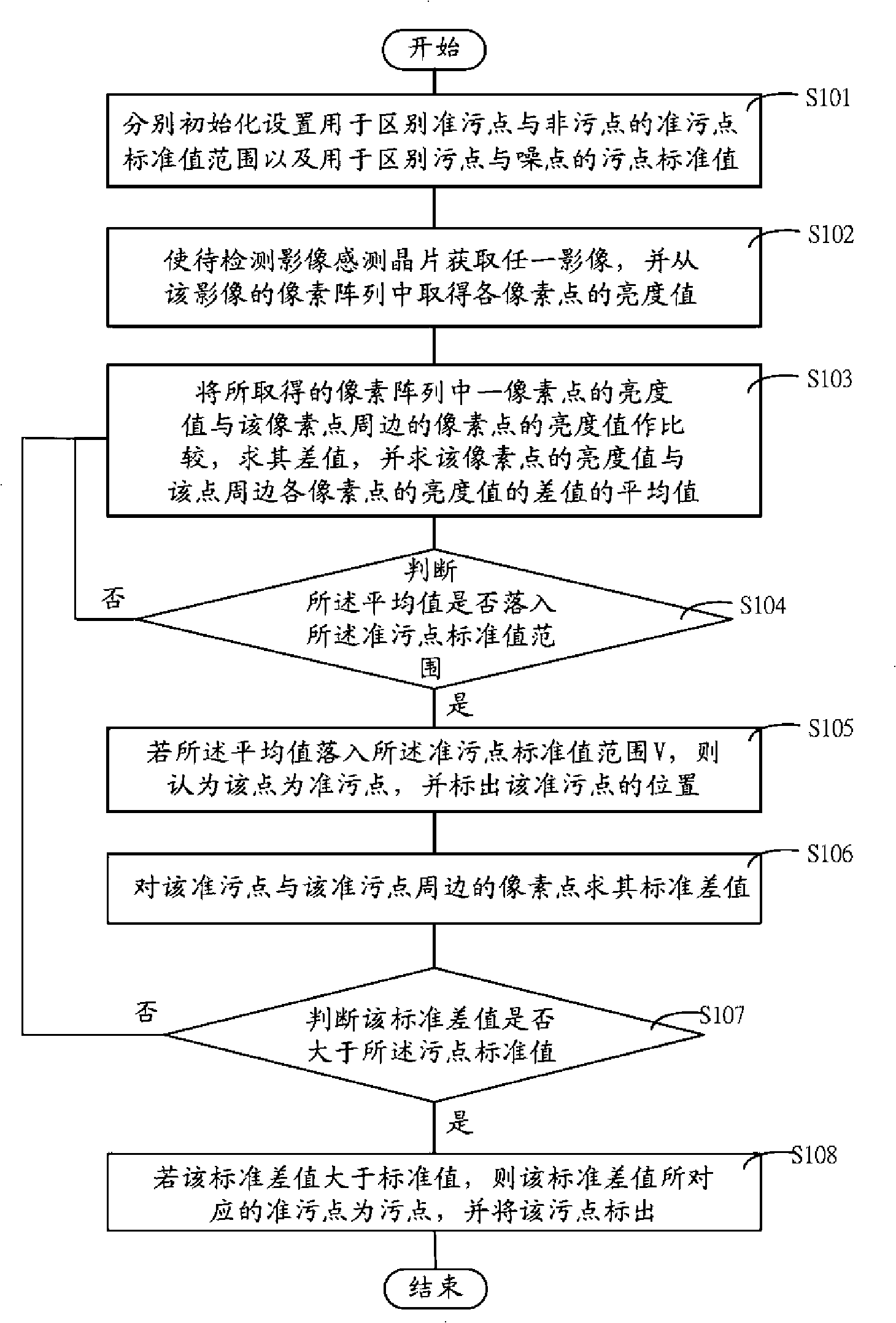

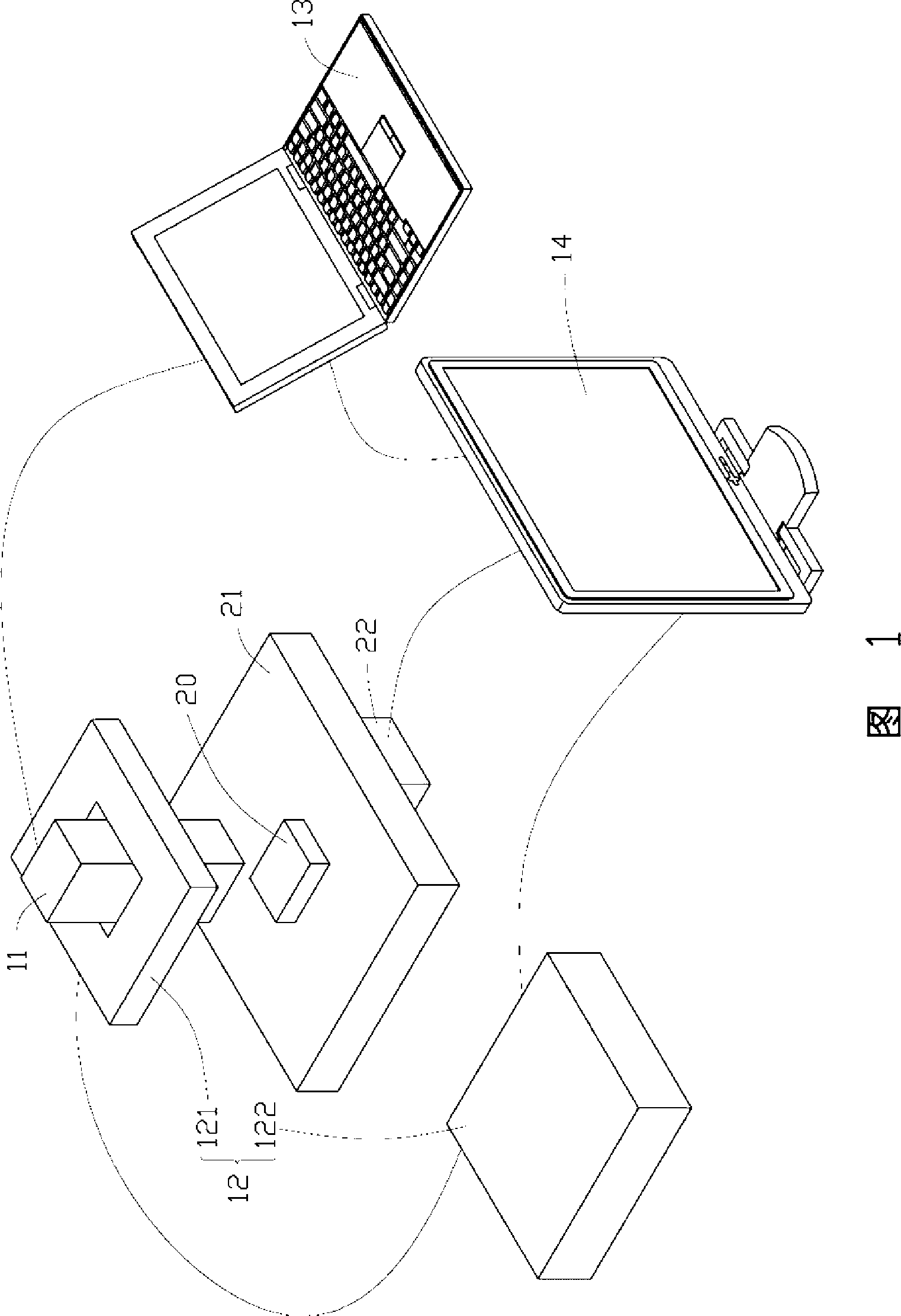

System and method for testing image sensing wafer stain and

InactiveCN101329281AOvercome the effects of noiseAccurate judgmentOptically investigating flaws/contaminationTelevision systemsComputer scienceBrightness perception

The invention provides an image sensing wafer stain detection system, comprising an initialization setting module which is used for initially setting a quasi-stain standard value range and a stain standard value, an image acquiring module which is used for acquiring the brightness value of each pixel in the acquired image, a calculating module which is used for calculating the average and the standard difference value, a comparison module which is used for comparing the average and the standard difference value with the quasi-stain standard value range and the stain standard value respectively, and a labeling module which is used for labeling the quasi-stain in the quasi-stain standard value range and the stains exceeding the stain standard value range. The image sensing wafer stain detection system avoids the problems of subjective factors and residual error rate by manpower eye detection, and further improves the detection qualification rate. The invention also provides a detection method for the image sensing wafer stain detection system.

Owner:FOSHAN PREMIER SCI & TECH CO LTD +1

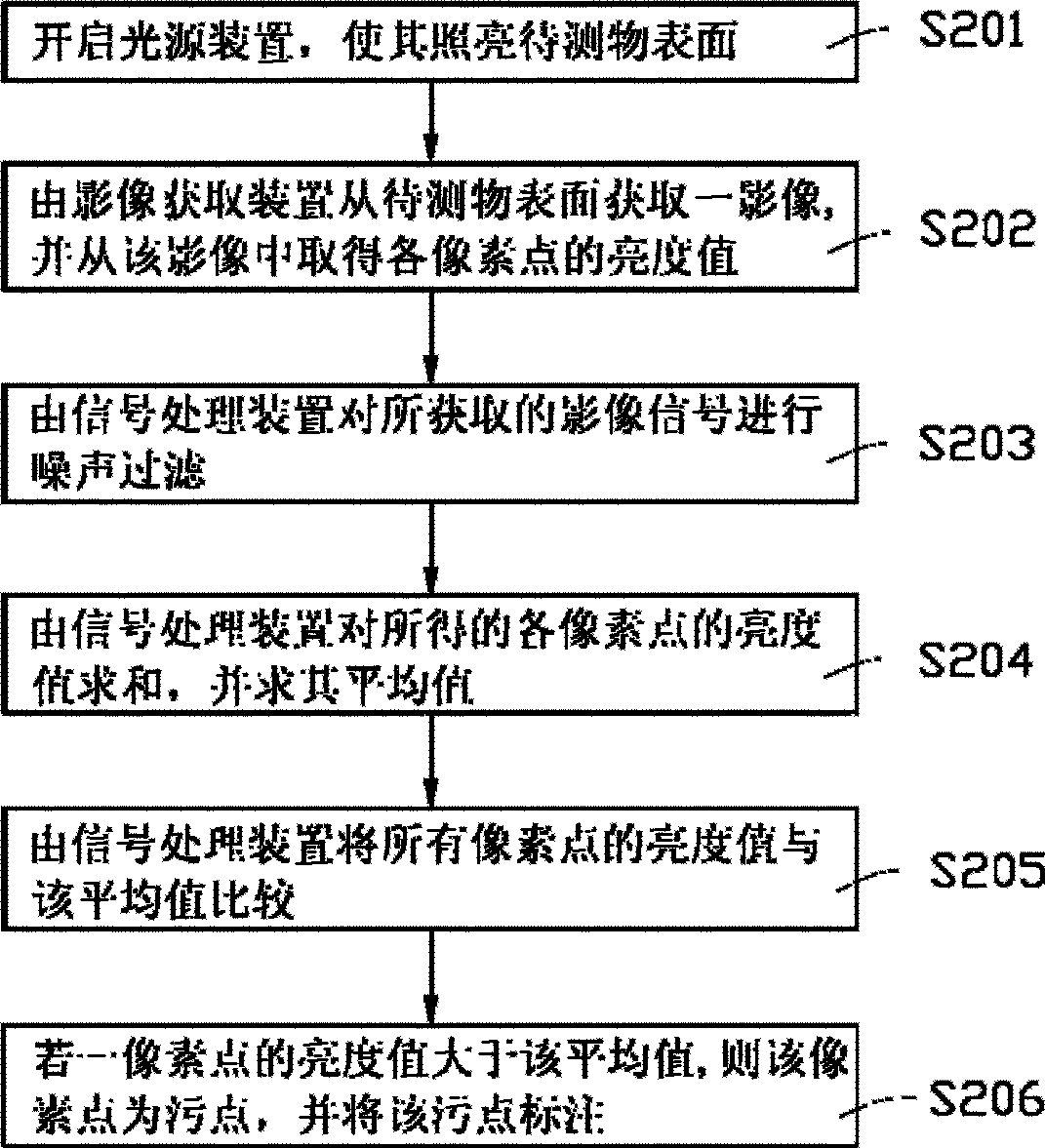

Surface blot detecting system and detecting method thereof

InactiveCN101382502AImprove the detection pass rateAccurate judgmentMaterial analysis by optical meansElectrical bondingArtificial intelligence

The invention discloses a surface stain detecting system which comprises at least one image acquiring device used for acquiring the image of surface information of an object to be tested; at least one light source device used for lighting the surface of the object to be tested; and a signal processing device electrically connected with the image acquiring device used for processing the image acquired by the image acquiring device so as to detect that whether the surface of the object to be tested conforms to a preset standard value, and marking the pixel of which the brightness value is more than the average value. With the coordination of the image acquiring device and the signal processing device, the surface stain detecting system can accurately judge the position where the stain exists, thus not only accelerating the detecting speed, but also avoiding the subjective factors existing in manual detecting and the omission factor thereof, thereby improving the detecting qualification rate. The invention also relates to a stain detecting method of the surface stain detecting system.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

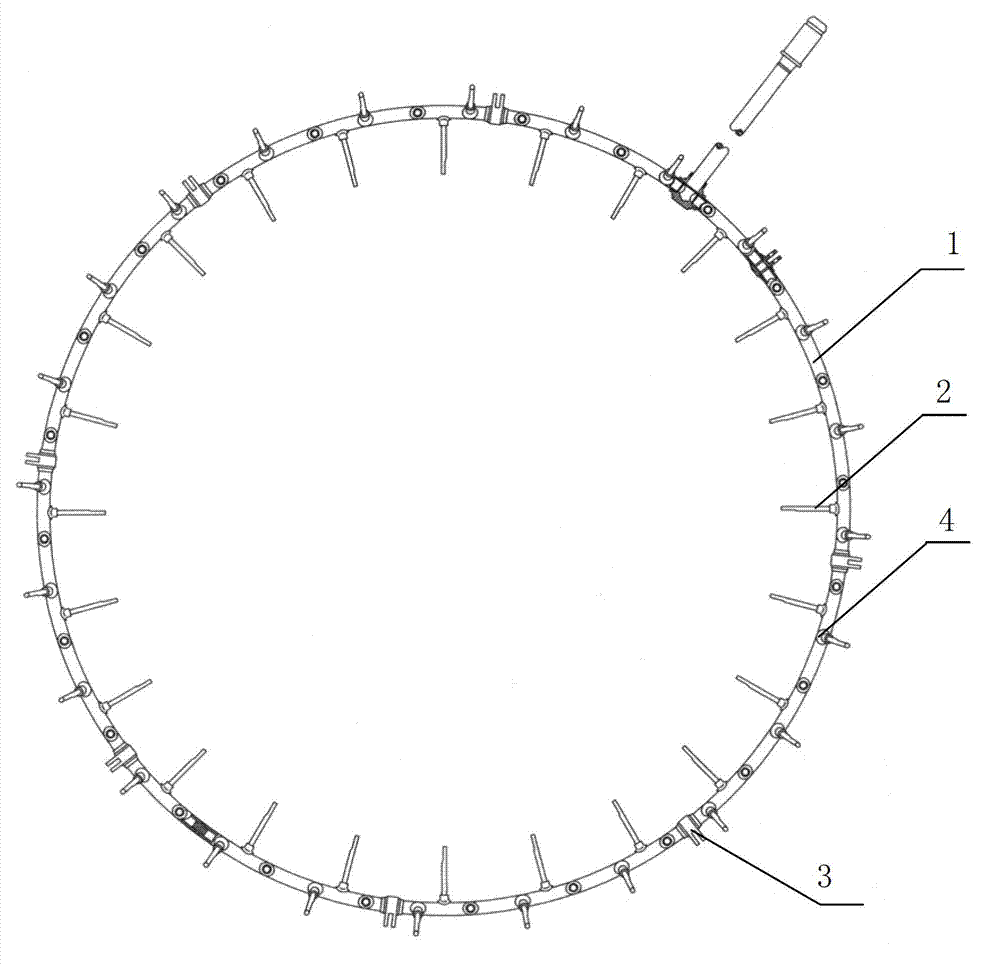

Welding method for main fuel tube of engine

The invention provides a welding method for a main fuel tube of an engine, and belongs to the technical field of manufacture of engines. The welding method is applied to welding of the main fuel tubes of various engines. The welding method for the main fuel tube of the engine, provided by the invention, is easy for removing faults and welding; the dimension and the form and location tolerance of the main tube welded by the method provided by the invention can be easily ensured; through the welding method, ideal welding forming and the welding quality can be achieved, and high production efficiency can be ensured. The welding method comprises steps of: welding a boss on a guide tube; welding a hanging part to one end of the guide tube; welding a spraying rod on the boss, so as to form a small main pipe section; and welding the small main tube sections on which the bosses, the hanging parts and the spraying rods are welded, so as to form a closed ring which is the main fuel tube of the engine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

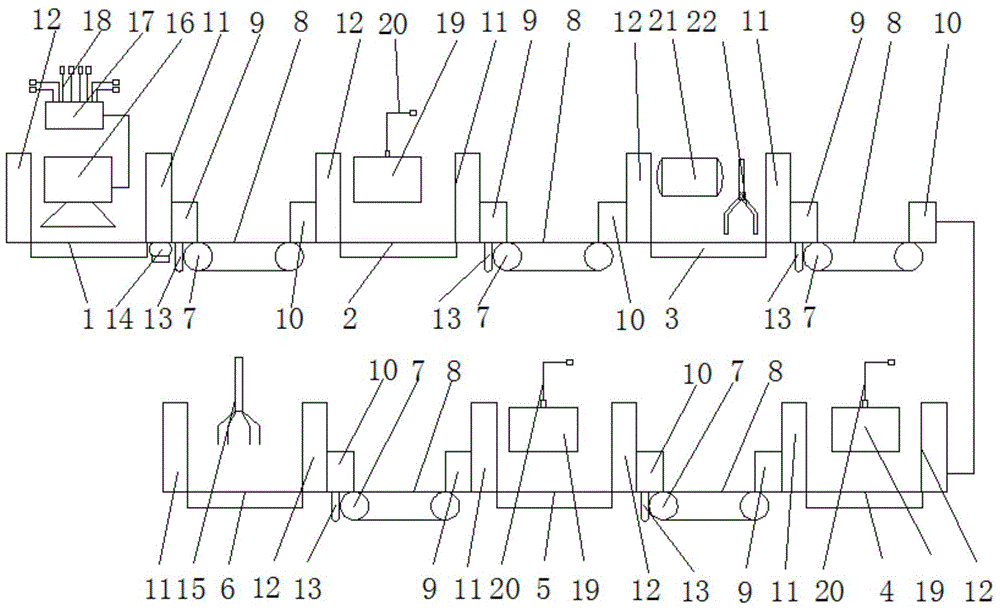

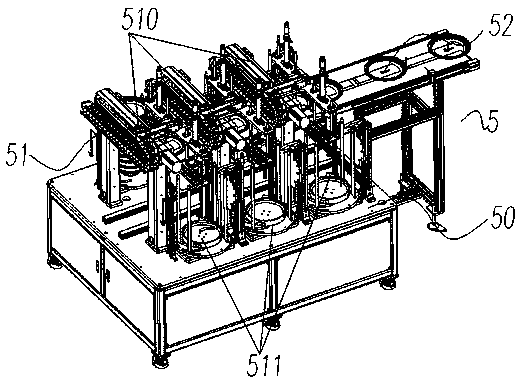

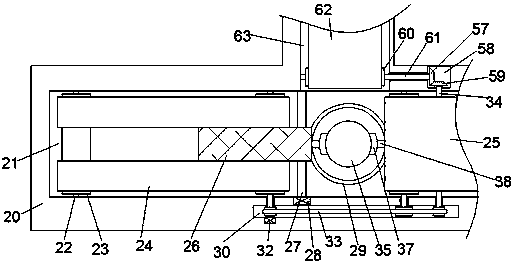

Mobile phone test assembly line

InactiveCN105338149ASimple structureMany types of testsSubstation equipmentHuman–machine interfaceAssembly line

The invention belongs to the technical field of assembly lines, and especially relates to a mobile phone test assembly line. The mobile phone test assembly line comprises a download testing device, a calibration device, a human-computer interface testing device, an echo testing device, a network testing device and a finished product packing device, wherein belt conveyors are orderly arranged between the download testing device, the calibration device, the human-computer interface testing device, the echo testing device, the network testing device and the finished product packing device; the belt conveyors are provided with conveyor belts; the two ends of the conveyor belts are provided with a material receiving port and a material transporting port; and the material receiving port is connected with a discharge port of a corresponding device and the material transporting port is connected with a feeding port of the corresponding device. The mobile phone test assembly line provided by the invention is multiple in test functions, high in detection qualification rate and fast in detection speed.

