Patents

Literature

58results about How to "Scattered distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

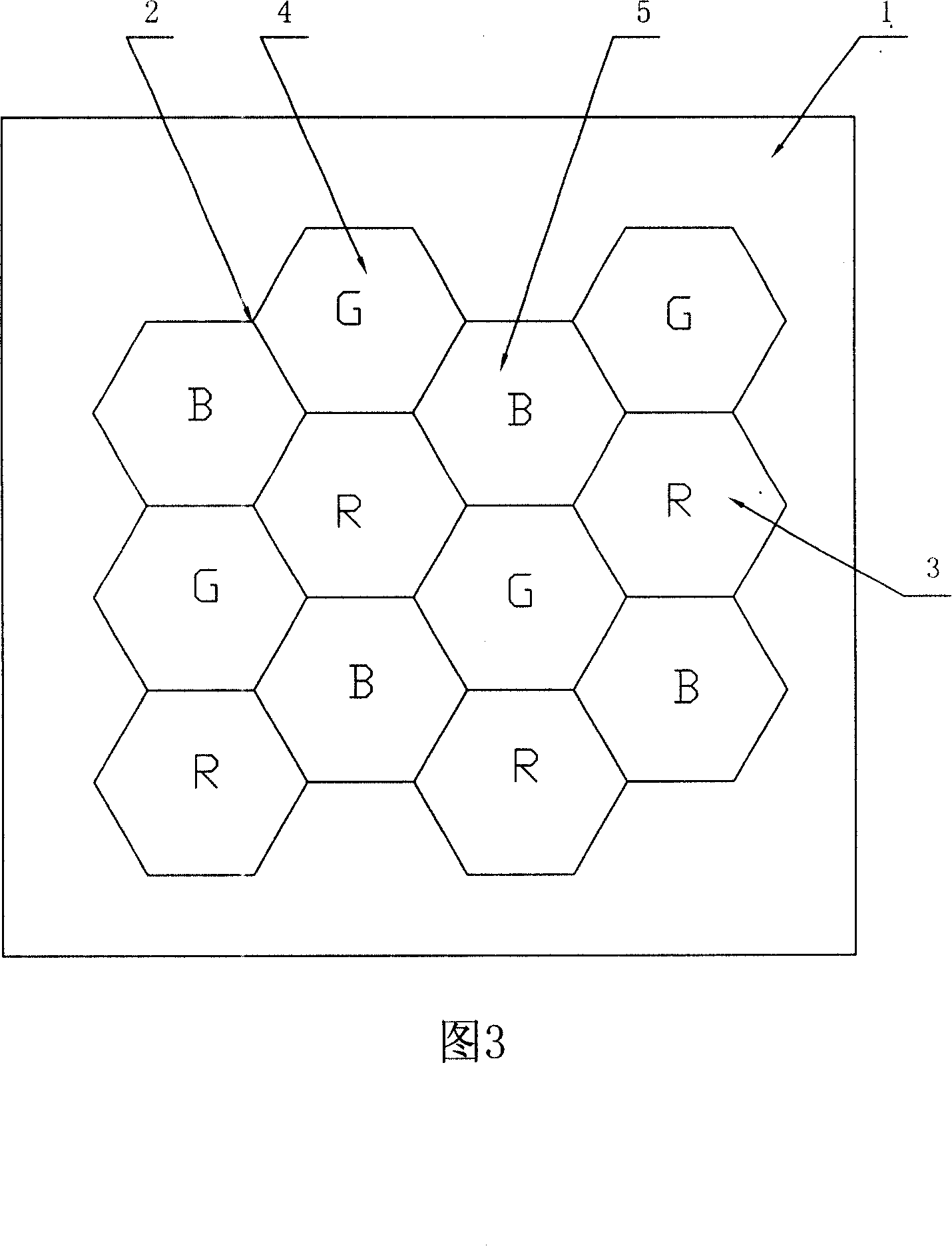

Colorful spectral filter

InactiveCN101153931AScattered distributionOperableNon-linear opticsOptical elementsScarf jointSpectral filtering

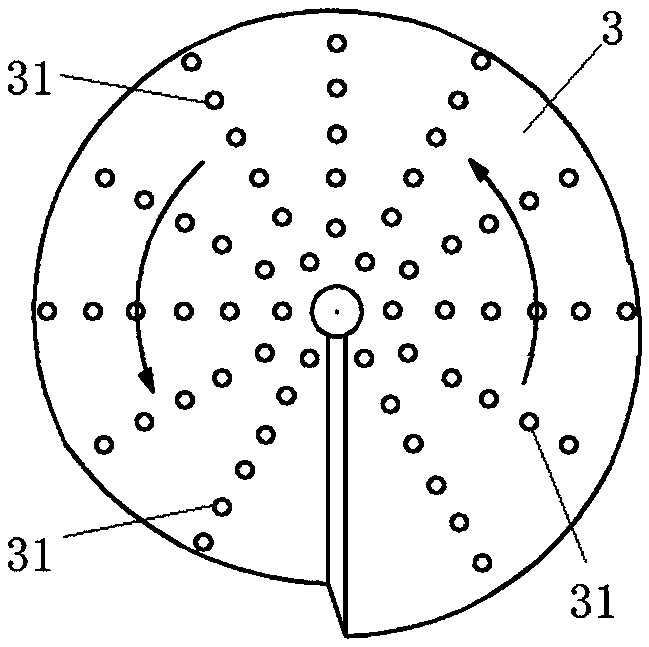

The present invention discloses a color filter which is provided with a transparent baseplate; a shading zone is formed on the baseplate and a plurality of pixels are also distributed on the baseplate, wherein, each pixel is provided with a first color zone, a second zone and a third zone, in particular the first color zone, the second color zone and the third color zone of each pixel are centrosymmetric hexagons, and with an arbitrary first color zone as the center on the transparent baseplate, six mutually spaced second color zones and third color zones are faveolately in scarf joint around. The color filter with the structure has good color display effect and can weaken sawtooth in the margin of image when the image is displayed obliquely.

Owner:BYD CO LTD

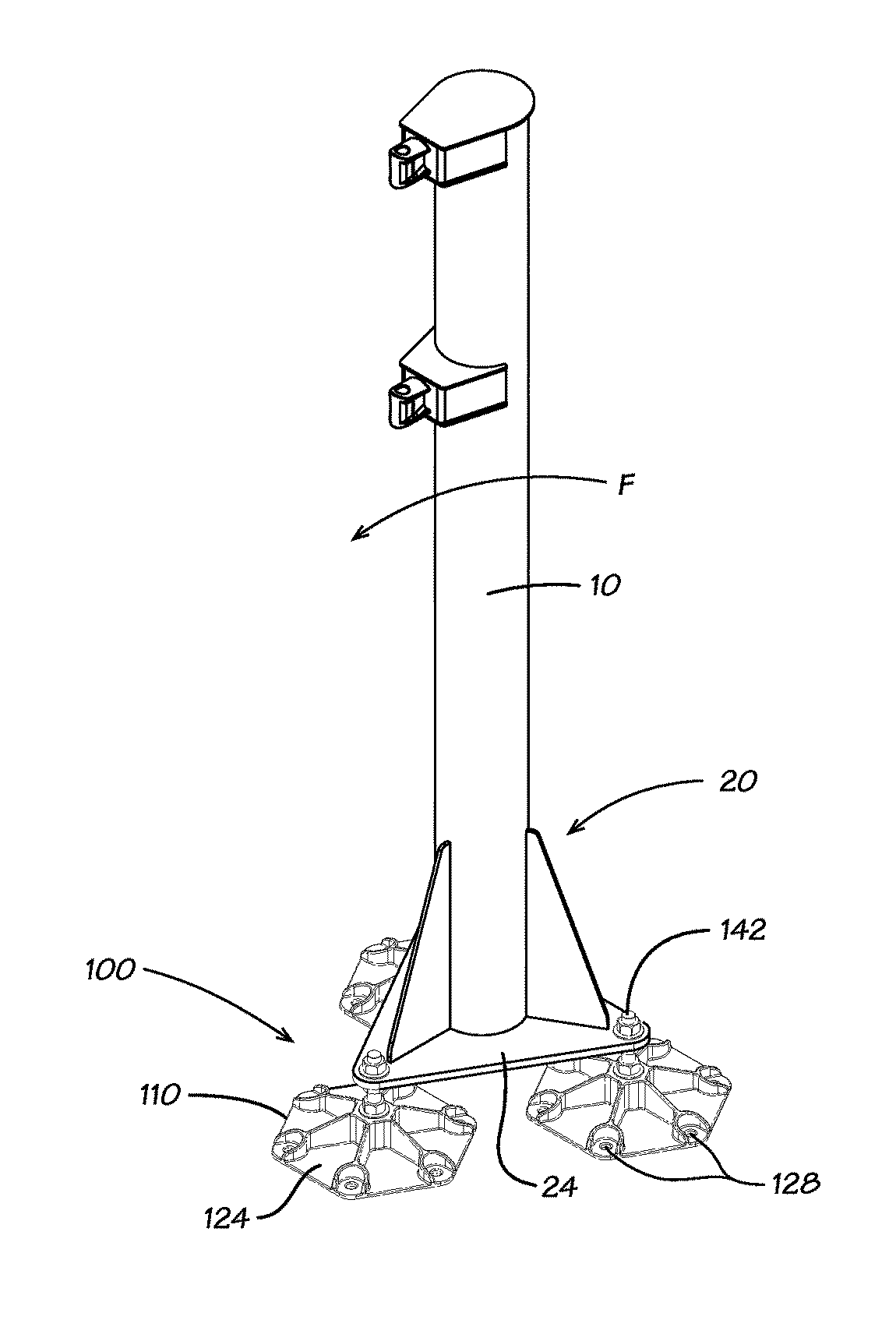

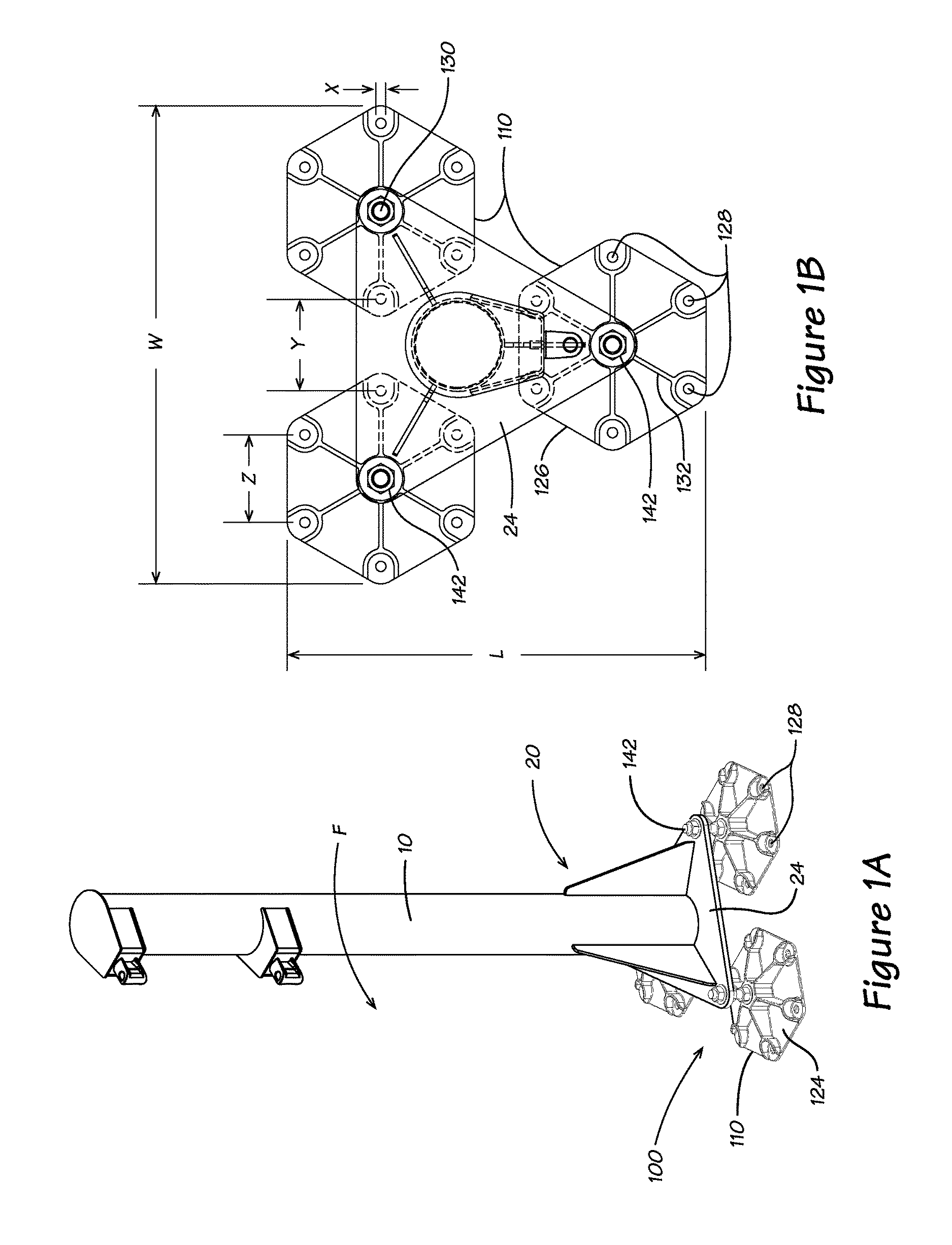

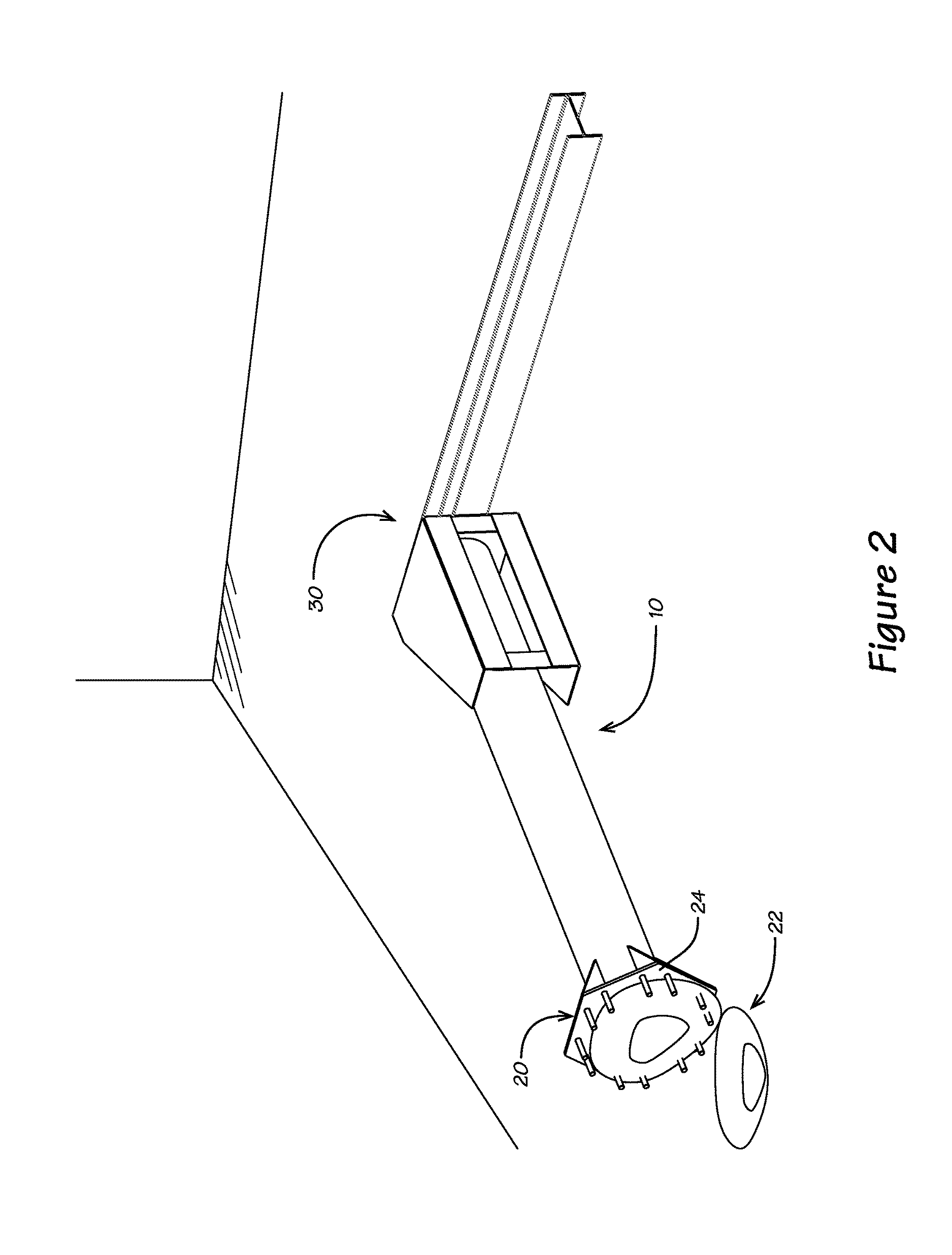

Anchoring system

An anchoring system to secure a mounting plate at a base of a pole or column to a concrete foundation includes a plurality of base plates. Each base plate has a planar surface, center-point, and plurality of fastener openings spaced about the center-point. A plurality of concrete anchoring fasteners having a common cross-sectional diameter secures each base plate to the foundation. An attachment bolt at the center-point of each base plate extends perpendicular to the planar surface for securing through an attachment bolt opening inside a peripheral edge of the mounting plate. The anchoring fasteners for securing the base plates to the foundation are spaced apart no less than ten times the common cross-sectional diameter.

Owner:KUNDEL INDS

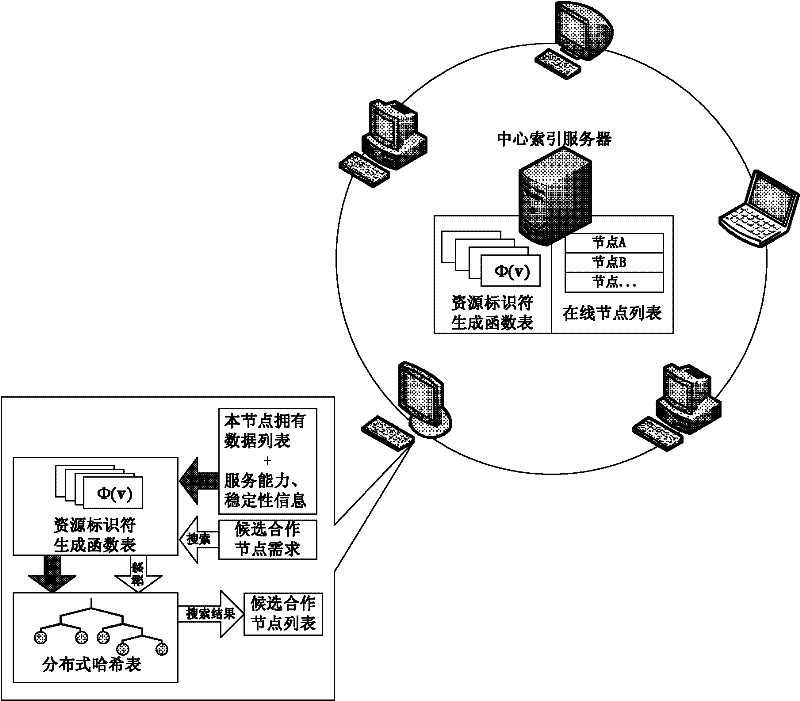

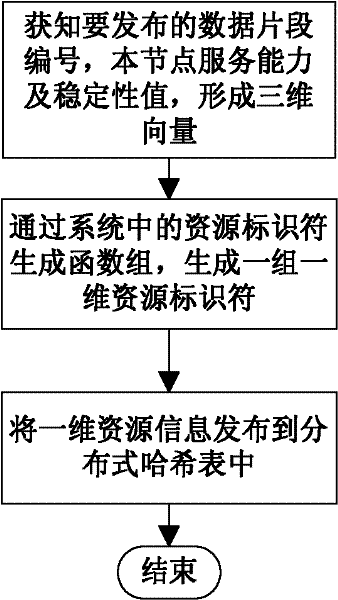

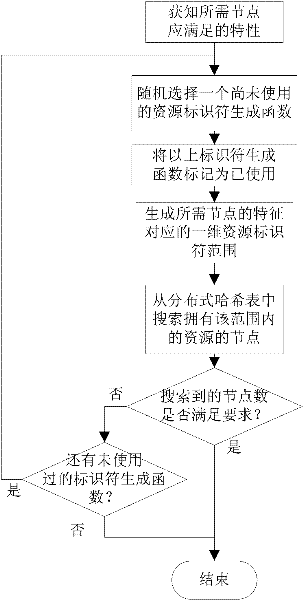

Method and system for obtaining candidate cooperation node in P2P streaming media system

InactiveCN102547471AImprove node qualityReduce maintenance difficultySelective content distributionData switching networksData informationMulti dimensional

The invention provides a method and a system for obtaining a candidate cooperation node in a P2P streaming media system. The method includes the step of using one-dimensional distributed Hashtable to maintain multi-dimensional information of each server node in the P2P streaming media system. In the step, each server node takes video data information owned by the server node, service ability of the server node and stability information as parameters to input a group of several multi-dimensional and one-dimensional resource identifiers with position sensitivity to generate function, a group of several one-dimensional identifiers are obtained, and composite information which comprises the information of the several identifiers is released to the distributed Hashtable. The method further includes the step of obtaining target server node information. When a node with an application requirement sends out application requirement information, the server node which meets the service requirement is searched for in the distributed Hashtable according to the application requirement information to serve as the target server node, and the target server node is taken as the candidate cooperation node of a data scheduling layer.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

