Air separator and separation method for separating tobacco leaves, tobacco stalks and leaves with stalks

An air separator and tobacco leaf technology, applied in chemical instruments and methods, separating solids from solids with airflow, solid separation, etc., can solve the problem of increasing the load of the leaf-threshing air subunit, low air separation efficiency, and large occupied space To achieve the effect of avoiding crushing and increasing the load, reducing the air volume of winnowing, and dispersing the distribution of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

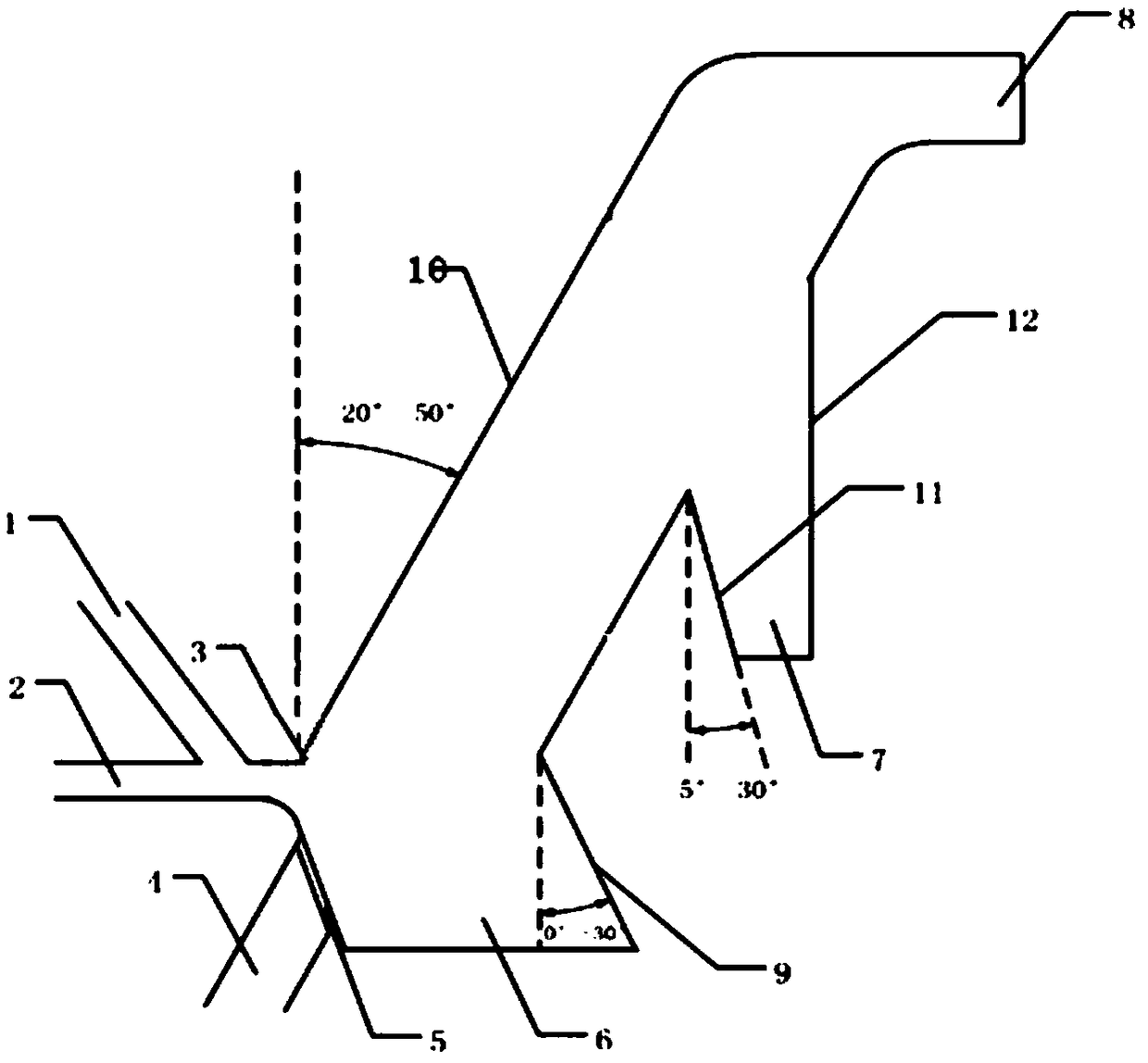

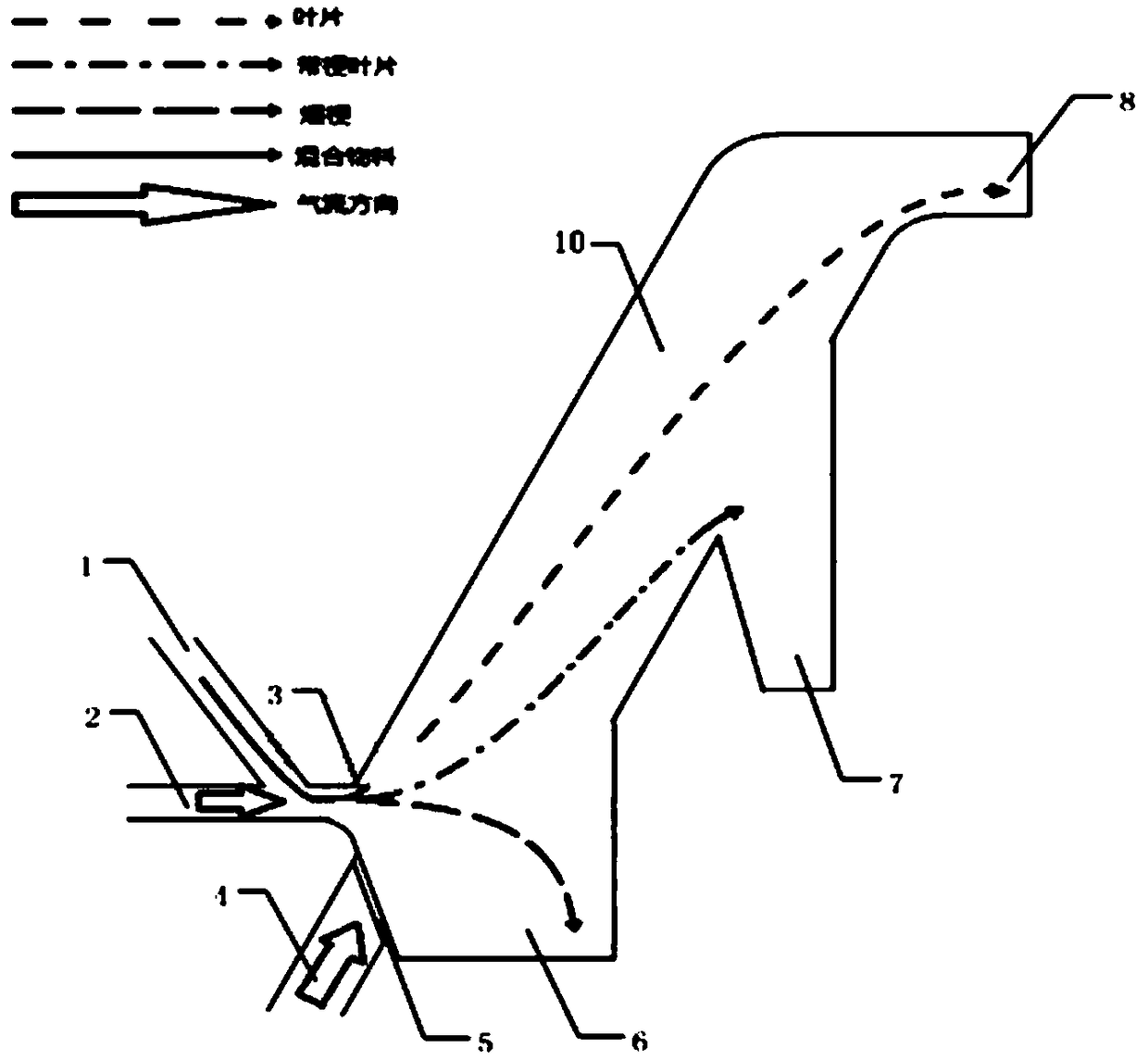

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings. The drawings are illustrative only and are not intended to limit the scope of the invention in any way.

[0027] The material processed by the leaf thresher is divided into tobacco leaves, tobacco stems and a mixture of stalked leaves. Into the air, the mixed material starts to accelerate in the feeding air pipe 2 under the action of wind force, and after the outlet of the feeding air pipe 2 is changed by the feeding air pipe adjustment device 3, it is thrown into the air distribution bin 10; adjust the air flow rate So that: in the lower part of the air distribution bin 10, the heavy tobacco stem part in the mixture moves forward for a certain distance under the action of inertia and falls into the first outlet 6 due to the gravity being greater than the upward lift force given by the wind field. The air lock is separated, and after being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com