Owner:天津福莱迪科技发展有限公司

Product detection and sorting device for detecting aperture and sorting unqualified products

ActiveCN102091697AImprove efficiencyImprove the detection pass rateMechanical diameter measurementsSortingEngineering

Owner:SUZHOU ALOME SCI & TECH

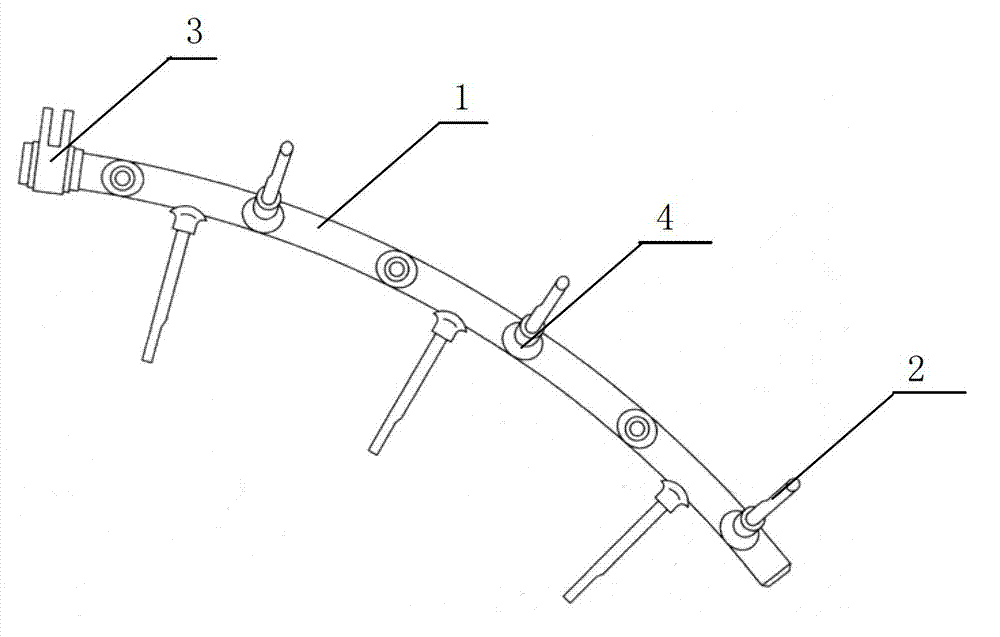

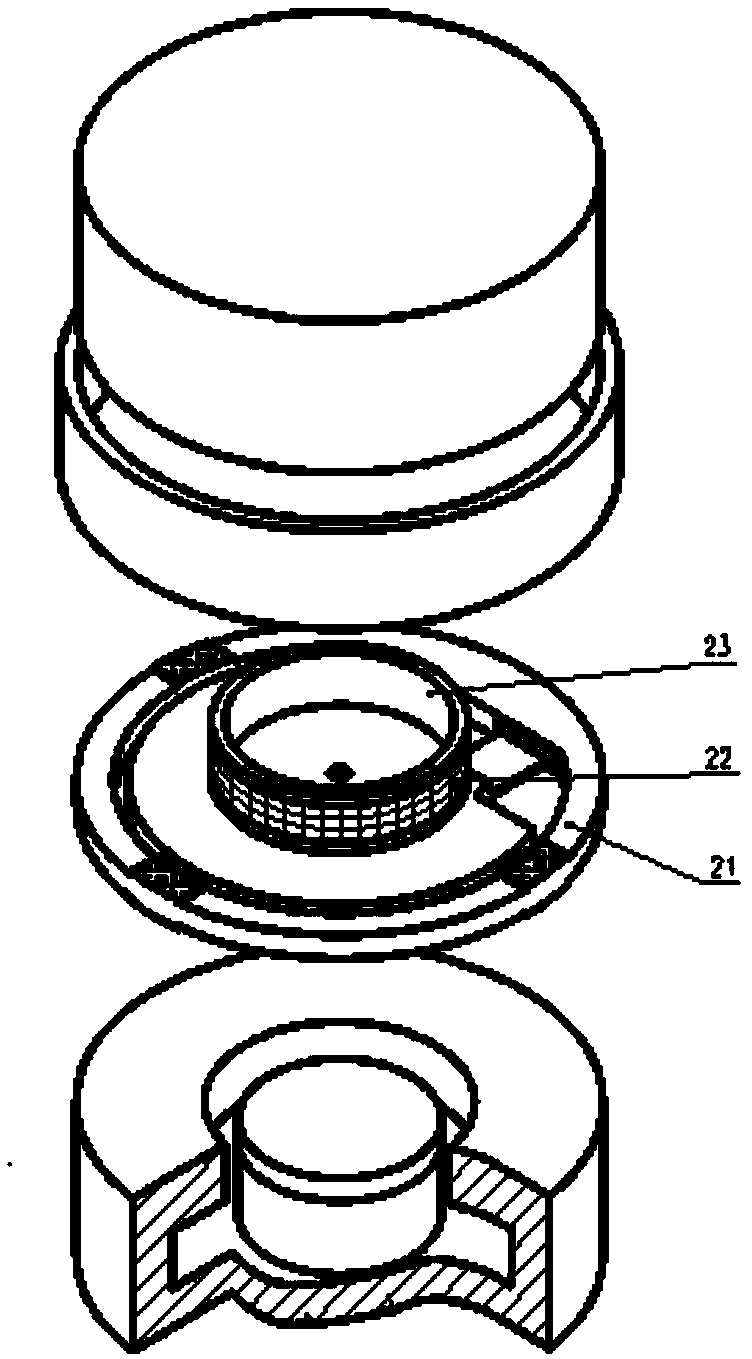

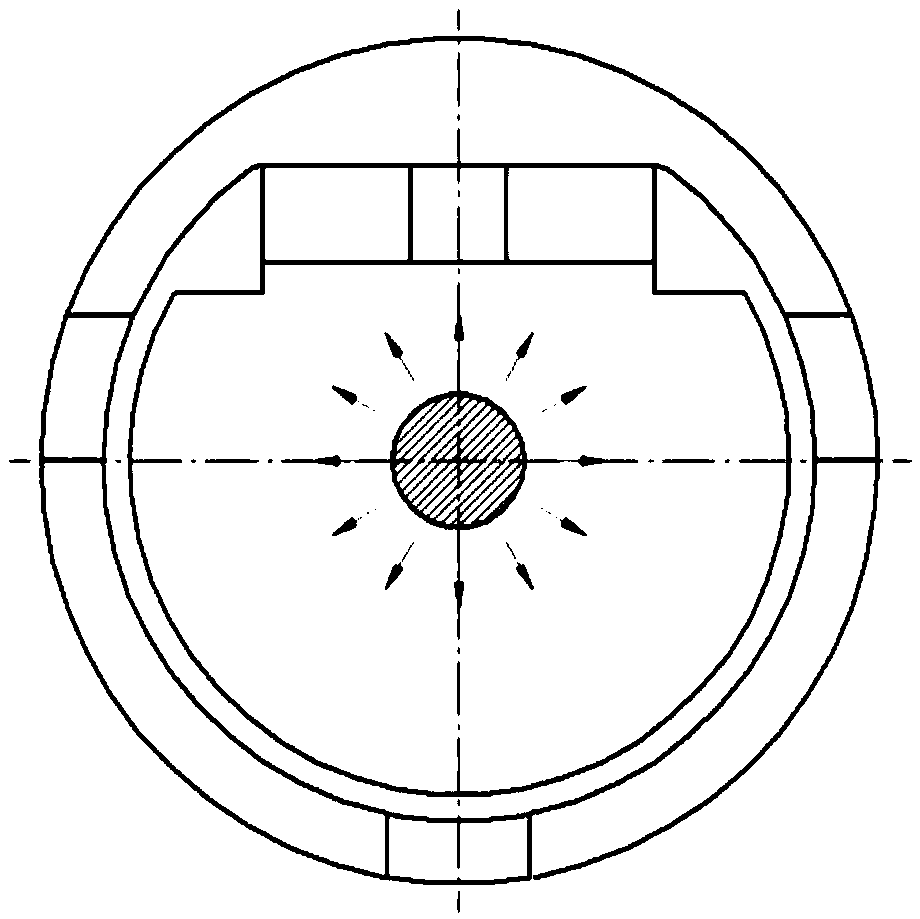

Novel quartz glass pendulous reed

InactiveCN109100536ASimple structureReduce sensitivityAcceleration measurement using interia forcesAccelerometerEngineering

The invention relates to a novel quartz glass pendulous reed. The novel quartz glass pendulous reed comprises a round support ring, two flexible support beams and a pendulous tongue which swings freely, wherein the two flexible support beams are to an axis in parallel; the pendulous reed is connected with the round support ring through the flexible support beams; three mounting positioning bossesare arranged on the round support ring; the three mounting positioning bosses are symmetrically distributed along a vertical axis; a vent hole is coaxially formed in the center of the round support ring; an isolation groove is formed in the round support ring between the vent hole and the flexible support beams; the isolation groove is coaxial with the vent hole; an opening is formed in the isolation groove; the direction of the opening is far away from the two flexible support beams and is left-right symmetrical. The novel quartz glass pendulous reed is put forward at home for the first time.By adoption of the structure form, the pendulous reed has the advantages of remarkably reducing the temperature sensitivity, improving the survival rate of the assembling process and improving the long-term stability of accelerometers when being compared with the original traditional structure, and can be applied to NJS / A type quartz accelerometers.

Owner:TIANJIN NAVIGATION INSTR RES INST

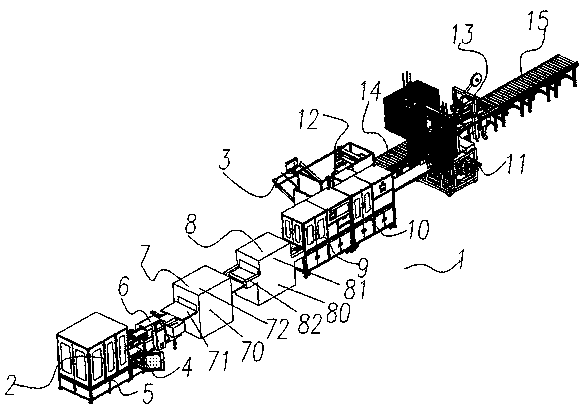

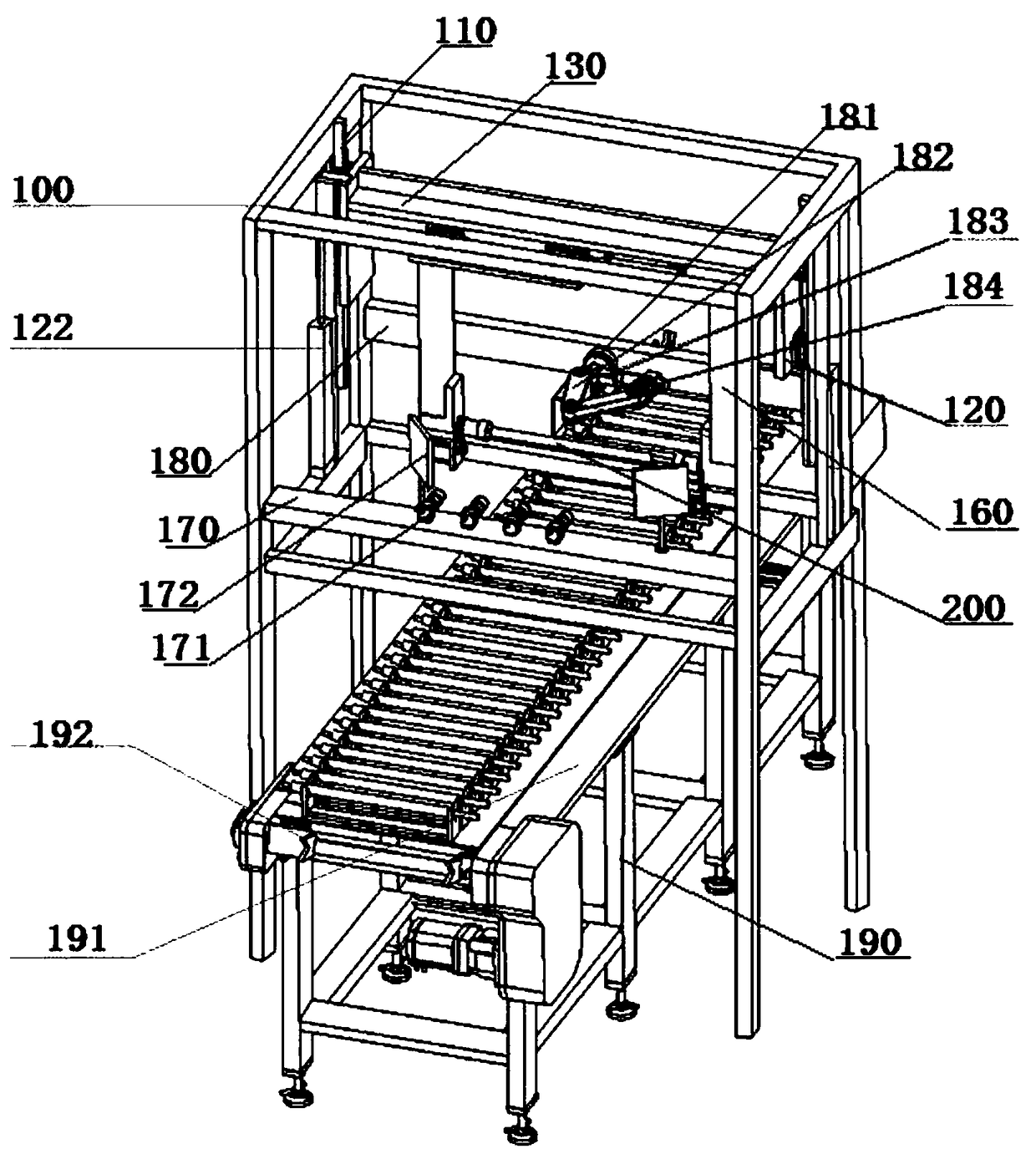

Full-automatic detection and packaging system for circular dinner plate and detection and packaging method

PendingCN110861811AImprove securityImprove efficiencyPackaging automatic controlPackaging machinesProcess engineeringManufacturing line

The invention discloses a full-automatic detection and packaging system for a circular dinner plate. The full-automatic detection and packaging system comprises a circular dinner plate full-automaticdetection packaging production line and a boxing packaging production line, wherein the circular dinner plate full-automatic detection packaging production line comprises a control box, a circular dinner plate splitting and feeding device, a weighing device, a dust removal device, a disinfection device, a visual detection device, an automatic stacking device and a packaging bag automatic packing device. The invention further discloses a detection and packaging method. According to the full-automatic detection and packaging system, the procedures of automatic sorting separation feeding, weighing detection, dust removal treatment, disinfection treatment, appearance detection, unqualified and qualified product sorting and qualified product automatic bagging packaging and boxing are integrated, the detection packaging efficiency and the product detection qualification rate are improved, the labor intensity of workers is reduced, the hygiene standards of products is improved, and the follow-up use of the products can be ensured; and the system can be used for detecting and packaging of the products with various specifications, the applicability is high, and the requirements of existingautomation and high-precision detection and packaging can be met.

Owner:GUANGDONG INTELLIGENT ROBOTICS INST +1

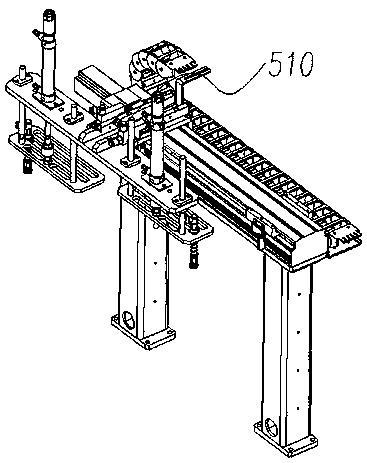

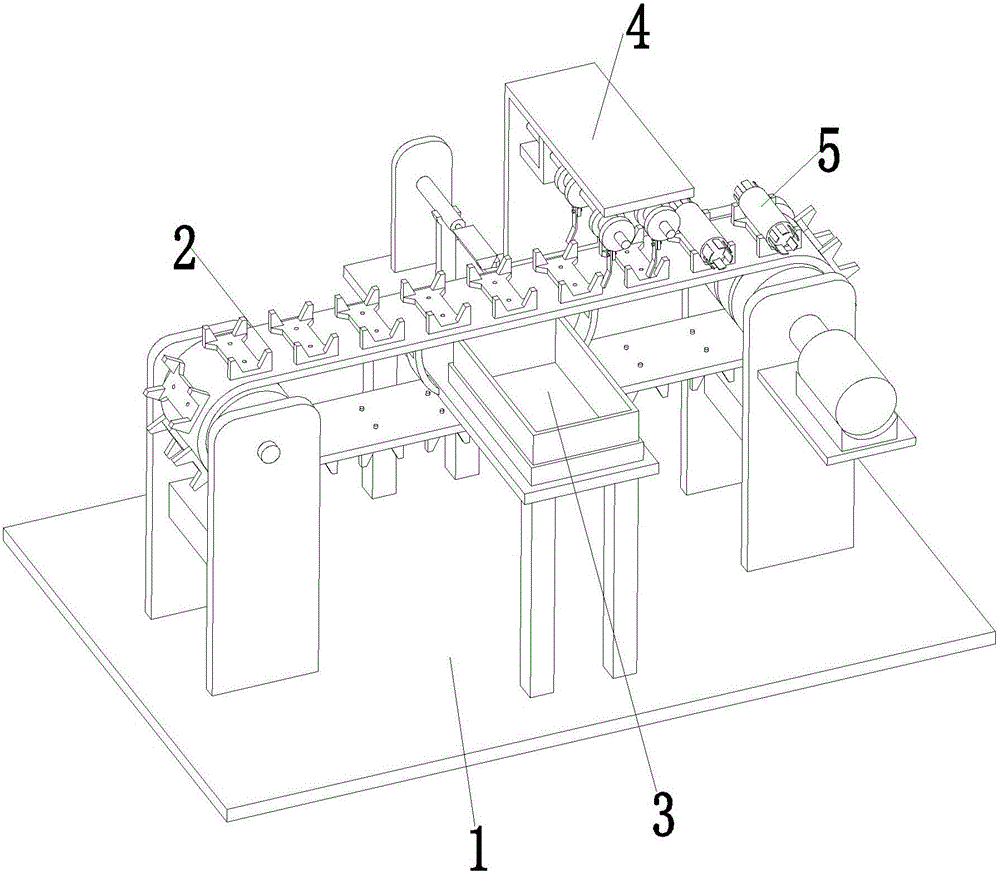

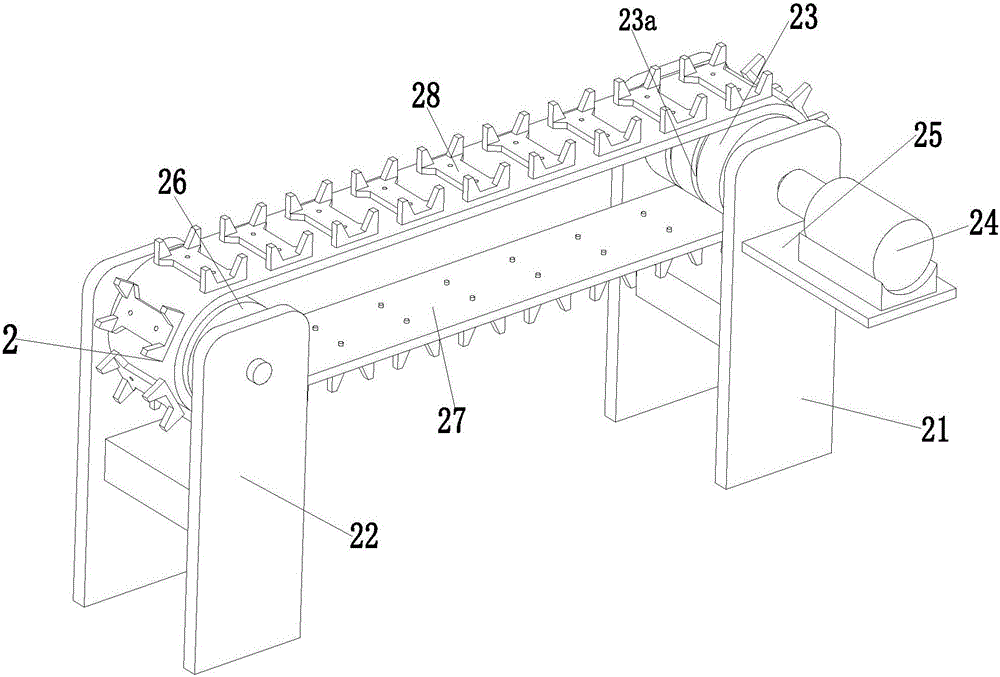

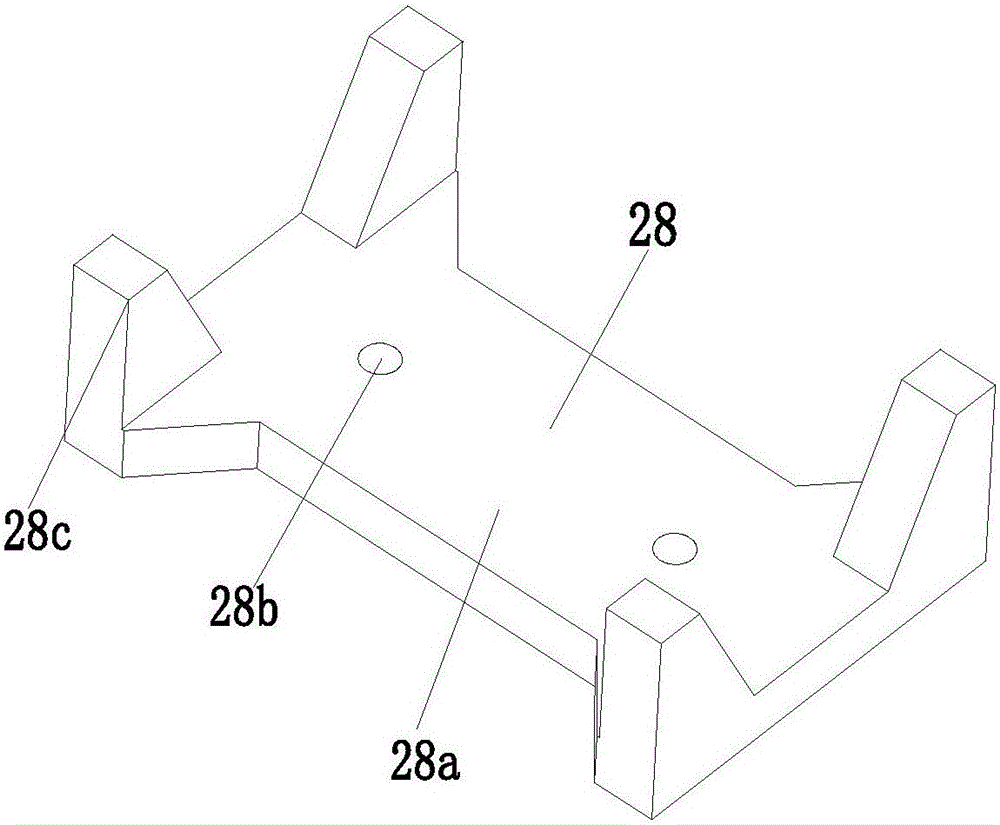

Battery cell transmission equipment with short circuit detection function

InactiveCN105977542AReduce pass ratePhenomenon that prevents position shiftingFinal product manufactureElectrolyte accumulators manufactureWaste productEngineering

The invention relates to a battery cell transmission equipment with a short circuit detection function. The battery cell transmission equipment comprises a bottom plate, wherein a battery cell transmission device is transversely arranged at the middle part of the upper end surface of the bottom plate; an automatic limiting transmission function on battery cell bodies can be realized by the battery cell transmission device; a waste product removing device is longitudinally arranged at the middle part of the upper end surface of thebottom plate; the middle part of the waste product removing device is arranged on the battery cell transmission device in a penetrating way; a short circuit detection device is arranged at the right side of the waste product removing device through a bolt,an accurate short circuit detectionfunctionfor the battery cell bodies canbe realizedby the short circuit detection device, and afunctionofautomatically removing a detected waste product can be realized by the waste product removing device; the battery cell bodies are uniformly arranged on the upper end surface of the battery cell transmission device. According to the battery cell transmission equipment disclosed by the invention, the functions of automatic limiting transmission, accurate short circuit detection and automatic waste product removing on lithium battery cells can be realized, and the novel automation equipment integratingthe functions of short circuit detection, waste product removing, batter cell transmission and the like is provided.

Owner:ZHEJIANG JINKAILAI NEW ENERGY TECH

All-position welding method for stainless steel pipeline for oil and gas transmission

ActiveCN110303261AImprove welding qualityImprove the protective effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSteel pipeline

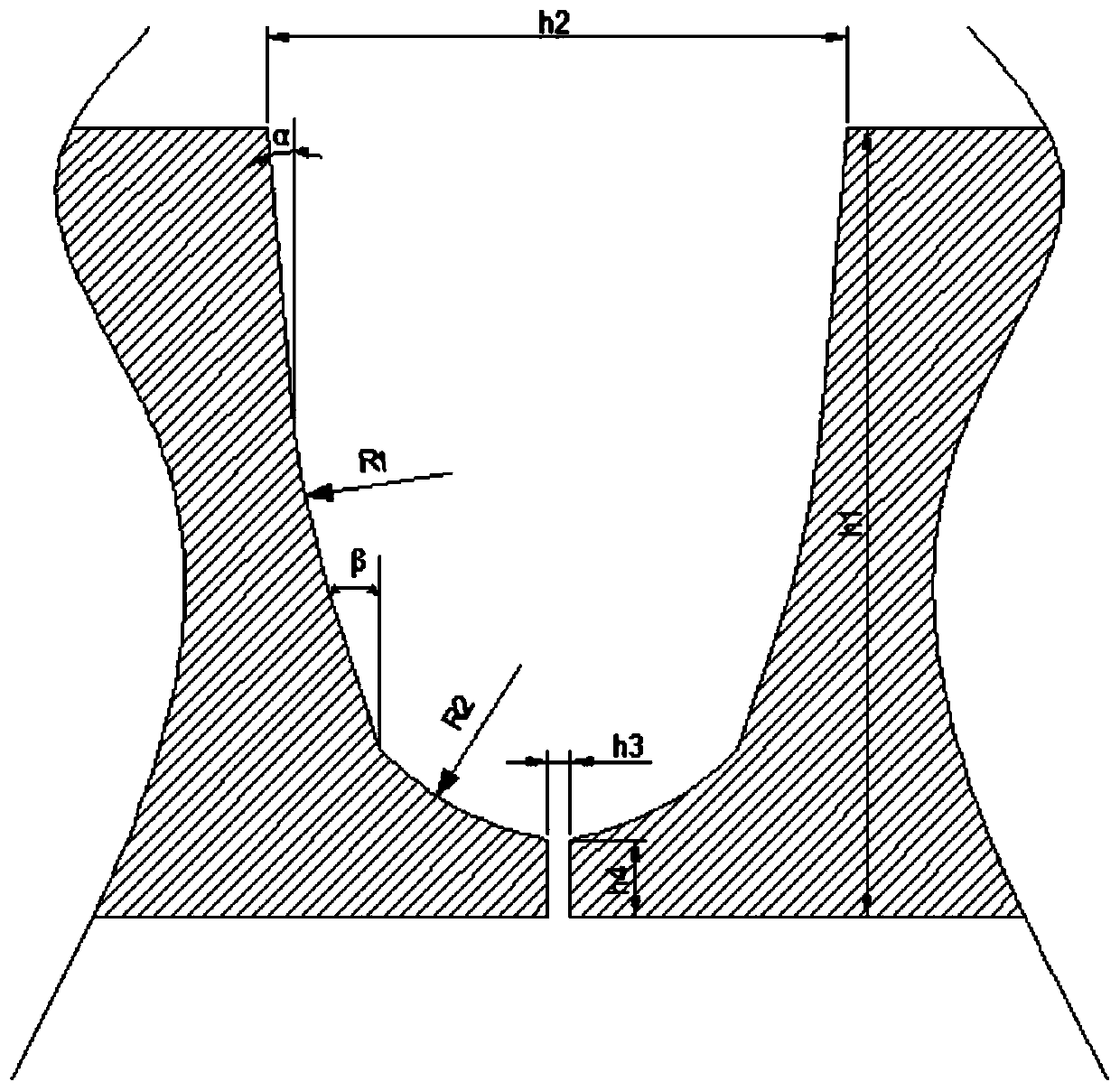

The invention discloses an all-position welding method for a stainless steel pipeline for oil and gas transmission. The all-position welding method comprises the following steps: clearing pipeline inner and outer walls of the stainless steel pipeline, and grooving, wherein grooves adopt dual-U-shaped designs; grinding and clearing the grooves, performing point fixation on the pipeline, clamping the pipeline, and mounting an all-position welding machine along a welding seam; and setting welding parameters and performing sectional positioning welding according to a point fixation position. The pipeline wall thickness h1 of the stainless steel pipeline is greater than or equal to 10 mm and smaller than or equal to 15 mm, opening width h2 between two grooves of the stainless steel pipeline isgreater than or equal to 8 mm and smaller than or equal to 12 mm, and root clearance width h3 between the grooves is greater than or equal to 0.2 mm and smaller than or equal to 0.5 mm, and truncatededge thickness h4 is greater than or equal to 1.3 mm and smaller than or equal to 2.0 mm; and each dual-U-shaped groove comprises an inclined surface section I, an arc surface section I, an inclined surface section II and an arc surface section II from outside to inside. The all-position welding method reasonably optimizes pipeline welding parameters, reasonably improves a welding cut structure, effectively improves welding quality of the welding seam, improves welding fusion depth, weld bead thickness and welding efficiency, and has a welding qualification rate of 99.6%.

