Patents

Literature

319results about How to "Guarantee the quality of inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

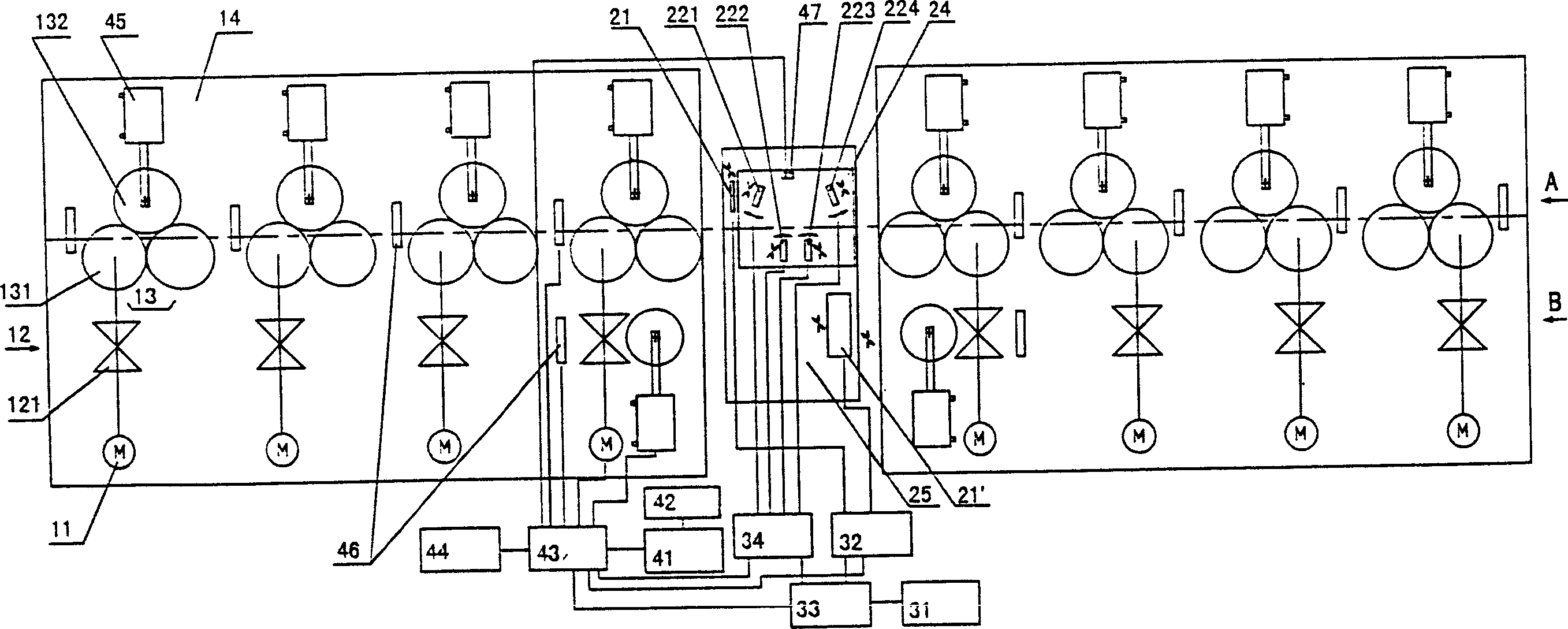

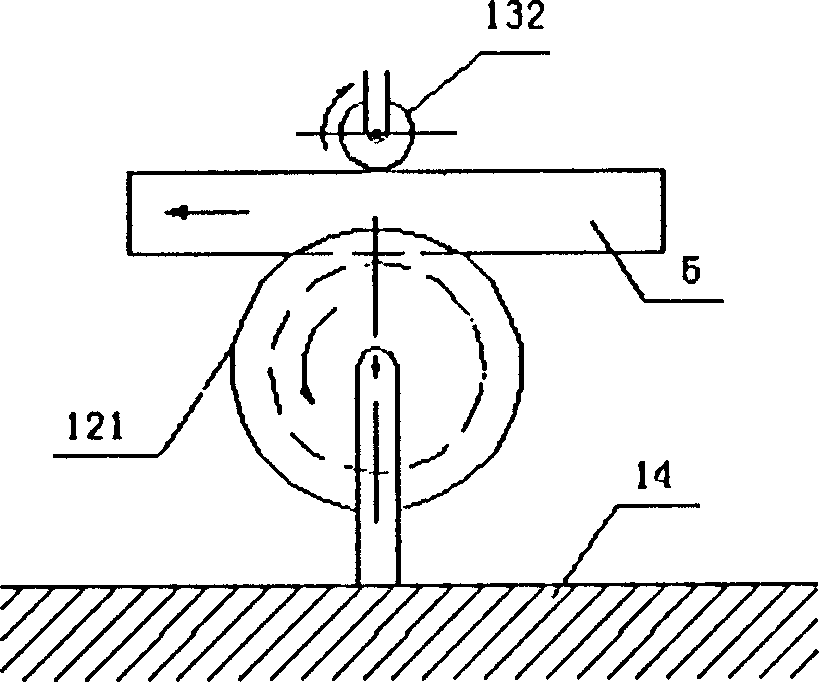

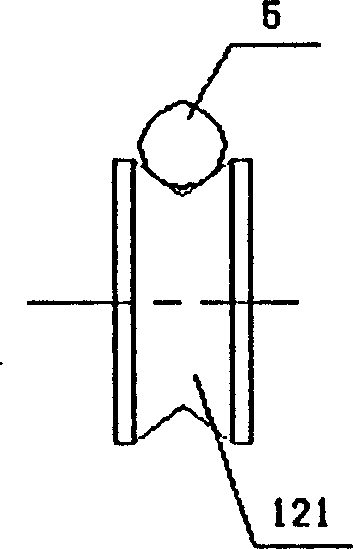

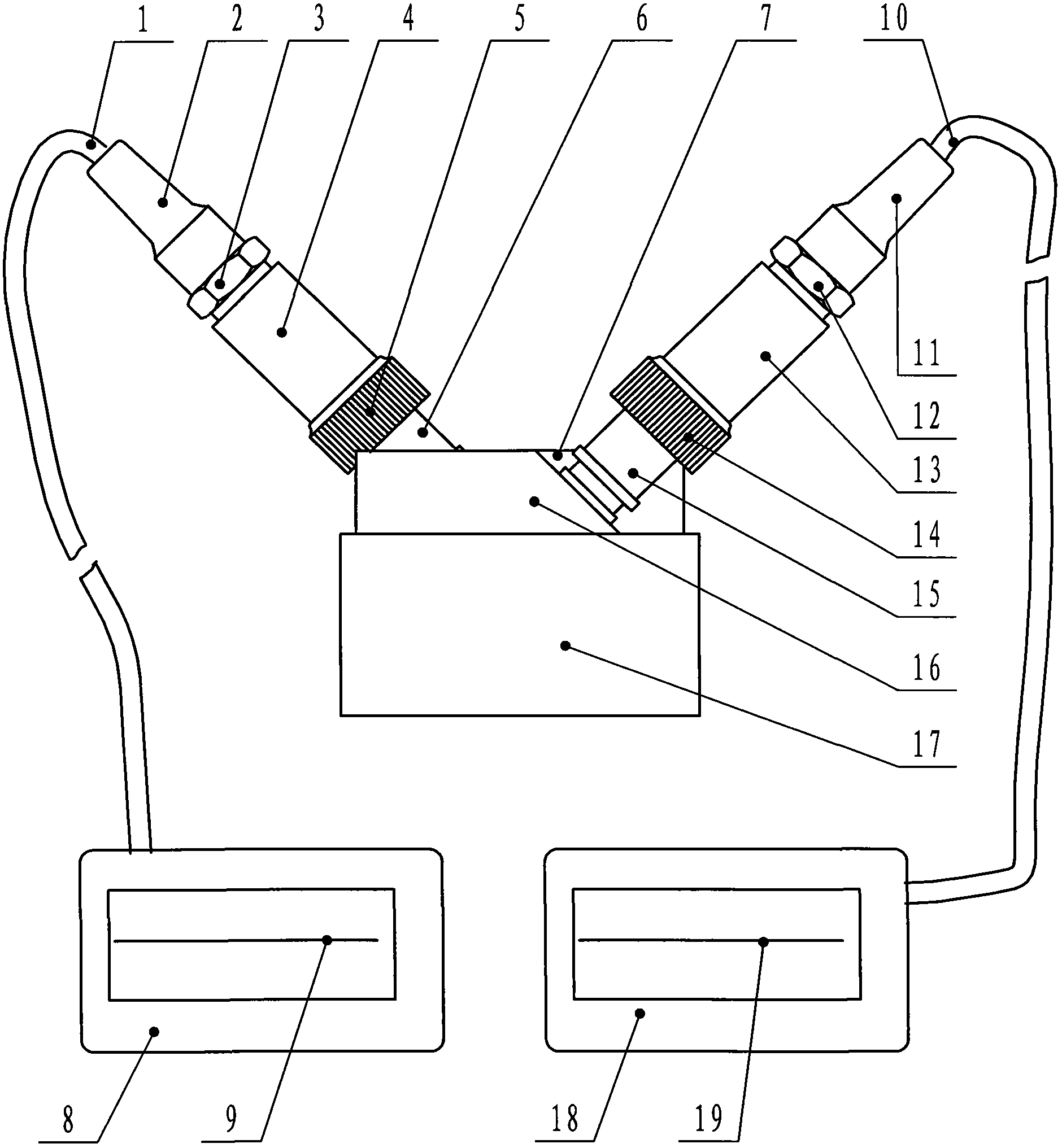

Supersonic and eddy composite automatic detector for pipe

InactiveCN1409107AGuarantee the quality of inspectionEasy for quality inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesAutomatic controlElectricity