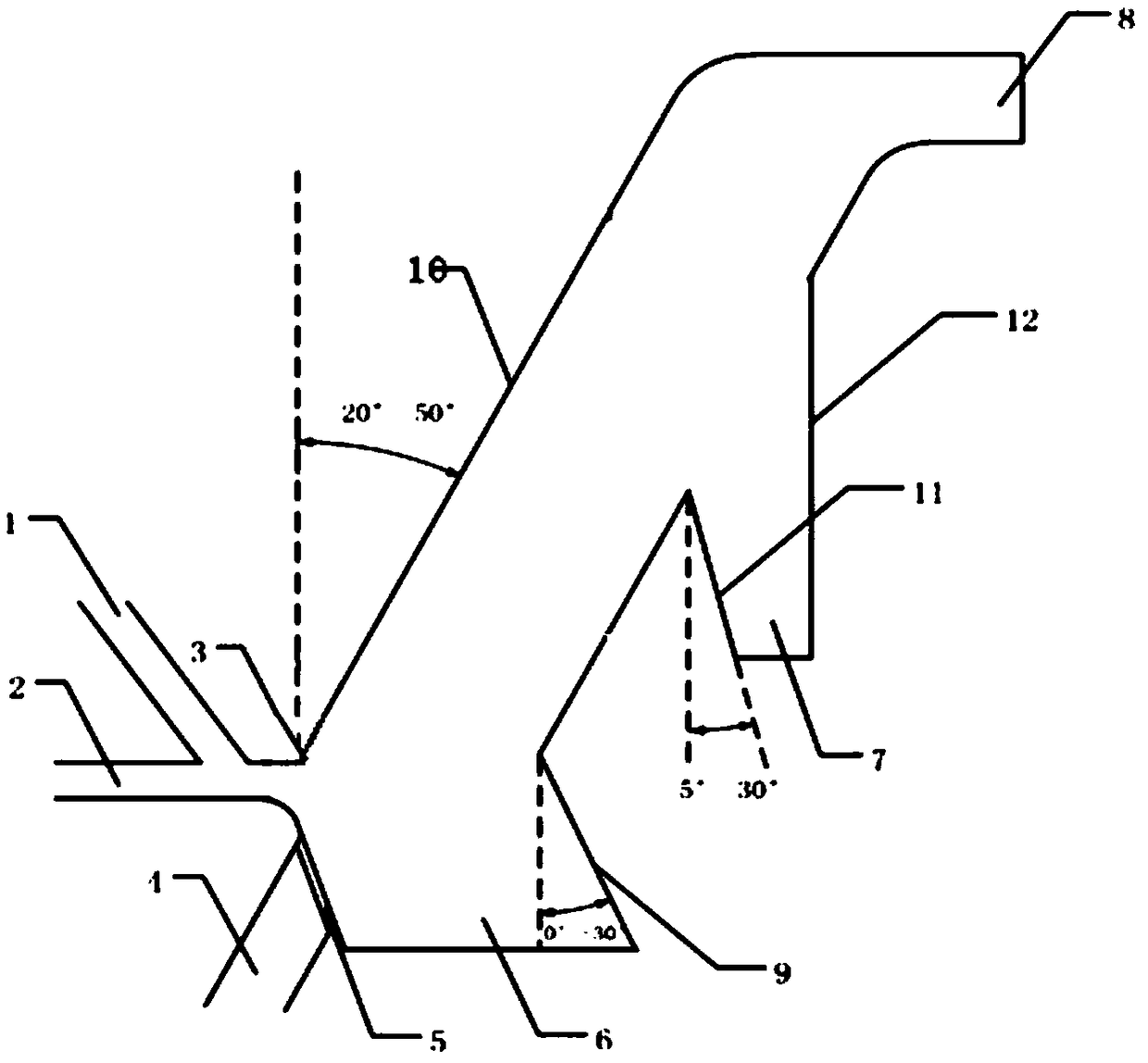

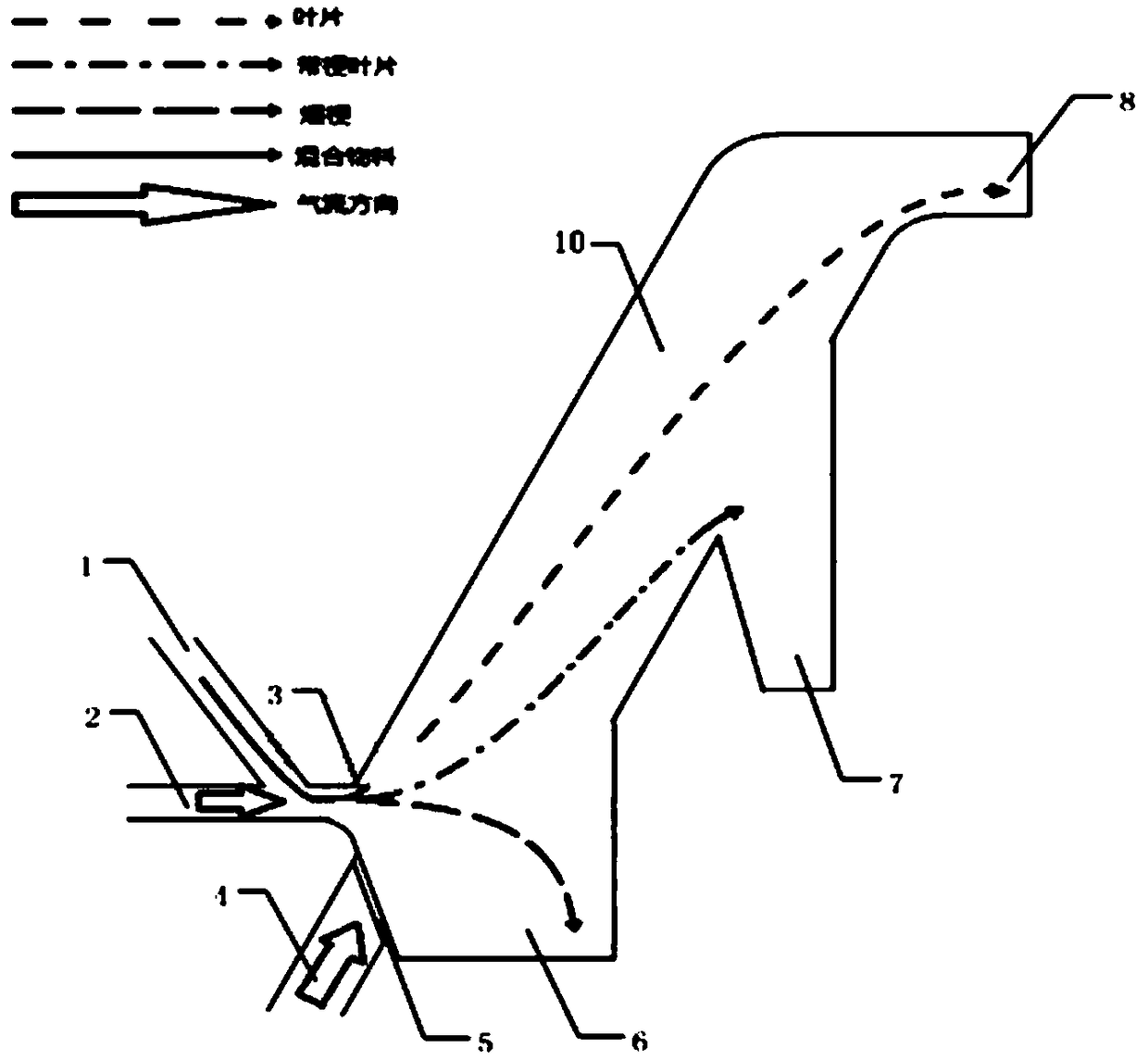

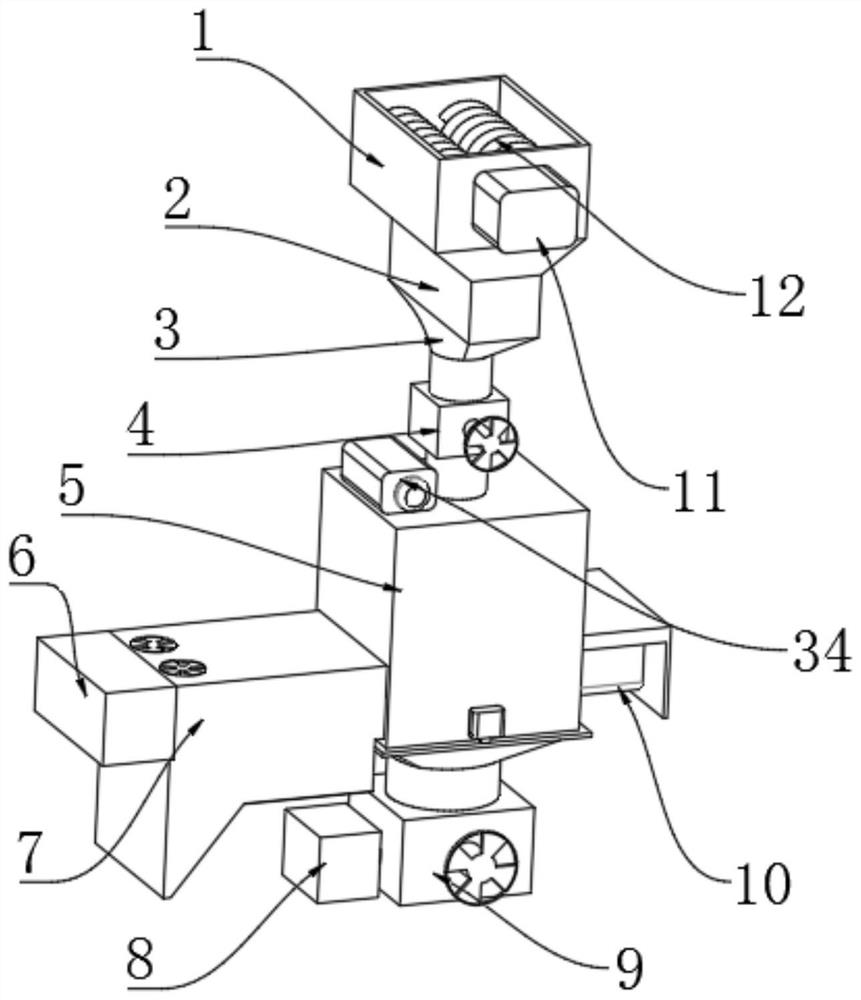

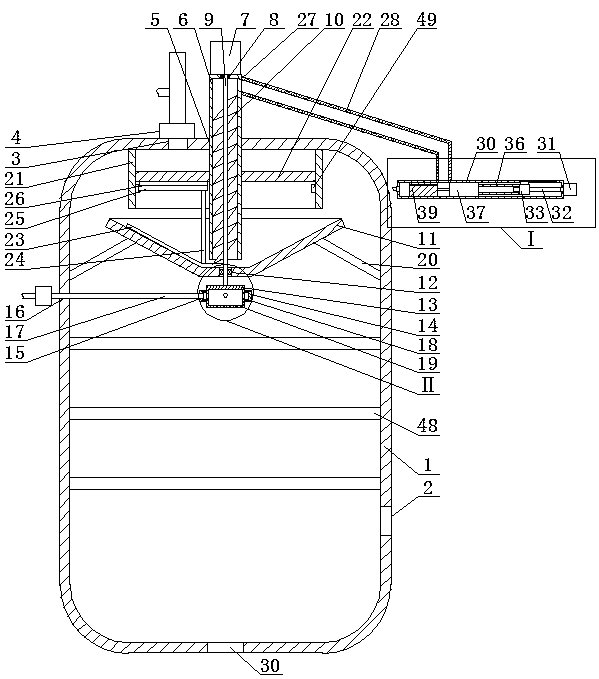

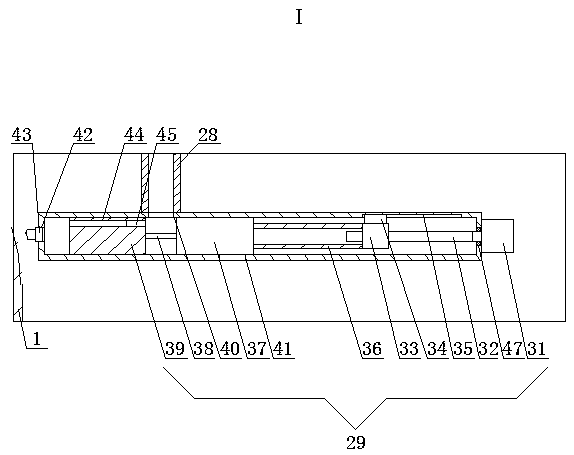

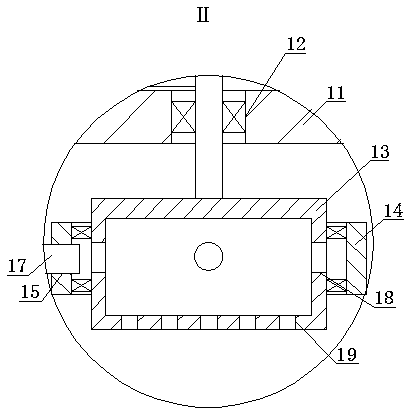

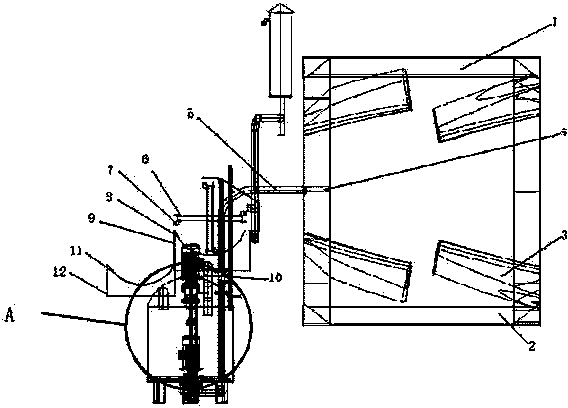

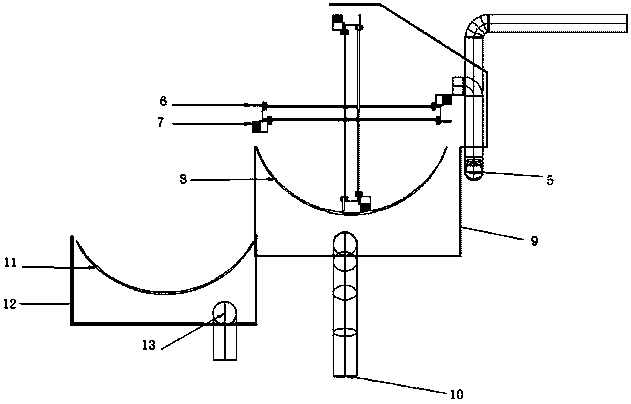

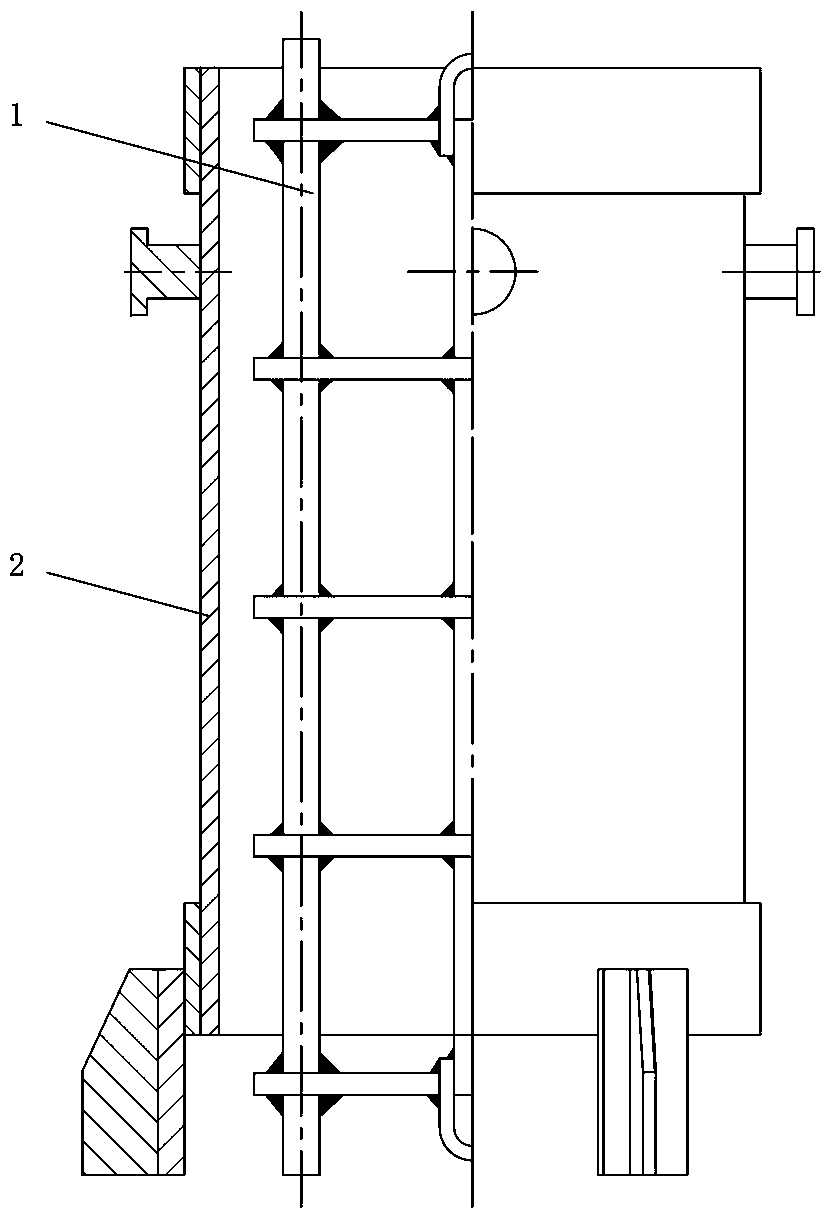

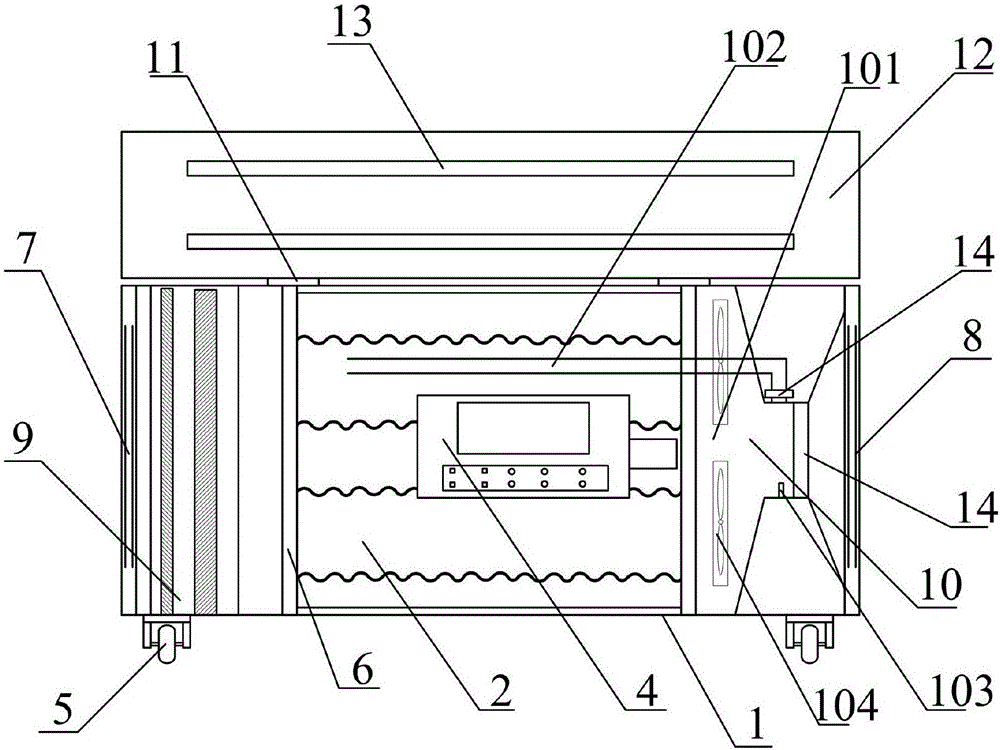

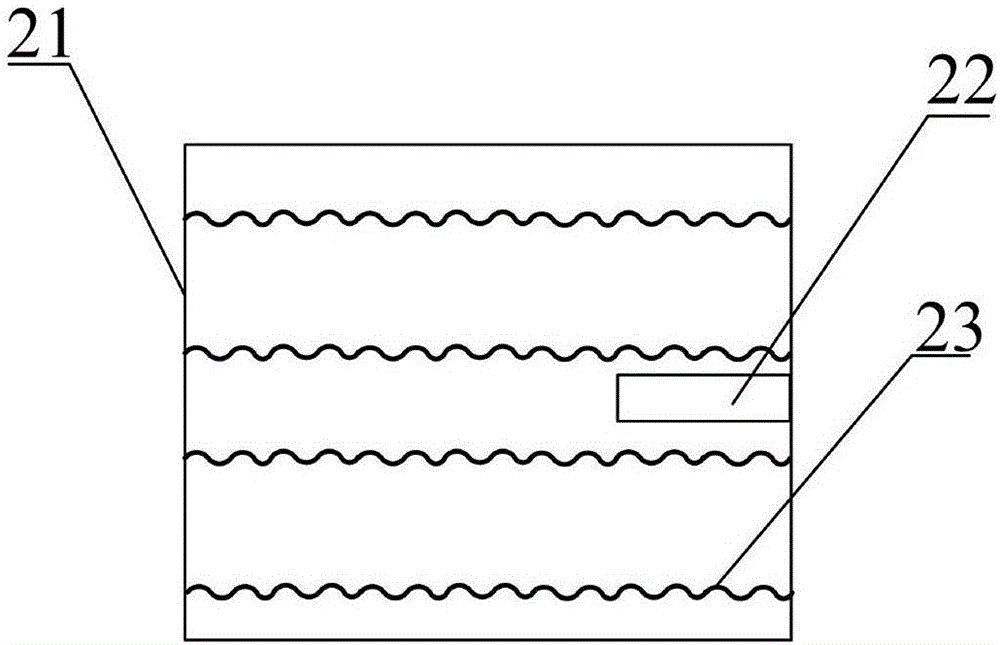

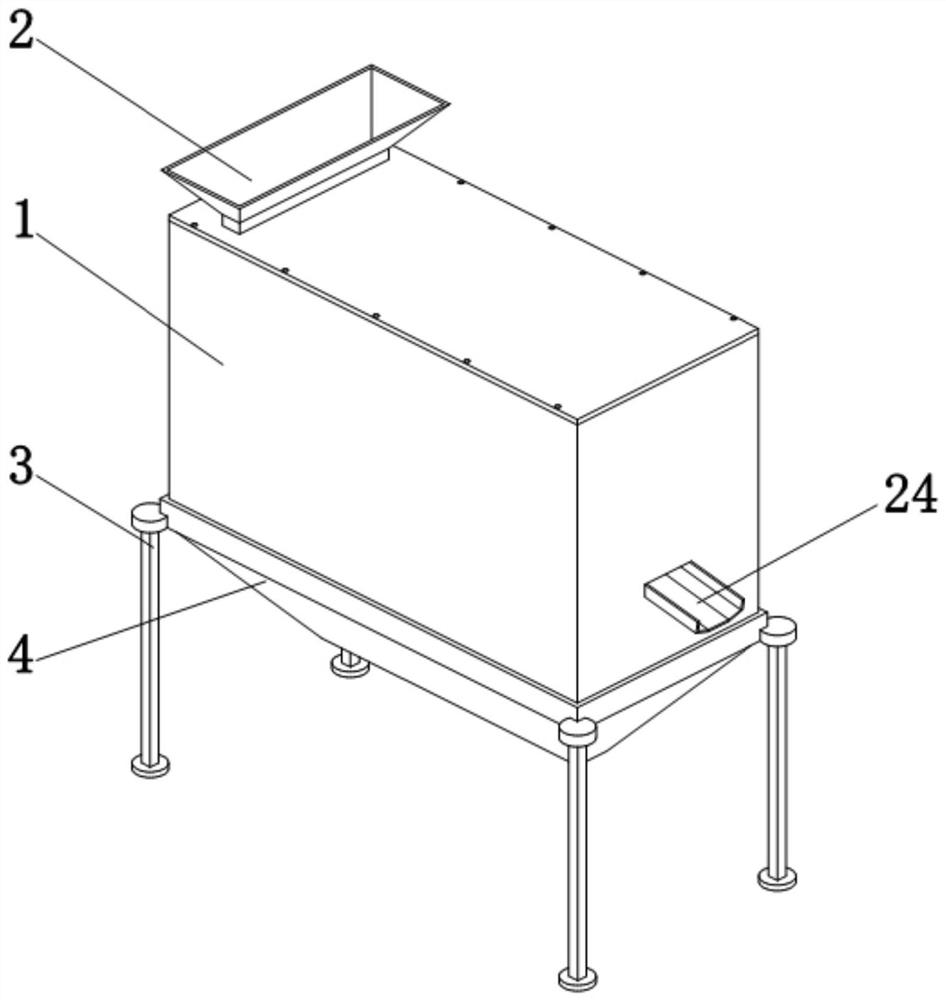

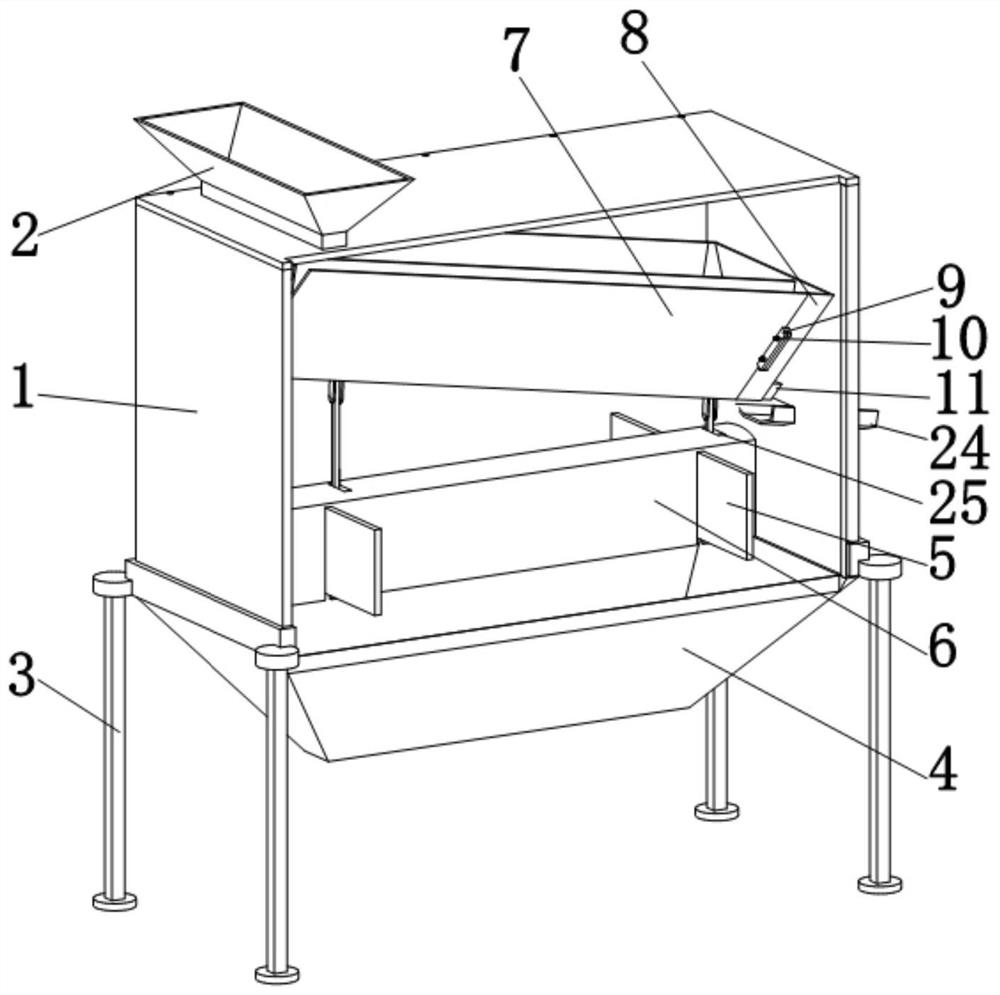

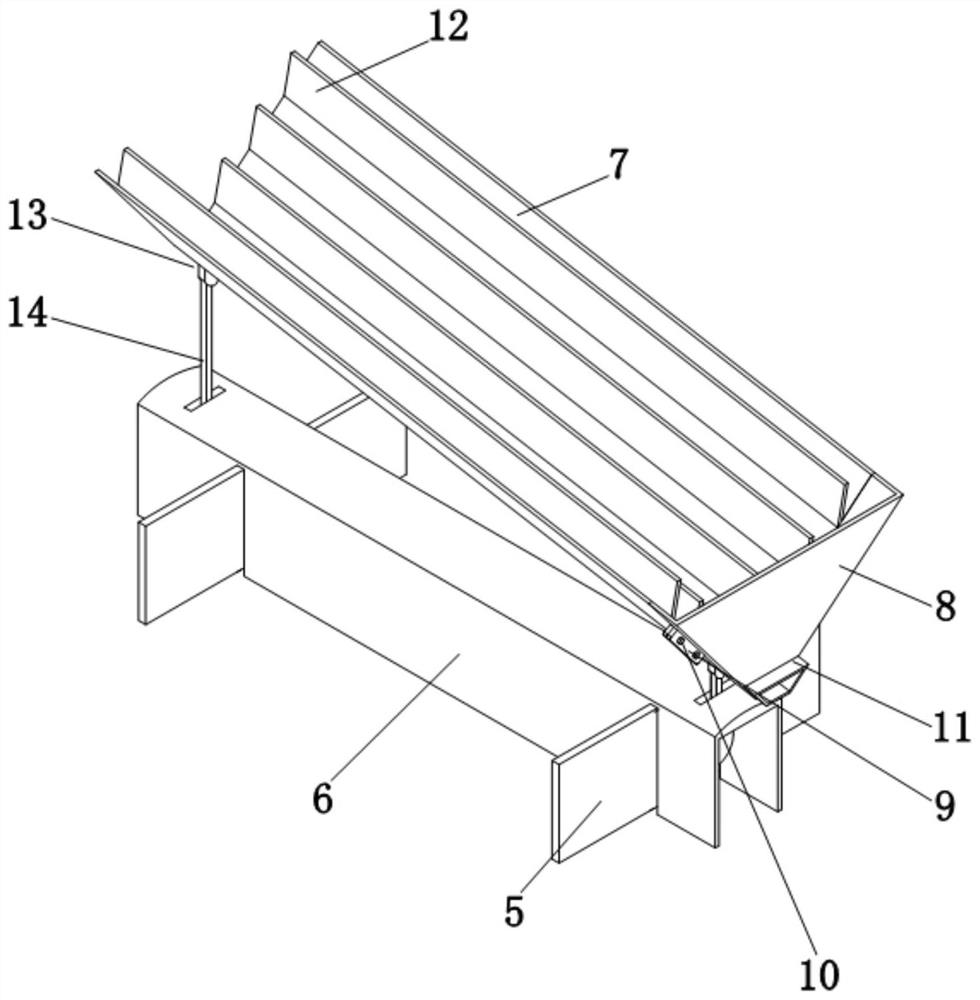

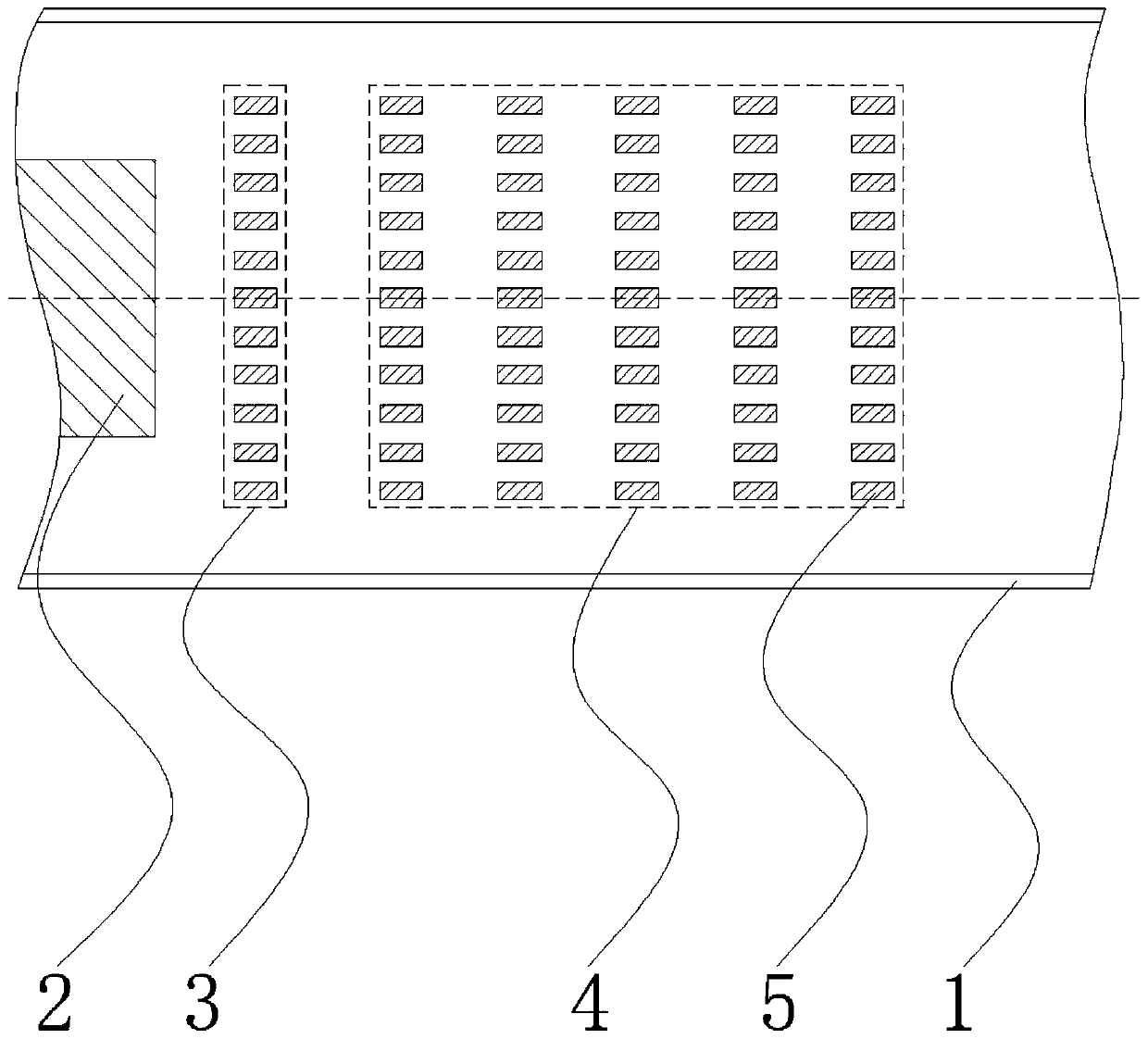

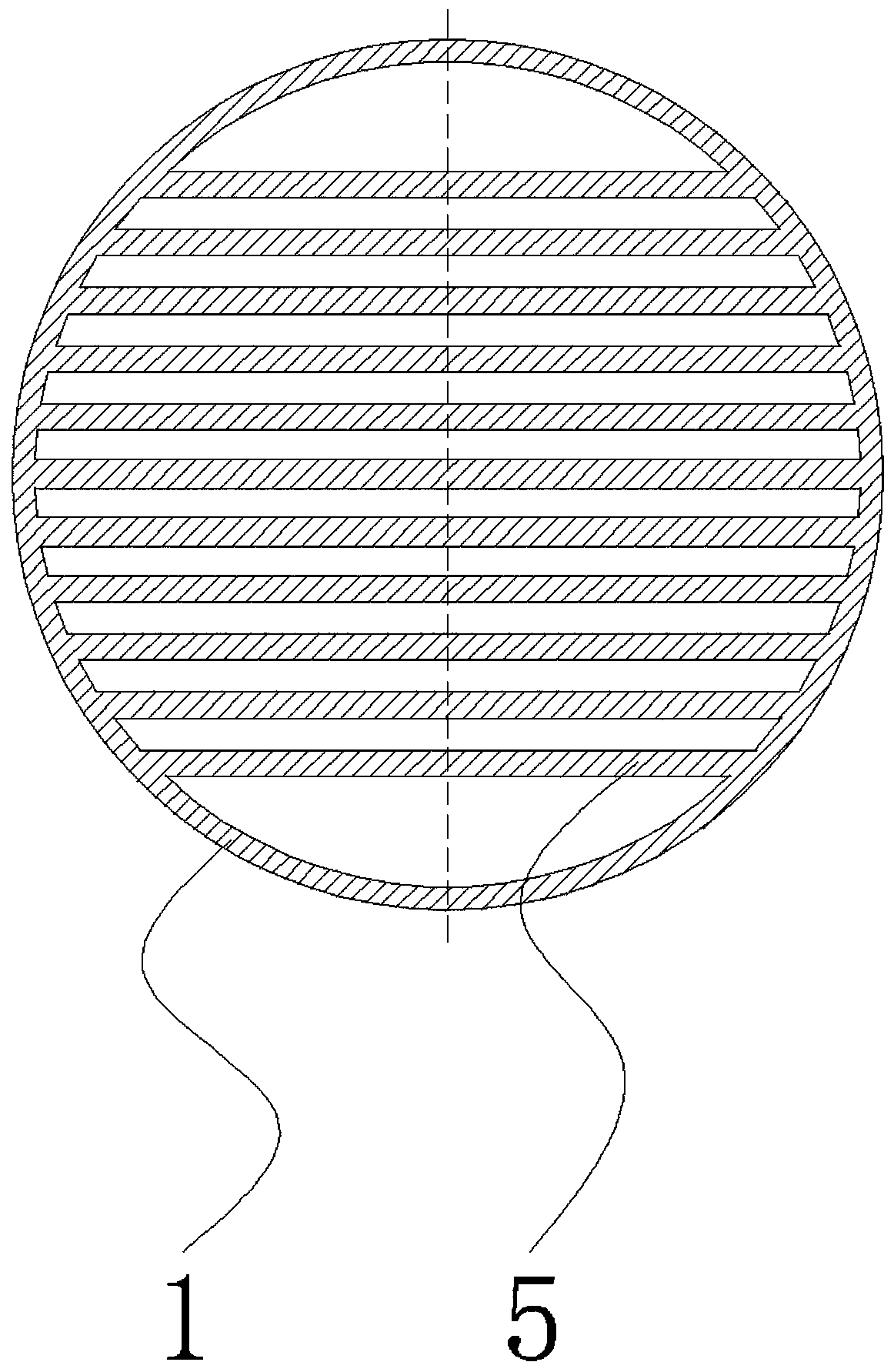

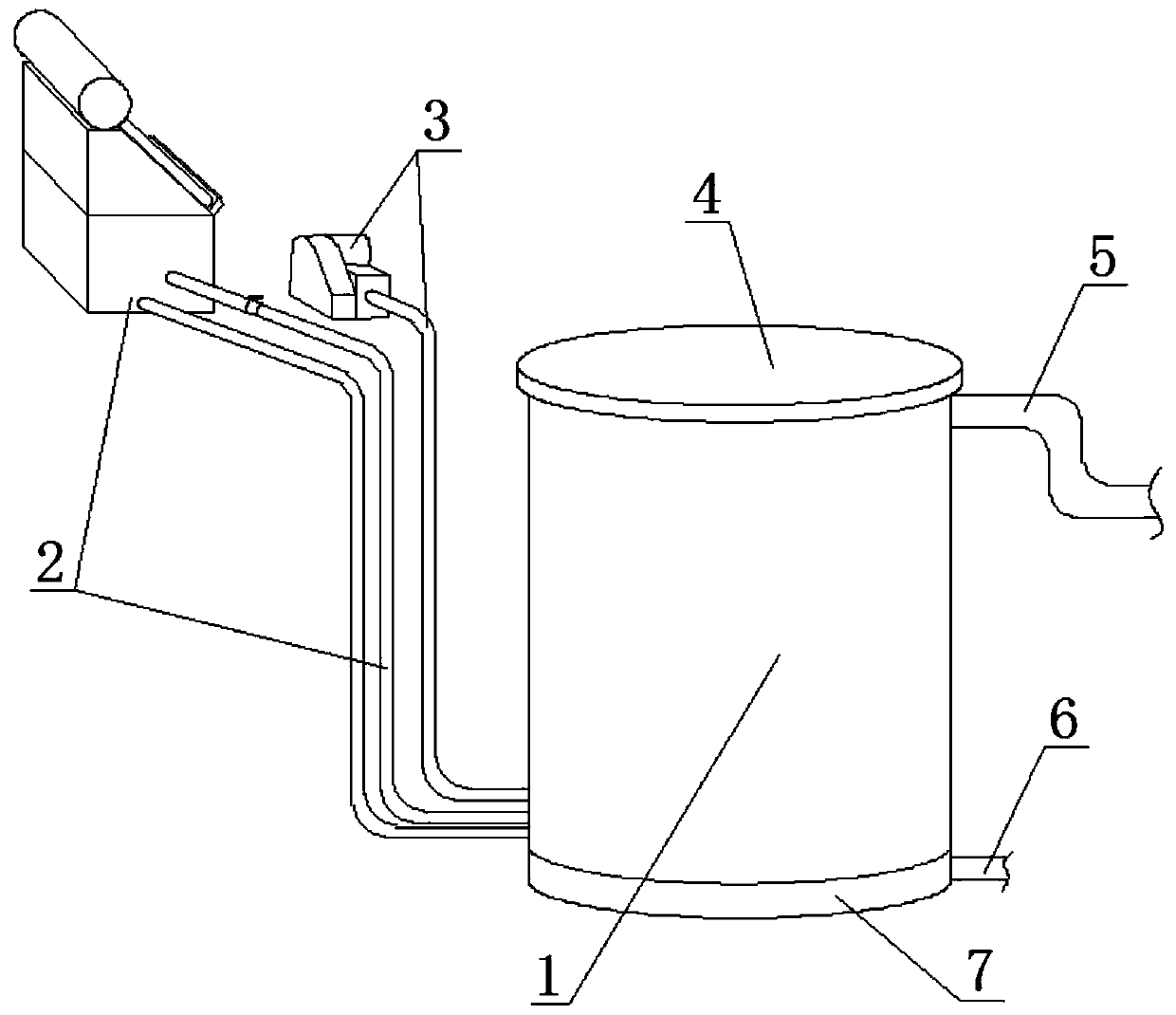

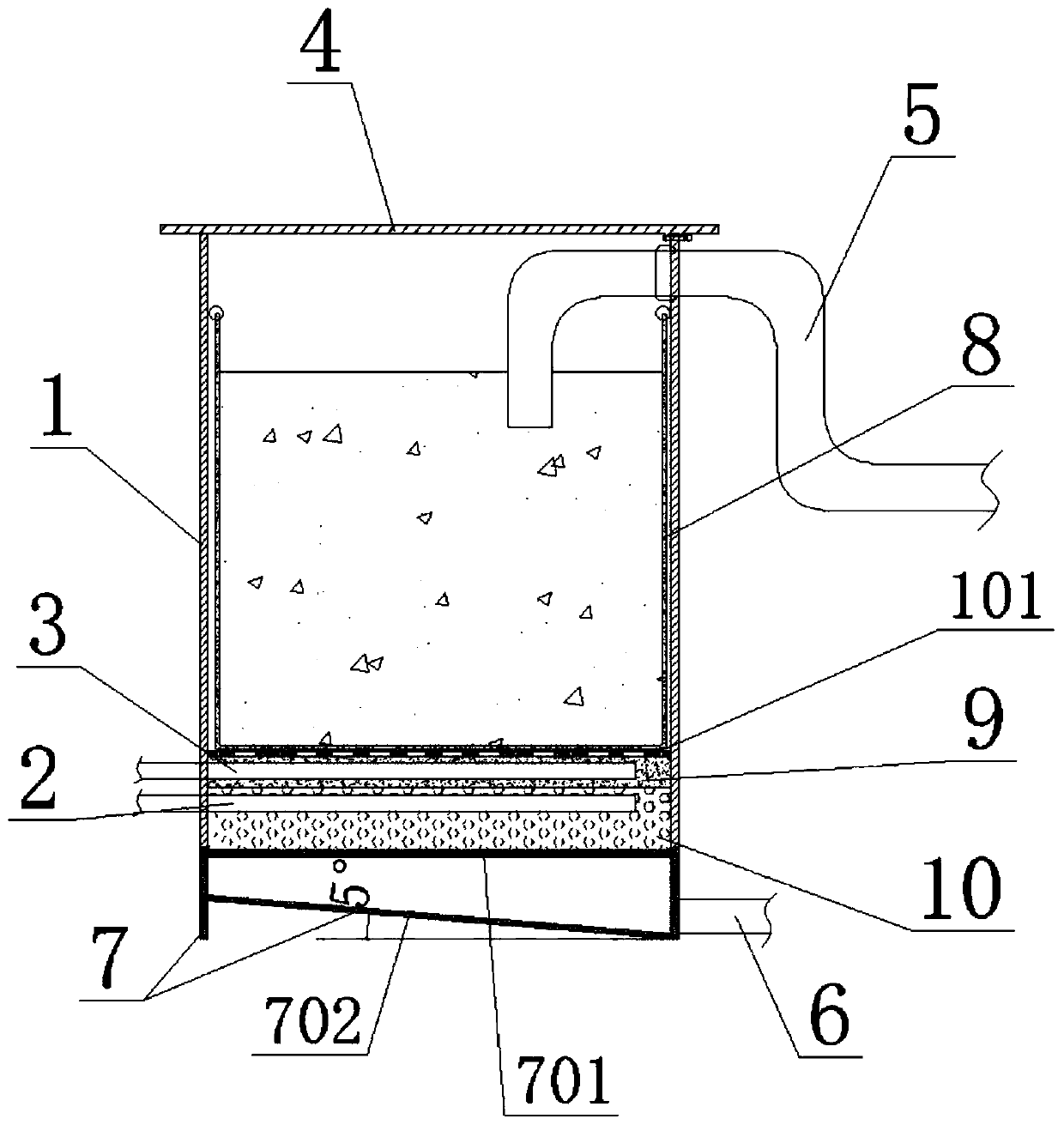

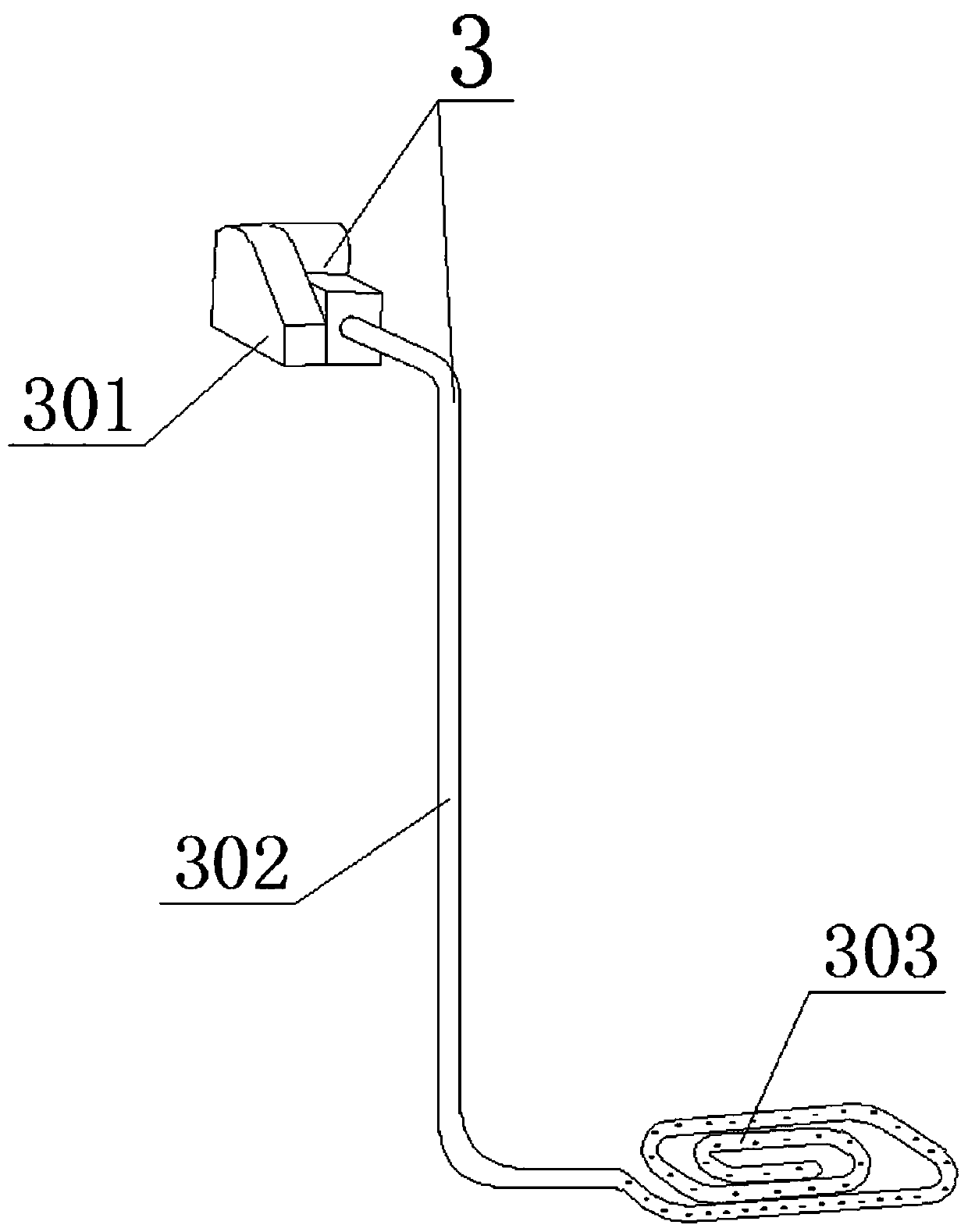

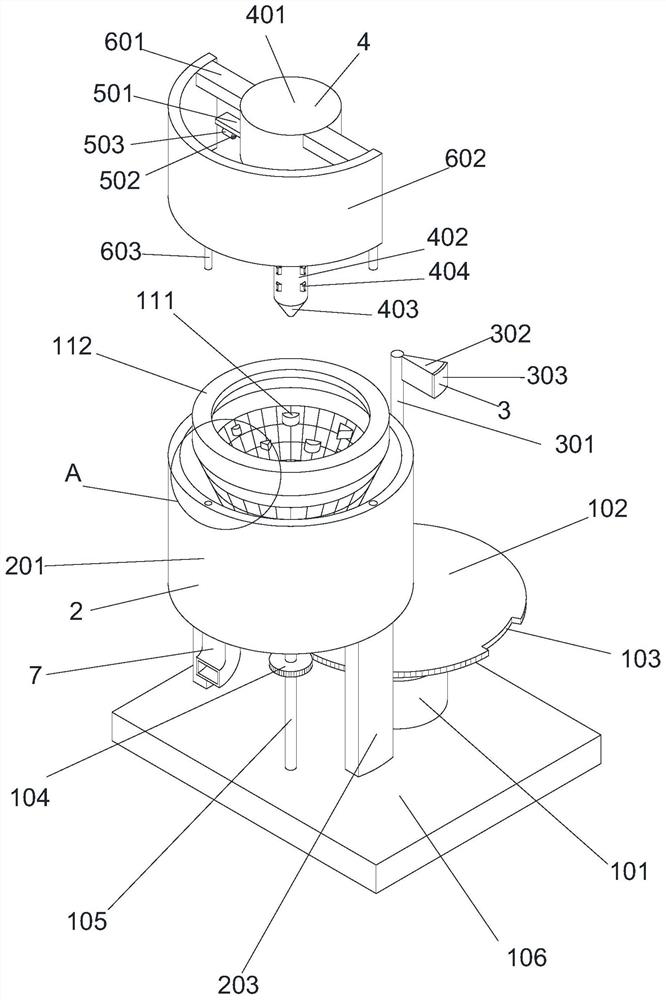

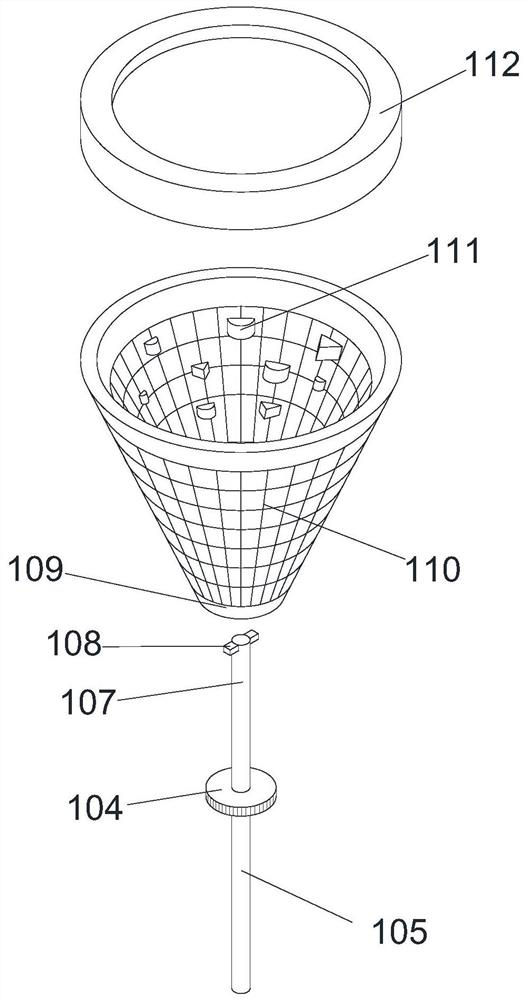

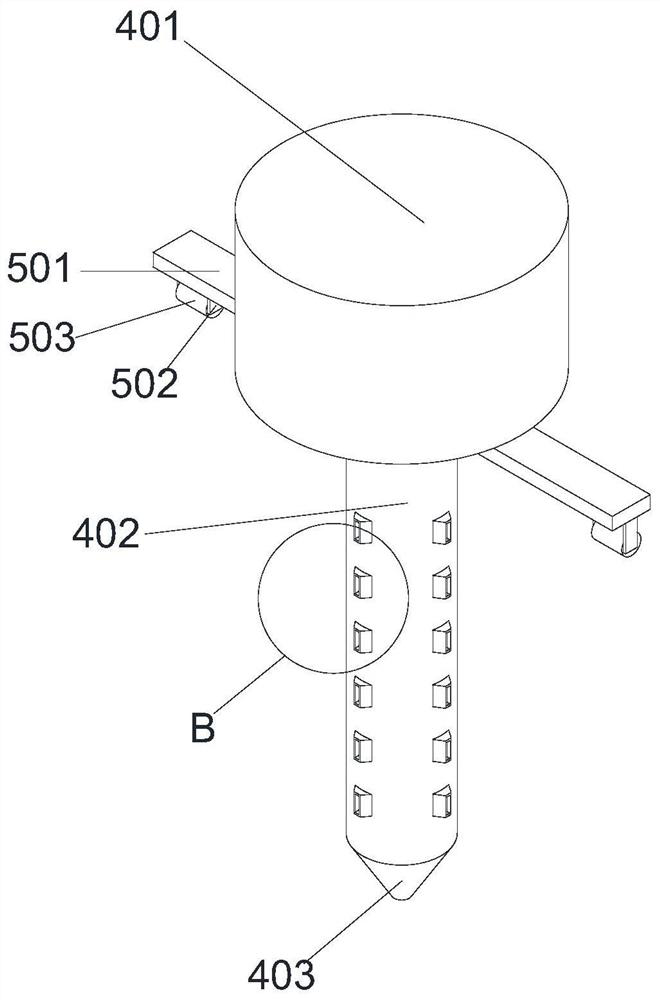

Air separator and separation method for separating tobacco leaves, tobacco stalks and leaves with stalks

PendingCN108838090AAvoid breakingImproving Separation DisadvantagesGas current separationEngineeringFeeding mode

The invention discloses an air separator and a separation method for separating tobacco leaves, tobacco stalks and leaves with stalks. The air separator includes an air separating bin (10) arranged obliquely, wherein an upstream segment, a midstream segment and a downstream segment are arranged on the air separating bin (10), wherein the cross sectional area of the midstream segment is largest. Afeed air pipe (2) and a main air inlet pipe (4) are arranged on the upstream segment of the air separating bin (10), and a feed inlet (1) is formed in the feed air pipe (2). A feed air pipe adjustingdevice (3) is arranged at the discharge outlet of the feed air pipe (2), and a first downward outlet (6) is formed in the upstream segment of the air separating bin (10). A second downward outlet (7)is formed in the midstream segment, a third outlet (8) is formed in the midstream segment, and a negative pressure fan is arranged on the third outlet (8). The air separator and the separation methodfor the separating tobacco leaves, the tobacco stalks and the leaves with the stalks adopt an air belt material feeding mode to feed materials, the air belt material can enable the materials in unit volume to distribute more dispersion, and the air separating efficiency is improved, compared with a conventional material throwing roller and a high-speed belt feeding mode.