Owner:江苏众信绿色管业科技有限公司

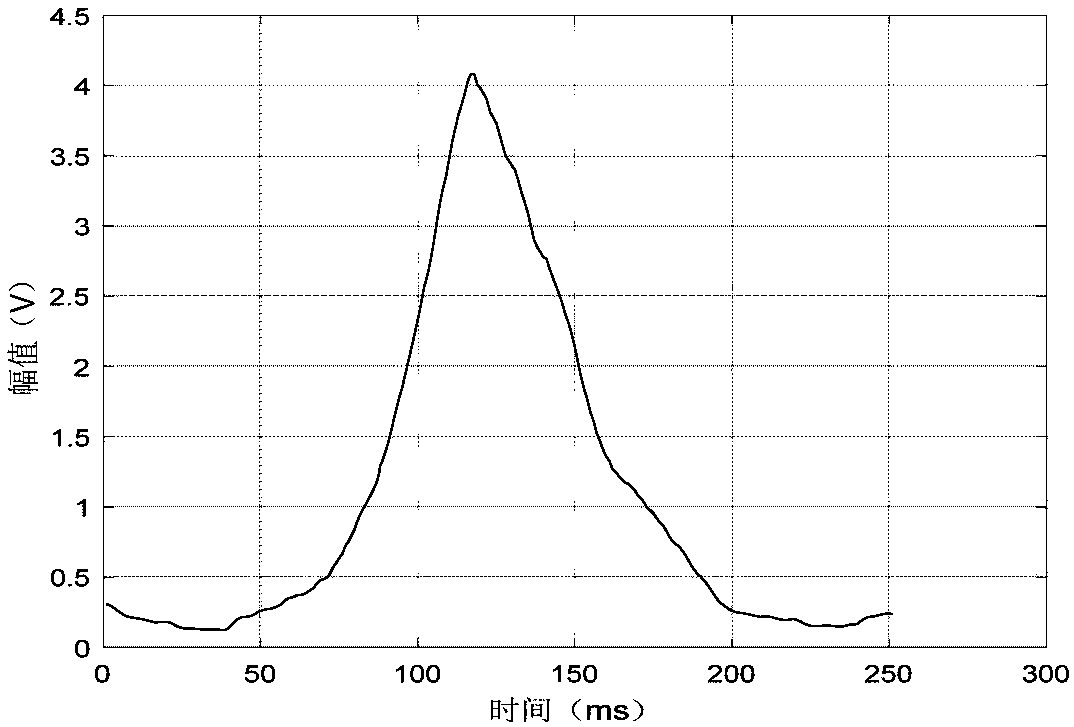

Yield strength estimation method based on full width at half maximum ratio and envelope area of MBN (Magnetic Barkhausen Noise) signal

InactiveCN108595784AYield Strength PredictionAchieving Lossless EstimationGeometric CADNeural learning methodsTest sampleEstimation methods

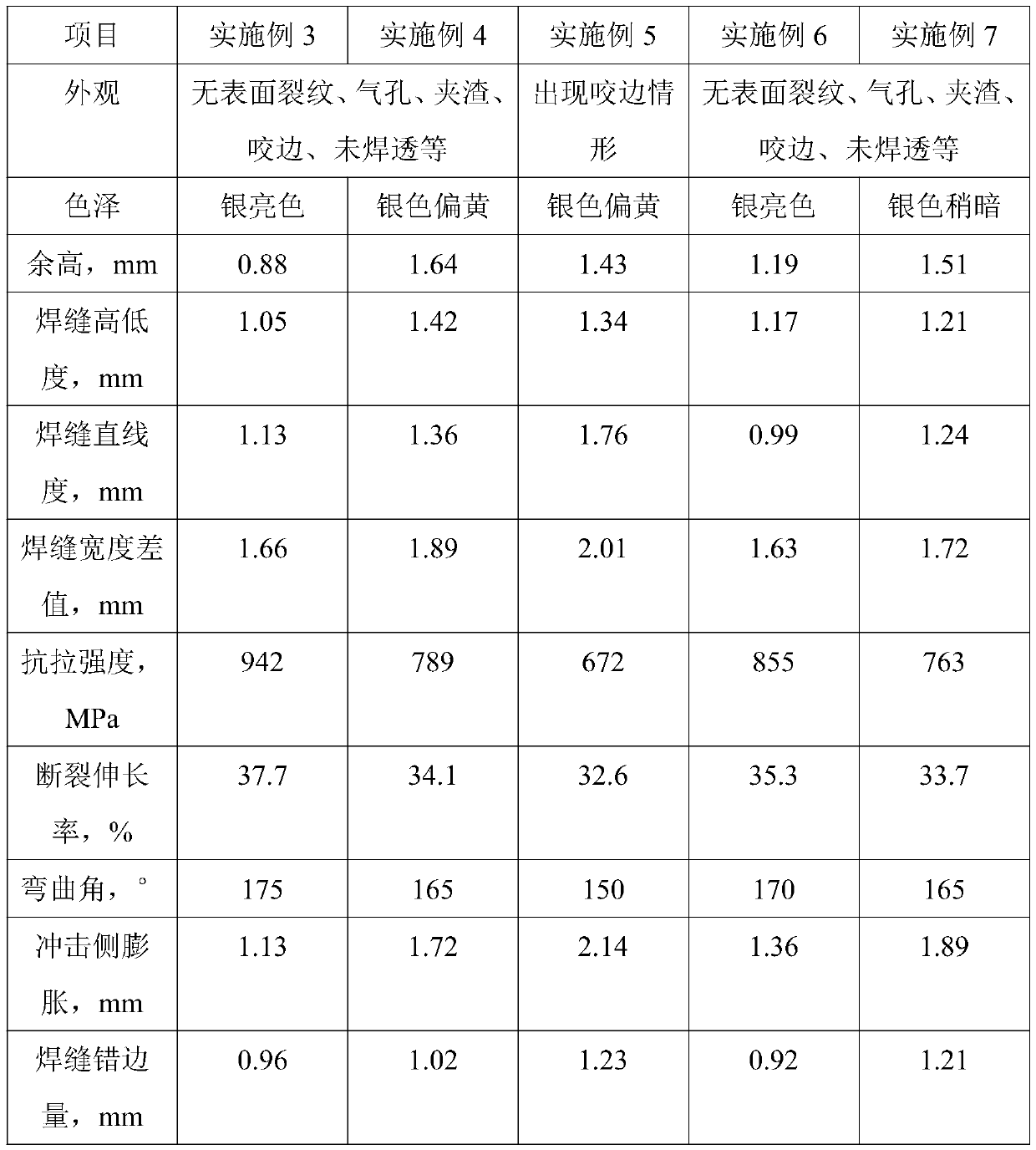

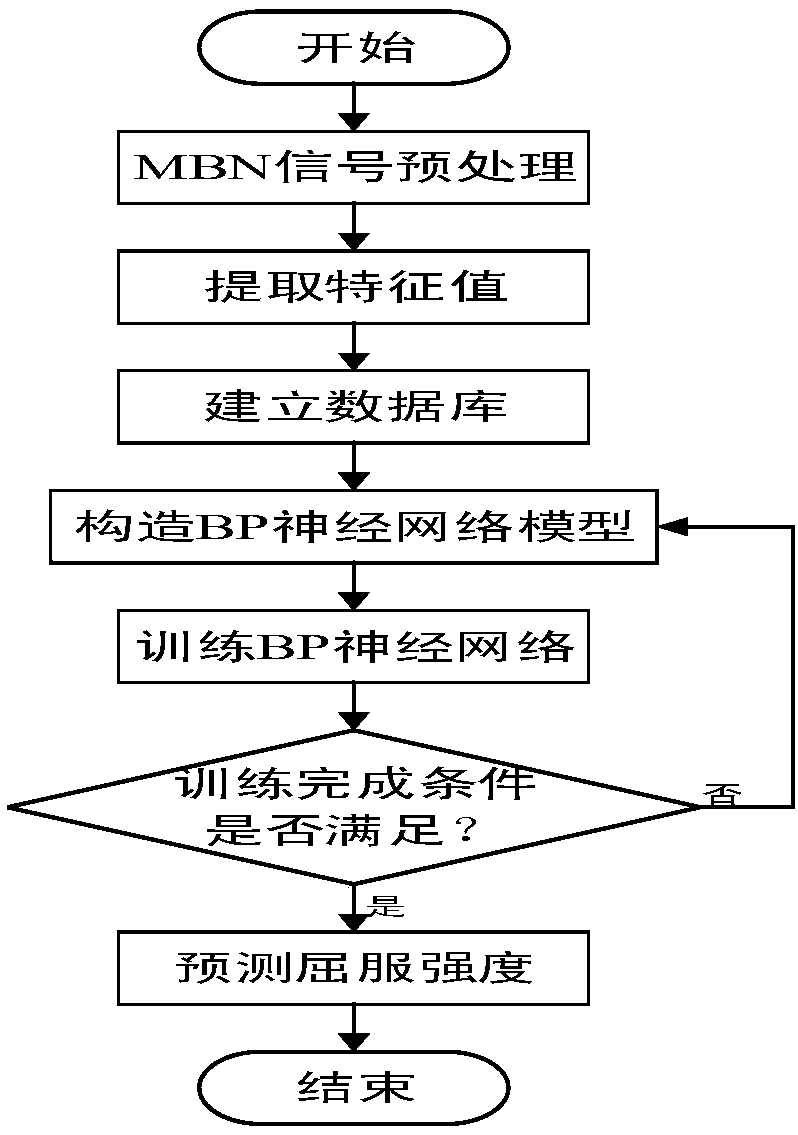

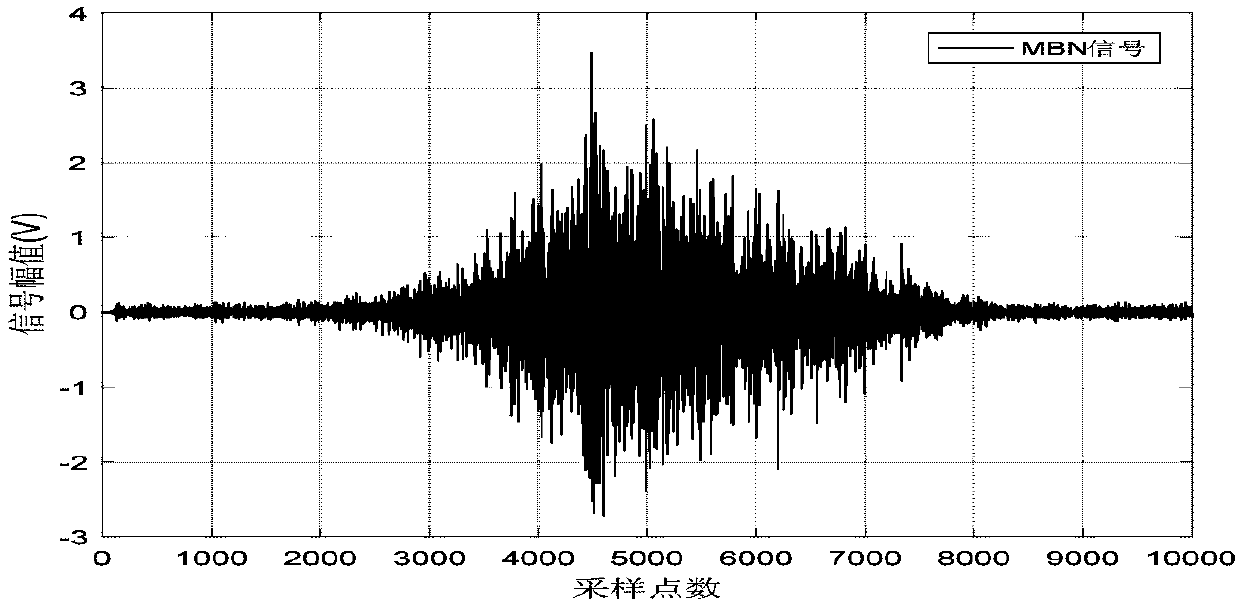

The invention discloses a yield strength estimation method based on the full width at half maximum ratio and the envelope area of a MBN (Magnetic Barkhausen Noise) signal. The method comprises the following steps that: (1) selecting a sine wave signal of which the frequency is 10Hz and the amplitude is 5V as an excitation source, collecting the MBN signal at sampling frequency of 200KHz, and carrying out filtering through a band-pass filter of which the frequency band range is 2-45KHz; (2) extracting two feature values, including the full width at half maximum ratio and the envelope area of the MBN signal; (3) establishing a sample database; (4) carrying out sample data preprocessing, and carrying out normalization on the sample data to be between 0 and 1; (5) constructing a BP (Back Propagation) neural network model; (6) according to a provided training sample, training the BP neural network model, and finishing the training when a training error is smaller than 0.001; and (7) utilizing the trained BP neural network model, and realizing the prediction of the yield strength according to an input parameter provided by a test sample. By use of the method, the quantitative estimationof the material yield strength can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

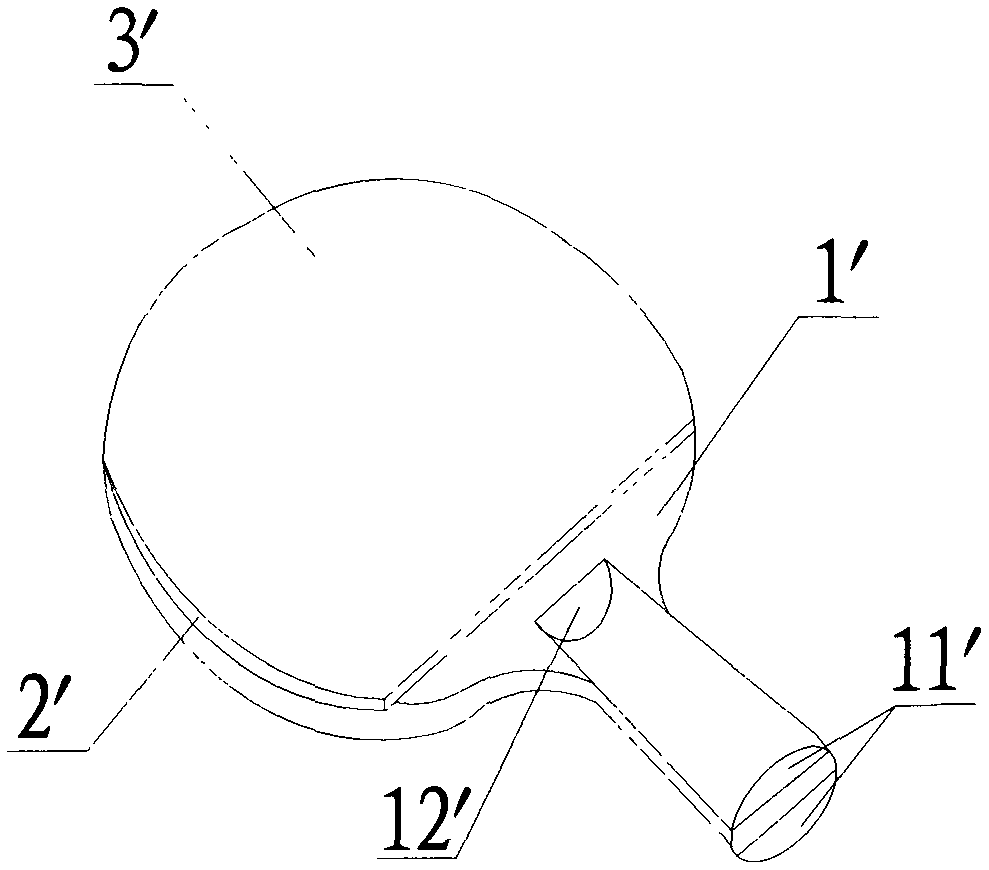

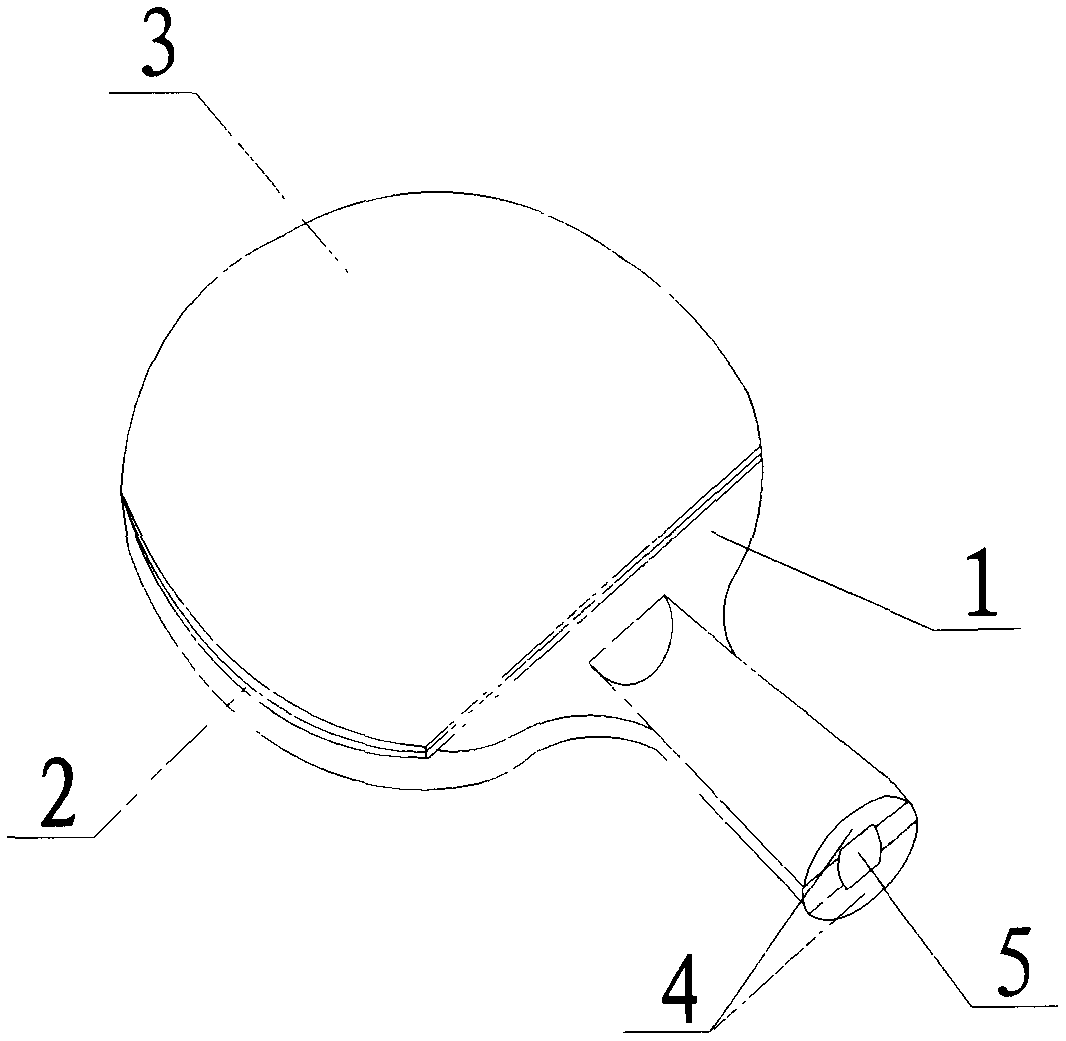

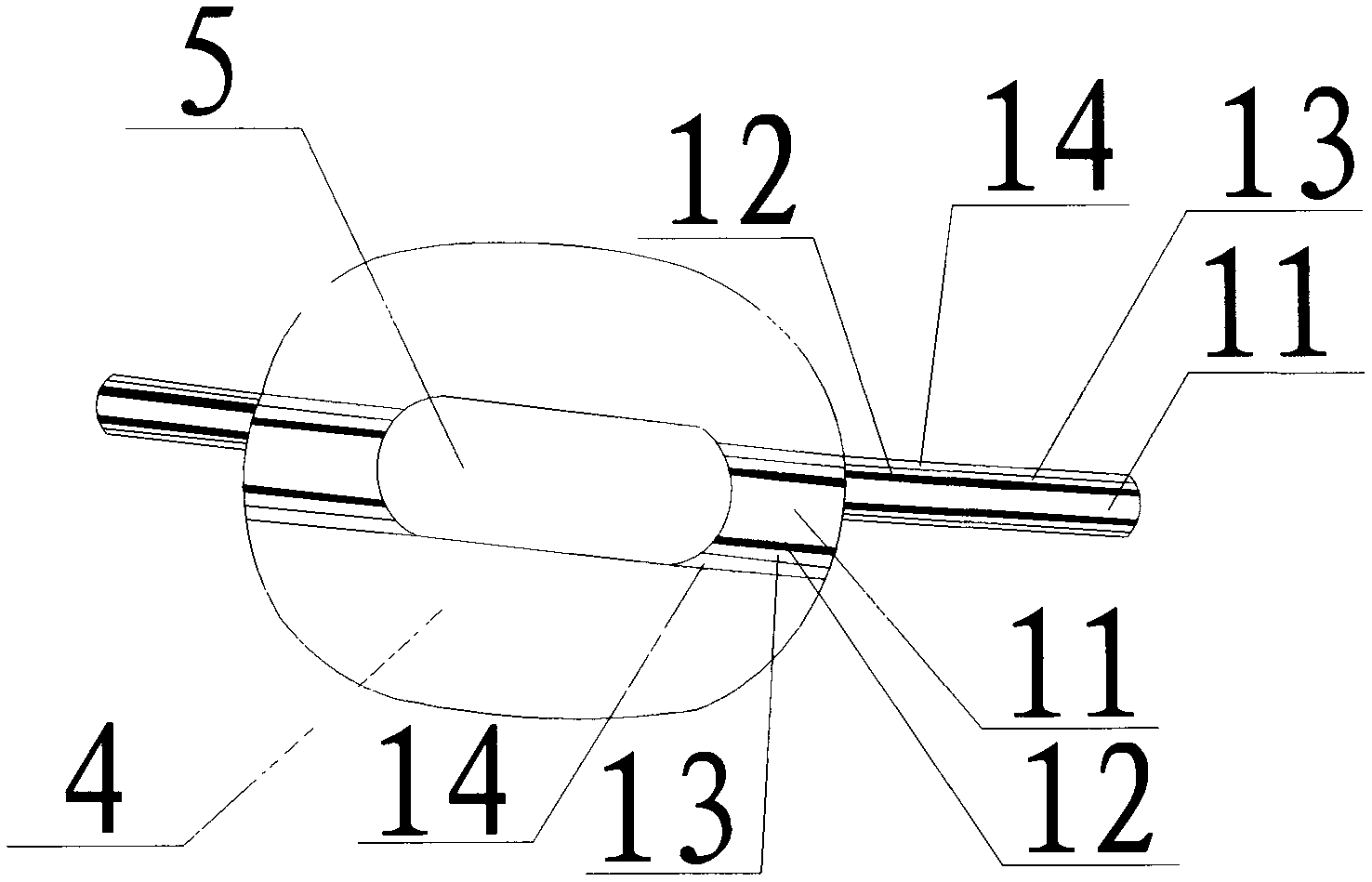

Environment-friendly table tennis racket base plate

The invention relates to an environment-friendly table tennis racket base plate which comprises a bamboo layer, a first wood layer, a black layer, a second wood layer, a black layer, a first wood layer and a bamboo layer which are sequentially bonded in an overlapping mode from bottom to top. Small lateral plates are symmetrically bonded to the base end portions and are formed by integrally molding bamboo. The upper surface and the lower surface of the table tennis racket base plate are made of the bamboo, the weight can be reduced, and the elasticity is improved. The small lateral plates are formed by integral molding the bamboo, glue is not required, and the base plate is environmentally friendly and high in detection pass percent. In addition, a developed capillary structure is arranged on the surface of the base plate and in the base plate, the base plate can effectively absorb sweat produced in the palm of a user to prevent a table tennis racket from slipping out of the hand, the bamboo is good in radiating performance, and the user can feel cool when holding the small lateral plates by the hand.

