PCB online detection equipment and PCB online detection method thereof

A testing equipment and technology to be tested, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problem of inability to maintain smooth and uniform transmission, improve accuracy and efficiency, ensure testing efficiency, and be targeted. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

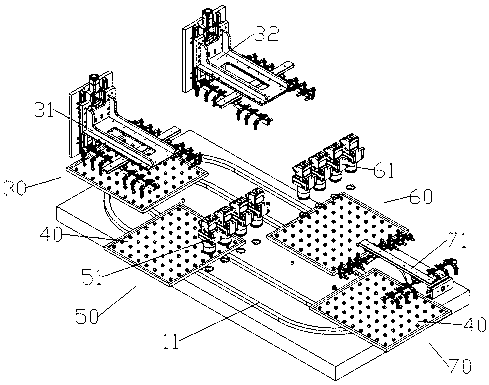

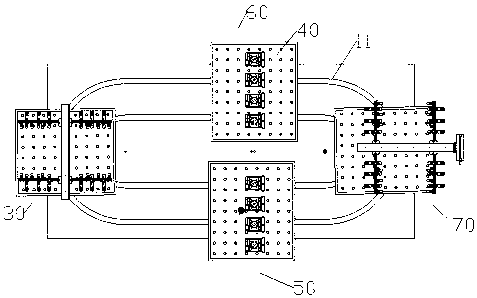

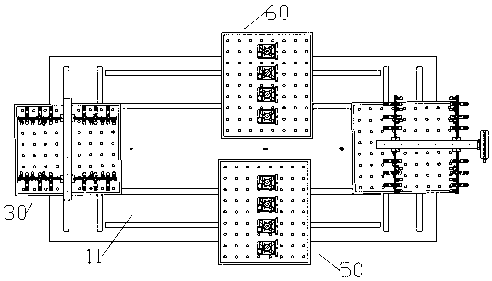

[0037] Such as figure 1 Shown in, a kind of PCB on-line detection equipment, comprises the cycle walking component 11;

[0038] The circulating walking assembly 11 is sequentially provided with a pick-and-place station 30, a first scanning station 50, a flipping station 70 and a second scanning station 60;

[0039] The pick-and-place station 30 is matched with a retractable mold assembly;

[0040] The first scanning station 50 is matched with a first scanning assembly 51; the second scanning station 60 is matched with a second scanning assembly 61;

[0041] The overturning station 70 is matched with an overturning assembly 71. A structure of the overturning assembly 71 includes a mechanical rotating hand and an overturning and rotating assembly. The PCB board is grabbed by the mechanical gripper, and then the PCB is turned over by the overturning and rotating assembly. ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com