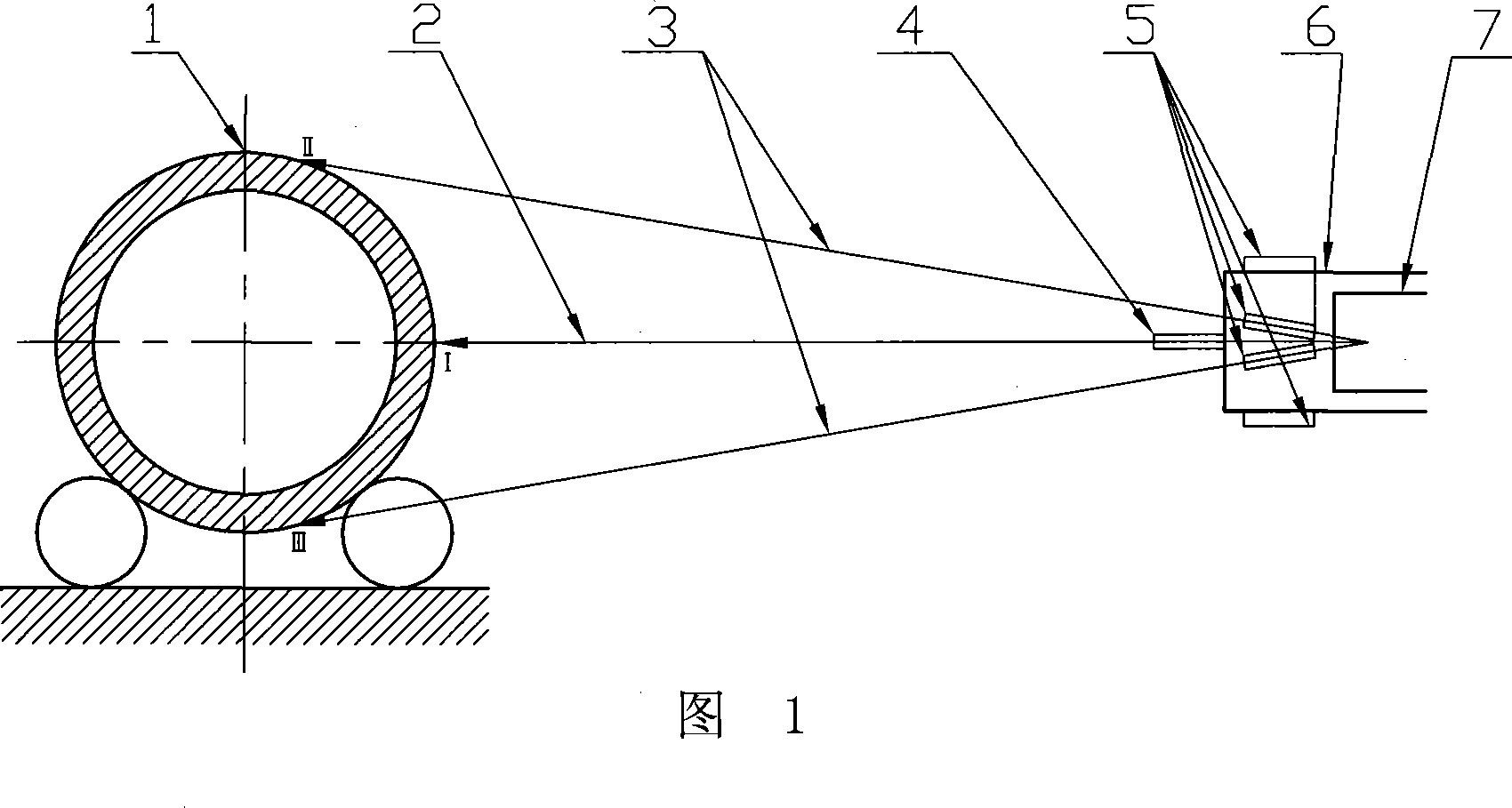

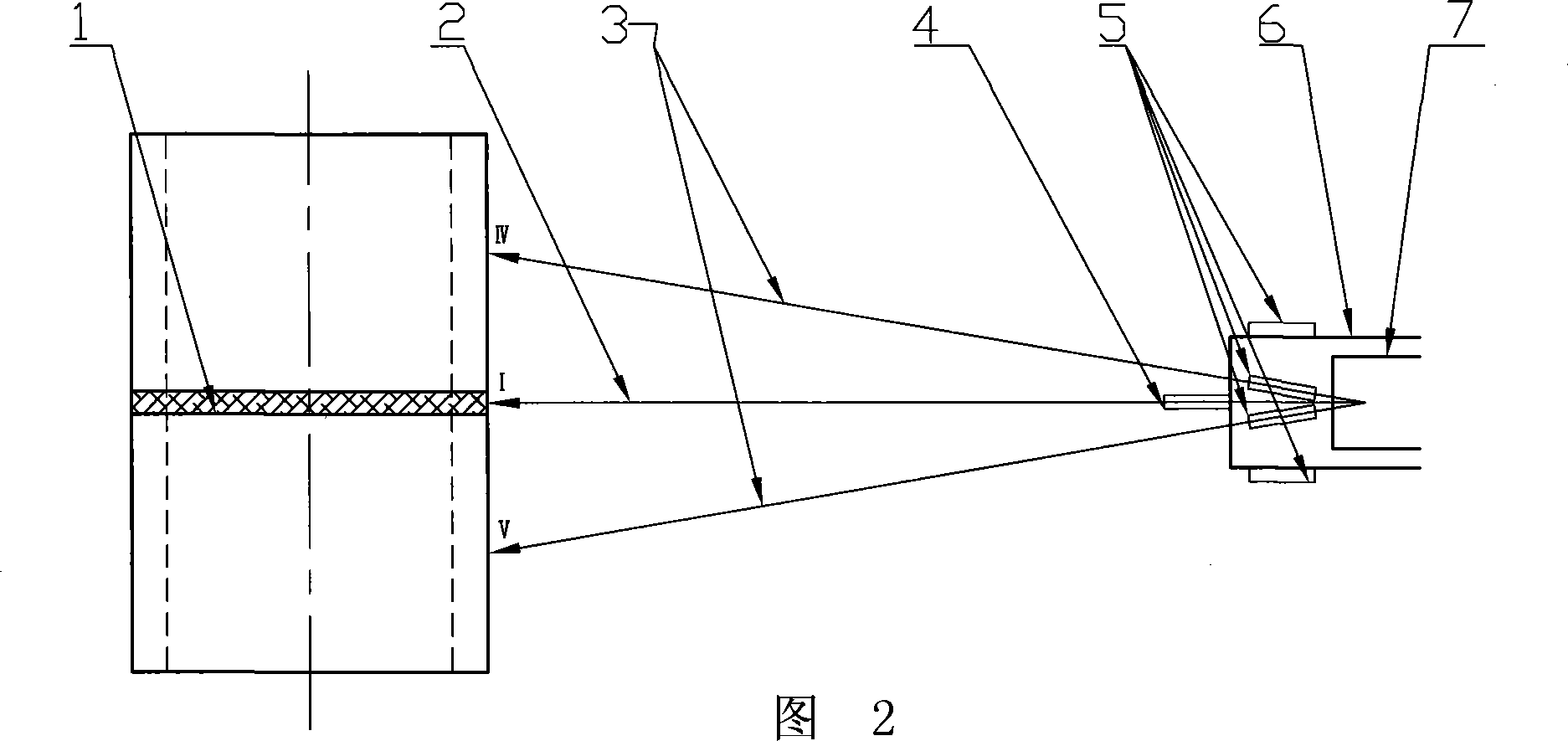

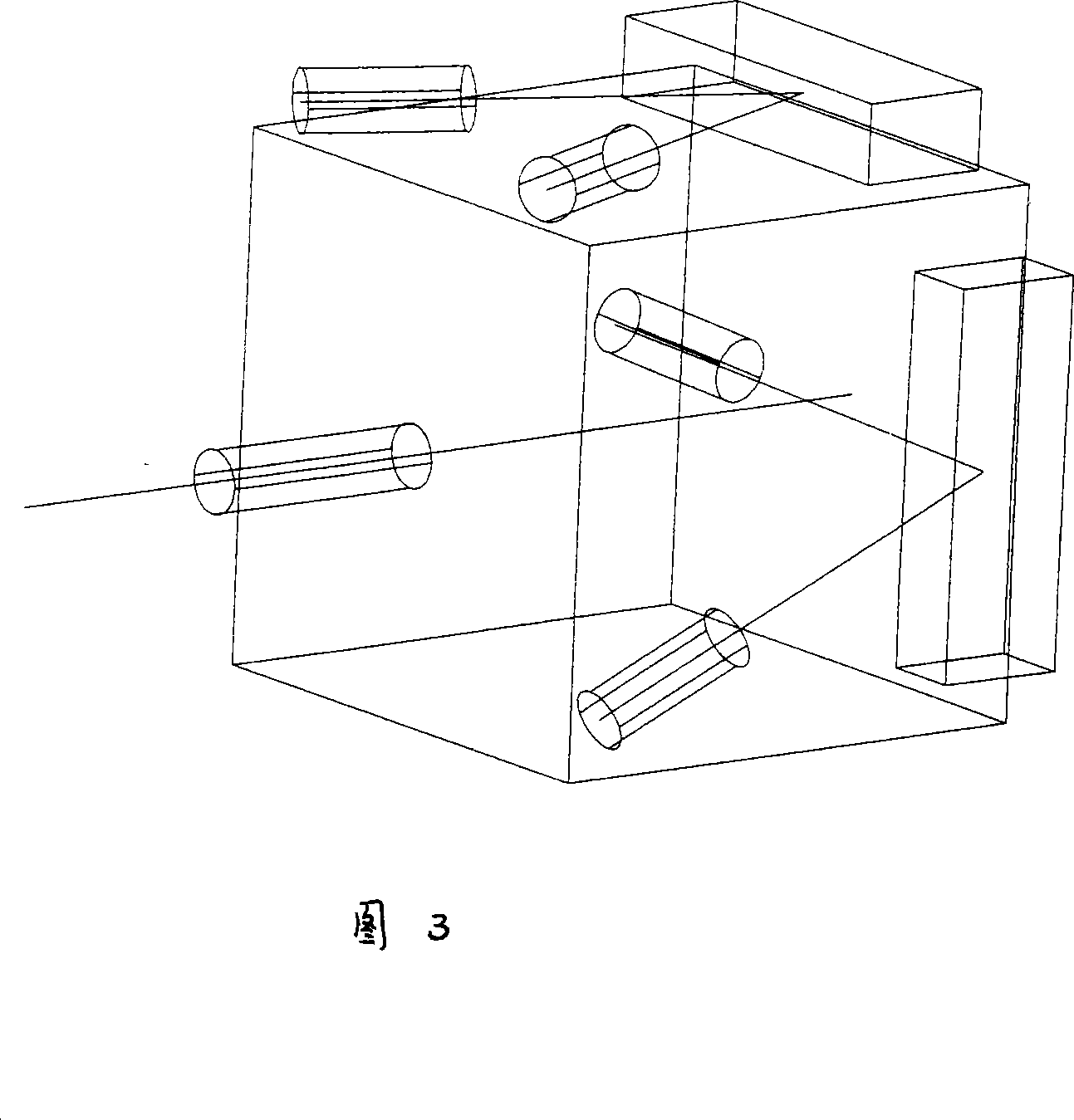

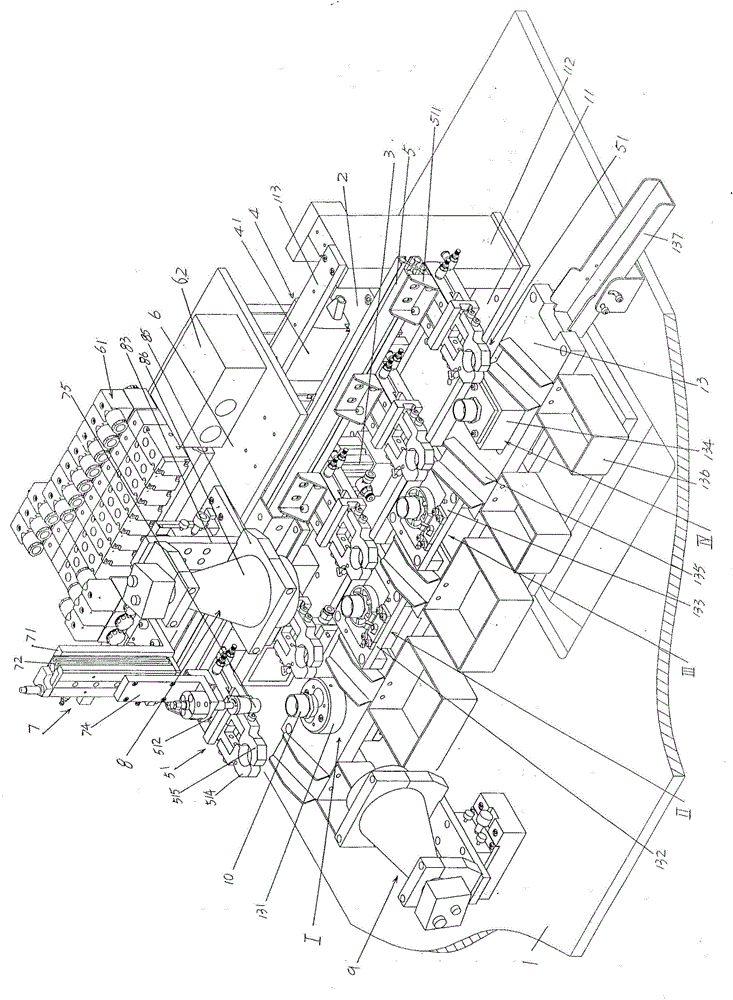

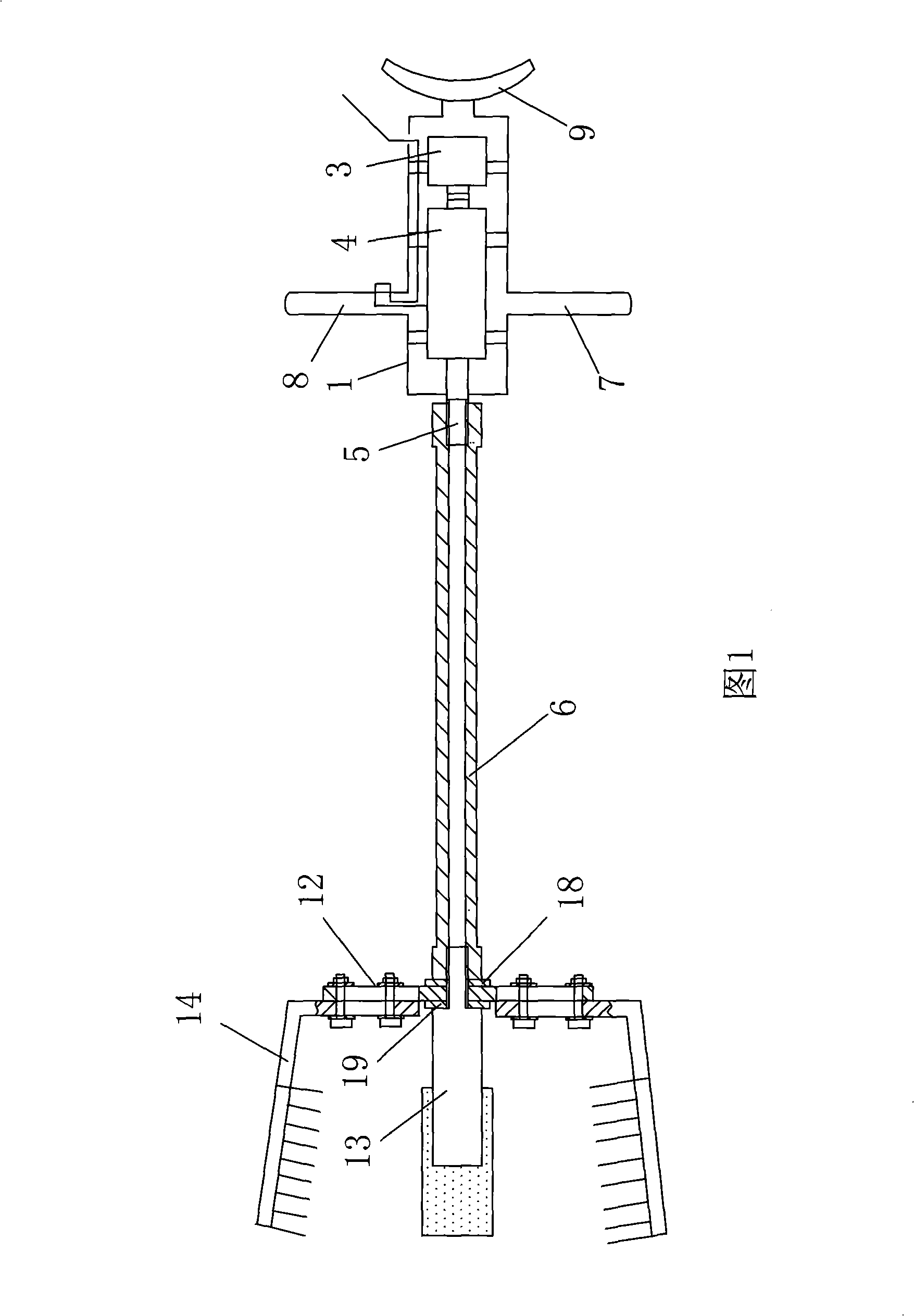

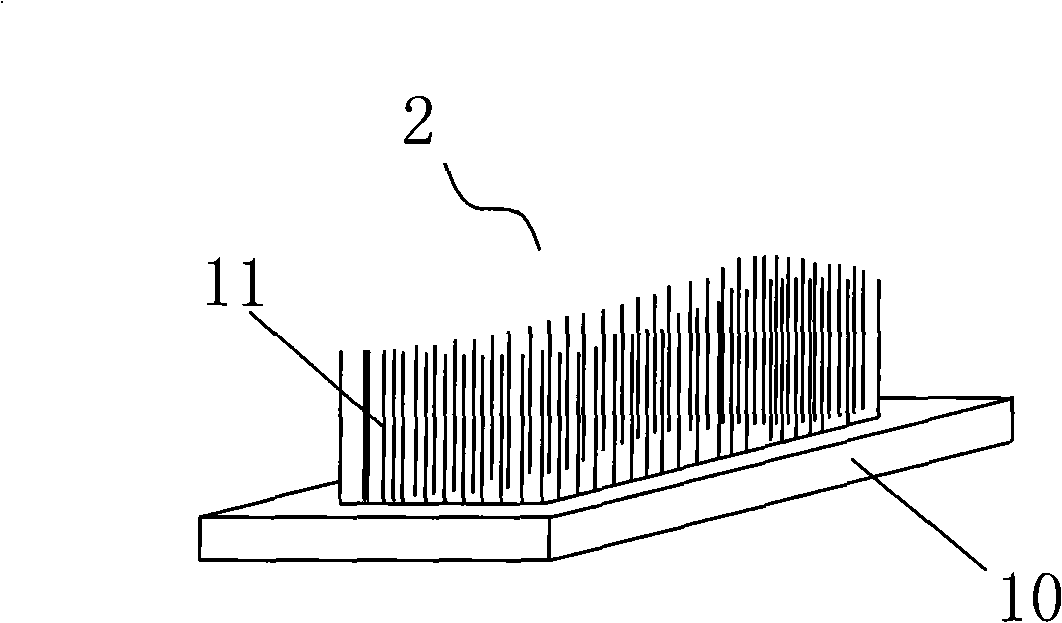

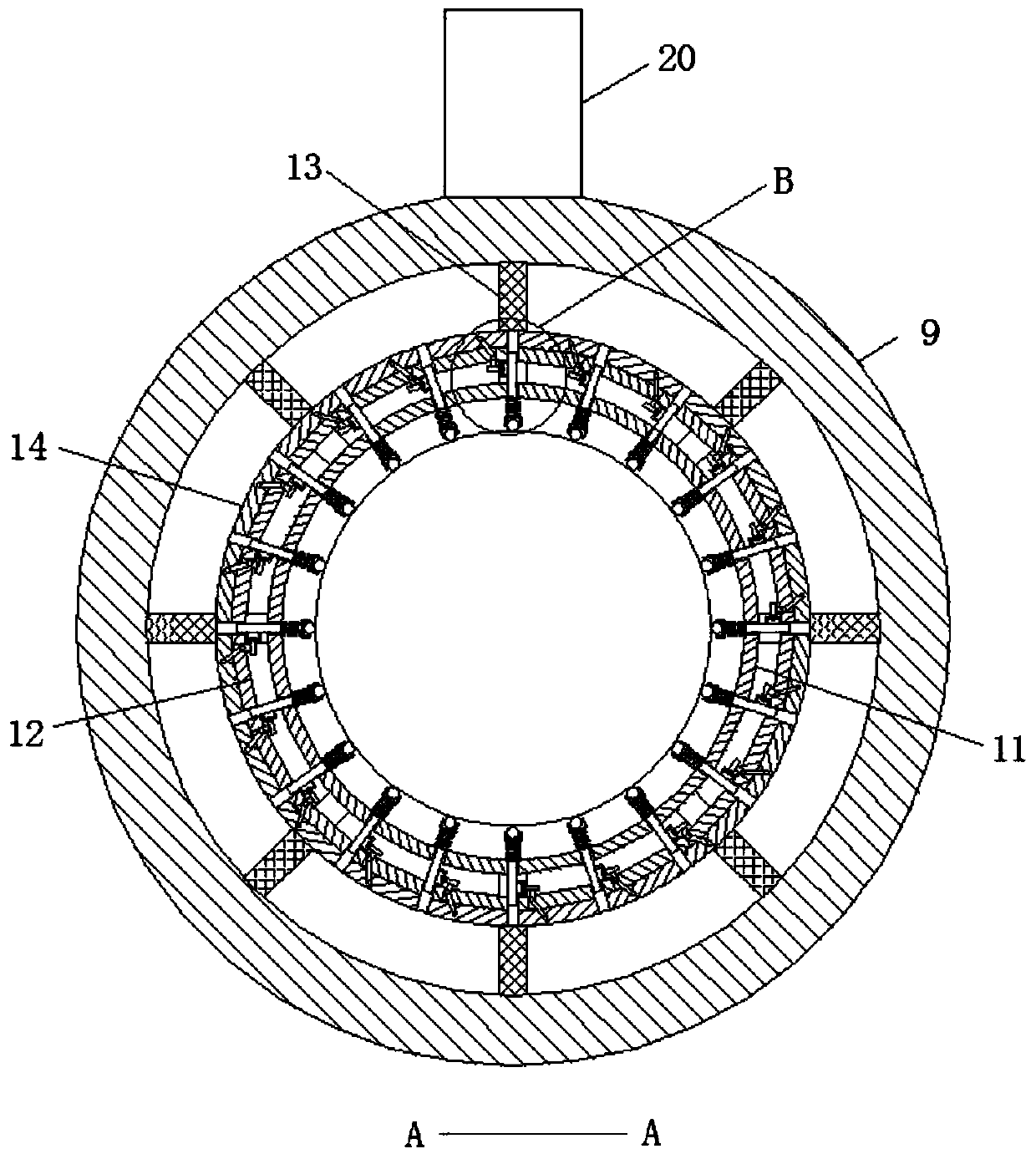

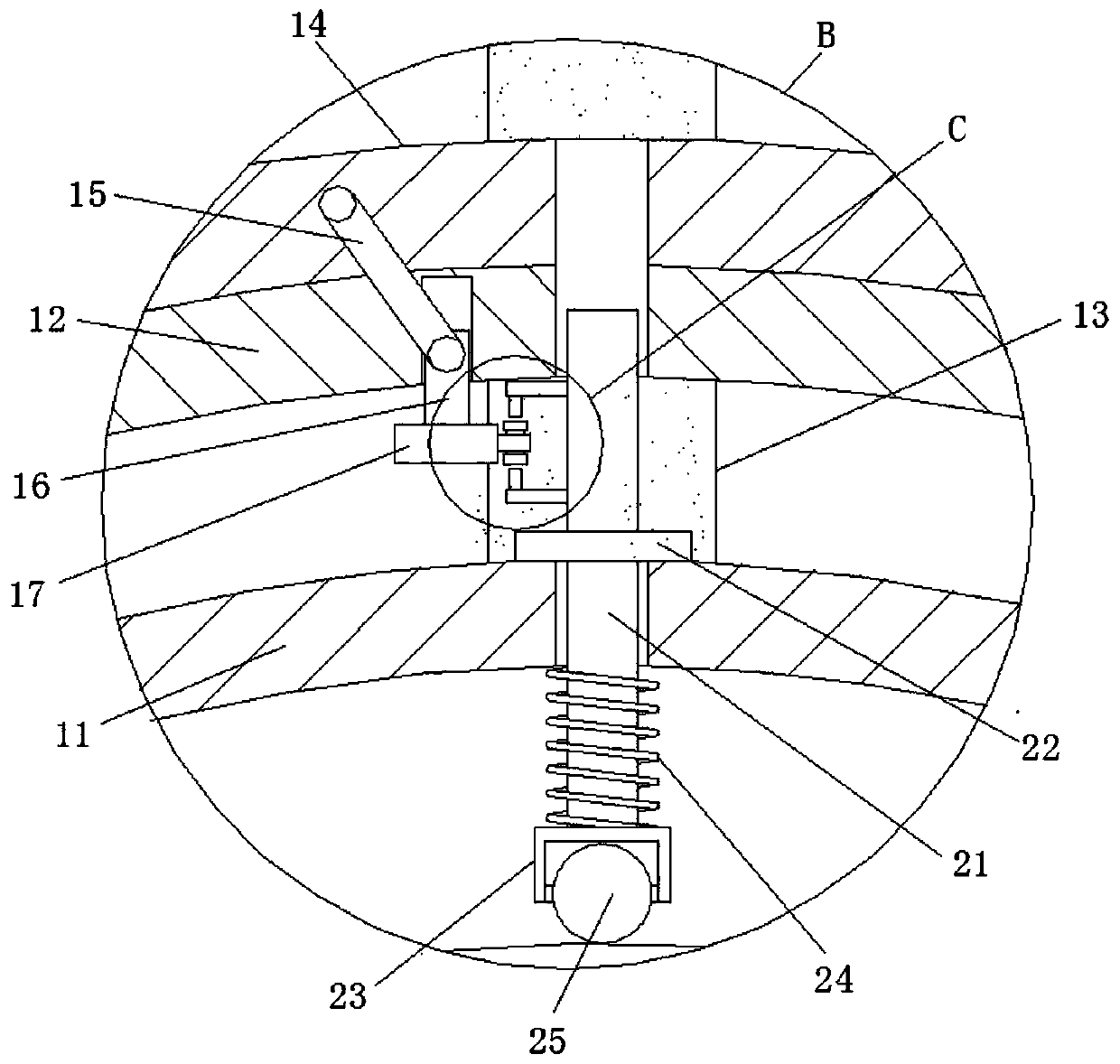

An automatic detecting device with combined ultrasonic and vortex flow for the material of bar and tube is composed of conveying mechanism and devices of detecting, detecting display, recording and automatic control, among which the conveying mechanism consists of motor, conveying roller way and three-wheel driver foring vortex detection line and vortex passing detection line, and the two lines are connected by driving and driven cone gears and universal coupling the detecting devices is composed of probe set, probe frame and probe water box, while the probe frame including adjusting mechanism, guide screw and sliding rail mechanism to be placed in the probe water box, and the probe set to be set on the probe frame outside the probe water box. A group of probes for longitudinal fault detection equiped with two ultrasonic water-dipped point focusing probes B and C, and a group of probes for transverse fault detection equioped with two ultrasonic water-dipped

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

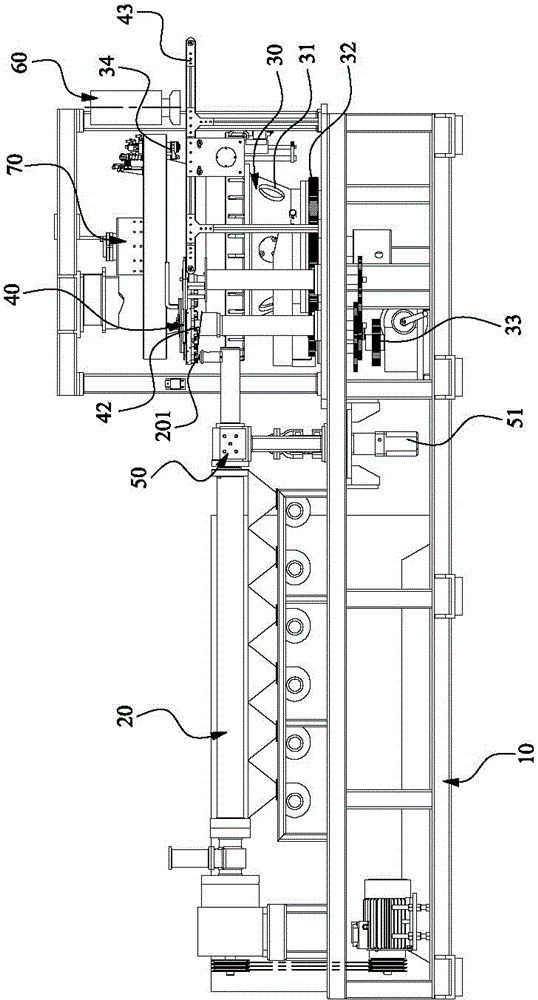

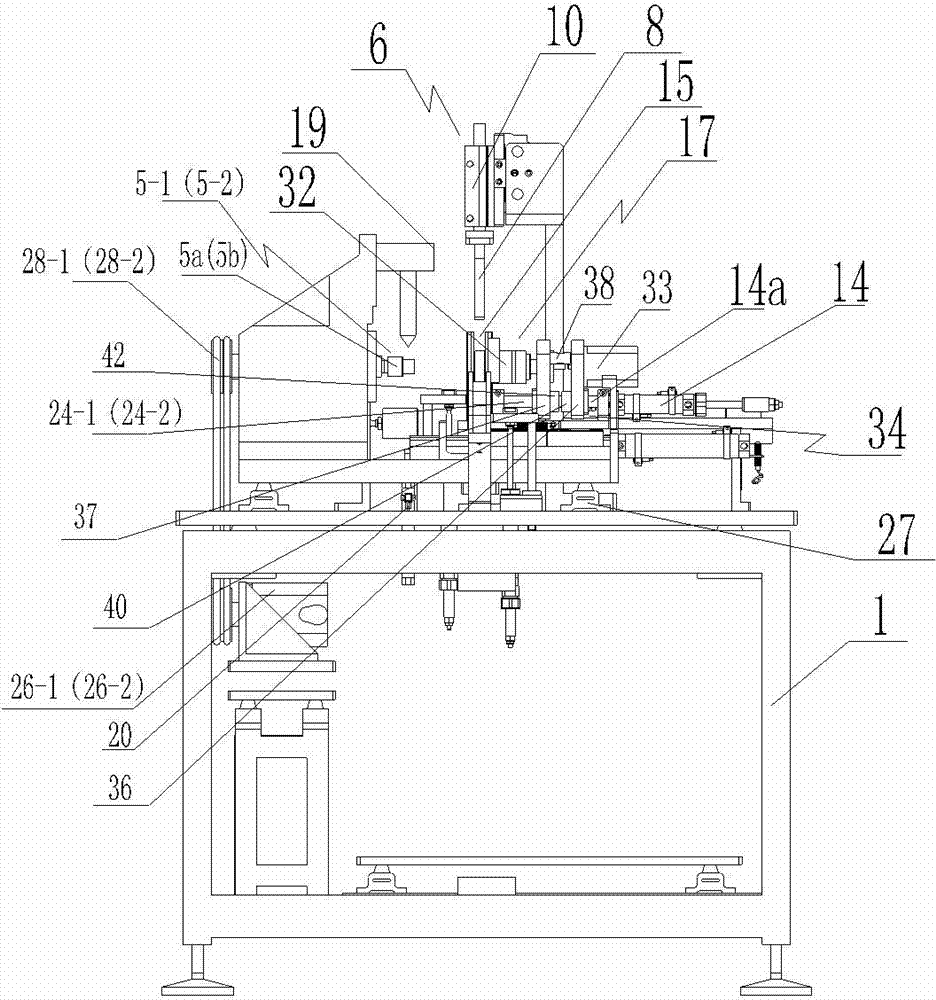

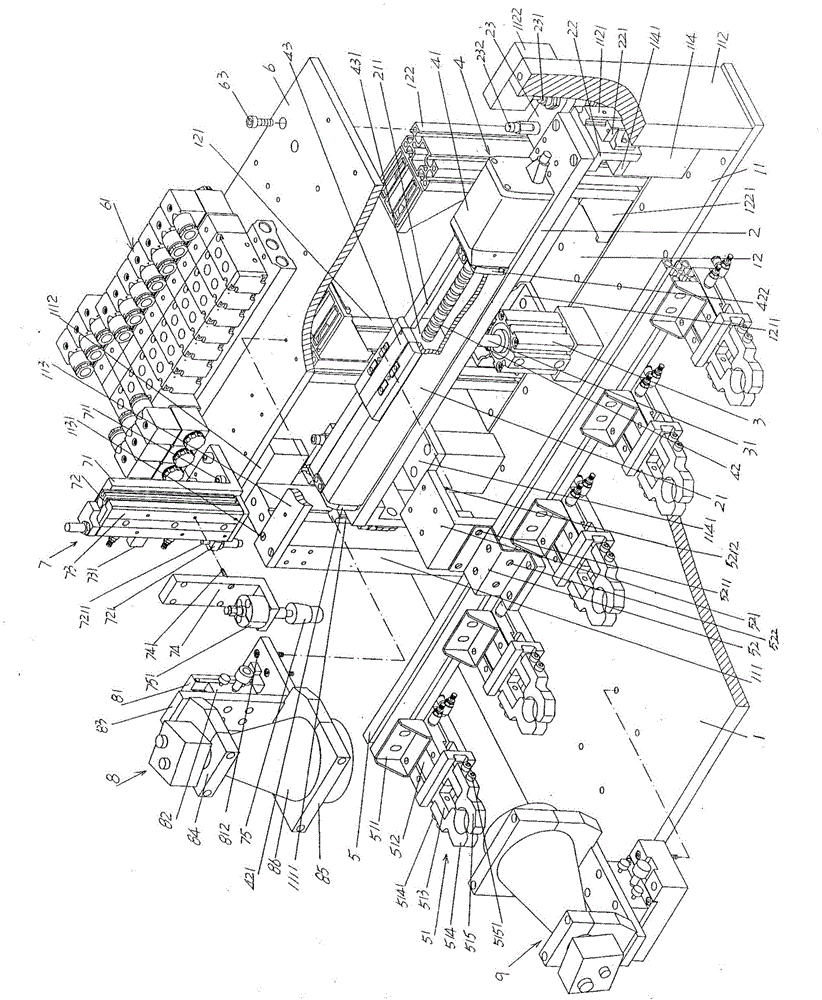

Fully-automatic die pressing lid maker

InactiveCN102862296ASmooth rotationGuarantee molding qualityDomestic articlesSortingEconomic benefitsEngineering

The invention discloses a fully-automatic die pressing lid maker, which comprises a rack, an extrusion module, a pressing module and a feeding and discharging module. The extrusion module is provided with an extrusion port. A metering pump is arranged on the extrusion module. The pressing module comprises a rotating main body, a rotating support and a driving device. A high-speed forming mold is arranged on the rotating main body. The rotating support is arranged between the rack and the rotating main body. The feeding and discharging module is arranged between the extrusion module and the pressing module. In such a way, the metering pump is used for accurately controlling feeding, and a high-frequency valve is matched to drive a piston head to move to accurately feed a blank. In addition, the rotating support is arranged between the rack and the rotating main body, and is used for enlarging the support area of the rotating main body, so that the rotating main body can rotate more stably. The fully-automatic die pressing lid maker is particularly applied to a heavy large-sized machine. Therefore, the forming quality of a bottle lid is ensured, a defective rate is lowered, and more economic benefits are created for an enterprise.

Owner:GUANGZHOU JEEPINE INTELLIGENT COMPRESSION MOLDING MACHINE CO LTD

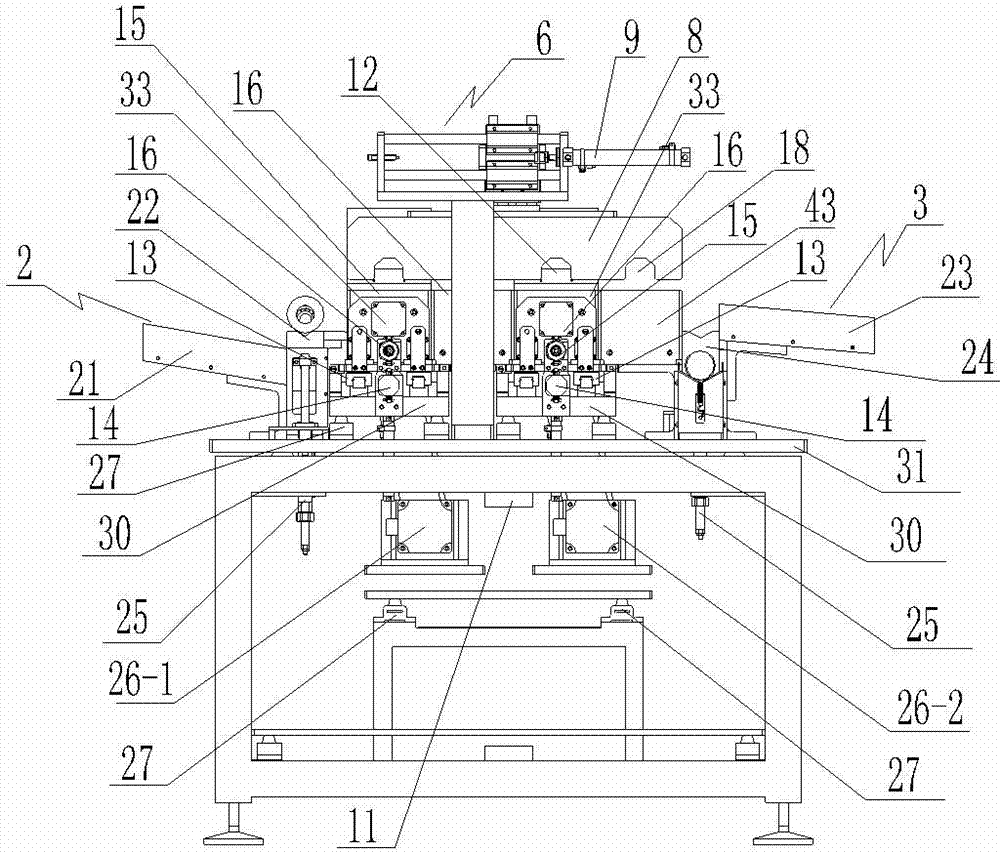

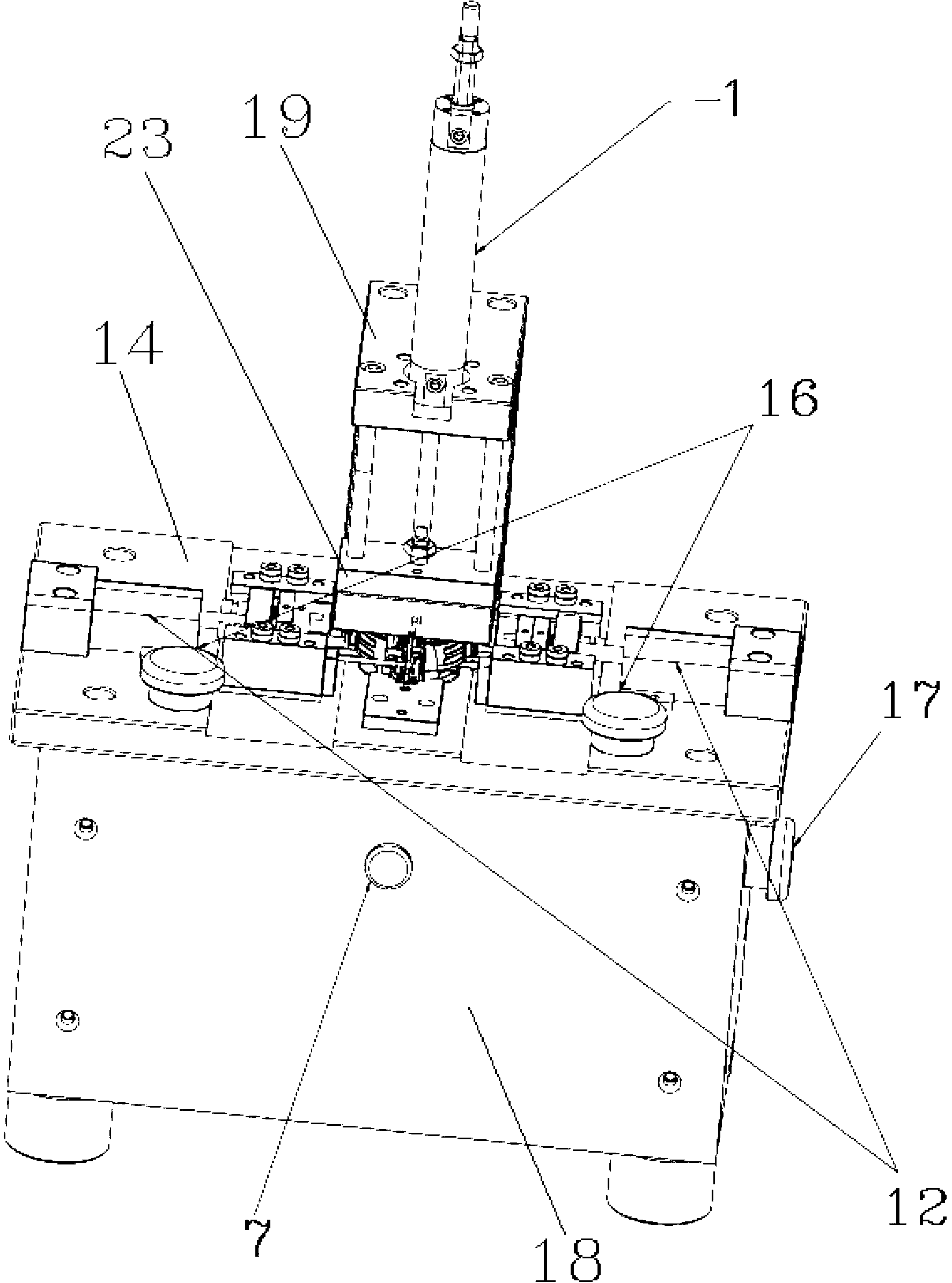

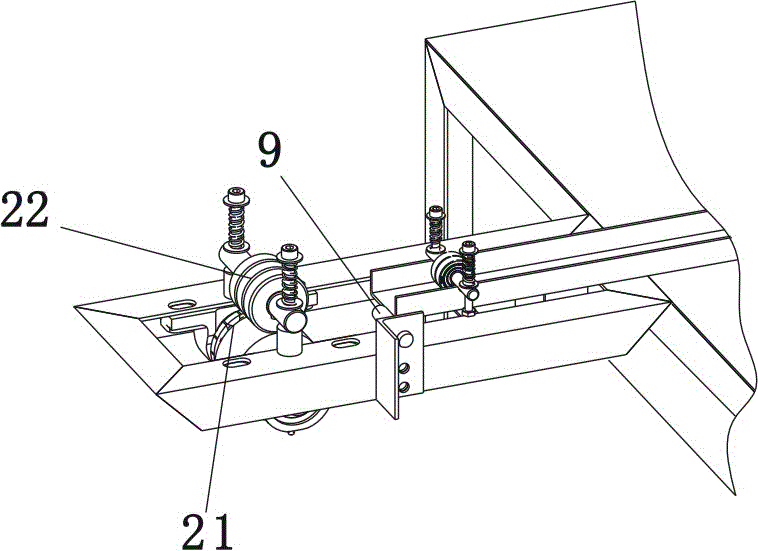

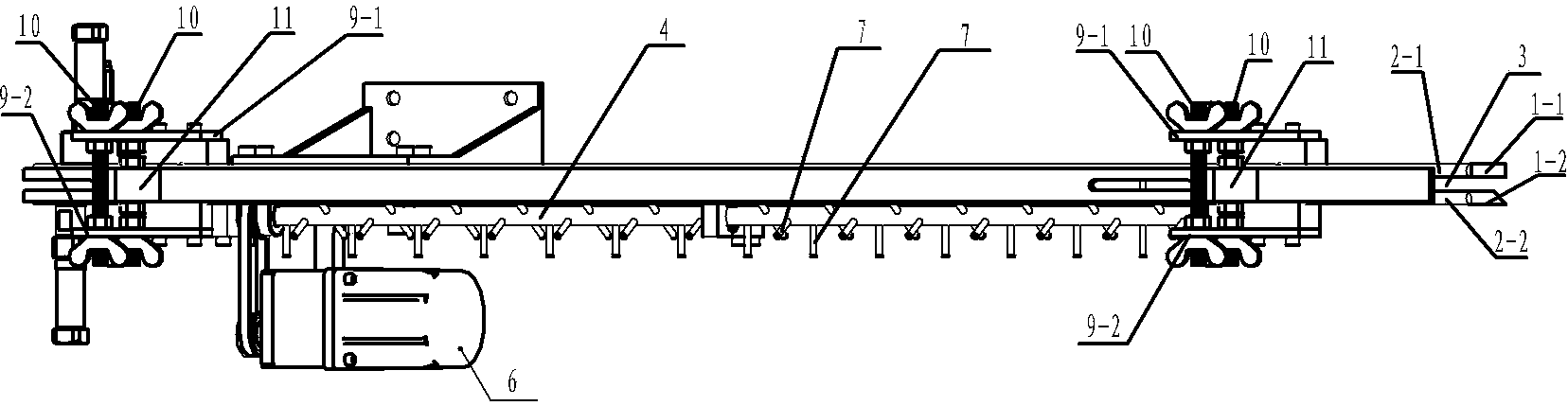

Bearing noise automatic detecting machine

ActiveCN104266748ARealize double-sided detectionFully automatedSubsonic/sonic/ultrasonic wave measurementMachine bearings testingAgricultural engineeringNoise detection

The invention provides a bearing noise automatic detecting machine which can automatically detect bearing noise, achieves double-face detection of bearing noise, improves detection efficiency and guarantees detection quality. The bearing noise automatic detecting machine comprises a machine frame, wherein two rotating devices are arranged on the machine frame, a bearing rotating head is arranged on each rotating device, and the machine frame is provided with a transverse bearing carrying mechanism and longitudinal bearing loading devices corresponding to the rotating devices respectively. The transverse bearing carrying mechanism comprises a forking plate, the forking plate is respectively connected with a transverse air cylinder and a longitudinal air cylinder, and three or more forking grooves corresponding to bearings are formed in the forking plate. Each longitudinal bearing loading device comprises a dragging plate, wherein the dragging plate is connected with a dragging plate conveying air cylinder, the dragging plate is provided with first bearing containing grooves corresponding to the forking grooves in the two sides of the forking plate, the machine frame is provided with a rotary second bearing containing groove corresponding to the forking groove in the middle of the forking plate, bearing loading heads are arranged on positions, corresponding to the first bearing containing grooves, of each dragging plate, and sensors are arranged on positions, corresponding to the first bearing containing grooves respectively, of the machine frame.