Owner:CHINA TOBACCO YUNNAN IND

Cold roll bulk heat treatment process

InactiveCN108103302AImprove plasticityGood welding performanceFurnace typesIncreasing energy efficiencyCold treatmentMedium frequency

The invention discloses a cold roll bulk heat treatment process. A roll is subjected to normalizing, annealing, quenching and tempering, medium-frequency hardening and cold treatment, the hardness, toughness and impact resistance of a final structure meet the operation requirements, and the service life of the roll is greatly prolonged. A batch-type furnace and a well type electric furnace are used for heating, an overall rapid heating and hardening method is adopted, and the hardening quality of 60CrMnMo steel cold roll can still be ensured.

Owner:CHANGZHOU ECCO ROLLER

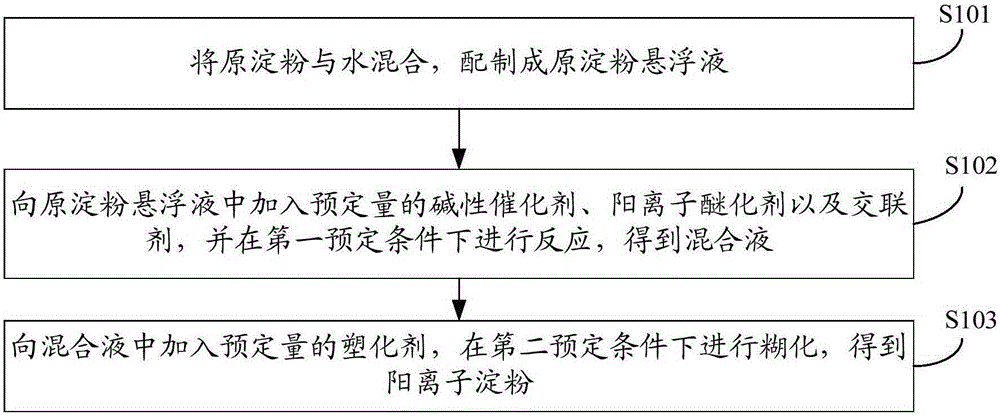

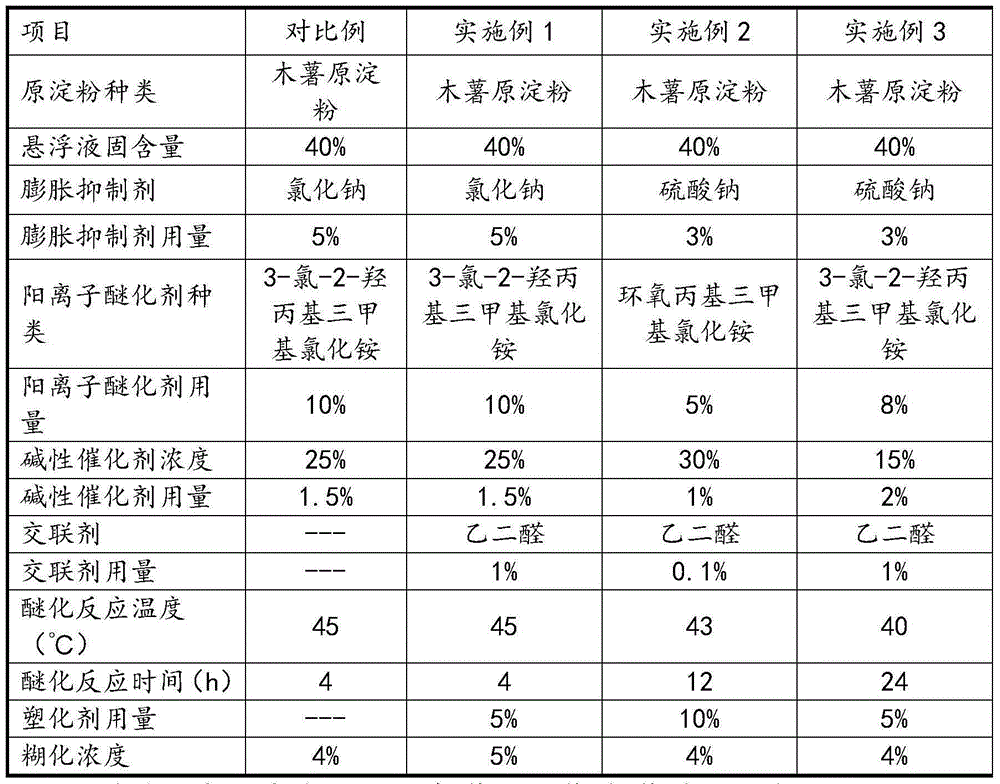

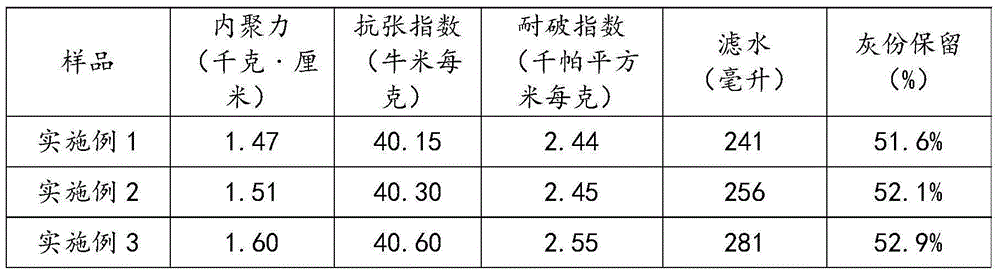

Preparation method of cationic starch

InactiveCN106608919AImprove retention and filtration performanceHigh strengthPlasticizerAlkaline catalyst

The invention discloses a preparation method of cationic starch. The preparation method comprises following steps: native starch is mixed with water so as to obtain a native starch suspension; certain amounts of a basic catalyst, a cationic etherifying agent, and a cross-linking agent are added into the native starch suspension, and reaction is carried out under first preset conditions so as to obtain a mixed solution; a preset amount of a plasticizer is added into the mixed solution, and gelatinization is carried out under second preset conditions so as to obtain the cationic starch. The preparation method is capable of improving retention properties and drainability of pulp, and increasing paper strength therefore.

Owner:GOLD EAST PAPER JIANGSU

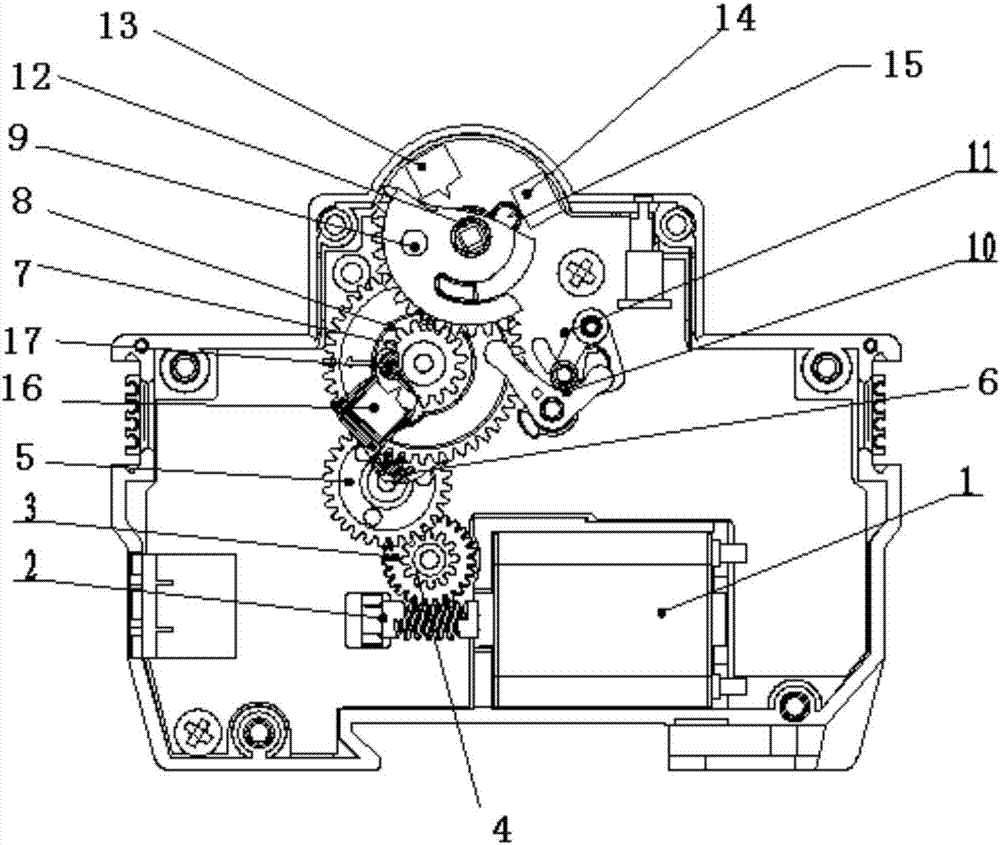

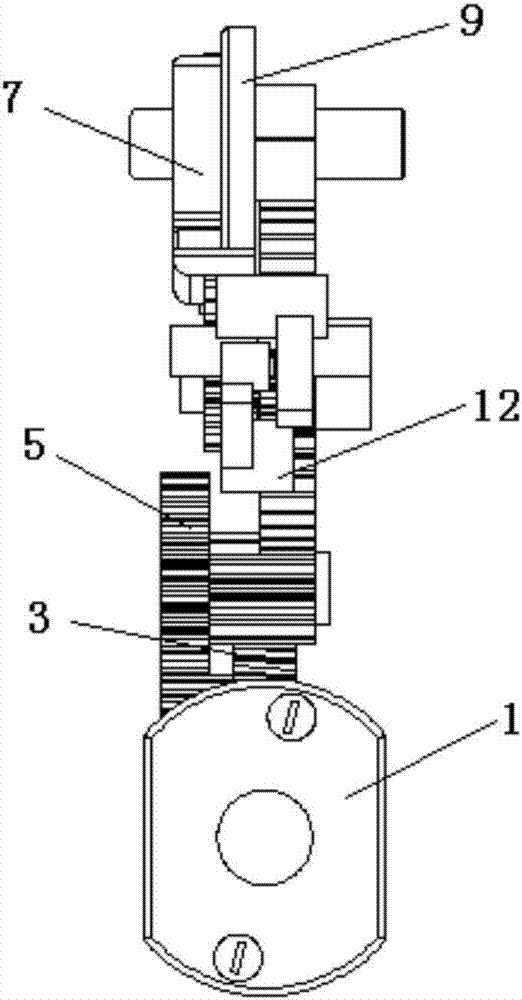

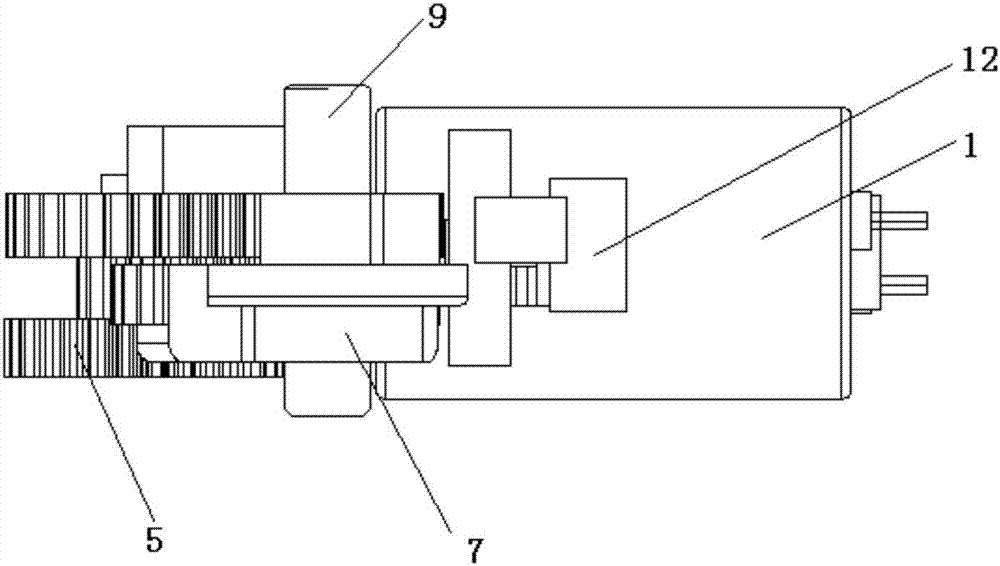

Electric operating mechanism of circuit breaker

ActiveCN107240535AScattered distributionNo false detectionProtective switch operating/release mechanismsDrive shaftElectric control

