Patents

Literature

78results about How to "No false detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

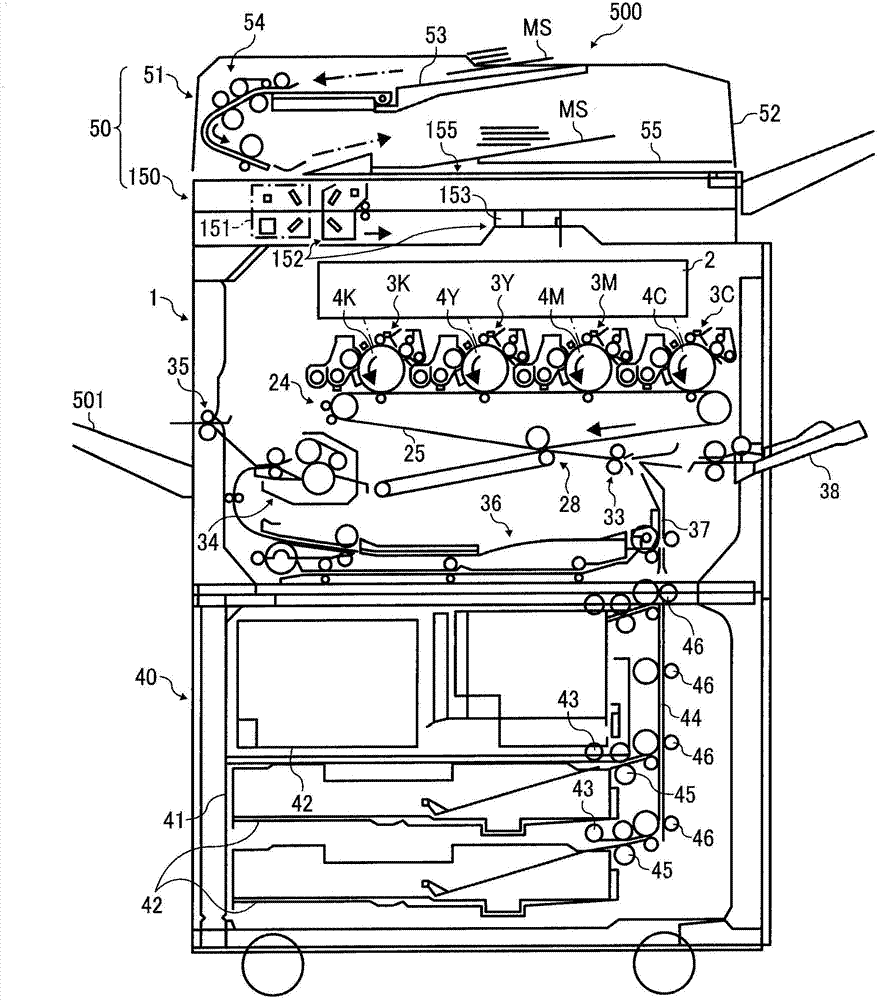

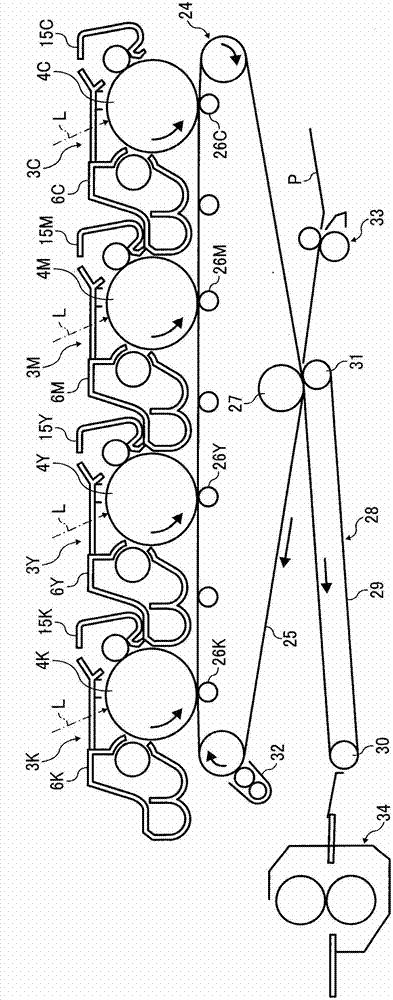

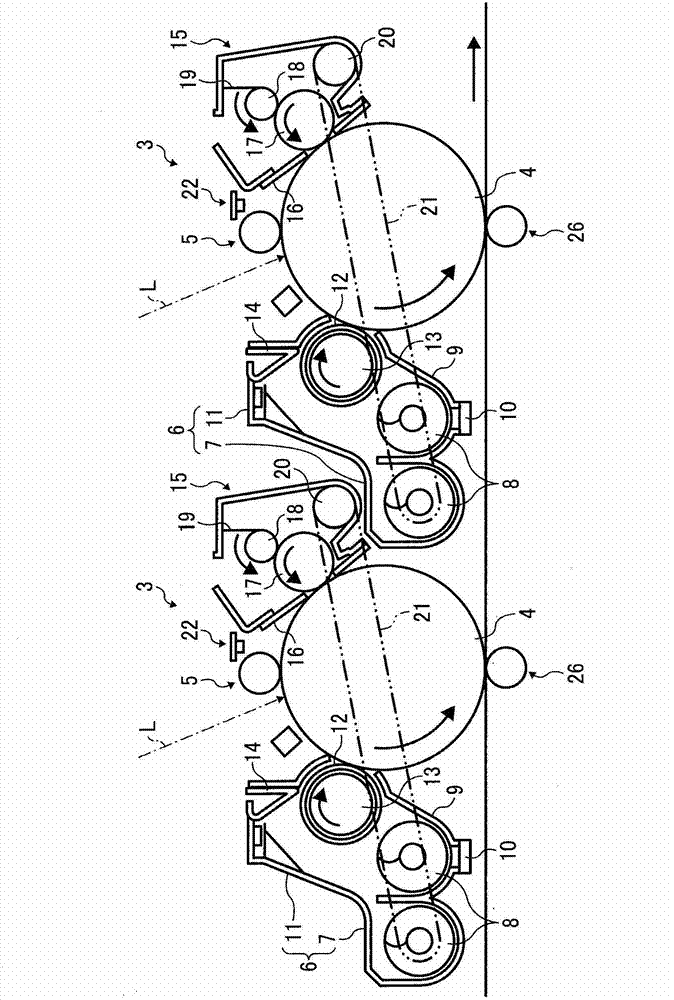

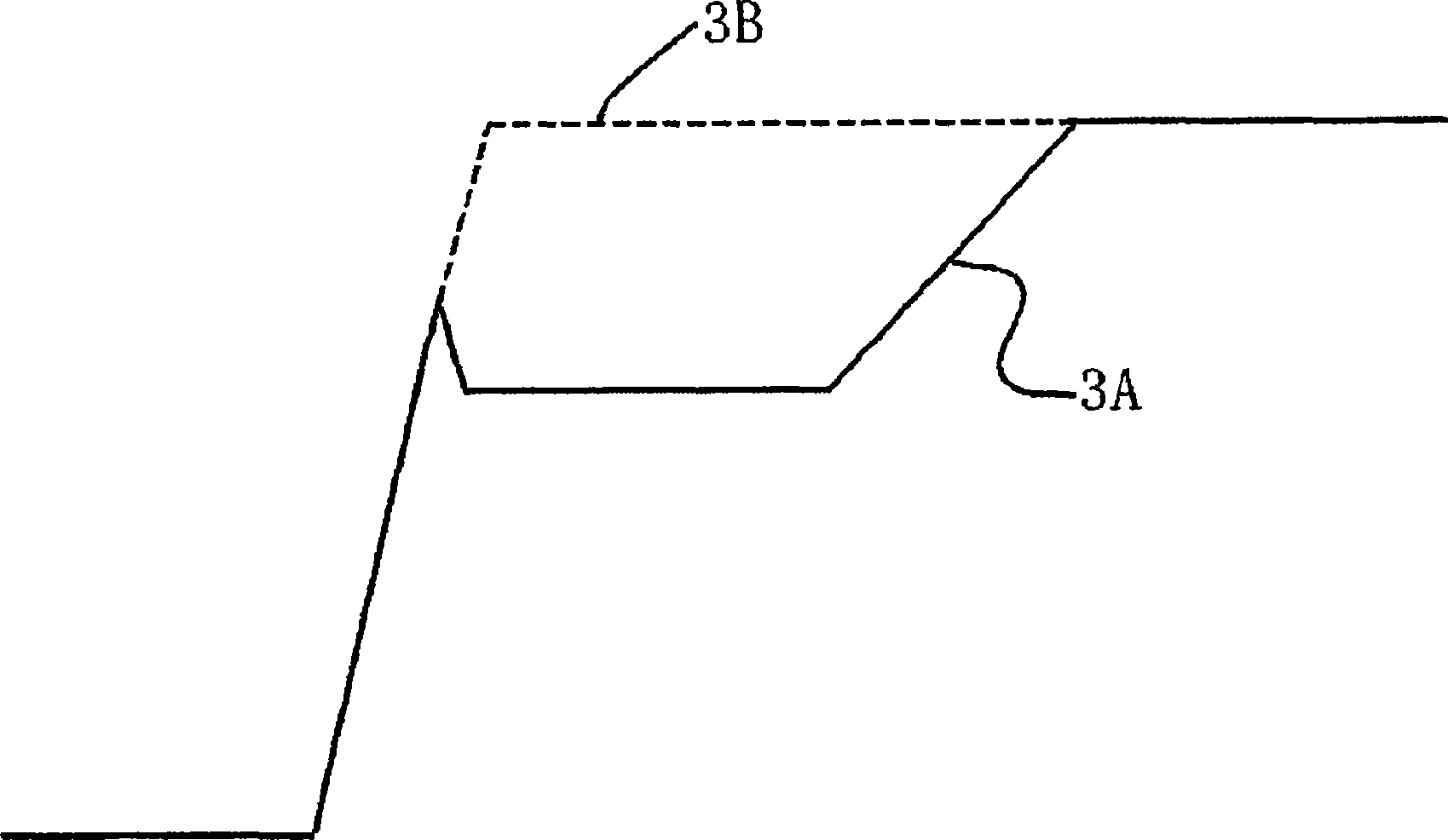

Sheet conveyance device, and image reading apparatus and image forming device

ActiveCN102815560AReduce distanceNo false detectionFunction indicatorsElectrographic process apparatusTrailing edgeMechanical engineering

The invention relates to a sheet conveyance device, an image reading apparatus and an image forming device. The trailing-edge detector (M1) includes a rotary follower such as a detection roller (141) and the like and a rotation detector to detect rotation of the rotary follower to detect the tail end of the material sheet, and the detection roller follows the material sheet. The rotation detector consists of an encoder wheel 143, a photosensor 144, a controller, and the like. Compared with comparative sheet conveyance devices in which a photosensor is used as a trailing end detector (M1), passage of the trailing end of the sheet at the trailing-edge detector can be detected promptly. Therefore, the reference length-exceeding distance between original document sheets can be checked. A sheet conveyance device, an image reading apparatus and an image forming device are provided, wherein the intervals between the reference length sheets can be reduced through the sheet conveyance device, and intervals between the specific size sheets can be reduced through the sheet conveyance device.

Owner:RICOH KK

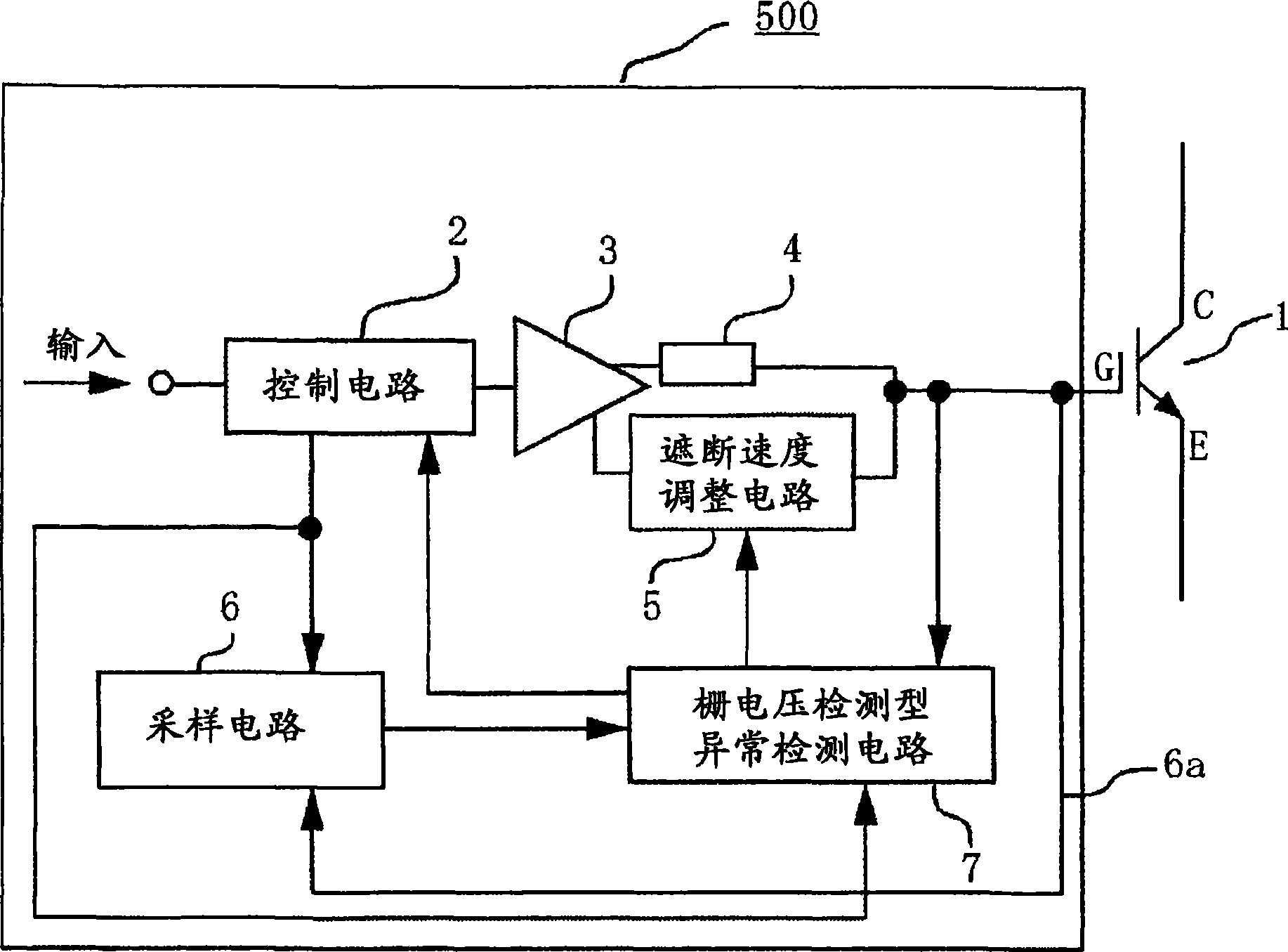

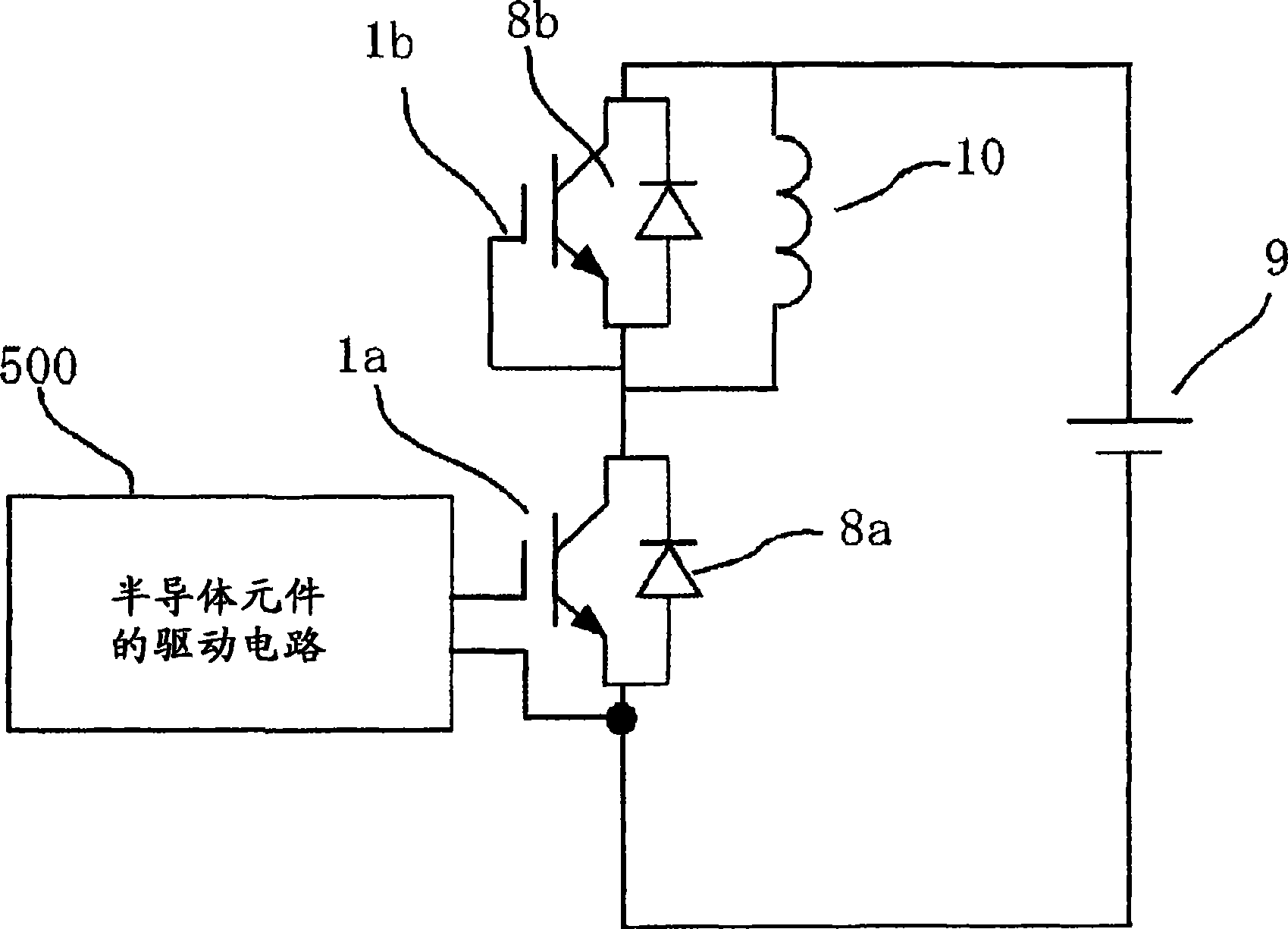

Driving circuit for semiconductor element

InactiveCN101421910ANo false detectionElectronic switchingPower conversion systemsGate voltageControl circuit

A driving circuit for a semiconductor element eliminates false detection of an abnormality of a semiconductor element (1) when a gate-on command is inputted in a status where the gate voltage of the semiconductor element (1) is not sufficiently lowered. A control quantity (gate voltage) of the semiconductor element (1) is permitted to be detected only during a period which corresponds to a control quantity (Qon) of the semiconductor element (1) when an on-signal is inputted to a control circuit (2), a detected control quantity (Qt) detected during the period is compared with a control comparison quantity (Qs) set by corresponding to the control quantity (Qon) to output an abnormal signal, and the semiconductor element (1) is shut off at a speed lower than a normal shutoff speed.