Owner:YANCHENG AST SPORTING GOODS

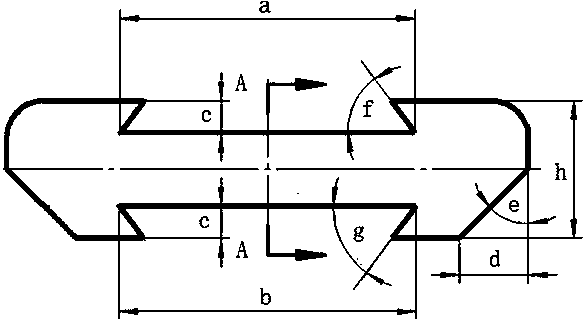

Go/no go gauge fast-checking dovetail size of brake blade and manufacturing method thereof

PendingCN108662962ALow costReduce testing costsAngles/taper measurementsAdditive manufacturing apparatusObservational errorBiochemical engineering

The invention provides a go / no go gauge fast-checking dovetail size of brake blade and manufacturing method thereof, the go / no go gauge comprises a gauge body, a dovetail through-end chute and a dovetail not-go-end chute; the dovetail through-end chute is arranged on one side of the gauge body; the dovetail not-go-end chute is arranged on the other side of the gauge body; the dovetail through-endchute and the dovetail not-go-end chute are symmetrically arranged on both sides of the gauge body, and the dovetail through-end chute and the dovetail not-go-end chute are trapezoid-shaped slots which are concave toward the gauge body; the go / no go gauge provided by the invention can greatly improve the detection efficiency, reduce the measurement error, and greatly reduce the production controlcost and the detection cost of the universal dovetail steel backing; moreover, the go / no go gauge is easy to be carried, has high wear resistance, is convenient for operators to use and can ensure thedimensional accuracy after being used for a long time, so as to effectively guarantee the long-time detection quality of the product.

Owner:北京浦然轨道交通科技股份有限公司 +1

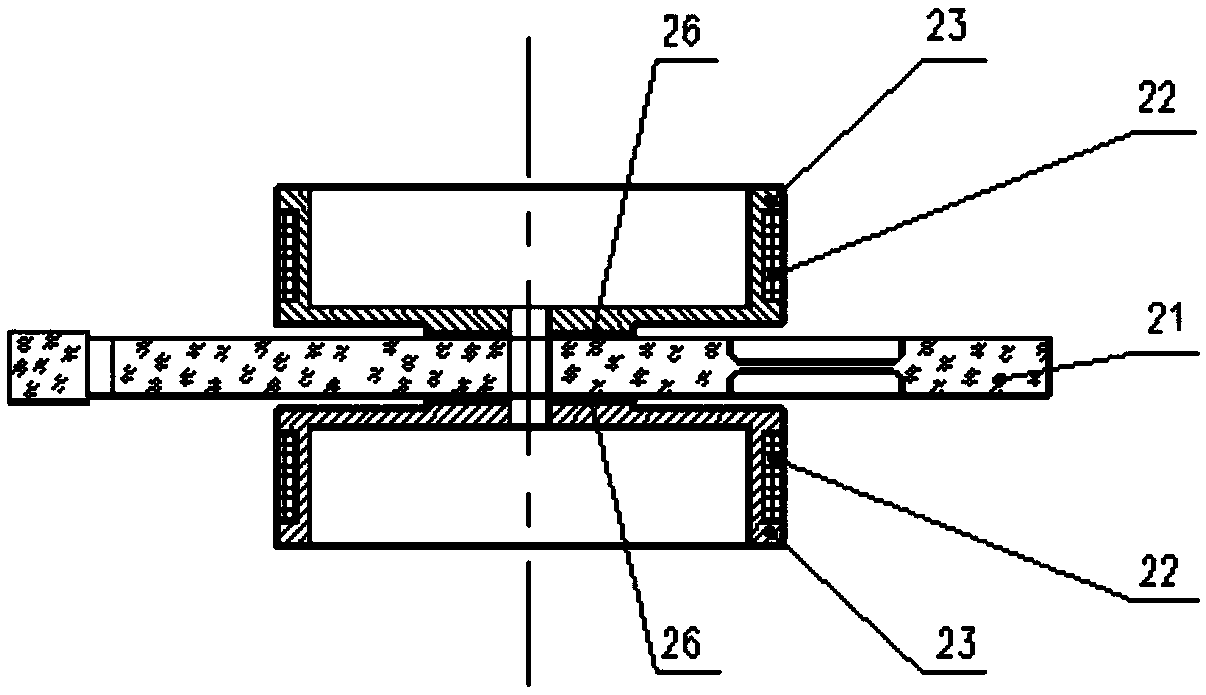

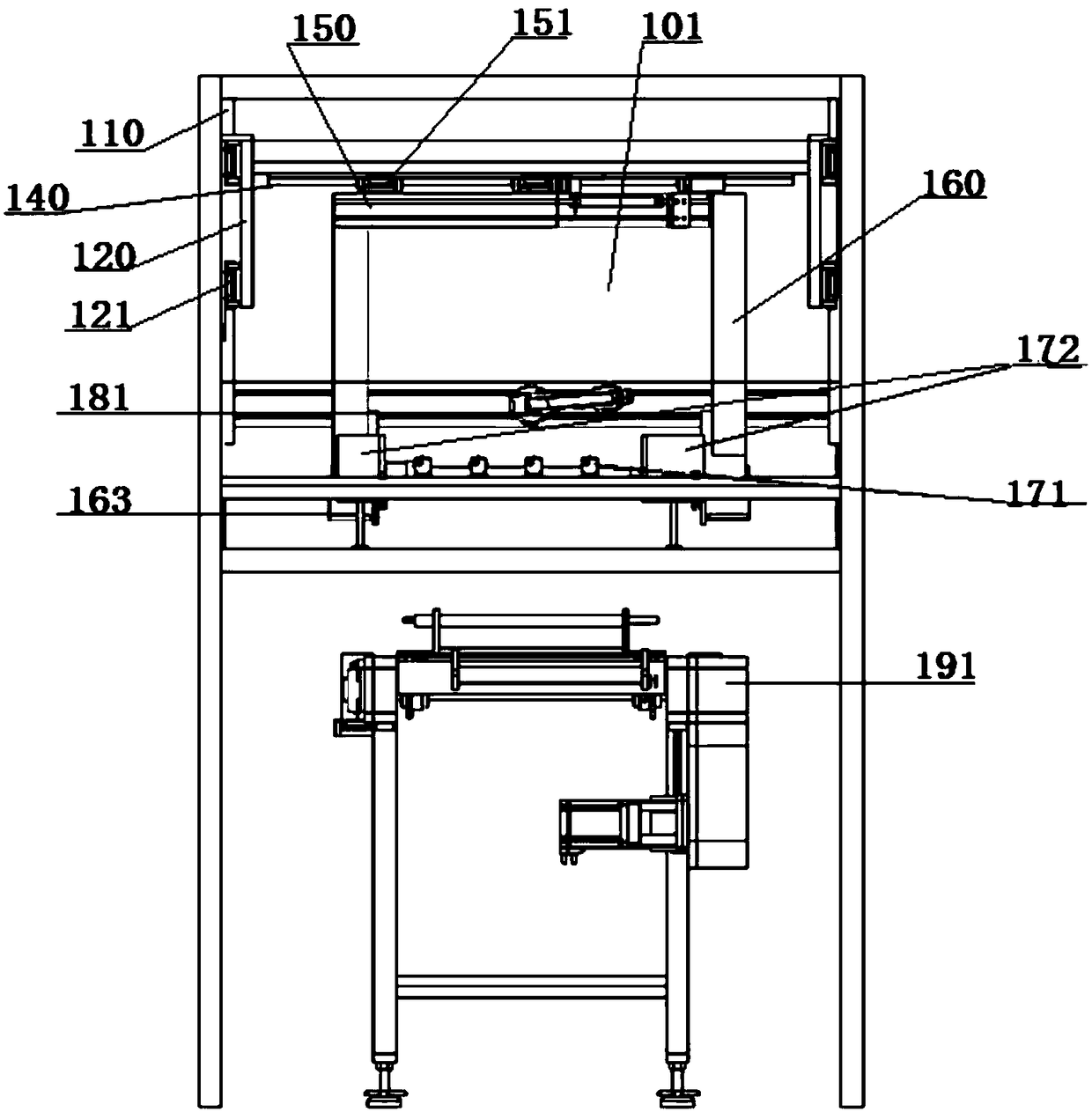

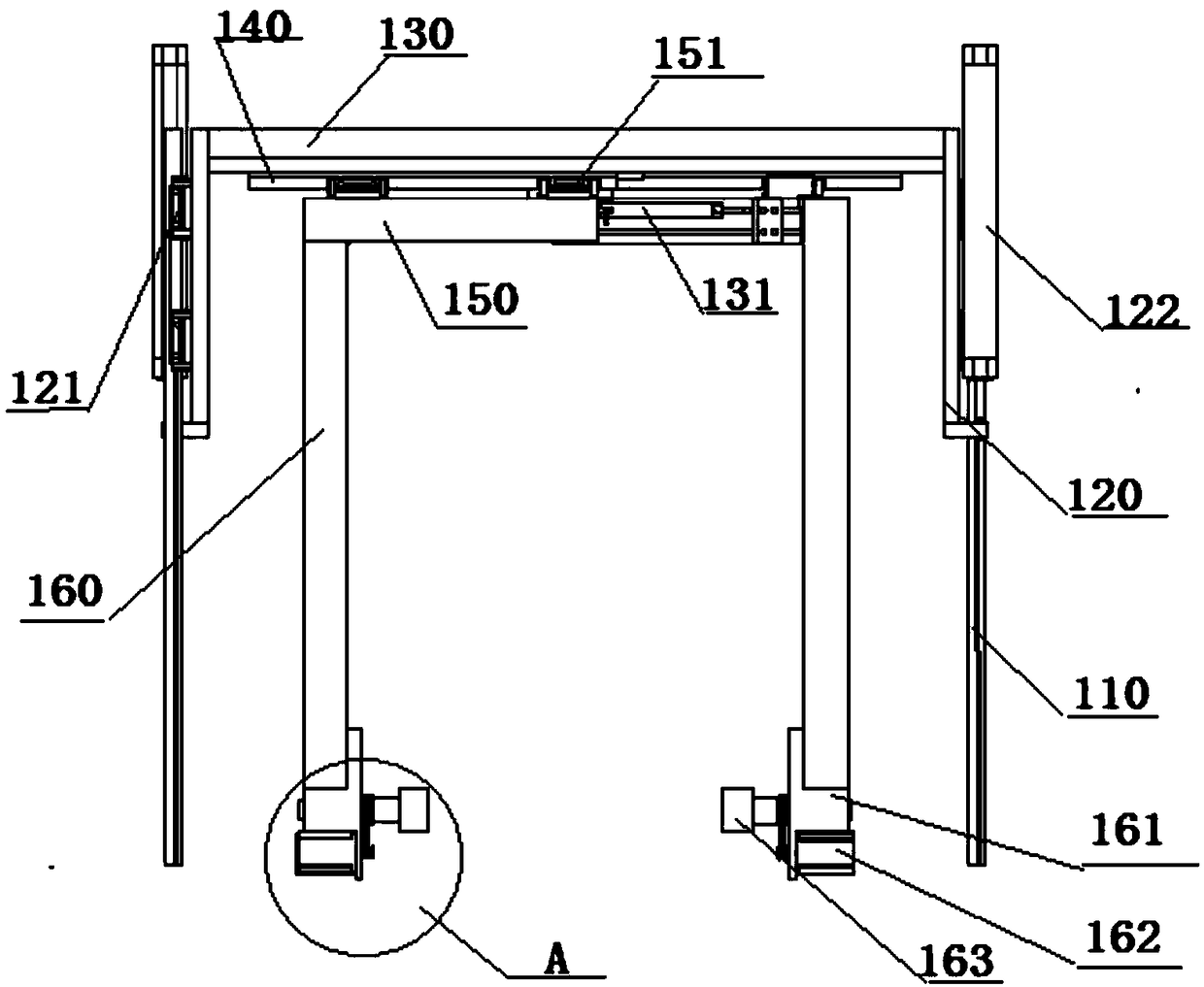

Surface flaw detection marking apparatus and method for absorber piston rod of automobile shock based on vision

PendingCN109085183AReduce labor costsCost of quality improvementMaterial analysis by optical meansEngineeringMechanical engineering

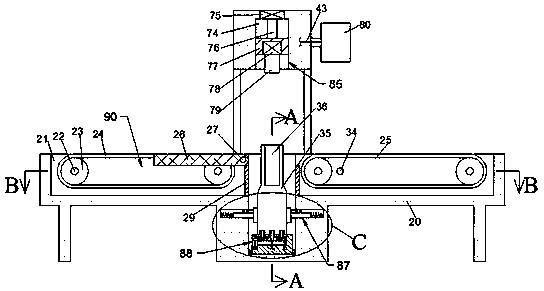

The invention discloses a surface flaw detection marking apparatus for an absorber piston rod of an automobile shock based on vision. The apparatus comprises: a frame body; first guide rails, which are symmetrically and vertically arranged on the upper side of the middle part in axial direction on two sides of the frame body; upper and lower sliders, which are symmetrically arranged between the first guide rails, and separately in sliding connection with the adjacent first guide rail; a connecting plate, which is horizontally arranged, and the axial ends of the connecting plate are fixedly connected with the upper and lower sliders; second guide rails, which are arranged on two sides of the bottom surface of the connecting plate in a staggered manner; transverse sliders, which are arrangedon the corresponding second guide rails in an axial sliding manner, and can move axially toward or away from the second guide rails; and clamping rods, which are symmetrically and vertically arrangedon two sides of the connecting plate, and top ends of the clamping rods are fixedly connected with the inner end surfaces of the outer sides of the corresponding transverse sliders. The invention further provides a surface flaw detection marking method for an absorber piston rod of an automobile shock based on vision, which can complete the feeding, vision detection, marking and discharging processes of the absorber piston rod of the automobile shock by machines.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

