Preparation method of cationic starch

A technology of cationic starch and cationic etherifying agent, which is applied in the field of starch modification, can solve the problems of retention and drainage aid and the insignificant effect of paper-forming strength, so as to improve water retention and drainage performance, improve paper strength performance, molecular chain Distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

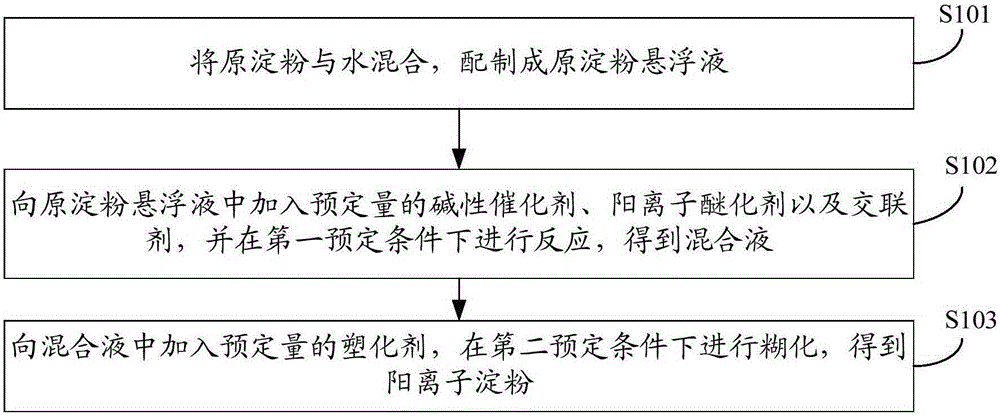

[0022] Such as figure 1 , the embodiment of the present invention provides a kind of preparation method of cationic starch, comprising:

[0023] Step S101: mixing raw starch with water to prepare a raw starch suspension;

[0024] The original starch can be one or more of cassava original starch, corn original starch, potato original starch, and wheat original starch; in the embodiment of the present invention, a certain amount of original starch is added to a certain amount of water, and Stir to disperse the original starch evenly in the water to obtain a starch suspension.

[0025] Step S102: adding a predetermined amount of basic catalyst, cationic etherification agent and crosslinking agent to the raw starch suspension, and reacting under the first predetermined condition to obtain a mixed solution;

[0026] In the embodiment of the present invention, the basic catalyst, the cationic etherifying agent and the crosslinking agent can be added to the starch suspension respec...