Owner:MITSUBISHI ELECTRIC CORP

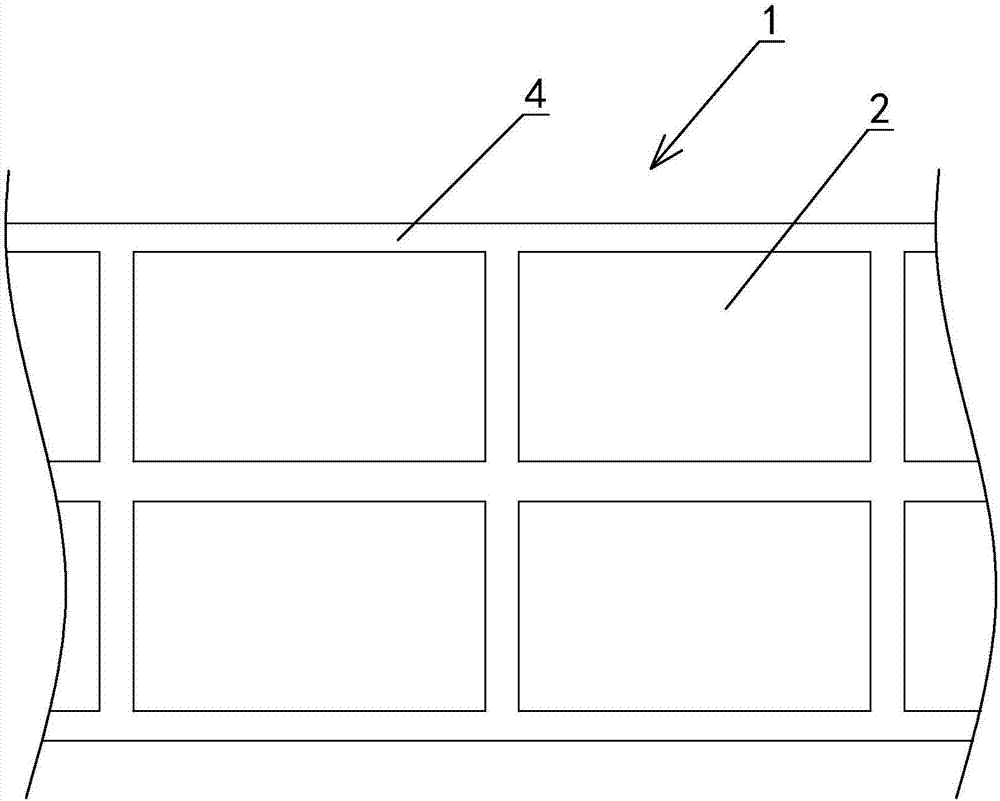

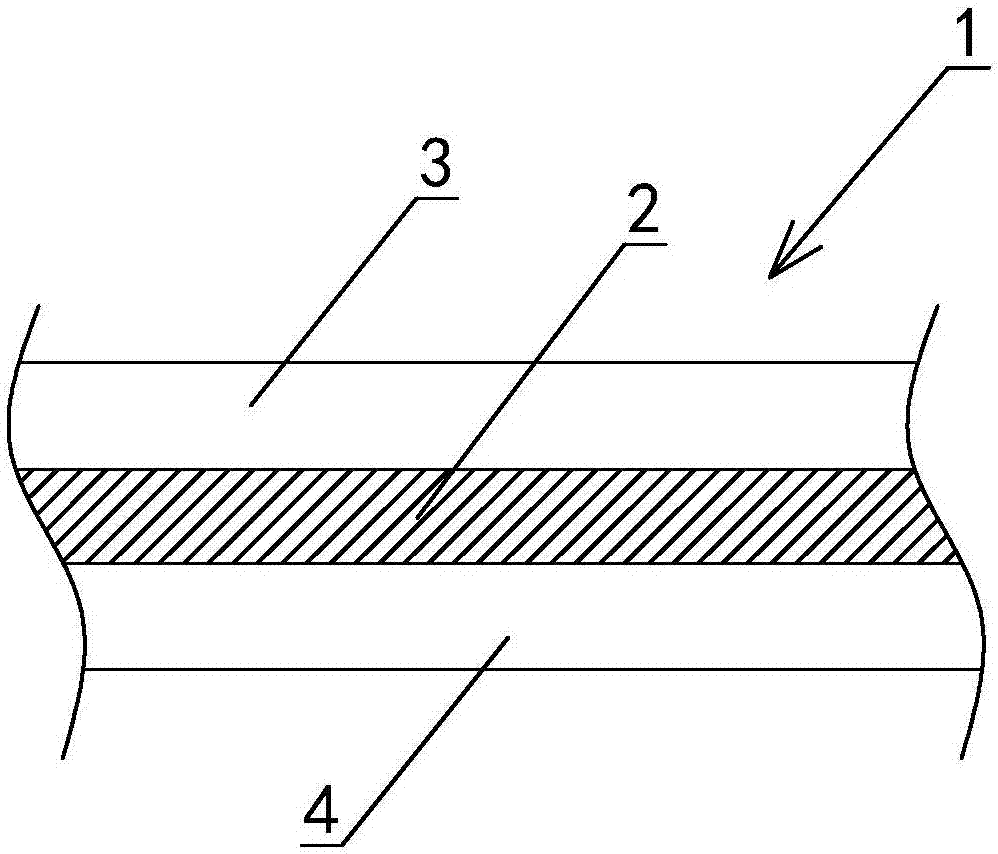

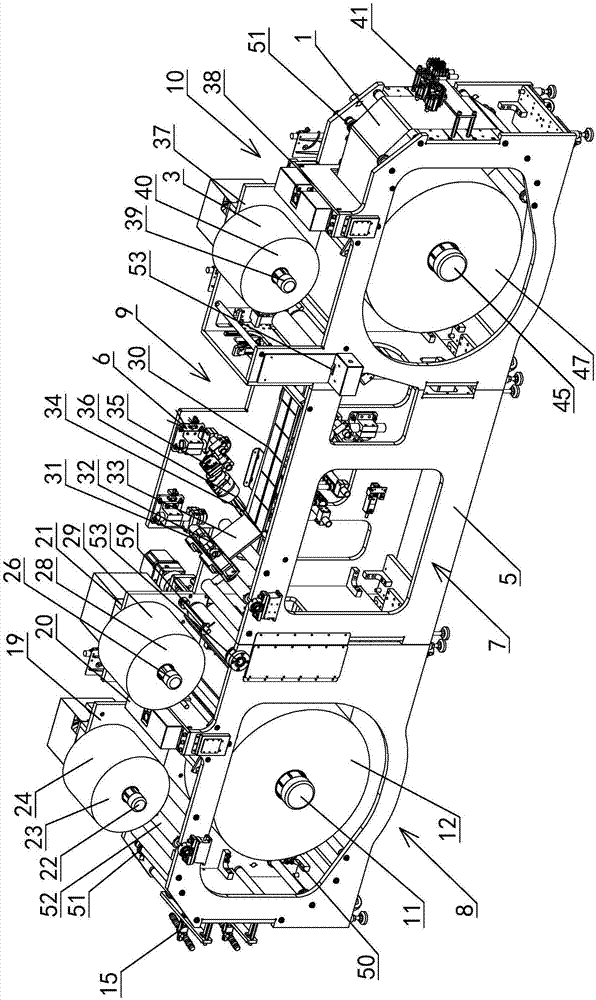

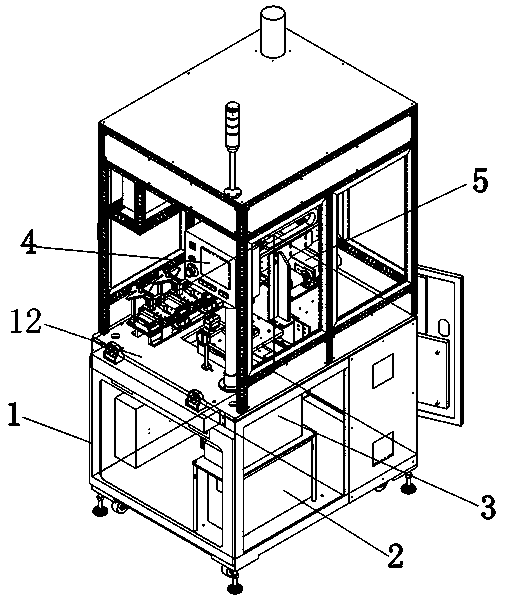

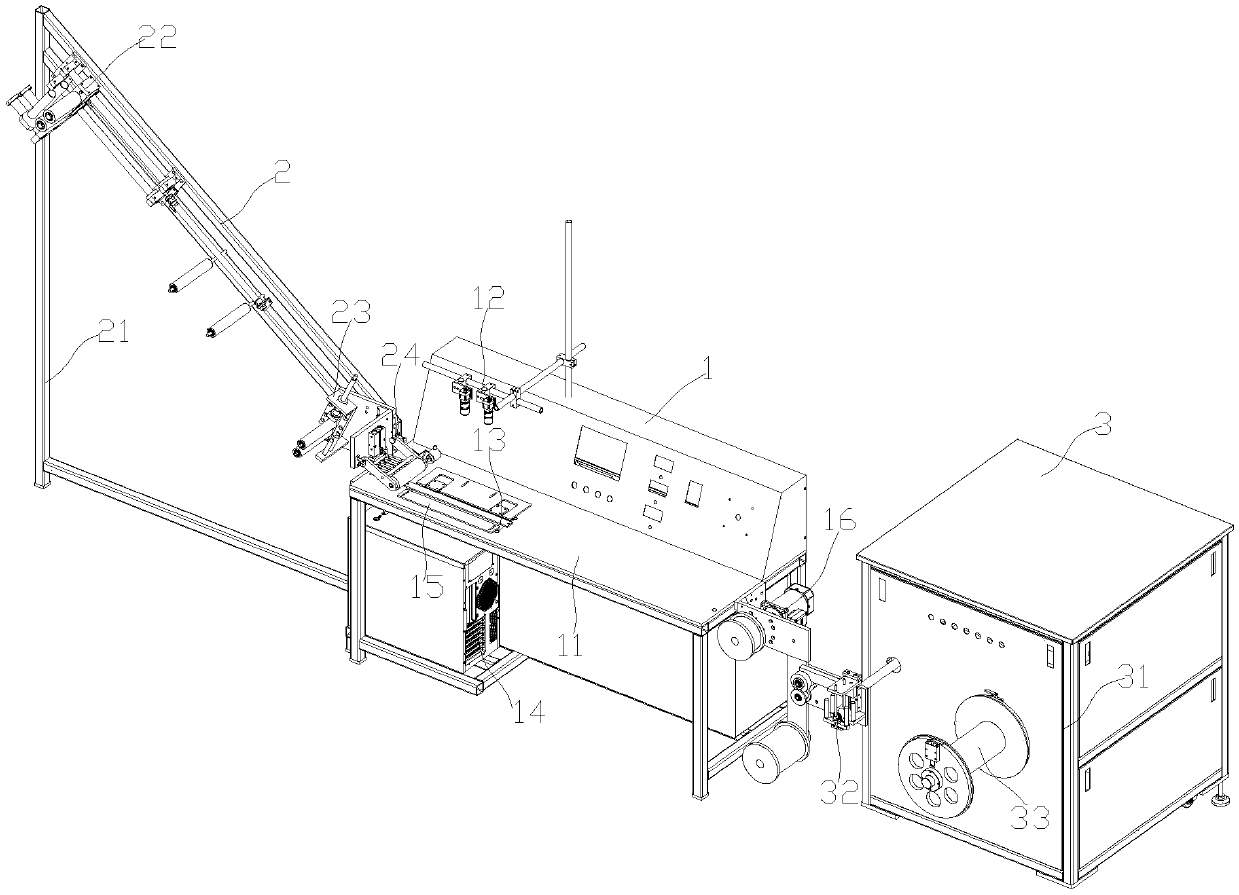

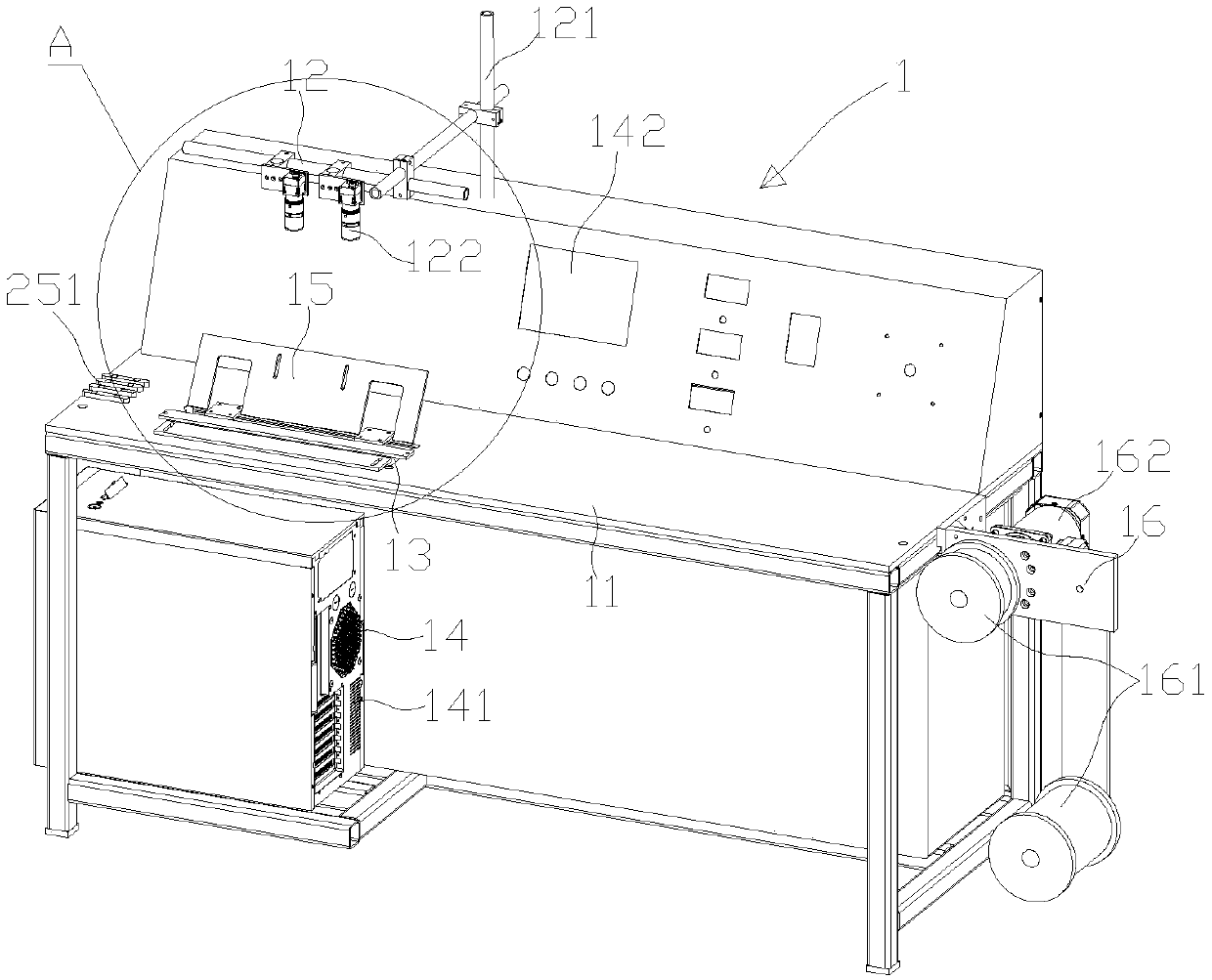

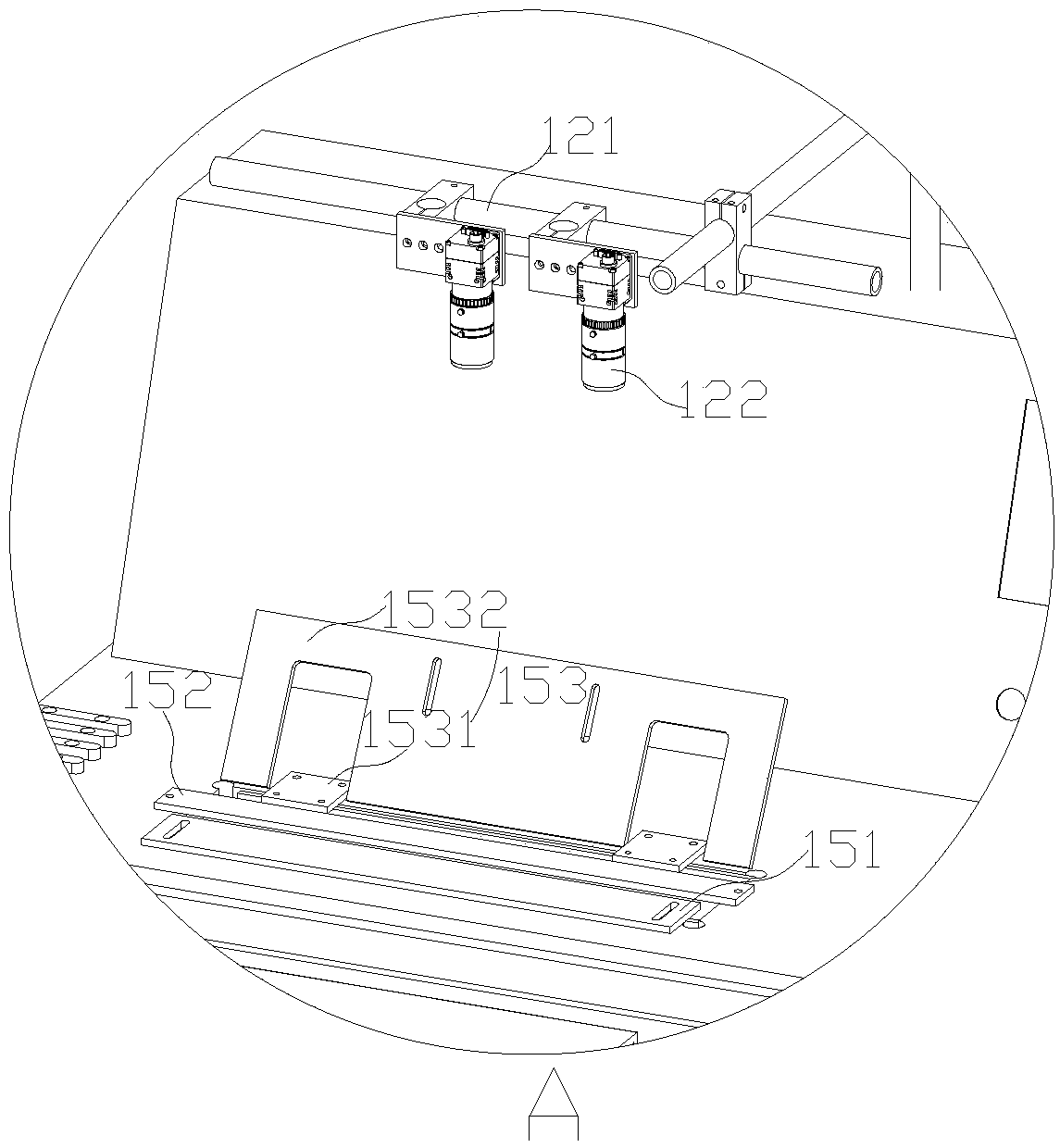

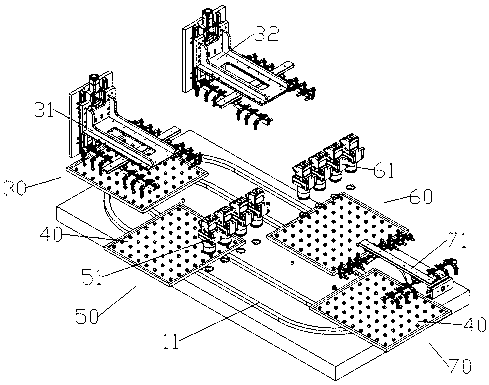

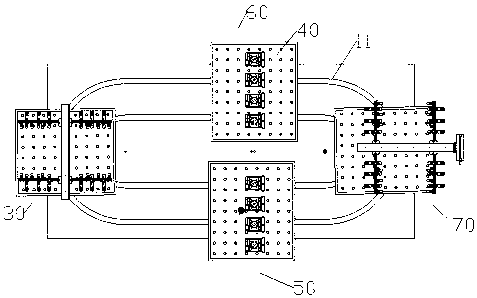

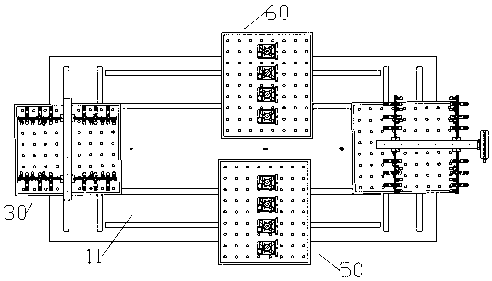

Optical film visual intelligent detection equipment

ActiveCN107315017AImprove defect recognition rateImprove detection efficiencyScattering properties measurementsOptically investigating flaws/contaminationTectorial membraneQuality control

Optical film visual intelligent detection equipment comprises a feeding unit, a detection unit and a collection unit; the feeding unit comprises a feeding module and a protection film uncovering mechanism, the protection film uncovering mechanism comprises an adhesive tape feeding module, an adhesive tape pressing and attaching module and a protection film uncovering module; the detection unit comprises a lighting module, a camera shooting module and an upper computer; the collection unit comprises a protection film attaching mechanism, a defective-product marking mechanism and a collection module, and the protection film attaching mechanism comprises a protection film feeding module and a protection film pressing and attaching module. The optical film visual intelligent detection equipment is mainly used for full-automatically detecting optical film products in a visual intelligent detection way to further screen out defected optical film products, and has the advantages of high detection efficiency, high detection reliability; meanwhile, because of relatively reasonable structure design, the advantages of compact structure, small occupied area and relatively low cost are achieved; above all, not only is the defect identification rate of the equipment to the optical film products high, but also false detection cannot occur, so that the quality control of the products is ensured.

Owner:苏州市朗电机器人有限公司

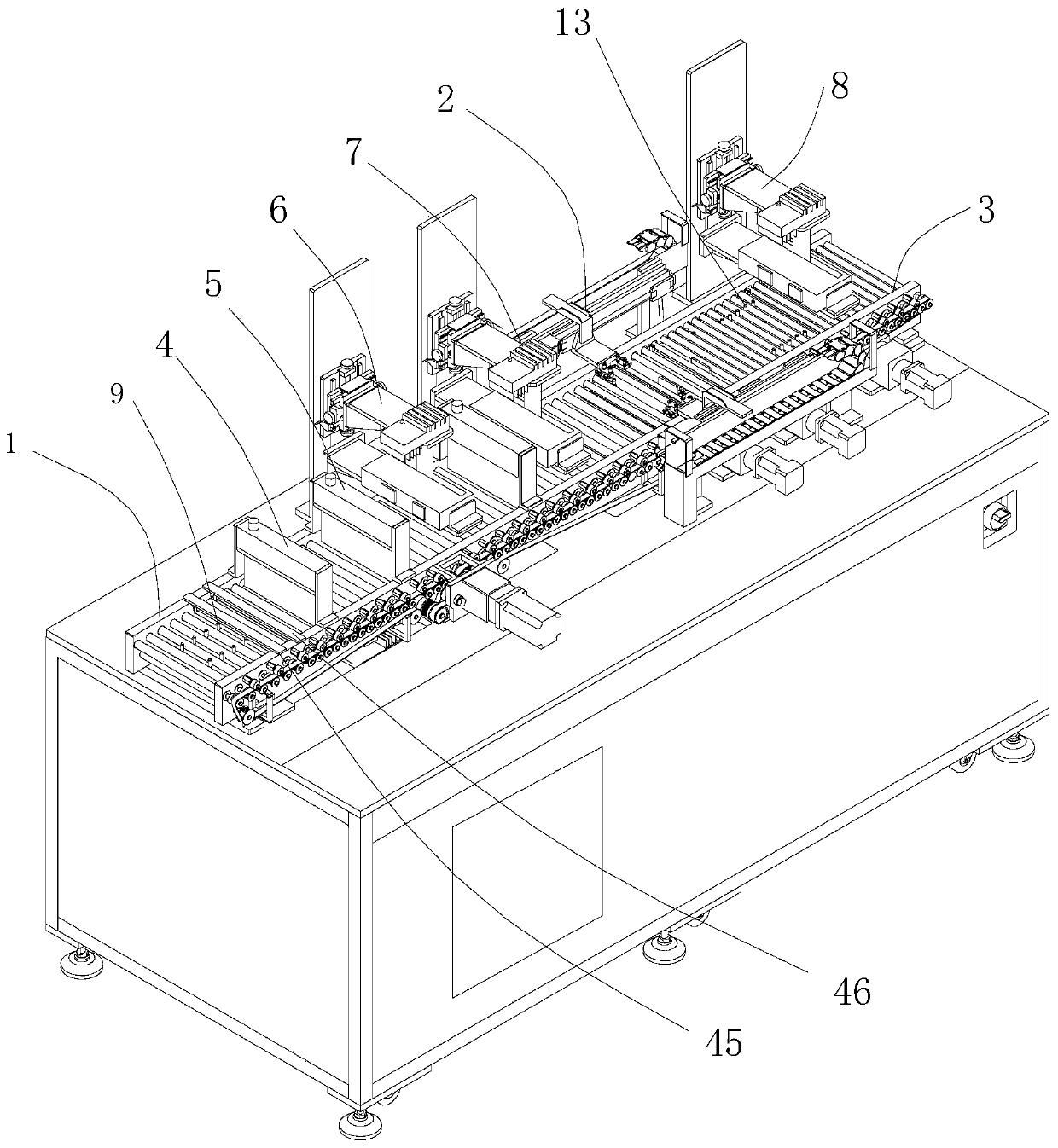

Plane glass product and display screen detection equipment

ActiveCN109987376ARealize automated detectionReduce labor intensityMaterial analysis by optical meansControl devices for conveyorsCollection systemEngineering

The invention discloses a plane glass product and display screen detection equipment. A control processing system, a first roller type conveying system, a first image collection system, a product rapid turning and moving device, a second image collection system and a second roller type conveying system are included; the first roller type conveying system, the product rapid turning and moving device and the second roller type conveying system are sequentially arranged from back to front, the first image collection system is used for collecting a product image on the first roller type conveyingsystem and sending the image to the control processing system, the product rapid turning and moving device is used for turning and moving the product conveyed by the first roller type conveying systemand then conveying the product to the second roller type conveying system, and the second image collection system is used for collecting the product image located on the second roller type conveyingsystem and sending the image to the control processing system. The equipment has the advantages of achieving product automatic detection, being small in labor intensity, and high in detection efficiency and avoiding leak detection and false detection.

Owner:NINGBO YUNSHENG INTELLIGENT TECHNOLOGY CO LTD +2

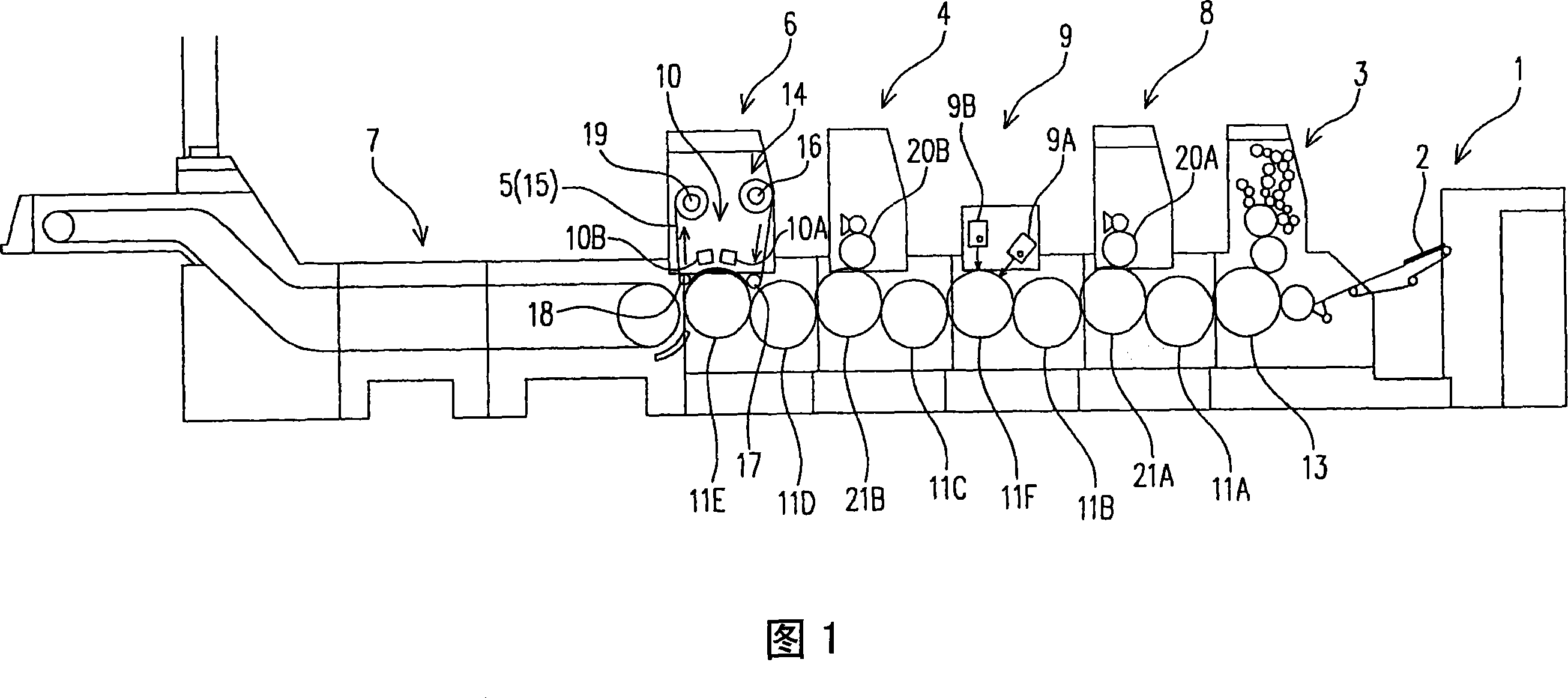

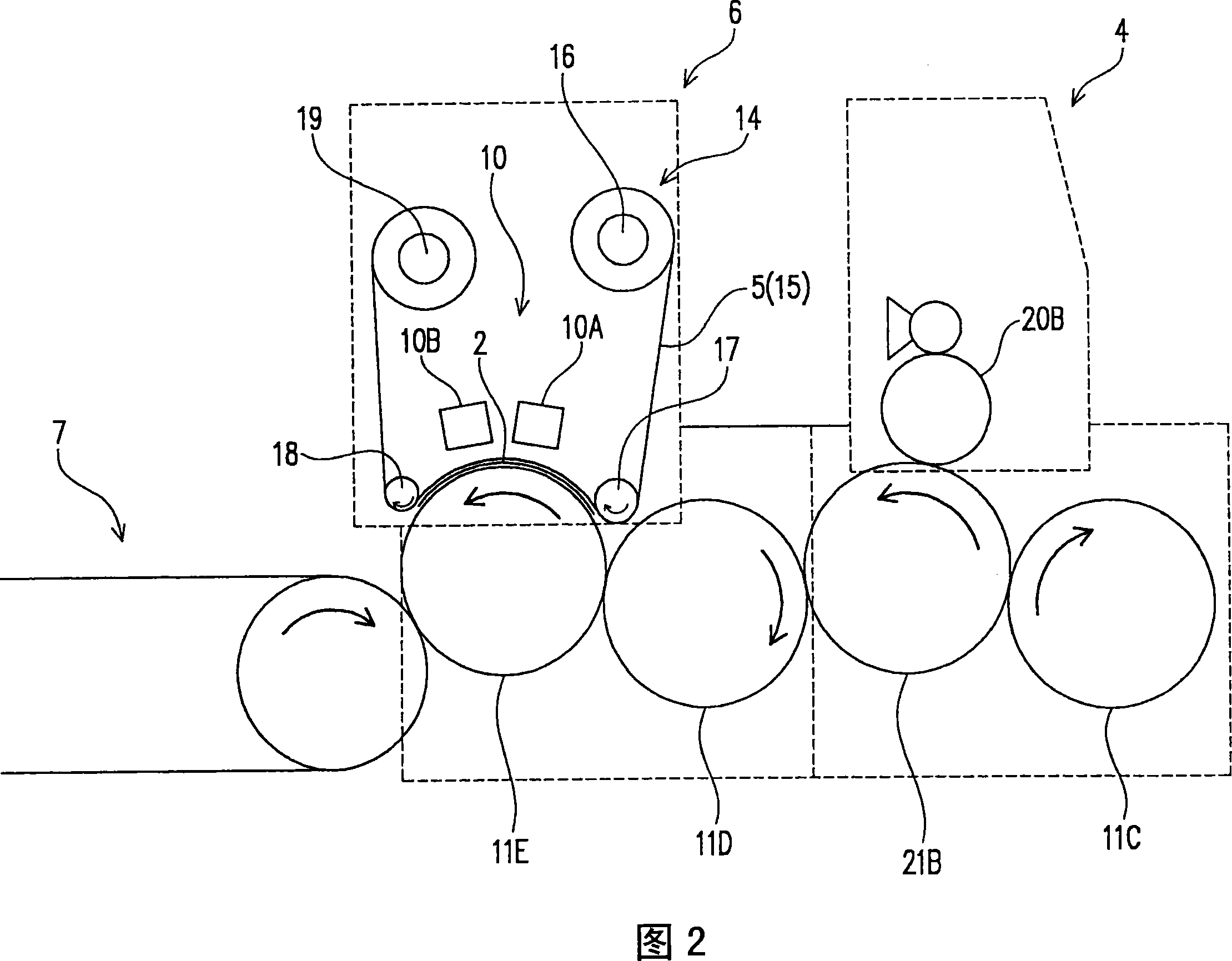

Single paper printing machine

InactiveCN101112813AImprove product valueIncrease added valueTransfer printingPrinting press partsPrinting pressTransfer mechanism

A sheet-fed printing press includes a printing section for printing on sheets of paper fed from a sheet feeding section, and a surface treating section for treating surfaces of the sheets of paper by pressing transfer films respectively onto the sheets of paper printed at the printing section. The surface treating section includes a downstream cylinder having a gripper for gripping each of the sheets of paper fed from an upstream cylinder for conveying the sheets of paper printed and fed thereto, and a film transfer mechanism that presses the transfer films respectively onto the sheets of paper on the downstream cylinder while at the same time conveying the transfer films in the same direction as the direction of the downstream cylinder.