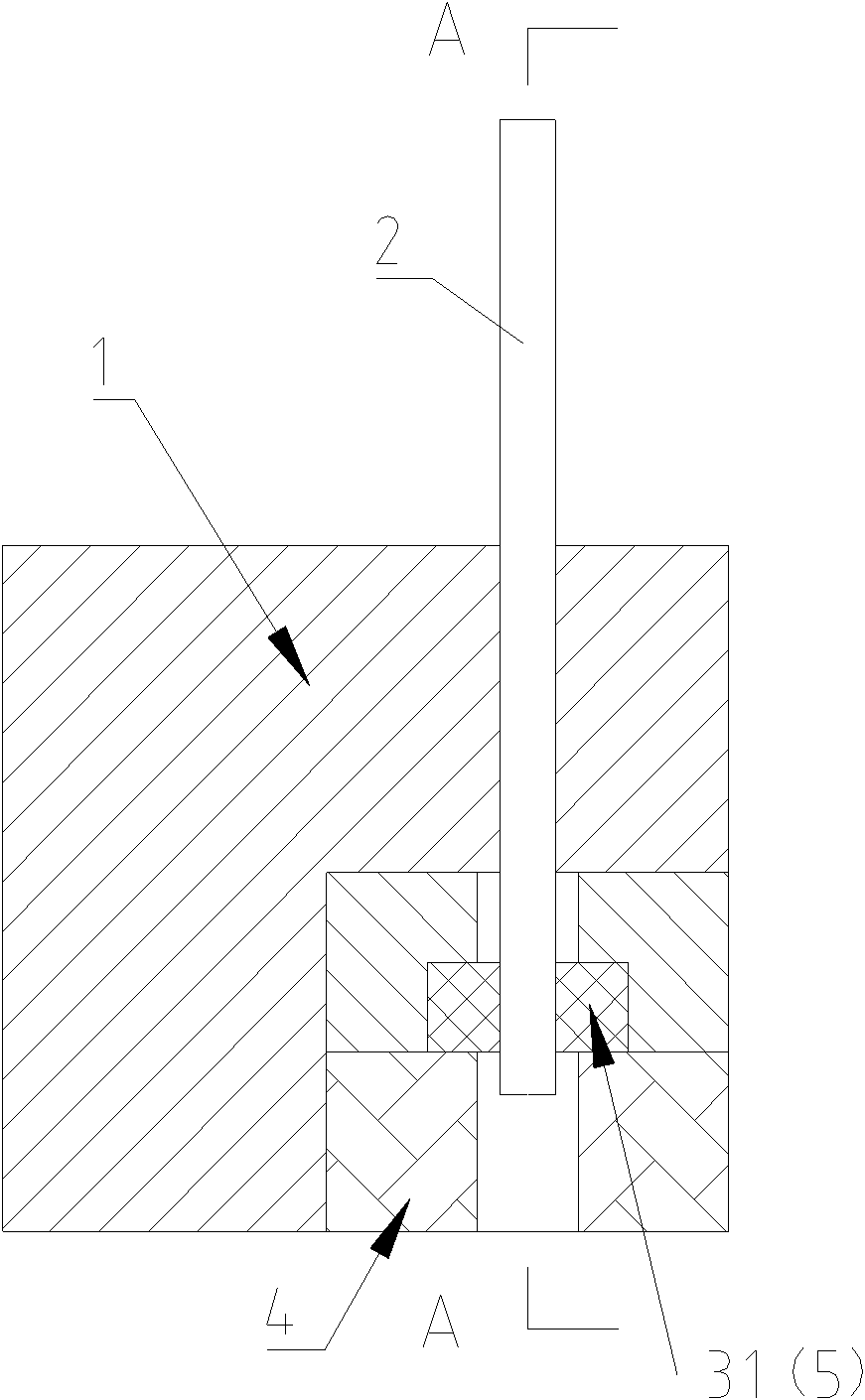

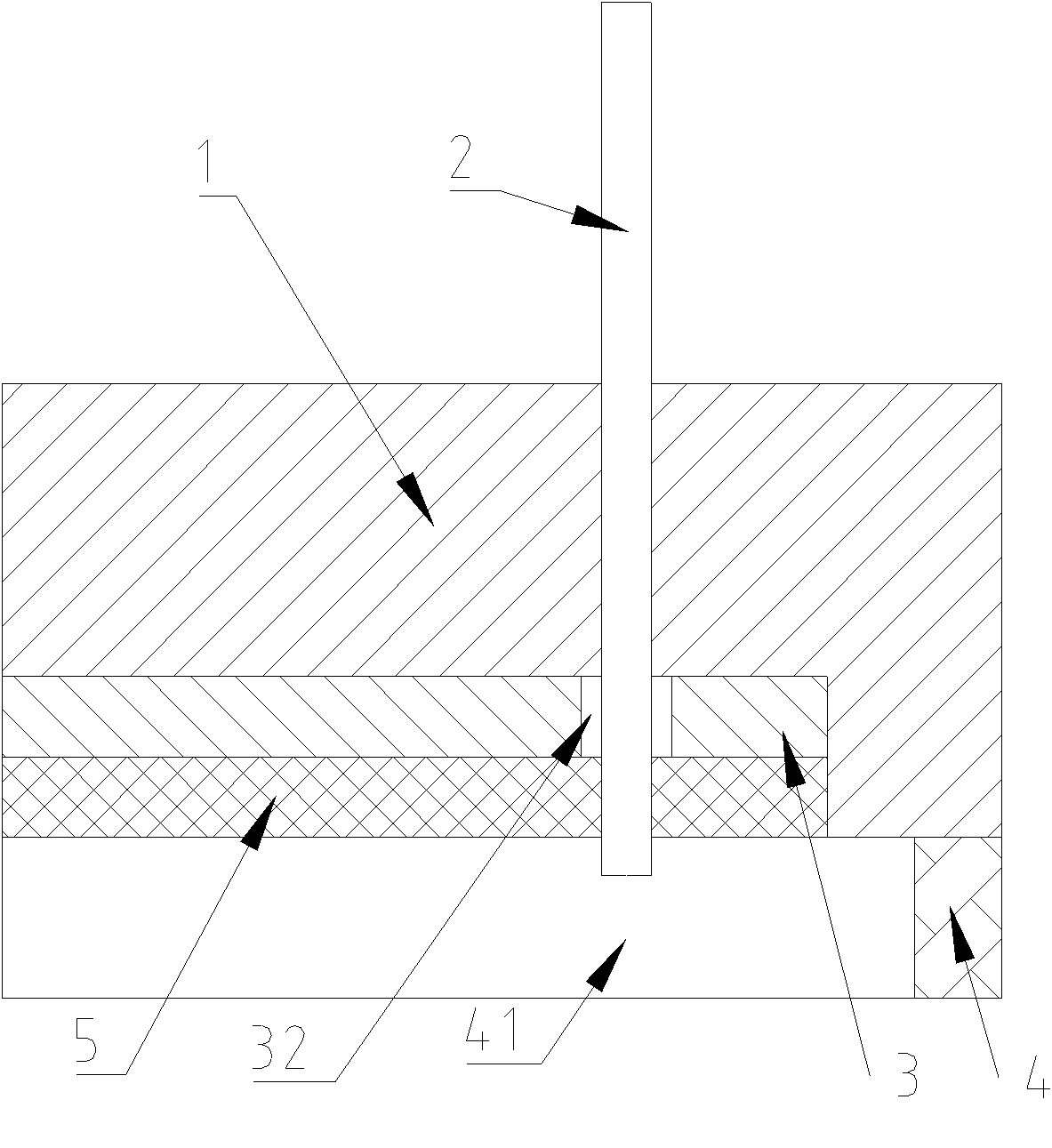

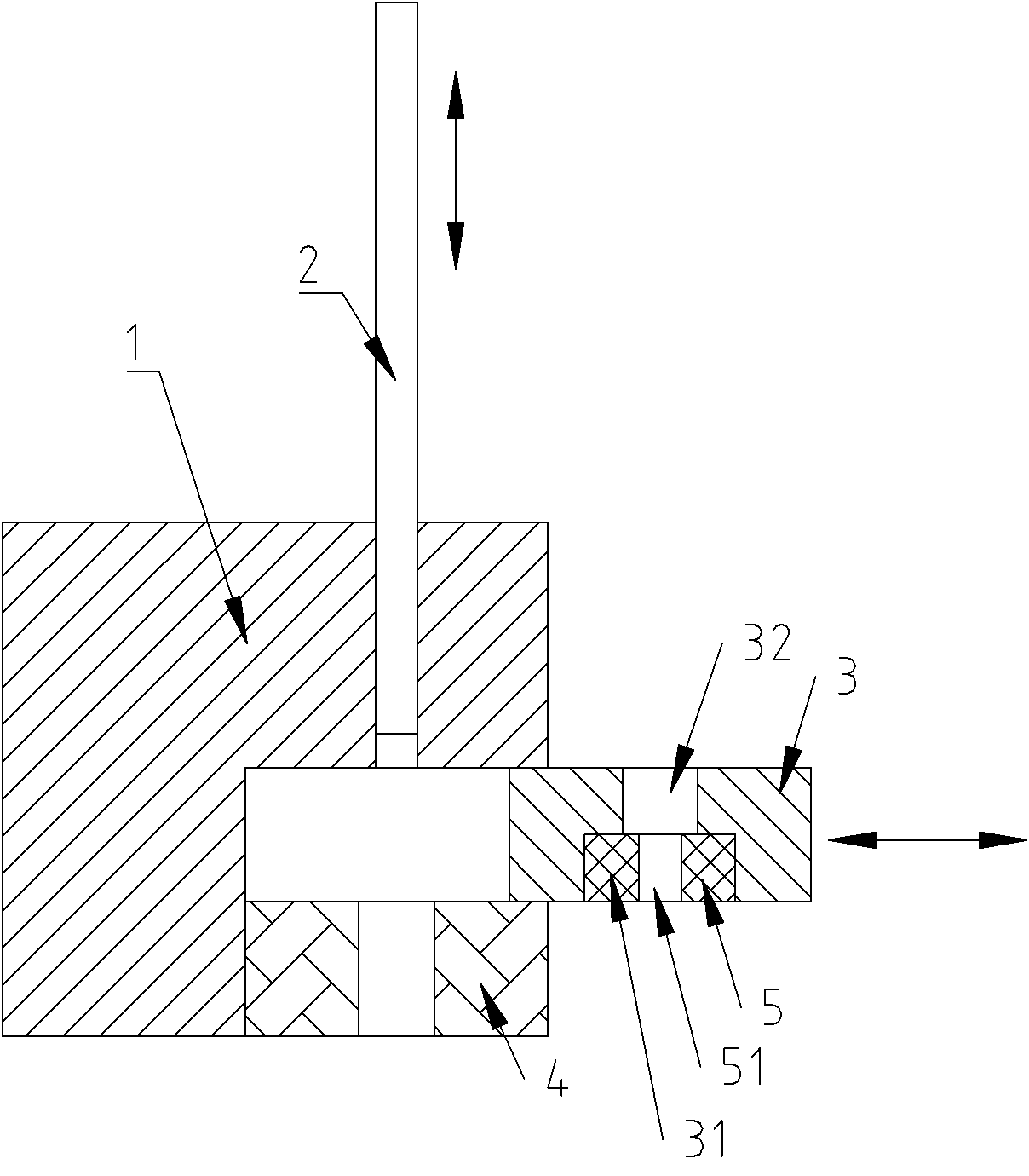

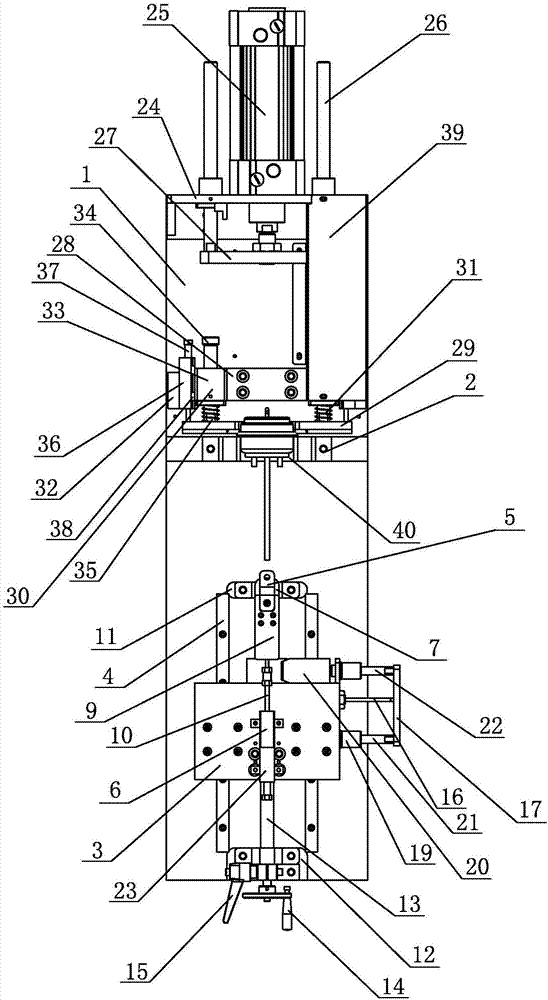

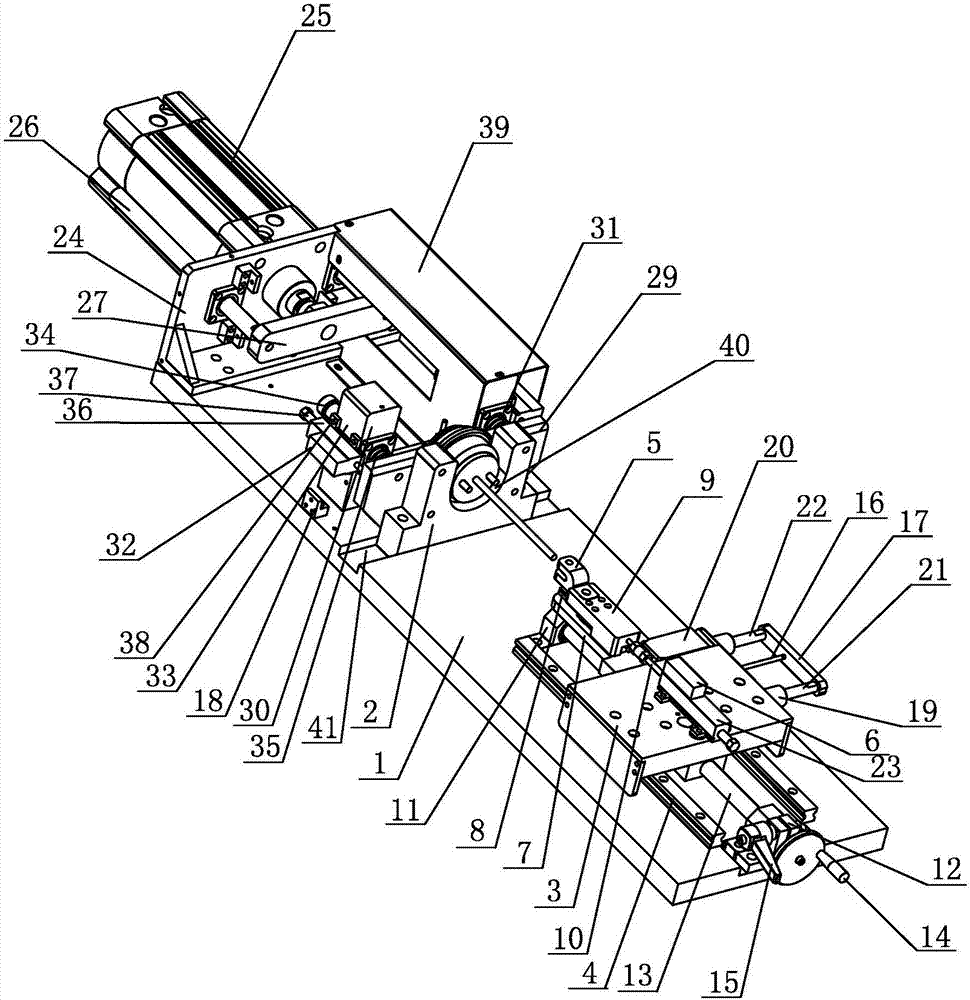

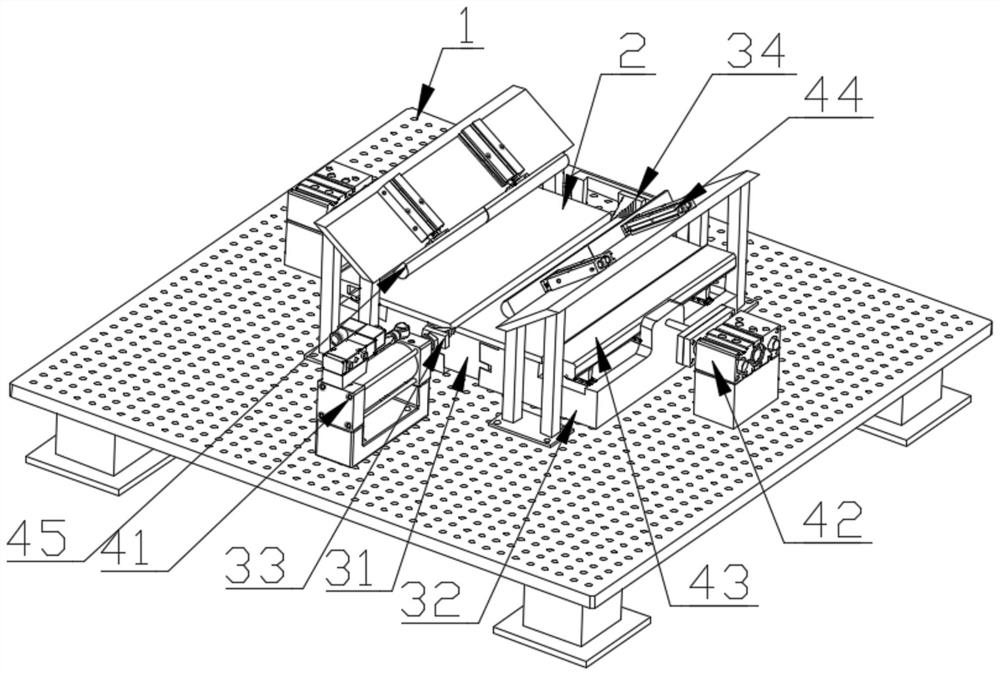

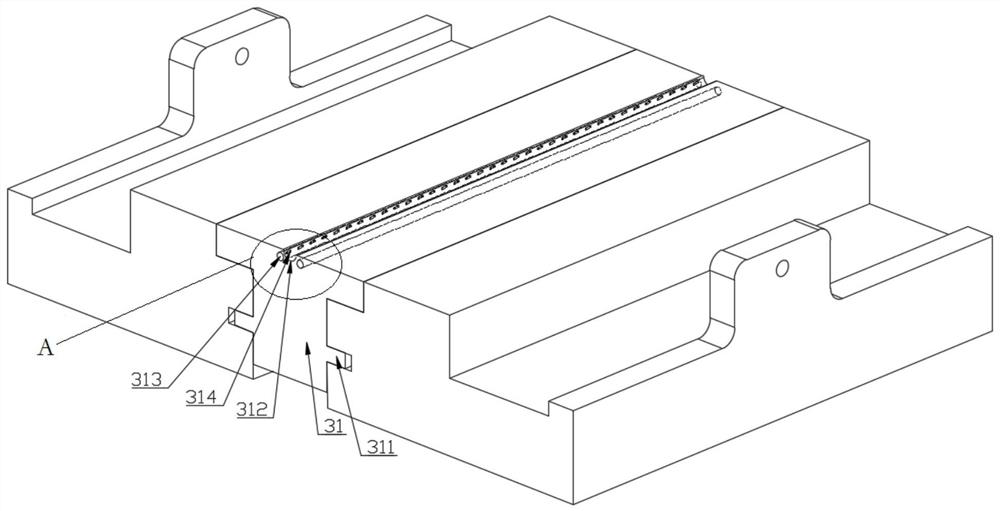

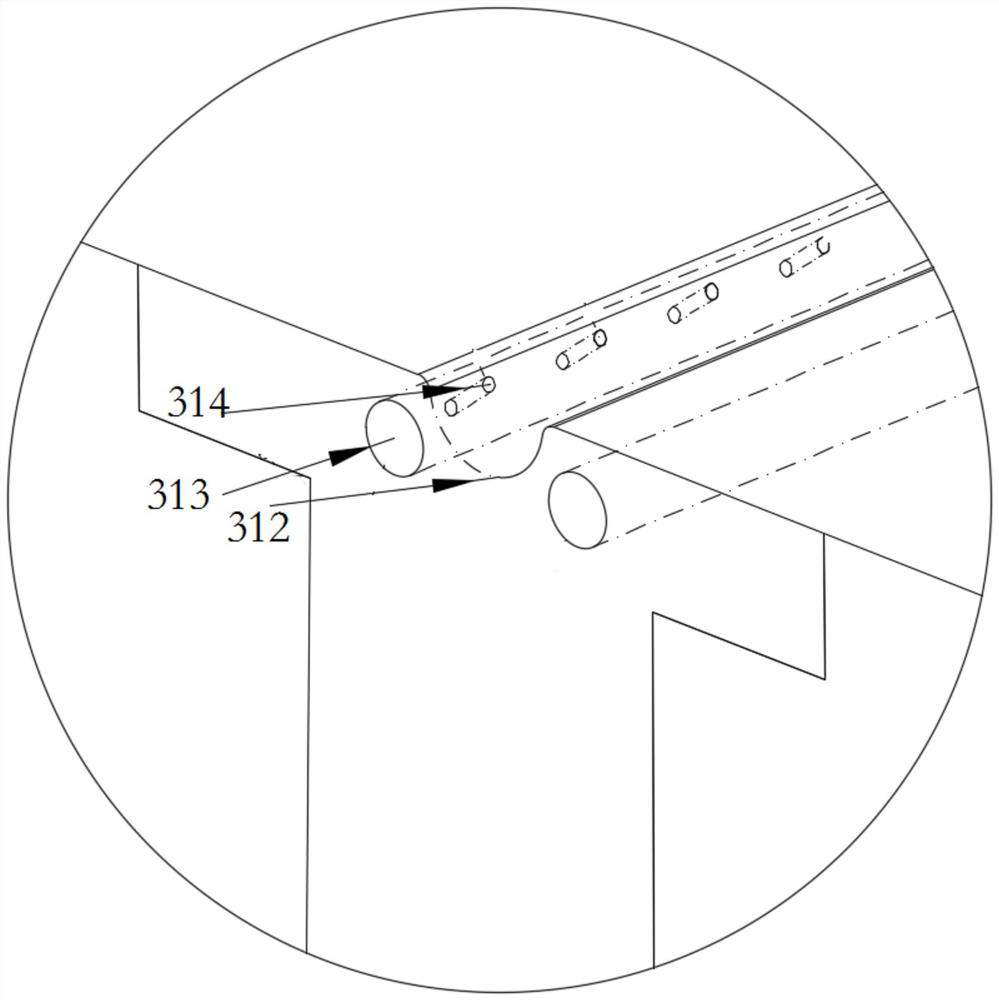

Actuator pressure stroke test device

PendingCN107228645AImplement automatic detectionGuarantee the quality of inspectionMeasurement devicesControl engineeringSlide plate

The invention discloses an actuator pressure stroke test device. The actuator pressure stroke test device is characterized in that the actuator pressure stroke test device comprises a bottom plate; a product supporting plate, a screw rod detection mechanism, a pushing mechanism and a thickness measuring mechanism are arranged on the bottom plate; the product supporting plate is mounted at the middle of the bottom plate; the screw rod detection mechanism is arranged to the right side of the product supporting plate; the pushing mechanism is arranged to the left side of the product supporting plate; the thickness measuring mechanism is arranged between the pushing mechanism and the product supporting plate; the thickness measuring mechanism is adjacent to the product supporting plate; the screw rod detection mechanism includes a slide plate, two slide rails, a U-shaped plate, a screw rod moving component and a first displacement sensor; the left end of the top surface of the slide plate is provided with an extension plate, a first slide rail and a displacement rod; an anti-error mechanism is arranged beside the slide plate; the anti-error mechanism is perpendicular to the slide rail; and the anti-error mechanism is connected with the slide plate. With the actuator pressure stroke test device of the present invention adopted, the detection quality of an actuator can be improved.

Owner:YK IND CO LTD

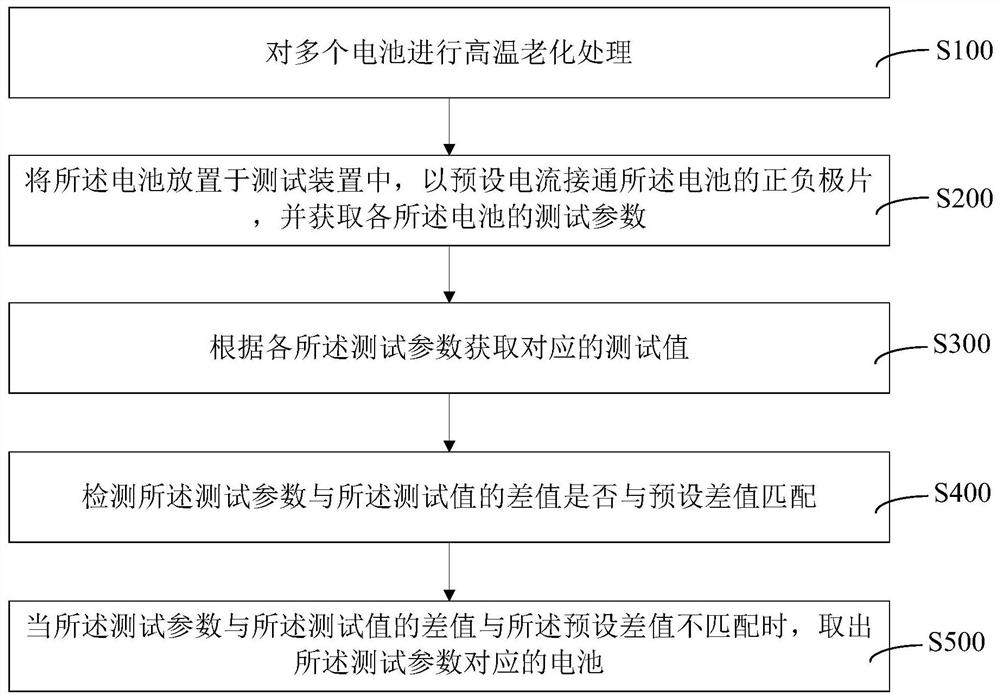

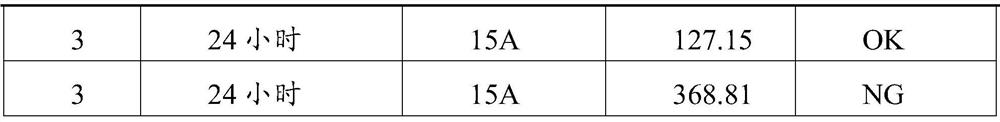

Battery pole piece breakage detection method and system

PendingCN111736025APrecise screeningImprove the detection pass rateContinuity testingEnvironmental/reliability testsElectrical and Electronics engineeringControl theory

The invention provides a battery pole piece fracture detection method and system. The battery pole piece fracture detection method comprises the following steps: carrying out high-temperature aging treatment on a plurality of batteries; placing the battery in a test device, connecting positive and negative pole pieces of batteries with a preset current, and obtaining test parameters of each battery; obtaining a corresponding test value according to each test parameter; detecting whether a difference value between the test parameter and the test value is matched with a preset difference value or not; and when the difference value between the test parameter and the test value is not matched with the preset difference value, taking out the battery corresponding to the test parameter. When a battery pole piece is broken, the test parameter is changed, wherein the difference between the test parameter and the test value reflects the change amplitude of the test parameter; and the unqualified battery is accurately screened out according to the comparison result between the difference value and the preset difference value, and thus the battery detection qualification rate is improved.

Owner:MEIZHOU LIANGNENG NEW ENERGY SCI & TECHCO

A vacuumizing degassing process

ActiveCN108758325ASimple operation processEvacuation treatment effect is goodVessel manufacturingVessel wallsNitrogenMass spectrometry

A vacuumizing degassing process is disclosed. The process includes subjecting a product to be vacuumized to helium mass spectrum leakage detection, then inflating the product with high-purity hot nitrogen, thoroughly heating the product by adopting inside and outside heaters as auxiliary, performing inflation with hot nitrogen, gas sealing, and discharging hot washing in order to vacuumize to obtain low vacuum, vacuumizing in a manner of interrupted discharging to obtain high vacuum, and other steps. Through the steps and process parameters specific to the process steps, effects of removing residual gas in an interlayer for products processed through the process, such as vacuum insulated cryopump sumps, vacuum insulated cryogenic tubes and vacuum insulated cryogenic valve boxes, are extremely good, and therefore, heat leakage of vacuumized products during application is greatly reduced, and using performance and service lifetime of the products are greatly improved.

Owner:CHENGDU CRAER CRYOGENIC EQUIP

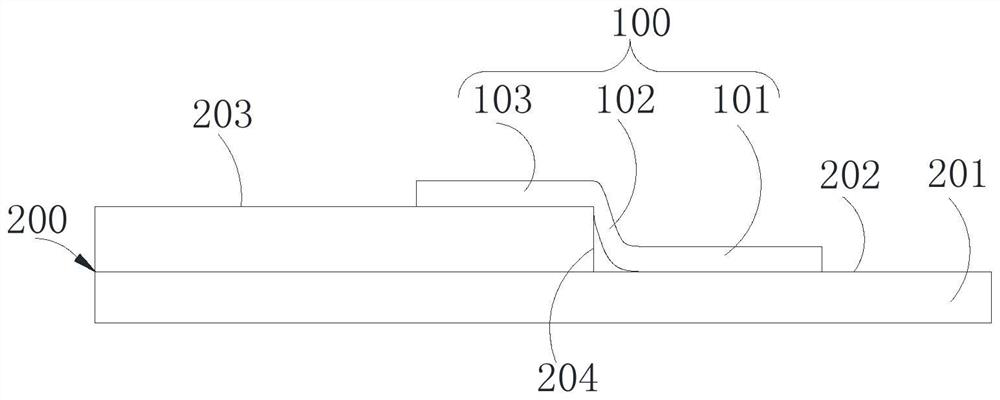

Conductive film attaching equipment

ActiveCN114103087AImprove detection accuracyImprove the detection pass rateDomestic articlesMechanical engineeringElectrical and Electronics engineering

The invention discloses conductive film attaching equipment, and relates to the technical field of automatic machinery, the conductive film attaching equipment comprises a primary attaching module, a pre-pressing module and a pressure maintaining module, the primary attaching module is used for attaching the edge, away from a second part, of a first part of a conductive film to the upper surface of the first edge of a metal backboard; the pre-pressing module is located at the downstream of the initial pasting module, and the pre-pressing module is used for integrally pasting the first part of the conductive film to the metal backboard; the pressure maintaining module is located on the downstream of the pre-pressing module and used for enabling the third part of the conductive film to be attached to the upper surface of the first edge of the display module and enabling the second part of the conductive film to be attached to the side wall of the first edge of the display module. The conductive film attaching equipment is used for attaching a conductive film and a display module. According to the conductive film attaching equipment, the attaching precision of the conductive film and the display module can be improved, so that the attaching quality of the conductive film and the display module is improved.