Owner:WUXI SHUANGYI PRECISION MACHINERY

Device for automatically detecting whether components are left out of installation

InactiveCN103257373AAvoid missingImprove detection efficiencyGeological measurementsEngineeringVertical cylinder

The invention relates to a device for automatically detecting whether components are left out of installation. The device comprises cylinders, an elastic top, a microswitch, a buzzer, a detecting assembly block, elastic ejector pins and an insulating plate, wherein a vertical cylinder and a horizontal cylinder are installed on a tooling table, and the elastic ejector pins are matched, so detection for assemblies of products is carried out one by one through a conductive mode or a mechanical mode. When installation missing or installation leakage occurs, signals are transmitted to a PLC, and alarming is carried out through the buzzer. According to the device, comprehensive detection is carried out on the components through a mode of matching of energizing detection and mechanical detection, the phenomena of the installation missing and the installation leakage can be effectively avoided, meanwhile efficiency of detection is improved to a great degree, and detection quality is guaranteed.

Owner:NINGBO TIANLONG ELECTRONICS

Intensity adjustable steel piece bending resistance detecting device facilitating limiting

ActiveCN110411857AEasy to limitSqueeze force changesMaterial strength using steady bending forcesArchitectural engineeringUltimate tensile strength

The invention discloses an intensity adjustable steel piece bending resistance detecting device facilitating limiting. The device comprises a base, a hydraulic rod and a transmission gear; a first sliding groove is formed in the inner surface of the upper end of the base, a supporting rod is installed at the outer side of the first sliding groove, a connecting block is installed at the upper end of the supporting rod, a rotating shaft is installed at the lower end face of the connecting block, the rotating shaft is connected with the supporting rod, a containing groove is formed in the inner surface of the upper end of the base, the containing groove is connected with the connecting block, and a first reset spring is fixedly connected to the outer surface of the supporting rod. According to the intensity adjustable steel piece bending resistance detecting device facilitating limiting, extrusion contact is performed on a placed steel piece along with downward motion of a pressing head,a traction rope connected with the pressing head can drive a second limiting roller to displace downwards synchronously along the support, and therefore a user can perform automatic limiting and fixing at the two ends of the steel piece automatically by folding two sets of limiting rollers without manual operation.

Owner:河北飞宇体育发展有限公司

LED lamp tube detector

The invention relates to an LED lamp tube detector which comprises a rack, a detection power source installed in the rack, a supply device, a receiving device and a rail arranged between the supply device and the receiving device. A pre-discharging mechanical hand is arranged at one end of the supply device. A CCD camera and a marking device are arranged above the rail in the horizontal direction in a spaced manner. A material taking and transferring mechanical hand is arranged on one side of the rail. A discharging and transferring mechanical hand is arranged on the other side of the rail. The detection power source is connected with the material taking and transferring mechanical hand. The LED lamp tube detector is simple in structure and convenient to operate, a product can be powered on only when the product passes the assigned region, and the product is prevented from being powered on too long; the high-end intelligent CCD camera is adopted, so that recognition is accurate and quick; two layers of material boxes can be placed in both a supply bin and a receiving bin at a time, so that the capacity is large, the supply and replacement frequency are reduced, and labor intensity is relieved; and the material boxes are lifted through a stepping motor module and can be accurately and quickly located, reliability is high, production efficiency is improved, and labor cost is saved.

Owner:JIANGSU BVM INTELLIGENT TECH

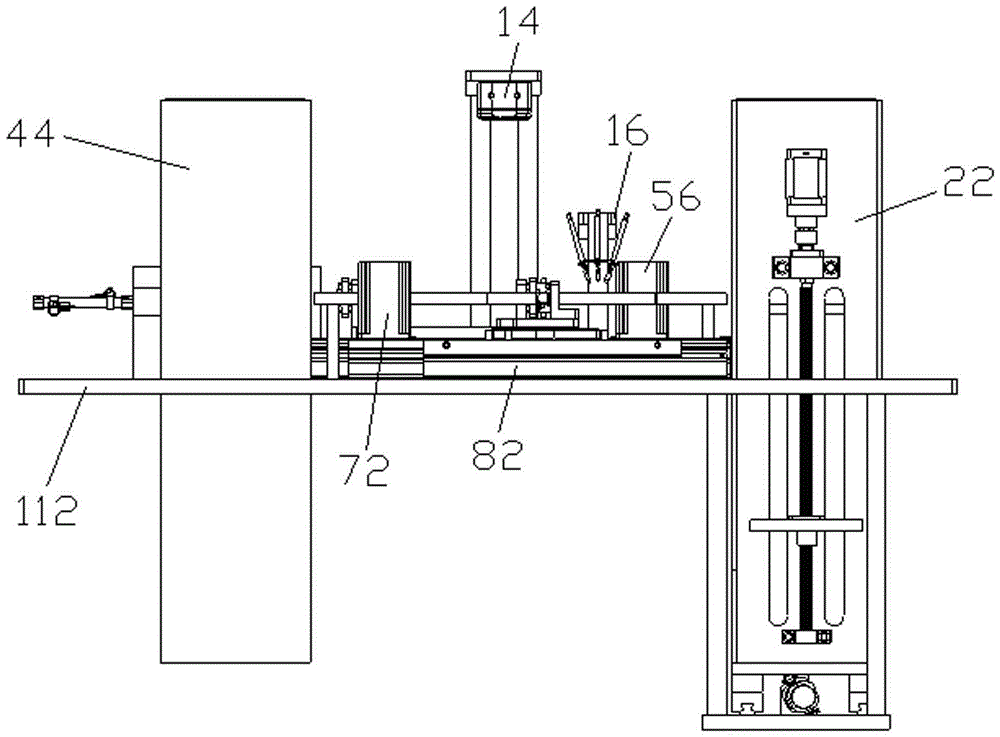

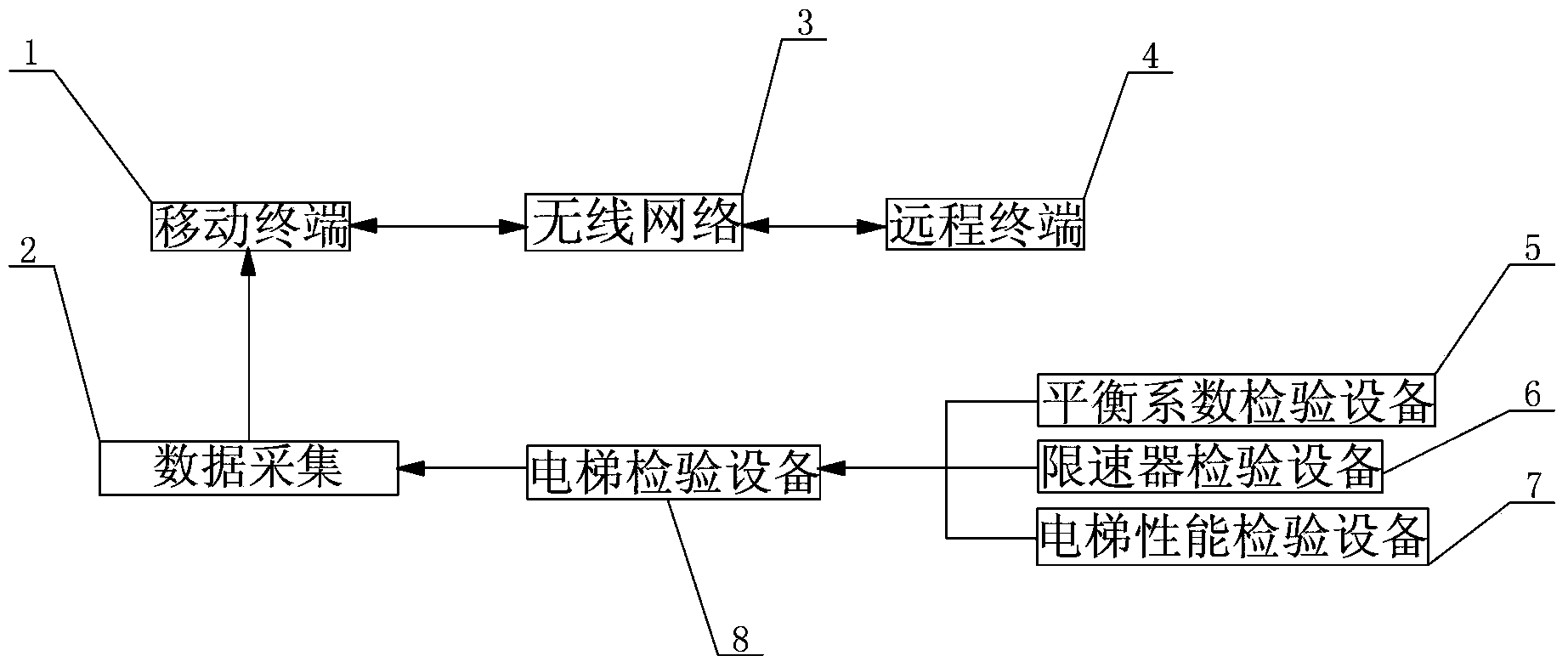

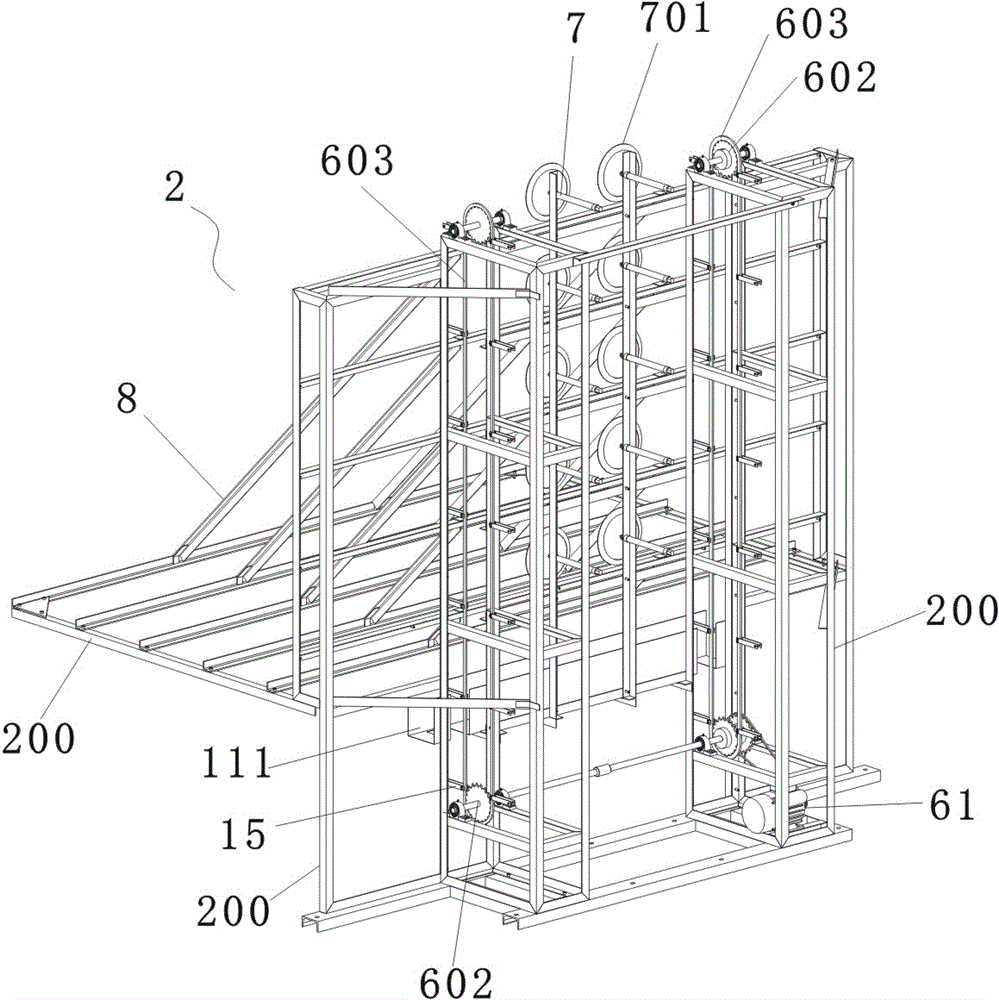

Intelligent elevator safety inspection platform

InactiveCN104140021AImprove work efficiencyGuarantee the quality of inspectionElevatorsData acquisition and loggingInformatizationQuality of work

The invention relates to an intelligent elevator safety inspection platform which is convenient to use and capable of realizing full-process informatization of special equipment such as elevators including on-site inspection, data acquisition, fill-in of source records and automatic generation of inspection report and the like, improving elevator inspection efficiency and inspection quality and realizing on-site intelligent inspection of inspection personnel. The intelligent elevator safety inspection platform comprises a mobile terminal (1), a data acquirer (2), a wireless network (3), a remote terminal (4), equilibrium coefficient inspection equipment (5), a speed governor inspection equipment (6), an elevator performance inspection equipment (7) and an elevator inspection equipment (8). The intelligent elevator safety inspection platform is characterized in that input and output of the mobile terminal (1) is connected with the wireless network (3), the wireless network (3) is connected with the remote terminal (4), input and output of the mobile terminal (1) is connected with the data acquirer (2), and the data acquirer (2) is connected with the elevator inspection equipment (8).

Owner:甘肃省特种设备检验研究院

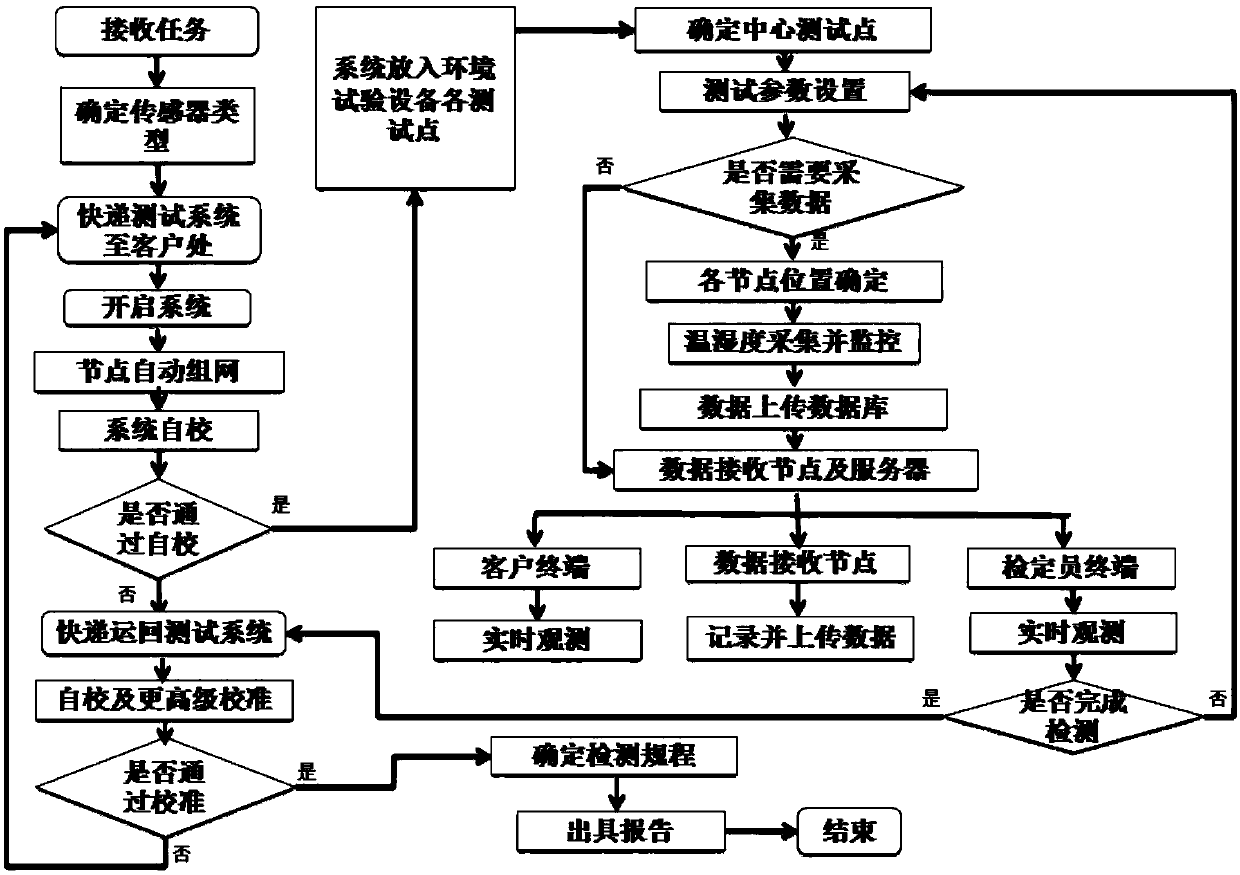

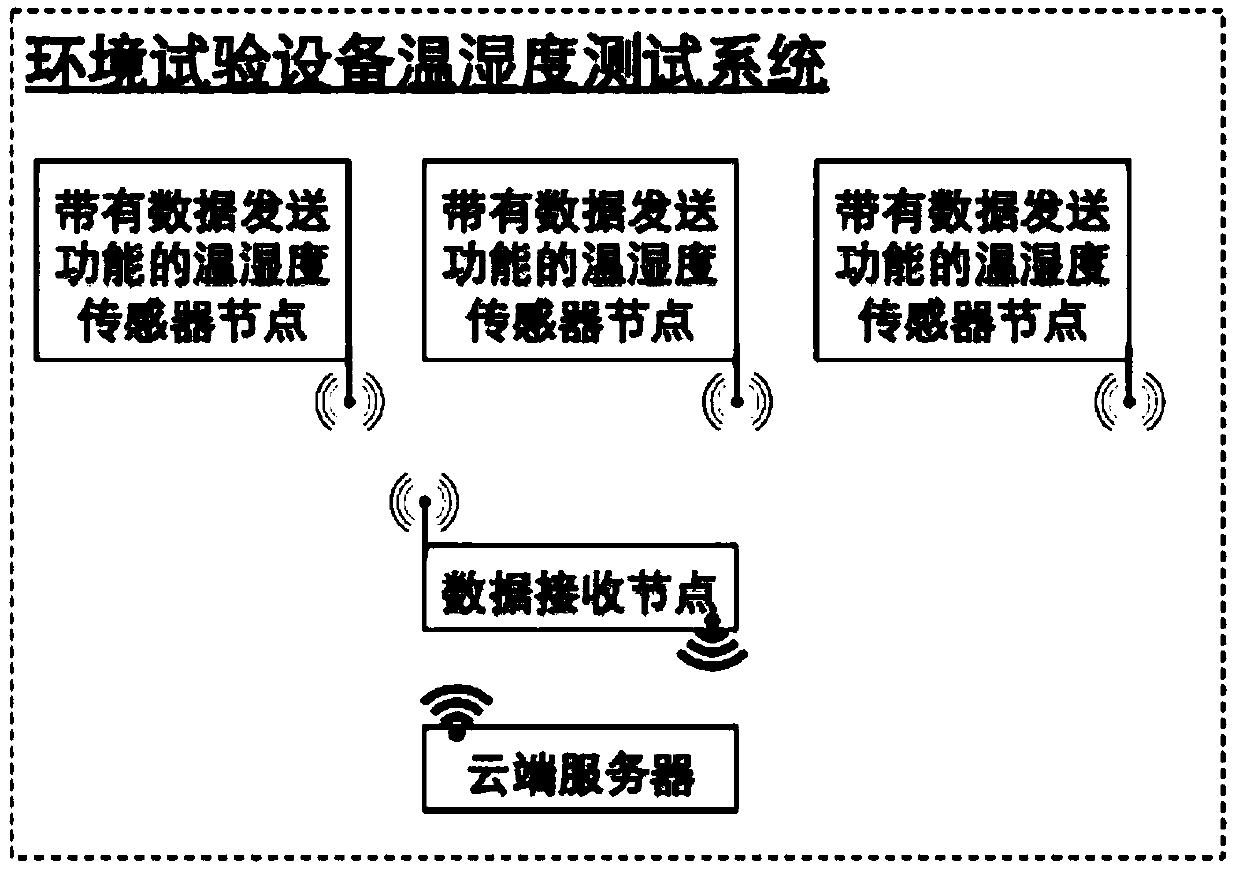

Remote temperature and humidity test system and test method for environmental test equipment calibration

ActiveCN110196075AReduce Human Judgment ErrorsExtended use timeMeasurement devicesEngineeringEnvironmental tests

The invention relates to a remote temperature and humidity test system for environmental test equipment calibration. The system comprises at least one temperature and humidity sensor node with the data transmission function, a data receiving node and a cloud server. Automatic networking between the temperature and humidity sensor nodes with the data transmission functions and between the temperature and humidity sensor nodes with the data transmission functions and the data receiving node is realized by using an ANT Wireless technology. The data receiving node and the cloud server are connected via the wireless internet. In addition, the invention also discloses a remote temperature and humidity test method for environmental test equipment calibration. With the internet+, the original modeof on-site equipment detection by the detection engineer is changed and thus the user can realize the access to the cloud server via the internet by using a mobile phone or a computer browser based on needs. Therefore, functions of detection process controlling, real-time data browsing, and one-key detection report issuing and the like can be realized. The test system and test method have the broad application prospects.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

Ultrasonic flaw detection method

InactiveCN102706959AGuarantee the quality of inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesA wave amplitudeWeld seam

The invention relates to an ultrasonic flaw detection method which comprises the steps as follows: (I) selecting two transverse wave ultrasonic probes with K; (II) respectively connecting the two ultrasonic probes with an ultrasonic flaw detector, and measuring the practical K values and incidence points of the ultrasonic probes with a test block CSK-I A; (III) placing one ultrasonic probe in a test block CSK-III A, adjusting the maximal echo of a phi 1*6 hole with depth of 10 mm to be 80% of reference wave, detecting the holes with depths of 20 mm, 30 mm and 40 mm, connecting the points corresponding to the wave crests to obtain a phi 1*6 distance-amplitude curve, and then increasing by 9 db; (IV) carrying out the operation of the step (III) on the other one ultrasonic probe; (V) fixing the two ultrasonic probes in parallel at oppositely directions; and (VI) carrying out detection by adopting sawtooth type scanning within the range of 2*K*T mm on two sides of welded seam. The ultrasonic flaw detection method can detect the flaws at different directions at one time.