Owner:RYOBI

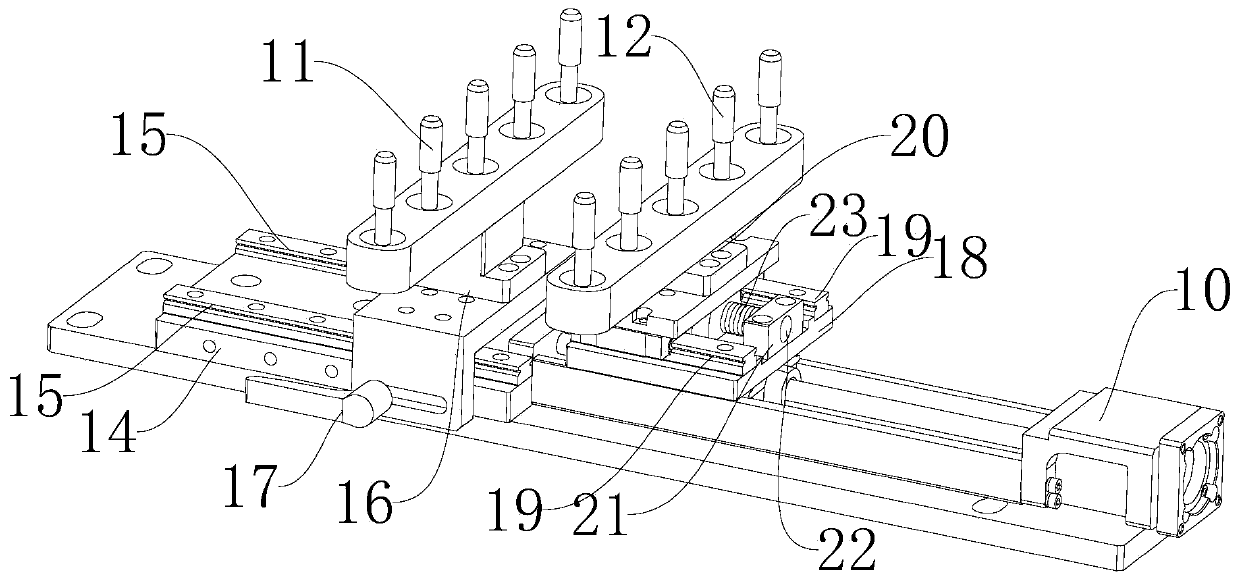

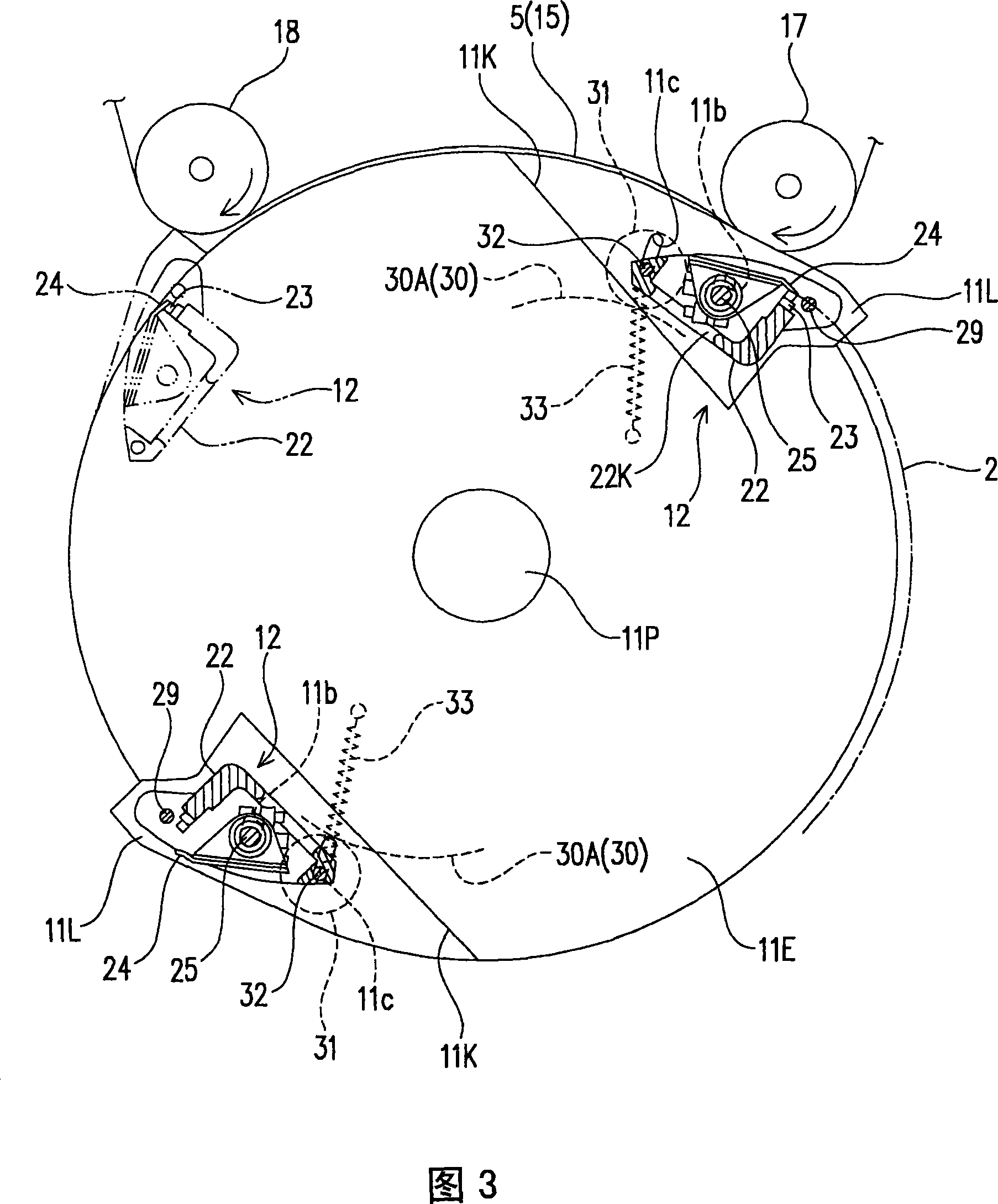

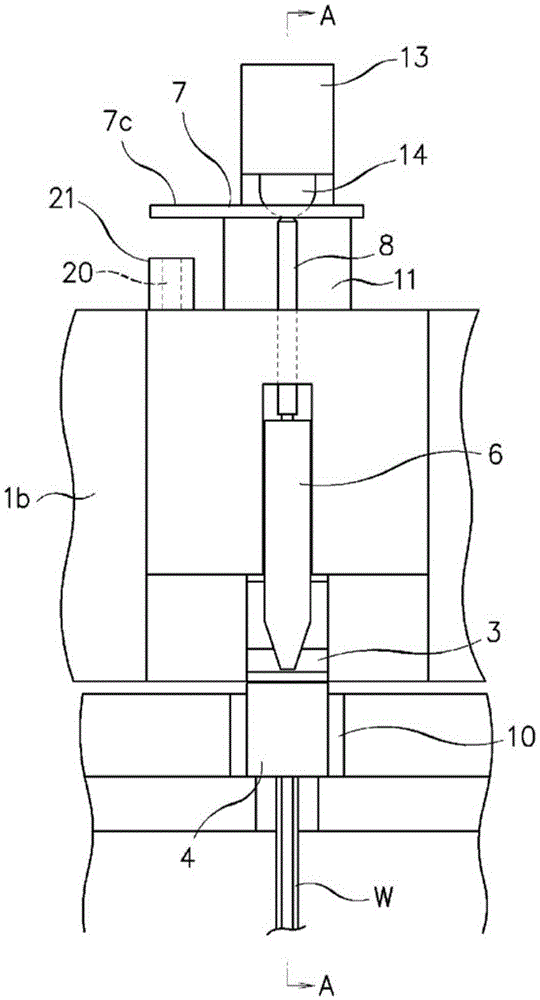

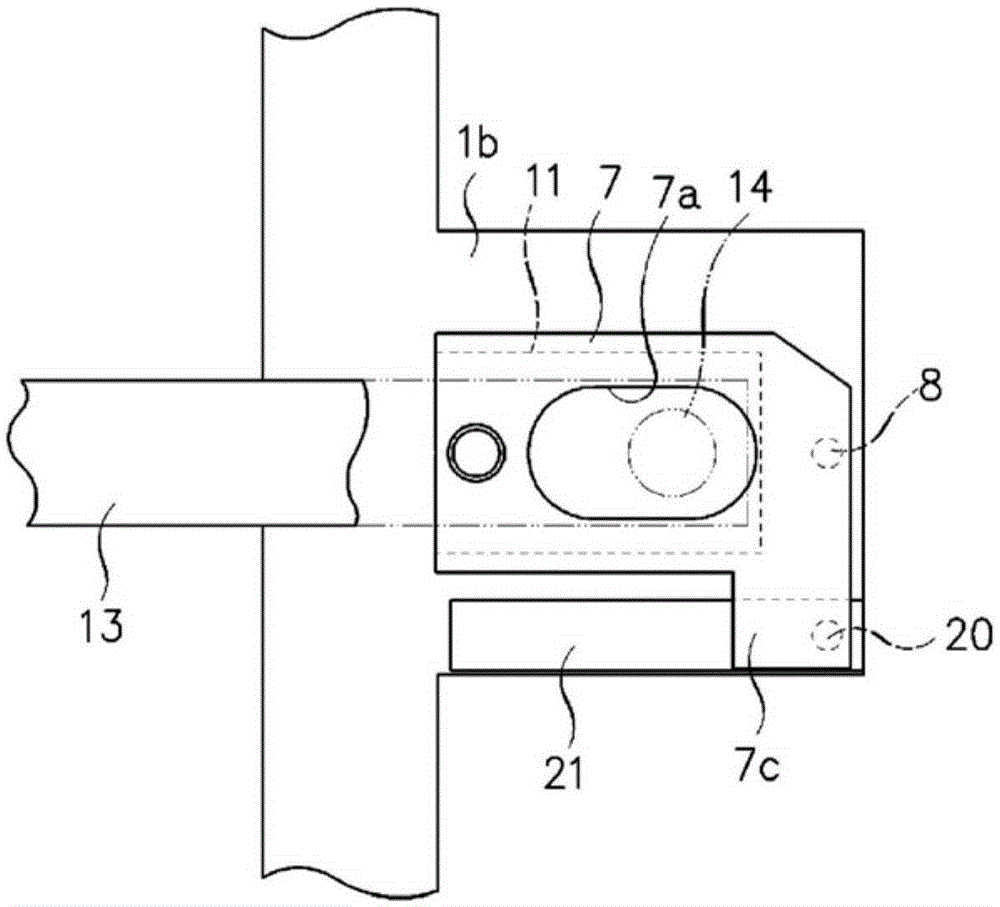

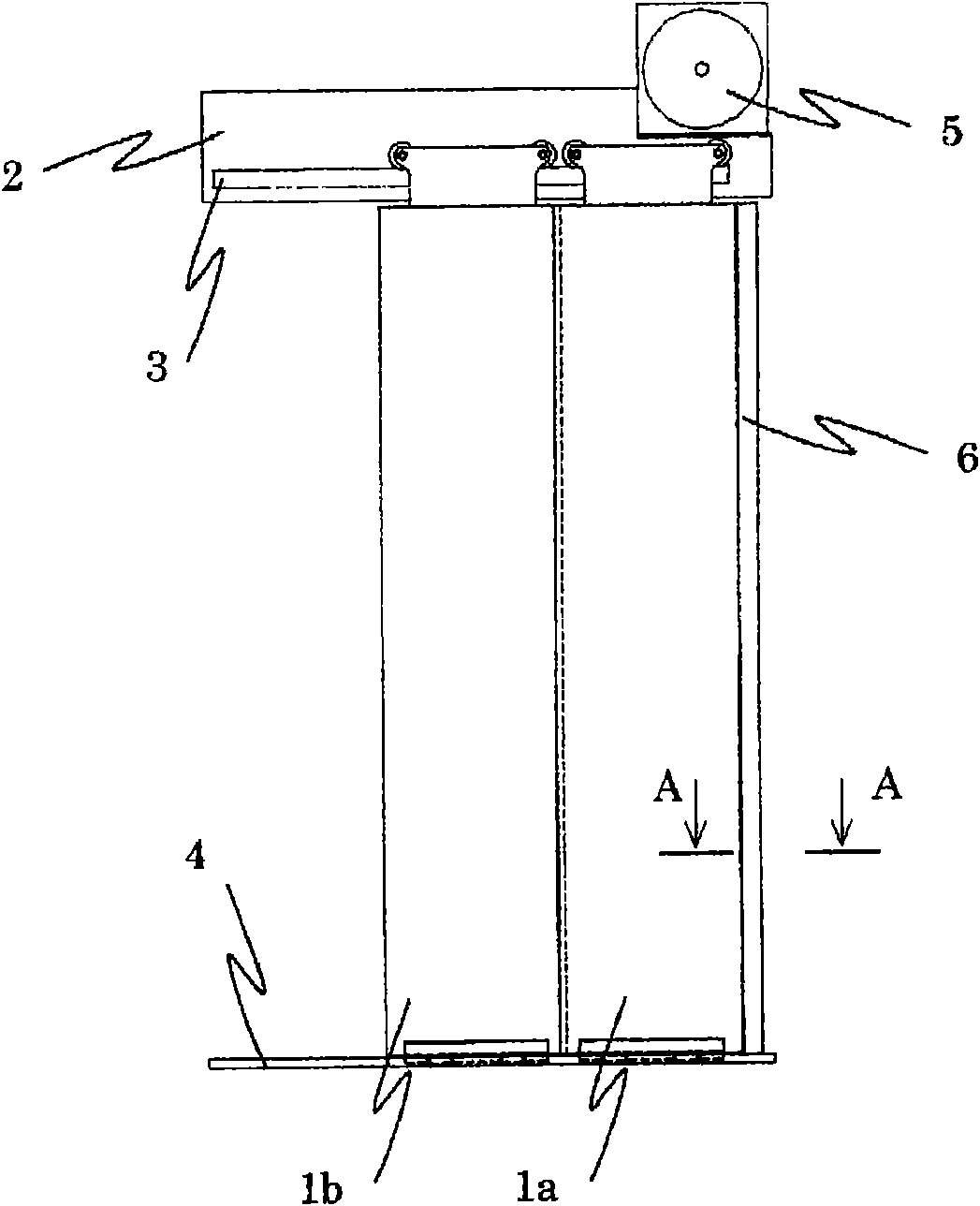

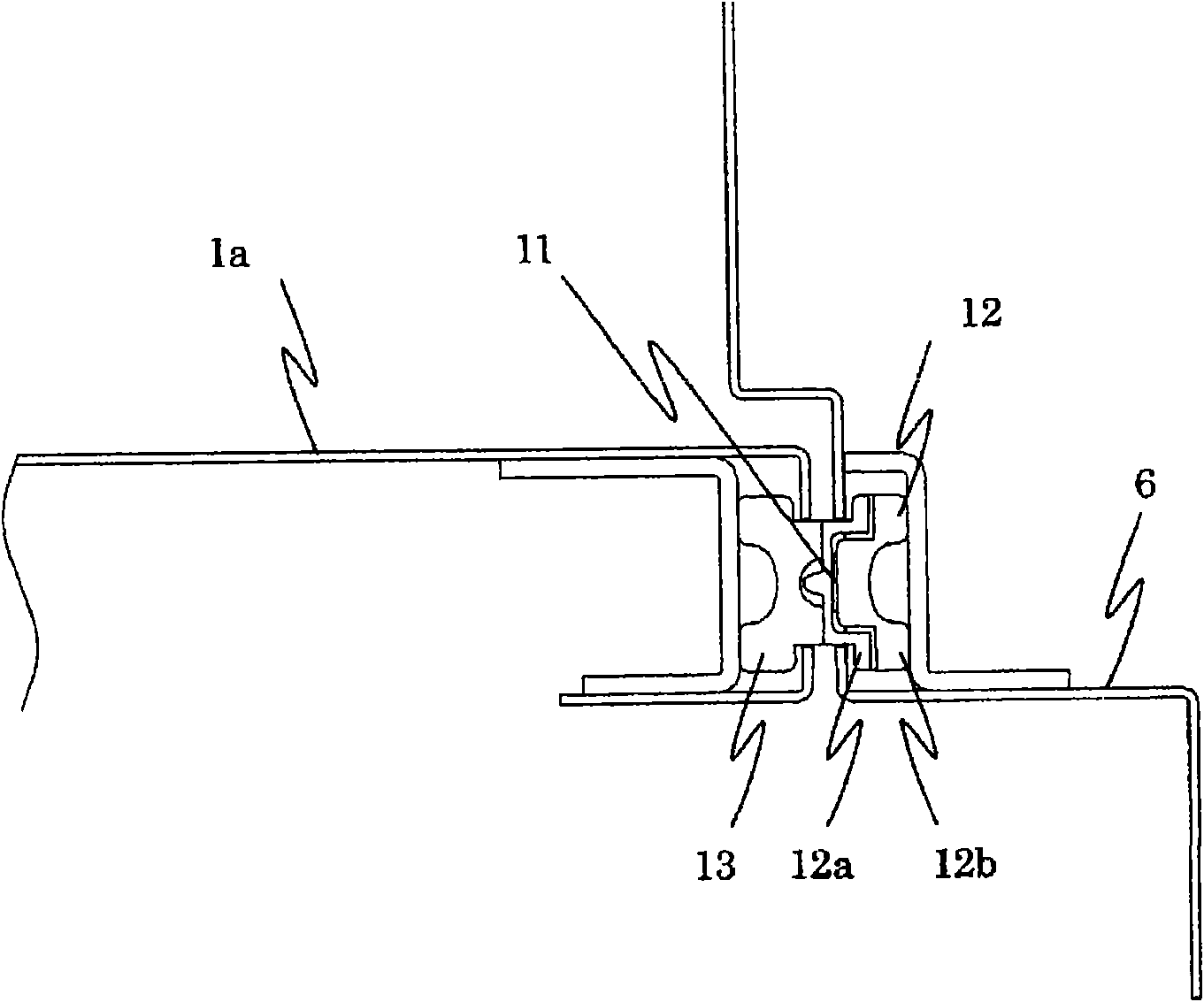

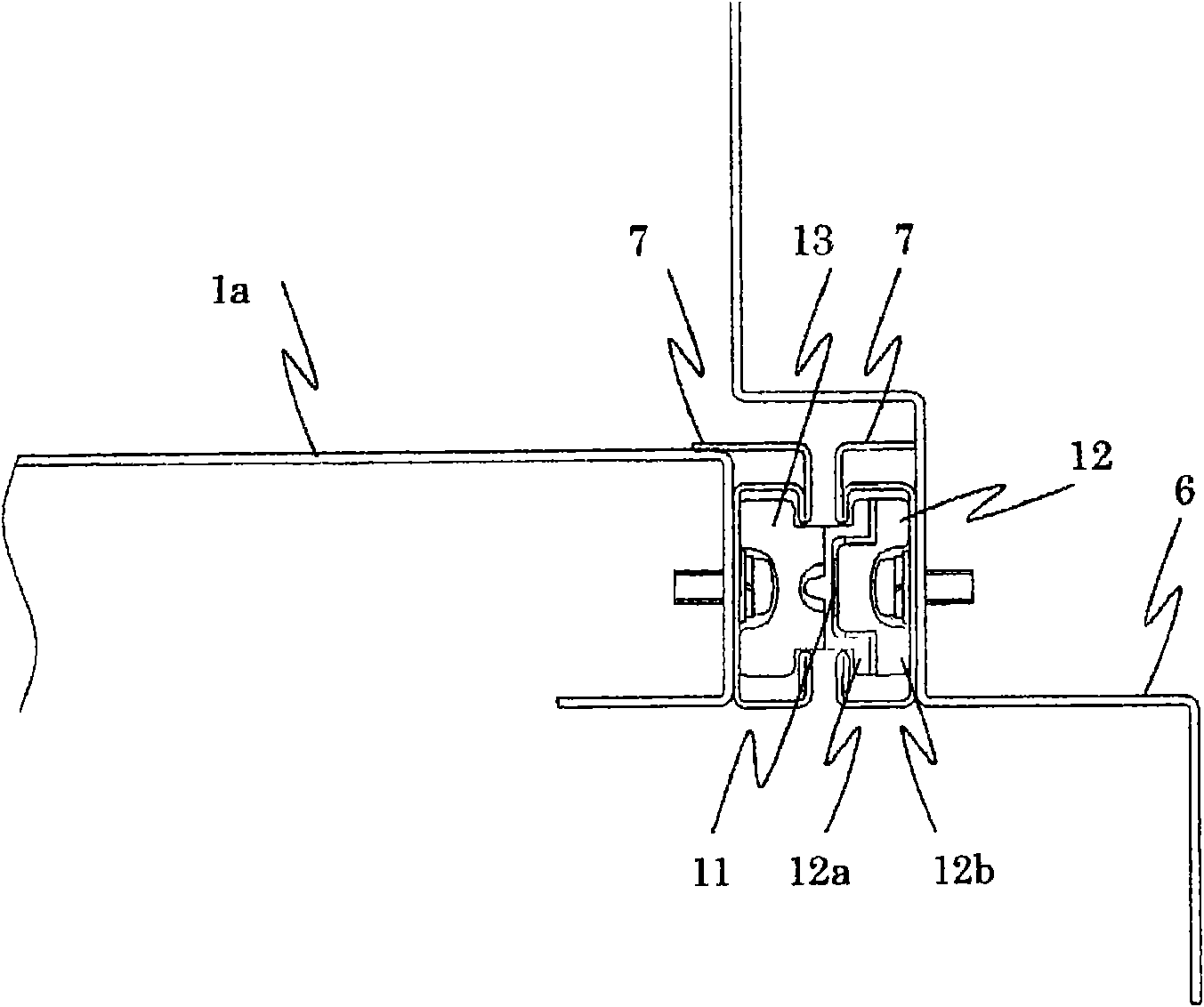

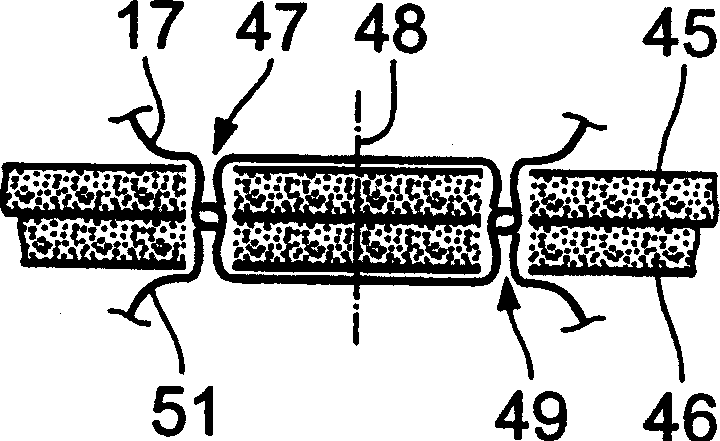

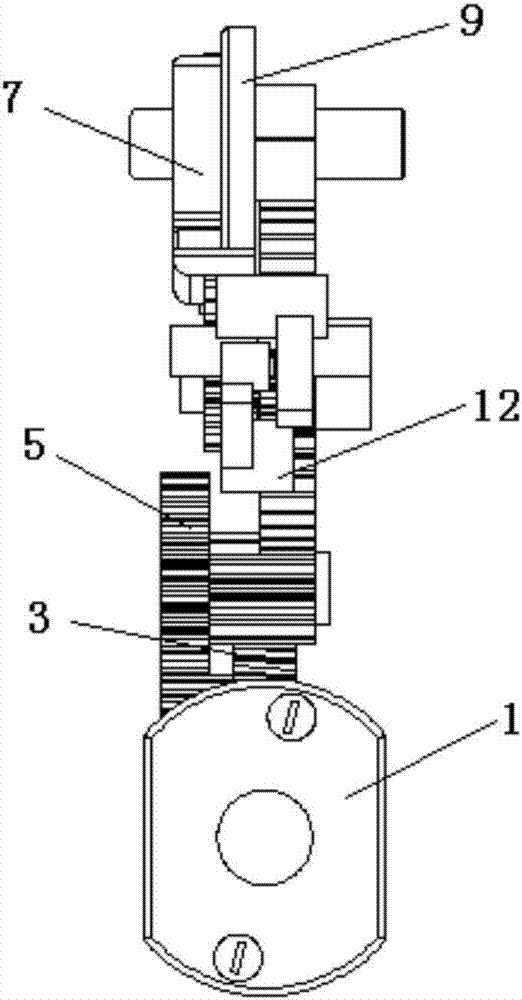

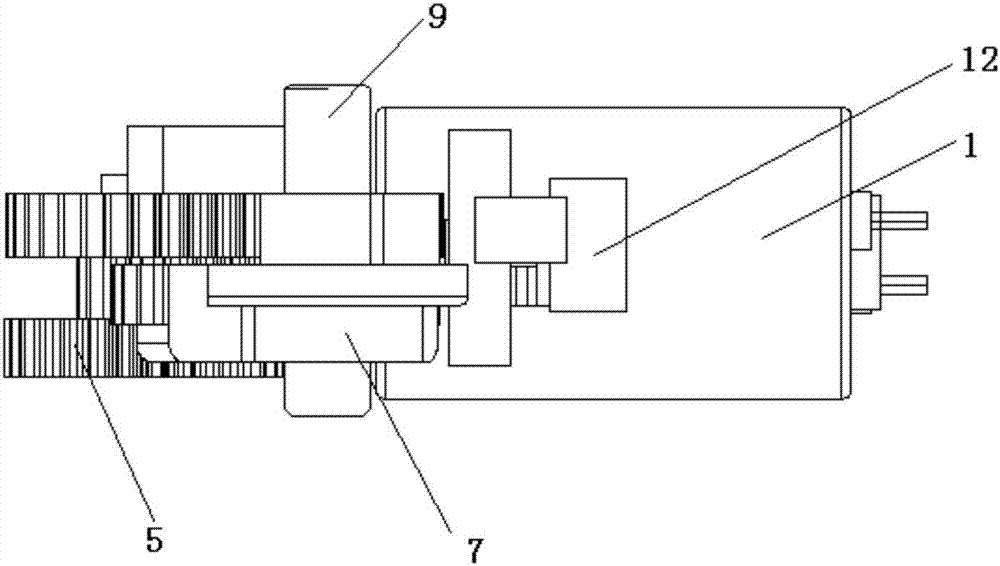

Element head-forming device for continuous fastener stringer-manufacturing machine

Provided is an element head-forming device for a continuous fastener stringer-manufacturing machine, the device being capable of detecting malfunctions with a sensor when press-forming the element material and stopping the continuous fastener stringer-manufacturing machine and of using a sensor with a short measurement distance. The element-forming device is configured so that when press-forming the head (WH) of an element material (WA) using a forming die (4) and a forming punch (5), the leg section (WH) of the element material (WA) is pressed against the forming die (4) by bringing a pressing punch (6), which is biased downward by a plate spring (7), into contact with the leg section (WH) and deforming the plate spring (7) upward. The element-forming device is configured so that: a sensor (20) is provided below the plate spring (7); the sensor (20) detects the distance between the sensor and the plate spring (7) in the vertical direction; and the continuous fastener stringer-manufacturing machine is stopped when a malfunction is detected as a result of the detected distance in the vertical direction differing from the normal distance in the vertical direction. Because the sensor (20) is provided below the plate spring (7), the distance between the sensor (20) and the plate spring (7) is reduced and a sensor with a short measurement distance can be used.

Owner:YKK CORP

Elevator door device

InactiveCN101570297AEasy to change jobsNo false detectionBuilding liftsEmbedded systemForeign substance

The invention provides an elevator door device, which is capable of not only preventing error detection, but also executing replacement operation of sensor conveniently. The elevator door device comprises an elevator door and a detection sensor, wherein the elevator door is used for opening and closing the entrance to the elevator cage, and the detection sensor is used for detection of foreign substance clamped in the elevator door. In the elevator door, the detection sensor is clamped in the buffering components capable of being divided, and disposed on the doorstop column of the elevator or door shield portion of at least one elevator door.

Owner:HITACHI LTD +1

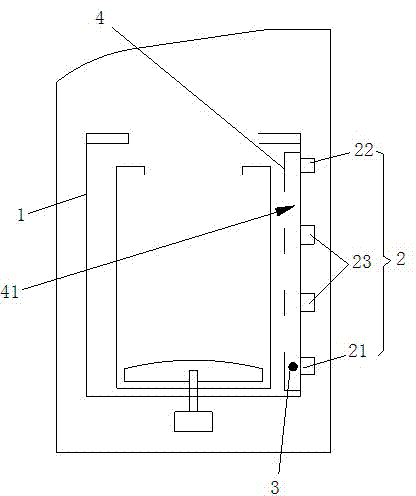

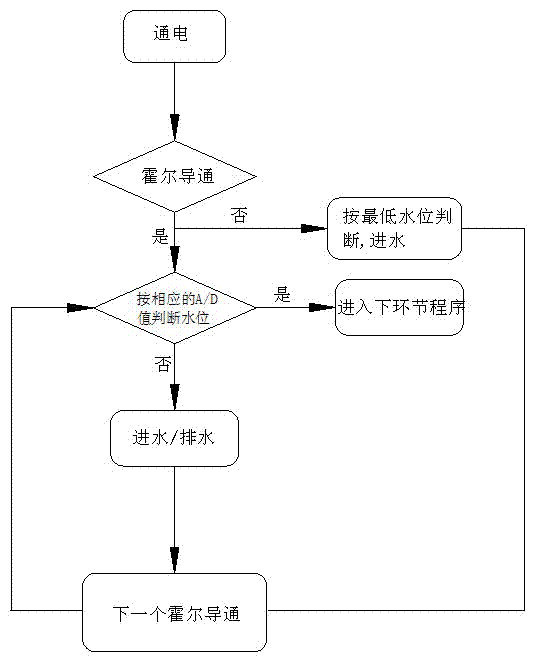

Device and method thereof for detecting water level height of pulsator washing machine

InactiveCN103114421AImprove stabilityAccurate judgmentOther washing machinesControl devices for washing apparatusEngineeringWater level

The invention relates to a device and a method of the device for detecting the water level height of a pulsator washing machine. The device comprises a Hall sensor which is arranged on an outer wall of an outer drum. A magnetic floating device which is capable of lifting along with the water level of the washing machine is arranged on an inner wall of the outer drum, the Hall sensor is communicated with the magnetic floating device at a corresponding position, and the Hall sensor is connected with a controller. The technical scheme indicates that the Hall sensor is arranged on the outer wall of the outer drum, and the magnetic floating device which is capable of lifting along with the water level is arranged on the corresponding position on the inner wall of the outer drum. Along with the raising of the water level in the washing machine, the magnetic floating device is communicated with the Hall sensor at different height. Signals are output from the Hall sensor to the controller, and then judgment of the water level height is made by the controller. The device is accurate in judgment, free from influences of factors of the temperature and tightness and high in stability.