The invention provides an electric operating mechanism of a circuit breaker. The electric operating mechanism comprises a housing, a transmission shaft, a driving device, a striking device, a position detection device and an electric control device, wherein the position detection device comprises a switch-on position detection device, a switch-off position detection device and a free position detection device; the switch-on position detection device and the switch-off position detection device are arranged on the two sides around the transmission shaft; and the free position detection device is arranged at the driving device far away from the transmission shaft. Distribution of the position detection devices is relatively disperse; the position detection devices are free from false detection when a first detection object and a second detection object are respectively detected; and a detection range is large due to the arrangement manner of the position detection devices.

Owner:合兴集团有限公司

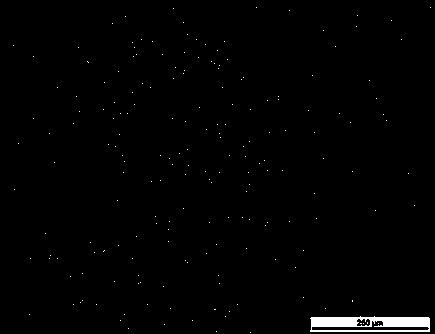

Rare-earth element europium alloying aluminum-silicon alloy and preparation method thereof

The invention relates to a rare-earth element europium alloying aluminum-silicon alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 9.0-13.5% of silicon, 0.06-0.09% of europium and the balance of aluminum. The preparation method comprises the following steps: heating an aluminum-silicon alloy in a graphite crucible to be molten, adding europium or an aluminum-europium intermediate alloy according to the weight percents of the components at 710-730 DEG C, and keeping the temperature for 10-15 minutes; performing intermittent ultrasonic treatment on the molten alloy under the conditions that the ultrasonic strength is 10-38 w / cm<2>, the total ultrasonic treatment time is 2-5 minutes, the ultrasonic time of each time is 20-30 seconds and the intermittence time is 20-30 seconds; and cooling the molten alloy to 680-700 DEG C, keeping the temperature for 10-180 minutes, and solidifying at a cooling rate of 40-60 DEG C / min. According to the invention, the refinement and nodularization of an alpha-Al phase can be obviously accelerated; acicular eutectic silicon is changed into punctate or stick-like silicon, and the distribution is more disperse and uniform, thus ensuring that the microscopic structure and mechanical property of the aluminum alloy are obviously improved; and the process is simple, safe, reliable and convenient to operate, and has no pollution caused by three wastes.