Owner:TAIYUAN IRON & STEEL GROUP

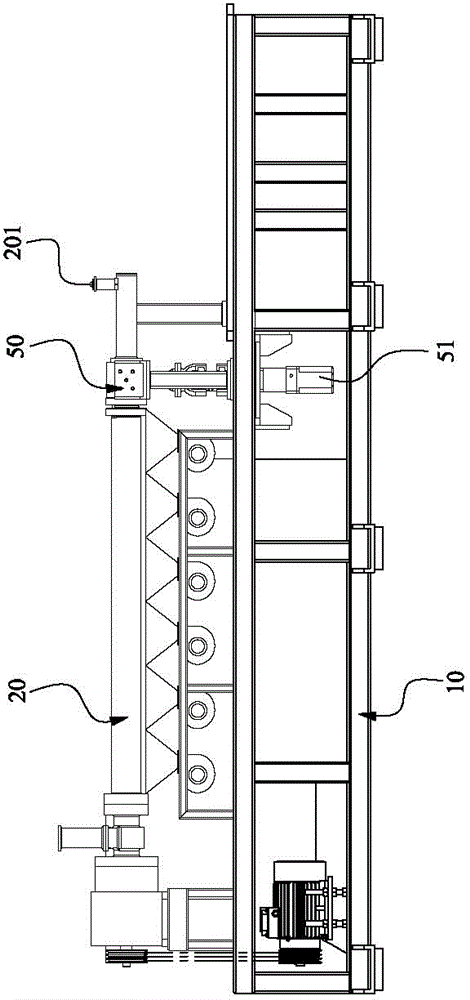

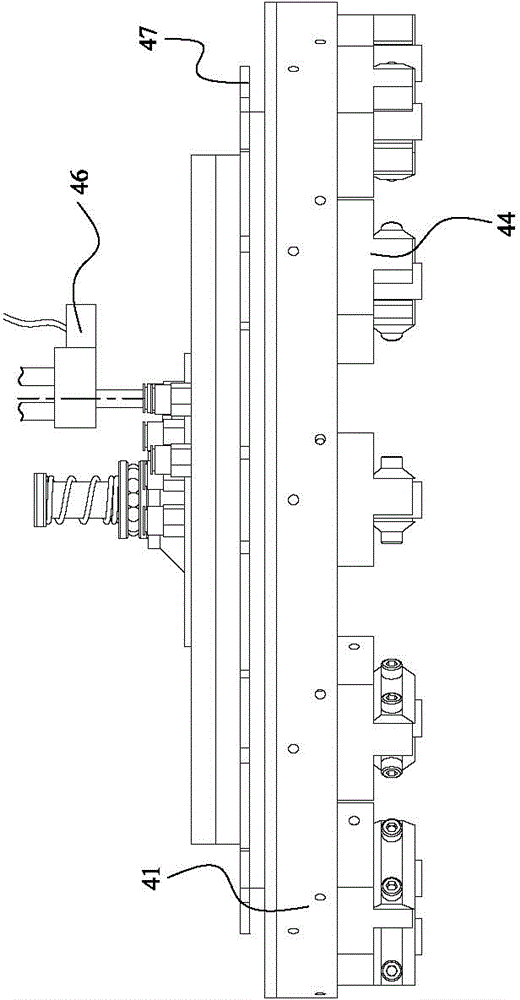

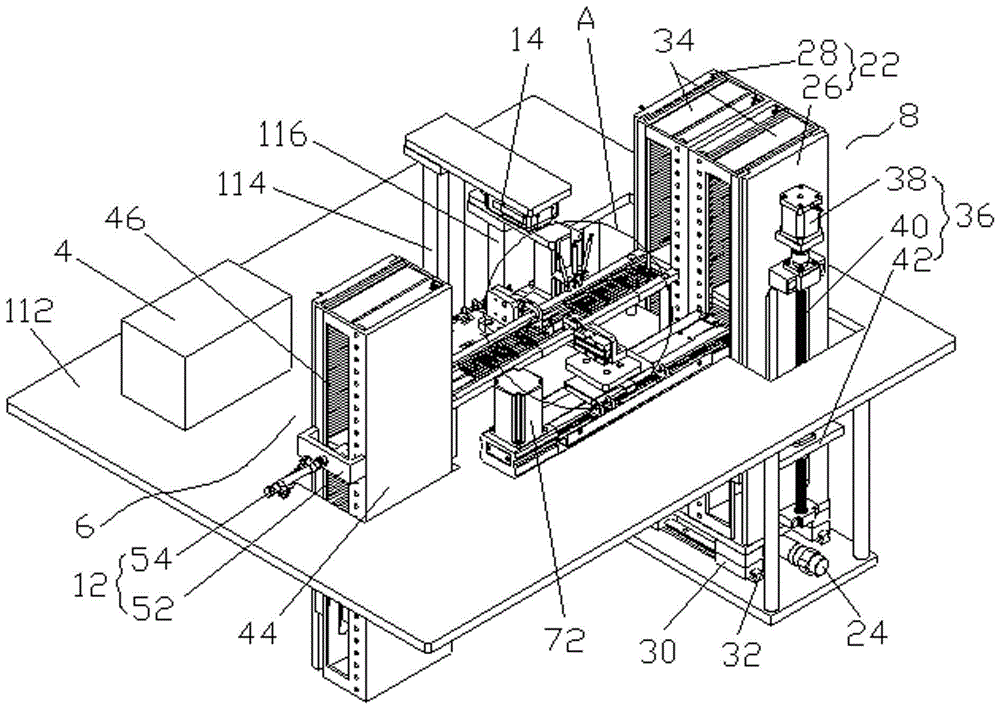

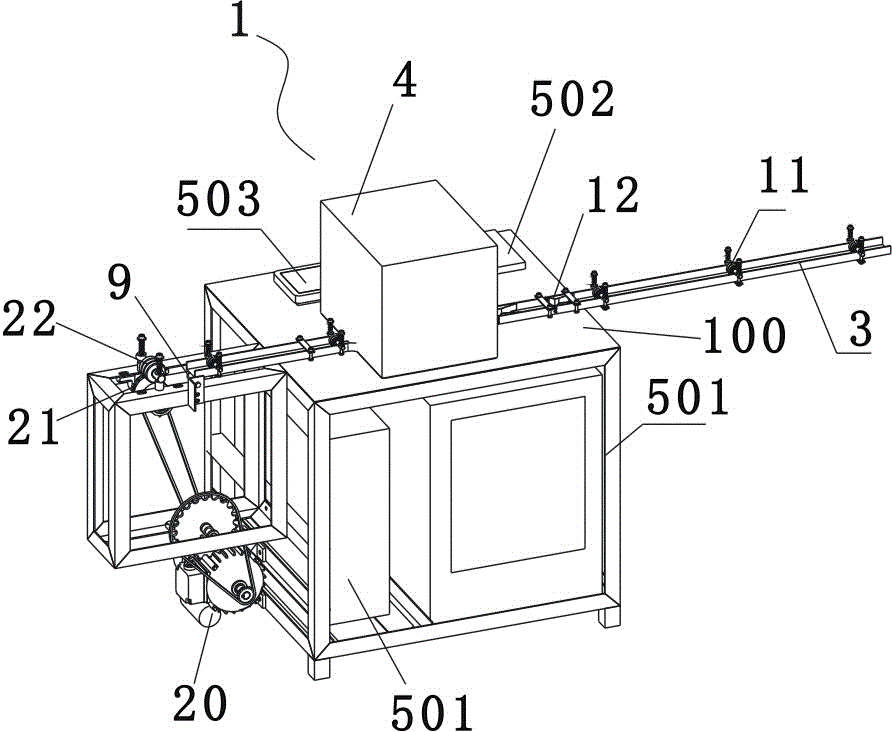

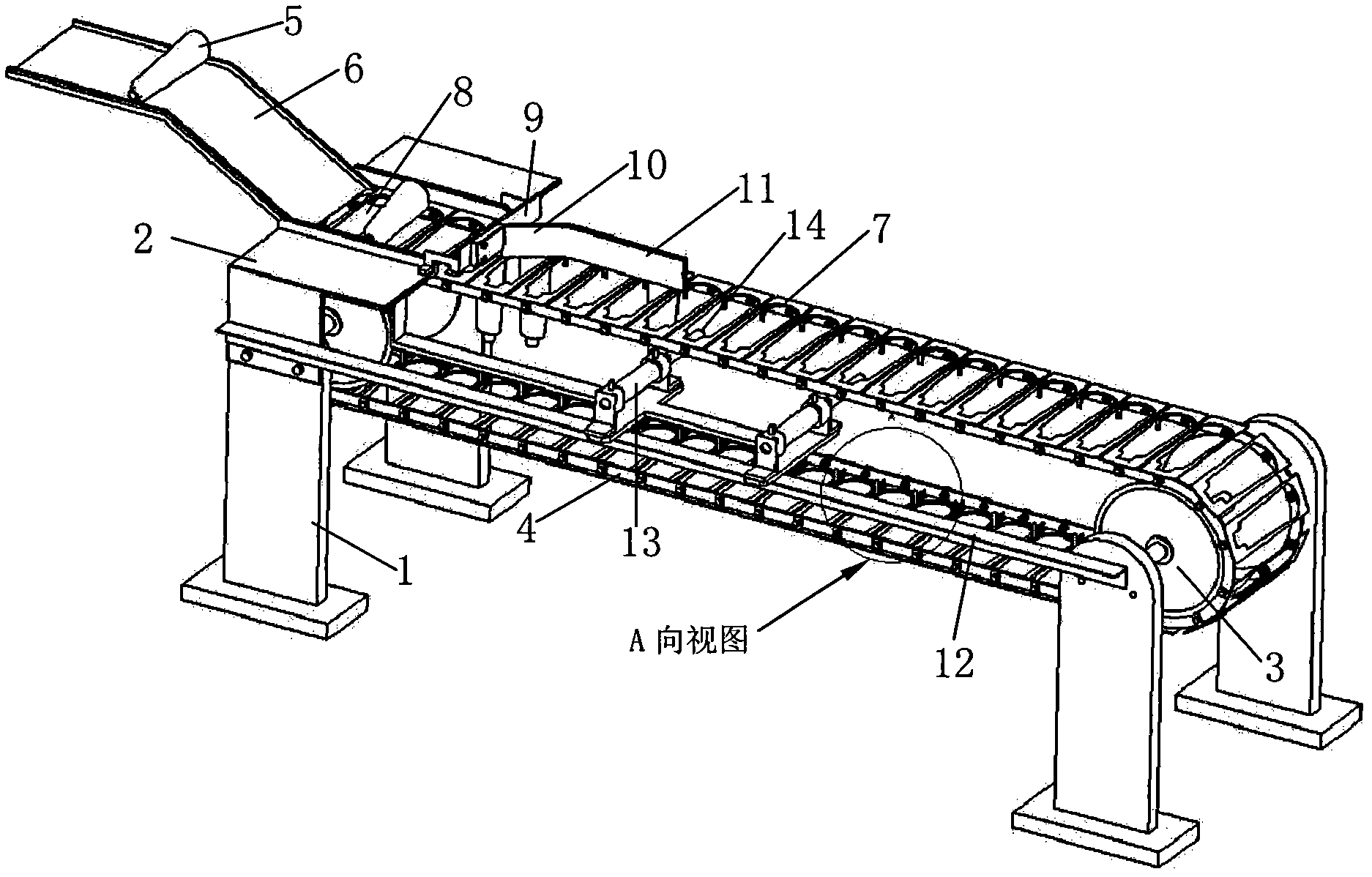

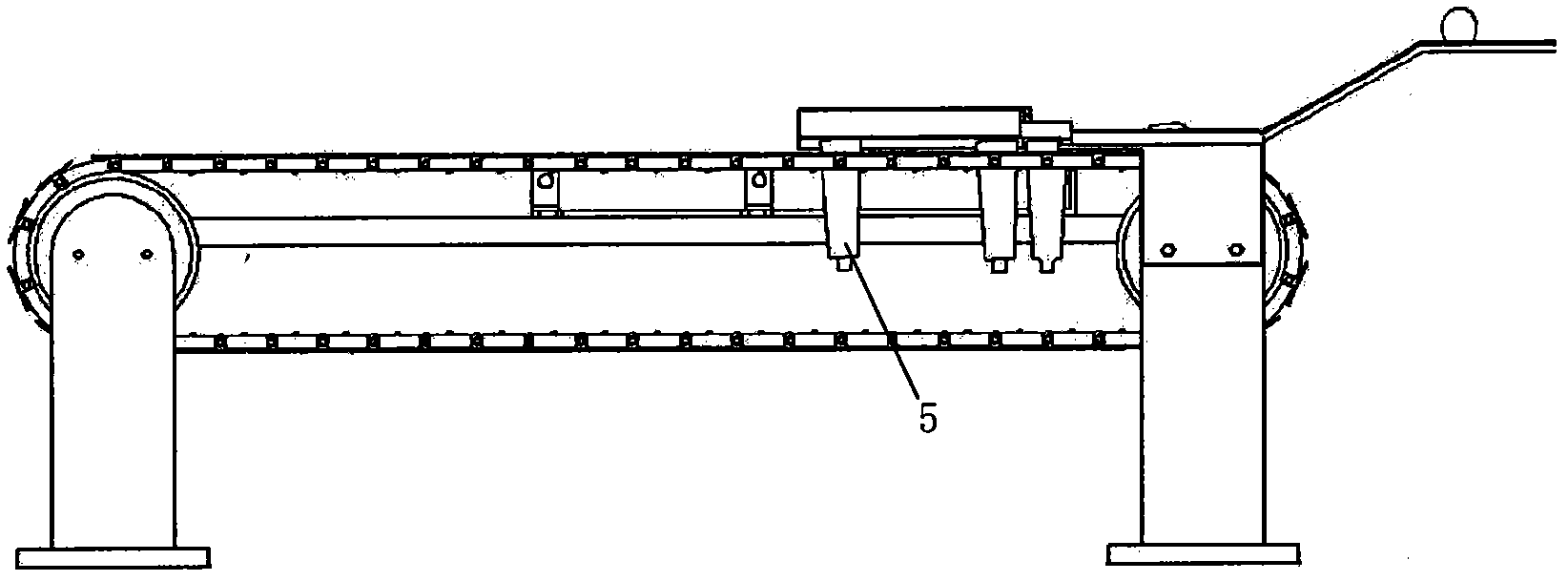

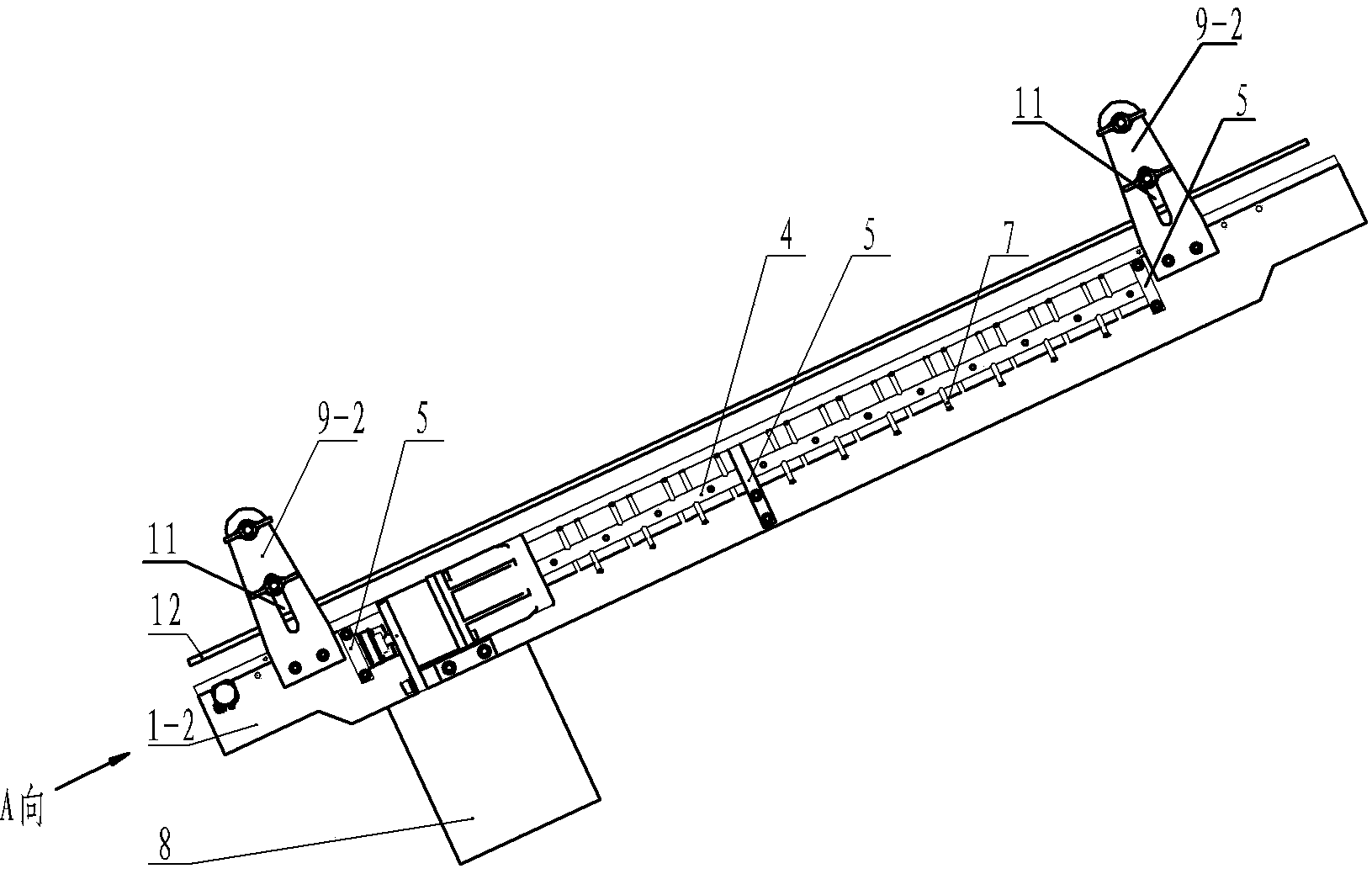

Batten sorting equipment and sorting method

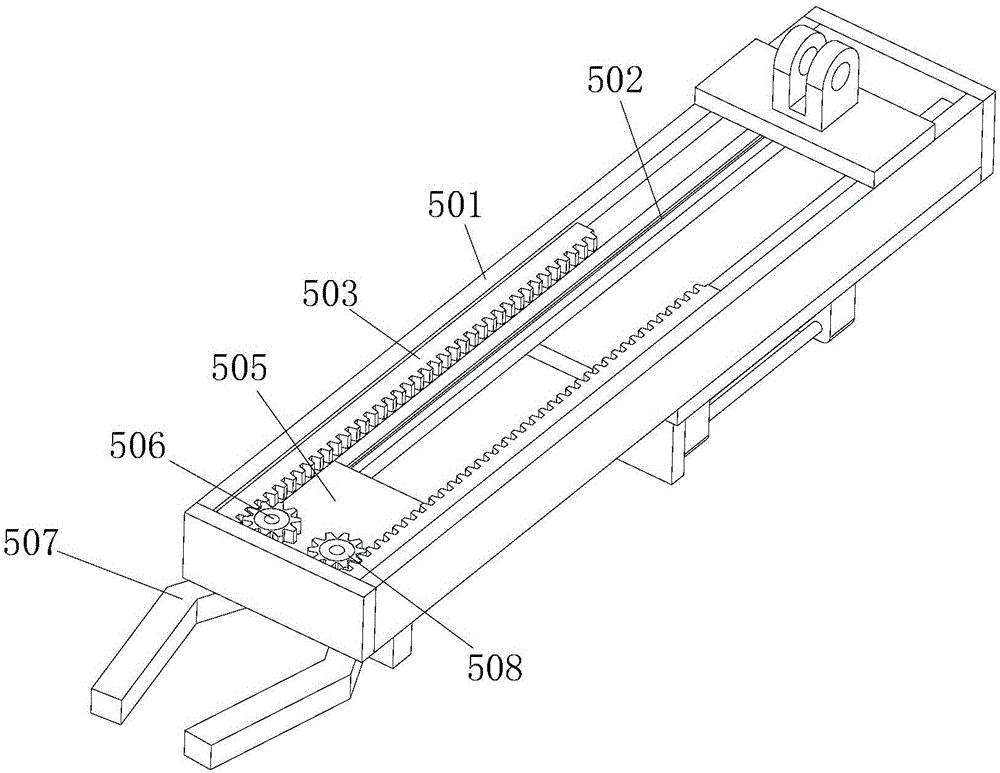

ActiveCN105363693AFully automatedGuarantee the quality of inspectionSortingElectricityProgrammable logic controller

The invention discloses a batten sorting equipment and sorting method. The batten sorting equipment comprises a controlling system, an inputting device and a sorting device, wherein the controlling system is electrically connected with the inputting device which is connected with the sorting device in a process; the sorting device comprises a rack, an accepting mechanism, a lifting mechanism and a classifying mechanism, the accepting mechanism is close to a traction end of an inputting channel, and the accepting mechanism is linked with the inputting channel in the process; the lifting mechanism comprises a lifting drive device. Battens can be preset into a plurality of classes by a PLC (programmable logic controller) in the controlling system, then detected data information is fed back to the controlling system through a visual detection box, then the controlling system controls the lifting drive device to lift corresponding battens to the heights corresponding to different classes, and accurate, efficient and automatic batten sorting work is realized.

Owner:HANGZHOU WEIYONG AUTOMATION TECH CO LTD

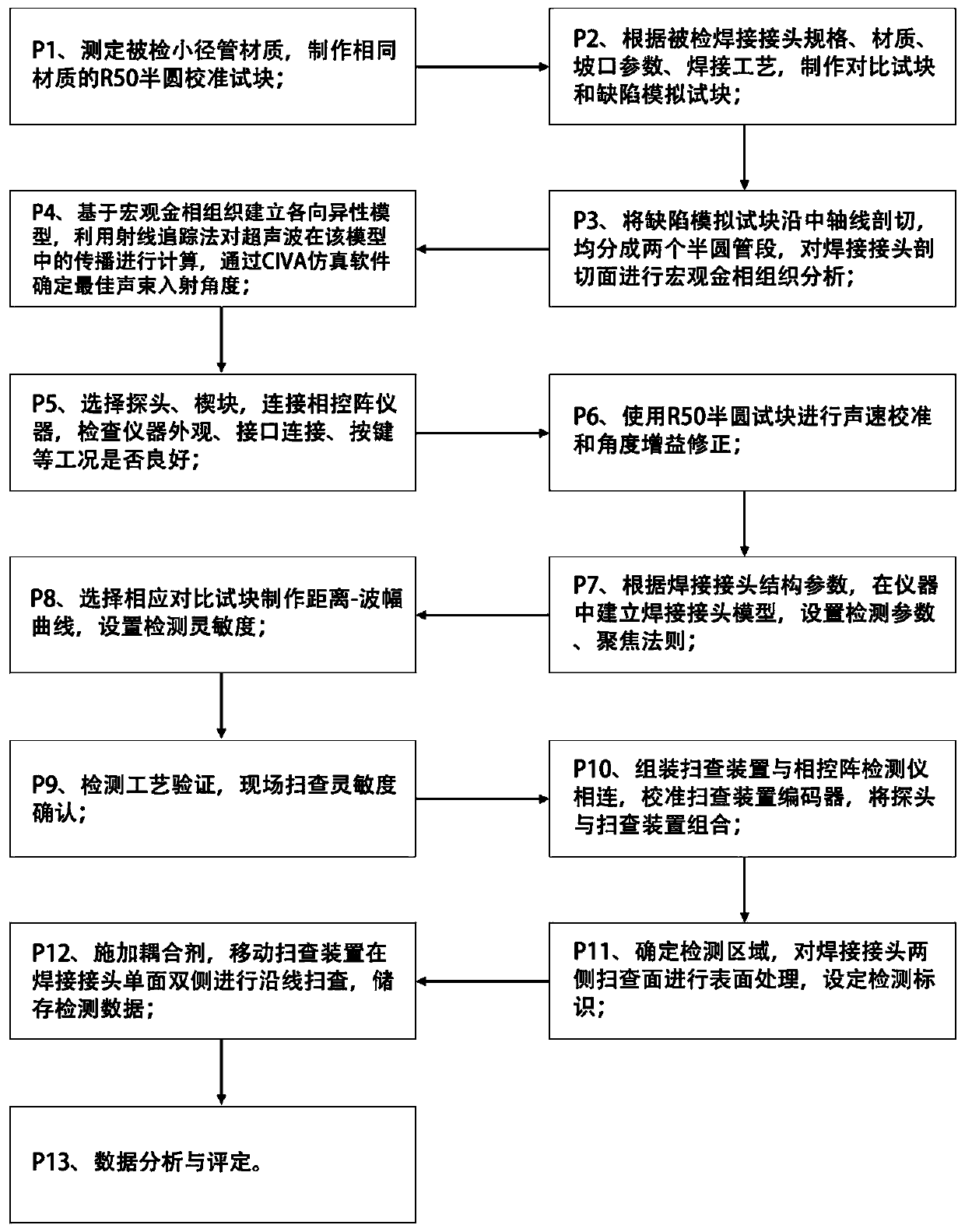

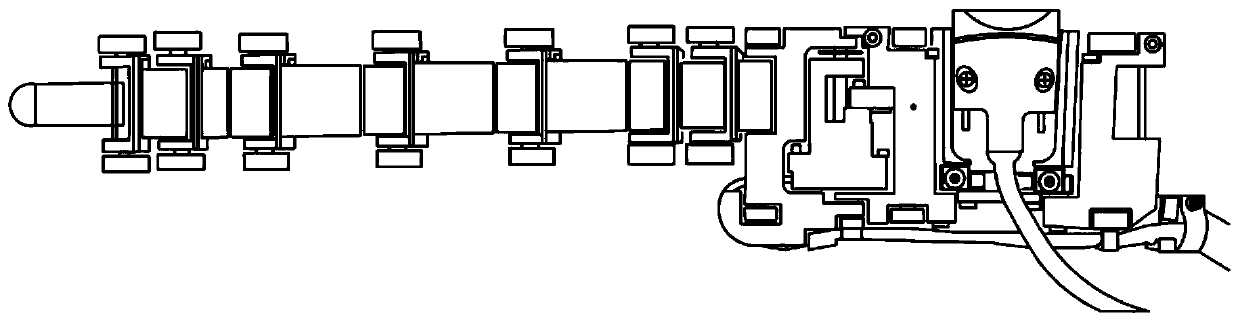

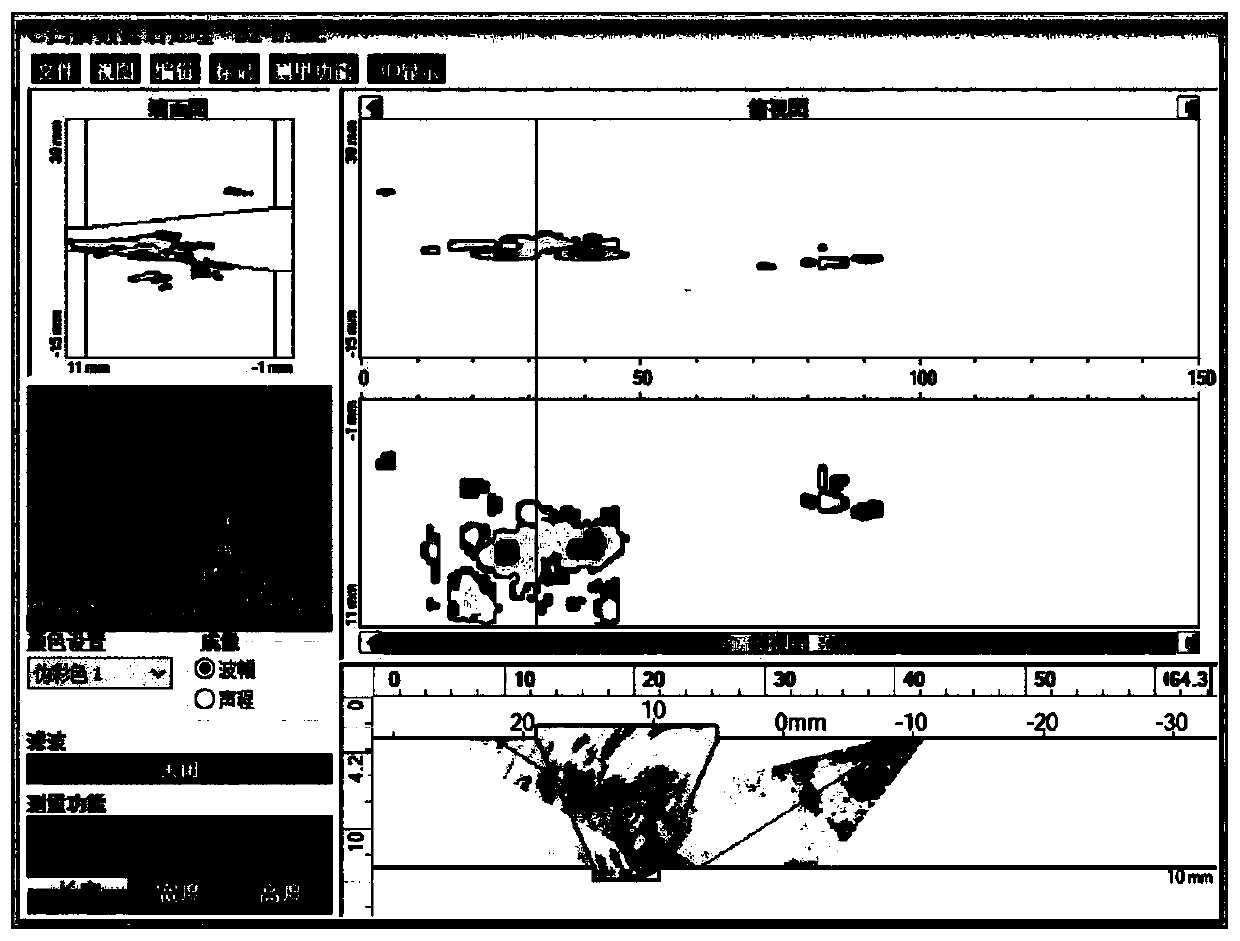

Phased array detection and evaluation method for austenitic stainless steel small-diameter pipe welding joint

PendingCN111537612AOptimizing Beam ParametersHigh detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalStructure analysisMetallurgy

The invention discloses a phased array detection and evaluation method for an austenitic stainless steel small-diameter pipe welding joint. The method comprises the steps of manufacturing a calibration test block; manufacturing a reference test block and a defect simulation test block; sectioning the defect simulation test block along the central axis, and carrying out metallographic structure analysis; establishing an anisotropic model, and determining an optimal acoustic beam incident angle; connecting a phased array instrument; carrying out sound velocity calibration and angle gain correction; establishing a welding joint model, and setting detection parameters; setting the detection sensitivity; verifying a detection process; assembling a scanning device; determining a detection area and carrying out surface treatment; applying a coupling agent, and scanning along the line; and conducting data analysis and evaluation. According to the method, the detection efficiency and precisionare improved, the detection quality of the austenitic stainless steel small-diameter pipe welding joint is guaranteed, and the radioactive source management risk and the detection cost are effectivelyreduced.