Owner:WHIRLPOOL CHINA

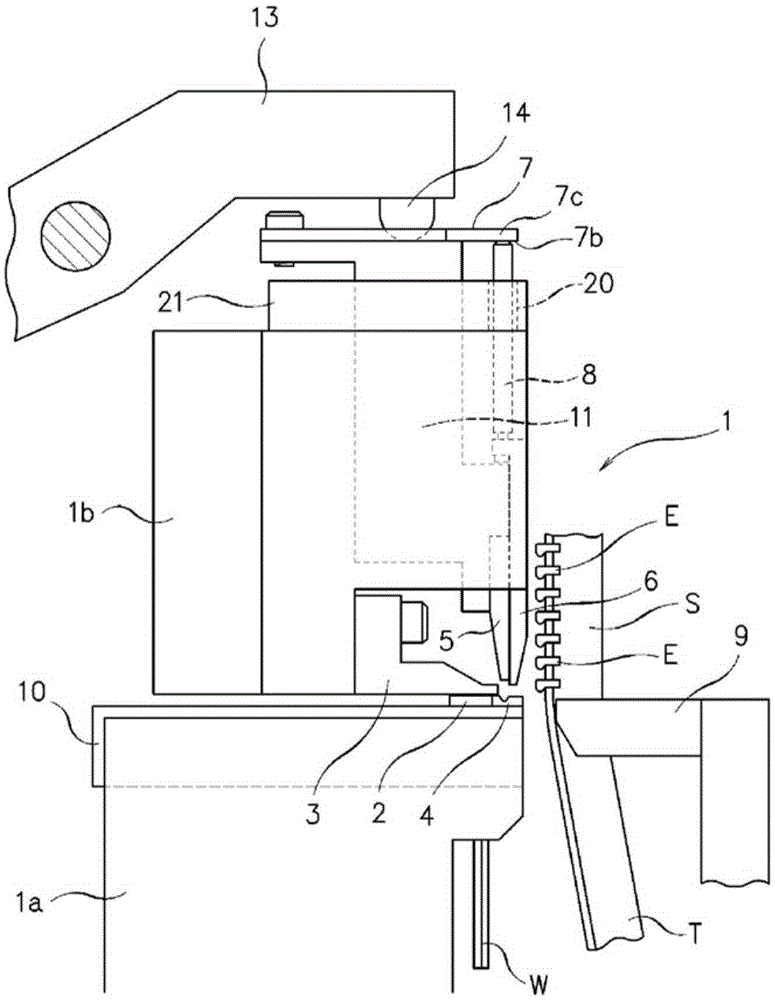

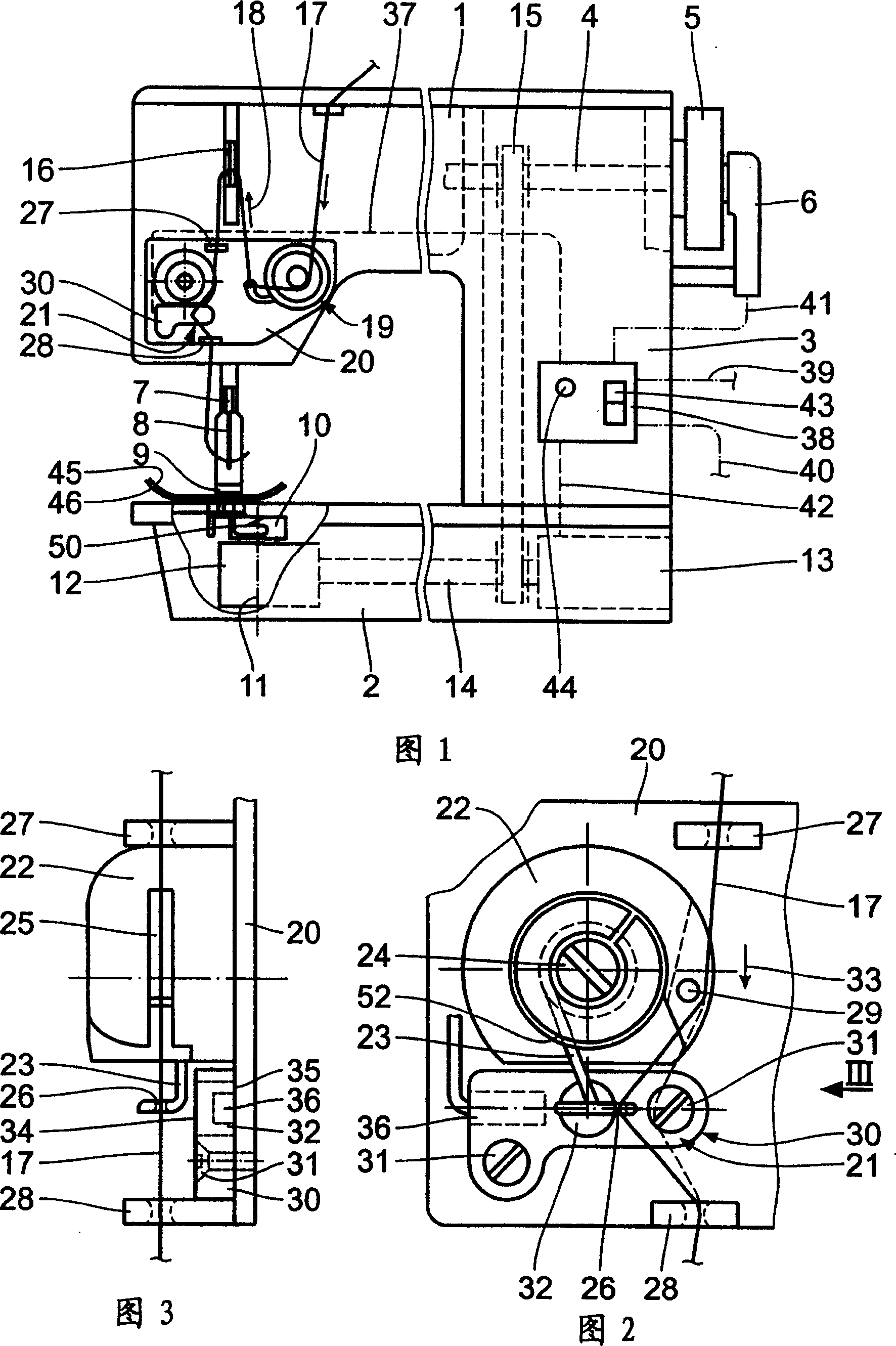

Sewing machine with faulty thread mark detection device

InactiveCN1664214AImplement error detectionNo false detectionDomestic stoves or rangesLighting and heating apparatusControl signalEngineering

The sewing machine is provided with a device (21) to detect an incomplete stitch disposed between a thread winding lever (16) and a needle. The incomplete stitch detection device guides the upper thread (17) and substantially crosses the main direction (33) of the upper thread (17) to have a deflective eye (26). The deflection of the eye (26) produces a change of a magnetic field created by a magnet (32). The change of the magnetic field is detected by a sensor (36) and changed to a control signal of the sewing machine.

Owner:DURKOPP ADLER AG

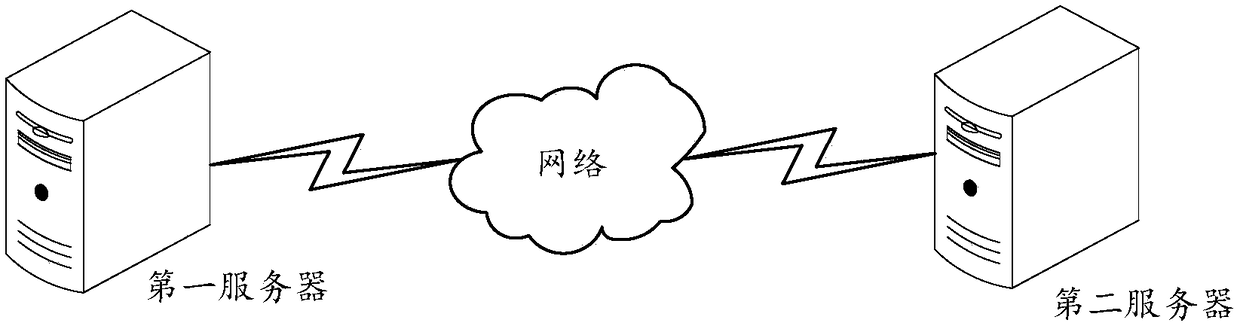

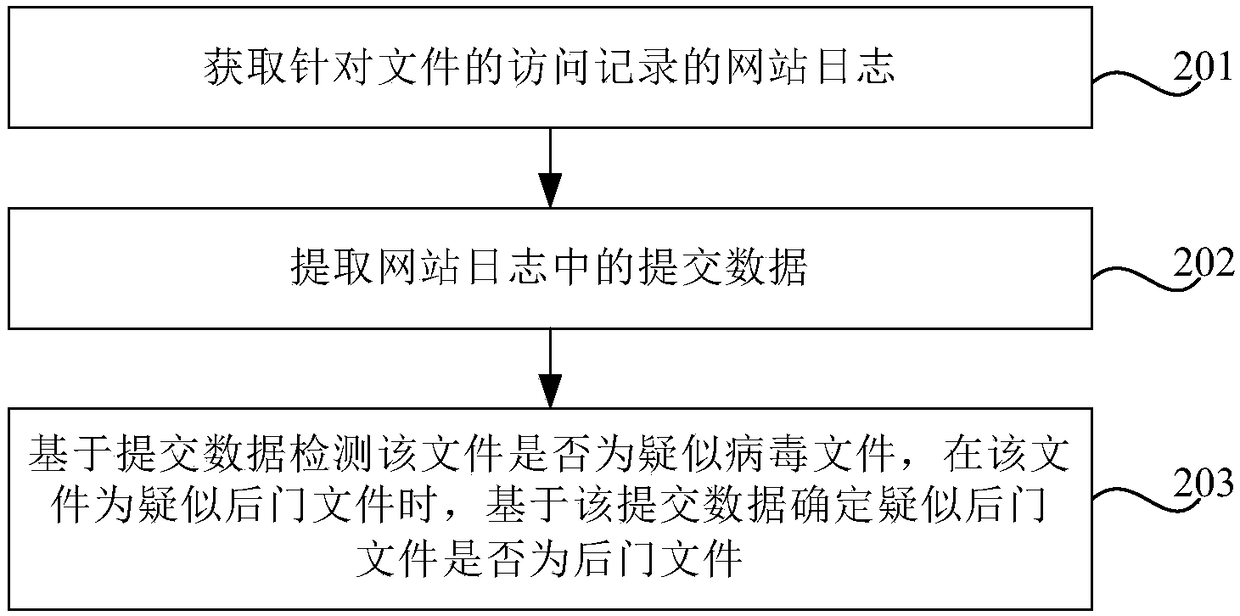

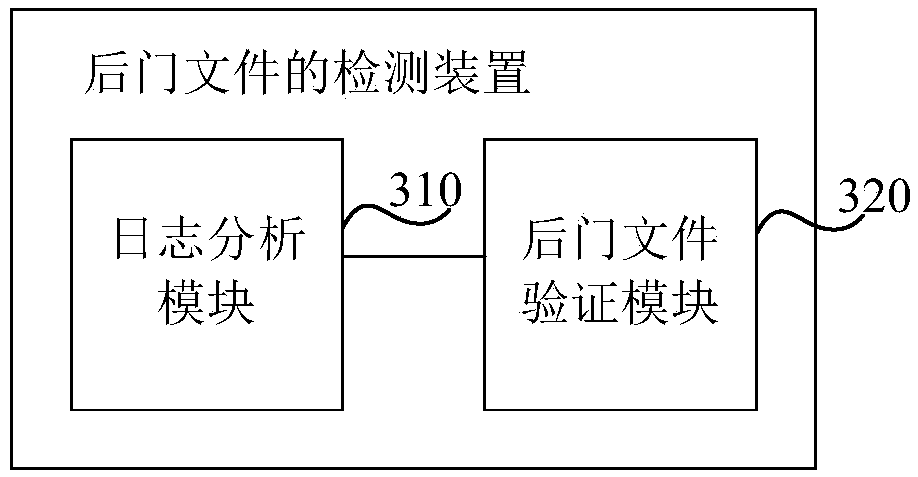

Backdoor file detection method and backdoor file detection device

ActiveCN108322420AProtection securityAccurate identificationTransmissionInternet privacyComputer science

The invention provides a backdoor file detection method and a backdoor file detection device, and the method may comprise the following steps: acquiring website logs aiming at access records of a file; extracting submitted data in the website logs; detecting whether the file is a suspicious backdoor file based on the submitted data, and when the file is the suspicious backdoor file, determining whether the suspicious backdoor file is a backdoor file based on the submitted data. Through the technical scheme provided by the invention, the backdoor file can be identified accurately, and securityof a website can be guaranteed.

Owner:ALIBABA GRP HLDG LTD

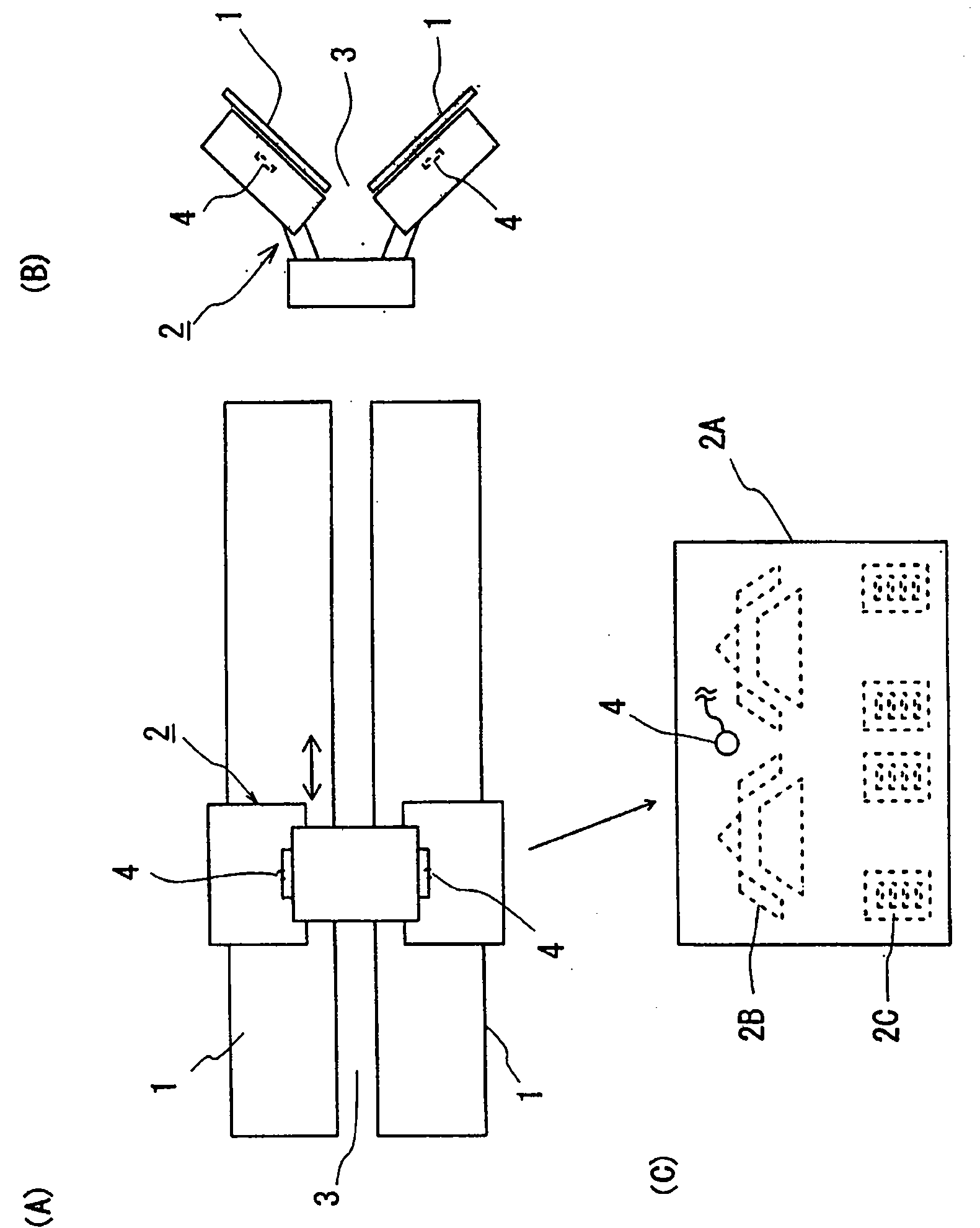

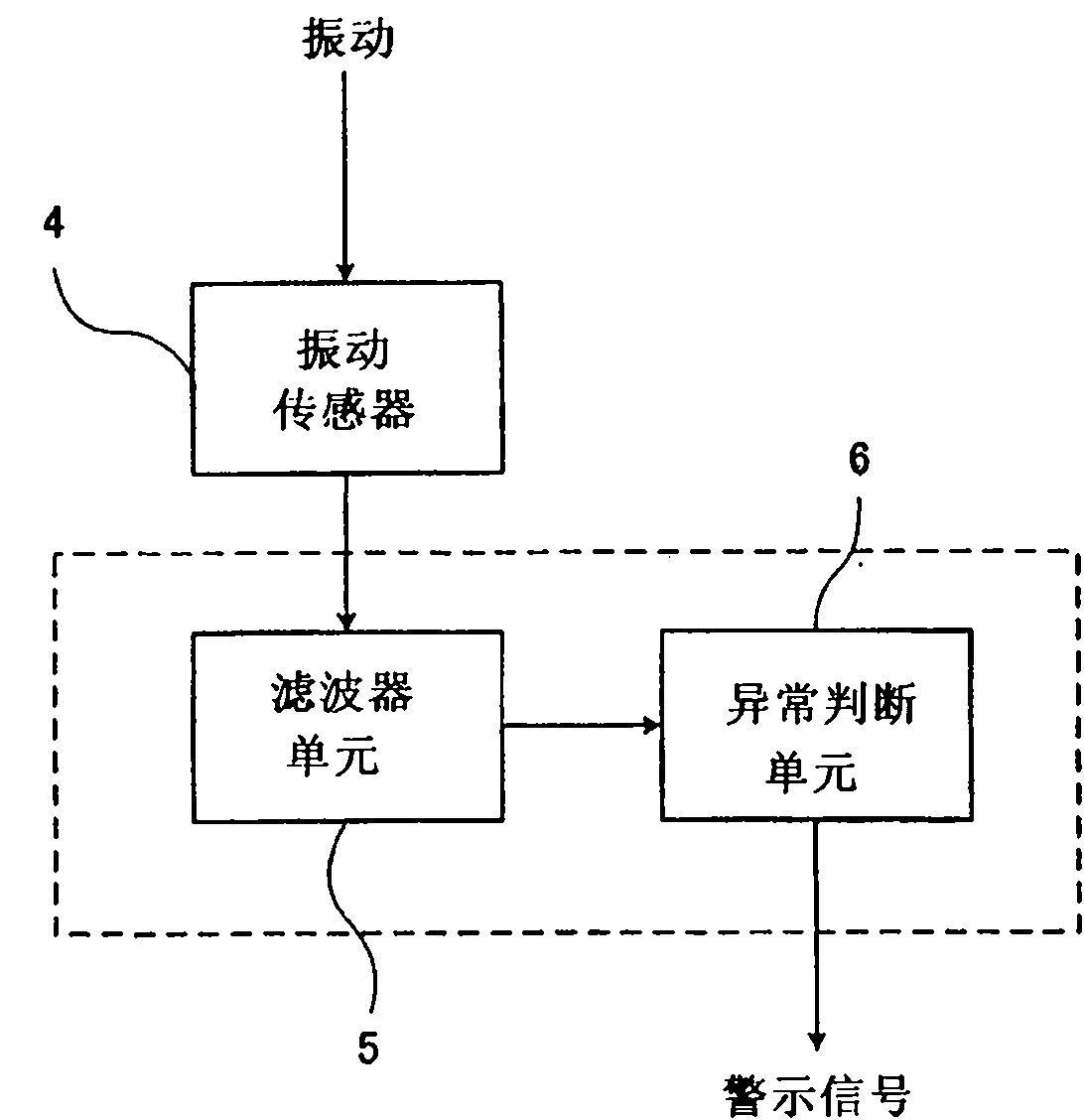

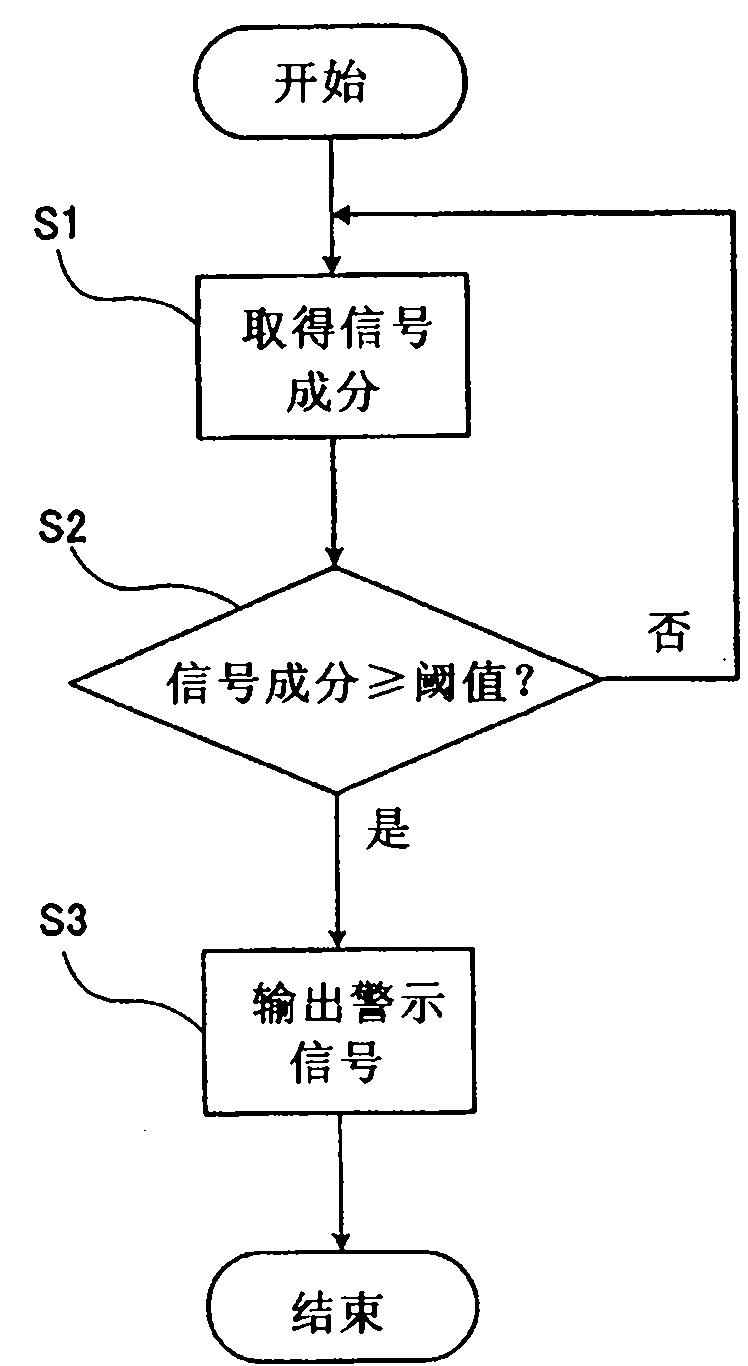

Weft knitting machine, and method for detecting abnormal vibrations in the weft knitting machine

ActiveCN101835930AAvoid missed detectionPrevent false detectionWeft knittingEngineeringVibration sensor

A weft knitting machine can detect abnormal vibrations resulting from an abnormal contact between a carriage and knitting needles, in a high sensitivity. A method can detect those abnormal vibrations. The weft knitting machine comprises a needle bed (1) having a plurality of knitting needles arrayed in parallel, and a carriage (2) running reciprocally over the needle bed (1) for moving the knitting needles back and forth. The carriage (2) includes vibration detecting means (or a vibration sensor (4)), which detects the vibrations to occur in a direction to intersect the running direction of the carriage (2). On the basis of the detection result, abnormal deciding means decides whether or not the abnormal vibrations are caused by the abnormal contact between the carriage (2) and the knitting needles. Even in case the running speed of the carriage (2) is high, the abnormal vibrations can be so detected as are discriminated from the vibrations accompanying the normal knitting operation.

Owner:SHIMA SEIKI MFG LTD

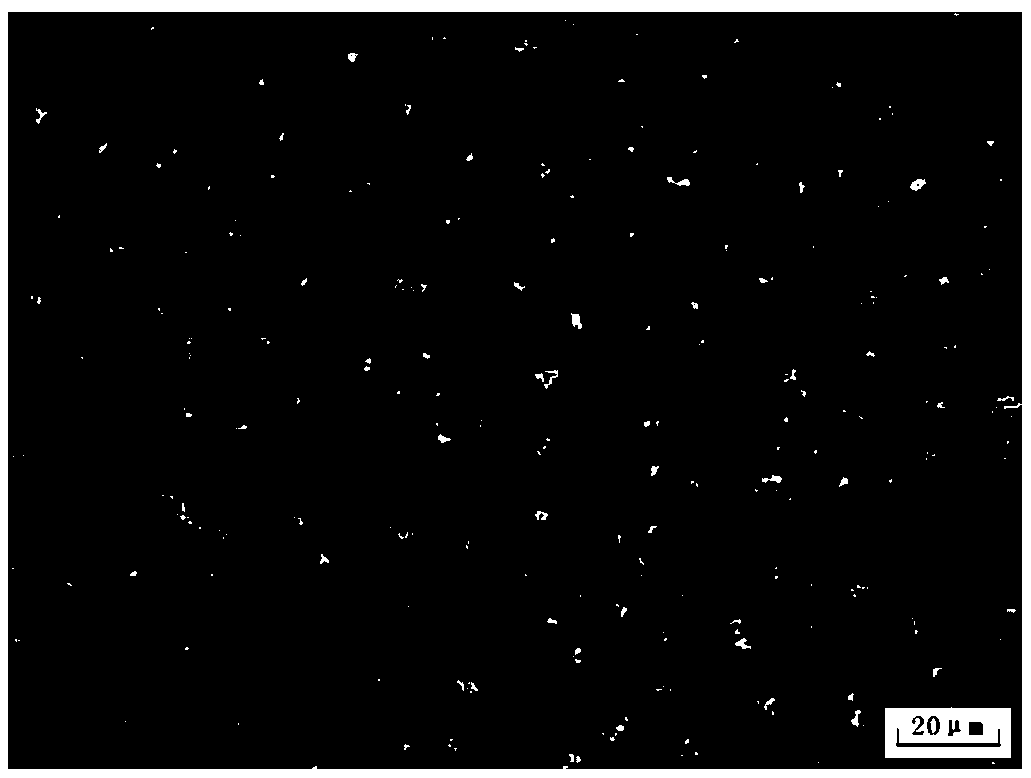

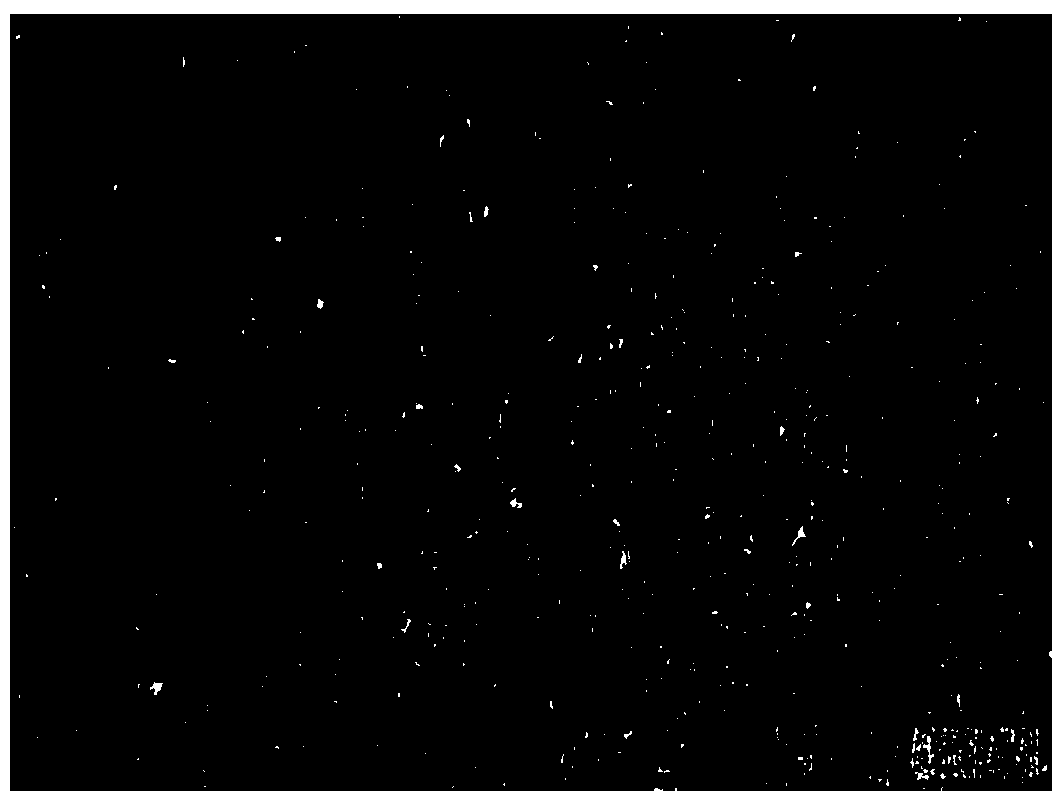

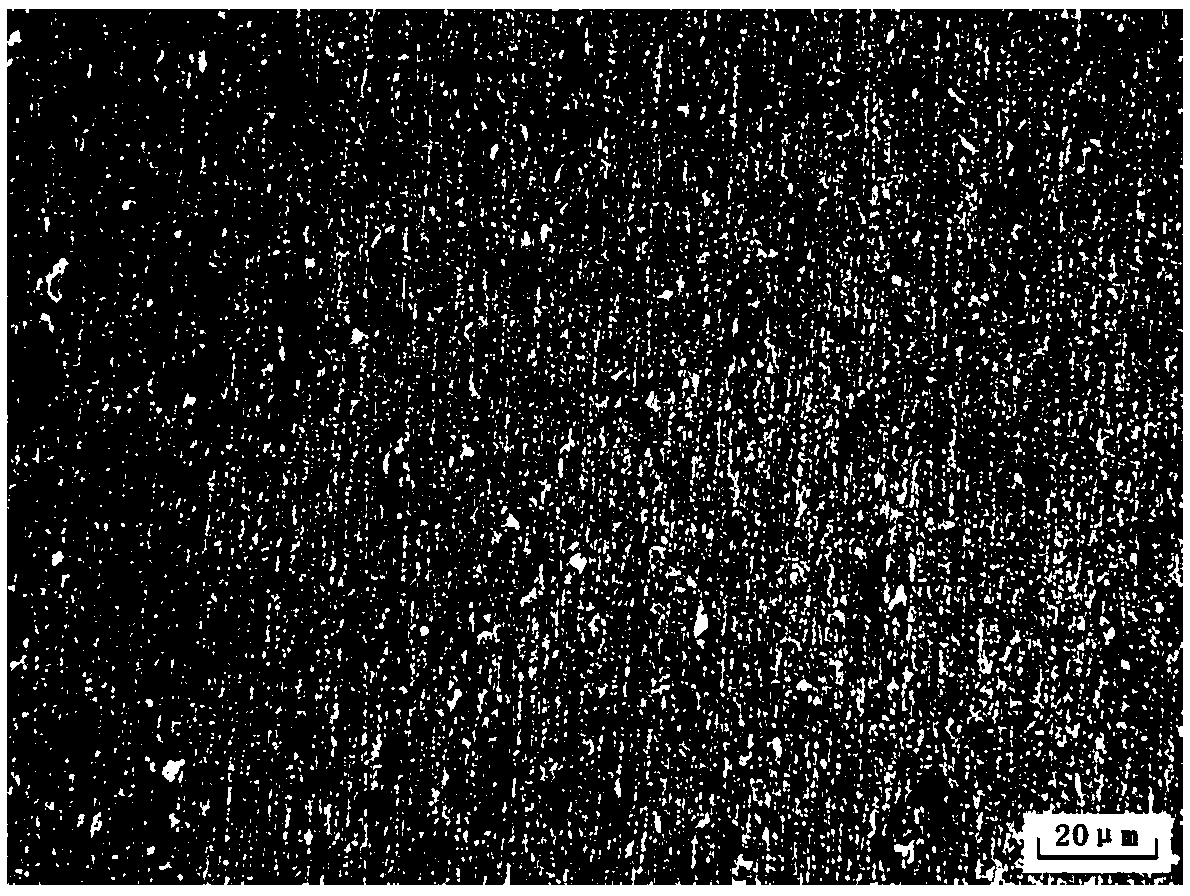

Method for detecting distribution and content of residual austenite in low alloy structure steel