Owner:优标易站(苏州)电子商务有限公司

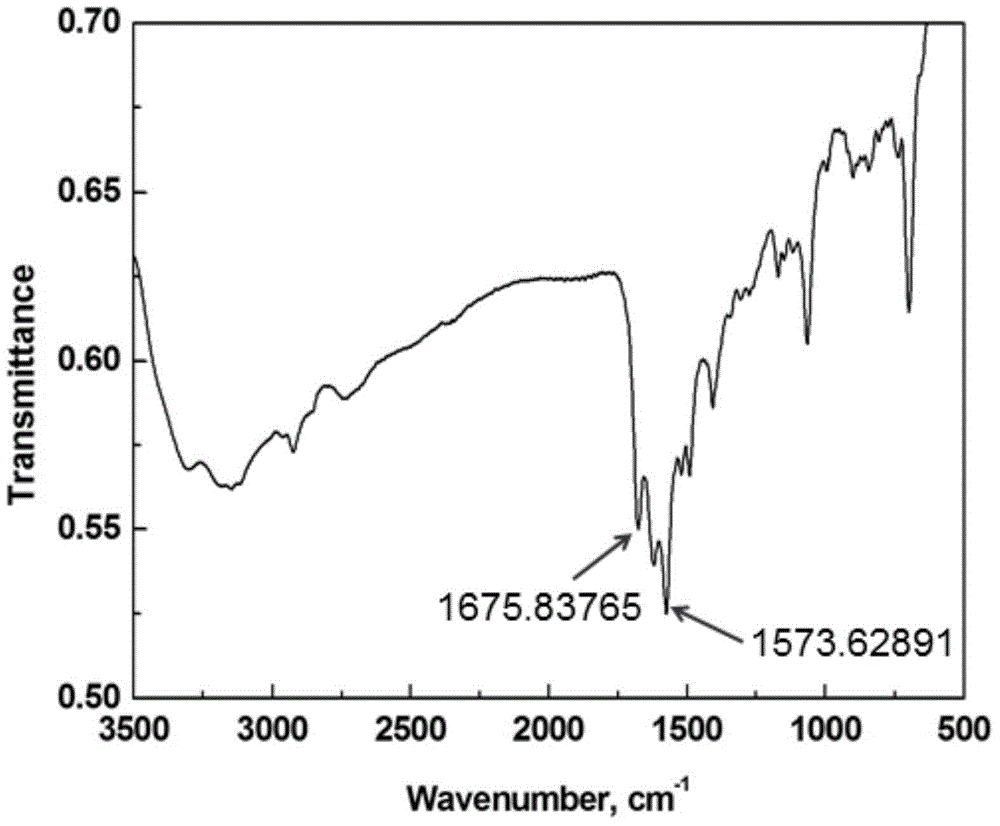

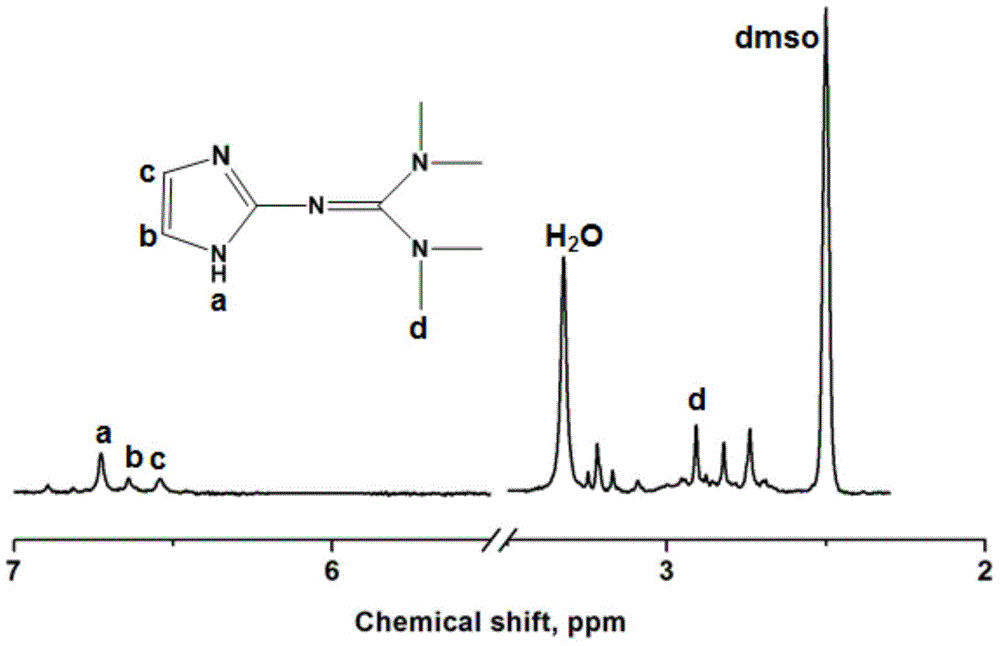

Cross-linking type anion membrane and preparation method thereof

InactiveCN104966843AScattered distributionGood alkali resistanceCell electrodesFuel cellsIon-exchange membranes

The invention discloses a novel anion-exchange membrane and a preparation method thereof. The anion membrane is prepared from a polymer containing halomethyl group and a binary ionization reagent containing dual resonance effects by crosslinking, and the ionic group of the membrane is provided with dual resonance effects, so that the positive charges are distributed more dispersely and the membrane has better chemical stability under alkaline environment. The binary ion conduction group can effectively increase ion conductivity; in addition, crosslinking can inhibit swelling. The anion membrane prepared by the invention has the advantages of better chemical stability, higher conductivity and swelling resistance, and the membrane is suitable for application in the aspect of alkaline fuel cells.

Owner:DALIAN UNIV OF TECH

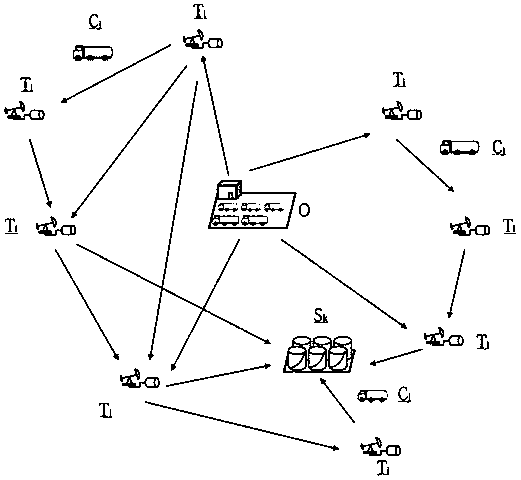

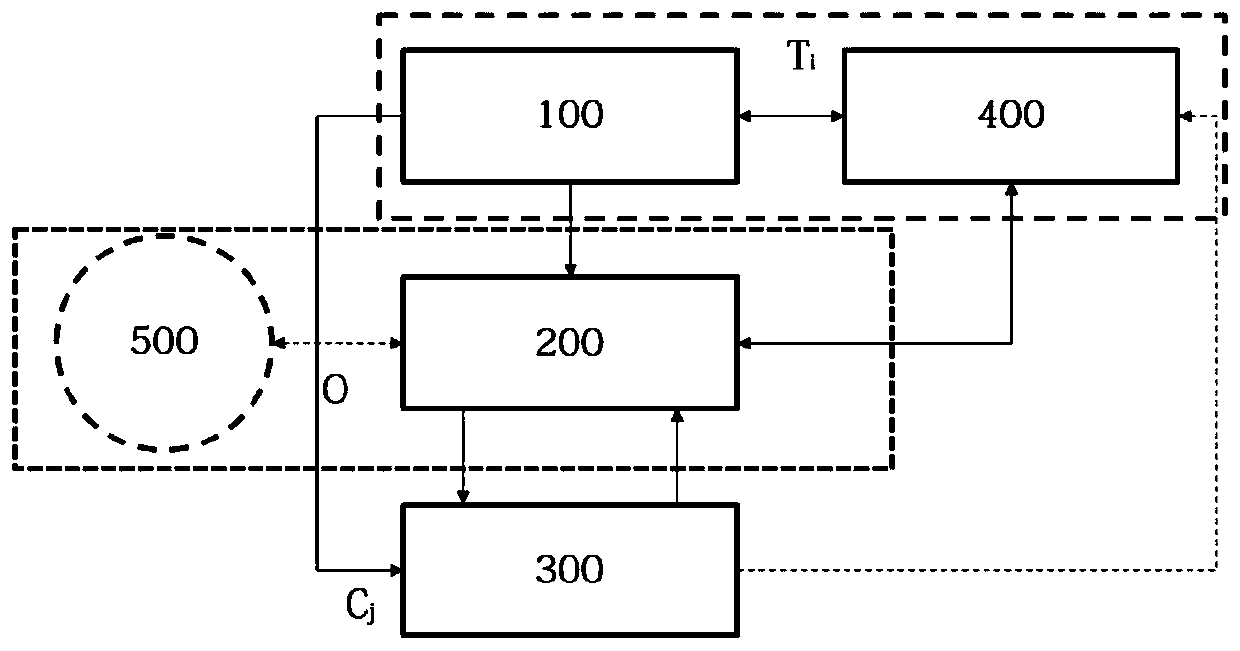

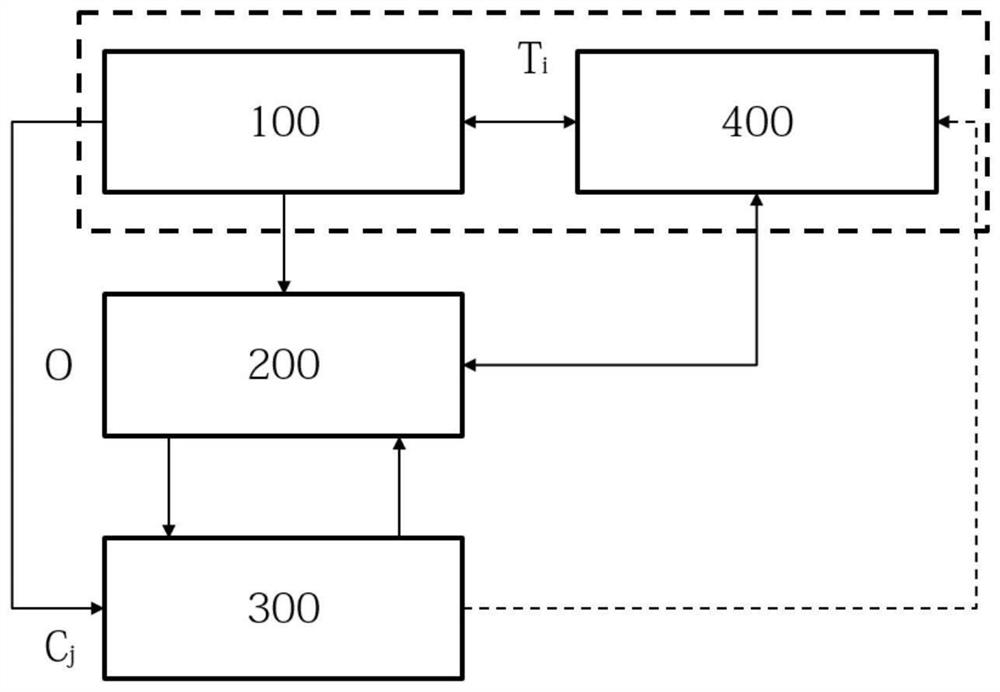

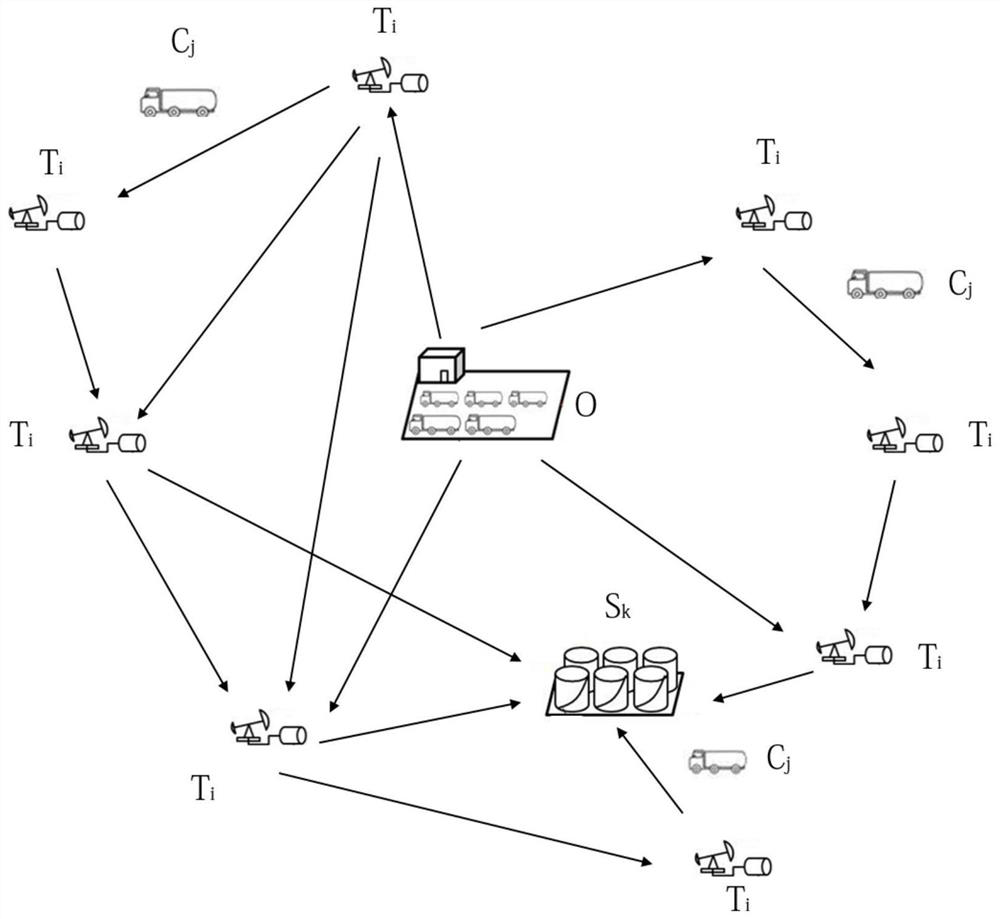

Oil field single-pull can well production operation scheduling optimization system and method based on Internet of Things big data

ActiveCN111506035AIncrease productionReduce shipping costsTotal factory controlProgramme total factory controlData connectionOperation scheduling

The invention relates to an oil field single-pull can well production operation scheduling optimization system based on big data of the Internet of Things. The system comprises a production sensing module used for collecting the production parameters of a single-pull can, a vehicle-mounted monitoring module used for collecting the working parameters of an oil pull vehicle, and a scheduling terminal arranged in an oil field command station. The scheduling terminal is in communication connection with the production sensing module and the vehicle-mounted monitoring module, so that the schedulingterminal can output an oil pulling scheme for the oil pulling vehicle to pull crude oil in single pulling tanks with different geographic positions to an oil unloading point based on the production parameters and / or the working parameters. The scheduling terminal is independent of an intranet of the oil field command station and can establish the data connection with the production sensing moduleand the vehicle-mounted monitoring module, so that the production sensing module and the vehicle-mounted monitoring module can be in communication connection under the condition that intranet data isnot obtained.

Owner:ANHUI FIRSTCON INSTR

Large-scale non-gathering oil well group production and transportation scheduling collaborative optimization system and method

The invention relates to a large-scale non-gathering oil well group production and transportation scheduling collaborative optimization system. The system comprises: a productivity acquisition moduleused for acquiring productivity parameters of a single-pulling tank, a vehicle-mounted monitoring module used for acquiring working parameters of an oil tank truck, and a scheduling cloud arranged inan oil field command center; the scheduling cloud is in communication connection with the capacity acquisition module and the vehicle-mounted monitoring module, so that the scheduling cloud can outputan oil transporting scheme for transporting crude oil in single-pulling tanks with different geographic positions to an oil unloading point by the oil tank truck based on the capacity parameters and / or the working parameters; the vehicle-mounted monitoring module is connected with an oil unloading module arranged in a well area through a near-field communication module. According to the invention, the oil tank truck can safely and reliably operate, and single-transporting-can controllable production is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

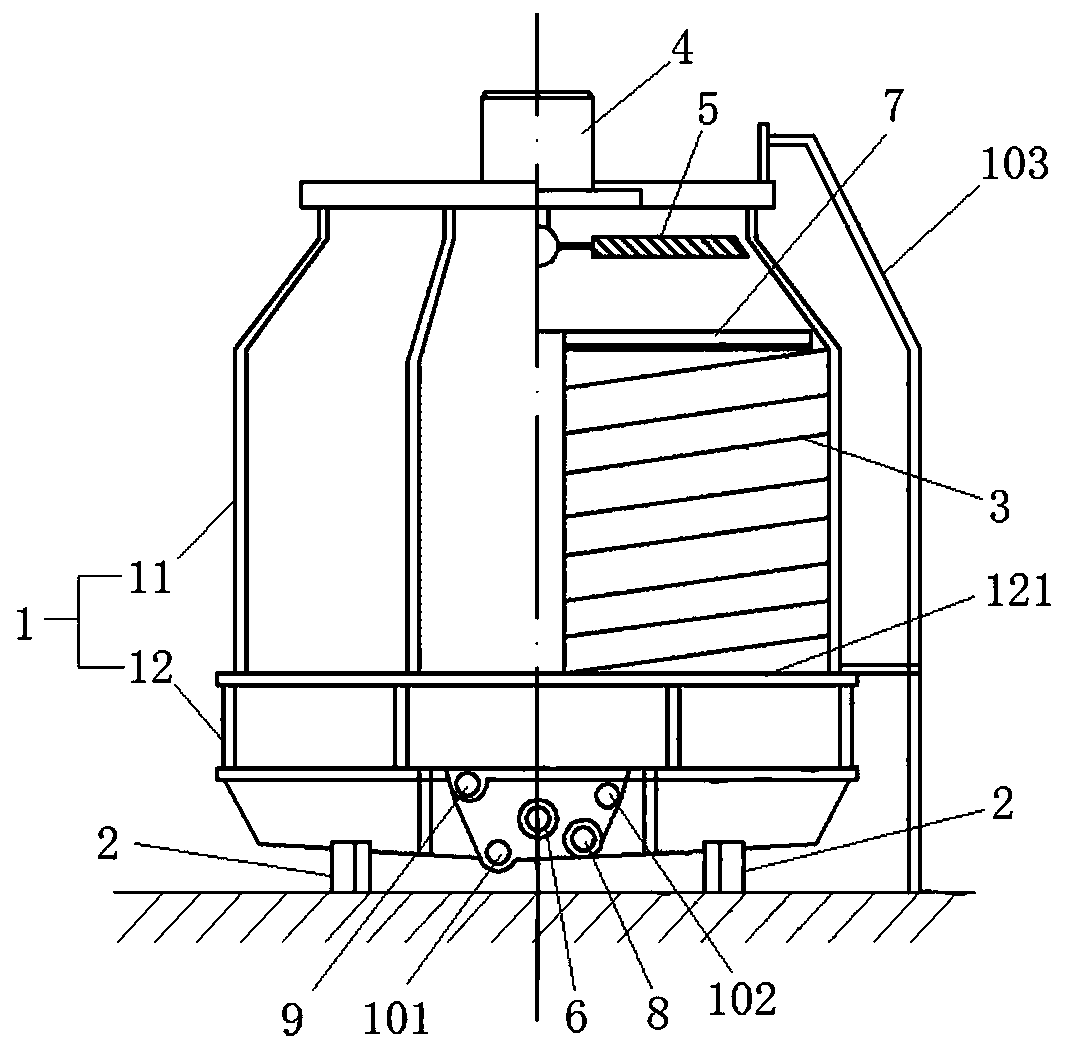

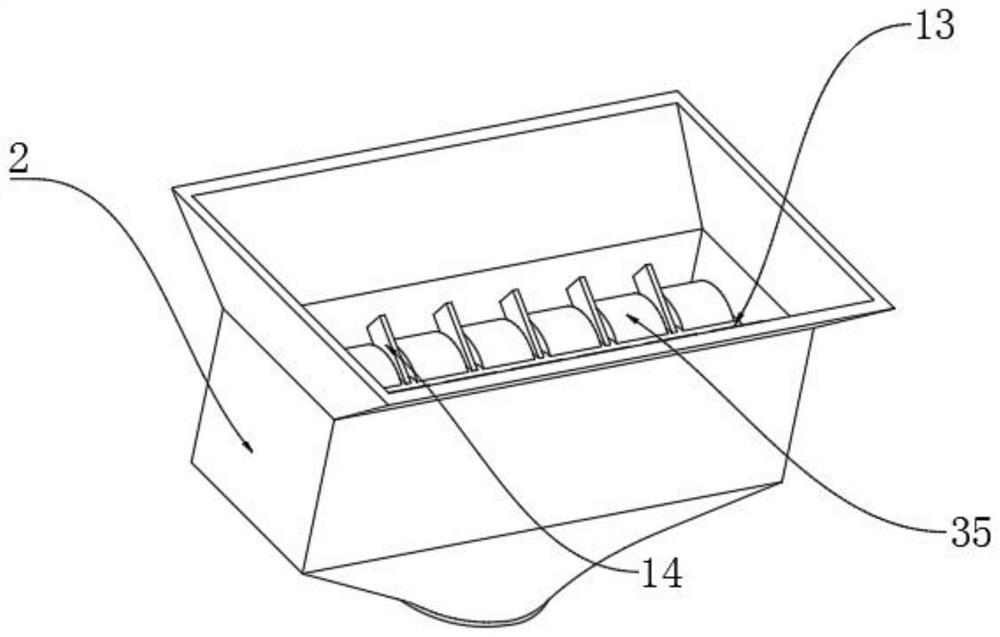

Cooling tower

The invention relates to the technical field of cooling equipment, in particular to a cooling tower. The cooling tower comprises a tower body, at least one water diversion plate, a water spraying device, a water collecting pool and a fan; the tower body is provided with a cooling cavity for cooling circulating water; the water diversion plates are fixed into the cooling cavity in a spiral shape from top to bottom; the water spraying device is arranged above the water diversion plates and used for being connected with a circulating water pipeline outside the cooling tower and spraying circulating water onto the water diversion plates; the upper surfaces of the water diversion plates are smooth so that the circulating water can flow downwards conveniently, the water diversion plates are provided with a plurality of water leakage holes, and part of the circulating water leaks through the water leakage holes when the circulating water flows downwards along the upper surfaces of the water diversion plates; the water collecting pool is arranged at the bottom of the tower body and used for collecting the circulating water; and the fan is arranged at the top of the tower body and used forextracting air from bottom to top and cooling the circulating water flowing from top to bottom through the reverse airflow. The cooling tower provided by the invention is good in cooling effect.