Owner:SHANDONG MECHANICAL ENG TESTING CO LTD

Bottle separation device

The invention discloses separation device capable of automatically separating filling bottles according to the spraying quality of bottle bodies. The separation device downwards overturns the bottles under own gravity of the bottles, sequentially arranges the bottles on a specially-designed bottle delivery device by clamping pieces and positioning pieces which are arranged subsequently so as to obtain high-quality bottle body spraying photos, evaluates the spraying quality by computer image processing technology and drives two separation cylinders to drive separation ejector rods to finish a bottle separation process. The device improves the separation efficiency on the premise of ensuring the separation quality.

Owner:SICHUAN UNIV

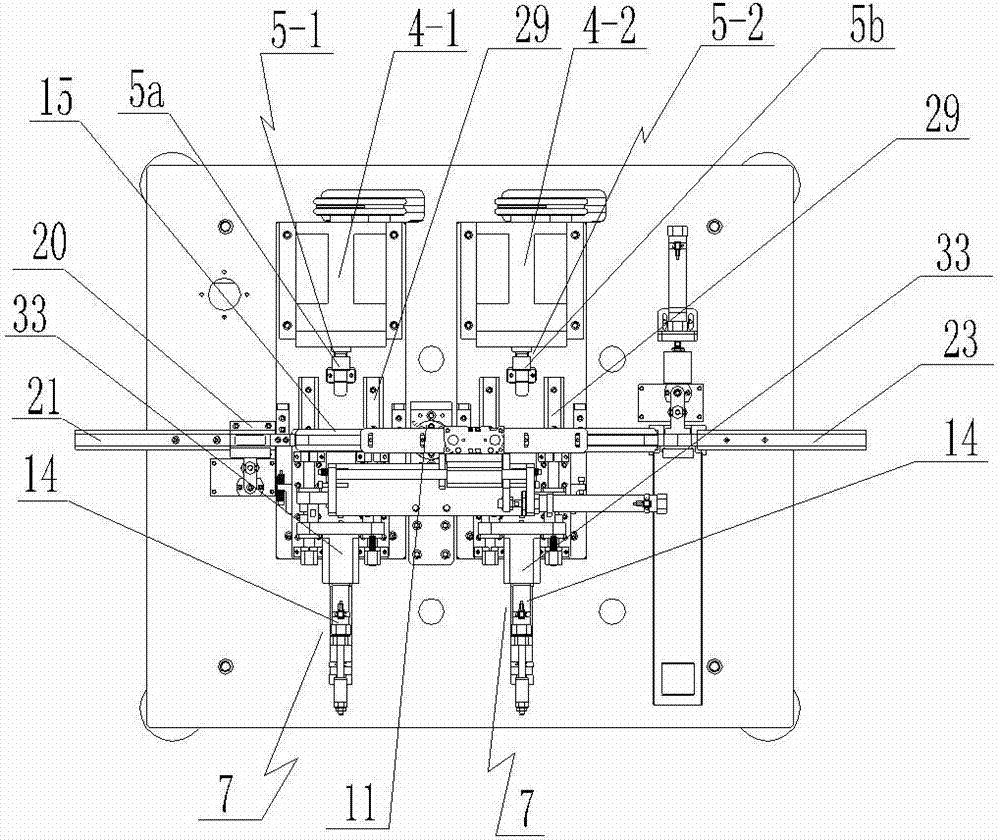

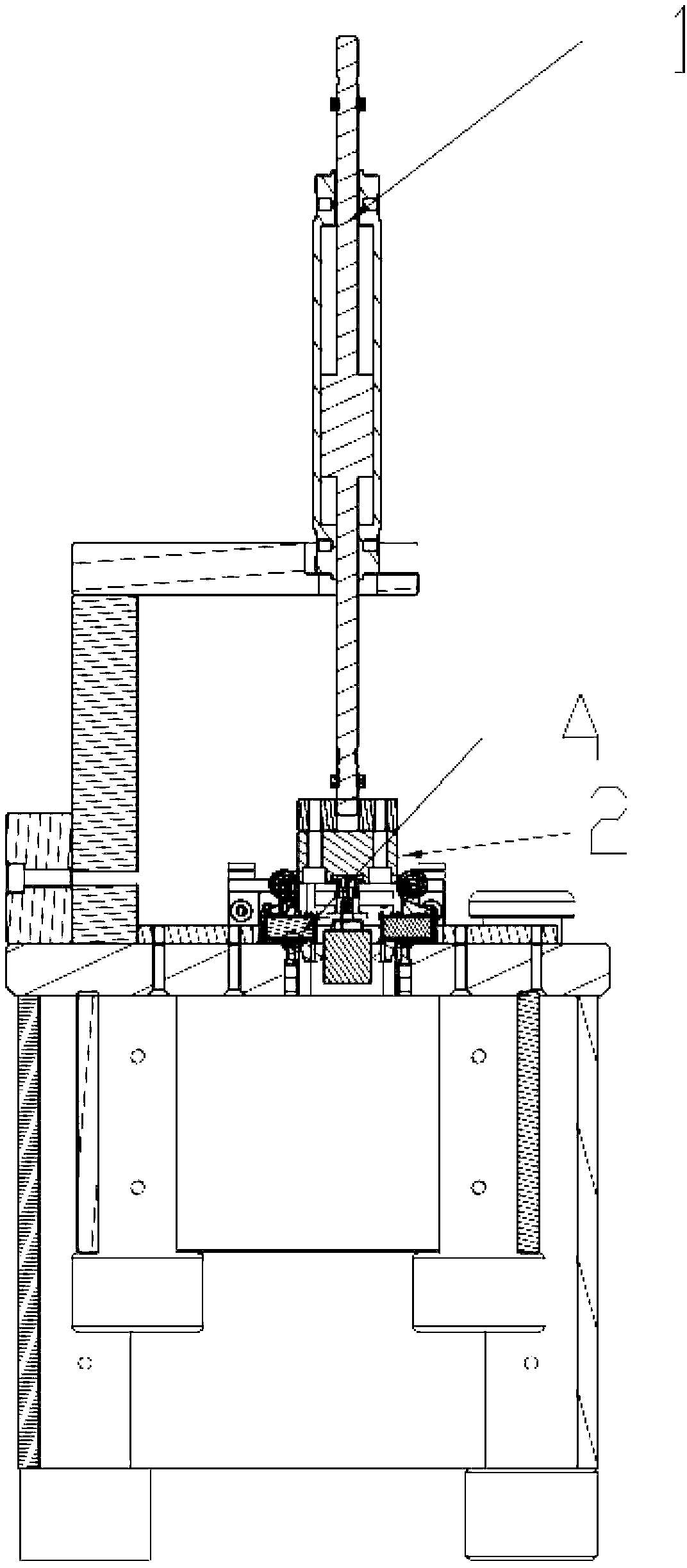

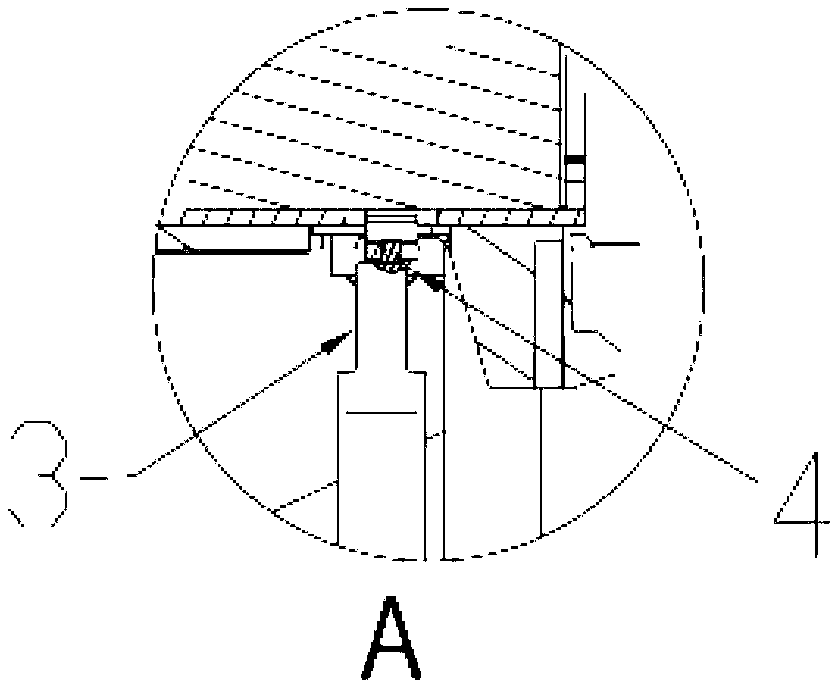

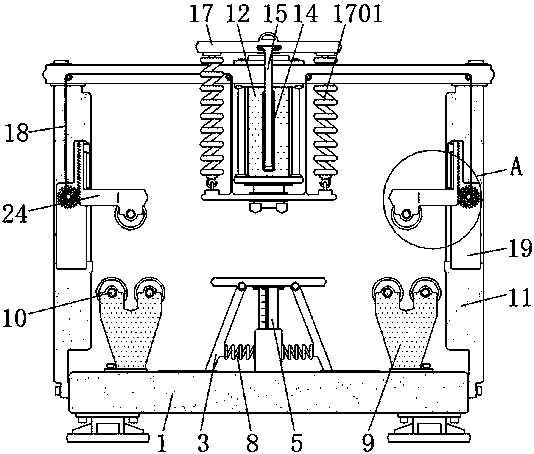

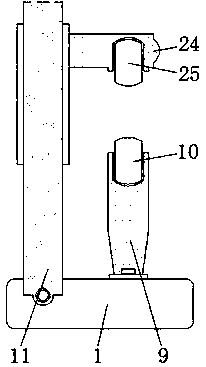

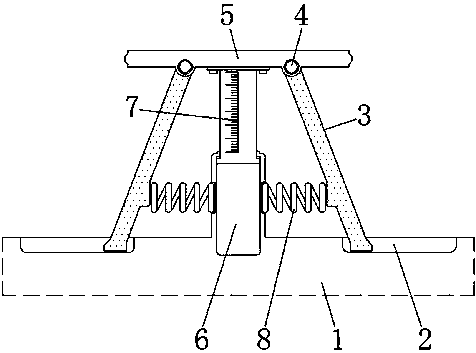

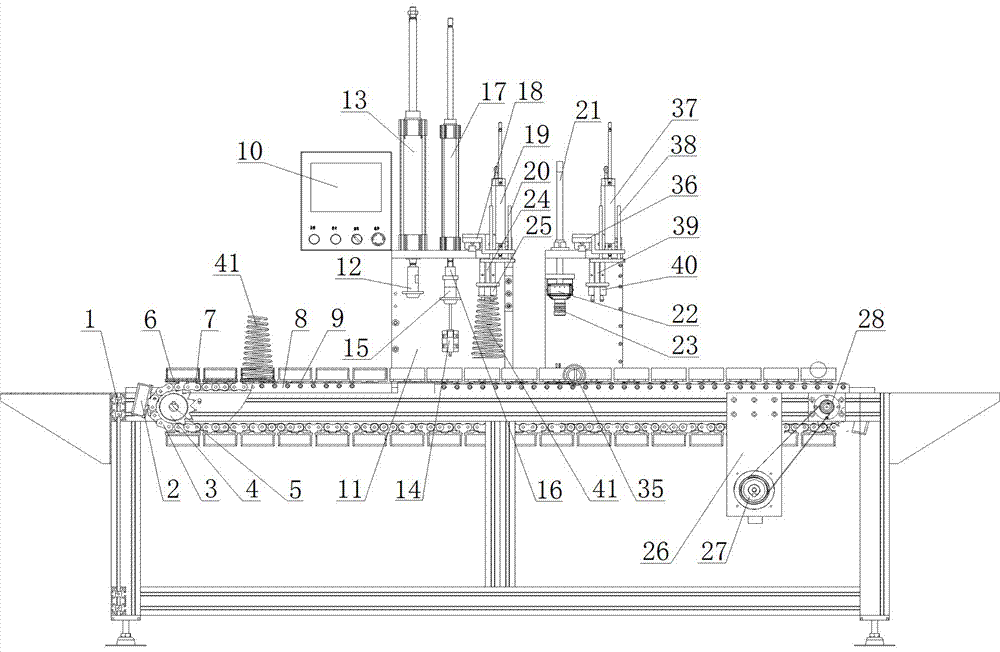

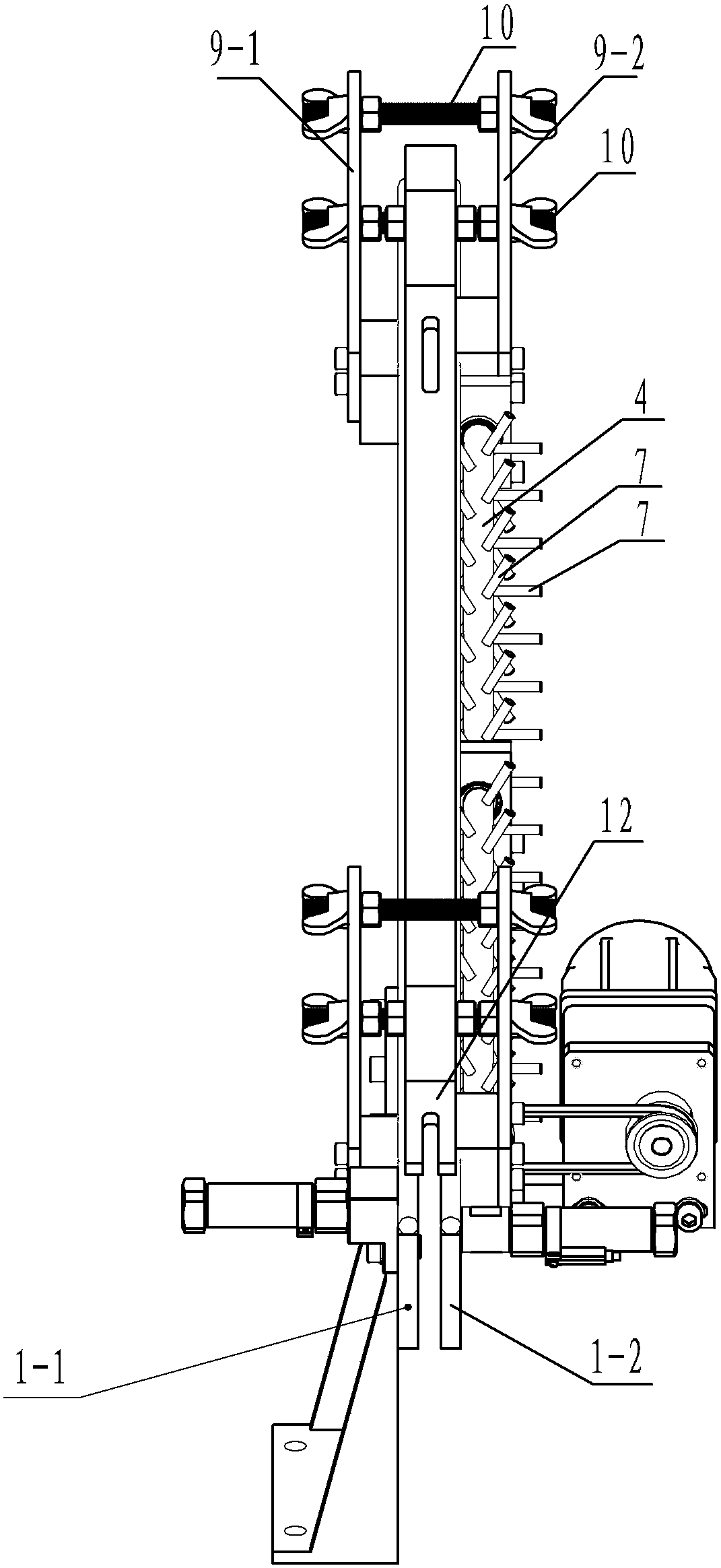

Conic spring pre-pressing and detecting all-in-one machine and detecting method thereof

PendingCN106964561AGuarantee the quality of inspectionSolve the technical problems of low detection efficiencyUsing optical meansApparatus for force/torque/work measurementProduction lineHuman–machine interface

The invention relates to a conic spring pre-pressing and detecting all-in-one machine and a detecting method thereof. The all-in-one machine comprises a workbench (1). Two sets of parallel conic spring conveying devices are mounted on the workbench (1). A pre-pressing detecting and disqualified product removing device and a concentricity detecting and disqualified product removing device are sequentially arranged corresponding to the conic spring conveying devices correspondingly from left to right along the workbench (1). Compared with the prior art, the conic spring pre-pressing and detecting all-in-one machine has the beneficial effects that a man-machine interface and PLC control are adopted, the two sets of conic spring conveying devices are arranged on the workbench at the same time, and a continuous, efficient and high-quality conic spring dual-station semi-automatic detection flow production line can be achieved in the manner of integrating pre-pressing and detecting through man-machine integration; the work of detecting conic spring mechanical performance parameters is achieved mainly through the detecting method of pre-pressing, moment and height detection and judgment and concentricity detection and judgment; operation is simple and convenient; the safety coefficient is high; and detection efficiency is high.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

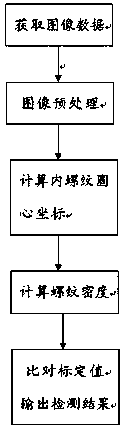

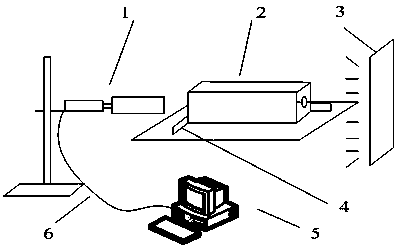

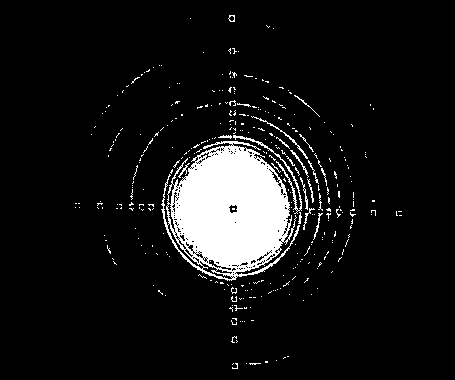

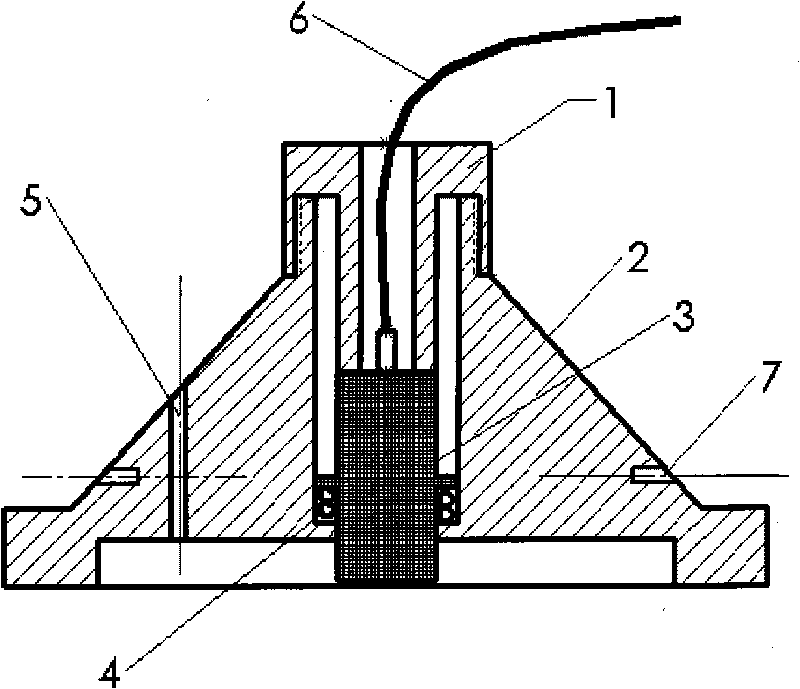

Internal thread detection method and system based on machine vision

ActiveCN109341570AImprove detection efficiencyReduce testing costsUsing optical meansMachine visionOperability

The invention discloses an internal thread detection method and system based on machine vision. The method and the system obtain a complete image of the internal thread through an industrial camera, upload the image data to an upper computer, and complete the internal thread parameter detection by running a detection algorithm in the upper computer. Multiple detection items such as internal threadparameter detection, central offset judgment, coarse tooth / fine tooth distinguishing and the like can be completed by one-time imaging. The detection method of the invention is reasonable and simple,has high operability and detection efficiency, the detection quality is guaranteed; the detection system is high in flexibility, low in cost and suitable for wide popularization and application.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