ActiveCN109142010AThe overall image is beautifulGood for metallographic observationPreparing sample for investigationMaterial analysis by optical meansAlloySolvent

The invention discloses a method for detecting distribution and the content of residual austenite in low alloy structure steel. Water is used as cooling liquid, metallographic waterproof abrasive paper is used for rough grinding and fine grinding of a test surface of a sample, the sample subjected to fine grinding is polished, sodium metabisulfite, picric acid, sodium hydroxide, distilled water, hydrochloric acid and absolute ethyl alcohol are mixed, stirred and heated to prepare a corrosion reagent, the polished sample is subjected to electrolytic polishing treatment, the sample subjected toelectrolytic polishing treatment is placed into prepared corrosion solvents to remove interference phases, and distribution and the content of the residual austenite of the sample are detected by metallographic observation and representation. The method is simple in operation and short in polishing corrosion time. After the low alloy structure steel is corroded, a residual austenite structure in the low alloy structure steel can be clearly displayed. Characteristic parameters such as the content, the size, the shape and distribution of the residual austenite can be rapidly, accurately and quantitatively analyzed by metallographic software.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

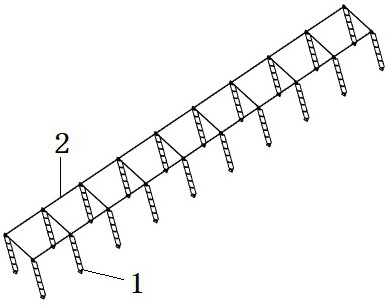

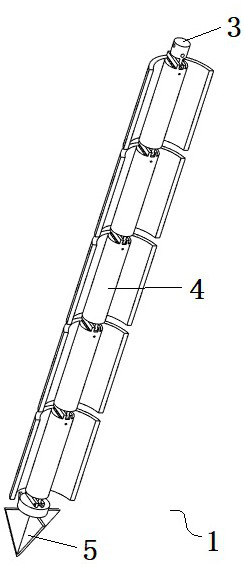

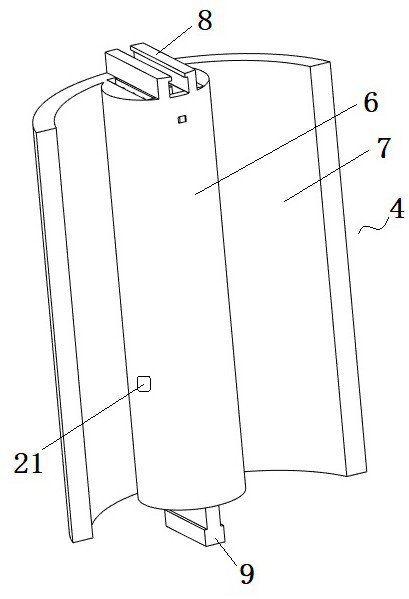

Mining area rock-soil layer disintegration and landslide early warning system

ActiveCN111811704APrevent slidingImprove consistencyForce measurementAlarmsEarly warning systemSoil science

The invention relates to a landslide early warning system, in particular to a mining area rock-soil layer disintegration and landslide early warning system, which comprises detection piles and pull rods. The pull rods are used for connecting all the detection piles; each detection pile comprises a plurality of detection modules, a hammering pull head and a conical head; and the detection modules are sequentially connected in the vertical direction. Each detection module is provided with a sliding block, a sliding closing plate, a mass block, a pore pressure sensor, a strain gauge type pressuresensor and a follow-up rod. When landslide occurs in a certain layer, the corresponding detection module is pushed to move, the sliding block pushes the follow-up rod on a sliding sealing plate to move, that is, a sliding deviation piece can move, and under the self-stabilization effect of the mass block, the sliding deviation piece and the follow-up rod can move in the direction opposite to thedisplacement direction of the detection module, a strain gauge type pressure sensor is attached to the side face of the follow-up rod, and an alarm is given for sudden increase of the numerical valueof the pore pressure sensor and the numerical value of the strain gauge type pressure sensor.

Owner:LIAONING TECHNICAL UNIVERSITY

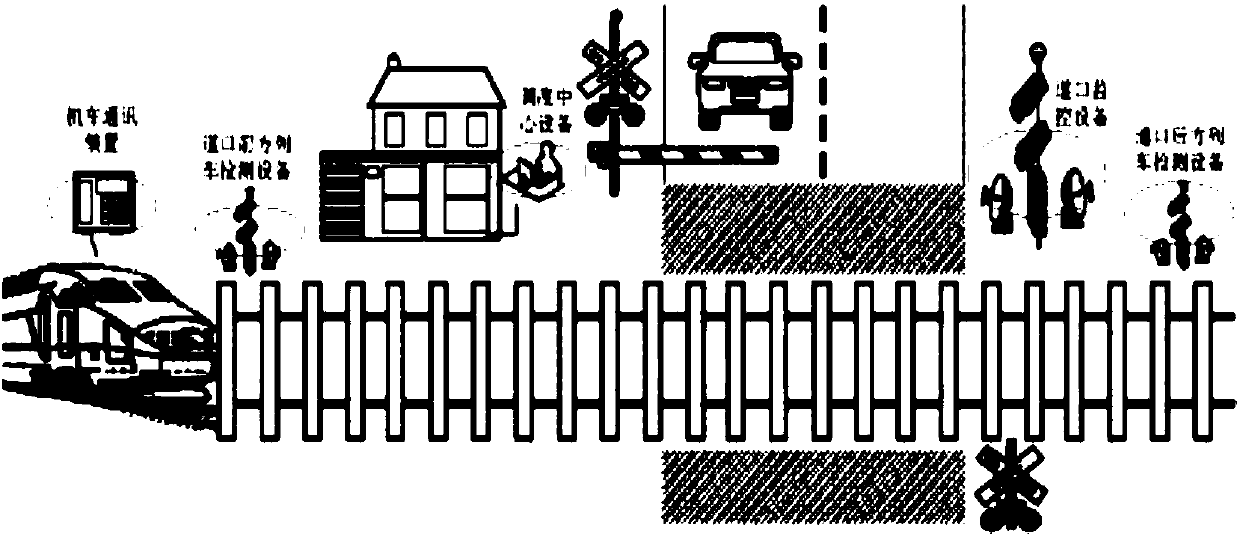

Railway crossing video monitoring and remote control system

InactiveCN107666602AFix jitterAdaptableTelevision system detailsColor television detailsVideo monitoringEngineering

The invention discloses a railway crossing video monitoring and remote control system comprising scheduling center equipment, train detection equipment placed on two sides of the crossing, crossing monitoring equipment, an outdoor power supply device, a locomotive communication device, a data transmission network and a remote control center; the scheduling center equipment and the locomotive communication device can realize wireless bidirectional connection through GPRS communications; the crossing monitoring equipment and the scheduling center equipment can unidirectionally communicate through the communication network; the output ends of the train detection equipment on two sides of the crossing are respectively unidirectionally connected with the scheduling center equipment and the crossing monitoring equipment through the communication network. The crossing monitoring equipment comprises an industrial control computer, a high definition network camera, a wireless network camera, awireless network transmit-receive device and an alarm device; the system is combined with a high efficient barrier identification algorithm so as to accurately distinguish whether a detected target isa barrier or not, thus preventing leak detection and false detection, and effectively improving the system reliability.

Owner:成都九壹通智能科技股份有限公司

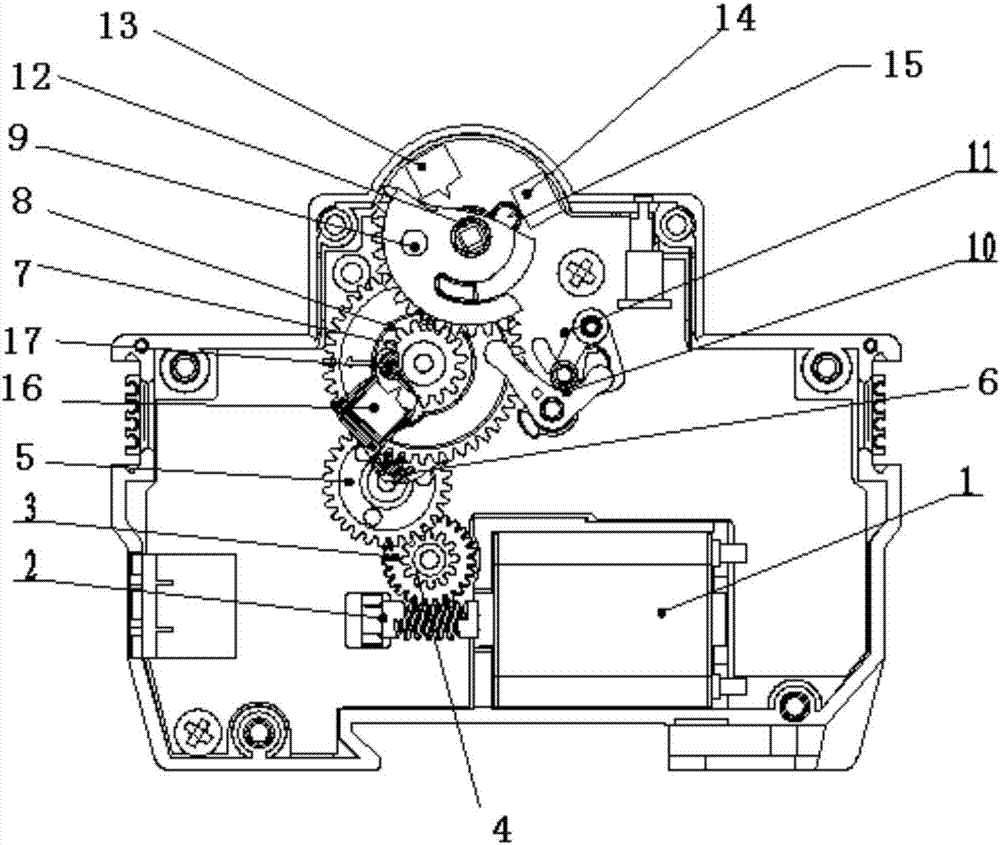

Electric operating mechanism of circuit breaker

ActiveCN107240535AScattered distributionNo false detectionProtective switch operating/release mechanismsDrive shaftElectric control

The invention provides an electric operating mechanism of a circuit breaker. The electric operating mechanism comprises a housing, a transmission shaft, a driving device, a striking device, a position detection device and an electric control device, wherein the position detection device comprises a switch-on position detection device, a switch-off position detection device and a free position detection device; the switch-on position detection device and the switch-off position detection device are arranged on the two sides around the transmission shaft; and the free position detection device is arranged at the driving device far away from the transmission shaft. Distribution of the position detection devices is relatively disperse; the position detection devices are free from false detection when a first detection object and a second detection object are respectively detected; and a detection range is large due to the arrangement manner of the position detection devices.

Owner:合兴集团有限公司

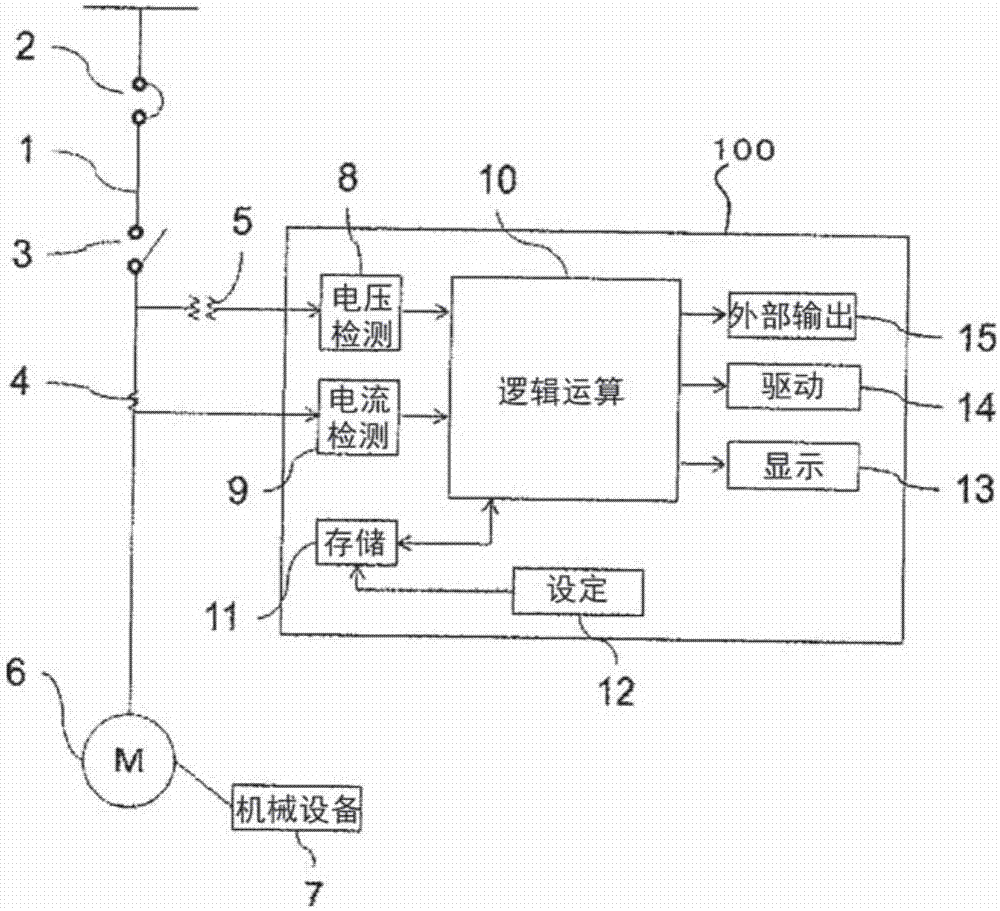

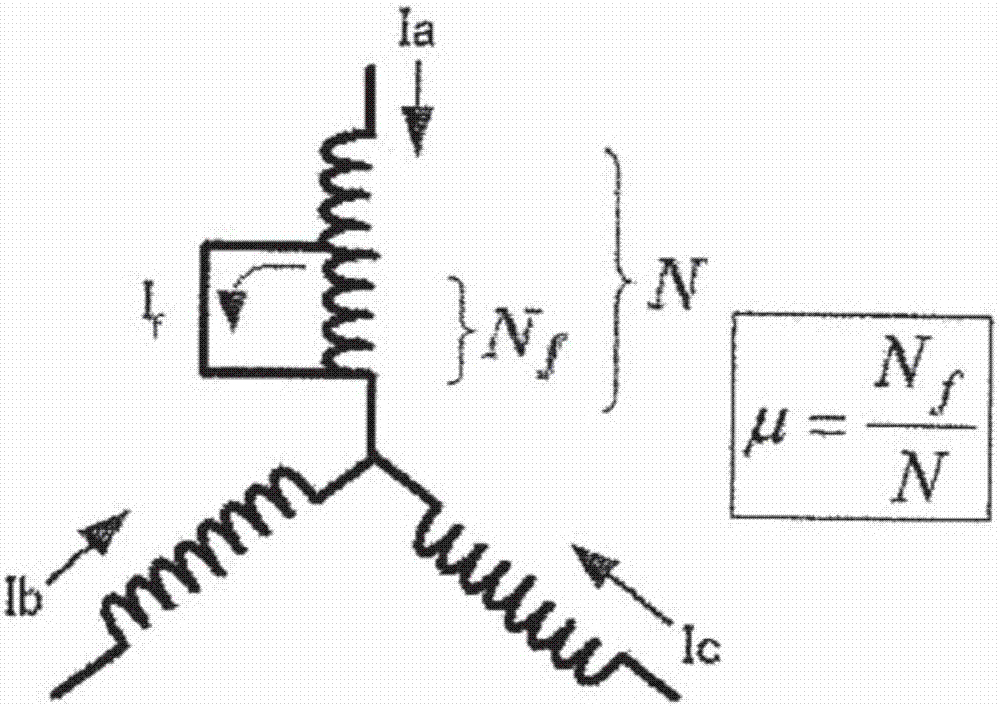

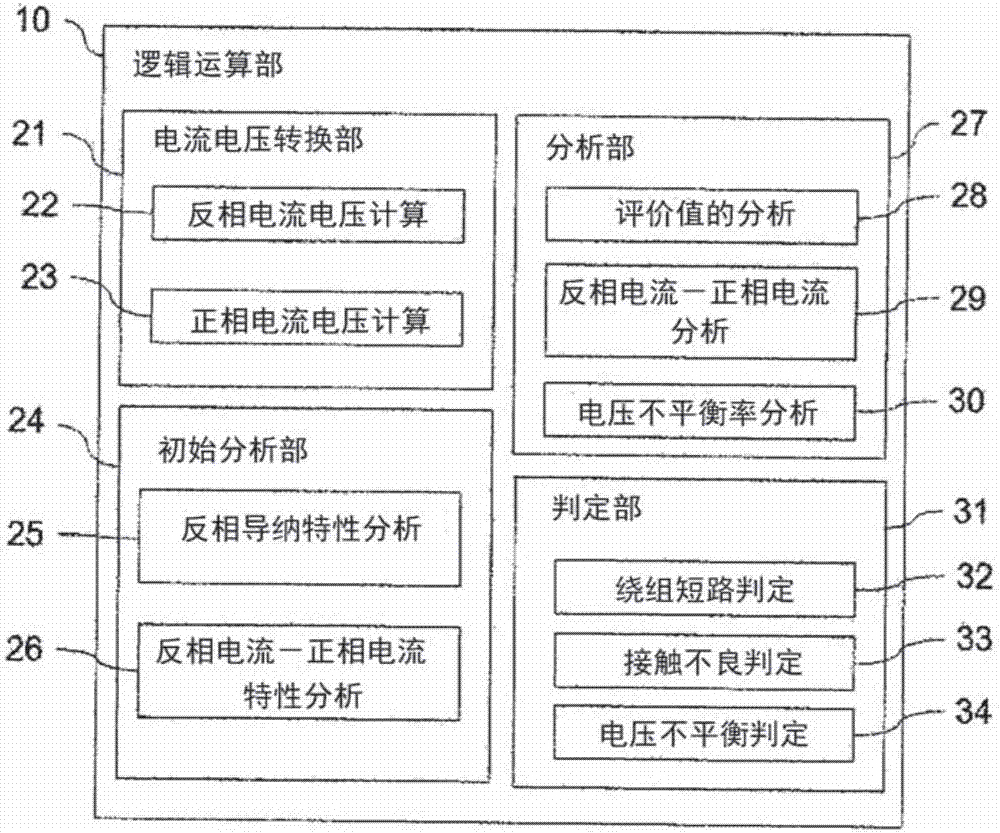

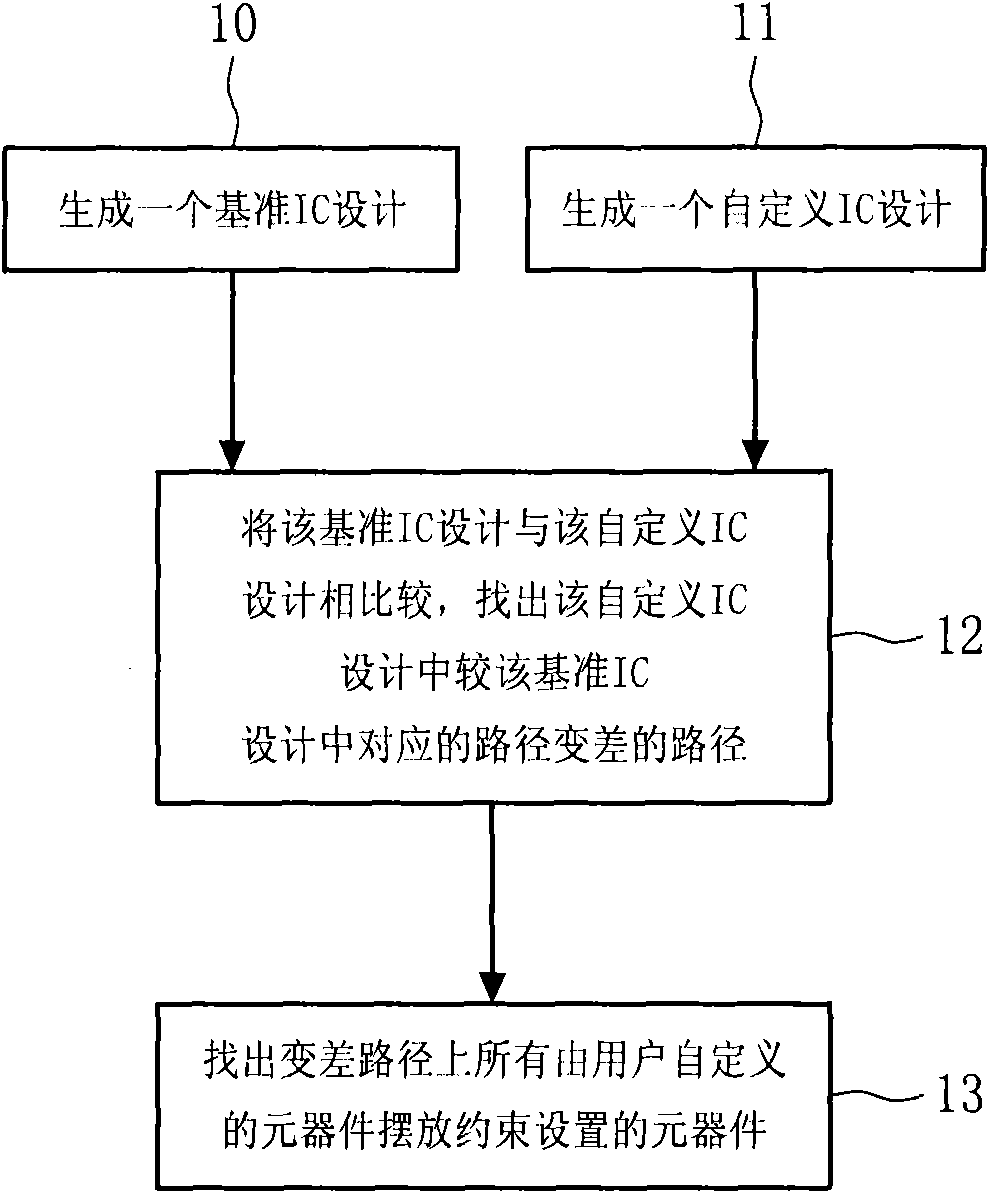

Electric motor diagnosis device

ActiveCN107155353ANo false detectionAC motor controlPolyphase network asymmetry measurementsStatorCurrent analysis

Short-circuit diagnosis devices for electric motor stator windings have had a problem wherein because calculation parameters are influenced by load torque fluctuation, power imbalance, and contact failure, it is difficult to correctly and highly accurately detect a winding short-circuit. The present invention is provided with a logical operation unit (10) that receives the output of a current detection circuit (9) for detecting the current of an electric motor (6) and a voltage detection circuit (8) for detecting the voltage of the electric motor (6) and a display unit (13) and external output unit (15) for respectively providing an abnormality indication and external notification when the logical operation unit (10) detects an abnormality in the electric motor. Through voltage and current analysis of the electric motor, the logical operation unit (10) distinguishes power supply imbalance and identifies and detects a winding short circuit on the basis of reverse-phase current, reverse-phase voltage, positive-phase current, and reverse phase admittance even if a load torque varies while the electric motor is operating.