Owner:HENAN UNIV OF SCI & TECH

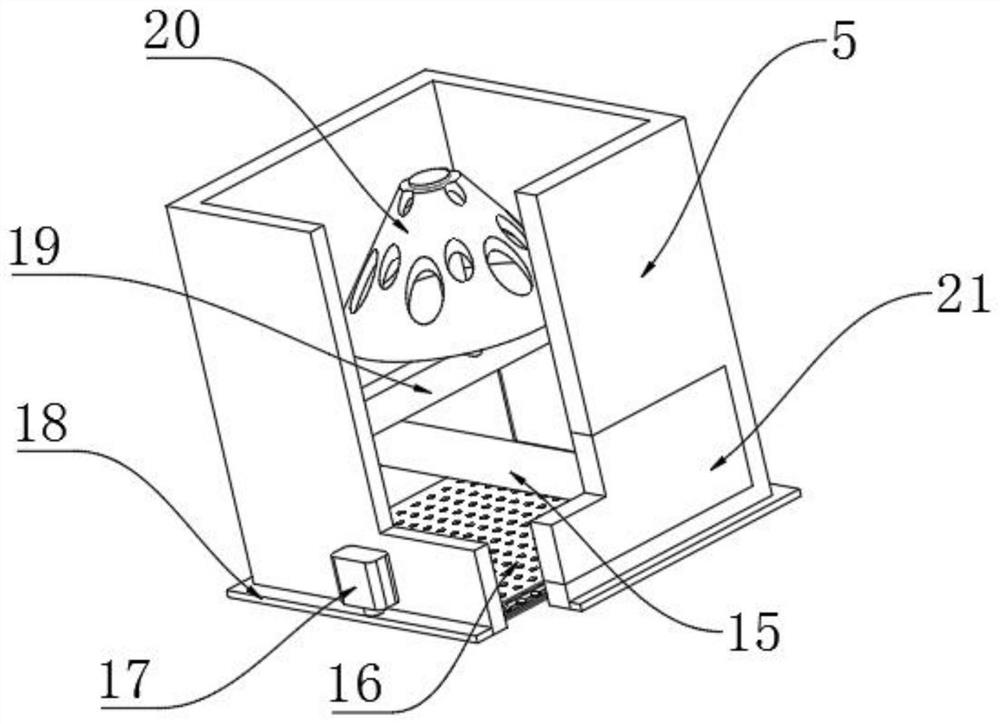

Graphite powder multi-stage grinding equipment for new energy battery production

InactiveCN111992324AAvoid oxidation reactionsProcessing speedSievingDrying solid materials without heatNew energyConical tube

The invention discloses graphite powder multi-stage grinding equipment for new energy battery production, and relates to the technical field of graphite powder multi-stage grinding. In order to solvethe problem that the surface of graphite contains impurities before grinding, the graphite powder multi-stage grinding equipment specifically comprises a pulverizer; the outer wall of one side of thepulverizer is connected with a pulverizing motor through bolts; the inner walls of the two sides of the pulverizer are fixedly connected with pulverizing assemblies; the outer wall of the bottom end of the pulverizer is connected with a cutting box through bolts; the outer wall of the bottom end of the cutting box is connected with a conical pipe through bolts; the outer wall of the bottom end ofthe conical pipe is connected with a first electric valve through bolts; the outer wall of the bottom end of the first electric valve is connected with a drying box through bolts; and the inner wall of one side of the drying box is fixedly connected with a filter screen through screws. According to the graphite powder multi-stage grinding equipment, the conical pipe and a second electric valve arearranged, water follows the graphite in the surface treatment process of graphite particles, the water can play a role in cleaning the surface of the graphite and cooling the graphite in the pulverizing and cutting process, and the graphite is prevented from being subjected to an oxidation reaction due to high temperature.

Owner:李俊强

Device for removing light components in maleic anhydride production

ActiveCN110665450AAvoid cloggingPrevent fallingChemical/physical/physico-chemical stationary reactorsFeed devicesPolymer scienceEngineering

The utility model discloses a device for removing light components in maleic anhydride production. The device comprises a reaction tank, an air inlet is formed in one side of the peripheral lower endof the reaction tank; an air outlet is formed in the top surface of the reaction tank; a negative pressure pump communicated with the air outlet is fixedly mounted on the top surface of the reaction tank; a first through hole is formed in the center of the top face of the reaction tank, a coaxial long pipe is fixedly installed in the first through hole, a first motor is fixedly installed on the top face of the long pipe, a second through hole is formed in the top face of the long pipe, a rotating shaft is installed in the second through hole through a bearing, and the upper end of the rotatingshaft is fixedly connected with the lower end of a first motor rotating shaft. The device is simple in structure, and skillful in design, is provided with a filter screen, is capable of filtering outpolymerized acrylic polymers; the filter screen can be continuously cleaned, the filter screen is prevented from being blocked, the acrylic polymer can be collected and prevented from falling to thebottom of the reaction tank or a tower tray, so that the corrosion of the acrylic polymer to the bottom of the reaction tank and the tower tray is reduced, and the collected acrylic polymer can be continuously discharged.

Owner:东营市科德化工有限公司

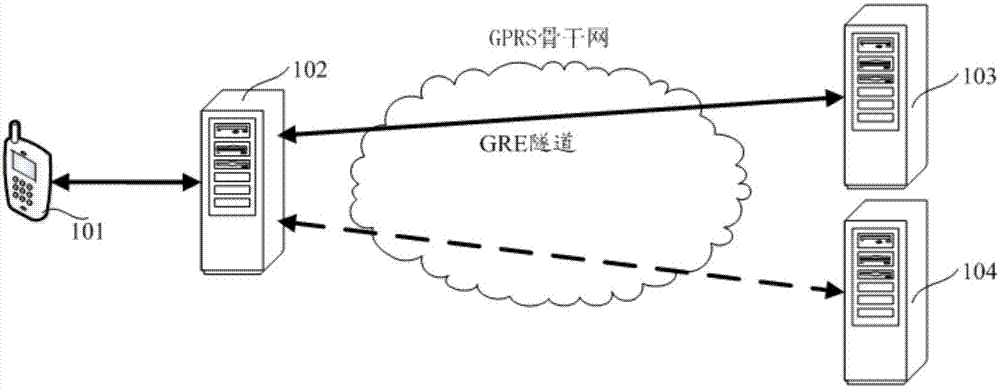

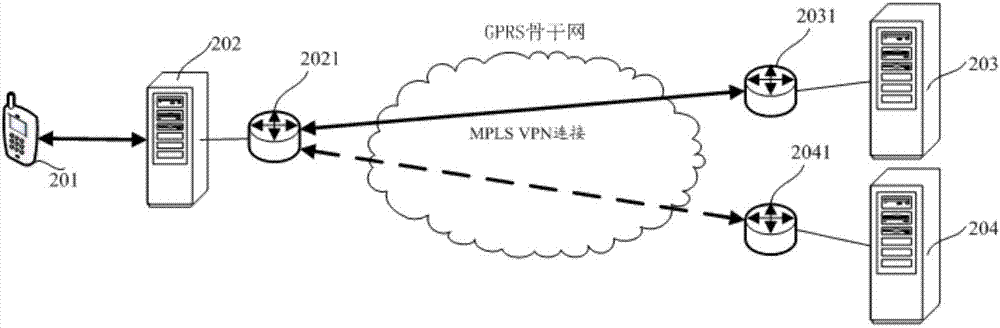

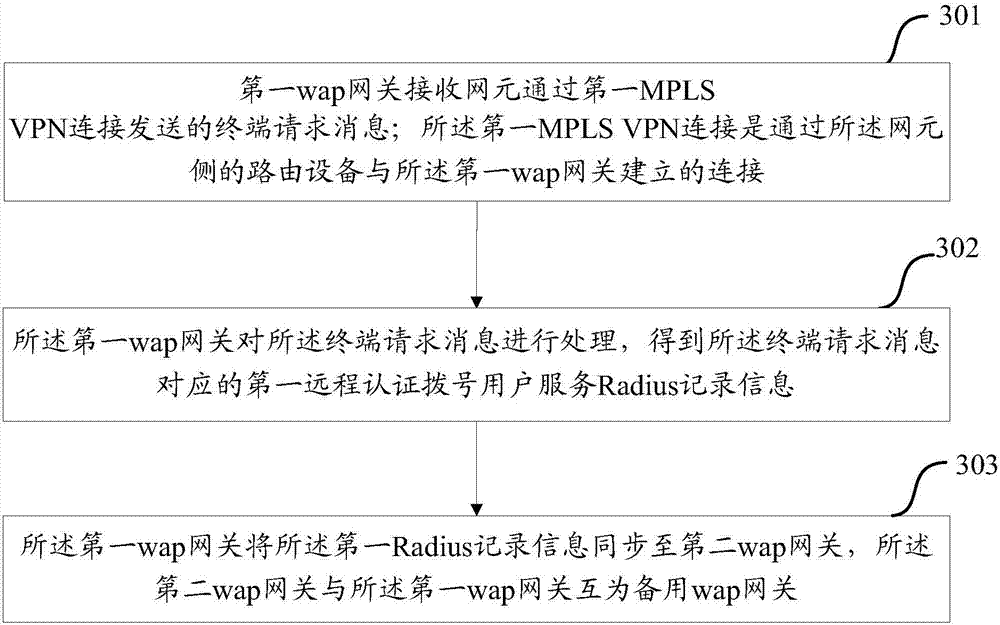

Data transmission method, wap gateway and data transmission system

ActiveCN107086958AReduce congestionScattered distributionConnection managementNetworks interconnectionTraffic capacityComputer terminal

The embodiment of the invention discloses a data transmission method, a wap gateway and a data transmission system. The method provided by the embodiment of the invention comprises the steps as follows: the first wap gateway receives a terminal request message sent by a network element via a first MPLA VPN connection, and first Radius record information corresponding to the terminal request message is acquired by processing the terminal request message, and is synchronized to the second wap gateway which is mutually backup to the first wap gateway. In the method provided by the embodiment of the invention, on the one hand, the VPN connection can fully utilize network node bandwidth to reduce network congestion, so as to be more suitable for large flow processing; on the other hand, when disaster-tolerance switching is performing, operation is no longer related to network element equipment, the first gateway synchronizes the first Radius record information to the second gateway to achieve backup, so that when the first gateway is switched to the second gateway, the operation of forcibly making a user be offline and online again to register is not needed, and disaster-tolerance switching efficiency is greatly improved.

Owner:CHINA MOBILE GROUP JIANGSU

Fur niter-dyeing machine

ActiveCN104388607AIncrease heightReduce strong mechanical actionLeather/skins/hides/pelt chemical treatment apparatusTemperature controlScrub brushes

The invention discloses a fur niter-dyeing machine. The fur niter-dyeing machine comprises a rotary drum structure, a filtering device and a stirring device. The rotary drum structure comprises a flat and straight baffle plate arranged at the inner surface of the drum body along an axis direction, an inclined baffle plate structure and inlet and outlet water pipes. The filtering device comprises a liquid inlet pipe, a primary filtering device and a secondary filtering device. The opening of a liquid outlet pipe is arranged above the primary filtering device. The primary filtering device comprises a rubber scrubbing brush, a hairbrush and a primary filtering screen. The rubber scrubbing brush is located in front of the hairbrush. The secondary filtering device comprises a secondary filtering screen and a secondary liquid outlet pipe. The stirring device comprises a temperature control device, a steam heating device and an inclined stirring device arranged in the cylindrical shell of the stirring device. A water outlet of the rotary drum structure is connected to the liquid inlet pipe of the stirring device. The primary liquid outlet pipe and the secondary liquid outlet pipe of the filtering device are respectively connected to the primary liquid inlet pipe and the secondary liquid inlet pipe of the stirring device. The fur niter-dyeing machine can be used in fur niter-dyeing and guarantees finished fur quality.

Owner:桐乡市鑫诺皮草有限公司

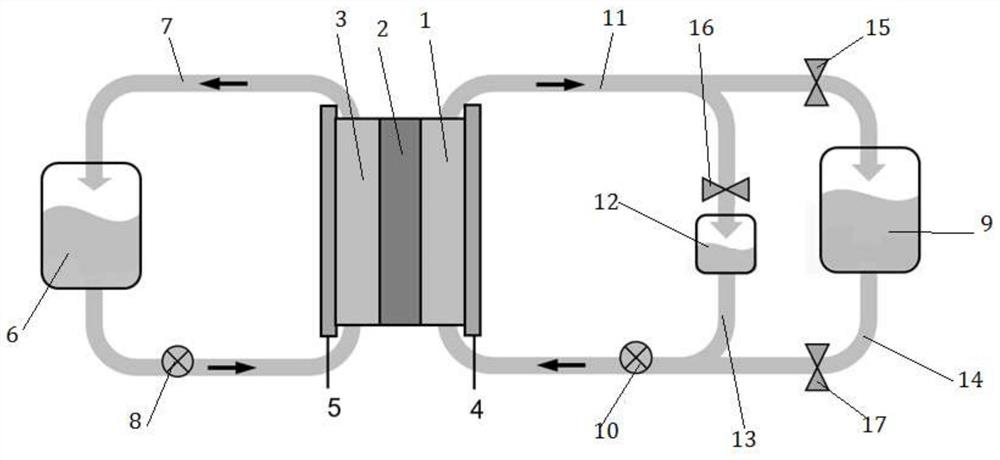

Catalyst in-situ preparation device for flow battery and catalyst preparation method

PendingCN112164805AImprove uniformityLow flow resistanceCellsCell electrodesElectrical batteryCharge and discharge

The present invention discloses a catalyst in-situ preparation device for a flow battery and catalyst preparation method. The catalyst in-situ preparation device comprises a positive electrode half battery and a negative electrode half battery, and in-situ electroplating of a catalyst can be carried out before charging and discharging of the flow battery through an electroplating bypass, an electroplating liquid storage tank and electroplating liquid which are arranged on one side of the negative electrode half battery; or after the flow battery is charged and discharged for a certain time andthe morphology of the catalyst is changed, the in-situ electroplating process is carried out again, and the ion concentration of the catalyst precursor ions in the electroplating liquid is improved by arranging the electroplating bypass, the electroplating liquid storage tank and the electroplating liquid, so that the catalyst is mroe uniformly distributed at the negative electrode of the flow battery. The catalyst electroplating preparation method of intermittent electroplating is utilized, so that catalyst particles are smaller, the particle density and the uniformity are higher, and the problems that an existing catalyst is uneven in distribution and blocks a porous electrode are solved.

Owner:SOUTHWEST JIAOTONG UNIV

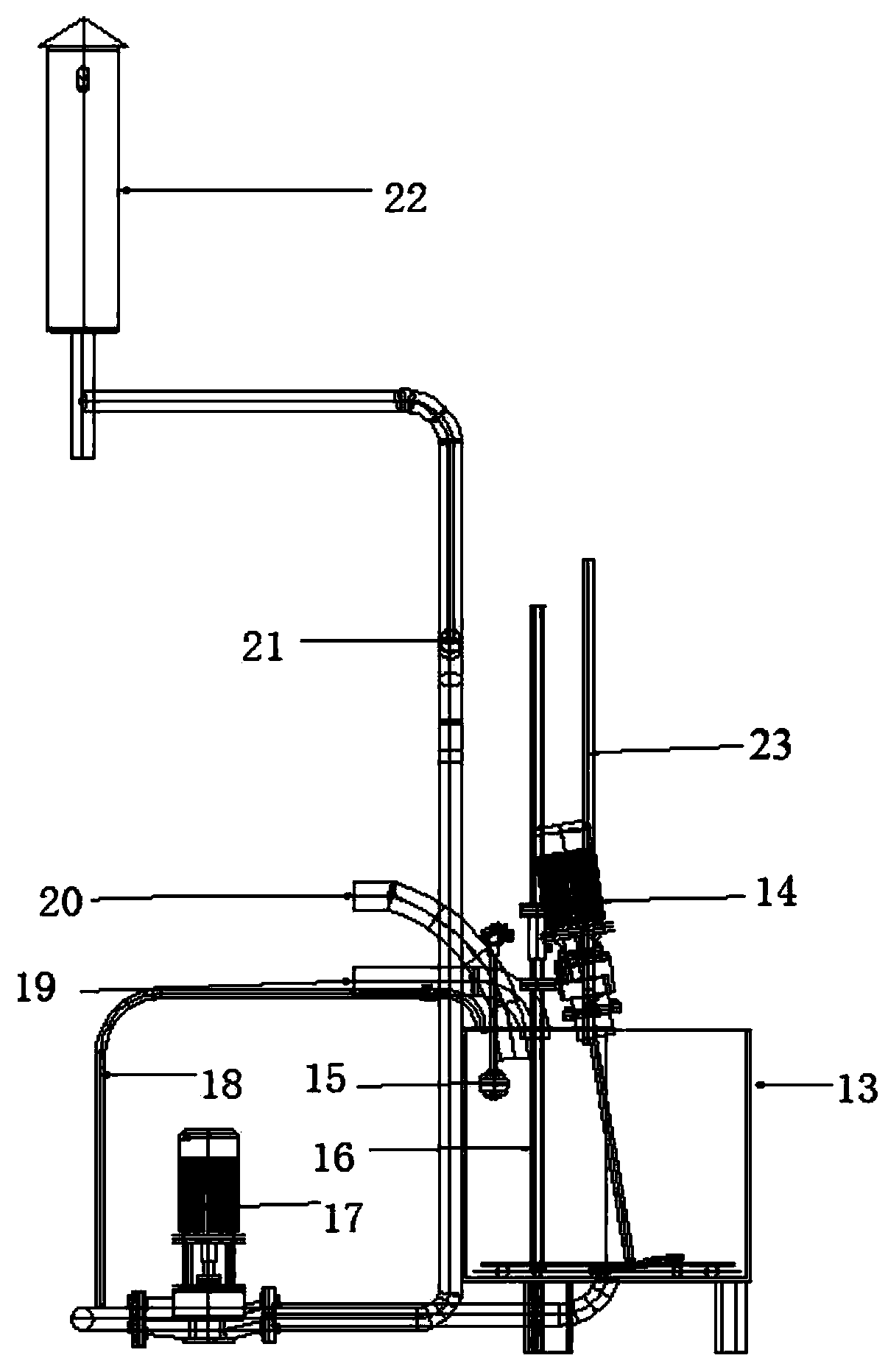

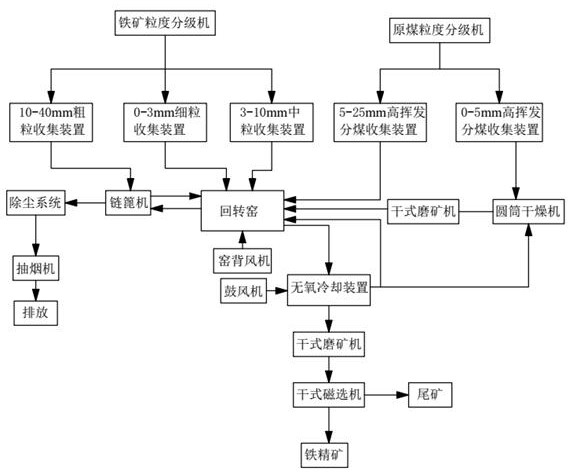

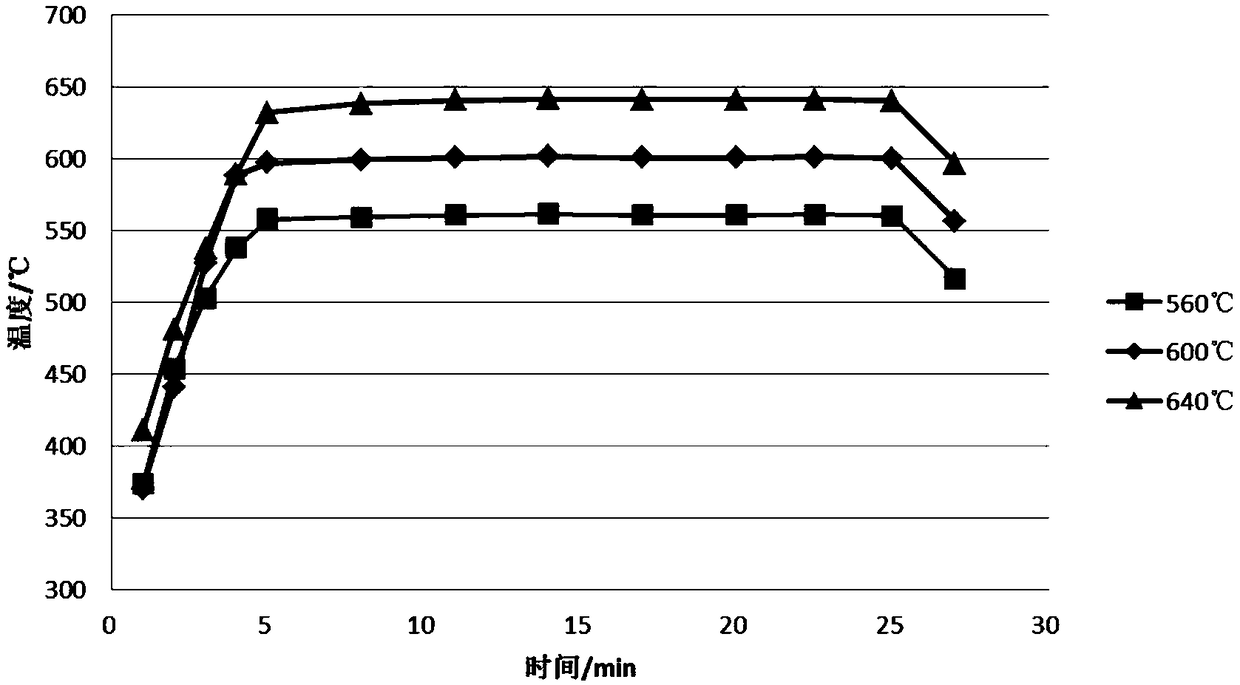

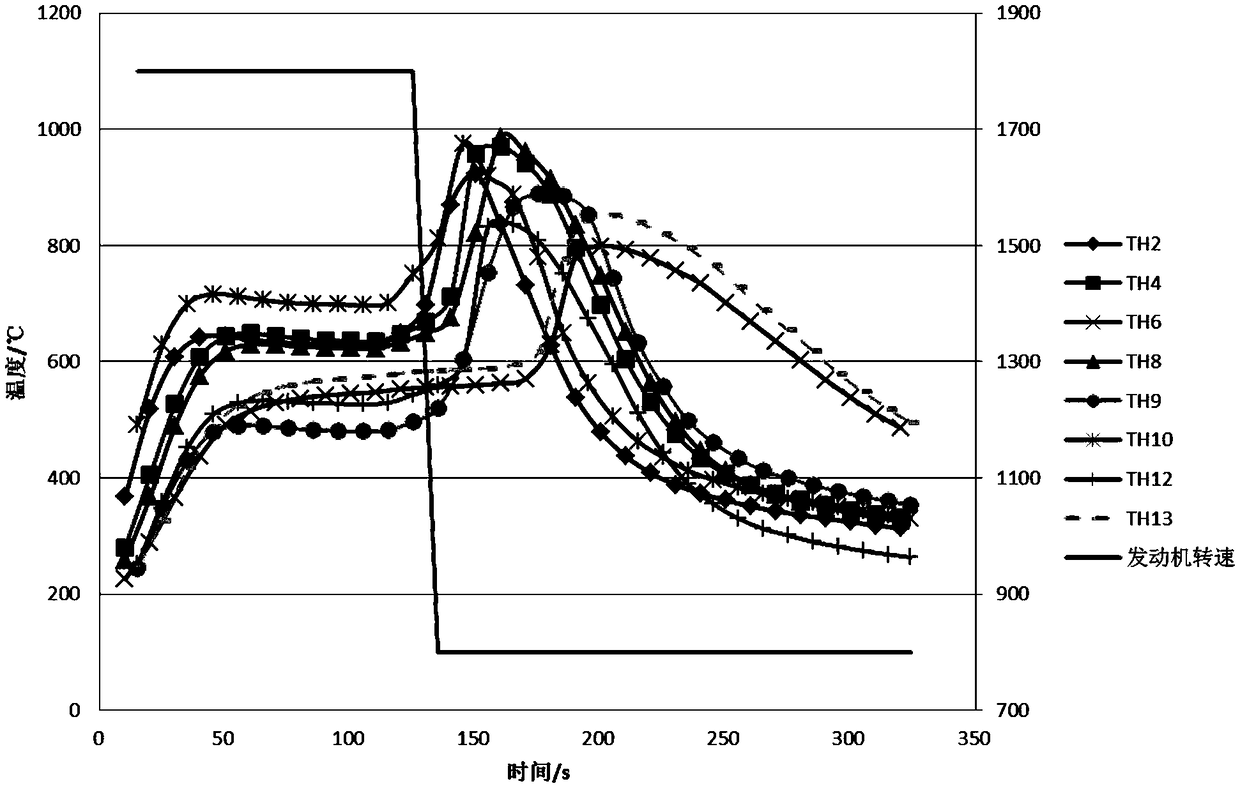

Technology and system for producing iron ore concentrate by iron ore chain grate machine-rotary kiln through shallow hydrogen metallurgy

InactiveCN111748684AHigh strengthImproving the quality of magnetization roastingRoastingMetal recycling

The invention relates to a technology and a system for producing an iron ore concentrate by an iron ore chain grate machine-rotary kiln through shallow hydrogen metallurgy. Iron ore of which the granularity is 40 mm or below is divided into three granular classes, wherein coarse-grain iron ore is dried and preheated through the chain grate machine to be added from the material adding end of the rotary kiln, high-volatility lignite is evenly sprayed and blown to be distributed in the length direction of the whole rotary kiln, middle-grain iron ore is sprayed and blown to the front section and the middle section of the shallow hydrogen metallurgy roasting area of the rotary kiln, and fine-grain iron ore is added into the rear section of the shallow hydrogen metallurgy roasting area and is processed through a shallow hydrogen metallurgy process to obtain iron ore concentrate. The chain grate machine is connected in front of a magnetization roasting rotary kiln in series, an early stage oxidizing roasting method and a later-stage reduction roasting method are adopted to further improve hydrogen utilization efficiency, roasting time is shortened, and the roasting quantity of the iron ore, the yield of the iron ore concentrate and a metal recovery rate can be greatly improved.