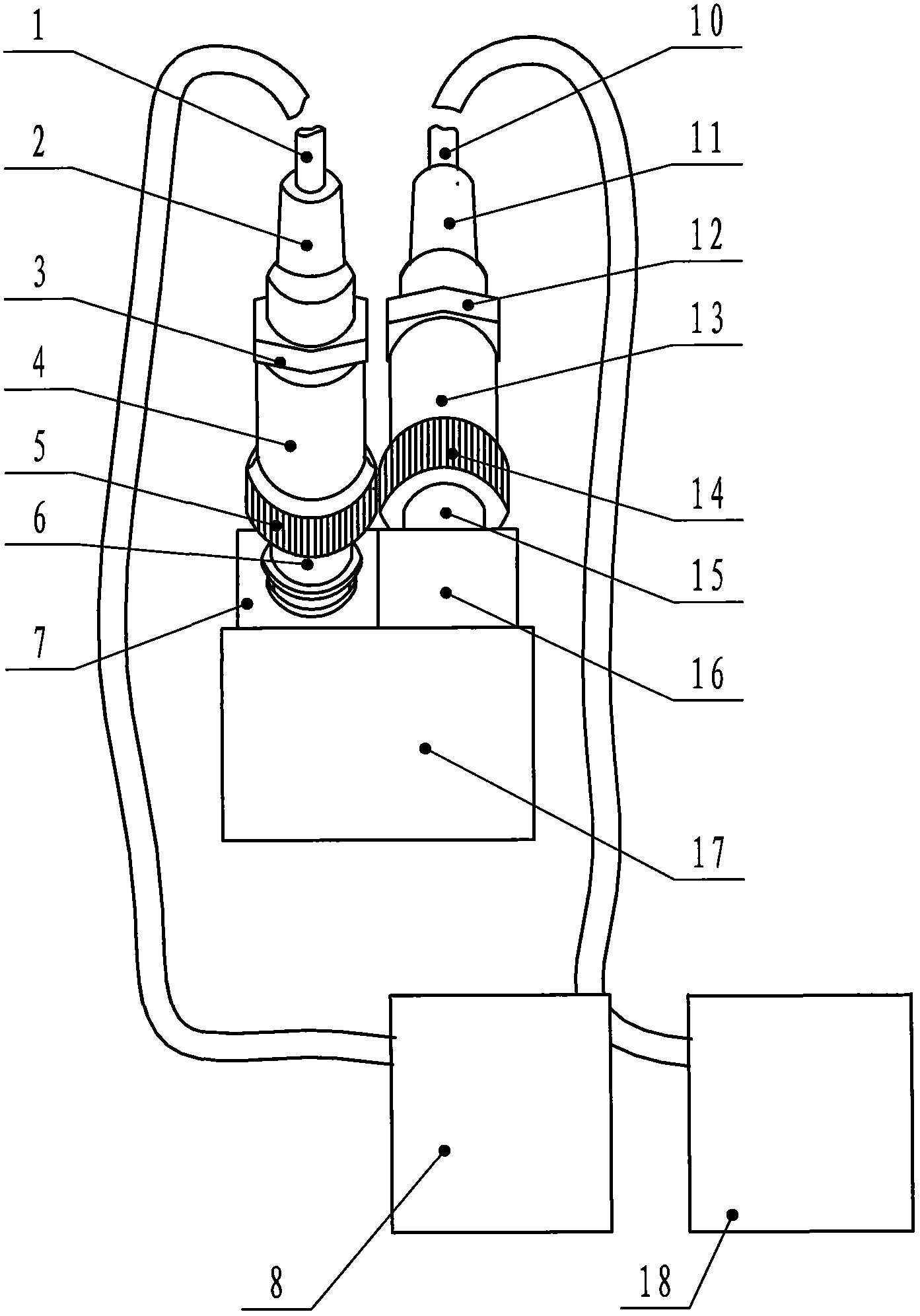

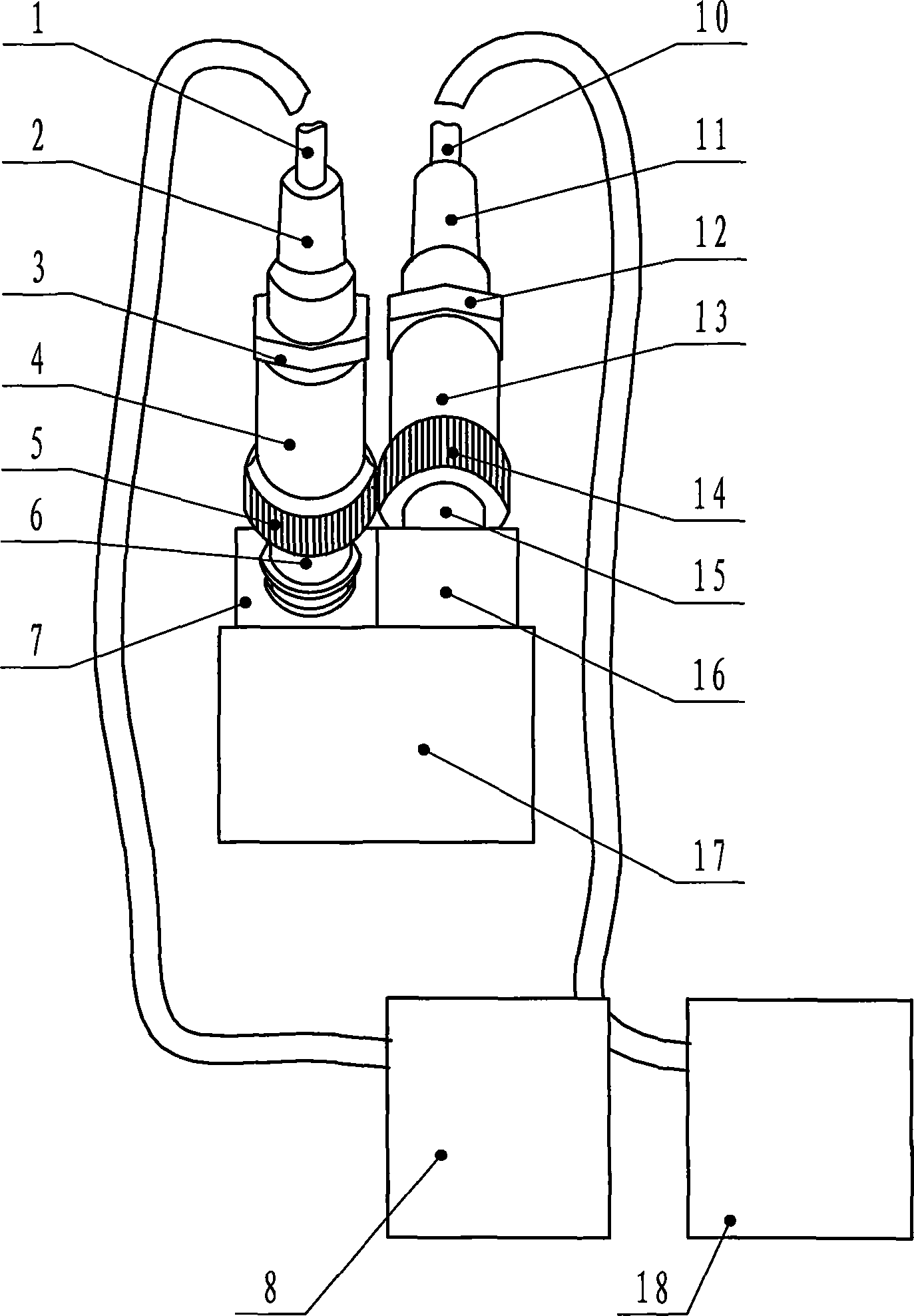

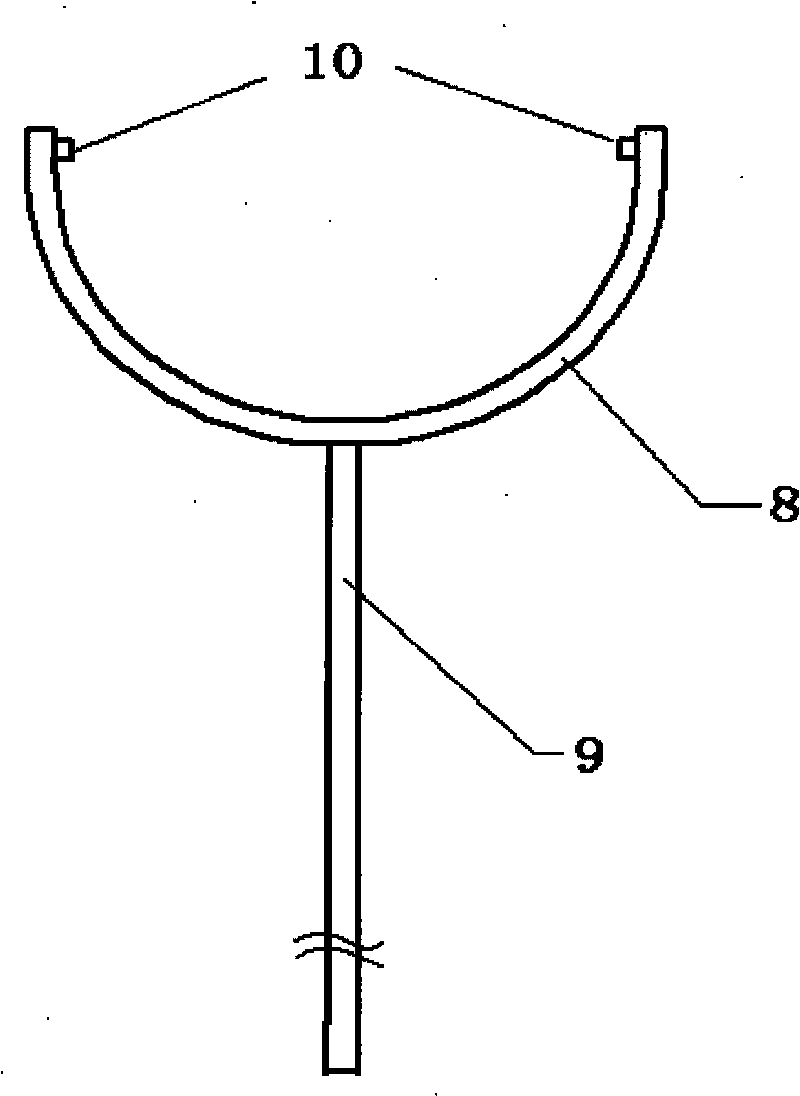

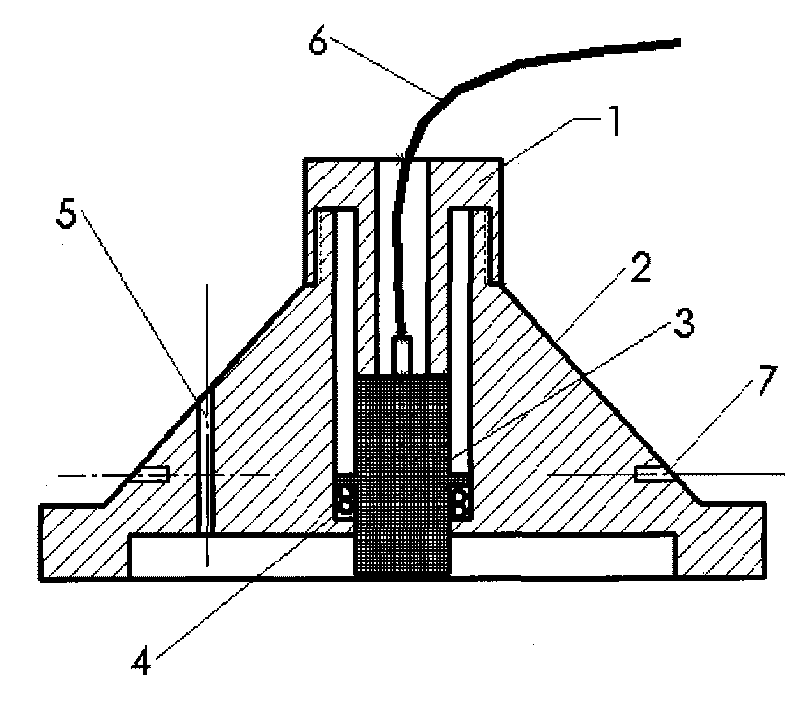

Ultrasonic flaw detection auxiliary device and operating method thereof

InactiveCN101694482AIncreasing the thicknessWeight increaseMaterial analysis using sonic/ultrasonic/infrasonic wavesSheet steelCoupling

The invention discloses an ultrasonic flaw detection auxiliary device and an operating method thereof. The device comprises a shell, a clamping cap and a spring, wherein the shell is cone-shaped, and the center of the shell is provided with a round hole provided with a probe; the spring is positioned on a platform at the bottom of the round hole; and the clamping cap is arranged at the upper part of the shell in a way of threaded connection. The operating method comprises the following steps: arranging the probe connected with a cable inside the round hole of the shell and pressing the probe on the spring; and then, screwing the clamping cap, and adjusting the contact gap between the probe and the surface of a steel plate by the pressure of the pressured spring and the adjusting action of the clamping cap, so that the best thickness of a coupling layer required by detection can be reached. As the contact gap between the probe and the surface of the steel plate can be adjusted by the pressure of the pressured spring and the adjusting action of the clamping cap, the invention can control the best thickness of the coupling layer required by detection. The shell has heavier weight and larger size, so that the stability of the flaw detection auxiliary device can be ensured in the process of flaw detection scanning of the steel plate.

Owner:CHINA FIRST HEAVY IND +1

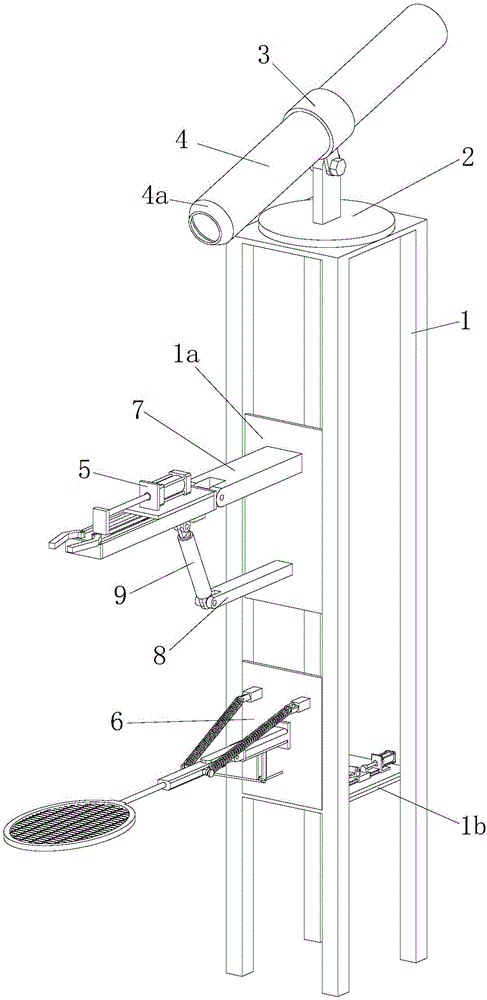

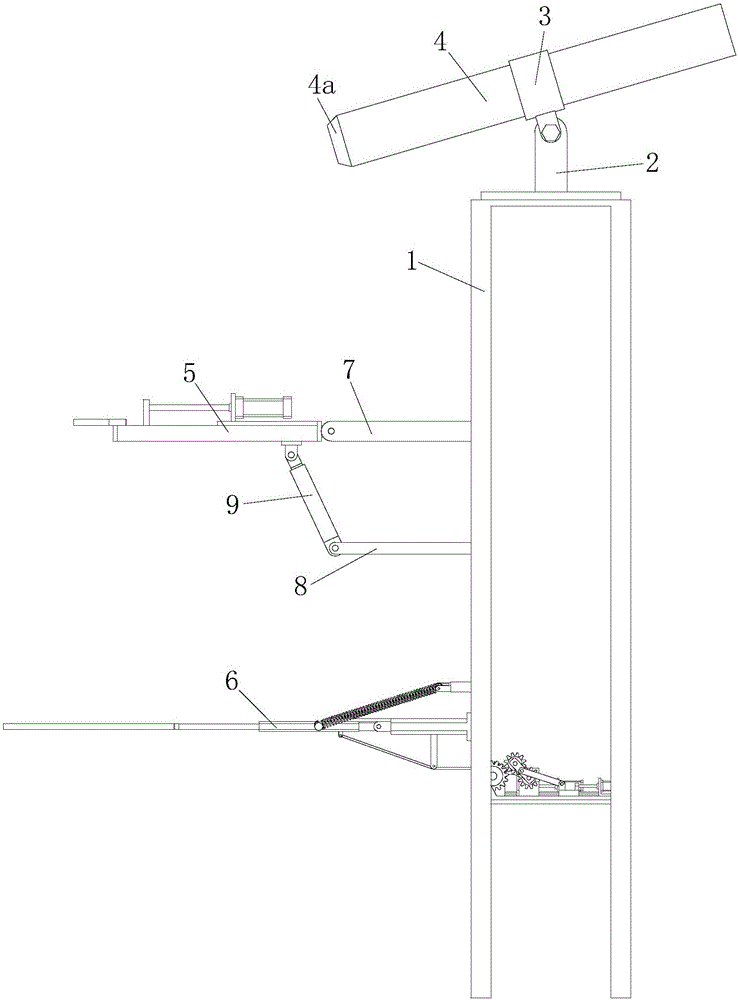

Badminton detector

ActiveCN105091933AImplement automatic detectionImprove detection efficiencyMeasurement devicesHydraulic cylinderEngineering

The invention discloses a badminton detector including a supporting frame. The top end of the supporting frame is equipped with a supporting platform. The top of the supporting frame is equipped with an O-shaped fixed ring. A badminton storage barrel is fixed to the inner wall of the O-shaped fixed ring. The bottom of the badminton storage barrel is provided with a frustum. A vertical plate is arranged in the middle of the supporting frame. A wide bracket is arranged at the upper end of the vertical plate, and a gripping device is fixed to the front end of the wide bracket. A short bracket is arranged at the lower end of the vertical plate, and a hydraulic cylinder is fixed to the front end of the short bracket. A transverse plate is arranged below the vertical plate, and a badminton hitting device is fixed to the upper end of the transverse plate. The badminton detector has the advantages of reasonable structure design, easy use, and the like. With the device, badmintons can be detected automatically, and manual detection is replaced by automatic detection. The badminton detector has a high degree of automation. The efficiency of badminton detection is improved, and manpower and resources are saved. By using the badminton hitting device to hit badmintons, the flying speed of badmintons and the quality of badminton detection are ensured.

Owner:ANHUI PROVINCE WUWEI COUNTY ZHENGDA FEATHER PROD

Method for detecting local moulded surface of component using hot melt adhesive

InactiveCN102445163AImprove cohesive strengthPrevent crystallizationUsing optical meansKeroseneHot-melt adhesive

The invention discloses a method for detecting a local moulded surface of a component using hot melt adhesive, wherein the method comprises the following steps of: (1), coating kerosene or lubricating oil on the surface of the moulded surface of a component to be detected; (2), heating up the hot melt adhesive to be paste, coating the paste to the surface of the moulded surface of the component to be detected; taking down the surface and slicing after stewing, and using a projector to detect. The method in the invention can save the detecting cost by more than 50%; the method is simple, the sizing time is short, the detecting precision is high, and the method can be applied to the detecting technology of all component local moulded surfaces, thus the detecting efficiency can be improved by more than 60% while the detecting quality is ensured.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method and device for confirming irradiation orientation of pressure container weld seam ray detecting ray bundle

InactiveCN101034072AReduce wasteGuarantee the quality of inspectionFluid-tightness measurementMaterial analysis by transmitting radiationClassical mechanicsWeld seam

This invention relates to a method and device of ascertain ray bundle transillumination azimuth of pressure container seam ray detecting. The invention base on the tangent length theorem and angle bisector theory in geometry, and adopt color Laser Beam emitted by minitype laser display. first lock locating Laser Beam at pressure container weld external transillumination point, regulate dimensional orientation of ray handpiece, make locating Laser Beam facula connecting line partly plumb and parallel with weld; at the same time orient Laser Beam's facula partly locate at equidistant position of both sides of transillumination point locating Laser Beam's facula; finally fixing dimensional orientation of ray handpiece, moving away orient laser display, carrying out ray detection without obstacle. Adopting this invention, detecting person can base on shape trait of pressure vessel and weld, utilize the position , space and such on information of beam spot that laser formed at pressure vessel surface, to ascertain dimensional orientation of transillumination ray bundle, thereby guarantee detecting quality, advance work efficiency, decrease film wasting.

Owner:CFHI DALIAN HYDROGENANT REACTOR

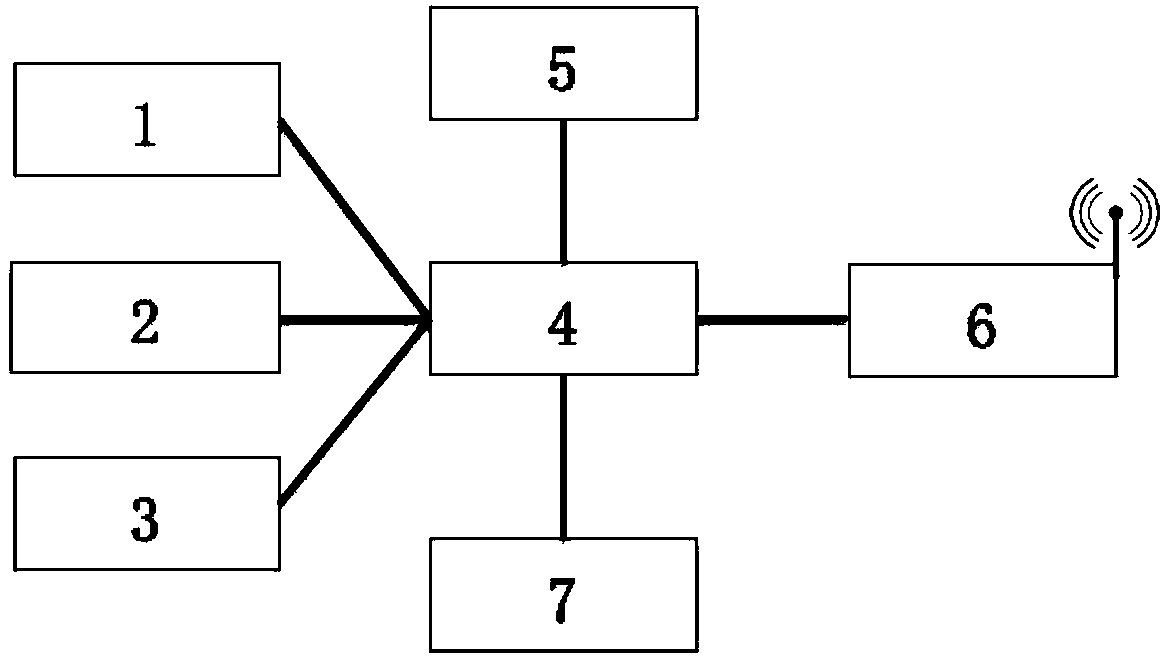

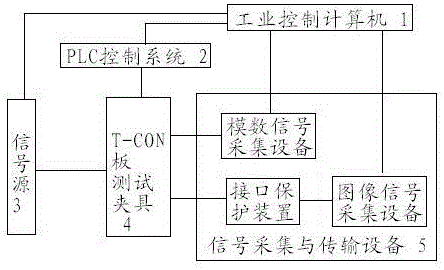

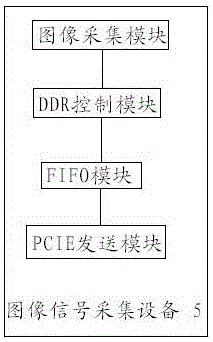

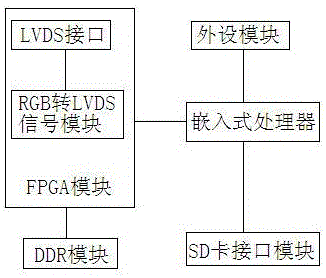

Labview-based multi-type signal online testing system

InactiveCN105161039AFully automatedAccurate and intuitive test resultsStatic indicating devicesControl systemCons

The invention discloses a Labview-based multi-type signal online testing system, which comprises an industrial control computer (1), wherein the industrial control computer (1) is respectively connected with a PLC control system (2) and a signal source (3), the PLC control system (2) is connected with a T-CON board testing fixture (4), the T-CON board testing fixture (4) is connected with signal acquisition and transmission equipment (5), and the signal acquisition and transmission equipment (5) is connected with the industrial control computer (1) through a data line; and the industrial control computer (1) is used for processing image signals and analog-digital signals which are output by a T-CON board to be tested and acquired by the signal acquisition and transmission equipment (5), comparing the processed signals with standard values, and judging whether the T-CON board to be tested is qualified or not through comparative results. According to the Labview-based multi-type signal online testing system, the T-CON board is tested automatically so that the testing results are more precise and direct, the production efficiency is improved and the missing test ratio is reduced.