Owner:MITSUBISHI ELECTRIC CORP

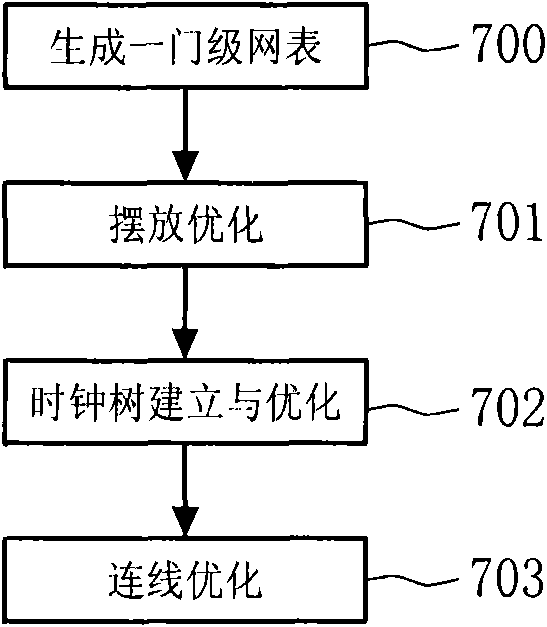

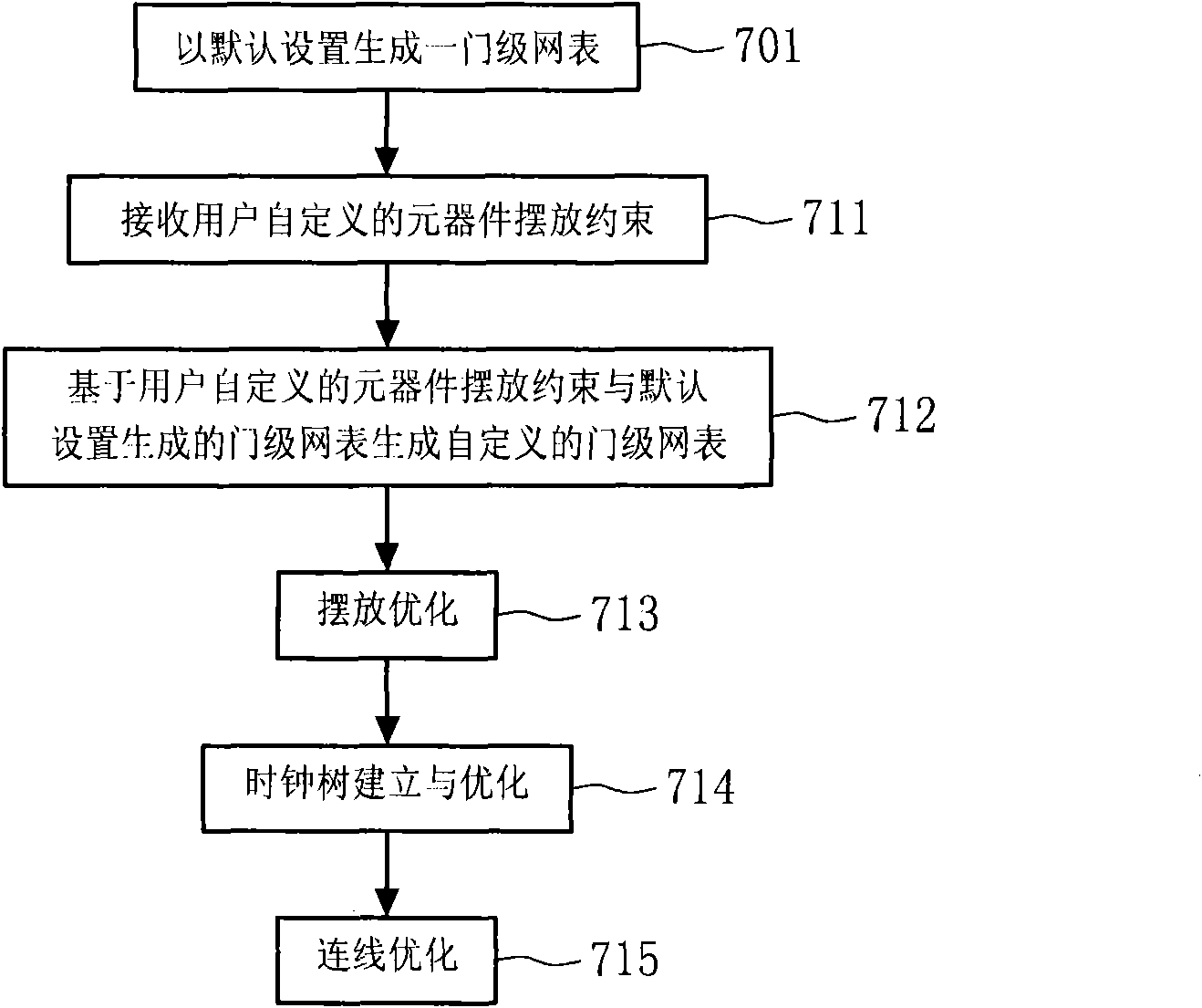

Method and device for detecting unreasonable component placement constraint

InactiveCN102054080ANo false detectionWill not missSpecial data processing applicationsComputer architectureCircuit design

The invention provides a method and a device for automatically detecting unreasonable RP constraints which are defined by a user, wherein the detection method comprises the following steps of: respectively producing a reference integrated circuit design and a user-defined integrated circuit design, wherein, in relation to the reference integrated circuit design, the user-defined integrated circuit design is added with component placement constraints which are defined by at least one user; then comparing the reference integrated circuit design with the user-defined integrated circuit design, and finding out all deviation paths of the user-defined integrated circuit design by means of a judgment standard in relation to the corresponding paths of the reference integrated circuit design; and then finding out all components which are defined by the component placement constraints defined by at least one user from the deviation paths, thereby finding out the unreasonable component placement constraints from the component placement constraints which are defined by at least one user. The method and the device for detecting unreasonable component placement constraints provided by the invention have the advantages that the detection result is accurate, the detection efficiency is high and the design results are more suitable to expected results.

Owner:SYNOPSYS SHANGHAI

Automatic spot welding machine

InactiveCN104339104AFast workReduce labor costsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding power supply

The invention discloses an automatic spot welding machine. The automatic spot welding machine comprises a machine frame and a welding power supply arranged on the machine frame, wherein the welding power supply is connected with a welding transformer, a pressure monitor, and a spin welding mechanism for preventing electrodes from sticking; the spin welding mechanism comprises a (X, Y and Z) three-axis servo module feeding system; the welding power supply, the welding transformer and the pressure monitor are connected with the spin welding mechanism. The automatic spot welding machine is provided with conveying equipment; the original spot welding function does not stick the electrodes, so that the working speed is improved and inspection omission and mistaken inspection can be avoided; the labor cost is saved and the production schedule is quickened.

Owner:SUZHOU NIPPO AUTOMATION TECH

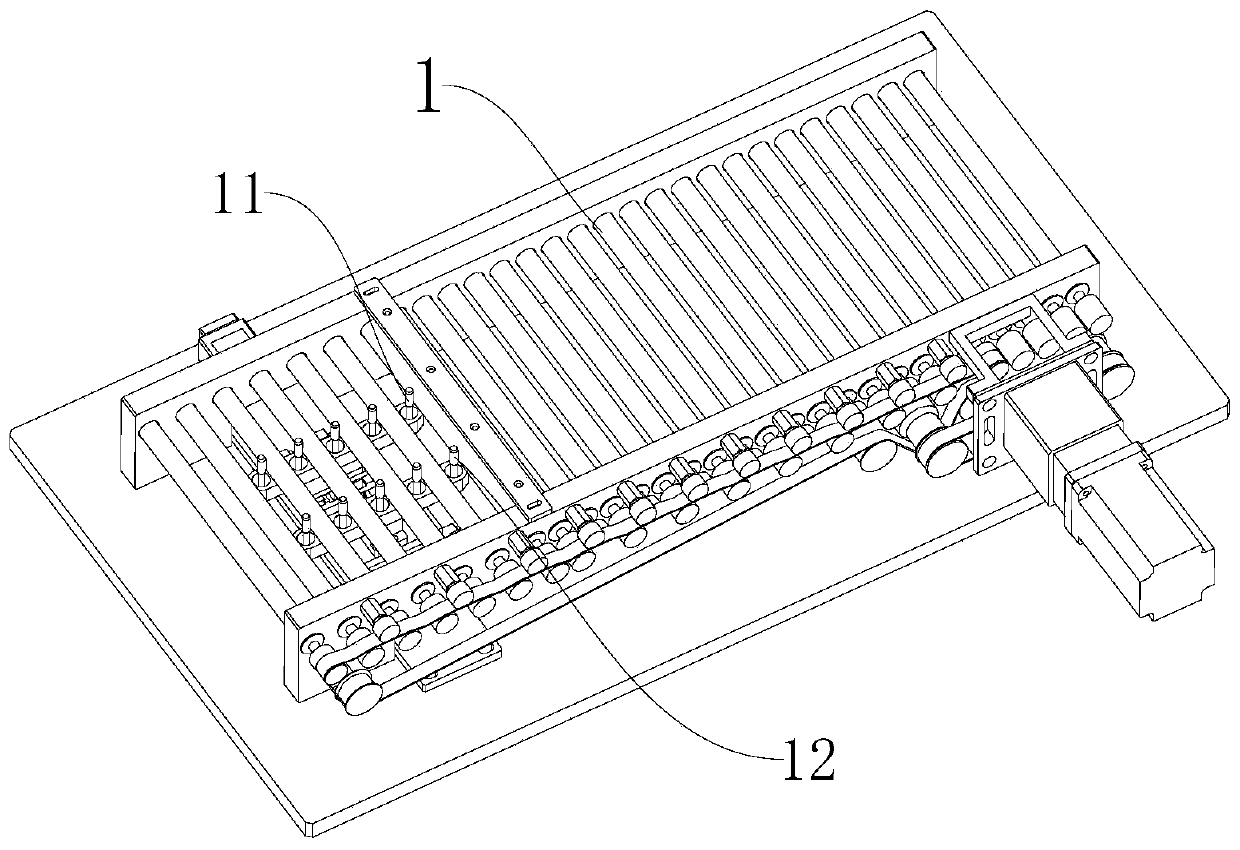

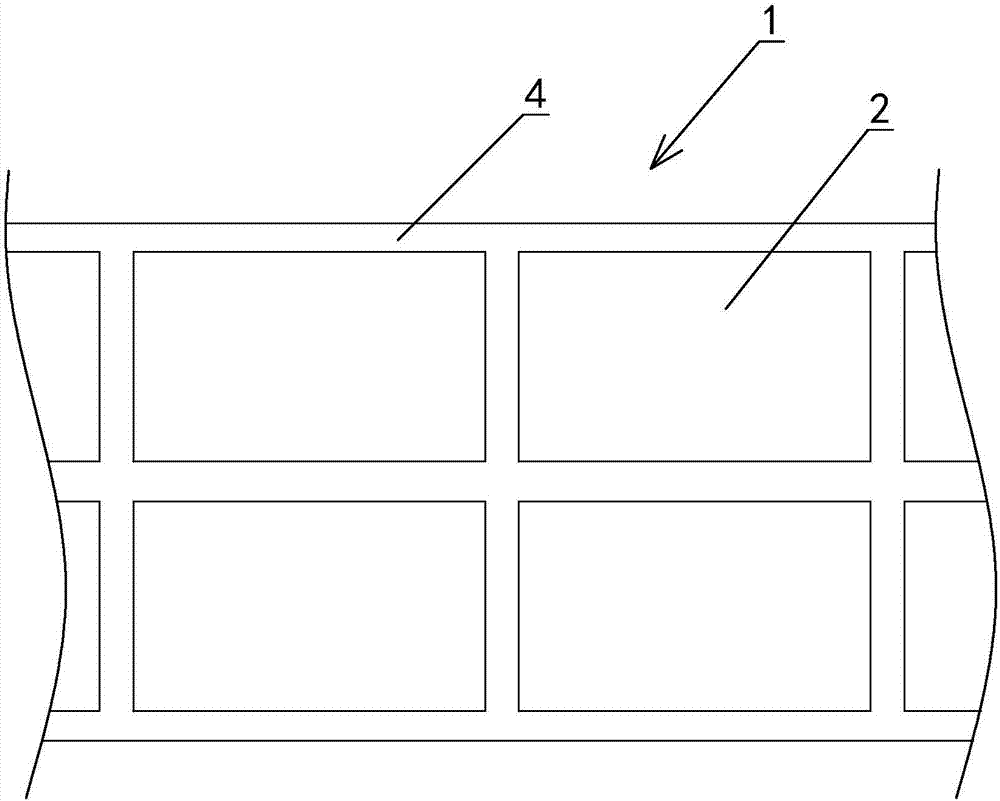

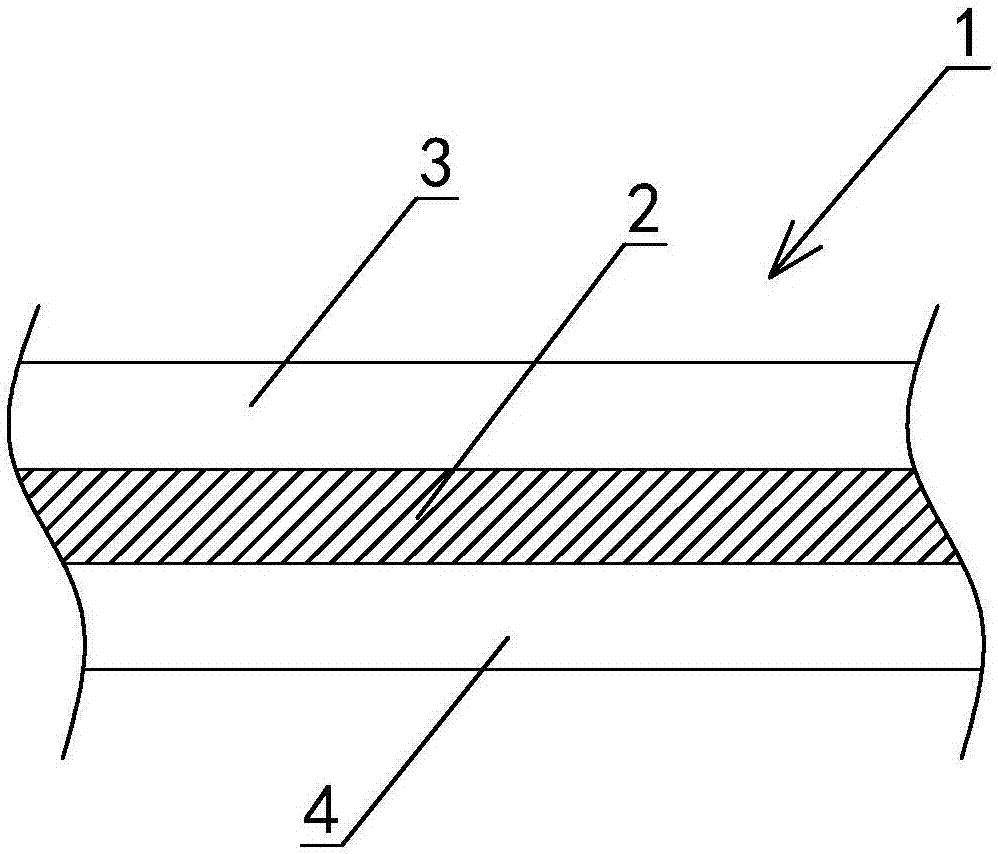

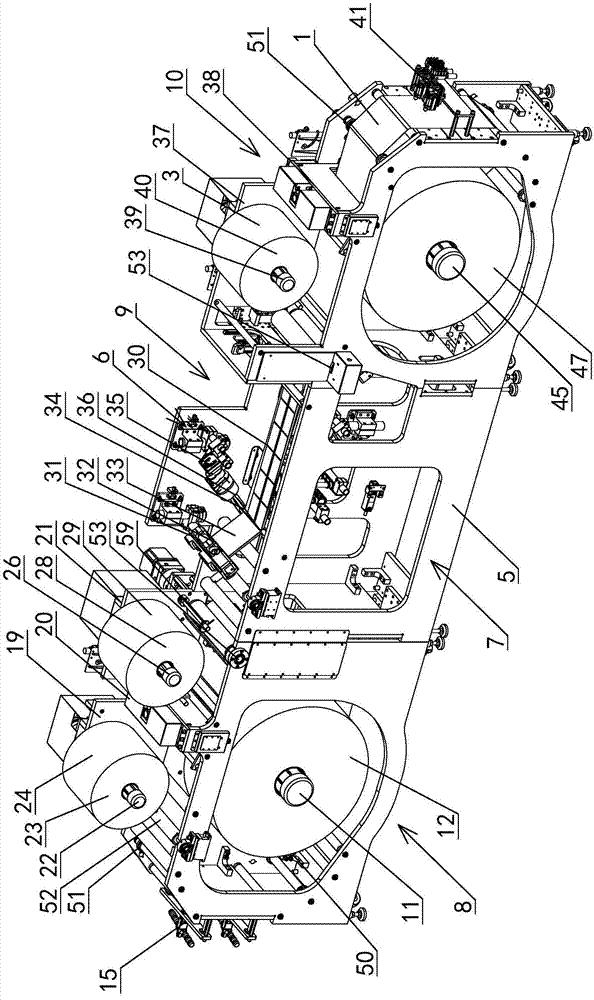

Optical film intelligent vision detection and defective product removal equipment

ActiveCN107362980AImprove defect recognition rateImprove detection efficiencySortingTectorial membraneQuality control

Optical film intelligent vision detection and defective product removal equipment comprises a feed unit, a detection unit, a defective product removal unit and a receiving unit, wherein the feed unit comprises a feed module and a protective film uncovering mechanism, and the protective film uncovering mechanism comprises an adhesive tape feed module, an adhesive tape pressing-sticking module and a protective film uncovering module; the detection unit comprises an illumination module, a camera shooting module and an upper computer; the defective product removal unit comprises a material tape positioning mechanism, a material tape shearing mechanism and a material tape splicing mechanism; the receiving unit comprises a protective film sticking mechanism and a receiving module; and the protective film sticking mechanism comprises a protective film feed module and a protective film pressing-sticking module. Optical film products are fully automatically detected mainly in a manner of intelligent vision detection, and then defective optical film products are identified and removed. The optical film intelligent vision detection and defective product removal equipment has the advantages of being high in detection efficiency and detection reliability. Meanwhile, structural design is reasonable, the defect recognition rate of the optical film products is high, false detection will not occur, and quality control over the products is guaranteed.

Owner:苏州市朗电机器人有限公司

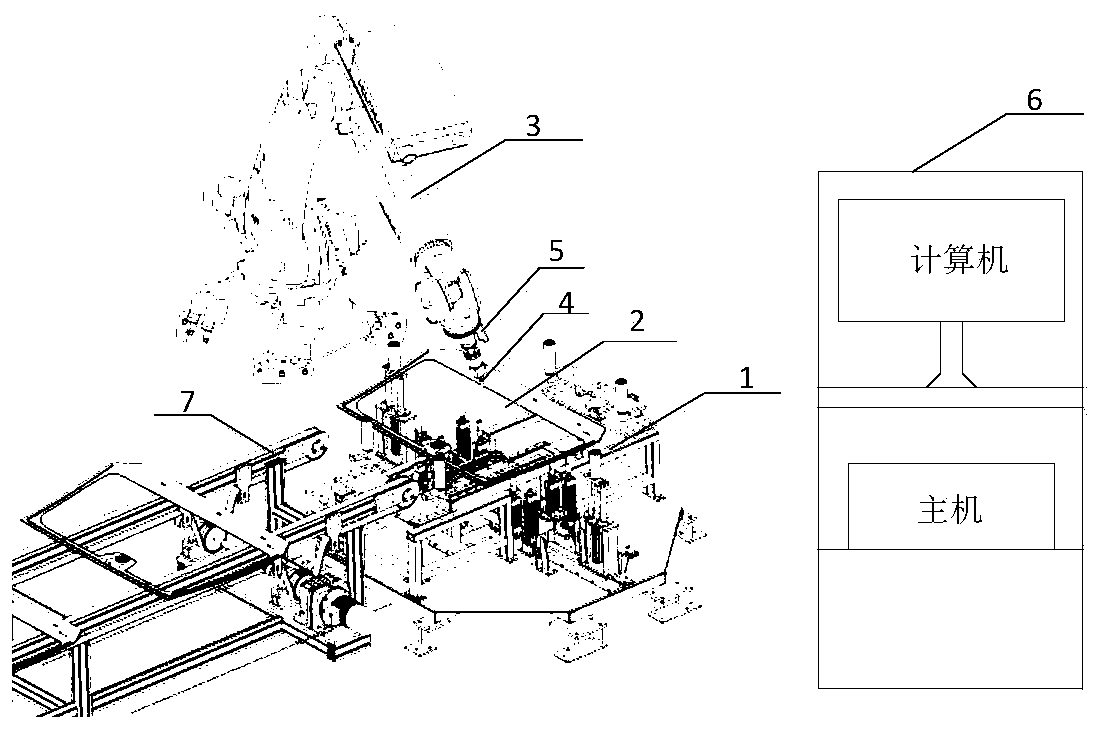

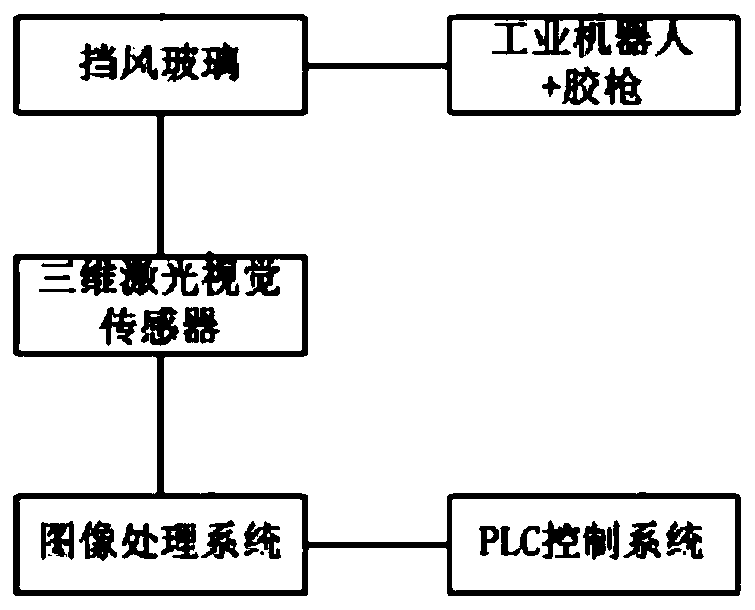

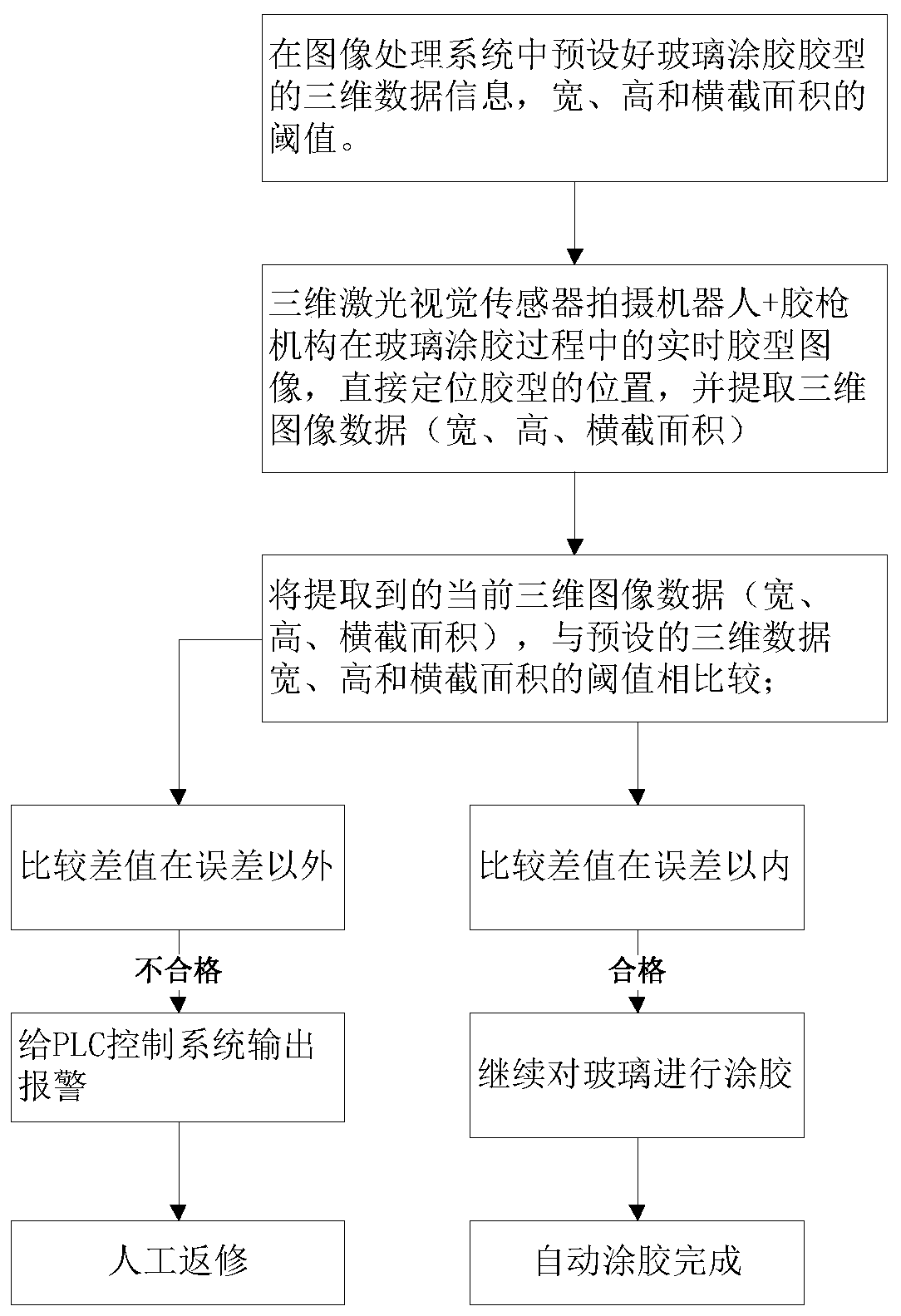

Online automobile glass coating type detection device, method and system

The invention discloses an online automobile glass coating type detection device, method and system. Three-dimensional data information, that is, thresholds of a width, a height and a cross-sectionalarea, of the automobile windshield glass coating type are preset; a real-time coating type image during the automobile glass coating process is photographed, the position of the coating type is positioned, and three-dimensional image data, that is, the width, the height and the cross-sectional area of the image are extracted; the extracted width, the extracted height and the extracted cross-sectional area of the image are compared with a preset width, a preset height and a preset cross-sectional area, and differences are obtained; whether the differences are in a preset range is judged, and ifyes, automobile windshield glass coating is continued until the coating is completed; or otherwise, the coating type is judged to be unqualified and alarm information is outputted. Environmental light is not required, and the applicability is strong.

Owner:CHANGSHA CTR ROBOTICS

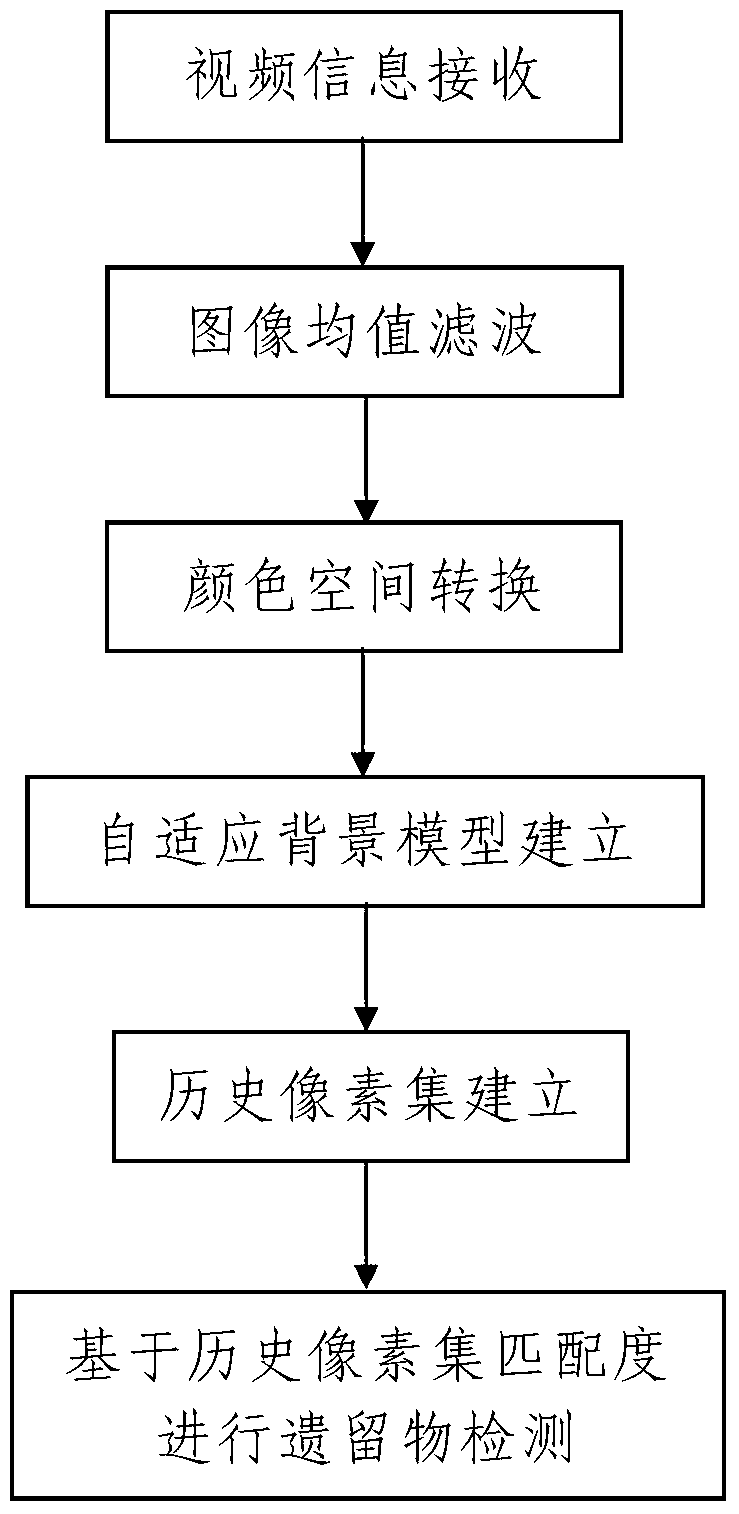

Remnant quick detecting method based on history pixel set matching degree

ActiveCN103268478AThe method steps are simpleReasonable designImage analysisCharacter and pattern recognitionPattern recognitionPoor adaptive skills

The invention discloses a remnant quick detecting method based on history pixel set matching degree. The method comprises the following steps that first, video information is received, namely the video information to be processed collected by video collecting equipment is received; second, a self-adaptive background model is established, namely the first N image data frames in the video information to be processed are respectively processed, the self-adaptive background model used for moving target detecting is established, the self-adaptive background model is a code book model; third, remnants are detected, namely history pixel sets of pixels are established first, and then the established history pixel sets are used for carrying out remnant detecting on image data frames after the Nth image data frame of the video information to be processed respectively. The steps of the method are simple, designing is reasonable, realization is convenient, detecting speed is high, detecting effect is good, and the problems that an existing remnant detecting method is bad in complex scene adaptive capacity, large in calculated amount, and low in detecting speed, and detecting again cannot be easily carried out when blocking and moving happen can be effectively solved.

