Heat treatment tool

A tooling and pallet technology, applied in the field of heat treatment, can solve the problems of increasing the processing cost, aggravating the deformation degree of the tooling, and being unsatisfactory, and achieves the effect of increasing the maximum furnace capacity, prolonging the service life and uniform heating degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

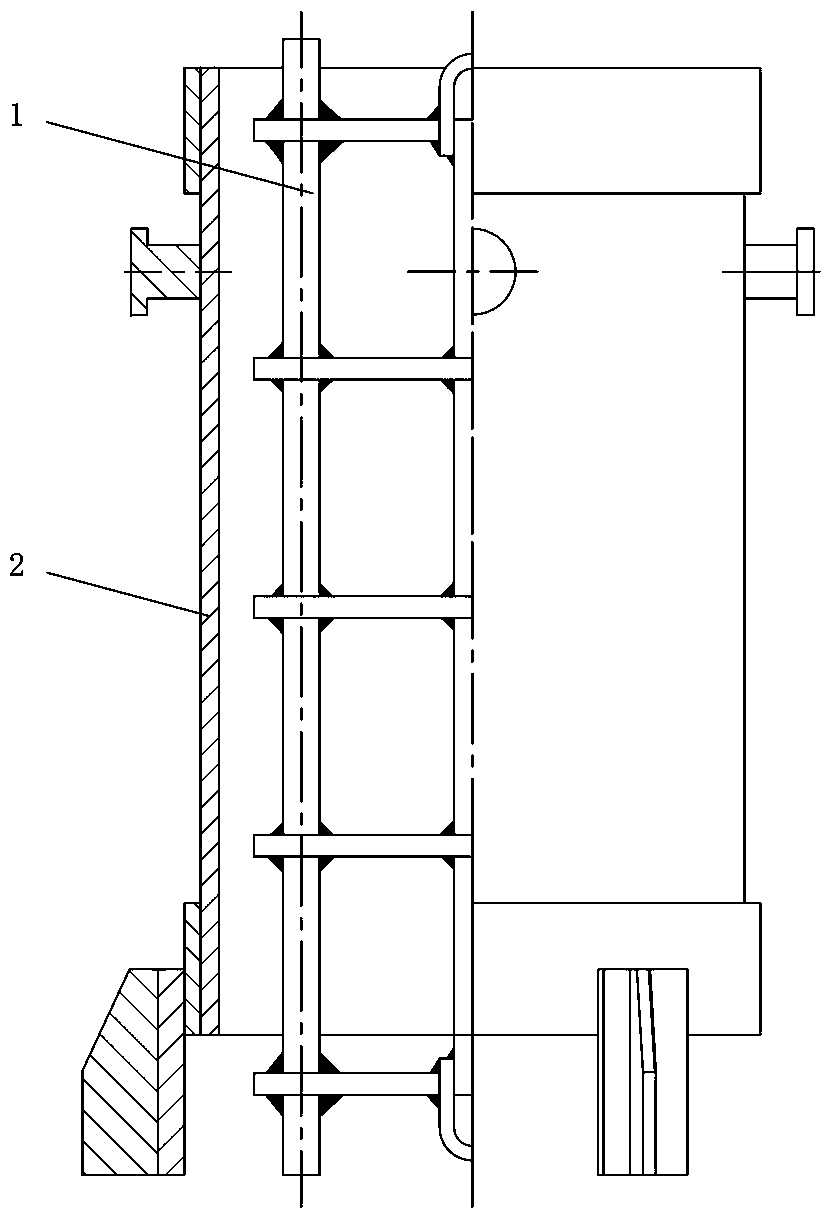

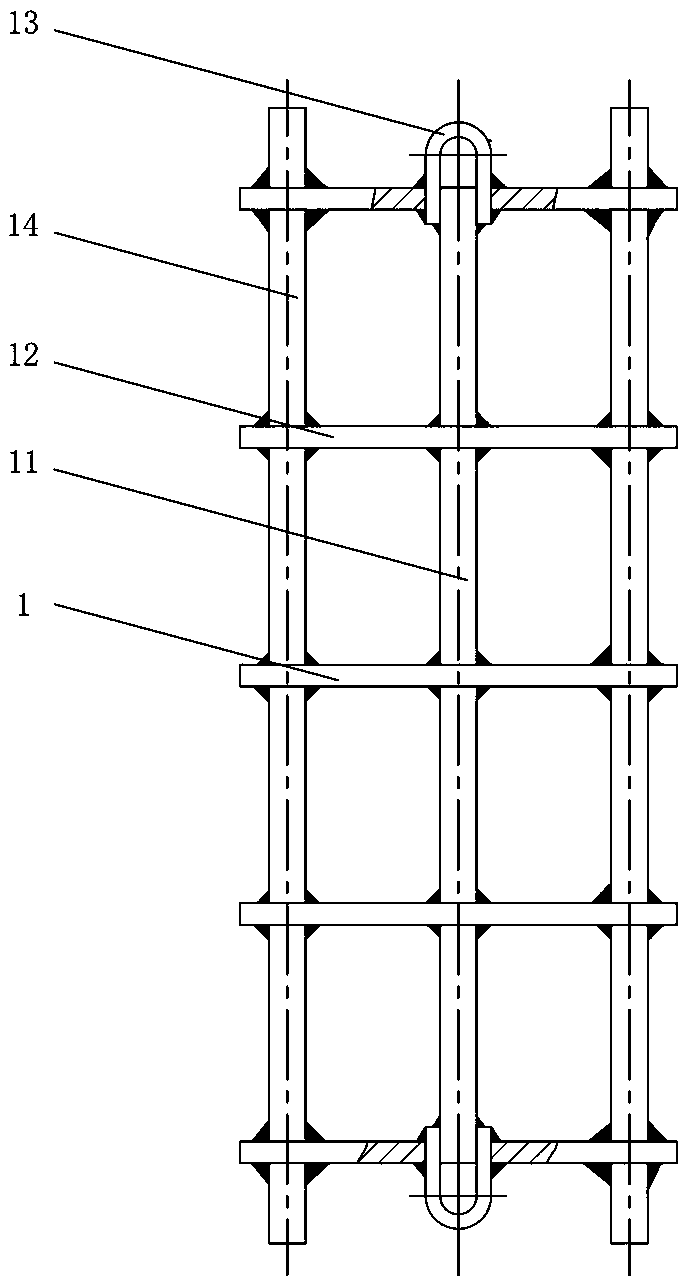

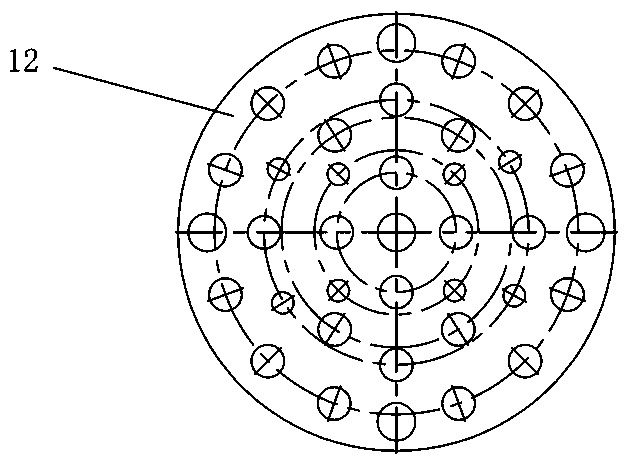

[0025] Such as figure 1 and figure 2 As shown, the heat treatment tooling of this embodiment is installed inside the furnace, including a frame 1 and a guide tube 2, the guide tube 2 is sleeved on the periphery of the frame 1, and the frame 1 includes a support shaft 11 and several trays 12. A plurality of trays 12 are perpendicular to the axis of the support shaft 11 and are fixed on the support shaft 11. When heat treating the parts, the parts to be processed can be placed on each tray 12. The multiple trays 12 arranged axially along the support shaft 11 can maximize the use of the vertical space in the heat treatment furnace, which not only increases the maximum furnace charge during a single treatment, speeds up the work efficiency, but also makes the waiting time The distribution of the processing parts is more dispersed, so that the heating degree of the parts is more uniform, and the load bearing of each layer of trays 12 is also reduced, prolonging the service life o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com