Owner:NANJING PANDA ELECTRONICS MFG

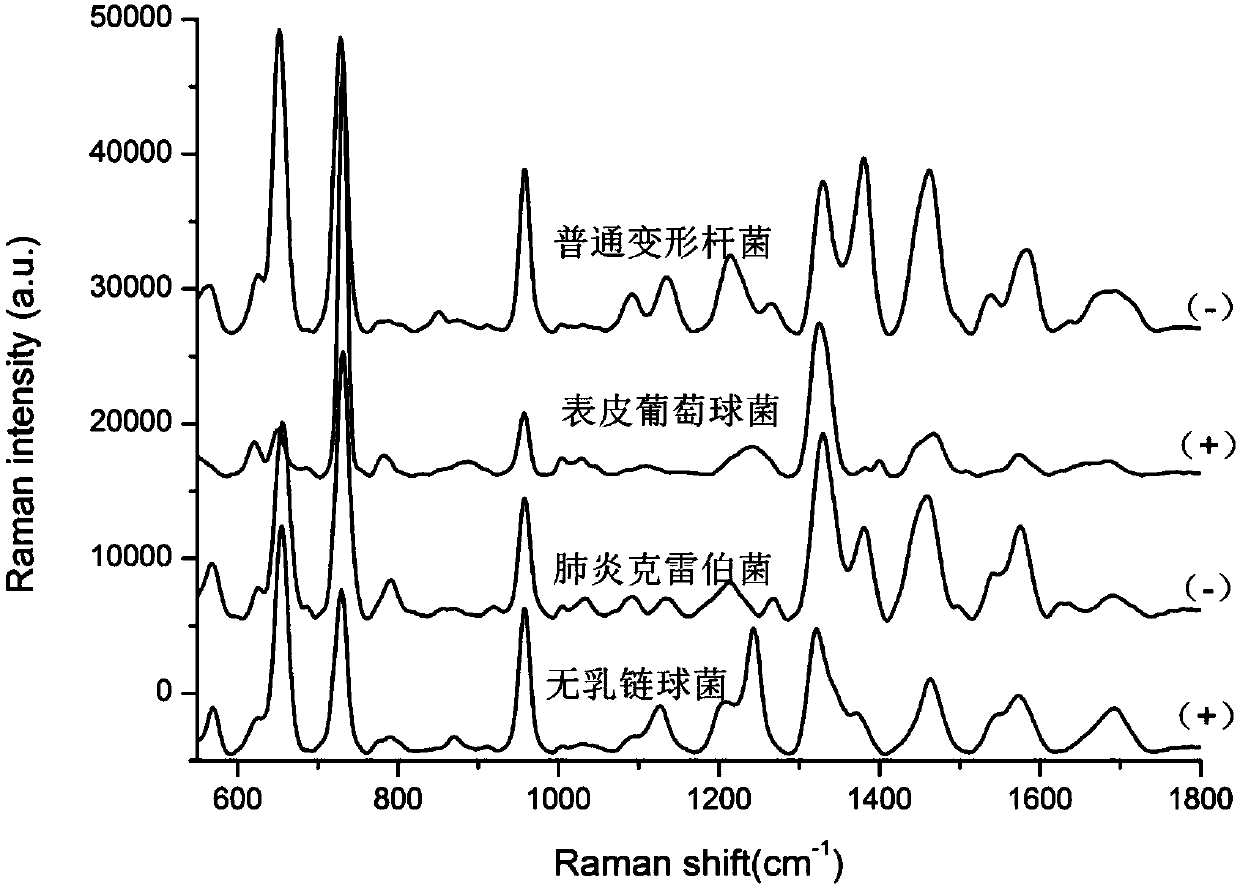

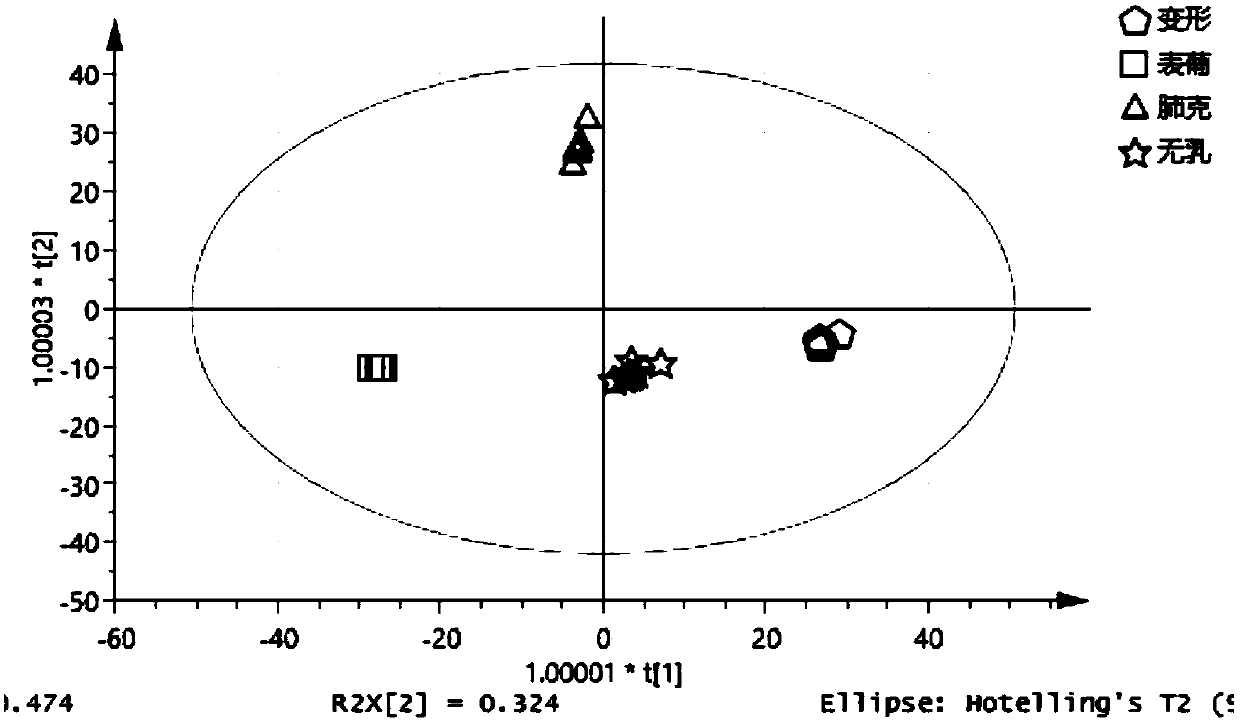

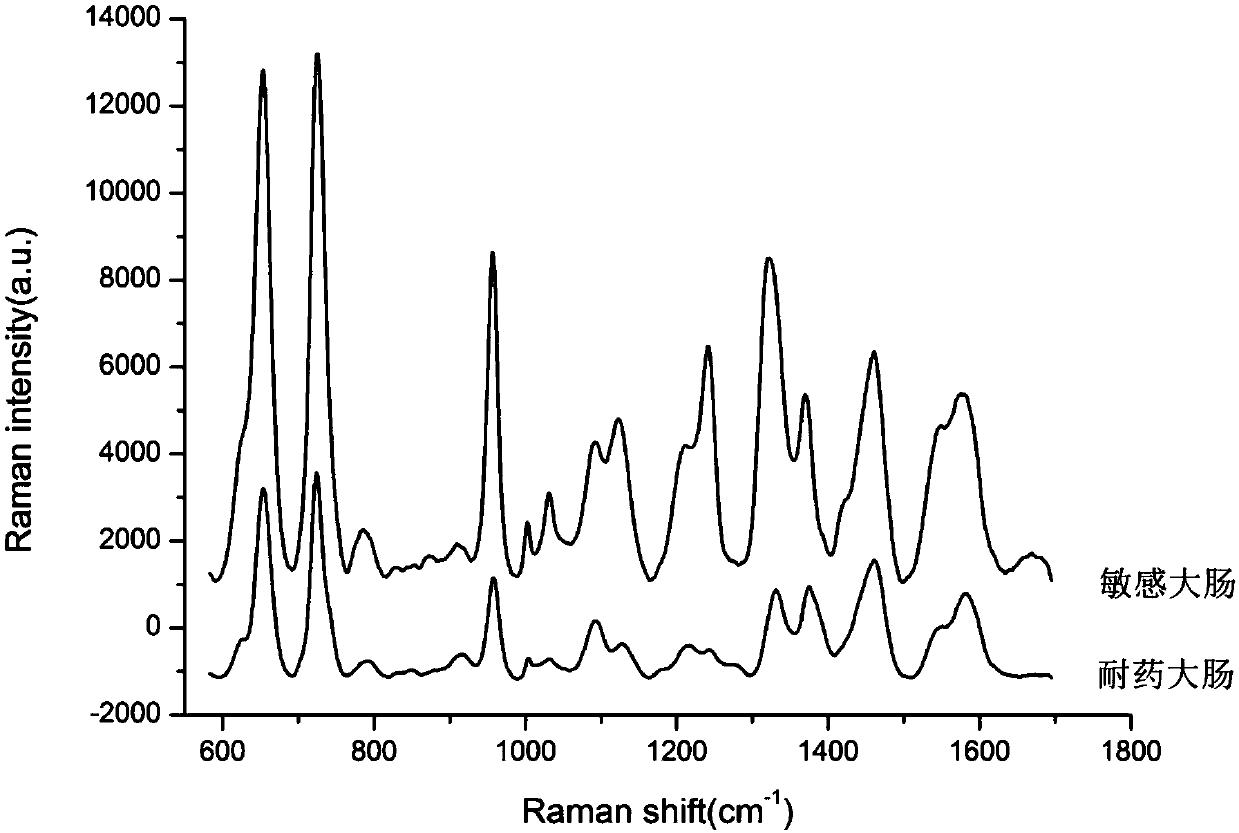

Rapid identification method for carbapenem drug susceptibility, based on Raman spectra technology

InactiveCN107586823AReduce dosageShort detection timeMicrobiological testing/measurementRaman scatteringStructure analysisRapid identification

The invention relates to a rapid identification method for carbapenem drug susceptibility, based on a Raman spectra technology. According to the method, a portable Raman detector is adopted, pathogenic bacteria to be detected is irradiated through laser, different types of nanostructures are taken as detection substrates, and scattered spectrum, the frequency of which is different from the frequency of incident light, is analyzed, so that information, such as molecular vibration, of a sample to be detected is obtained, corresponding molecular structure analysis is performed, obtained spectroscopic data of carbapenem drug sensitive bacteria and drug-resistance bacteria is analyzed through a chemometrics method, so that drug-resistance bacteria and sensitive bacteria are distinguished, and the method becomes an ultrasensitive pathogenic bacteria rapid detection tool. Compared with the clinically traditional drug sensitivity pathogenic microorganism detection method, the detection technology has the advantages that the quantity of samples is less, the detection time is short, the sensitivity is high, the detection time of clinical samples is shortened, and particularly as for detection samples with complex chemical and biochemical components, the detection efficiency is improved on the basis that the detection quality is guaranteed.

Owner:XUZHOU MEDICAL UNIV

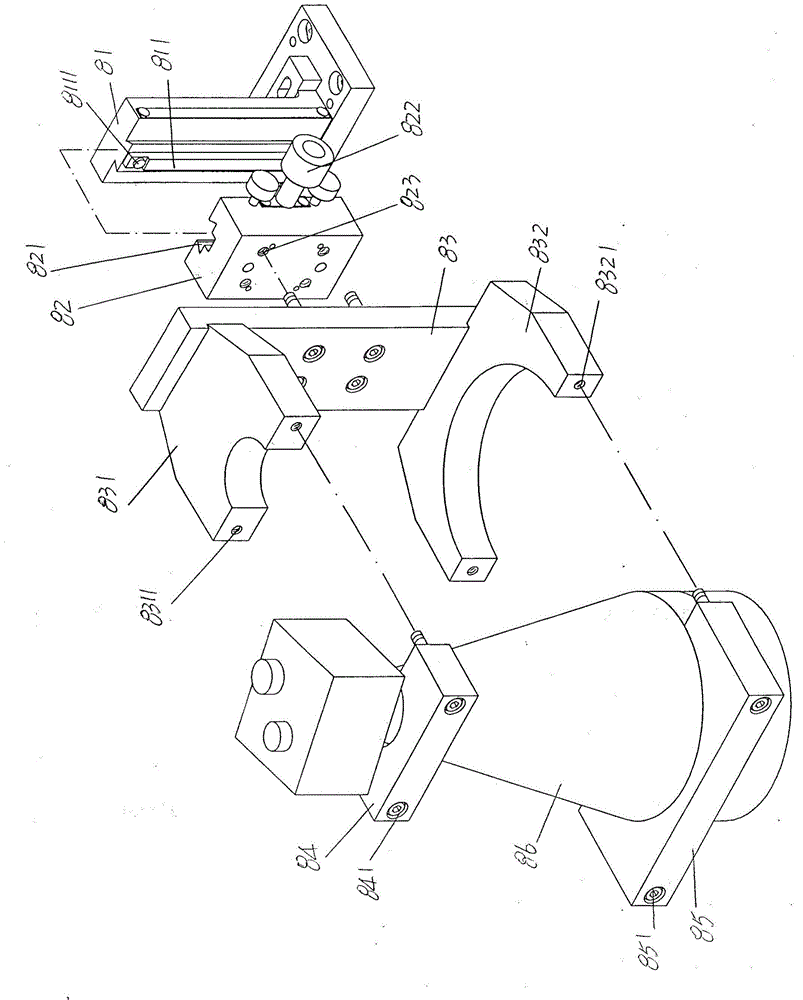

Mechanical arm used for propeller boss detection

ActiveCN104802170AReduce work intensityGood automation effectMeasurement devicesManipulatorPropellerEngineering

The invention discloses a mechanical arm used for propeller boss detection and belongs to the technical field of automated machines. The mechanical arm comprises a detecting worktable, a lifting beam, a lifting beam driving acting cylinder, a mechanical arm moving beam driving mechanism, a mechanical arm moving beam, a top plate, a plug track lifting mechanism, an overlook photographic mechanism and a horizontal photographic mechanism, wherein a guide rail stand column bottom plate and a main stand column bottom plate are fixed on the detecting work table; a left guide rail stand column is fixed at the left end of the guide rail stand column bottom plate while a right guide rail stand column is fixed at the right end of the guide rail stand column bottom plate; a lifting beam left sliding guide rail is fixed on one side of the left guide rail stand column; a lifting beam right sliding guide rail is fixed on one side of the right guide rail stand column; a left main stand column is fixed at the left end of the stand column bottom plate while a right main stand column is fixed at the right end of the stand column bottom plate; a sliding seat guide rail is arranged at the upper part of the lifting beam; the lifting beam driving acting cylinder is fixed on the guide rail stand column bottom plate; the mechanical arm moving beam driving mechanism is arranged on the lifting beam; the mechanical arm moving beam is connected with the mechanical arm moving beam driving mechanism; an electronic control valve is arranged on the top plate; the plug track lifting mechanism is arranged at the left end of the front side of the top plate; the overlook photographic mechanism is arranged on the top plate; the horizontal photographic mechanism is arranged on the detecting work table. The mechanical arm used for the propeller boss detection is high in detection efficiency and capable of reducing the manpower investment and ensuring the detection quality.

Owner:SOHBI CRAFT CHANGSHU

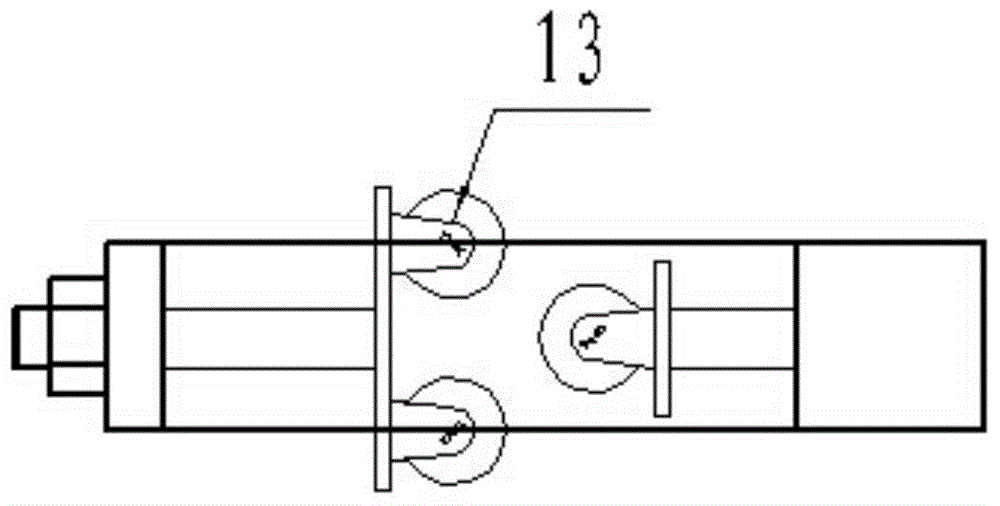

Automatic cleaner for greasy dirt on surface of petroleum drilling tool joint outside screw

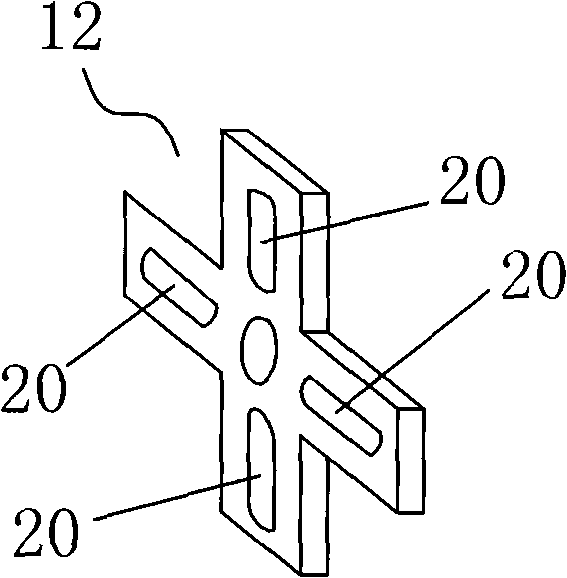

The invention discloses an automatic cleaner for cleaning oil stains on the external thread surface of a petroleum drilling tool joint. The automatic cleaner comprises a power device and a steel wire brush; the power device comprises a housing as well as a motor and a speed reducer which are fixed in the housing; the steel wire brush comprises a hollow connecting sleeve, a cross connecting frame, a stabilizing bar, a brush head and a clamping plate; one end of the hollow connecting sleeve is connected with an output shaft of the speed reducer by screw thread, the cross connecting frame is sheathed in the thin end of the stabilizing bar, the other end of the hollow connecting sleeve is connected with the stabilizing bar by screw thread, and the cross connecting frame is clamped between the thick end of the stabilizing bar and the hollow connecting sleeve; the brush head consists of a brush plate and steel wires; the clamping plate consists of a brush head clamping part and a connecting part, a brush plate of the brush head is connected with a clamping part of the brush head by a slot, and the four connecting arms of the cross connecting frame are correspondingly connected with the connecting parts of the four clamping plates by bolts and nuts. The automatic cleaner for cleaning oil stains on the external thread surface of the petroleum drilling tool joint in the invention has the advantages of convenience in carrying and operation, saving manpower and thorough cleaning.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

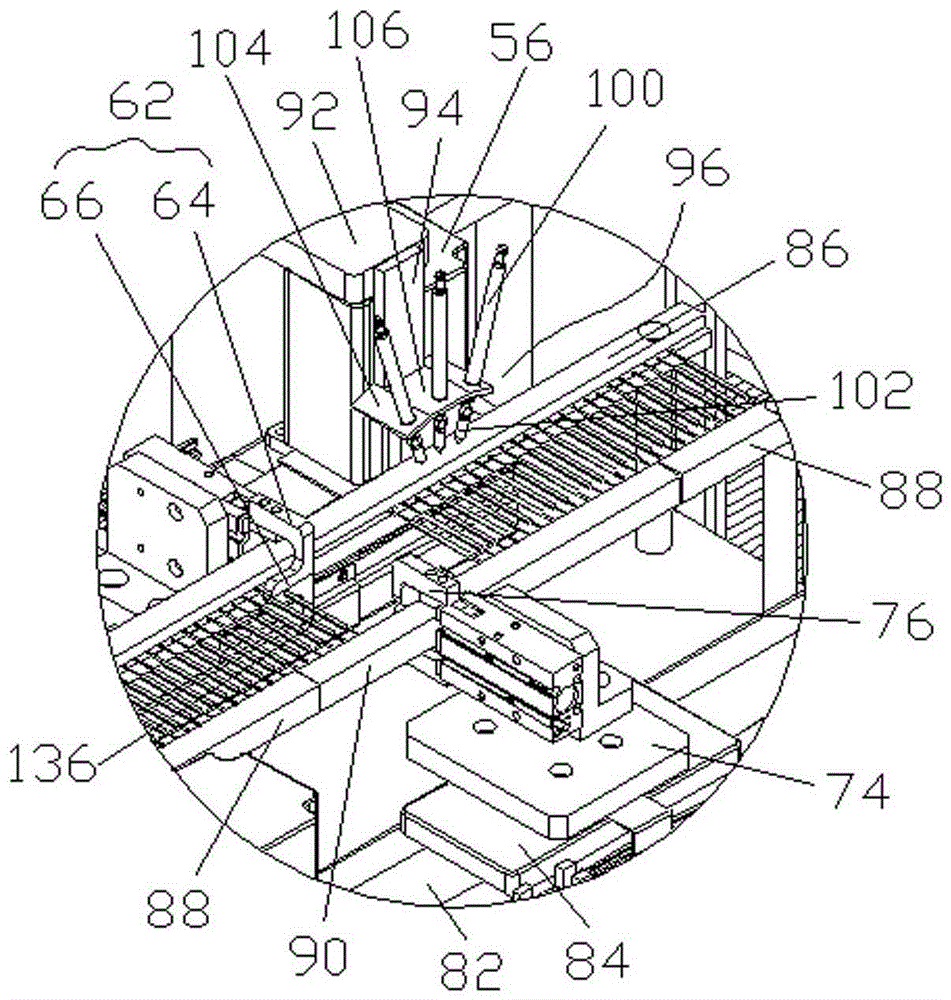

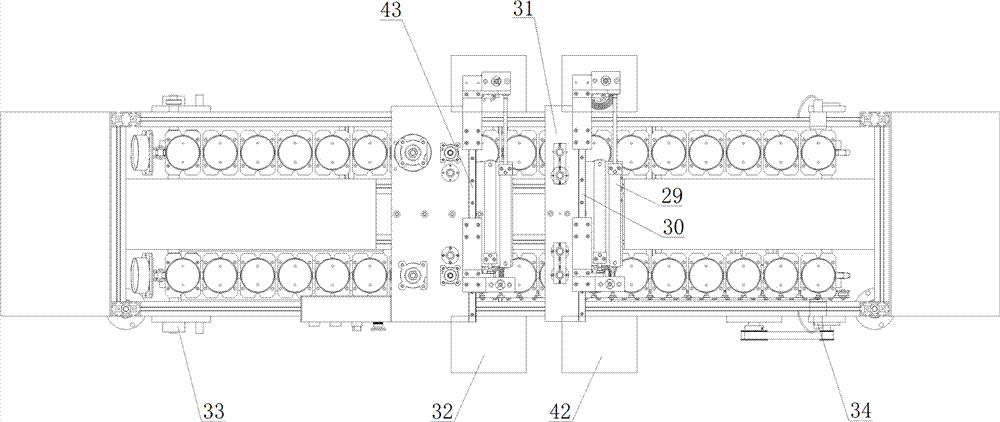

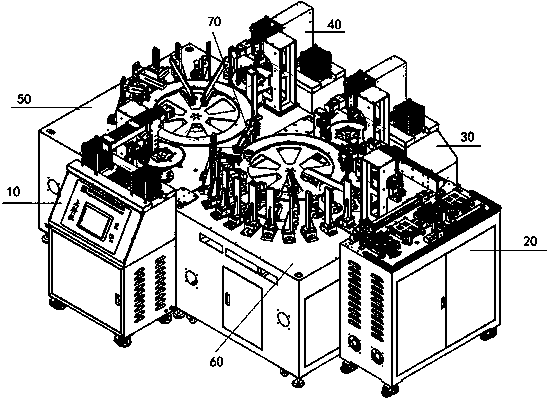

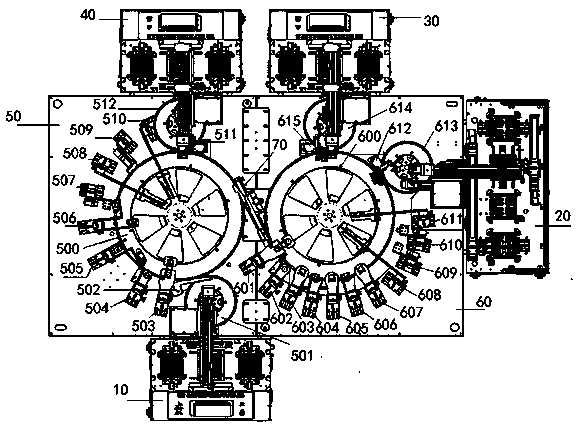

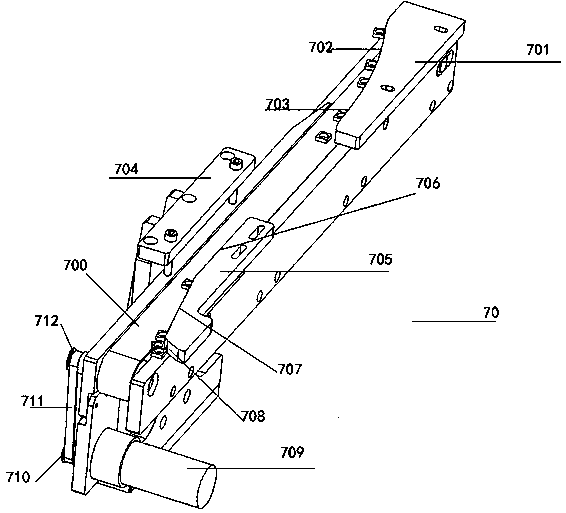

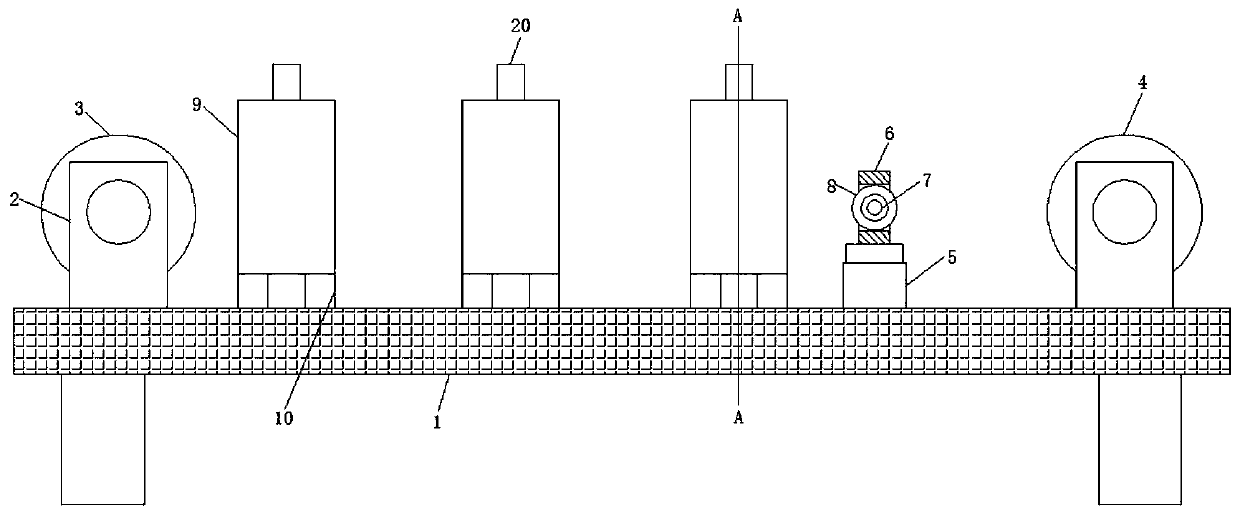

Automatic detection and screening system with multiple conveying disks

ActiveCN109985820AGuarantee the quality of inspectionAvoid missing detectionSortingEngineeringAutomatic testing

The invention relates to an automatic detection and screening system with multiple conveying disks. A feeding device (10) guides an object to be detected into a first rotary disk body (500) of a firstdetection unit (50). A plurality of photographing detection devices on the periphery of the first rotary disk body (500) conduct photographing on the object to be detected in different directions. The object to be detected gets into a second rotary disk body (600) of a second detection unit (60) through a connecting mechanism from the first rotary disk body of the first detection unit (50). A plurality of photographing detection devices on the periphery of the second rotary disk body conduct photographing on the object to be detected in the different directions. A computer analyzes and judgeswhether the object to be detected is a good product or a defective product according to pictures photographed by the photographing detection devices. Defective products detected by the first detection unit are discharged through a third discharging device (40). Defective products detected by the second detection unit are discharged through a second discharging device (30). Good products detectedby the second detection unit are discharged through a first discharging device (20).

Owner:东莞市雅创自动化科技有限公司

Novel equipment polling method

InactiveCN107424237ACorrect randomnessImprove the quality of workChecking time patrolsStanding PositionsComputer science

The invention aims to provides a novel equipment polling method which comprises the following steps: A, making a global graph of a polling area, ensuring that a polling route covers all equipment to be polled and the polling route is a shortest one, and marking orientation of the polling route on site; B, marking optimal polling standing positions, observation directions and polling modes of the equipment to be polled; C, marking corresponding inspection items of all equipment to be polled, classifying the equipment to be polled, respectively marking key degrees, and respectively setting corresponding polling cycles; D, making problem feedback report procedures, and marking the procedures at the equipment to be polled; and E, performing polling by polling operators according to the polling route, performing polling according to the polling cycles of the equipment to be polled, and if the equipment to be polled has problems, feeding back the problems according to the problem feedback report procedures. The novel equipment polling method is capable of overcoming the defects that the prior art is large in randomness and low in efficiency, and has the characteristics of being reasonable in planning, comprehensive in coverage and timely in feedback.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Efficient detection device for polymer cable production

InactiveCN110487719AImprove detection efficiencyLow production costUsing mechanical meansElectric/electromagnetic audible signallingPolymerRolling-element bearing

The invention discloses an efficient detection device for polymer cable production, which includes a detection platform. The four corners of the lower end face of the detection platform are fixedly connected with support legs through screws. The two sides of the upper end face of the detection platform are fixedly connected with support seats through screws, and two support seats are arranged on each side. A take-up roller and a pay-off roller are installed between the two support seats on the same side. Three detection rings are arranged in the middle of the detection platform. Fixed columnsare welded on the two sides of the lower end of each detection ring. The lower ends of the fixed columns are fixed on the detection platform by screws. An installation ring is arranged on the inner side of each detection ring. An adjustment ring is arranged on the outer side of each installation ring. Support rods are respectively fixed between the installation rings and the adjustment rings on one hand and the inner walls of the detection rings on the other hand by screws. The outer wall of each adjustment ring is rotationally connected with a rotating ring through rolling bearings. A connecting rod is hinged to the side wall of one end of each rotating ring. A sliding slot is formed in the side wall of one end, close to the connecting rod, of each adjustment ring.