Owner:西安地山视聚科技有限公司

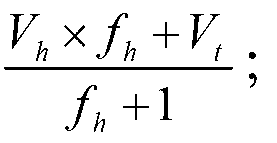

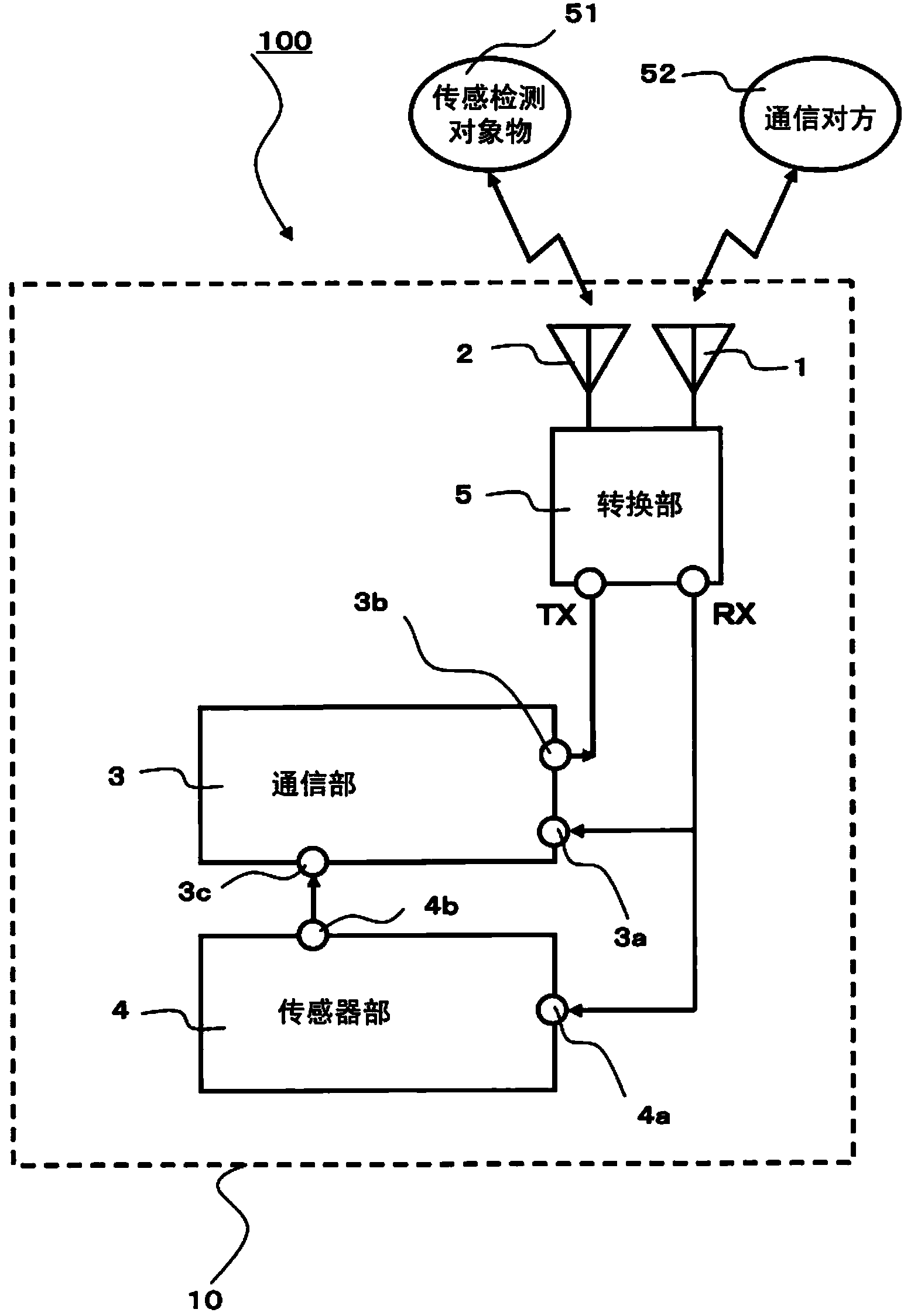

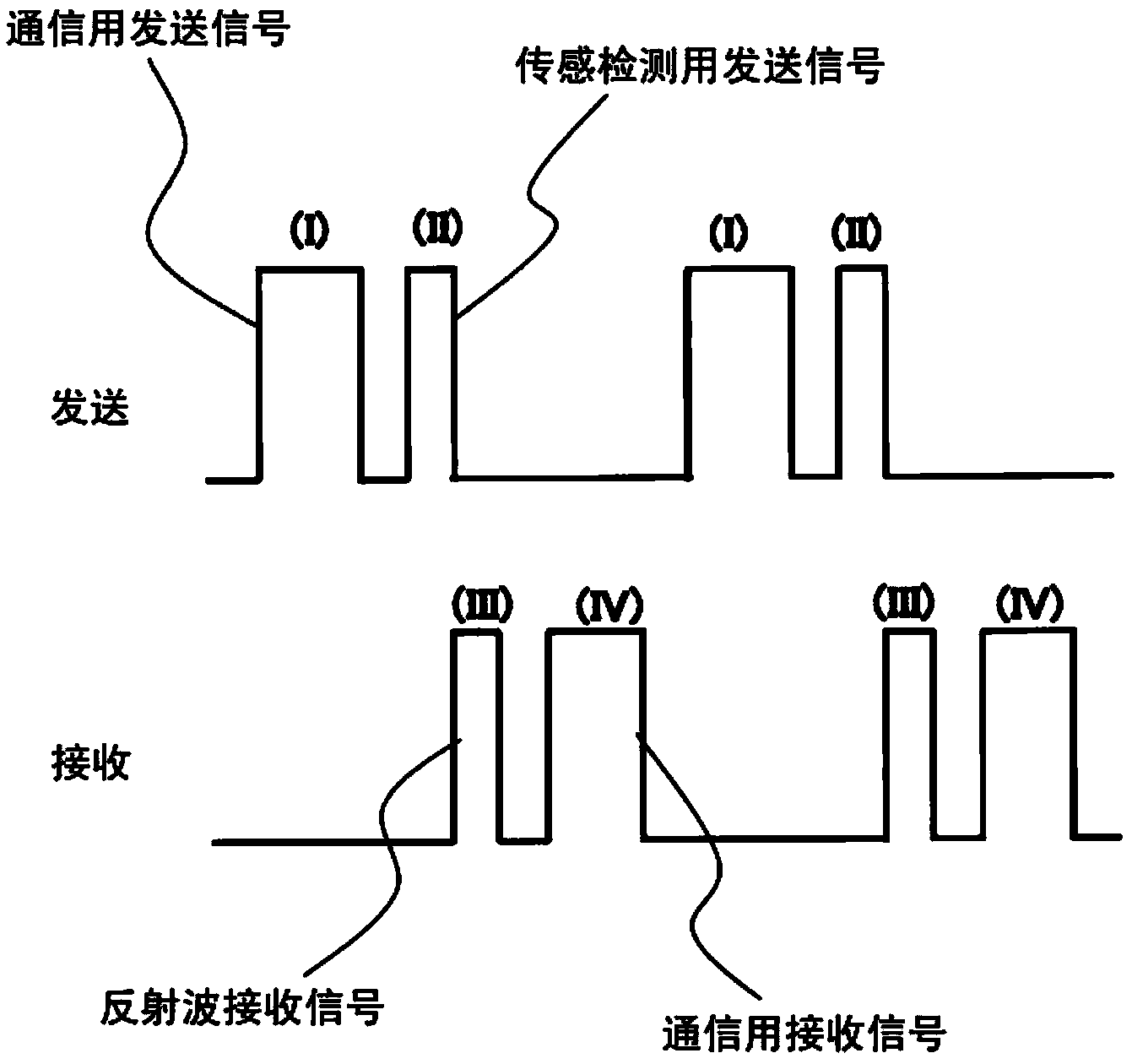

A communication sensor device

InactiveCN104237878AAccurate detectionNo false detectionTransmissionRadio wave reradiation/reflectionDirectional antennaTime-sharing

The invention provides a communication sensor device which can accurately detect information related to actions of an object of sensor detection, and can carry out processing based on the information. According to the communication sensor device (100), a first antenna (1) which carries out electromagnetic transmission and reception, a second antenna (2) which carries out electromagnetic transmission and reception, a communication portion (3) which carries out data communication with a communication opposite side (52) and a sensor portion (4) which detects actions of the sensor detection object (51) are arranged in a same module (10). The first antenna is composed of an non-directional antenna, and the second antenna is composed of a directional antenna and is also provided with a transition portion (5) which can be utilized to carry out time-sharing switching of the first antenna and the second antenna. The first antenna is utilized to carry out transmission and reception used for data communication, and the second antenna is utilized to carry out transmission of sensor detection of the sensor detection object.

Owner:ALPS ALPINE CO LTD

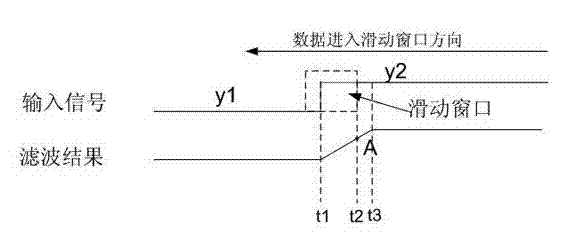

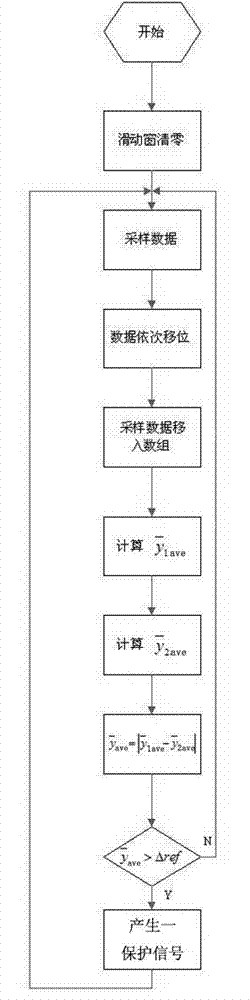

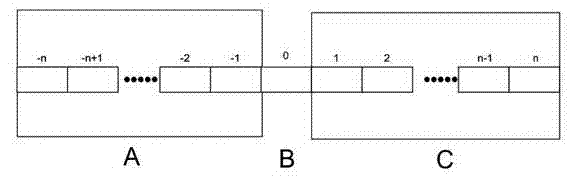

Step signal detection method for smoothing of double sliding windows with dead zone unit

ActiveCN103323032AAddress testing requirementsEffective filteringMeasurement arrangements for variableMutation detectionSlide window

The invention relates to a step signal detection method for smoothing of double sliding windows with a dead zone unit. In a fixed cycle, an input signal is sampled, sample data are sequentially shifted into the double sliding windows with the dead zone B according to sampling time, meanwhile the data in the sliding window A and the sliding window C are averaged, the average value of the sliding window A and the average value of the sliding window C are respectively calculated, and a difference value between the average values of the two sliding windows is calculated and serves as a mutation value; when the input signal mutates, the mutation value can be immediately detected after sliding for the time of one sliding window. Due to the facts that the difference value between the average values of the two sliding windows is appropriately arranged and the length of the sliding windows is appropriately arranged, the mutation detection requirement for mutation duration time can be accurately achieved.

Owner:KEHUA DATA CO LTD

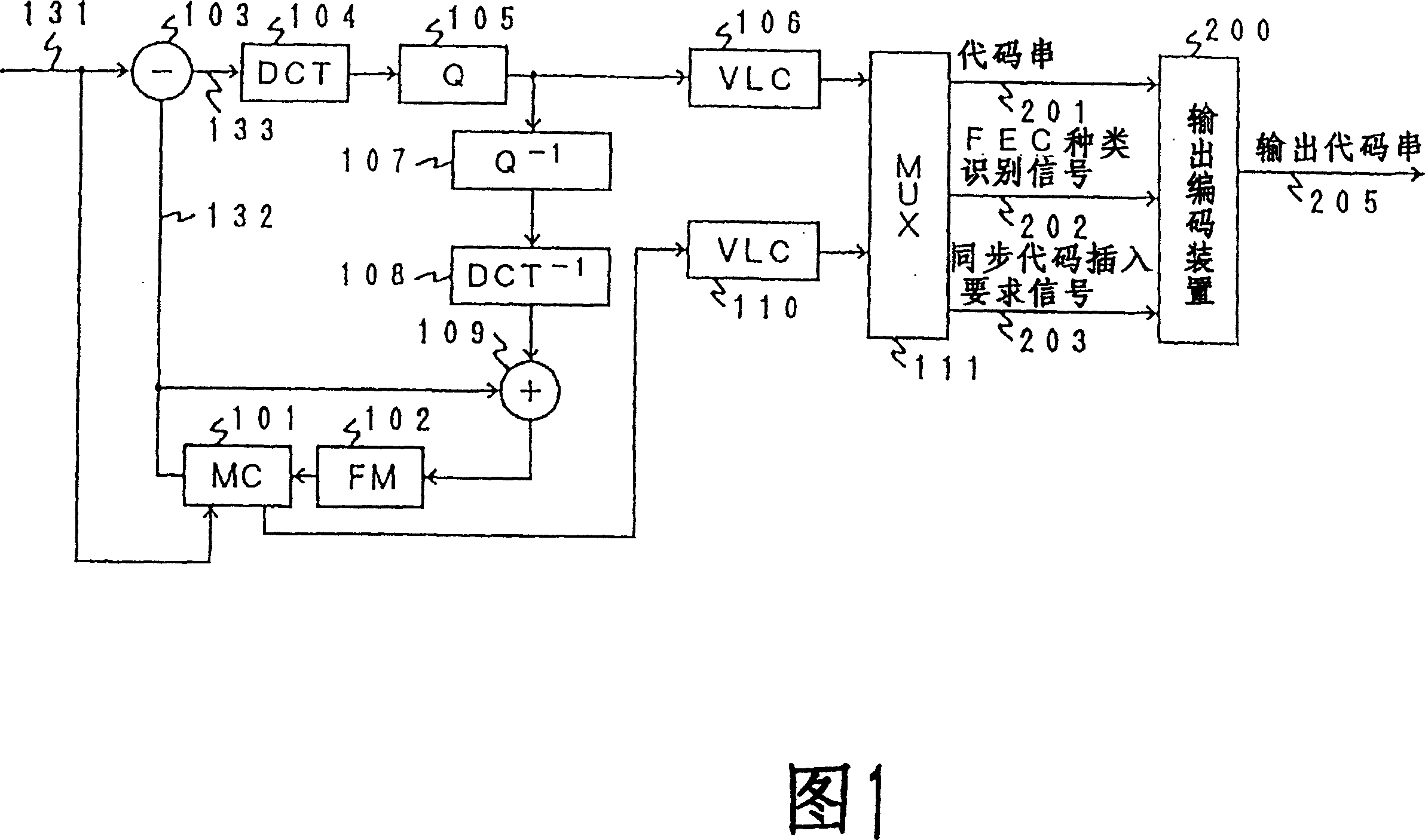

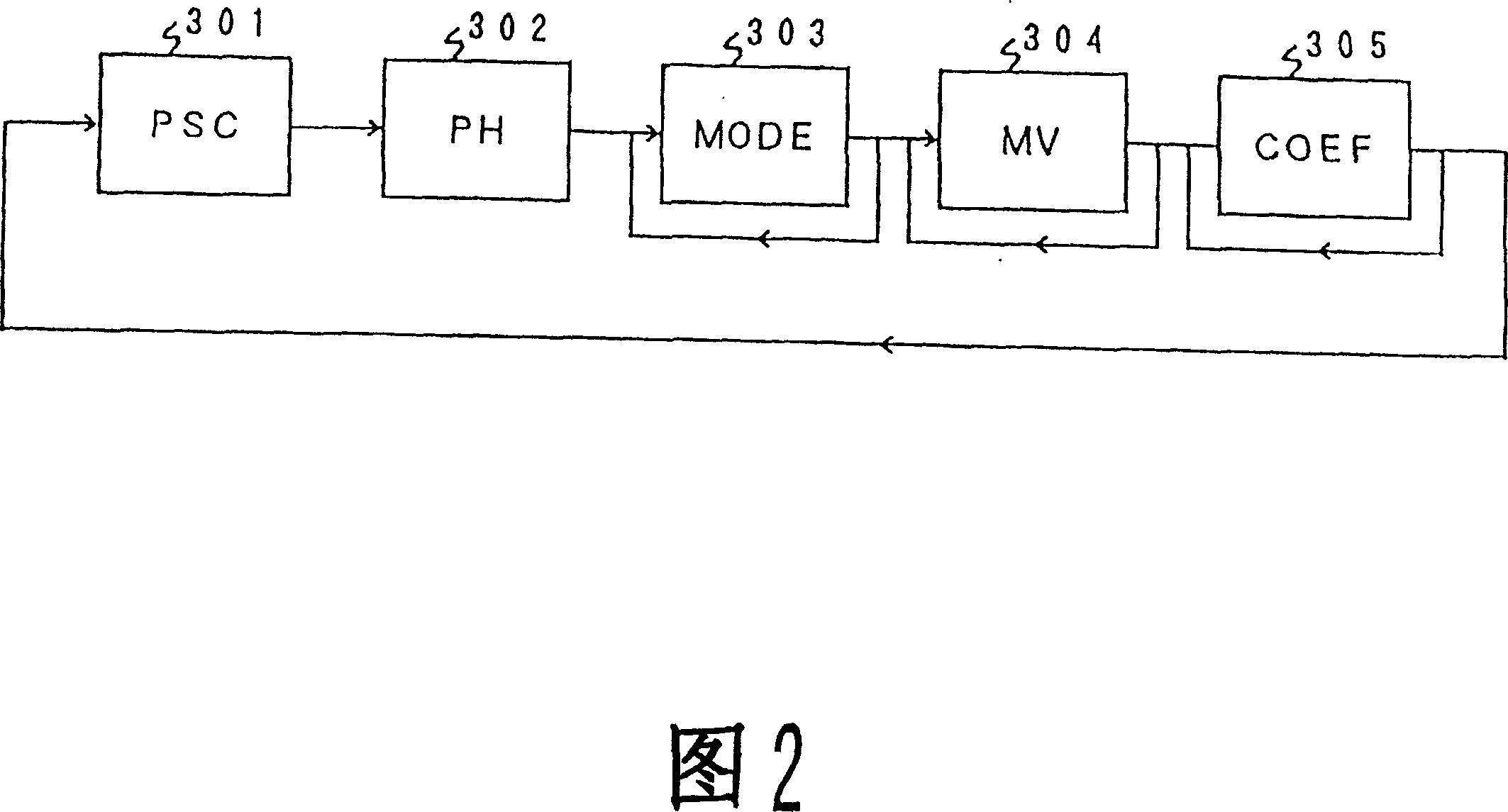

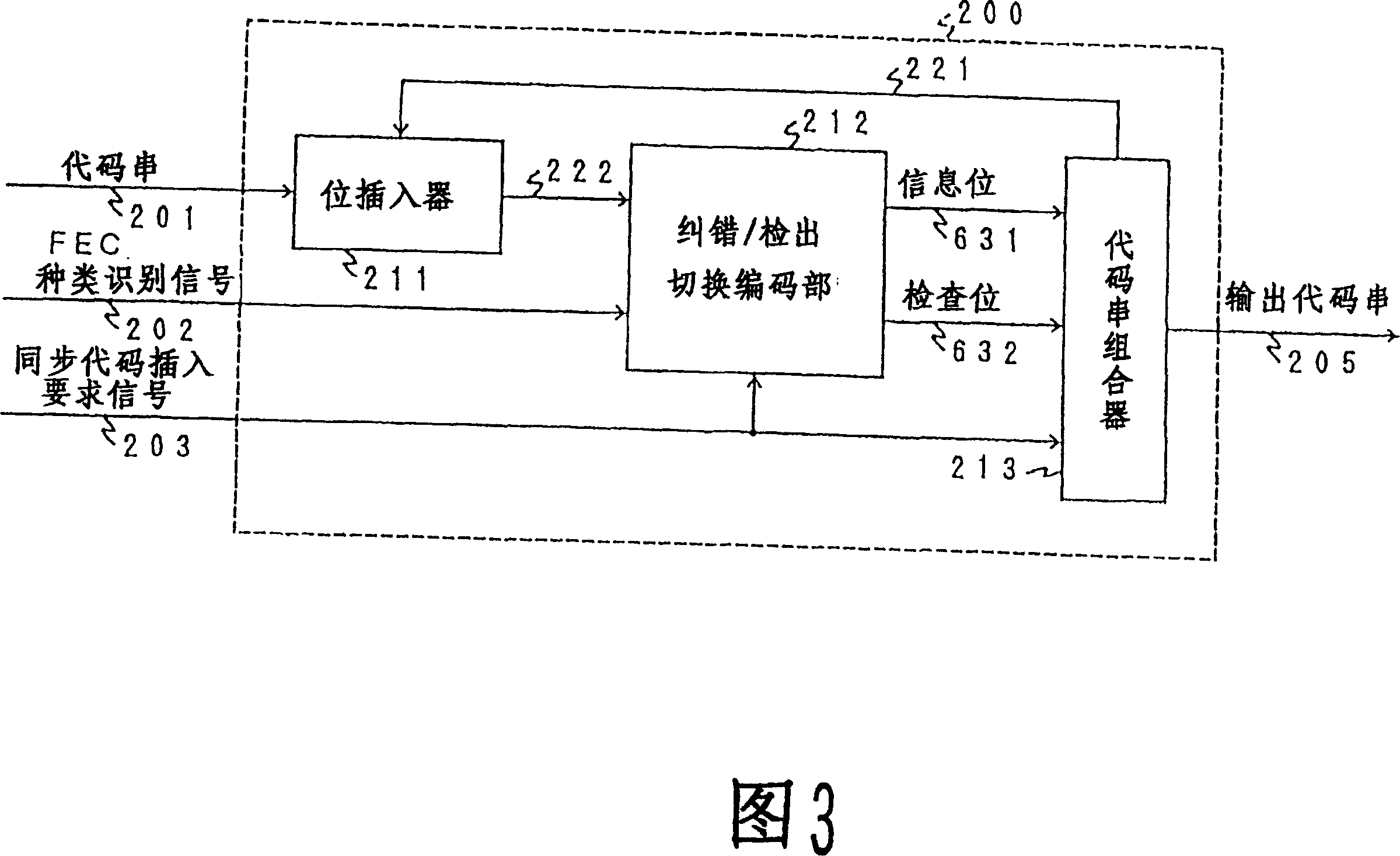

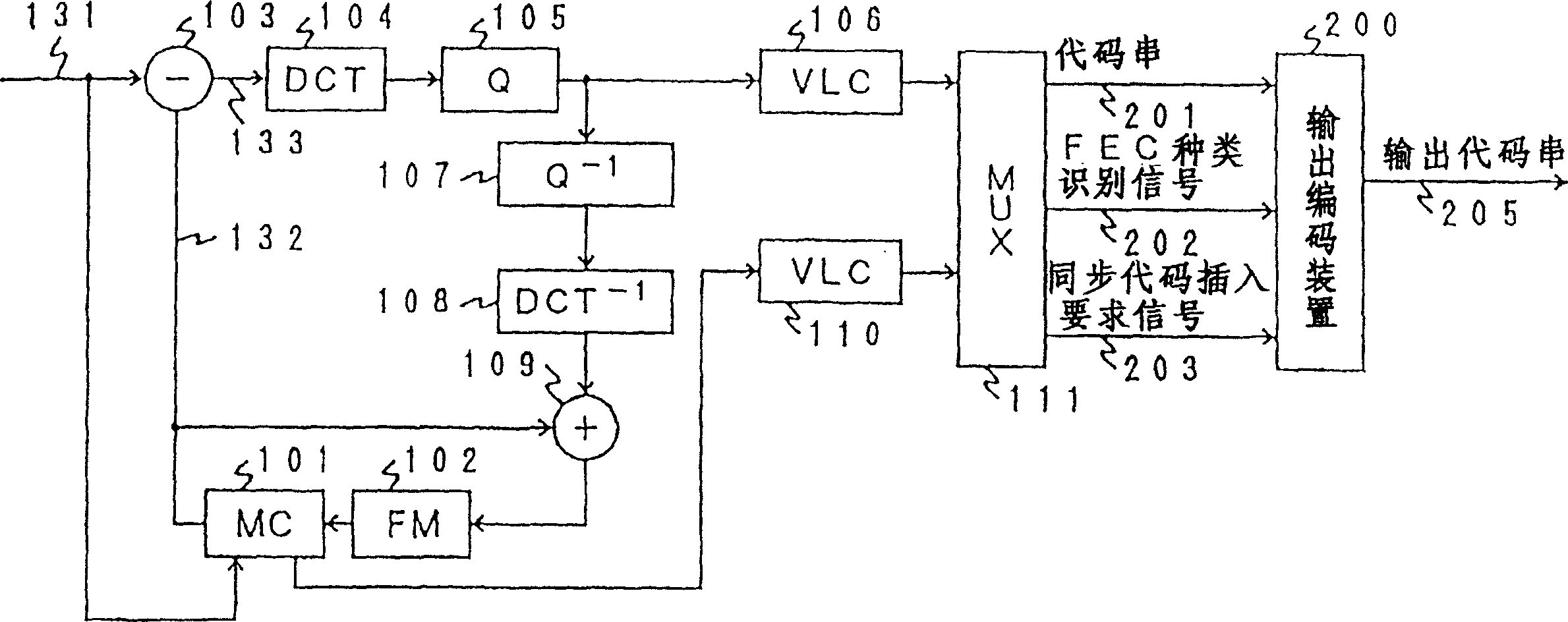

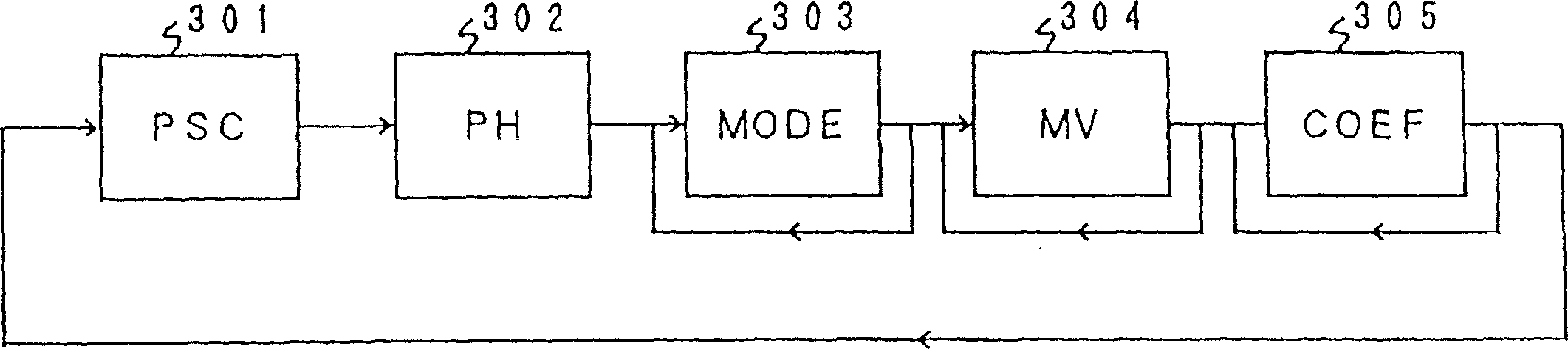

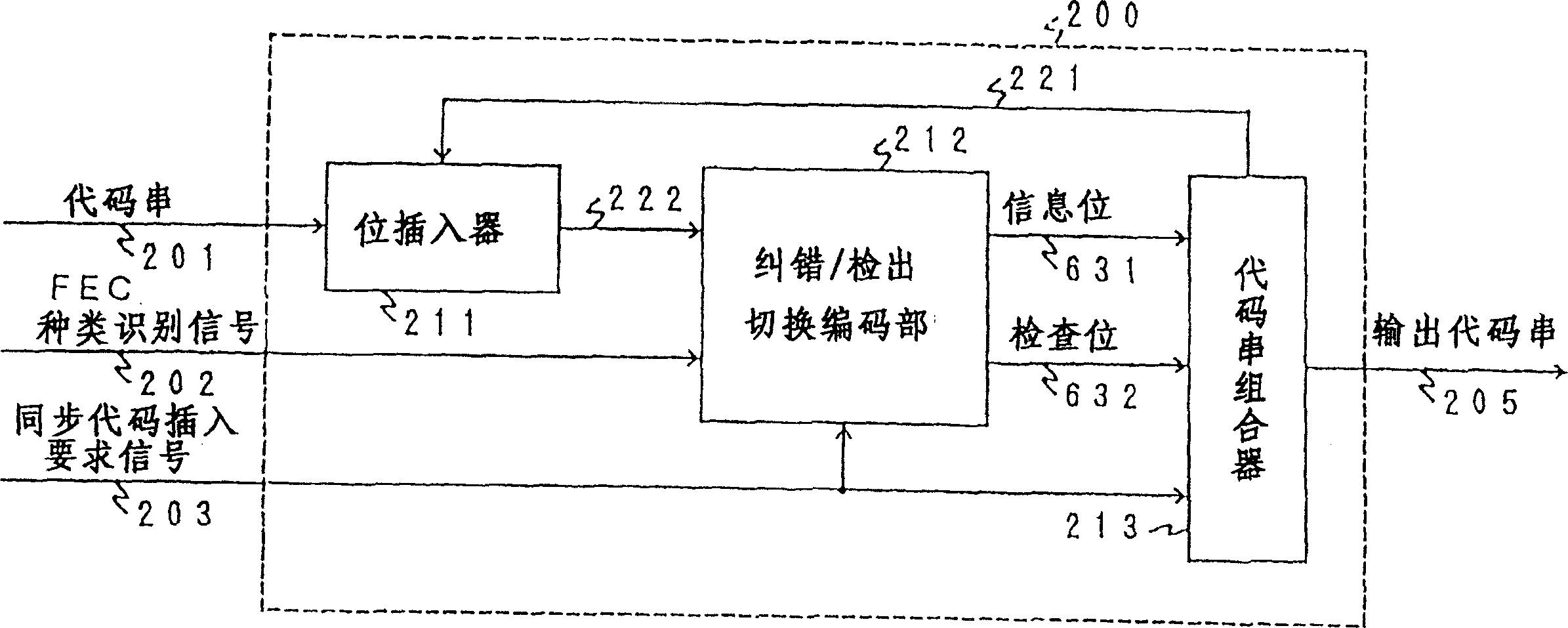

Decoding and decoding system

InactiveCN1921375AThere is no possibility of synchronous detectionAvoid difficultiesError preventionCode conversionComputer hardwareDecoding methods

In a coding system wherein an error correction / detection coding is combined with a synchronization recovering technique using a synchronization code, the problems of a pseudo synchronization and a step out due to error detection are solved. There is provided a coding part 212 for coding an input multiplexed-code string 201 to an error correcting- / detecting code comprising an information bit and a check bit, and code string assembling part 213 for inserting a synchronization code into any one of a plurality of periodically predetermined synchronization code inserting positions in the code string 201, for arranging the information bit at an optional position in the code string, and for arranging the check bit at a position other than the synchronization code inserting positions in the code string 201 to assemble an output code string 205.