Owner:惠州深科达智能装备有限公司

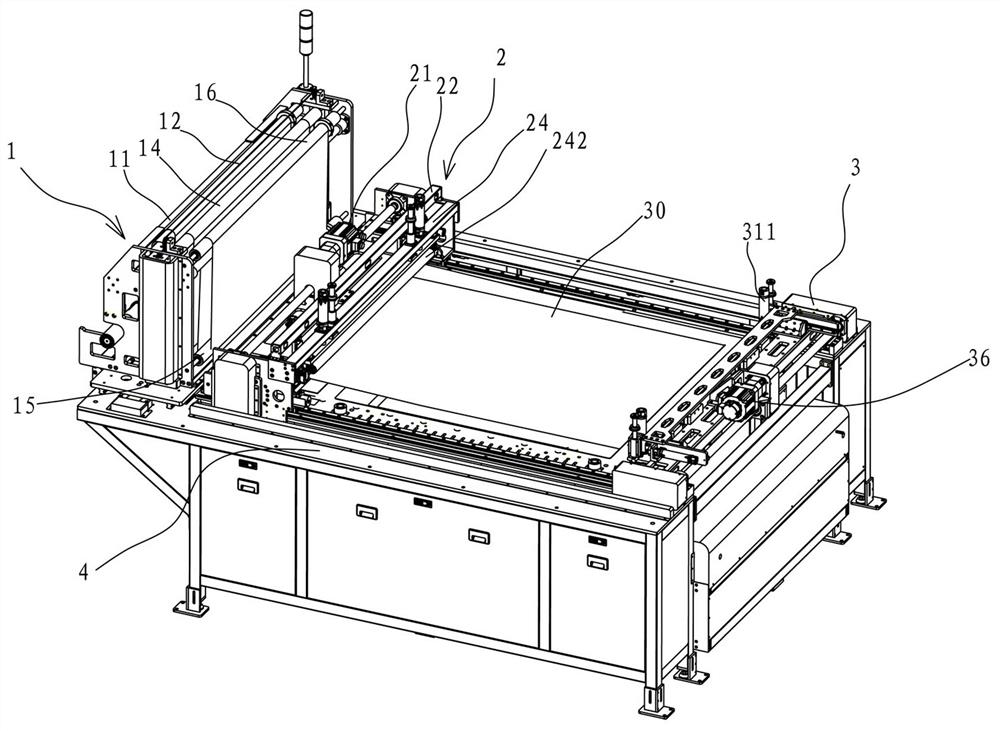

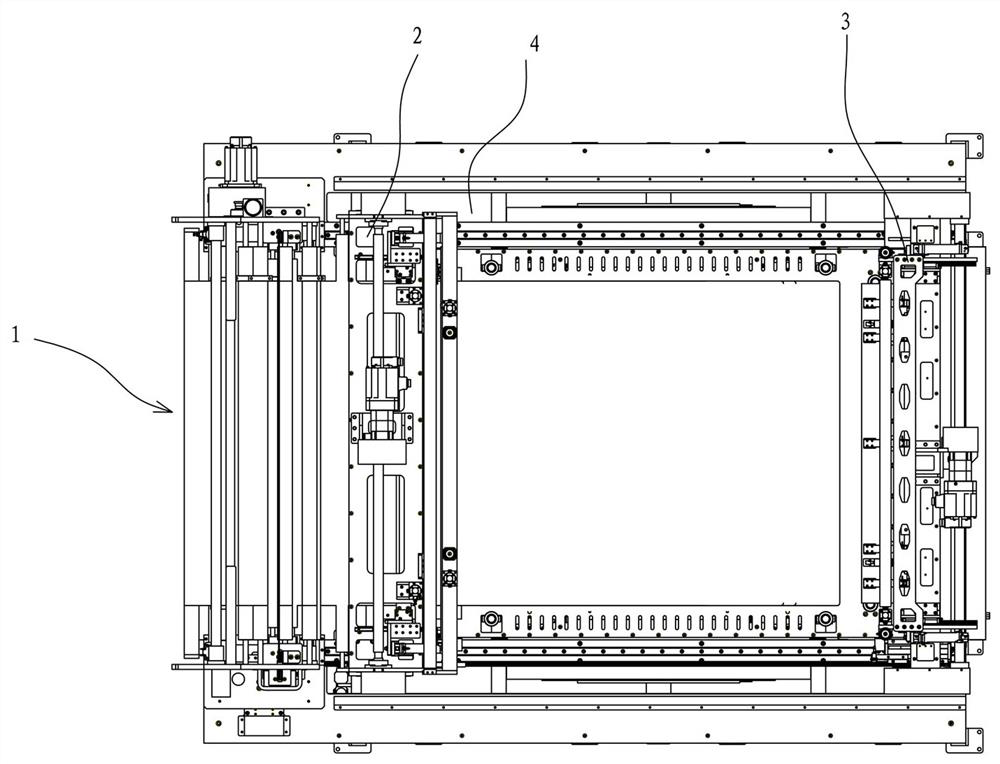

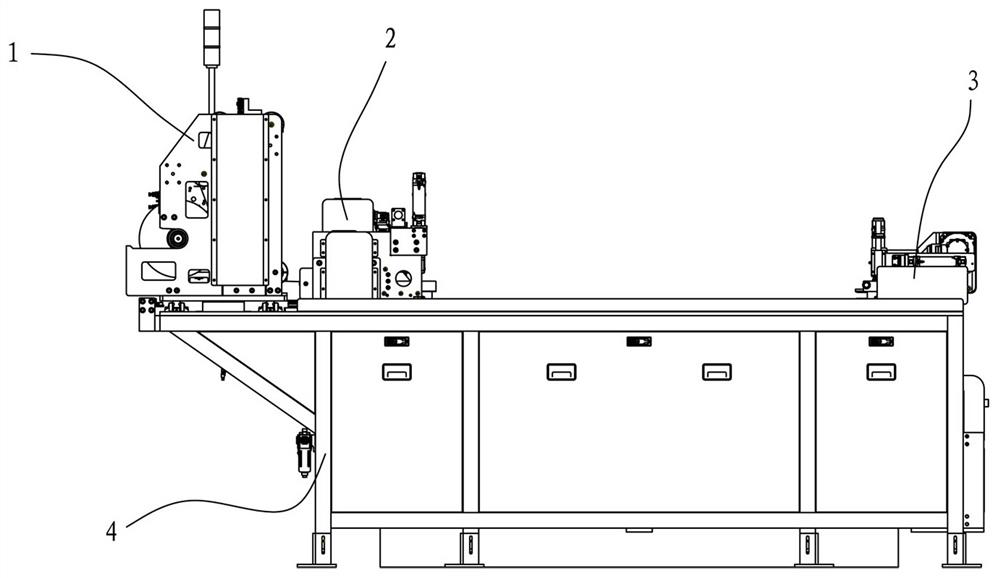

Film laying system for copper-clad laminate combination equipment and copper-clad laminate combination equipment comprising same

PendingCN111717721AReduce configurationGood film laying effectUnfolding thin materialsArticle deliveryMechanical engineeringComposite material

The invention provides a film laying system for copper-clad laminate combination equipment and the copper-clad laminate combination equipment comprising the same. The film laying system involves a film supply mechanism, a film laying mechanism and a film pressing mechanism, wherein the film laying mechanism is arranged between the film supply mechanism and the film pressing mechanism, and the filmlaying mechanism comprises a driving assembly, a film clamping assembly, a film cutting assembly and a film laying assembly; and the film clamping assembly clamps a film provided by the film supply mechanism, under the driving of the driving assembly, the film is conveyed to the film pressing mechanism to be pressed at a film head of the film, the film clamping assembly loosens the film and retreats to the position behind the film cutting assembly, the film laying assembly presses the film downwards, the film laying mechanism retreats to a preset position, and the film cutting assembly cuts off the film. The film laying system for the copper-clad laminate combination equipment and the copper-clad laminate combination equipment comprising the same have the advantages that the film laying effect is good, the performance is stable, the detection qualification rate of final products is high, configuration of operators is reduced, uncontrollable factors of operation specifications are avoided, the automation degree is high, the traditional manual film laying mode in the industry is changed, and the production efficiency is improved.

Owner:超技工业(广东)股份有限公司

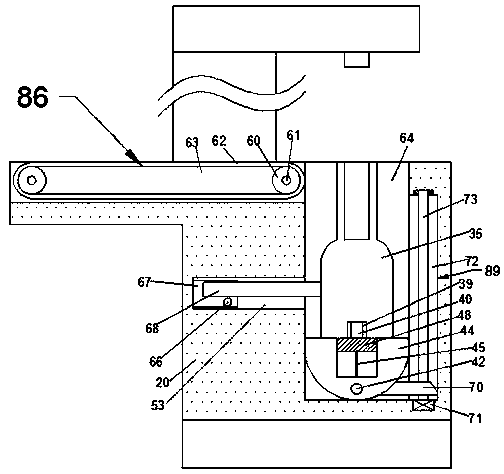

Pressurization detection device of pressure sensor

ActiveCN110987294ARealize automatic culling workImprove detection accuracyFluid pressure measurementMachineForce sensor

The invention discloses a pressurization detection device of a pressure sensor. The detection device comprises a machine body, a conveying cavity is formed in the machine body; and a conveying deviceis arranged in the conveying cavity. The conveying device comprises a first conveying belt and a second conveying belt which can rotate. The first conveying belt and the second conveying belt have thesame rotating directions and are used for conveying sensors. According to the invention, the conveying device drives the sensor to convey rightwards; in the delivery process, the pressure of the sensor is detected through the detection device and a pressurizing device; the detection process is in full automation; each sensor can be detected, so that the detection accuracy and the pass percentageare improved. Besides, the detected qualified sensors are directly output rightwards to be packaged, the unqualified sensors are output backwards to be recycled in a centralized mode, so that automatic rejecting work of defective products is realized. The device is high in working efficiency and detection precision, automatic in operation and convenient to use.

Owner:英赛维思智能设备(武汉)有限公司

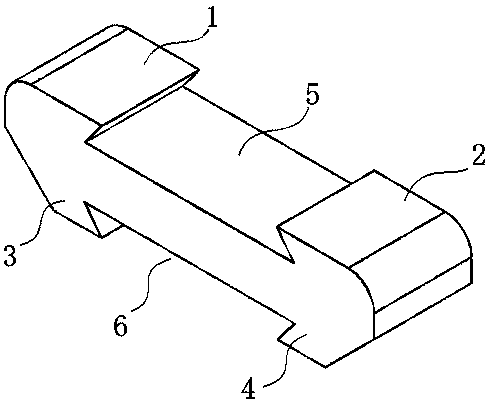

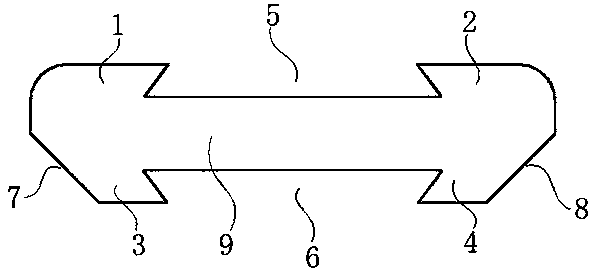

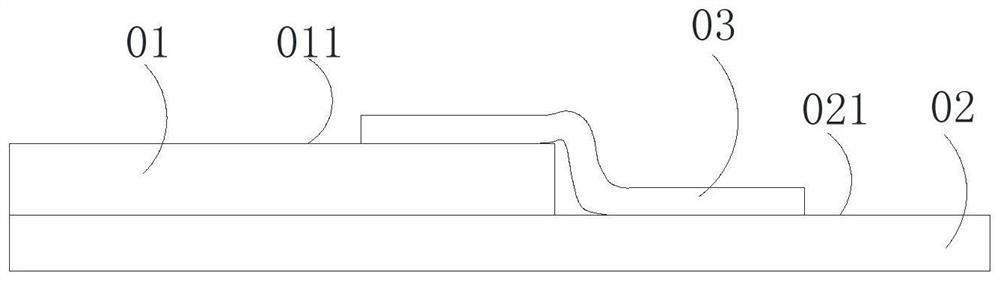

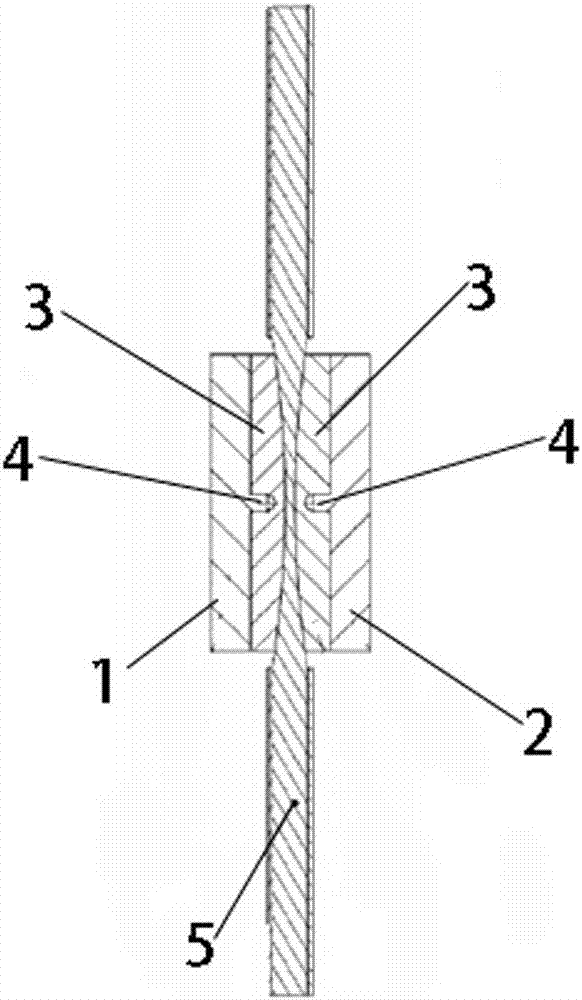

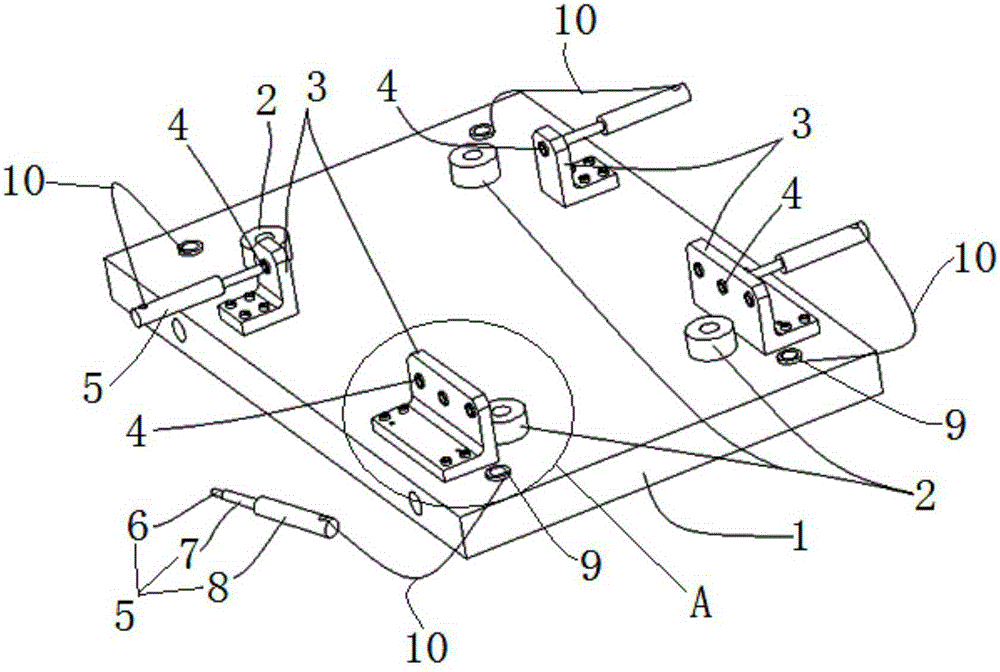

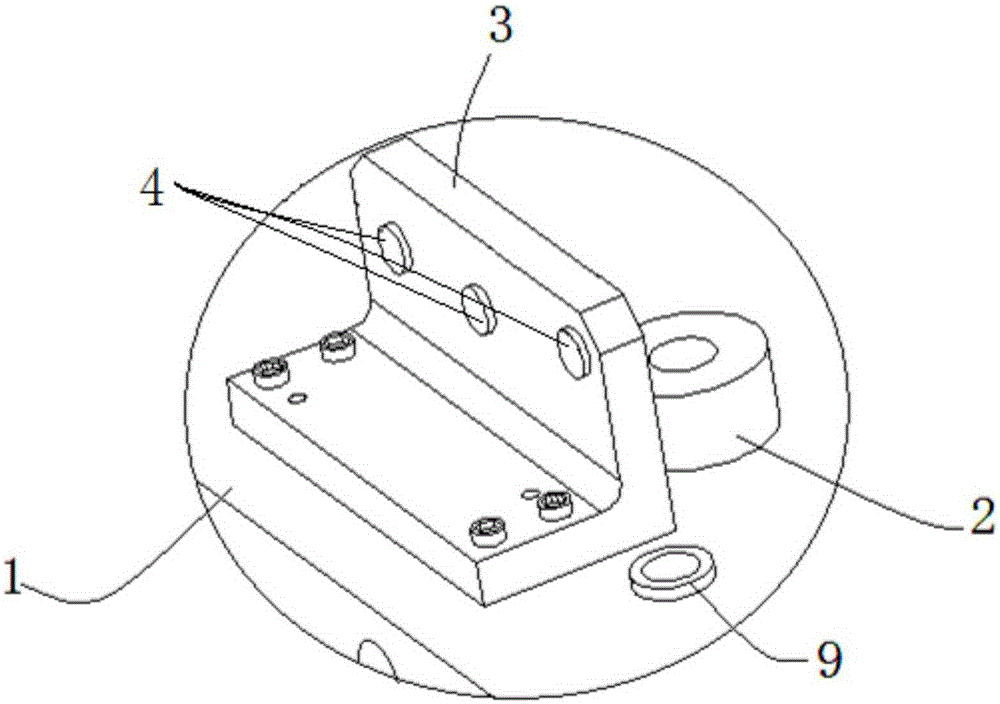

Testing clamp and method for improving mechanical fatigue performance of composite material

The invention relates to a testing clamp and a testing method for improving mechanical fatigue performance of a composite material. The clamp comprises a left clamping plate (1) and a right clamping plate (2), wherein the bottom surface of the left clamping plate and the top surface of the right clamping plate are fixedly connected with a protection pad (3) simultaneously; and the protection pad (3) has a protruding cambered surface. Through the clamp and the method for detecting the strength of a reinforced material through the clamp, the stability of test data is further ensured. A bronze drum clamp is used for clamping a spline, so that the stability of the spline is protected to the maximal extent; testing is facilitated; the application range is relatively wide; and the qualified rate of testing is relatively high. In addition, breaking points of the spline tested by using the clamp provided by the invention and the method provided by the invention are effective and consistent; and the data result is accurate and stable.

Owner:ZHEJIANG HENGSHI FIBER FOUND CO LTD

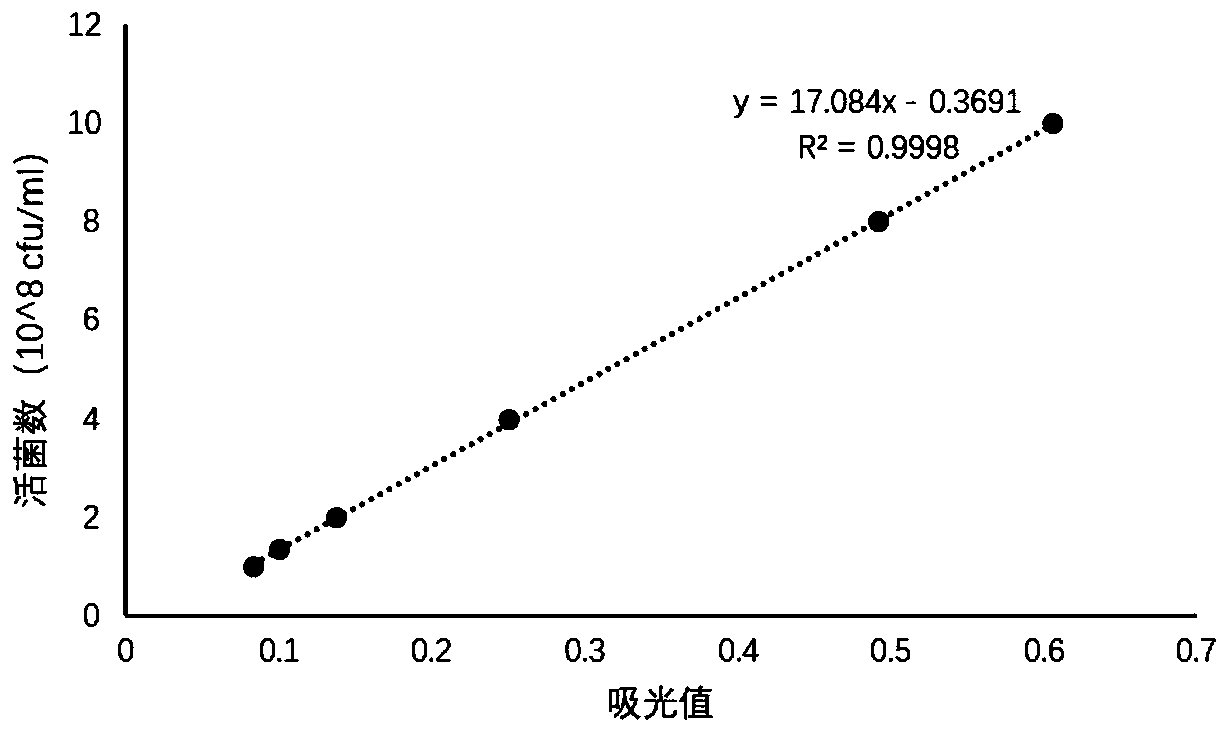

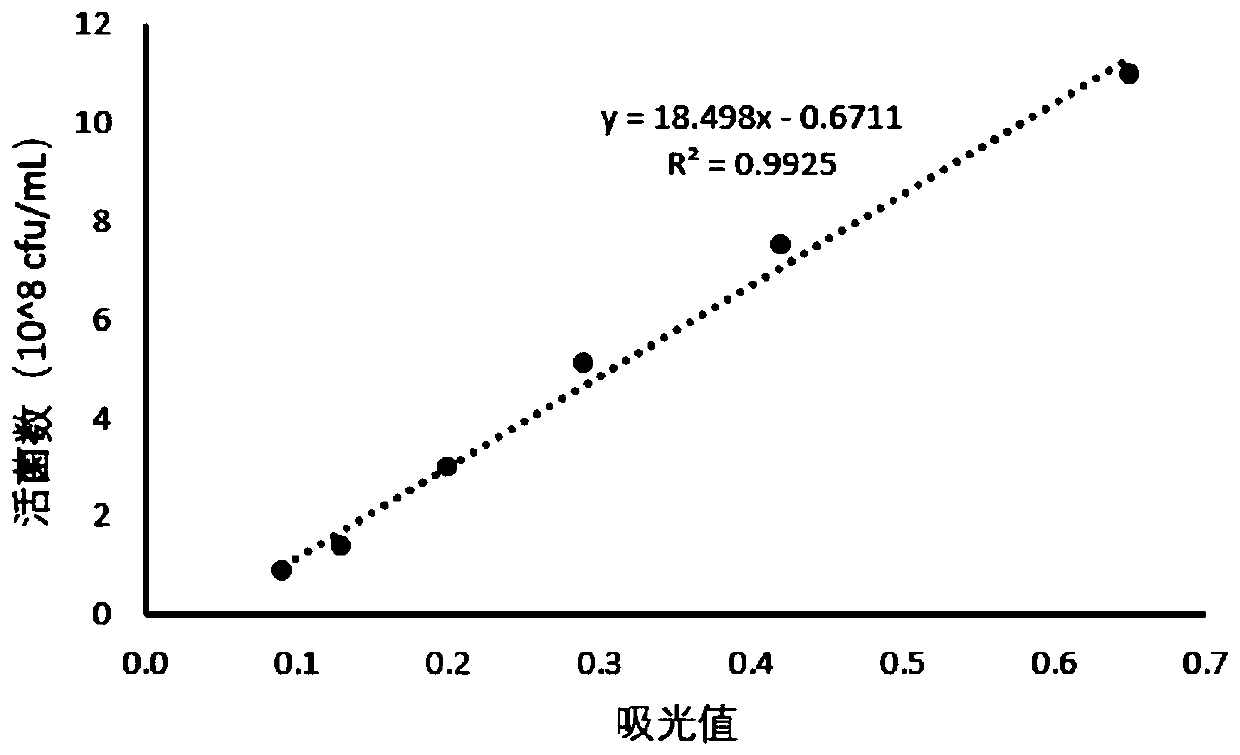

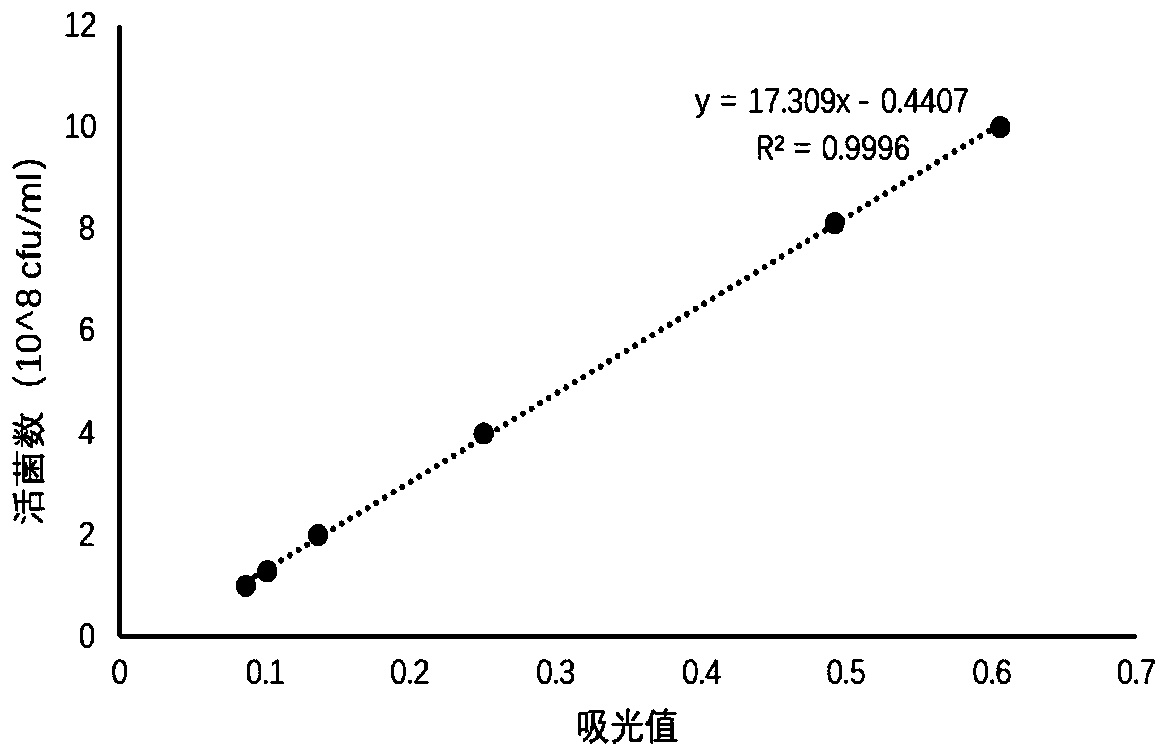

Method for detecting viable count in pre-coated feed microecological preparation product