Owner:JING FENG GRP

Dual internal spline coaxiality inspection device

InactiveCN102486367ASimple connection structureEasy to manufactureMechanical measuring arrangementsStileEngineering

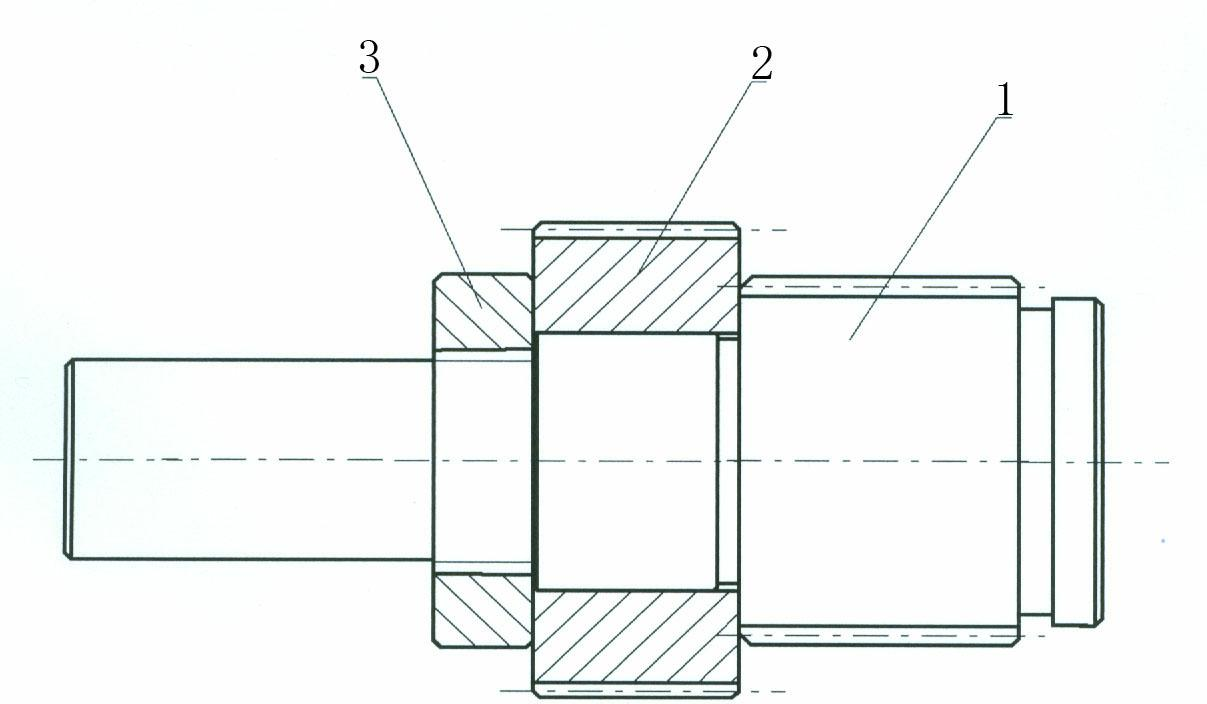

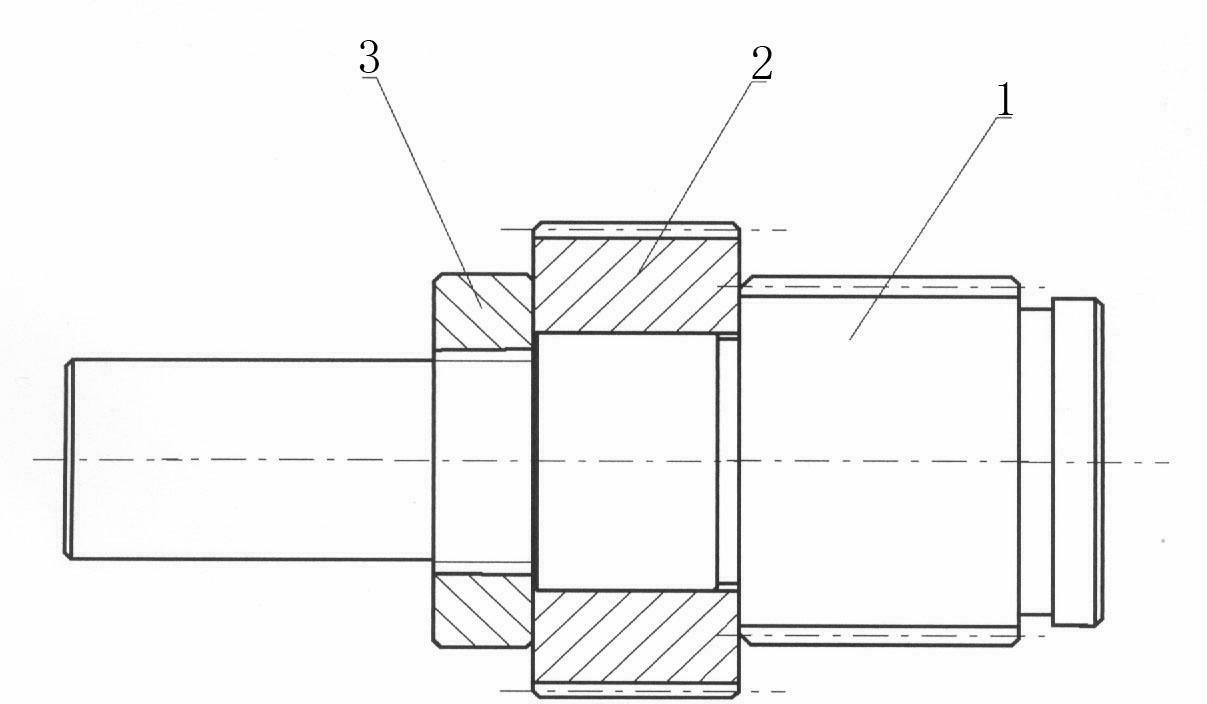

The invention discloses a dual internal spline coaxiality inspection device. The inspection device is composed of a fixed plug gage, a movable plug gage and a nut, wherein the fixed plug gage is of a vertical stepped shaft structure, the outer wall of the bottom section of the fixed plug gage is axially provided with external splines, the middle section of the fixed plug gage is provided with a cylindrical shaft, and the cylindrical shaft section is provided with an external thread matched with the nut; the movable plug gage is in a pored flange shape, a middle through hole is in clearance fit with the cylindrical shaft at the middle section of the fixed plug gage, and the outer wall of the movable plug gas is axially provided with external splines; and the movable plug gage and the fixed plug gage are coaxially sleeved and axially limited by the nut, thereby simultaneously forming a fixed plug gage rotational structure relative to a unlimited movable plug gage. According to the invention, the fixed plug gage is utilized as a standard, the movable plug gage is used for testing the coaxiality of double splined sleeves, if the two internal splines have a teeth position error, the adjusting position of the movable plug gage is rotated, and the structure is not influenced by the teeth position error in a coaxiality test. The inspection device provided by the invention has the advantages of convenience in check operation, high efficiency, and capability of objectively and qualitatively judging the coaxiality deviation condition of the double splined sleeves, thus being especially suitable for being used in a production field.

Owner:JIANGSU AIRSHIP GEAR

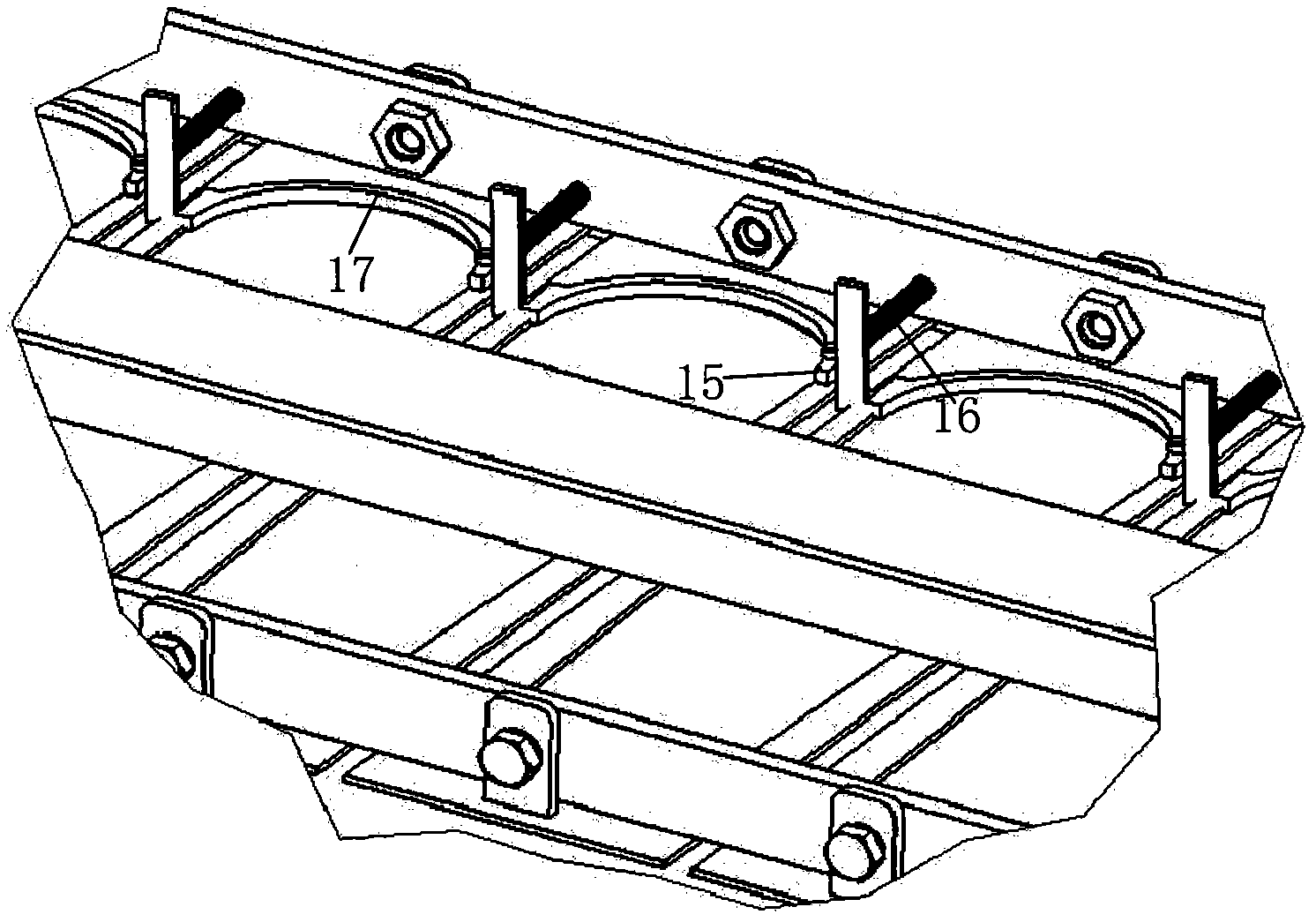

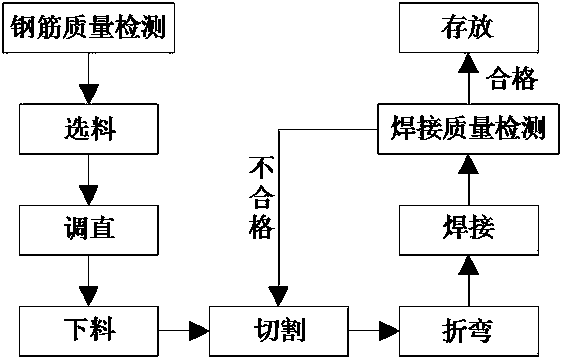

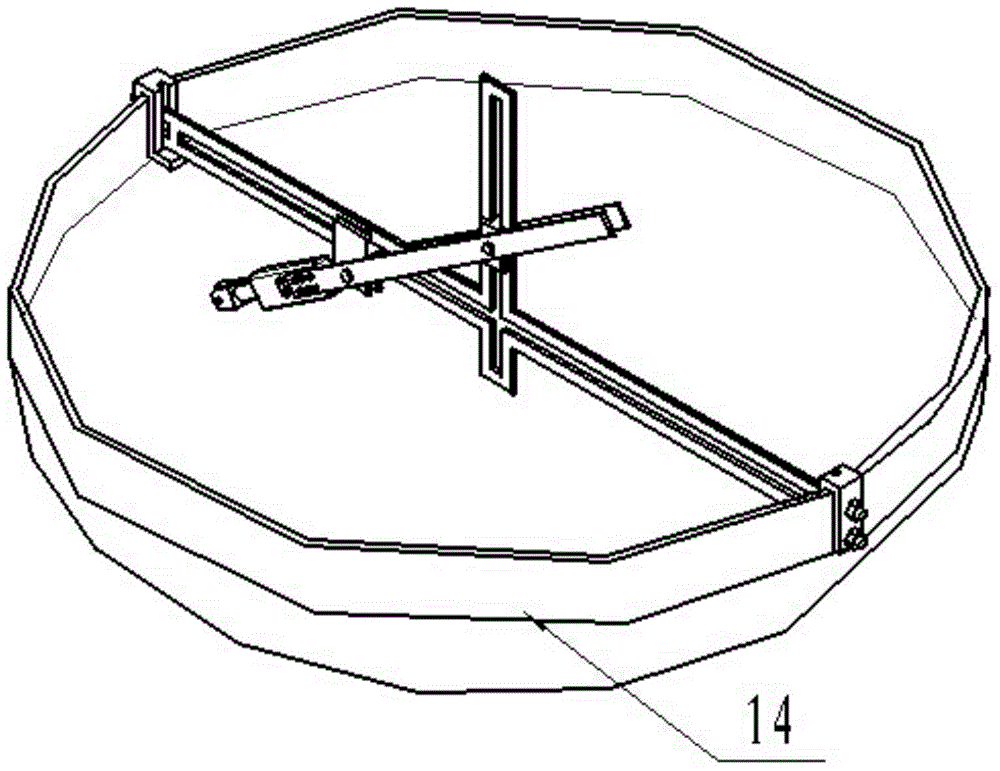

Machining method of cylindrical reinforcing cage

InactiveCN109201974AGuarantee the quality of inspectionExtended service lifeWire networkRebarUltimate tensile strength

The invention discloses a machining method of a cylindrical reinforcing cage. The machining method comprises the following steps of steel bar quality detection, material selection, straightening, blanking, cutting, bending, welding, welding quality detection and storage. In the step of steel bar quality detection, various specifications and grades of steel bars are detected, professional steel barstrength detection devices shall be carried to detect the steel bars, and then the steel bars can be used only after factory certificates and entrance inspection reports are obtained. According to the machining method, the steel bars with various specifications and grades need to be detected before reinforcing cage machining, the professional steel bar strength detection devices shall be carriedto detect the steel bars, and then the steel bars can be used only after the factory certificates and the entrance inspection reports are obtained; after welding, detection personnel need to check whether welding points are firmly welded and detect the anti-seismic effect of the reinforcing cage; when the detection quality is unqualified, rework processing should be carried out, and when the detection quality is qualified, storage is carried out, so that the factory quality of the reinforcing cage is ensured.

Owner:河南永益同丰智能科技有限公司

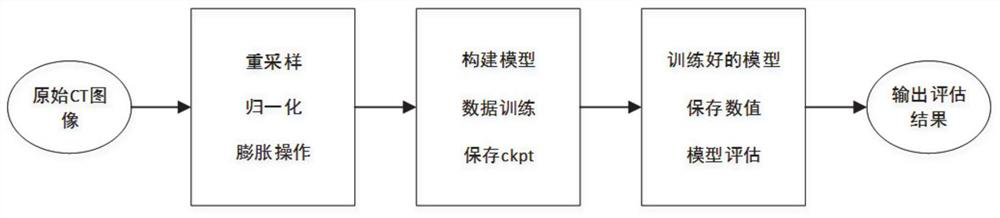

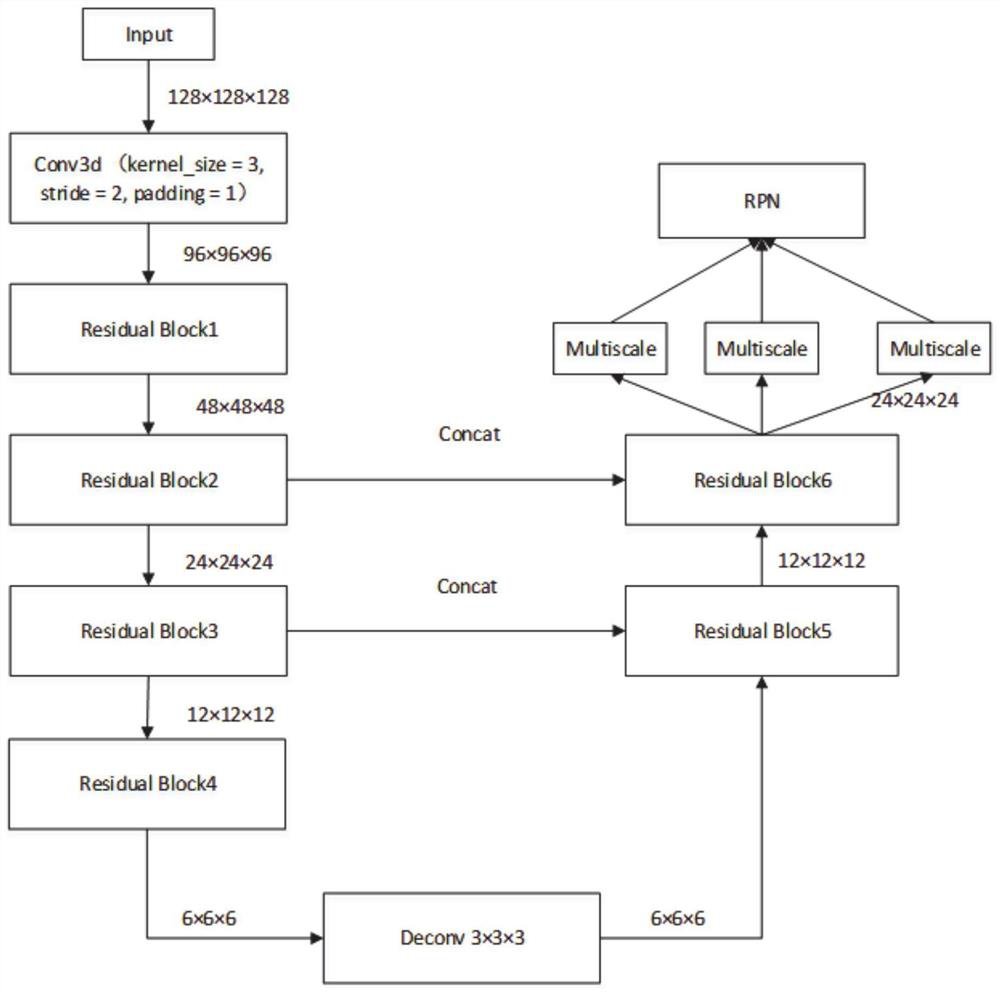

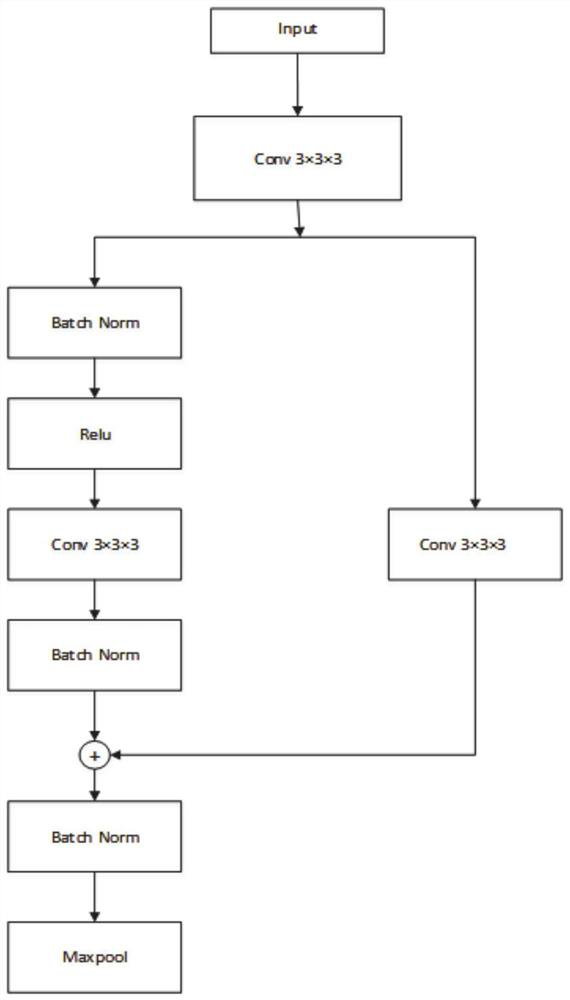

Pulmonary nodule detection method and system

PendingCN113744183AAccurate detectionImprove stabilityImage enhancementImage analysisPulmonary noduleRadiology

The invention provides a pulmonary nodule detection method and system, and belongs to the technical field of image recognition, and the method comprises the steps of obtaining a to-be-detected lung CT scanning image; performing resampling and normalization on the obtained lung CT scanning image to be detected, and performing expansion operation processing on the mask; processing the processed to-be-detected lung CT scanning image by using the trained detection model to obtain a detection result, wherein the detection result comprises whether the pulmonary nodule exists in the to-be-detected lung CT scanning image and the calibration position and the area size of the pulmonary nodule, the trained detection model is obtained through training by using a training set, the training set comprises a plurality of lung CT scanning images and labels for labeling positions and areas of pulmonary nodules in the images. According to the invention, accurate detection of the pulmonary nodule area is realized, the detection efficiency is improved, the detection quality is ensured, and the stability and efficiency of assisting doctors in disease diagnosis are improved.

Owner:SHANDONG NORMAL UNIV

Buffer feeding device of air valve

ActiveCN104108599AAvoid Rigid CollisionsGuarantee the quality of production and testingConveyor partsEngineeringMaterial storage

The invention provides a buffer feeding device of an air vale. Automatic feeding in the air valve production and detection process is achieved, production efficiency is improved, rigid collision between air valves in the feeding process is effectively avoided, and air valve production and detection quality is guaranteed. The buffer feeding device of the air vale comprises material receiving plates on the two sides, the upper end of each material receiving plate is provided with a material storage rod, and then a material channel is formed. The buffer feeding device of the air vale is characterized in that rotary shafts are arranged corresponding to the lower ends of the material receiving plates, a plurality of material blocking bars are arranged on the rotary shafts, and the adjacent material blocking bars are arranged in an intersection mode.

Owner:WUXI SHUANGYI PRECISION MACHINERY

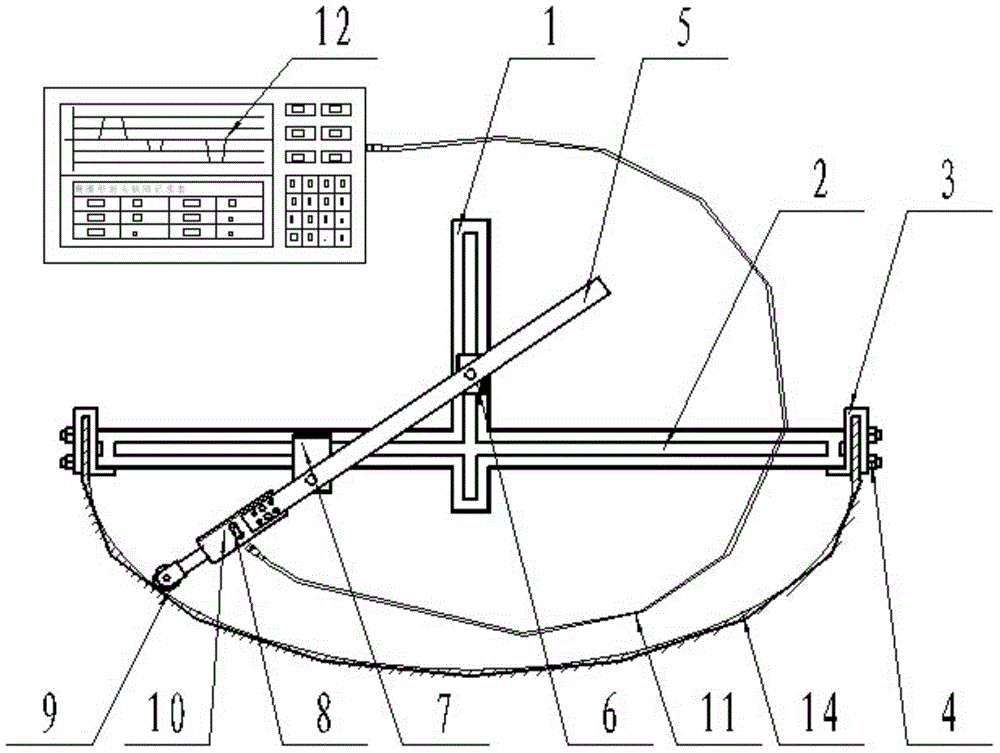

Inspection instrument for pressure vessel ellipsoidal head based on ellipsograph

ActiveCN104833304AGuarantee the quality of inspectionOmit productionElectric/magnetic contours/curvatures measurementsEngineeringPressure vessel

The invention relates to an inspection instrument for a pressure vessel ellipsoidal head based on an ellipsograph, and belongs to the field of pressure vessel inspection equipment. The instrument mainly comprises an ellipsograph slide rail with a sliding groove. Two ends of the ellipsograph slide rail are provided with fixing clips and fastening bolts installed in a matched manner. The ellipsograph slide rail is provided with a slide bar through a center vertical sliding block and an eccentric horizontal slide block. The eccentric end of the slide bar is a push rod with a high-precision displacement sensor. The tail end of the push rod is provided with a high-precision displacement sensor roller. The high-precision displacement sensor is connected with a handheld terminal through a data cable. Beneficial effects of the instrument are that ellipsoidal head inspection precision and inspection efficiency are improved, quality of the pressure vessel ellipsoidal head is effectively ensured, manufacturing and maintenance steps of a sample plate are not needed, and situation of being lack of automation inspection equipment all the time in an ellipsoidal head inspection industry is improved.

Owner:烟台市特种设备检验研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com