Owner:JIUQUAN IRON & STEEL GRP

Catalyst for lowering regeneration temperature of diesel particulate filter (DPF) and preparation method of catalyst

PendingCN109395757AHigh mechanical strengthImprove thermal stabilityExhaust apparatusHeterogenous catalyst chemical elementsDiesel particulate filterComposite oxide

The invention relates to a catalyst for lowering the regeneration temperature of a diesel particulate filter (DPF) and a preparation method of the catalyst, and belongs to the technical field of catalyst preparation. The catalyst comprises a carrier and a coating layer on the carrier, wherein precious metal is loaded in the coating layer, the coating amount of the coating layer is 5-20g / L, and thecoating amount of the precious metal is 0.1-1.1g / L. When coating is carried out, one or more of gamma-aluminium oxide, Ce, Zr, Mg, Mn, La, Ti and oxides or composite oxides of the above materials aremade into precious-metal-free slurry, and the precious metal Pt and Pd are added into the precious-metal-free slurry to prepare the precious metal slurry. When coating is carried out, coating is carried out for one time from the gas outlet end of the DPF to the direction of the gas inlet end of the DPF. After drying is carried out, second coating is carried out from the gas inlet end of the DPF to the gas outlet end of the DPF. The catalyst has the characteristics of simple material and easy operation, and the prepared DPF has lower regeneration temperature and prolonged service life.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

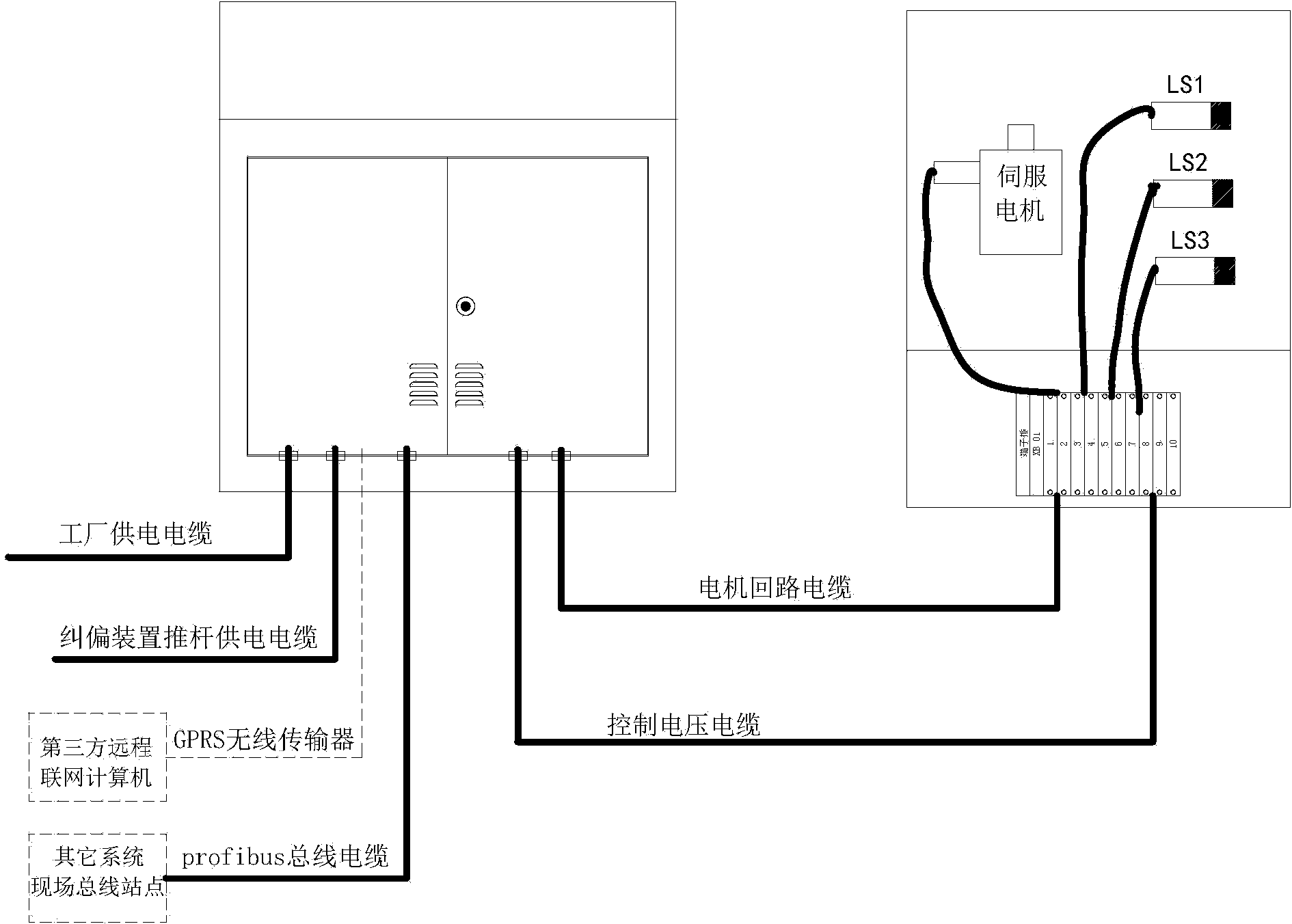

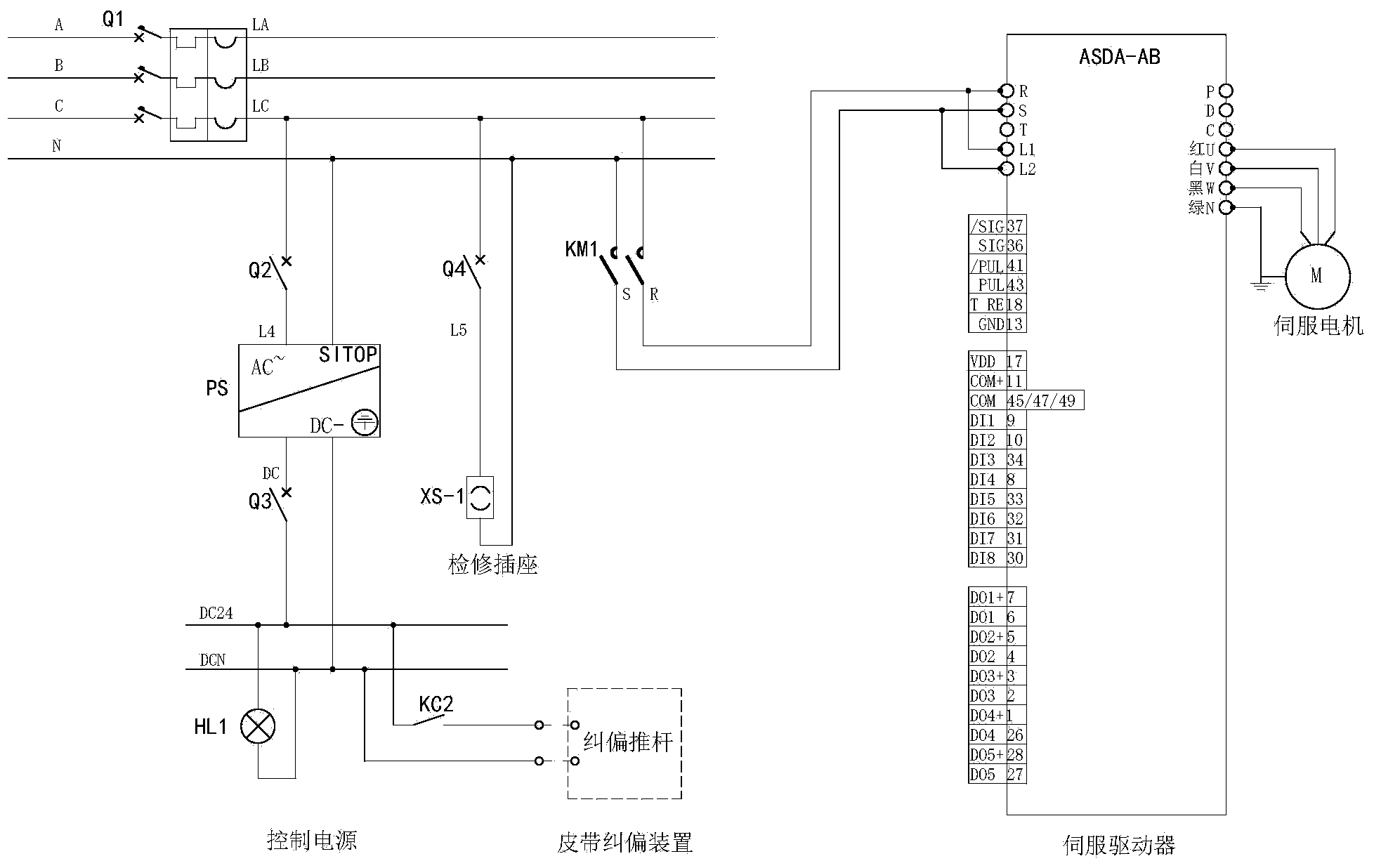

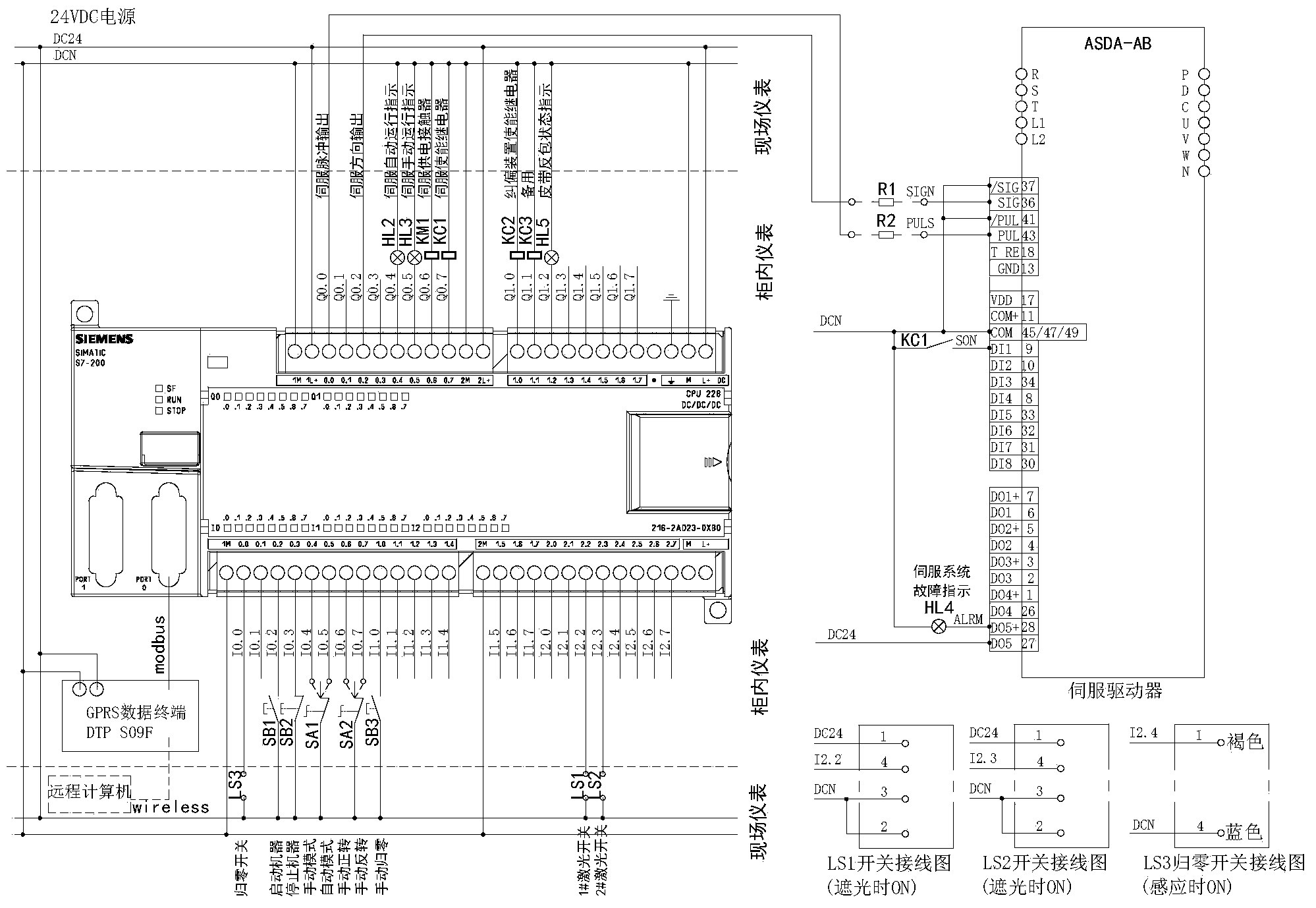

Off-tracking distortion protection control system for tubular belt conveyor

ActiveCN104291089AProtect safe operationSolve deviationConveyorsControl devices for conveyorsLaser sensorWireless transmitter

An off-tracking distortion protection control system for a tubular belt conveyor comprises a field device unit, an electrical control cabinet unit and a communication unit. The field device unit comprises, at least, a belt real-time congruent point tracking laser sensor and a servo motor. The electrical control cabinet unit comprises a PLC, a servo driver and an electrical loop, wherein the PLC is connected with the servo driver through the electrical loop, and the servo driver is connected with the servo motor of the field device unit. The communication unit comprises a connecting cable, a GPRS wireless transmitter and a PROFIBUS cable. The off-tracking distortion protection control system conducts real-time offset monitoring on possibly-occurred belt deviation and distortion faults and the like of the tubular belt conveyor, automatically starts a deviation rectifying device through the PLC, achieves the purposes of belt deviation rectifying, thoroughly solves the problems of belt off-tracking and distortion faults and effectively ensures safe operation of the tubular belt conveyor. The PROFIBUS and GPRS data transmission facilitates installation of the whole protection control system, the protection control system is convenient to maintain technically, and debugging cost is saved.

Owner:湖北凯瑞知行智能装备有限公司

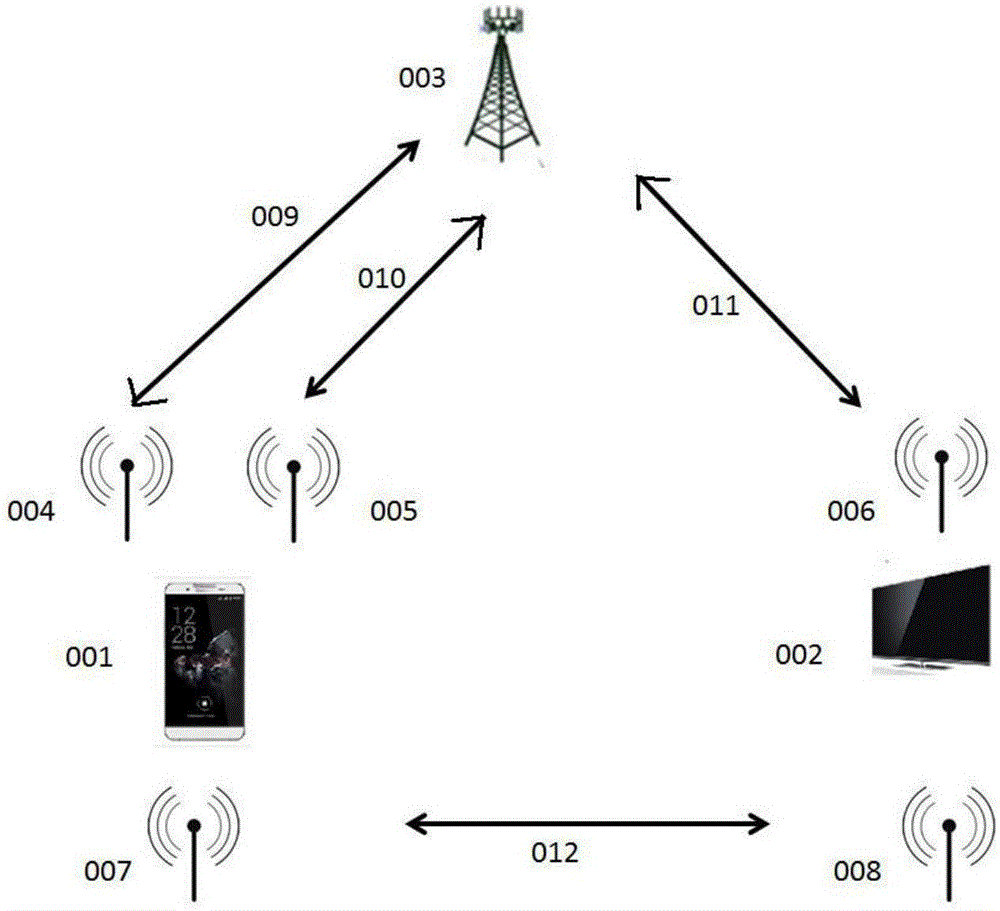

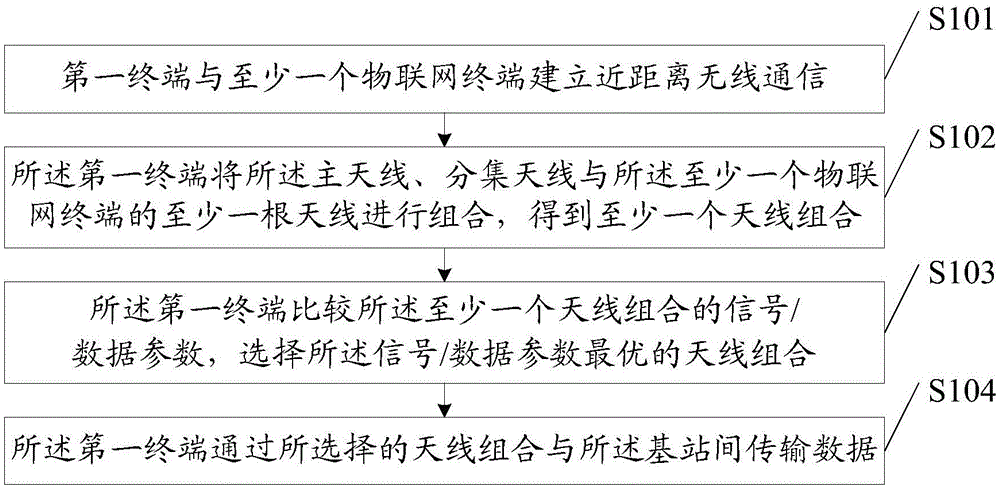

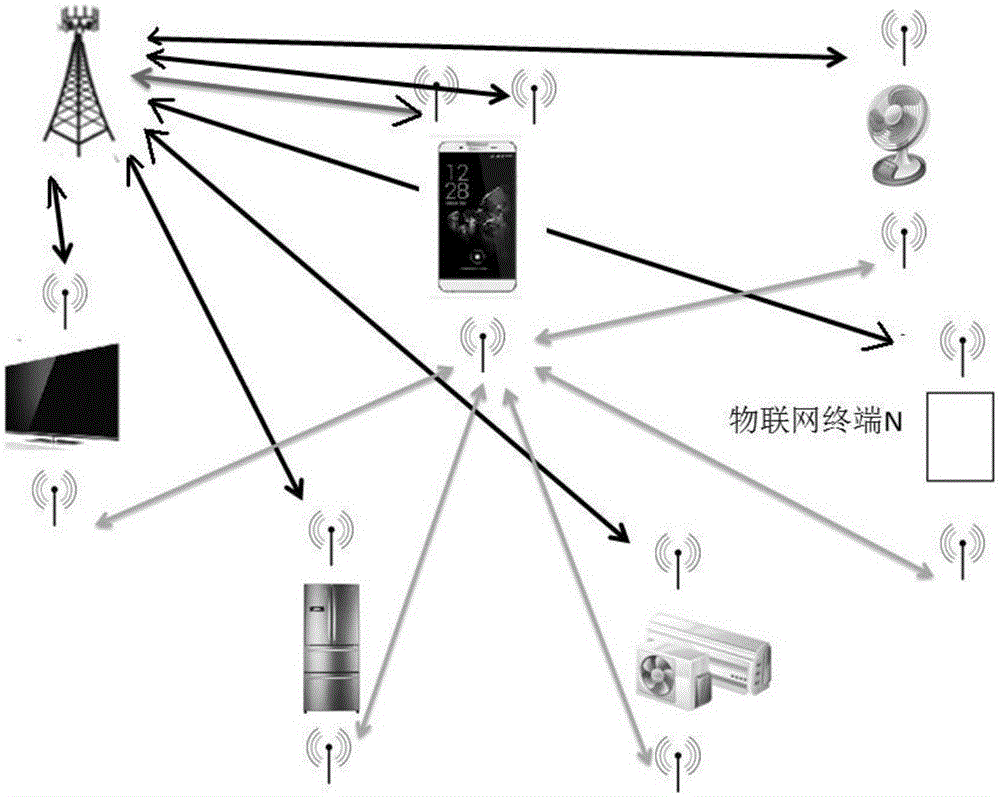

Data transmission method and terminal

InactiveCN105578500AStable data throughput businessScattered distributionNetwork traffic/resource managementMultiple antennaData transmission

The invention discloses a data transmission method and a terminal. The terminal establishes short-distance wireless communication with one or multiple internet of things terminals. The main antenna and the diversity antenna of the terminal are combined with the antennas of the internet of things terminals so as to obtain multiple antenna combinations. The signal / data parameters of multiple antenna combinations are compared, and the antenna combination with the optimal signal / data parameters is selected. The terminal performs data transmission with a base station through the selected antenna combination. The connection mode adopted between the terminal and the internet of things terminals is the more stable short-distance wireless connection so that the quite stable data throughput service can be provided. Besides, the internet of things terminals are dispersedly distributed, antenna performance of the internet of things terminals is better than that of the terminal, and the antenna combination with the optimal signal / data parameters is selected from the antenna combinations of the terminal and the internet of things terminals to perform data interaction with the base station, and thus data throughput of the terminal can be enhanced.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Heat treatment tool

InactiveCN109852774AExtended service lifeLighten the loadFurnace typesHeat treatment furnacesEngineeringHearth

The invention discloses a heat treatment tool. The tool is arranged in a hearth and comprises a frame tool and a flow guide cylinder; the flow guide cylinder is arranged on the periphery of the frametool in a sleeving manner and comprises a supporting shaft and multiple trays, the trays are perpendicular to the axis of the supporting shaft and are fixed to the supporting shaft in a penetrating manner, and the heat treatment tool has the advantages of being wide in application range, large in charge batch, uniform in atmosphere, long in service life and the like.