ActiveCN111562210AEffectively break upImprove parallelismPreparing sample for investigationColor/spectral properties measurementsBiotechnologySterile water

The invention relates to a method for detecting viable count in a pre-coated feed microecological preparation product. The method comprises the following steps: (1), culturing free bacteria, carryingout gradient dilution to count the viable count, centrifuging a proper amount of bacterial liquid, and carrying out resuspension with sterile water to obtain a bacterial suspension for later use; (2),taking the bacterial liquid obtained in the (1), carrying out gradient dilution, reacting with an MTT solution to obtain a precipitate, dissolving the precipitate with DMSO, and carrying out colorimetry by using a microplate reader to measure a light absorption value; (3), preparing a standard curve by using the viable count of the free bacteria obtained in the (1) and the light absorption valuemeasured in the (2); (4), crushing and sieving a pre-coated sample, adding the crushed and sieved pre-coated sample into a conical flask added with glass beads, adding a capsule breaking solution, andbreaking the capsule to obtain a bacterial suspension; (5), carrying out ultrasonic treatment on the bacterial suspension to obtain a discrete bacterial suspension, centrifuging the discrete bacterial suspension, adding DMSO for resuspending, performing diluting to different gradients, and measuring a light absorption value in the same (2); and (6), calculating the viable count in a pre-coated microecological preparation according to the standard curve obtained in the (3).

Owner:TIANJIN BIOFEED TECH CO LTD

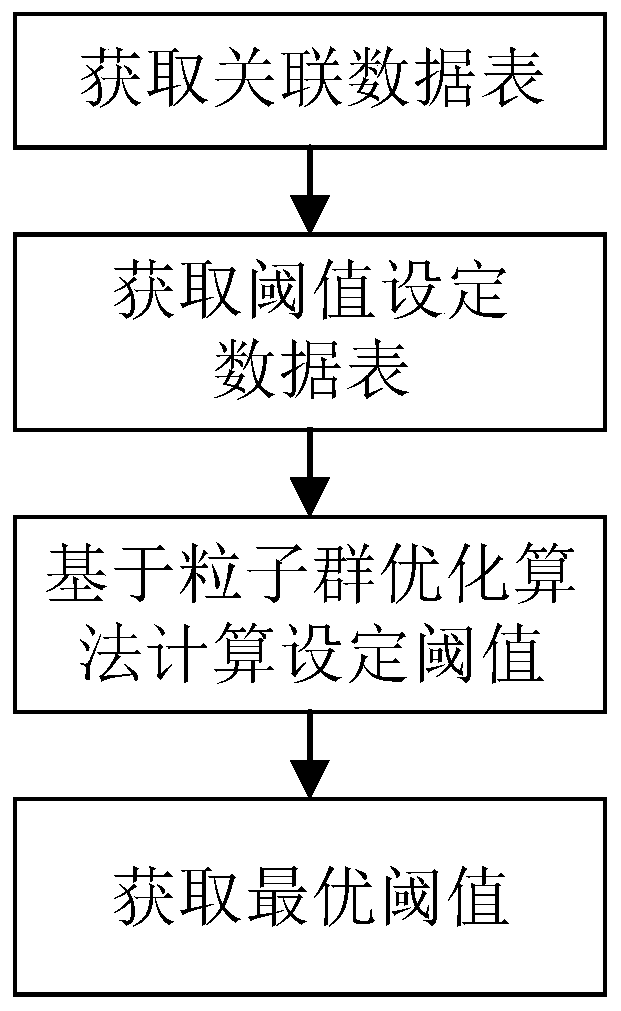

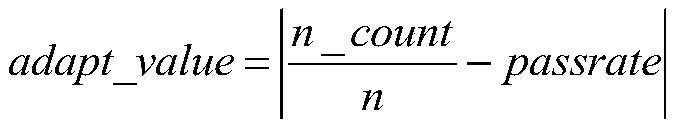

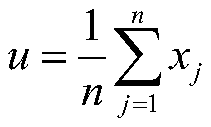

SMT production line detection threshold setting method based on particle swarm optimization algorithm

ActiveCN110533278AImprove the detection pass rateReduce the risk of non-compliance with production process requirementsArtificial lifeResourcesProduction lineSolder paste

The invention provides an SMT production line detection threshold setting method based on a particle swarm optimization algorithm. The method is used for solving the technical problem that in the prior art, the product percent of pass is low due to the fact that a detection threshold of an SMT production line is set unreasonably, and comprises the implementation steps that an associated data tableis obtained, then a threshold setting data table is obtained, a set threshold is calculated through a particle swarm optimization algorithm, and finally an optimal threshold is obtained. According tothe invention, the production data of the SMT production line is utilized; the detection qualification rate of the SPI solder paste detector on the SMT production line is used for calculating the individual fitness in the particle swarm optimization algorithm; through iteration of the particle swarm optimization algorithm, the detection qualified rate of the SPI solder paste detector can be improved through the obtained multiple groups of detection threshold values, so that the product qualified rate of an SMT production line is improved, and the risk that the obtained multiple groups of detection threshold values do not meet the requirements of a production process is reduced.

Owner:XIDIAN UNIV

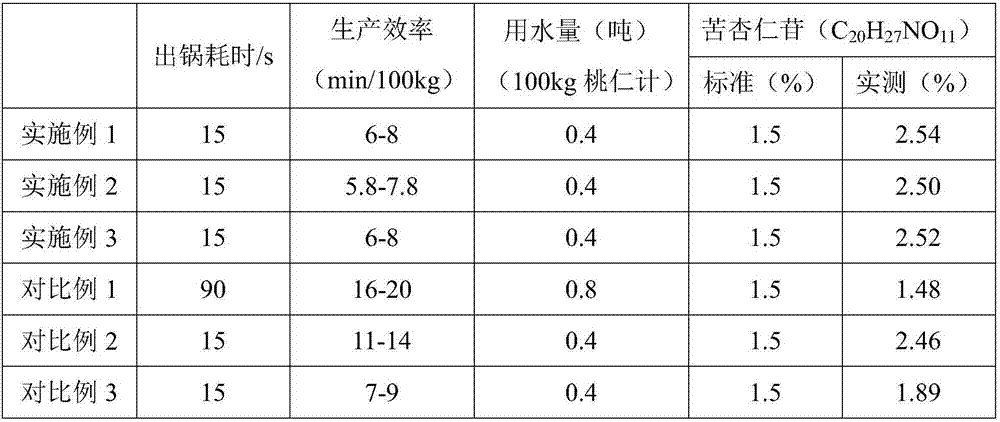

A processing method of scalded peach seed decoction pieces

InactiveCN107468779AReduce cooking timeAvoid uneven qualityPlant ingredientsBiotechnologyWater discharge

A processing method of scalded peach seed decoction pieces is disclosed. The method includes a boiling step, namely a step of adding water into a scalding pot and boiling the water; a first-batch scalding step, namely a step of taking a dish out with the bottom of the dish being provided with a plurality of water discharging holes, adding the dish into the scalding pot, adding a first batch of peach seeds into the dish, and immersing the first batch of peach seeds with the boiling water; a step of scalding, with the scalding time being less than 4 min; a cooling step, namely a step of taking the dish out of the scalding pot, and washing the first batch of peach seeds with cooling water; a coat removing step, namely a step of removing seed coats of the first batch of peach seeds to obtain a semi-finished product; and a drying step, namely a step of drying the semi-finished product to obtain the decoction pieces. The method has few steps and a simple procedure, the production efficiency can be greatly increased, loss of nutrients of peach seeds can be avoided to the utmost, and the yield is high. In addition, product quality is uniform, water is saved, and the cost is reduced.

Owner:KANGMEI PHARMA

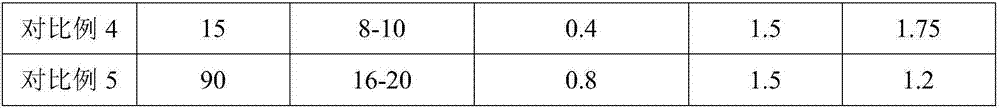

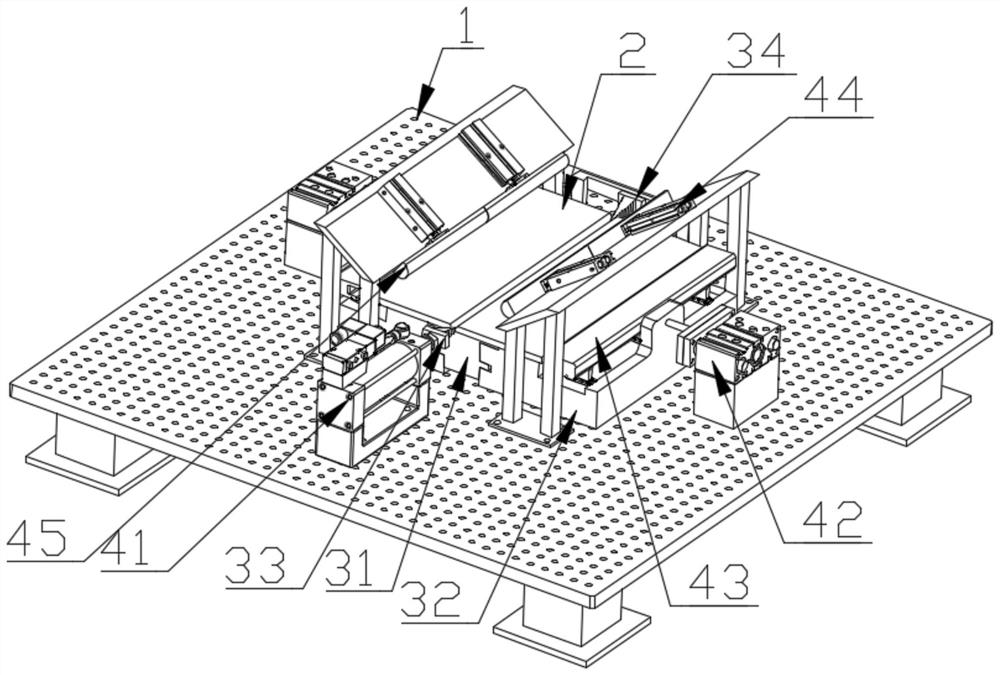

Adjustable pneumatic tool for aluminum welding type test

ActiveCN112025191ASave materialImprove thermal conductivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPneumatic tool

The invention belongs to the technical field of tool clamps, and relates to an adjustable pneumatic tool for an aluminum welding type test. A back support on a porous platform is inserted between twobottom fixing supports, a U-shaped back through groove is formed in the back support below a welding seam formed by two welding test plates, and argon intake grooves are formed in the back support ontwo sides of the U-shaped back through groove; argon side air discharging holes communicating with the U-shaped back through groove are evenly formed in the argon intake groove, a movable end limitingblock is slidably installed on the front side of the back support, a fixed end limiting block is fixedly installed on the rear side of the back support, the movable end limiting block and the fixed end limiting block are both in a step shape, and a movable end jacking air cylinder is fixedly installed on the outer side of the movable end limiting block; and side pushing clamping blocks are clamped on the two fixed bottom supports, and side pushing air cylinders are installed on the outer sides of the side pushing clamping blocks. The problems that the welding efficiency is low, the labor intensity is high, the operation is complex, and the welding position precision error is large when automobile body weld joints are manually assembled and welded are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