Embodiment 1

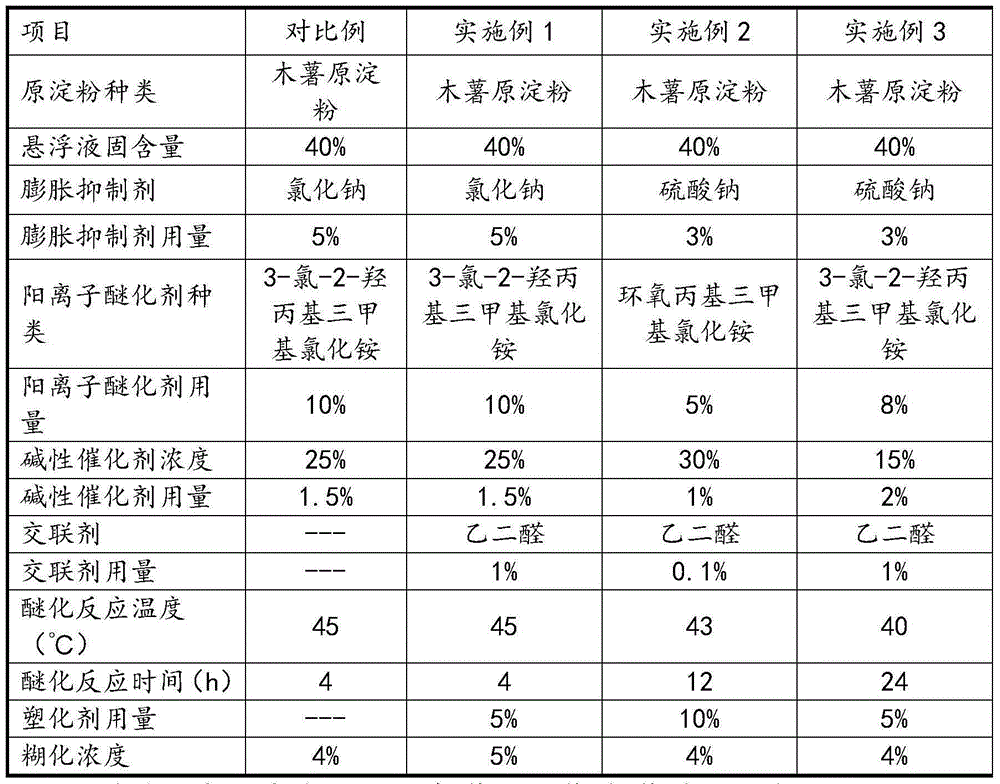

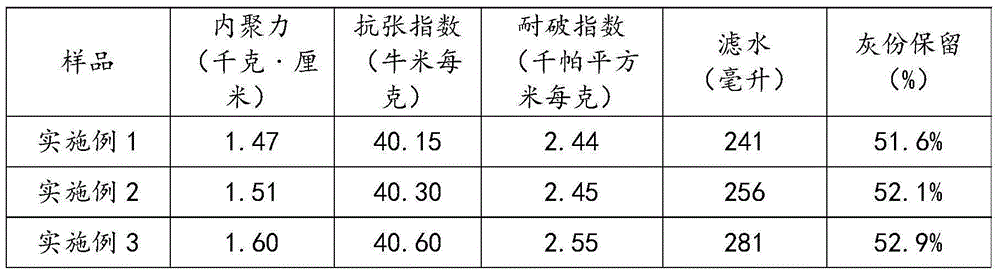

[0051] Take by weighing 348.8g cassava raw starch (moisture content 14%) and add into 401.2g water under stirring state, stir evenly, obtain the raw starch suspension that solid content is 40%. Add NaCl expansion inhibitor to the uniformly dispersed above-mentioned raw starch suspension, the amount of expansion inhibitor added is 5% of the dry mass of cassava raw starch, stir evenly, and then add a sodium hydroxide solution with a concentration of 25% to pre-activate 3-chloro-2-hydroxypropyltrimethylammonium chloride solution (concentration is 70%), wherein the sodium hydroxide solution consumption is 1.5% of the absolute dry mass of native tapioca starch, and the etherifying agent 3-chloro-2- The dosage of the hydroxypropyltrimethylammonium chloride solution is 10% of the absolute dry mass of the original tapioca starch, and at the same time, 1% glyoxal with a mass of 1% of the absolute dry mass of the original tapioca starch is added, and the temperature is raised to 45° C. f...

Embodiment 2

[0053] Take by weighing 348.8g cassava raw starch (moisture content 14%) and add into 401.2g water under stirring state, stir evenly, obtain the raw starch suspension that solid content is 40%. Add Na to the above-mentioned raw starch suspension that is uniformly dispersed 2 SO 4 Swelling inhibitor, the amount of swelling inhibitor added is 3% of the absolute dry mass of the original tapioca starch, stir evenly, then add the glycidyltrimethylammonium chloride solution that is preactivated by the sodium hydroxide solution with a concentration of 30% (concentration is 70%), wherein the sodium hydroxide solution consumption is 1% of the absolute dry mass of the original tapioca starch, and the etherifying agent epoxypropyl trimethyl ammonium chloride solution consumption is 5% of the original tapioca starch absolute dry mass, At the same time, 0.1% glyoxal with a mass of 0.1% of the absolute dry mass of the raw cassava starch was added, and the temperature was raised to 43° C. f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com