Owner:ZHUZHOU JIUZHOU TRANSMISSION MACHINERY

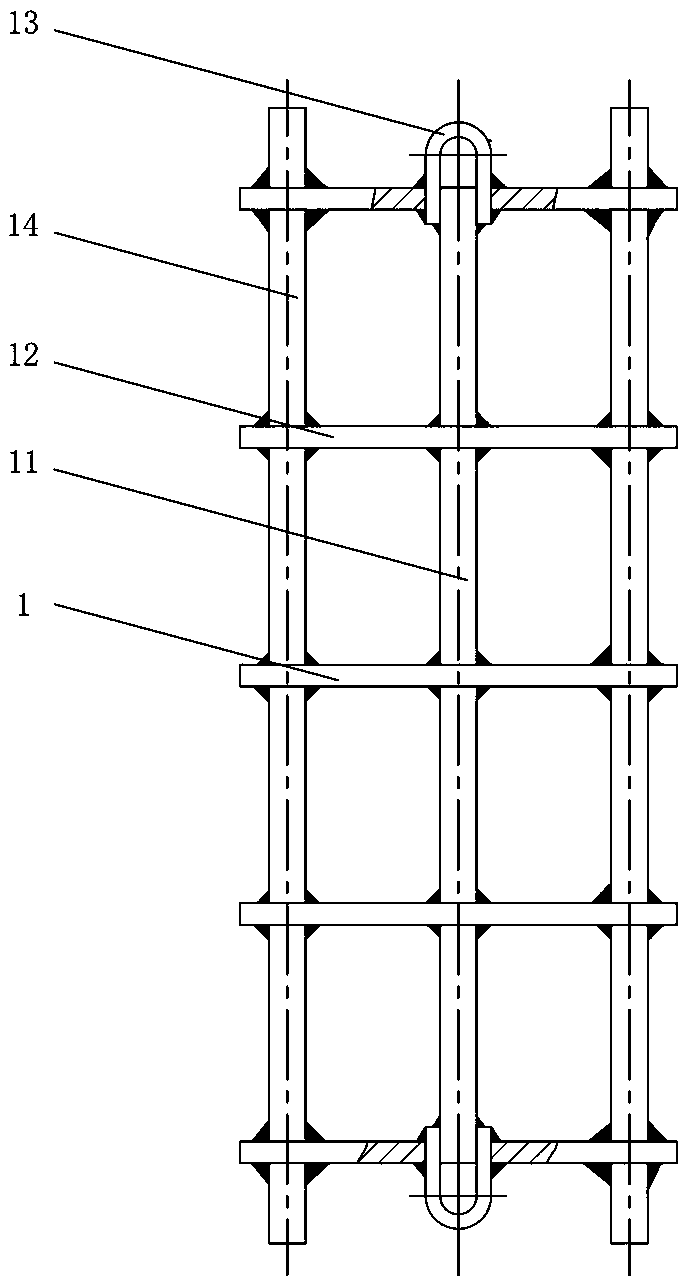

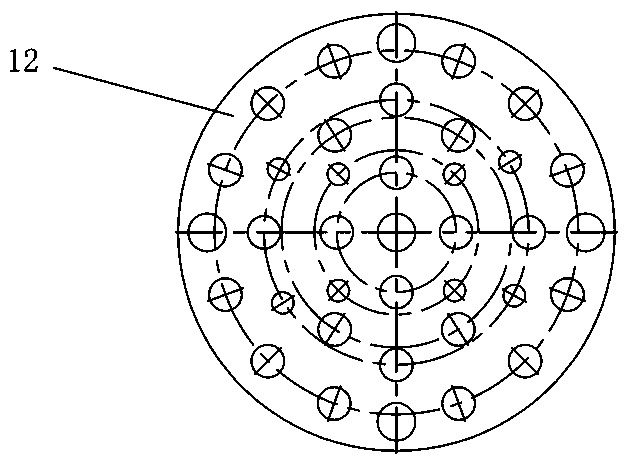

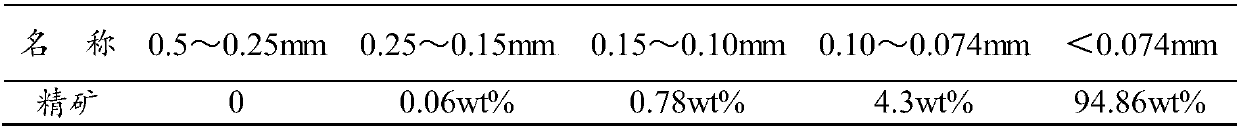

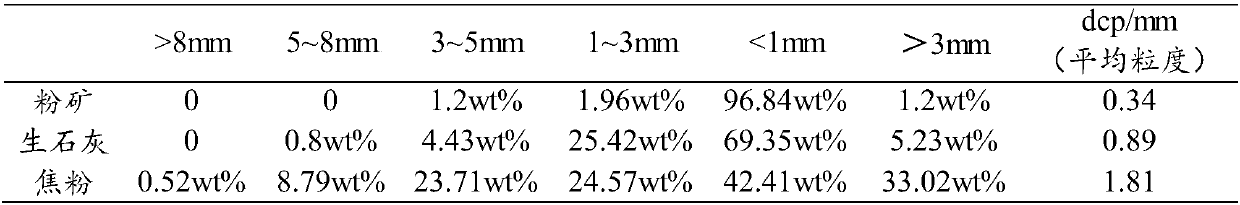

Sintered mixture and preparation method thereof

InactiveCN108676940AAdd evenlyScattered distributionBlast furnace detailsGranularityParticle-size distribution

The invention provides a preparation method of a sintered mixture. The preparation method comprises the following steps that mineral powder, fuel, first flux and water are subjected to first mixing toobtain a first mixture; the first mixture is screened, and aggregates with the grade of -3 mm and aggregates with the grade of + 3 mm are obtained; the aggregates with the grade of -3 mm, second fluxand water are subjected to second mixing so as to obtain a second mixture; and the second mixture and the aggregates with the grade of + 3 mm are mixed to obtain the sintered mixture. According to the preparation method, the flux is added multiple times so that the flux can be added more uniformly, the distribution is more dispersed, and the granulation effect is better; the flux is added multiple times, so that the prepared sintered mixture can use various kinds of flux instead of being limited to use one kind of flux; and moreover, step-by-step mixing is adopted, and mixtures with small grades are subjected to reinforced granulation and then are mixed with mixtures with medium grades so that the particle size distribution in the mixture can be effectively improved. The invention furtherprovides the sintered mixture.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Low temperature ion deodorization device

InactiveCN107519740AImprove purification efficiencyDispersed ion distributionGas treatmentDispersed particle separationIonDistribution control

The invention provides a low temperature ion deodorization device which comprises a deodorization device main body, an ion generator, a catalytic gas adding device and a power distribution control cabinet, wherein the ion generator is arranged on a central position in the deodorization device main body and is electrically connected with the power distribution control cabinet; the power distribution control cabinet is arranged on the front surface of the deodorization device main body; the catalytic gas adding device is arranged on a back surface of the power distribution control cabinet and is connected with the deodorization device main body. According to the invention, the catalytic gas adding device is arranged for adding oxygen and increasing the rate of generating the positive and negative ions of the ion generator and is beneficial to the promotion of purifying efficiency; a trundle is arranged for flexibly and conveniently moving; a circular purifying device is arranged for detecting the purifying effect and re-purifying the purified gas which does not reach the standard.

Owner:赣州团团科技有限公司

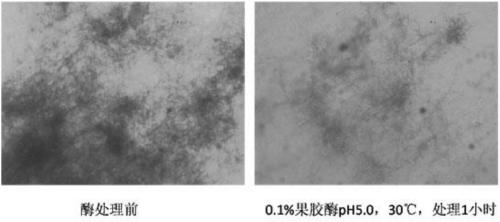

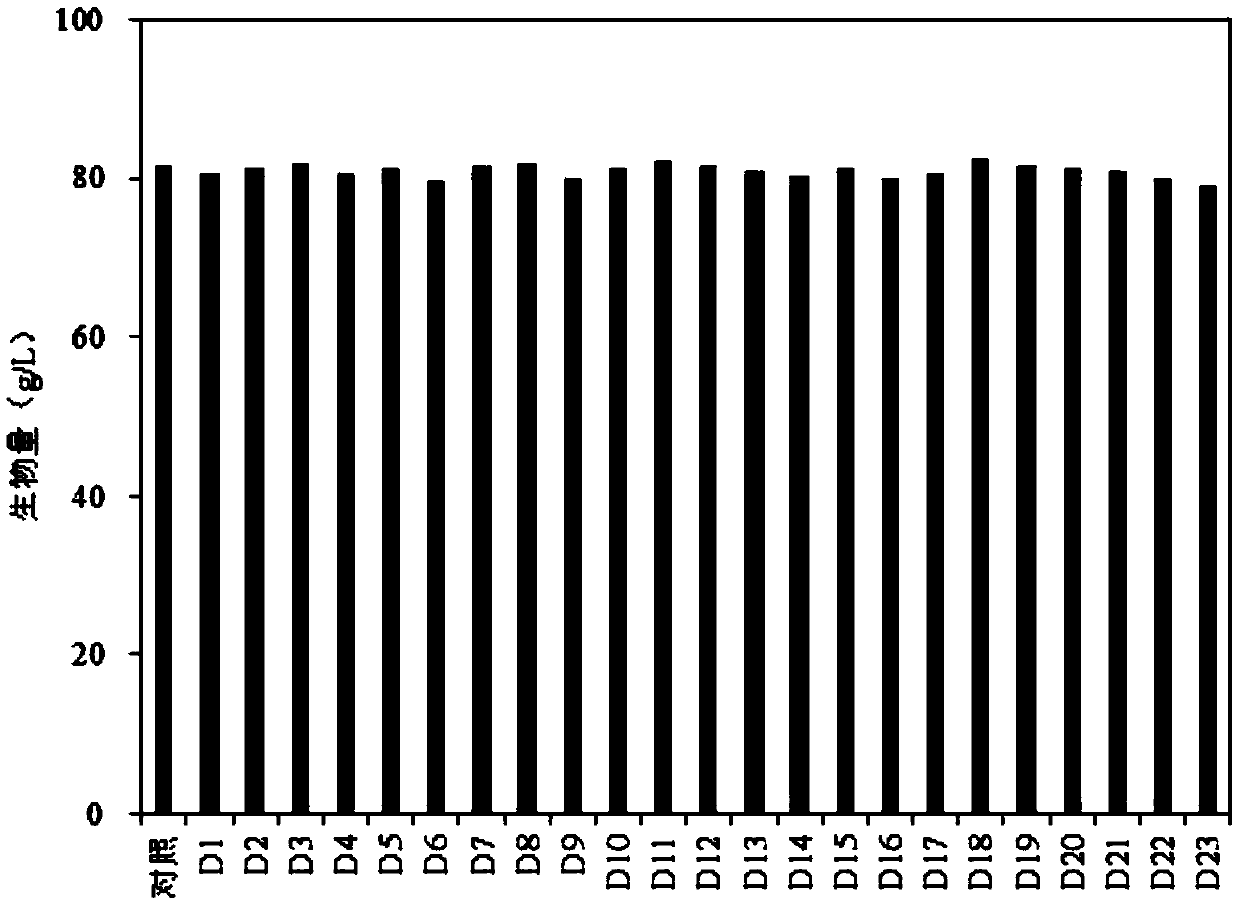

Method for preparing beta-carotene

ActiveCN109536558AIncrease productionReduce adhesionMicroorganism based processesFermentationPectinaseBeta-Carotene

The invention relates to a method for preparing beta-carotene: in seed stage, blakeslea trispora positive bacteria and blakeslea trispora negative bacteria are respectively treated through enzymolysis; then the positive bacteria and negative bacteria are mixed according to certain ratio to perform fermentation cultivation; after the fermentation, produced thalluses are collected, and the beta-carotene is extracted therefrom. The enzyme is one, or is a compound enzyme formed by optionally mixing any two to four, of pectinase, cellulase, neutral protease or lipase. According to the modified technology, the seed liquids of blakeslea trispora positive bacteria and blakeslea trispora negative bacteria are treated through enzymolysis, so that by means of reducing adhesion and winding of the mycelia in the thallus, the dispersion degree of the mycelia is increased; when the thalluses are mixed, conjugation efficiency between the positive bacteria and negative bacteria is improved and zygospore yield is increased, thereby increasing yield of the beta-carotene.

Owner:CABIO BIOTECH WUHAN CO LTD

Preparation method of novel titanium-doped tungsten oxide-based methylbenzene steam detection sensor

InactiveCN107817276AImprove film qualityGood repeatabilityTungsten oxides/hydroxidesMaterial resistanceGas detectorColloid

The invention relates to a preparation method of a novel titanium-doped tungsten oxide-based methylbenzene steam detection sensor and is suitable for the field of preparation of a gas sensor with methylbenzene steam with a high selective characteristic. The preparation method comprises the following steps: by adopting a sol-gel method, adding hexadecyl trimethyl ammonium bromide in a sol process;then drying and grinding a colloid, cleaning the colloid and carrying out annealing at high temperature; coating a ceramic tube with the prepared powder material through hexadecyl trimethyl ammonium bromide; and carrying out secondary annealing to prepare a gas sensitive sensor; and then carrying out aging. In the colloid preparation process, hexadecyl trimethyl ammonium bromide is added to be beneficial to generation of a stable colloid favorably; during coating, hexadecyl trimethyl ammonium bromide is added, so that the specific surface area of the material is increased, and in the apparatuspreparation process, the molar ratio of titanium to tungsten is controlled to be 1:5 to 1:9, so that the sensitivity and selectivity of the gas sensitive element are improved. The gas sensitive element prepared by the method has a sensitive characteristic on methylbenzene steam, and can detect the methylbenzene steam from much organic steam.

Owner:HEBEI UNIV OF TECH

Sand screening equipment for road and bridge construction

ActiveCN112893106AAvoid hard-to-reach sievesImplement automatic cleanupSievingScreeningEnvironmental geologyStructural engineering

The invention belongs to the technical field of sand screening, and discloses sand screening equipment for road and bridge construction, which comprises a device shell; an upper funnel is arranged at the top of the device shell; a bottom funnel is arranged at the bottom of the device shell; a barrier cover is arranged on the inner wall of the device shell; the inner wall of the device shell penetrates through the barrier cover and is provided with a plurality of supporting plate; two motors are arranged at the bottom of the inner side of the barrier cover; output shafts of the motors are provided with turbines; the circumferential side faces of the turbines are connected with gears in a meshed mode; rotating rods are arranged in the gears, and the rotating rods are movably connected to the interiors of the supporting plates through bearings; and both ends of the rotating rods are provided with a first rotating disc and a second rotating disc. According to the sand screening equipment for the road and bridge construction provided by the invention, partition screening is conducted on a trapezoidal sieve plate, the screening efficiency of the trapezoidal sieve plate is improved, the trapezoidal sieve plate is still subjected to the effect of a partition plate to conduct screening work in the descending process by means of the rotation effect of the partition plate, and meanwhile, partition cloth can be driven to clean fine sand at the top of the barrier cover in the rotating process of the partition plate.

Owner:李志伟

Waveguide-filled metal grid array type C-band virtual cathode oscillator

ActiveCN110706990AReduced self-magnetismImprove stabilityTransit-tube cathodesTransit-tube cooling methodsMetal gridBeam transmission

The invention discloses a waveguide-filled metal grid array type C-band virtual cathode oscillator, which comprises a metal circular waveguide, and a cathode coaxial with the metal circular waveguideis arranged at one end in the metal circular waveguide; a first metal grid and a metal grid array are sequentially arranged in the metal circular waveguide in the electron beam transmission direction,and the metal grid array is formed by periodically arranging a plurality of groups of metal grids; the distance between the first metal grid and the metal grid array is slightly larger than the distance between the first metal grid and the cathode; the distance between the first metal grid and the metal grid array is 1.65 cm, and the arrangement period of the metal grids in the metal grid array is 1 / 4-1 / 2 of the wavelength of radiation microwaves; each group of metal grids consists of 11 metal sheets which are arranged at intervals in the radial direction; electron beams emitted by the cathode are transmitted in the oscillator, and C-band high-power microwaves with the wavelength of 7.14 cm are generated through radiation. The waveguide-filled metal grid array type C-band virtual cathodeoscillator is impact-resistant, fast in heat dissipation and suitable for electron beam repetition frequency emission.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

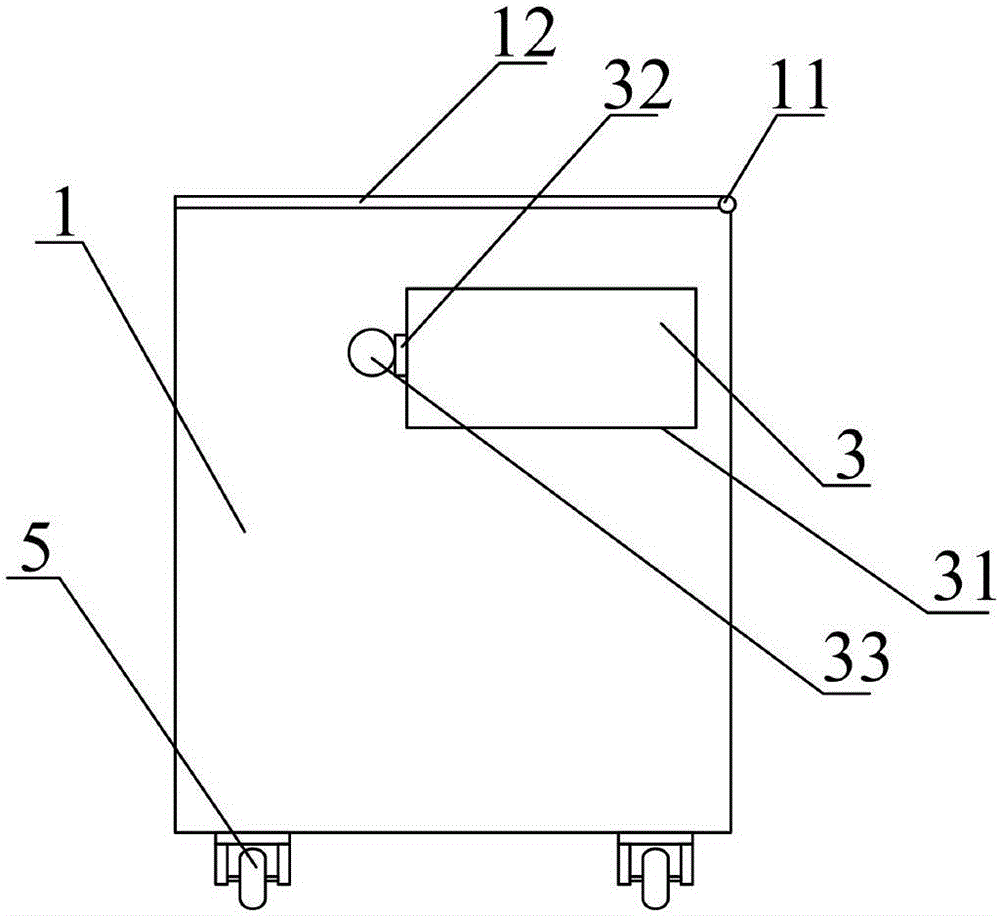

Energy-saving sludge drying equipment

PendingCN110451765ALow costImprove efficiencySludge treatment by de-watering/drying/thickeningBiological sludge treatmentSolar waterWater circulation

The invention discloses energy-saving sludge drying equipment, and belongs to the field of sludge drying equipment. The energy-saving sludge drying equipment comprises a sludge feeding pipe, a dryingbox, a cover plate, a bottom support and a water outlet pipeline, wherein the sludge feeding pipe is arranged on the side surface of the drying box in a penetrating manner; the cover plate is mountedon the top surface of the drying box in a screwed manner; the water outlet pipeline is mounted on the outer side of the lower portion of the bottom support in a penetrating manner; and the bottom support is integrally connected with slots surrounding the bottom of the drying box. The energy-saving sludge drying equipment is characterized by further comprising a filter cloth bag, an aeration deviceand a solar water circulation heating device. According to the energy-saving sludge drying equipment, the sludge can be dried in situ, the problem of difficulty in treatment of excess sludge generated by rural sewage treatment is solved, in combination with the characteristics of small amount and scattered distribution of excess sludge generated by a rural sewage treatment device, solar hot watercirculation heating, filter cloth bag microfiltration and aerobic digestion are coupled, and the energy-saving sludge drying equipment is suitable for treating the excess sludge generated by the rural sewage treatment device, and has the advantages of low cost, high efficiency, simplicity and high universality.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

Household garbage broken bone drying device

ActiveCN112665319AScattered distributionAvoid the problem of poor dehydration effect when stacked together and invertedDrying solid materials without heatDrying gas arrangementsGear wheelSurface tooth

The invention discloses a household garbage crushbone drying device, and relates to the technical field of garbage treatment. The household garbage crushbone drying device comprises a motor and a dewatering barrel, wherein a bottom plate is fixedly connected to the lower surface of the motor; a gear disc is fixedly connected to the upper surface of a rotating shaft of the motor; a gear groove is formed in the circumferential side face of the gear disc; a gear is meshed with the left side face of the gear disc; a supporting shaft is fixedly connected to the lower surface of the gear; the lower surface of the supporting shaft is rotationally connected with the upper surface of the bottom plate through a bearing; the upper surface of the gear is fixedly connected with a first connecting shaft; the upper end of the circumferential side face of the first connecting shaft is fixedly connected with a clamping block; and a groove is formed in the lower surface of the dewatering barrel. The household garbage crushbone drying device solves the problems that when an existing bone crusher is used for crushing bones, the bones are often filled with water or mucus from food residues, the bones are too hard to crush, and after the crushing treatment is finished, a large amount of bone residues are easy to remain on a blade of the bone crusher, and the bone crusher is inconvenient to clean.

Owner:杨成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com