Element head-forming device for continuous fastener stringer-manufacturing machine

A manufacturing machine and zipper element technology, which is applied in the field of fastener element head forming devices, can solve the problems of induction rod vibration, false sensing, and difficulty in realizing high-speed zipper fastener tapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

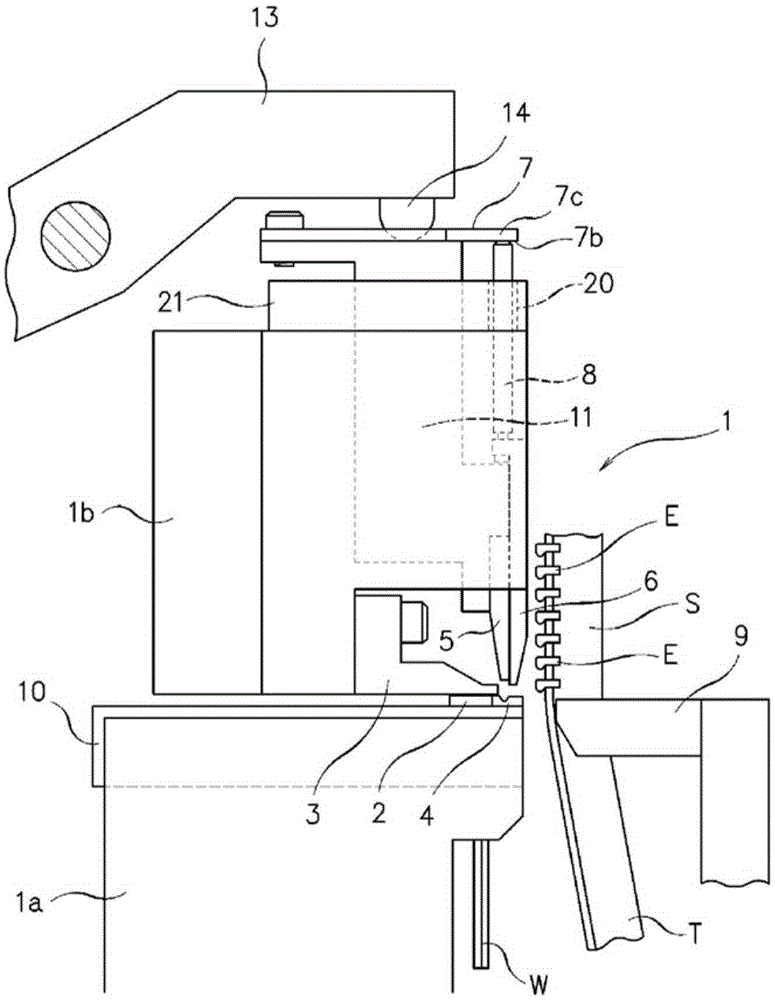

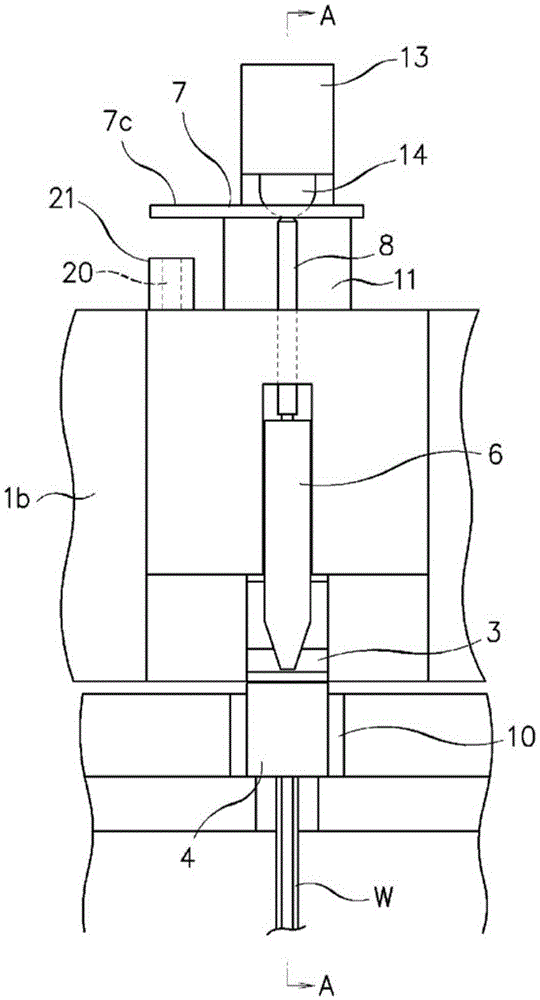

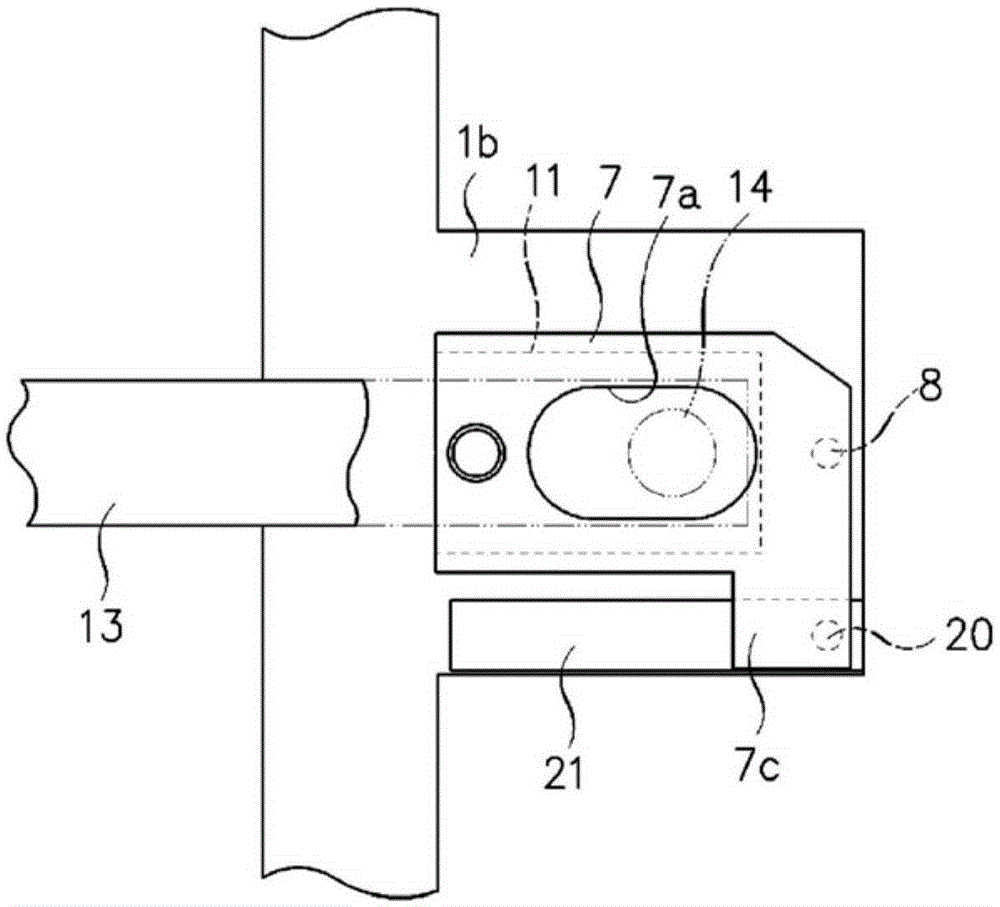

[0070] Such as Figure 1 to Figure 4 As shown, the metal wire W for the fastener element is intermittently fed into the metal wire material W for the fastener element by the conveying device for the metal wire for the fastener element, which is not shown, to the forming and embedding part 1 of the fastener element of the zipper fastener stringer continuous manufacturing machine. The supply device of the fastener tape sends out the fastener stringer S, thereby supplying the fastener tape T intermittently.

[0071] Chain teeth with metal wire W such as Figure 5 Shown is a long bar, and includes: a prism-shaped head WH having a thickness a and a width b, and a pair of legs provided on both sides in the width direction of one end of the head WH in the thickness direction facing the thickness direction WL has a groove WO between one end in the thickness direction of the head WH and the pair of legs WL, and has a substantially Y-shaped cross section.

[0072] The shaped embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com