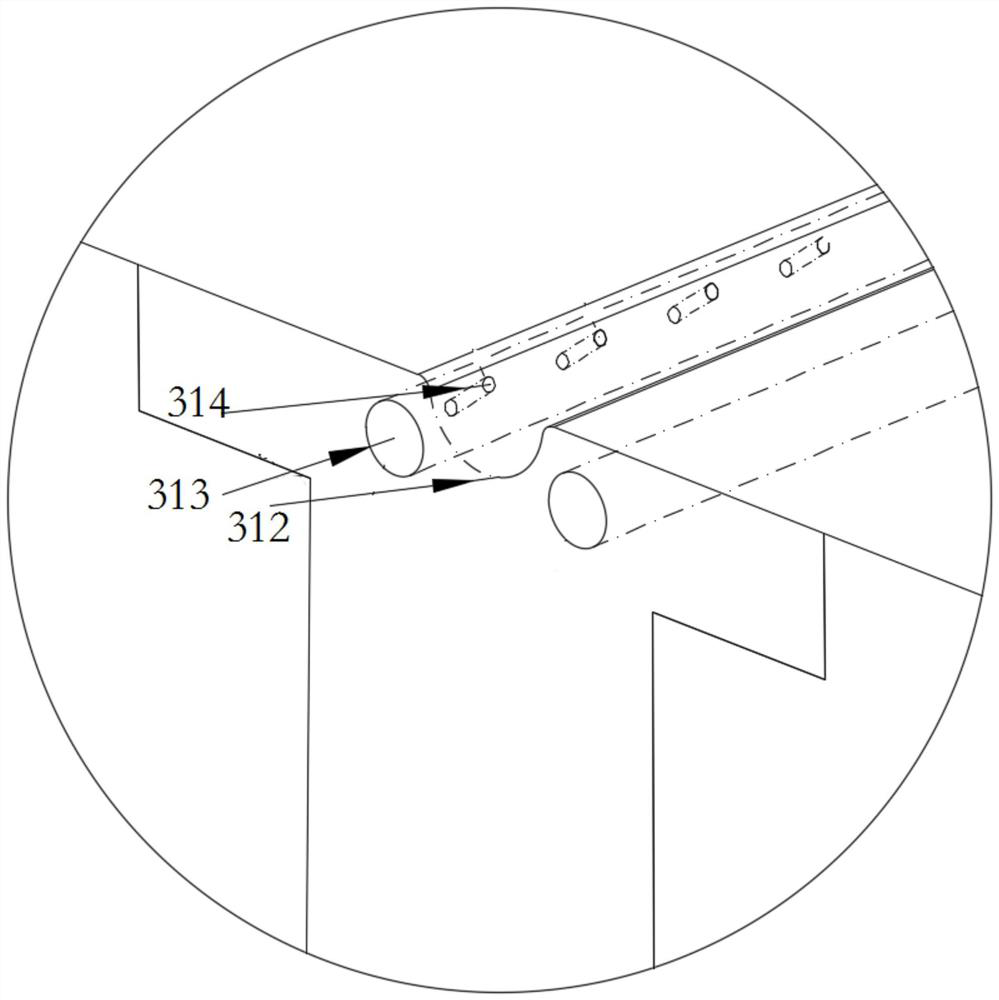

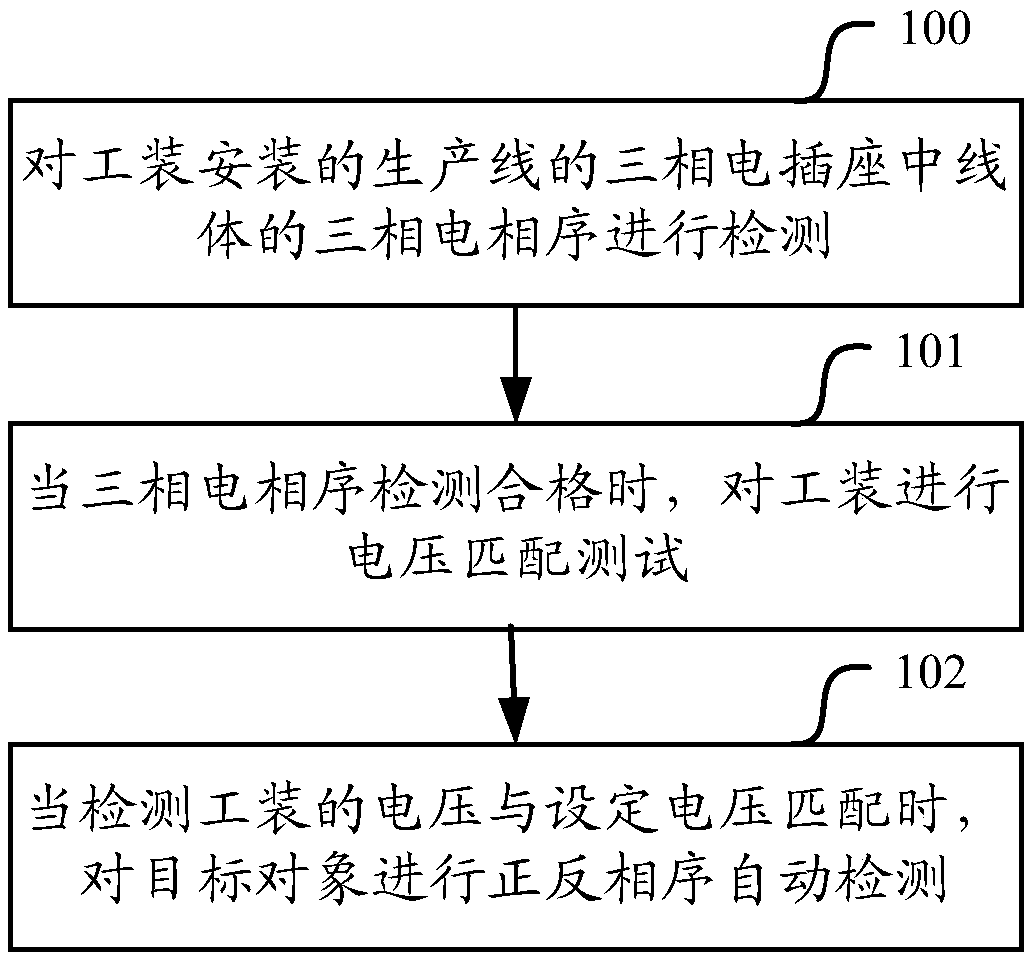

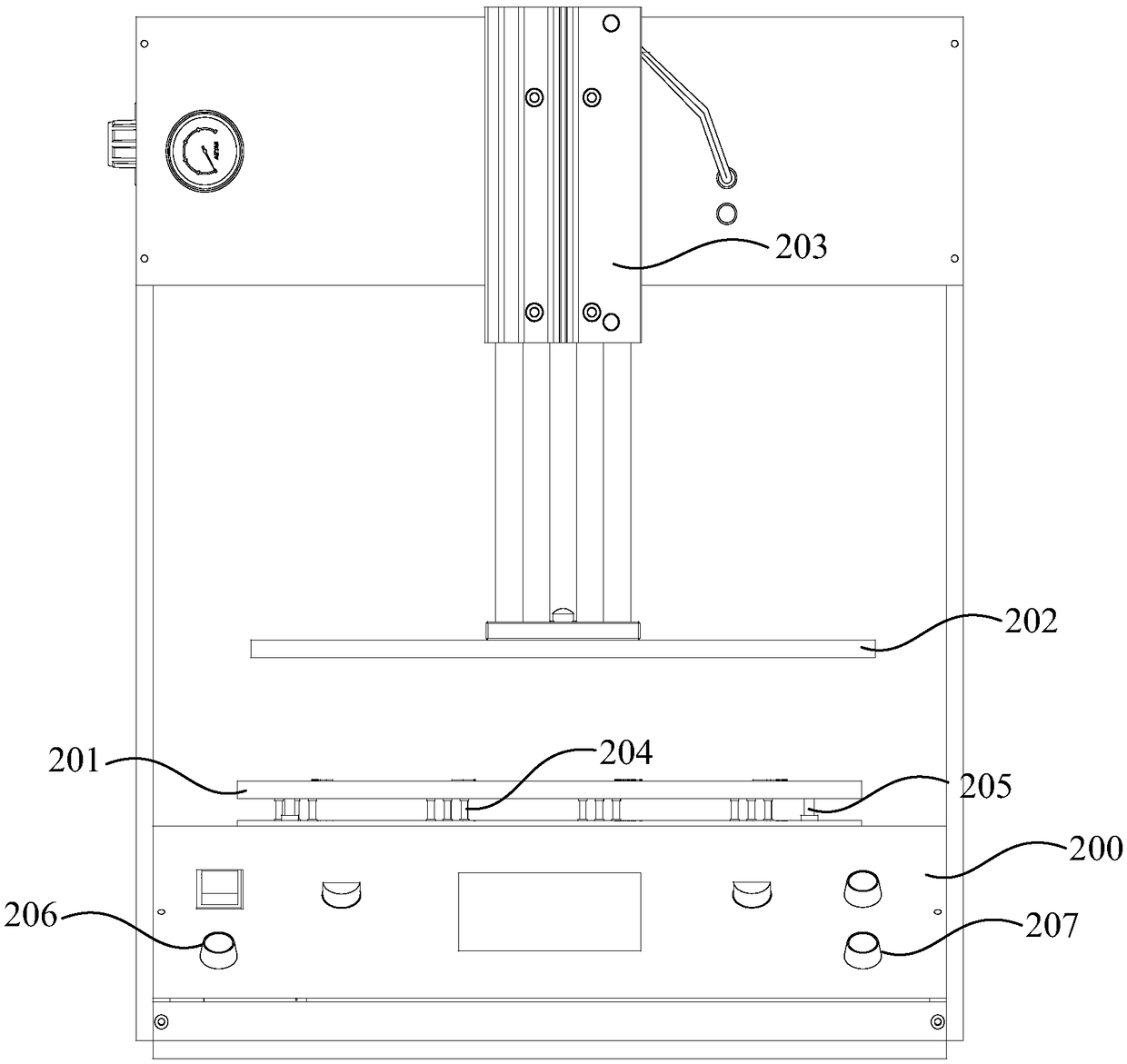

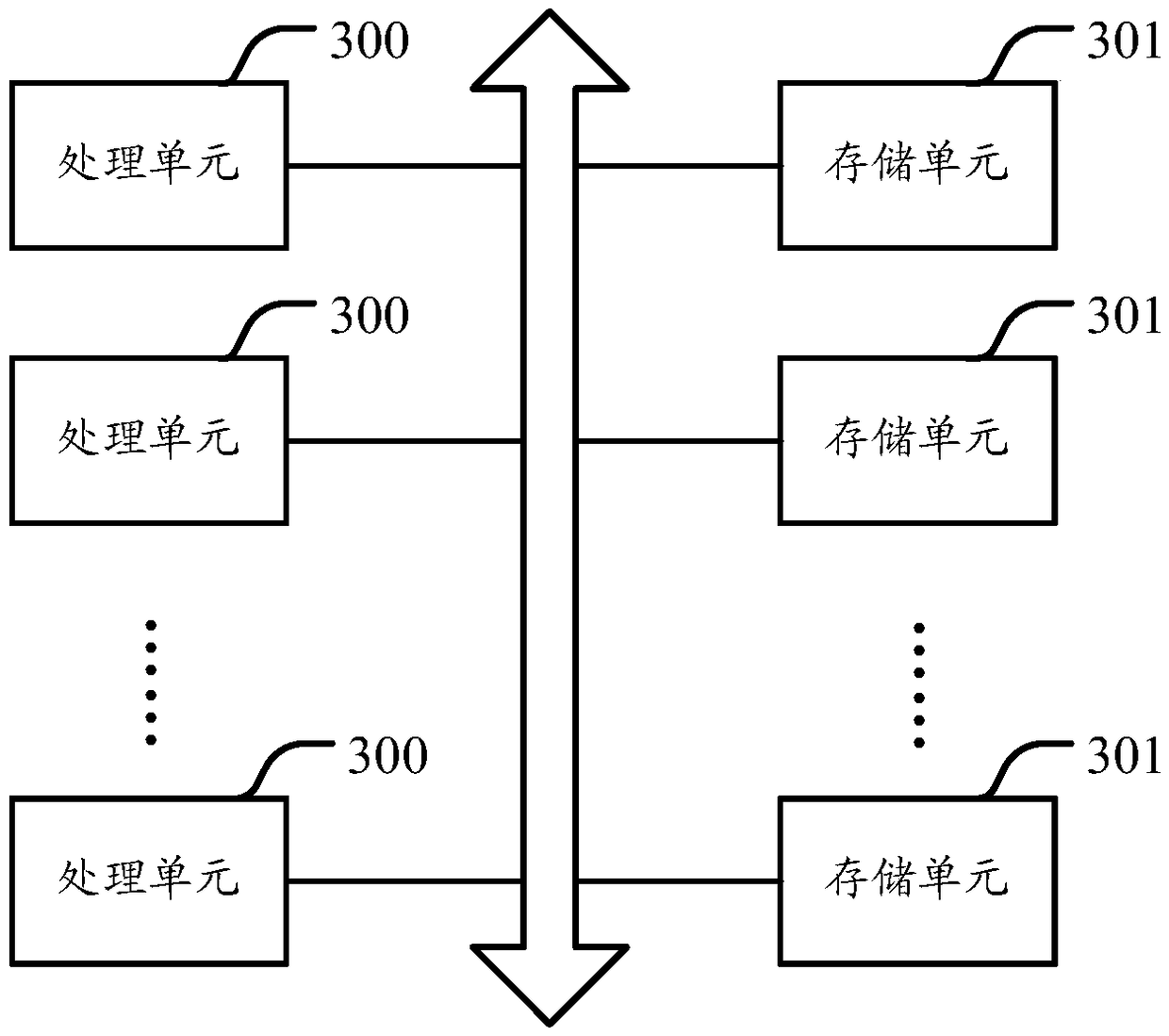

Method and tooling for automatically detecting target object

InactiveCN108957155ASolve the problem of testing as a qualified productImprove the detection pass ratePhase sequence/synchronism indicationProduction lineMatching test

The invention discloses a method and tooling for automatically detecting a target object which are used to solve the problem that an unqualified product is tested to be a qualified product due to incorrect voltage of a tooling in the prior art. According to embodiments of the invention, firstly, a three-phase electrical phase sequence of a line body of a three-phase electric socket of a productionline installed by the tooling is detected; when the three-phase electric phase sequence of the line body of the three-phase electric socket of the production line installed by the tooling is qualified, a voltage matching test is performed on the tooling then; and, when voltage of the tooling matches preset voltage, the target object is subjected to positive and negative phase detection then. Thevoltage matching test is performed on the tooling, and, when the fact that the voltage of the tooling matches the preset voltage is detected, the target object is subjected to the positive and negative phase detection then, so the problem that the unqualified target object is detected to be the qualified target object when the voltage of the tooling does not match the set voltage can be solved, and then the detection qualification rate of the tooling is improved.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

Stone pile crusher inverse insertion frequency counting device

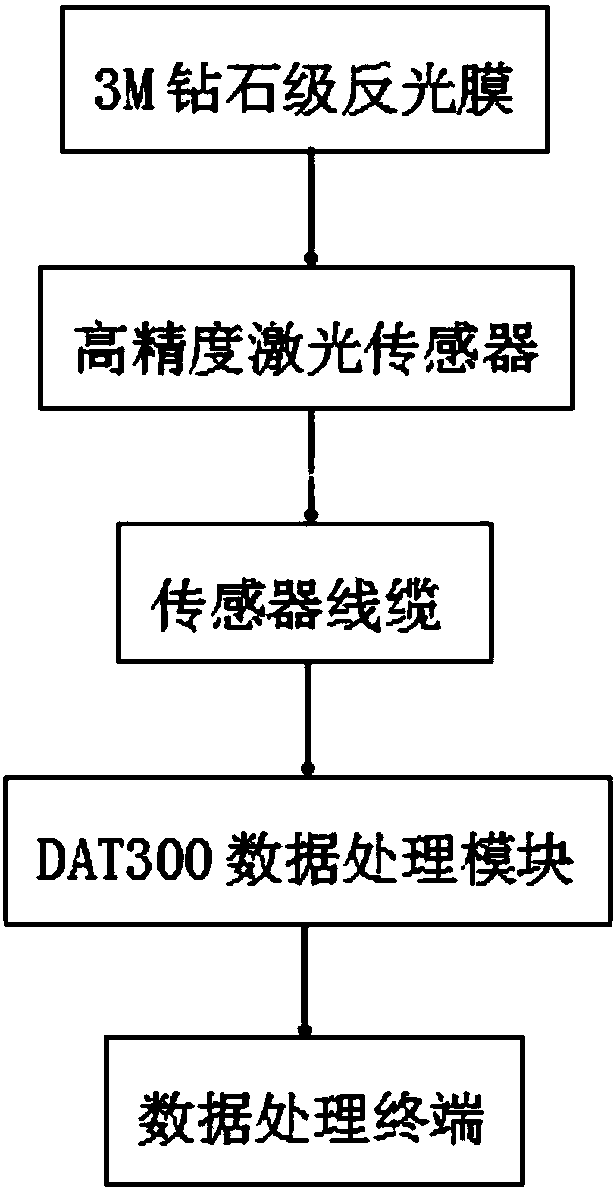

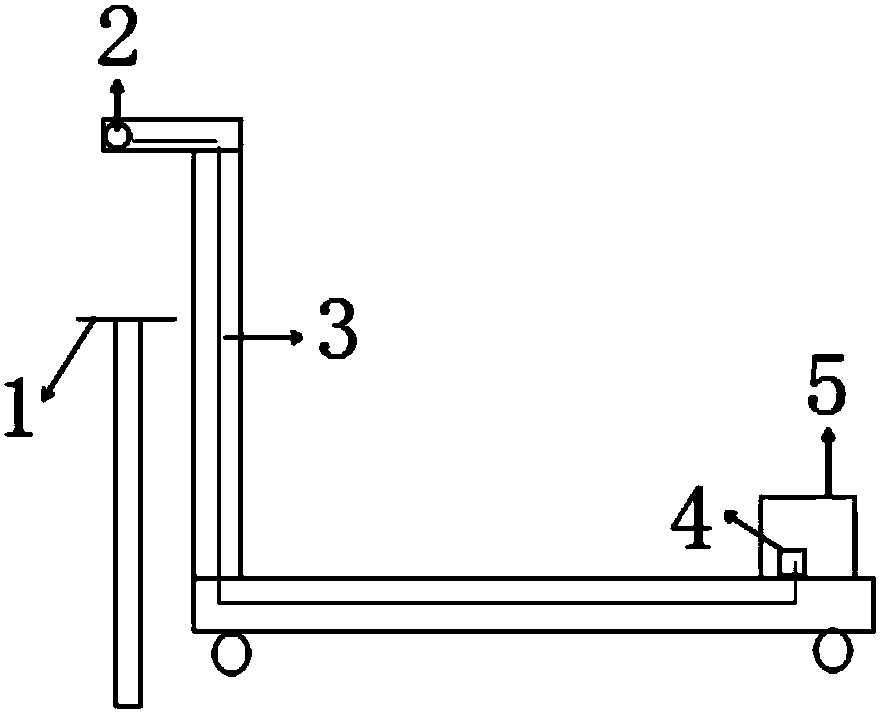

PendingCN107862372AReal-time monitoring of reverse insertion timesShorten monitoring timeCounting mechanisms/objectsLaser sensorEngineering

The invention relates to the technical field of stone pile crusher intelligent monitoring, particularly to a stone pile crusher inverse insertion frequency counting device. The stone pile crusher inverse insertion frequency counting device comprises a laser sensor module, a reflective film, a data processing module and a data processing terminal, wherein the laser sensor module is arranged at thetop of the support of a stone pile crusher; the reflective film is laid at the top of the hammer of the stone pile crusher and right against the laser sensor module; laser signals transmitted by the laser sensor module can be transmitted to the reflective film and reflected and refracted by the reflective film back to the laser sensor module, the laser sensor module transmits received signals to the data processing module, and the data processing module processes the received signals and transmits results to the data processing terminal. The stone pile crusher inverse insertion frequency counting device counts the number of times of inverse insertion of the stone pile crusher through high-precision laser sensors, thereby saving detecting time, reducing personal errors, improving the pilingquality and uniformity, ensuring the piling quality of roadbed construction and greatly improving the construction efficiency.

Owner:北京中企卓创科技发展有限公司 +1

Automobile seat basin welding assembly detection method

InactiveCN105180739AQuality improvementQuality assuranceMechanical diameter measurementsEngineeringWall plate

The invention discloses an automobile seat basin welding assembly detection method, comprising that: positioning posts are installed on a platform; detection plates are installed on the outer side of a wall plate on the detection platform; detection guiding holes are arranged on the detection plates which are corresponding to installation holes; detection pins are placed on the detection platform; the front end of the detection pin is a detection head; a guiding part is positioned in the middle part of the detection pin which is in connected to the detection head; the diameter of the guiding part is greater than the detection head; the back end of the detection pin which is connected to the guiding part is provided with a detection pin rear end part with the diameter being greater than the guiding part and the detection guiding hole; the seat basin welding assembly is placed on the detection platform; the bottom end positioning pin of the seat basin welding assembly passes into the positioning post; the detection pins are inserted into the installation holes after passing through the detection guiding holes; if the detection head can be inserted into the installation hole; the position of the installation hole and aperture accord with the requirement; if the detection head can not be inserted into the installation hole, the installation hole position and / or aperture is not in line the requirement. The automobile seat basin welding assembly detection method can realize the simultaneous detection of the installation hole and the aperture, and improves the qualified rate.

Owner:FUZHUO AUTOMOBILE INTERIOR ANHUI

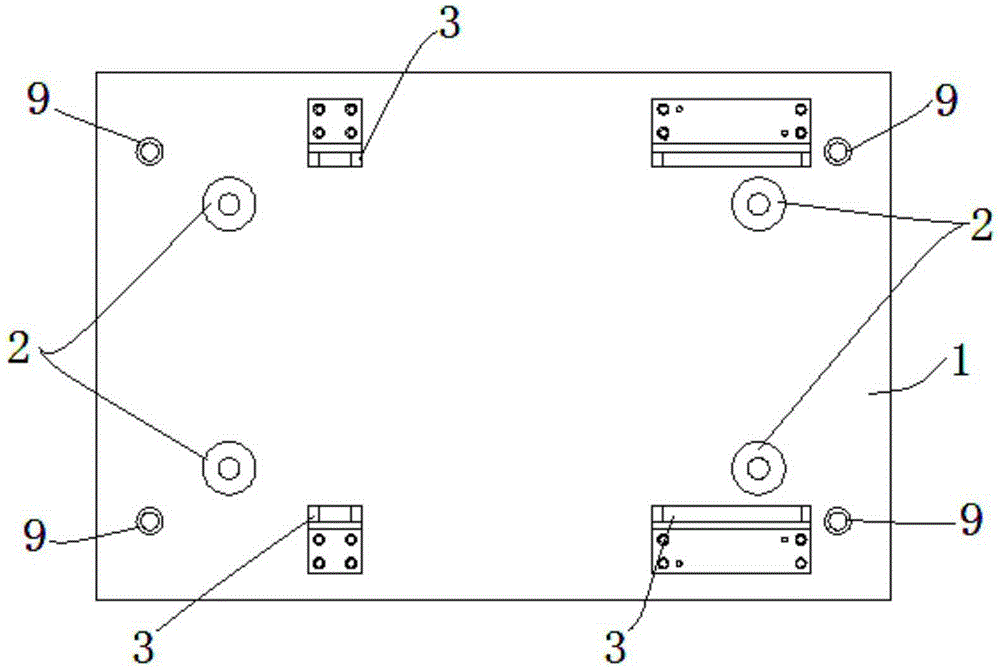

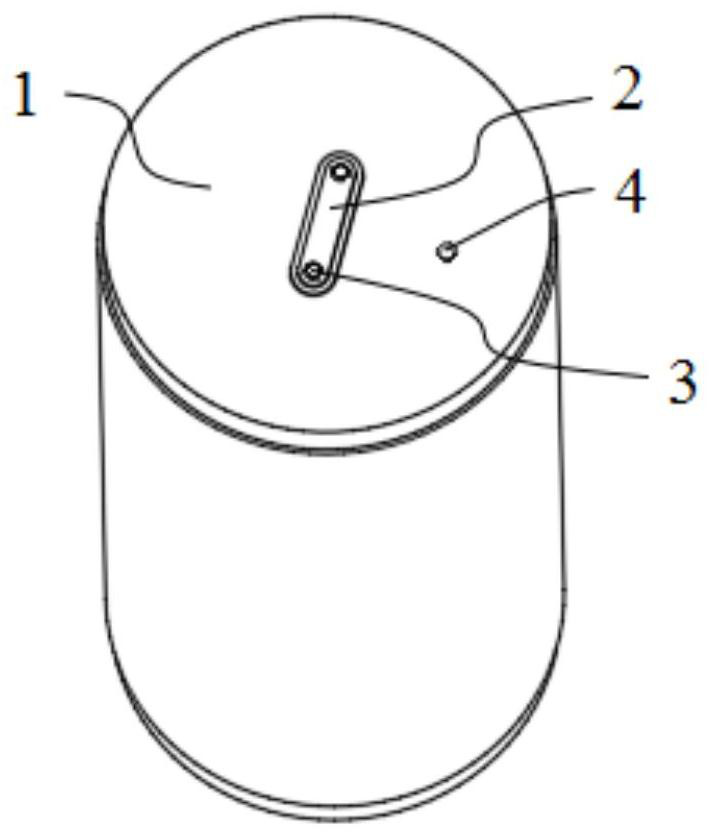

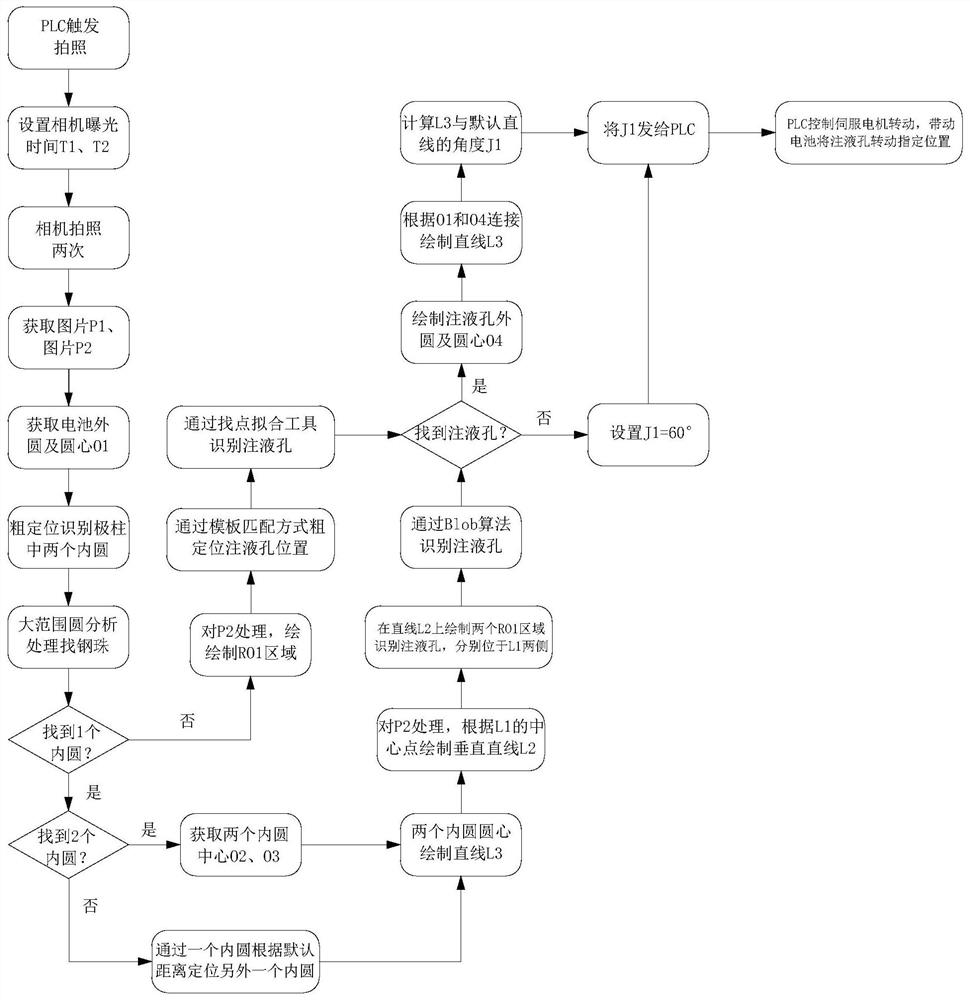

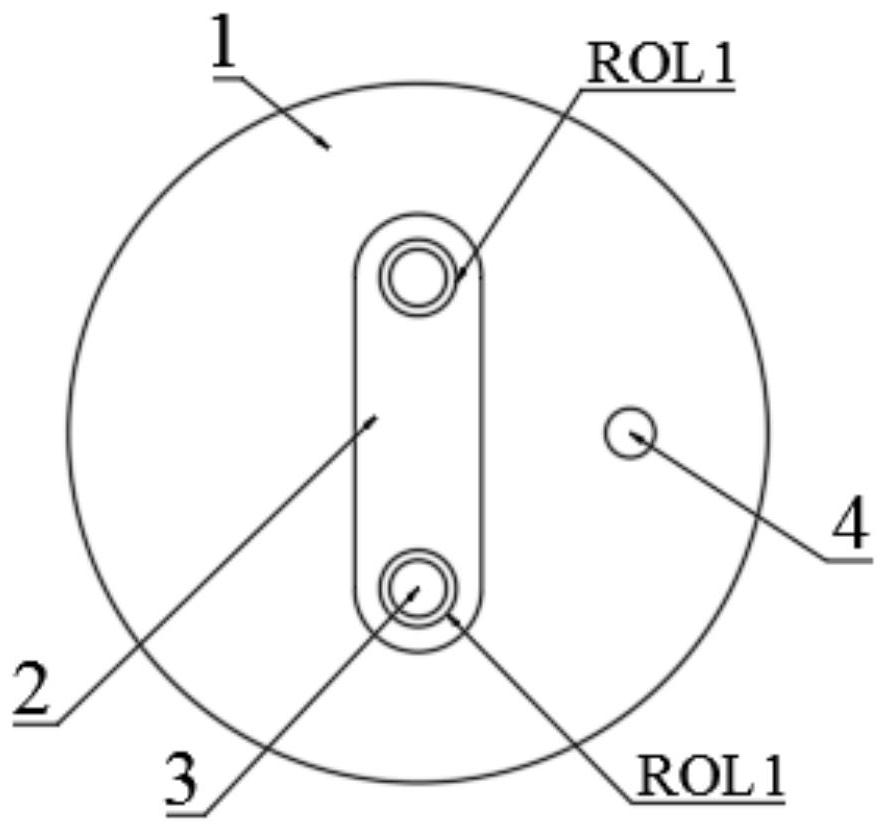

Cylindrical battery liquid injection hole aligning method and system

PendingCN114024106AImprove injection efficiencyReduce misjudgmentImage enhancementImage analysisImaging processingMechanical engineering

The invention discloses a cylindrical battery liquid injection hole aligning method and system, and the method comprises the following steps: S1, photographing the upper end of a cylindrical battery through a camera, obtaining a picture of the cylindrical battery, and uploading the picture to a processor; S2, on the basis of the picture of the cylindrical battery obtained in the step S1, firstly finding out the positions of screws at the two ends of a pole by using an image processing algorithm, then finding out the position of a liquid injection hole, and sending the current angle of the liquid injection hole to a PLC; and S3, controlling the servo motor by the PLC to drive the cylindrical battery to rotate, and rotating the liquid injection hole to a designated position. According to the hole aligning method, through a mode of firstly finding the screws at the two ends of the pole and then finding the liquid injection hole, misjudgment caused by the edge of the pole can be reduced, the hole aligning qualification rate can be greatly improved, and the production efficiency can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

An adjustable pneumatic tooling for aluminum welding test

ActiveCN112025191BSave materialImprove thermal conductivityWelding/cutting auxillary devicesAuxillary welding devicesBack supportArgon gas

The invention belongs to the technical field of tooling and fixtures, and relates to an adjustable pneumatic tooling for aluminum welding tests. The upper back support of the porous platform is inserted between two fixed bottom supports, and the back support under the weld seam formed by two welding test plates There is a U-shaped back through groove on the top, and an argon gas inlet groove is opened on the back supports on both sides of the U-shaped back through groove, and argon gas side outlet holes connected to the U-shaped back through groove are uniformly opened on the argon gas inlet groove , the front side of the back support is slidingly installed with a moving end limit block, and the rear side of the back support is fixedly installed with a fixed end limit block. Both the moving end limit block and the fixed end limit block are in the shape of steps. There is a mobile end clamping cylinder fixedly installed, and two fixed bottom supports are equipped with a side clamping block, and a side clamping cylinder is installed on the outside of the side clamping block, which solves the problem of manual butt welding of car body welds, and has high welding efficiency Low, labor-intensive, complicated operations, and large errors in welding position accuracy.

Owner:辽宁忠旺铝合金精深加工有限公司

A vacuum degassing process

ActiveCN108758325BSimple operation processEvacuation treatment effect is goodVessel manufacturingVessel wallsProcess engineeringNitrogen gas

A vacuumizing degassing process is disclosed. The process includes subjecting a product to be vacuumized to helium mass spectrum leakage detection, then inflating the product with high-purity hot nitrogen, thoroughly heating the product by adopting inside and outside heaters as auxiliary, performing inflation with hot nitrogen, gas sealing, and discharging hot washing in order to vacuumize to obtain low vacuum, vacuumizing in a manner of interrupted discharging to obtain high vacuum, and other steps. Through the steps and process parameters specific to the process steps, effects of removing residual gas in an interlayer for products processed through the process, such as vacuum insulated cryopump sumps, vacuum insulated cryogenic tubes and vacuum insulated cryogenic valve boxes, are extremely good, and therefore, heat leakage of vacuumized products during application is greatly reduced, and using performance and service lifetime of the products are greatly improved.

Owner:CHENGDU CRAER CRYOGENIC EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com