Waveguide-filled metal grid array type C-band virtual cathode oscillator

A metal grid and metal filling technology, which is applied to the cathode of the transit time type electron tube, the transit time type electron tube, the cooling method of the transit time type electron tube, etc., can solve the problem of microwave output performance index and microwave power output efficiency Low, virtual cathode is difficult to repeat frequency emission and other problems, to achieve the effect of enhancing microwave conversion efficiency, reducing self-magnetism, and structure impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

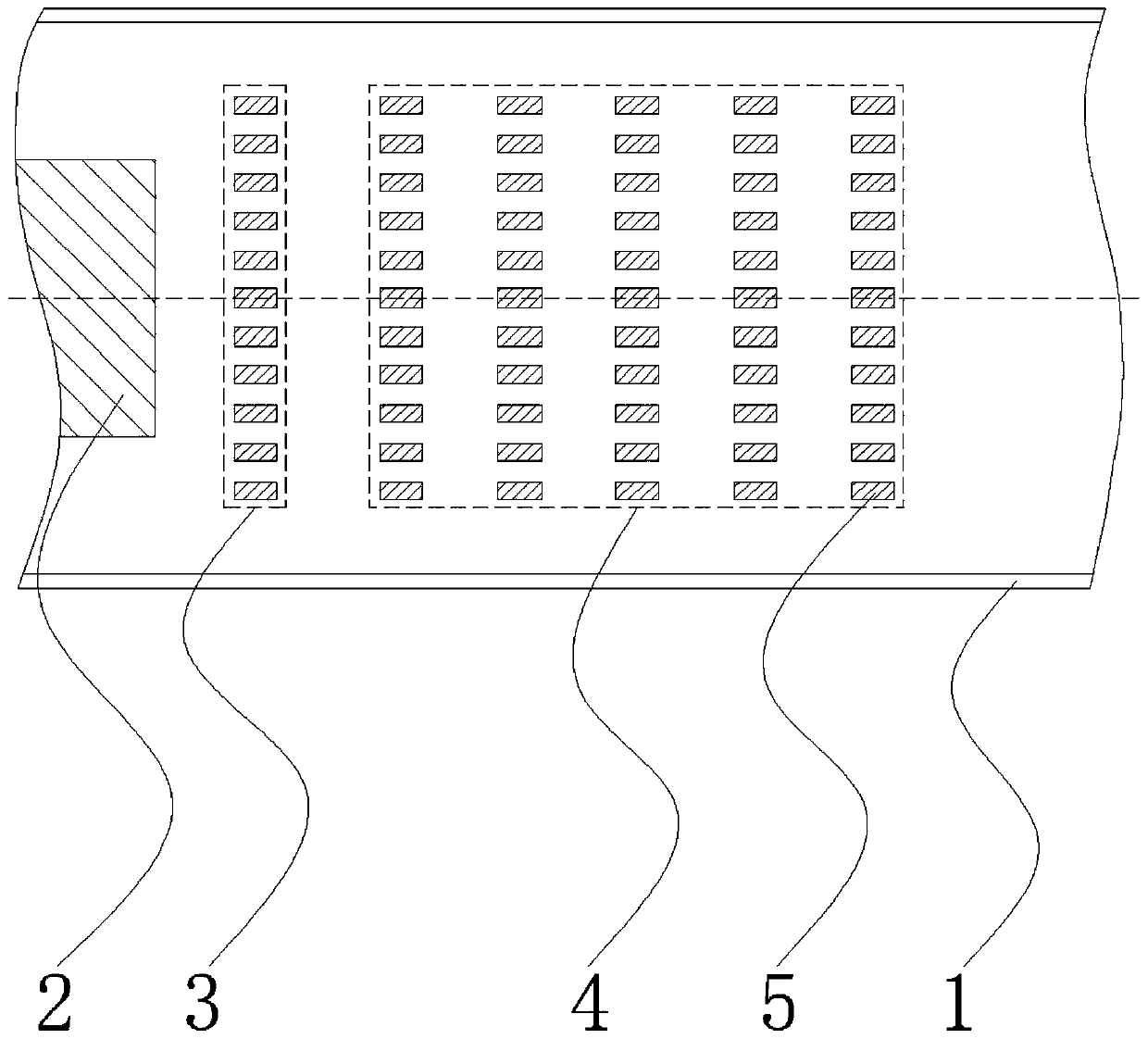

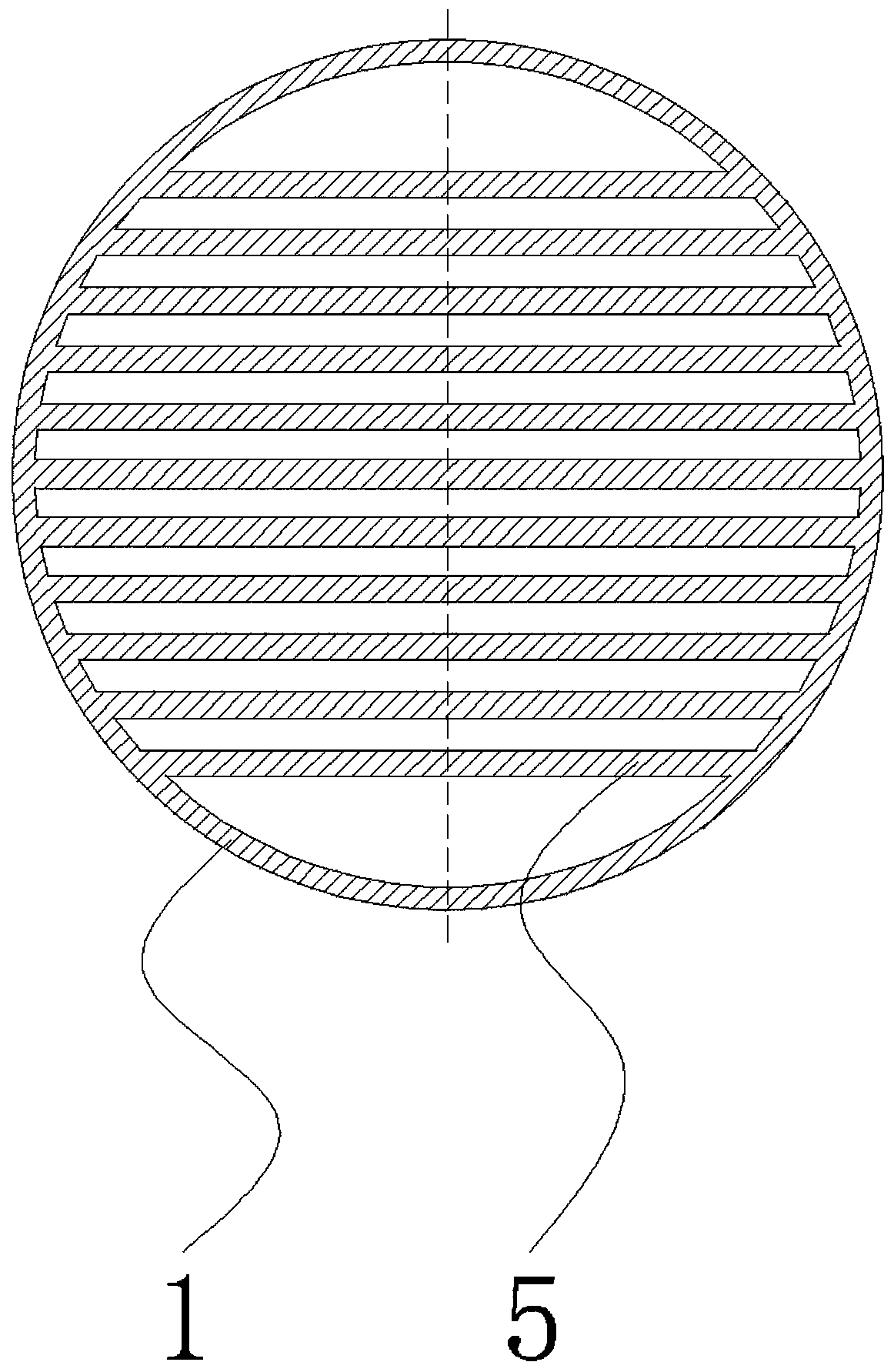

[0028] Such as figure 1 As shown, a metal grid array type C-band virtual cathode oscillator filled in a waveguide in this embodiment includes a metal circular waveguide, and a cathode coaxial with the metal circular waveguide is arranged at one end of the metal circular waveguide, and the electron beam emitting end of the cathode is a circular surface ; A first metal grid and a metal grid array are sequentially arranged in the metal circular waveguide along the electron beam transmission direction, and the metal grid array is composed of multiple groups of metal grids periodically arranged;

[0029] The distance between the first metal grid and the metal grid array is slightly larger than the distance between the first metal grid and the cathode; the distance between the first metal grid and the metal grid array is 1.65cm, and the metal grid in the metal grid array The arrangement period is 1.79cm; the first metal grid and each group of metal grids in the metal grid array are ...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the arrangement period of the metal grids in the metal grid array is 3.57 cm, and the microwave conversion efficiency is 17%.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that the arrangement period of the metal grids in the metal grid array is 2.68 cm, and the microwave conversion efficiency is 18%.

[0036] In summary, the metal grid array type C-band virtual cathode oscillator filled in the waveguide of the present invention has a shock-resistant structure and fast heat dissipation, which is very suitable for electron beam repetition frequency emission; the self-magnetism of the beam is reduced, The stability of the virtual cathode is improved; the microwave conversion efficiency of the virtual cathode is enhanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com