Owner:KK TOSHIBA

Visual detection system and visual detection method using same

ActiveCN109682427AAvoid knotsImprove smooth performanceMeasurement devicesFilament handlingConductor CoilComputer science

The invention discloses a visual detection system, which comprises a feeding device, a detection device and a winding device, and also discloses a lamp belt detection method which comprises the visualdetection system and comprises the following steps: S1, feeding, wherein a lamp belt is input to the light supplementing plate of the detection device through a buffer device, and the buffer device buffers the lamp belt; S2, detecting, wherein the light supplementing plate is used for supplementing light to a parallel port of the lamp belt, and the detection device is used for detecting the lampbelt; S3, winding, wherein a qualified lamp belt is put into a winding device for winding. According to the invention, the continuous detection of the lamp belt can be ensured, the false detection cannot occur due to the parallel connection port, the fluency of the detection of the lamp belt is improved, the working efficiency of the detection of the lamp belt is improved, and the accuracy of thedetection of the lamp belt is improved; and the lamp belt is wound after the detection is finished, so that the qualified lamp belt can be conveniently detected to be packaged, sold, stored, transported and the like. The automation level of the lamp strip detection is improved, and the integral production process of the lamp belt is optimized.

Owner:广东大唐永恒智能科技有限公司

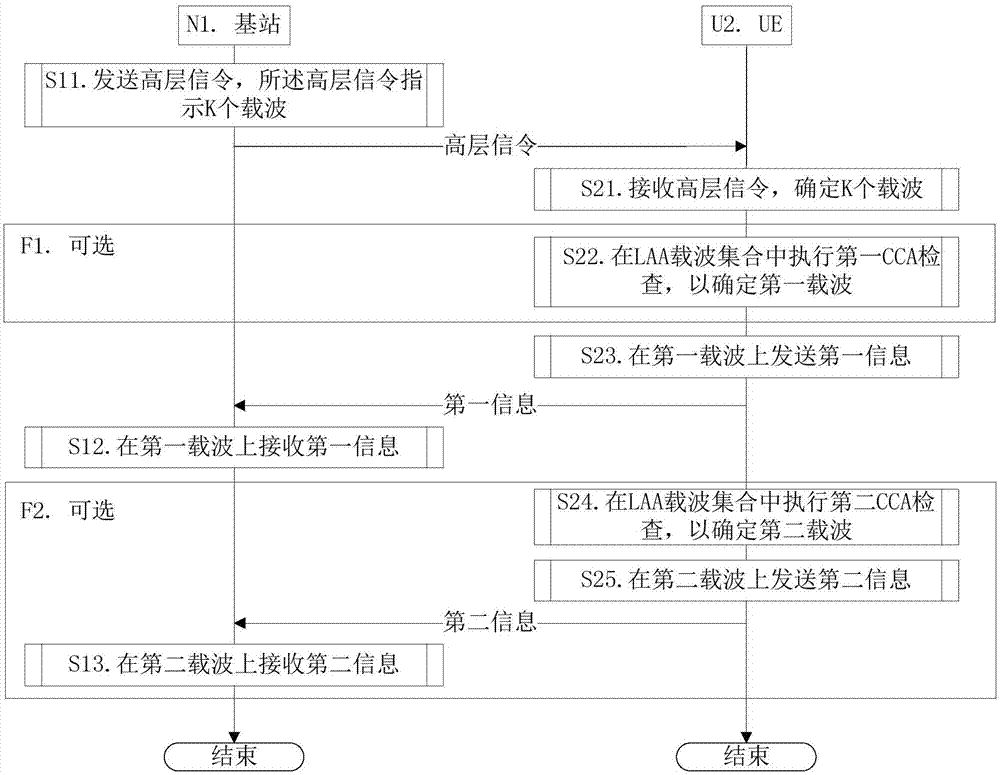

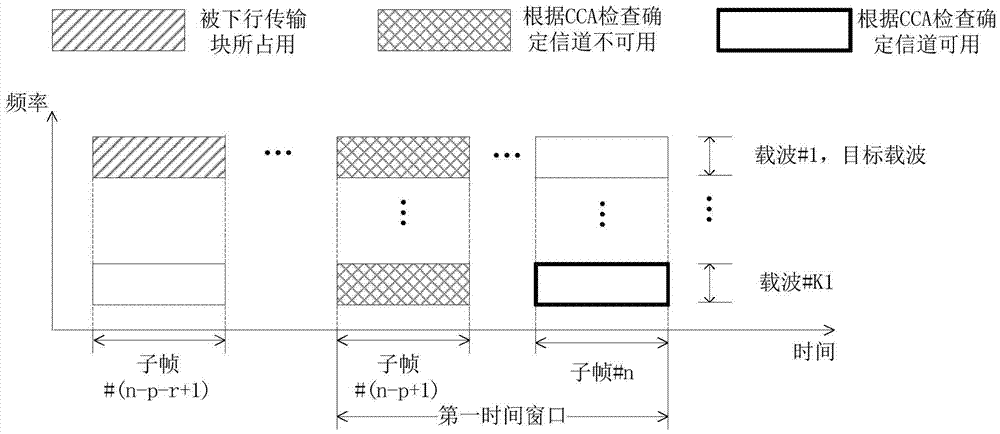

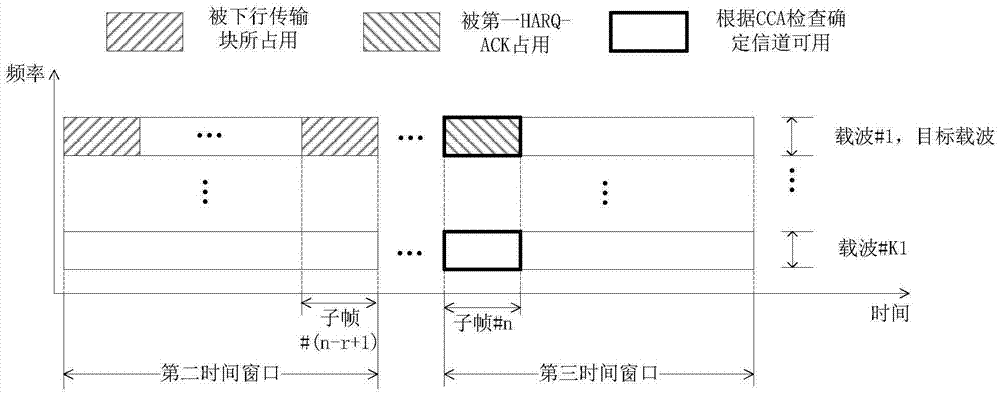

LAA method and LAA device of wireless communication

ActiveCN106961320AReduce false alarm probabilityImprove transmission efficiencyError prevention/detection by using return channelSignal allocationCarrier signalTelecommunications

The invention discloses an LAA method and an LAA device of wireless communication. UE is used to receive high-level signaling, and K carriers are determined. First information is transmitted on a first carrier. UCI related to a target carrier can be transmitted on the K carriers, and K is a positive integer greater than one. The first carrier is one of the K carriers, and the first information comprises at least one of first HARQ-ACK and first CSI. The first HARQ-ACK is used to indicate whether a transmission block on the target carrier is correctly decoded, and the first CSI aims at the target carrier. The stability of the HARQ-ACK transmission is guaranteed, and consumption of uplink resources of authorized carriers is reduced, and integrated frequency spectrum efficiency of a system is improved.

Owner:SHANGHAI LANGBO COMM TECH CO LTD

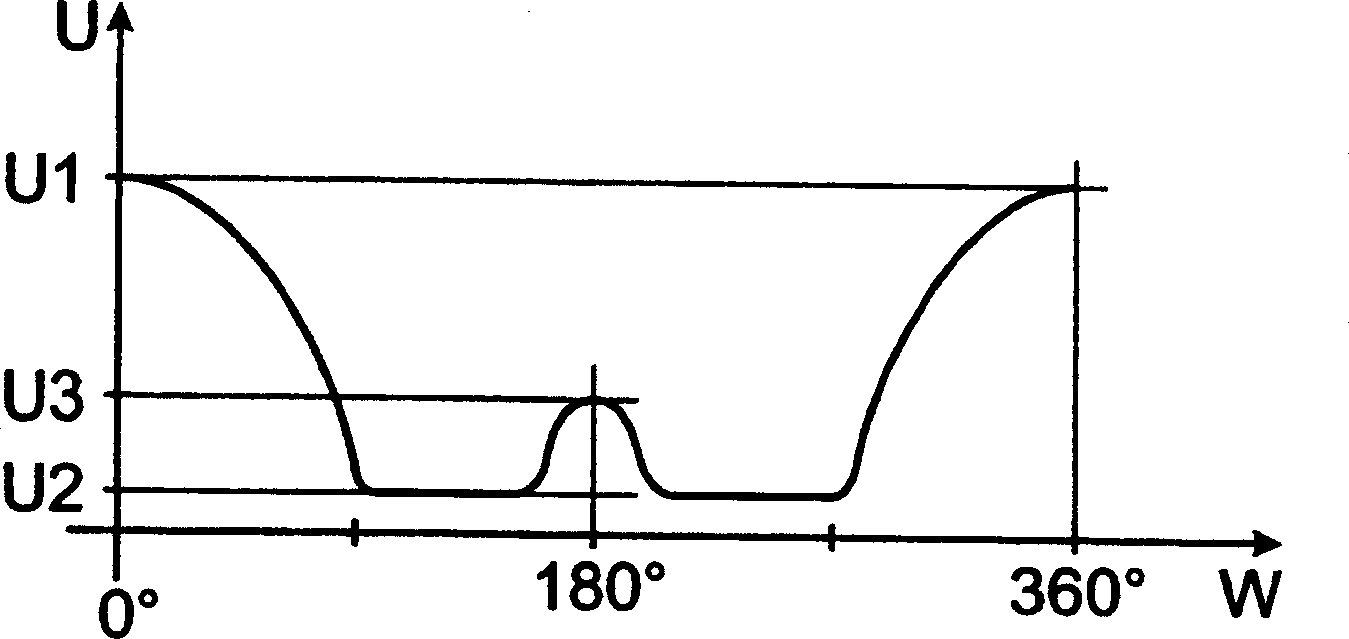

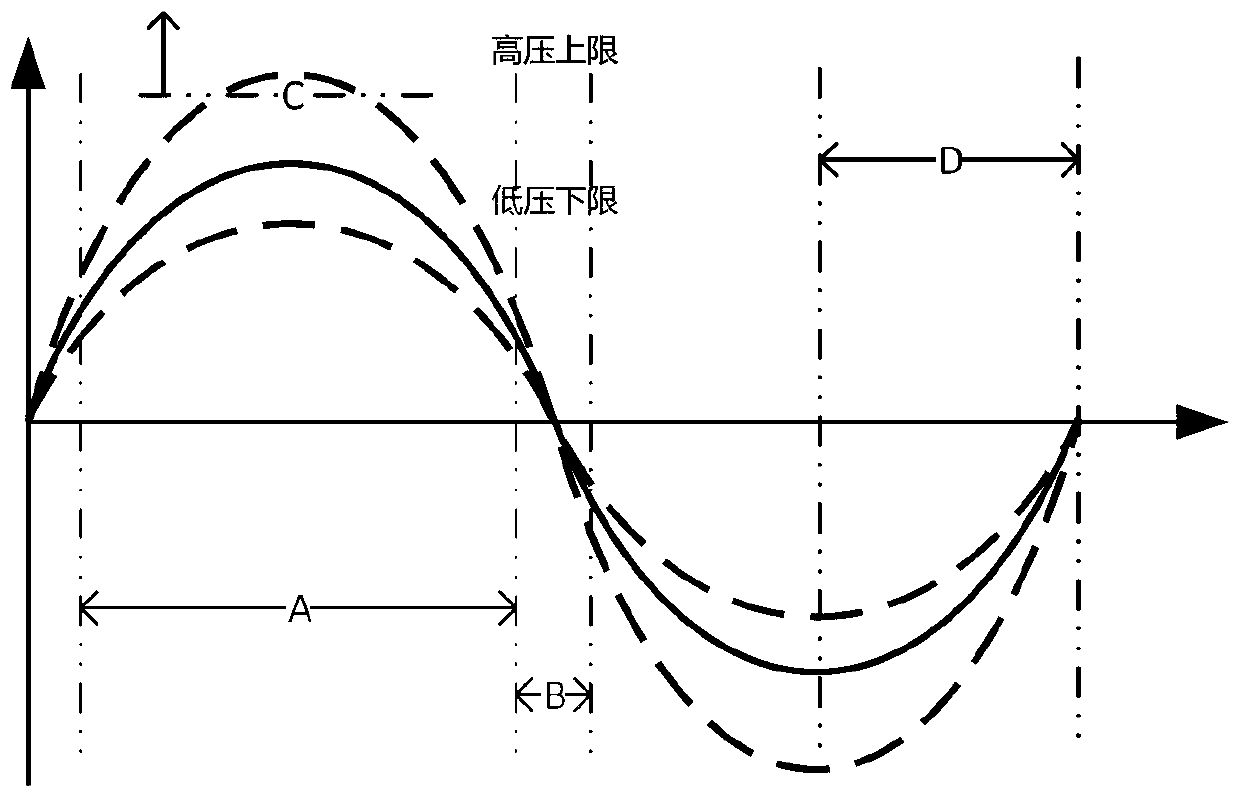

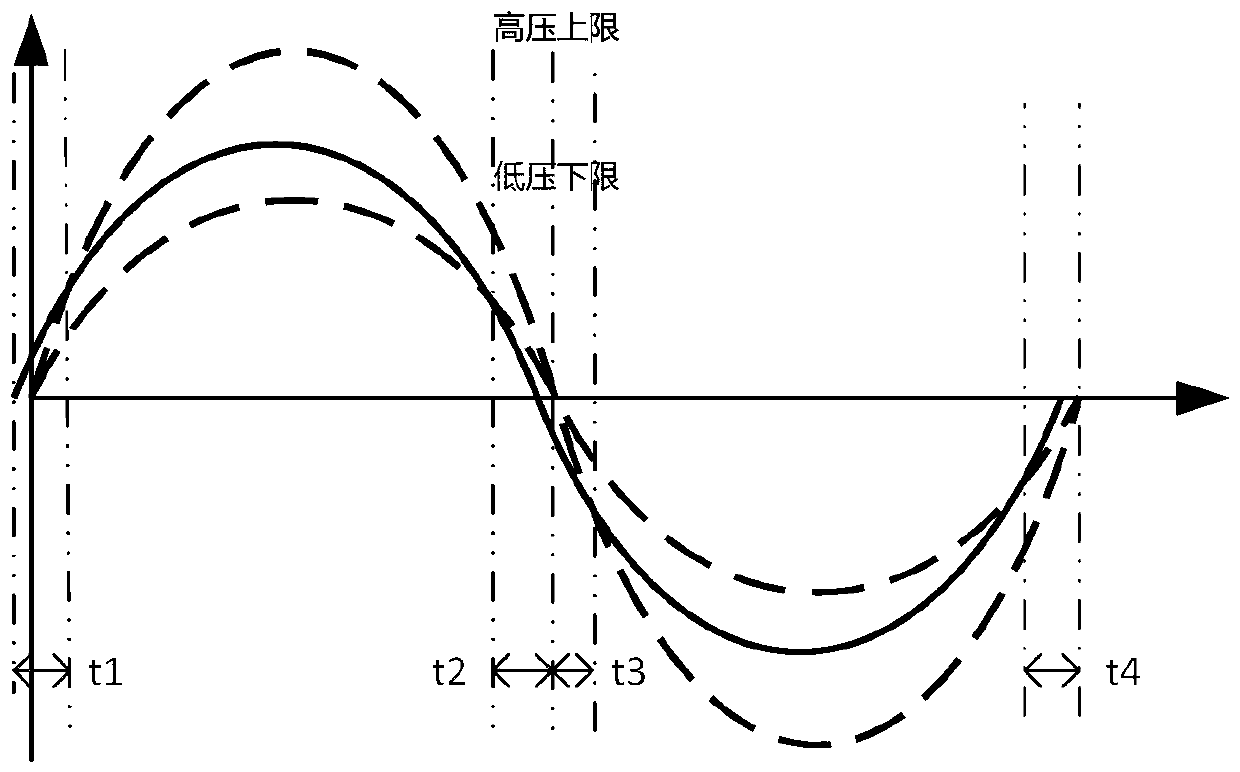

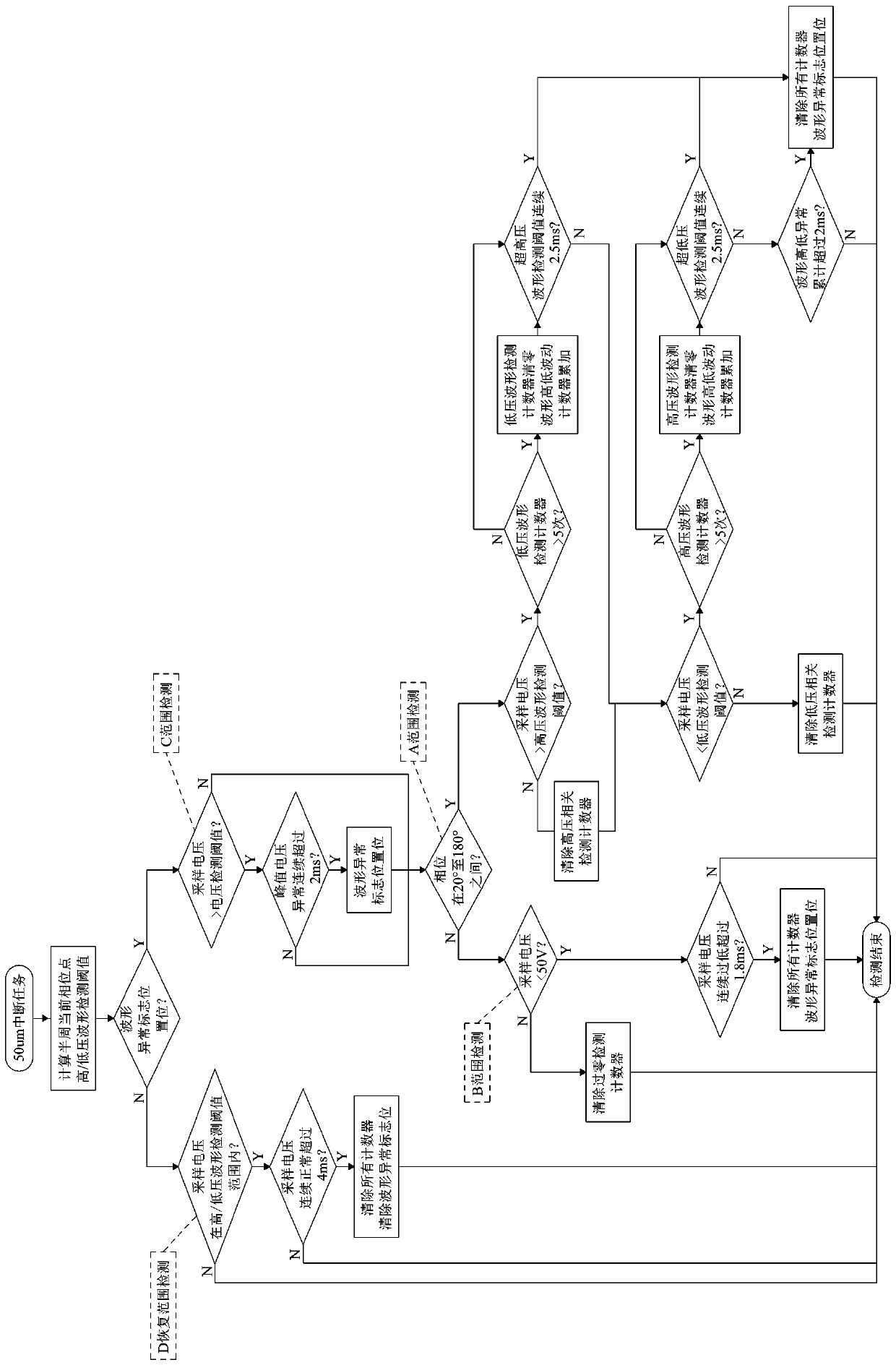

Quick off-grid detection method for energy storage inverter

ActiveCN107907763AOvercoming the time-consuming problem of off-grid detectionAdaptableElectrical testingElectricityLow voltage

The invention relates to a quick off-grid detection method for an energy storage inverter, which can detect mains supply signals and judge whether a waveform abnormal state appears and further providea basis for quick off-grid switching for the energy storage inverter. The method comprises steps: the mains supply signals are sampled to acquire sampled signals; after each time of sampling, based on the voltage and the phase of the sampled signals and in combination of a calculated high-voltage waveform detection counter threshold, a low-voltage waveform detection threshold, a preset voltage detection threshold, a voltage judgment threshold and various time thresholds, whether the mains supply signals are abnormal is judged. The problem that the existing off-grid detection consumes over long time can be overcome, whether the mains supply is subnormal can be quickly judged, and a favorable advantage is provided for a subsequent off-grid action of the energy storage inverter. The method has good adaptability, error detection on abnormality of the mains supply in a normal specific harmonic injection condition does not happen, and the accuracy is high.

Owner:JIANGSU GOODWE POWER SUPPLY TECHNOLOGY CO LTD

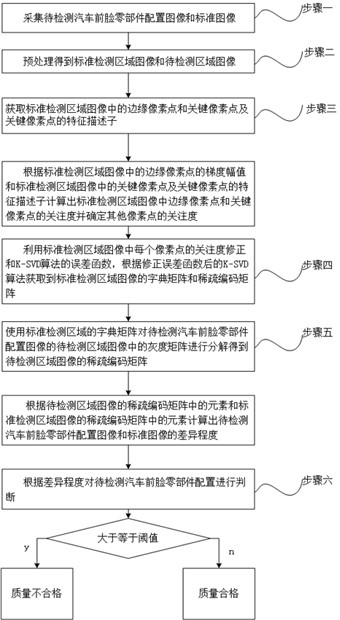

Intelligent detection method for automobile front face part configuration

ActiveCN114820626AEasy to detectNo false detectionImage enhancementImage analysisPattern recognitionEngineering

The invention relates to the field of computer vision, in particular to an intelligent detection method for automobile front face part configuration, and the method comprises the steps: carrying out the image preprocessing of a to-be-detected automobile front face part image and a standard image, and obtaining a to-be-detected region image and a standard detection region image; edge pixels, key pixels and feature descriptors of the edge pixels and the key pixels of the standard detection area image are obtained, the attention of the pixels in the standard detection area image is calculated, a loss function of a K-SVD algorithm is corrected through the attention, and a dictionary matrix and a sparse coding matrix of the standard detection area image are obtained; and decomposing the gray matrix of the to-be-detected area image by using the dictionary matrix of the standard detection area to obtain a sparse coding matrix of the to-be-detected area image, and calculating the difference degree between the to-be-detected automobile front face part image and the standard image according to the sparse coding matrix of the to-be-detected area image and the sparse coding matrix of the standard detection area image. The method is high-efficiency and accurate, and whether qualification is achieved is judged according to the difference degree.

Owner:南通浩盛汽车科技有限公司

Decoding device and method

InactiveCN1913423AThere is no possibility of synchronous detectionAvoid difficultiesError preventionCode conversionComputer hardwareDecoding methods

The problems of pseudo-synchronization and out-of synchronization caused by erroneous detection of synchronization codes of an encoder in which an error correction / detection coding and a synchronism restoring method using synchronization codes. There are provided a coding unit (212) for encoding a sequence of inputted multiplex codes (201 ) into error correction / detection codes comprising information bits and inspection bits; and a code sequence assembling unit (213) for assembling a sequence of output codes (205) by inserting a synchronization code into any of a plurality of periodically predetermined synchronization code insertion positions in the code sequence (201) and by arranging the information bits in arbitrary positions in the code sequence and the inspection bits in positions other than the synchronization code insertion positions in the code sequence (201).

Owner:KK TOSHIBA

PCB online detection equipment and PCB online detection method thereof

PendingCN109720817ANo false detectionHigh precisionControl devices for conveyorsInstabilityLeak detection

The invention relates to PCB online detection equipment and a PCB online detection method thereof. The PCB online detection equipment comprises a circular walking assembly. A pick-and-place station, afirst scanning station, an overturning station and a second scanning station are successively arranged on the circular walking assembly; a mold folding and releasing assembly is arranged in the pick-and-place station in a fit manner; a first scanning assembly is arranged in the first scanning station in a fit manner; a second scanning assembly is arranged in the second scanning station in a fit manner; and an overturning assembly is arranged in the overturning station in a fit manner. The PCB online detection equipment has the beneficial effects that the problem of no constant speed and instability of the state of a circuit board in a conventional belt adsorption or compression roller transfer process is solved; leak detection and mistaken detection are avoided, so that the equipment detection precision and efficiency are improved greatly.

Owner:广东科视光学技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com