Patents

Literature

149 results about "Reverse airflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat Energy Recapture And Recycle And Its New Applications

InactiveUS20080155985A1Benefit maximizationReduce constructionReciprocating combination enginesEngine fuctionsFusion powerEngineering

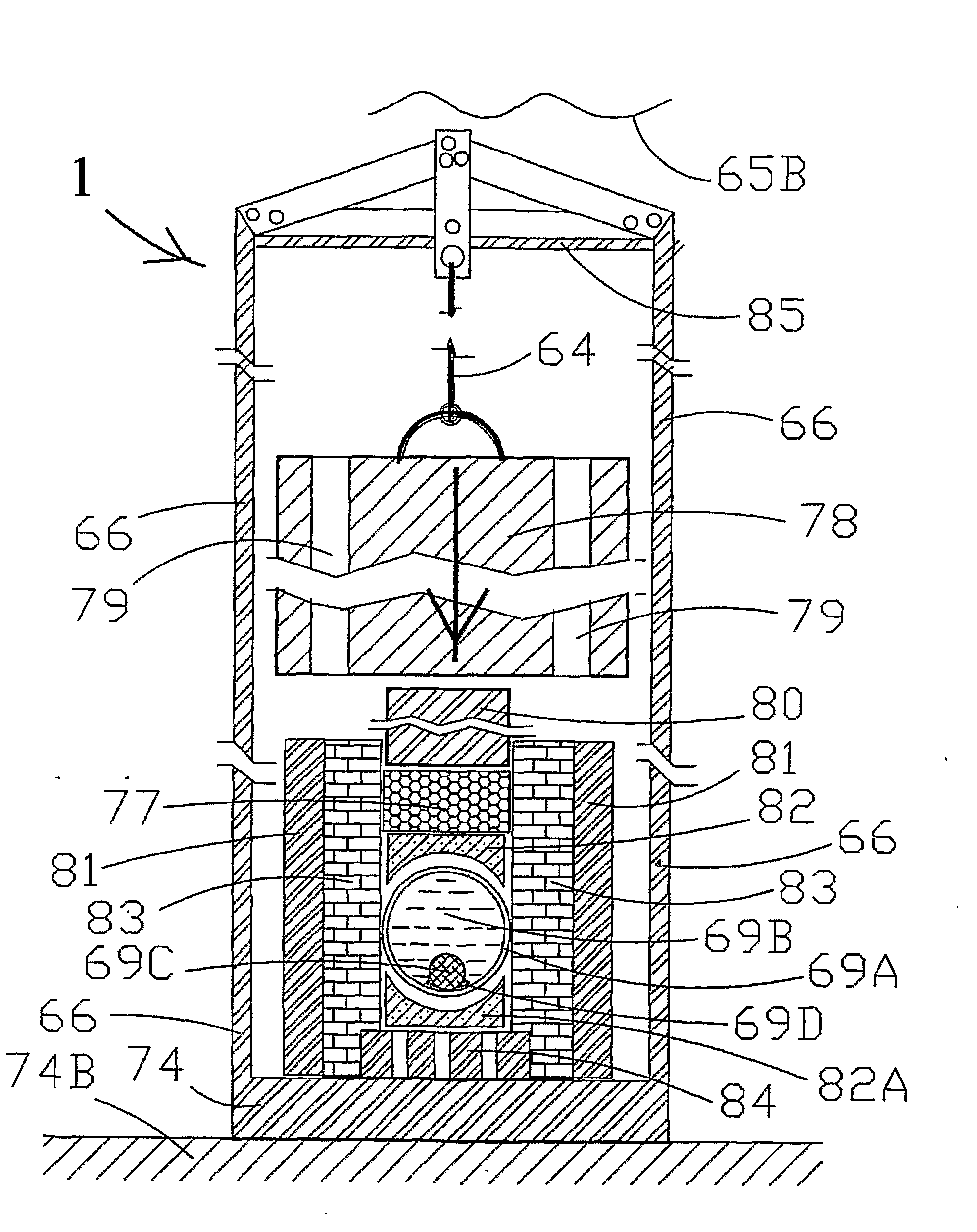

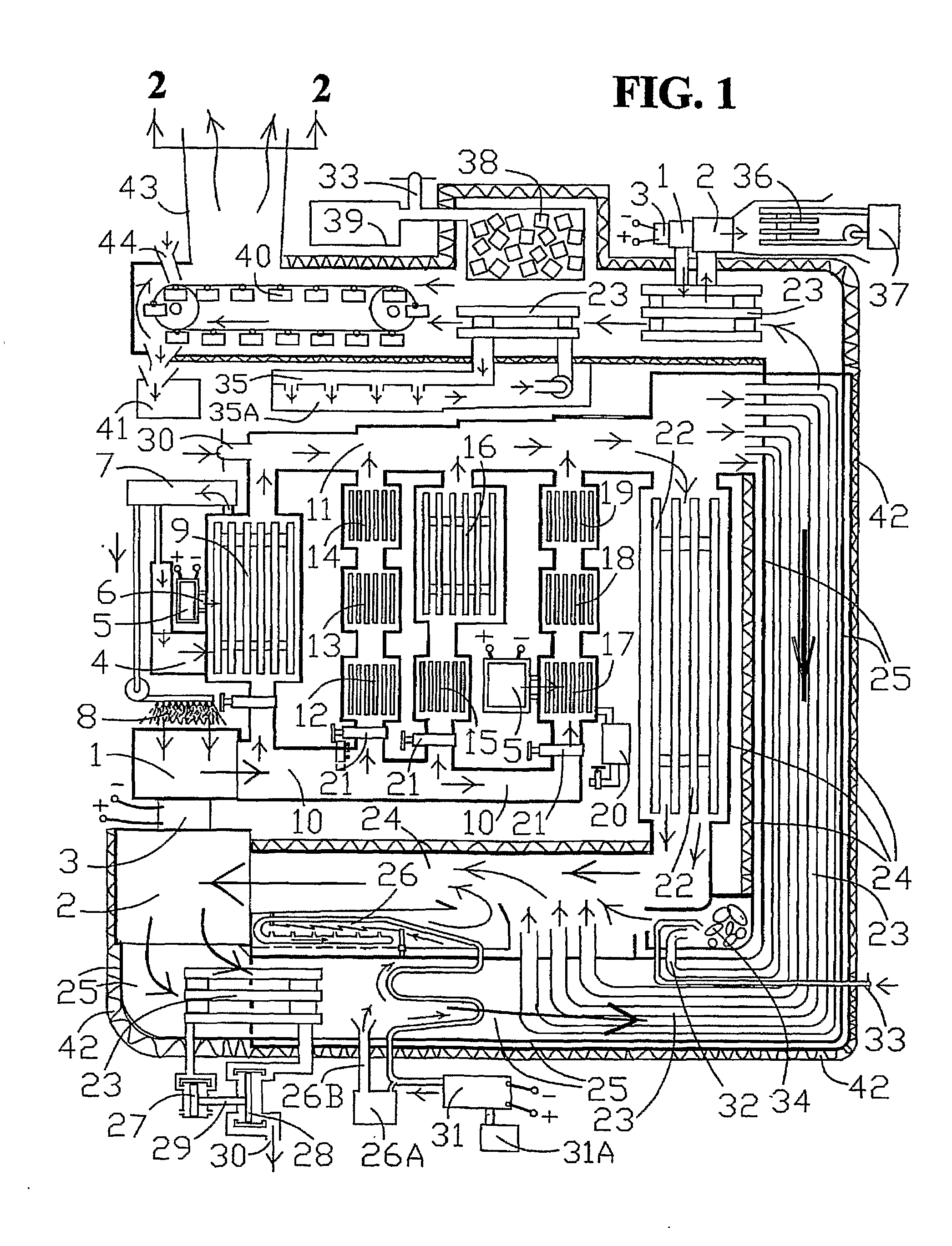

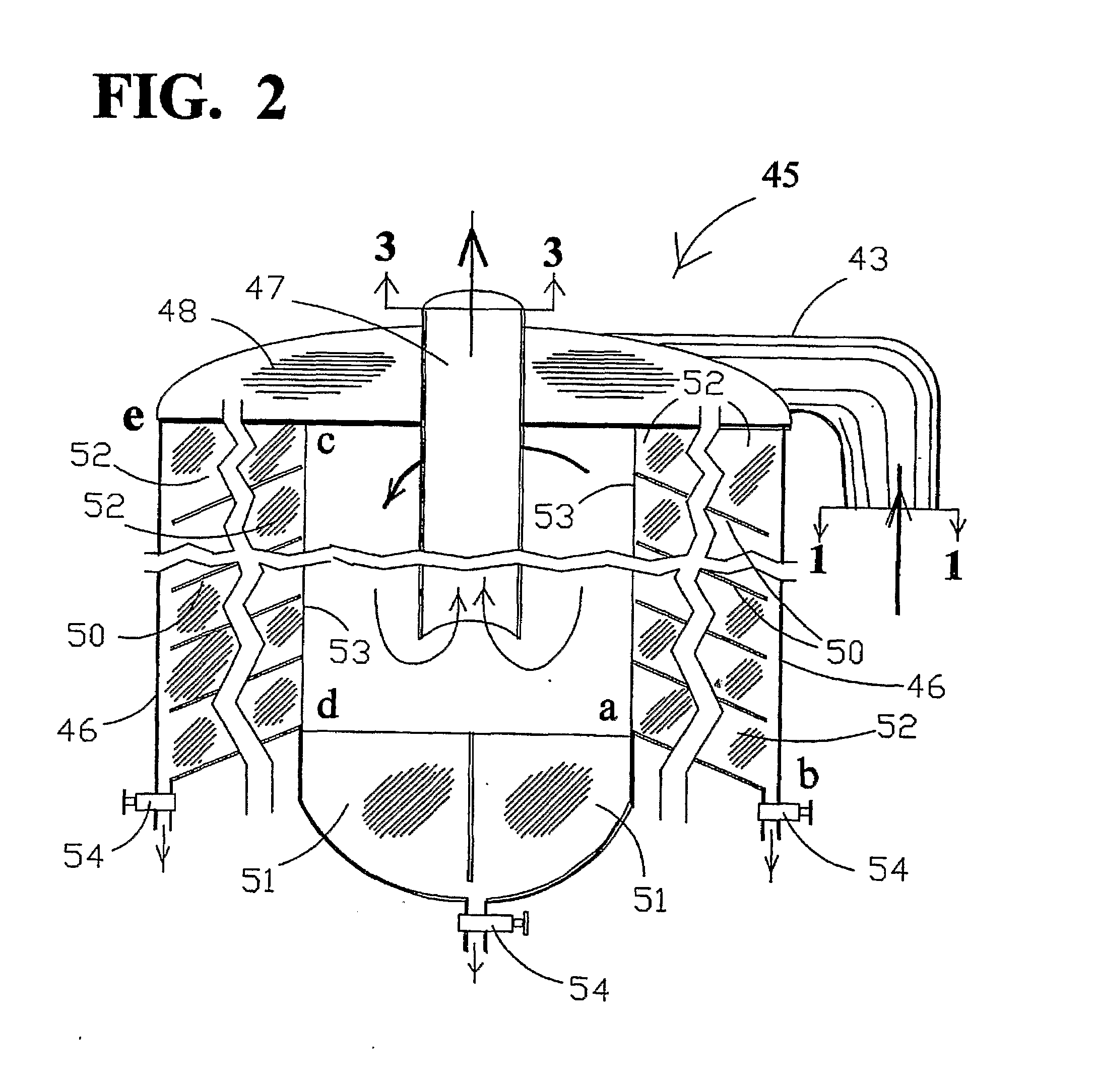

A heat absorbing radiator and a gas turbine engine or a reciprocating piston engine are used to recapture and reconvert wasted heat energies into electric power and finally into hydrogen-deuterium fuel by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow to further drive the same engine. In order to capture fusion heat energy a hydrogen bomb is detonated in deep ocean to catch the flames by the water and the hot water energizes compressed air inside heat absorbing radiator pipes. In order to produce fusion energy an electric arc is passed thru / across liquid or gaseous deuterium by an electro-plasma torch and by a sparkplug in an internal combustion engine, or by detonating a dynamite inside liquid deuterium. Diamond is produced by placing carbon inside a hydrogen bomb which is then detonated in deepwater. Deuterium fusion flame is used first in smelting glass into large structural sizes before running an engine.

Owner:LABRADOR GAUDENCIO AQUINO

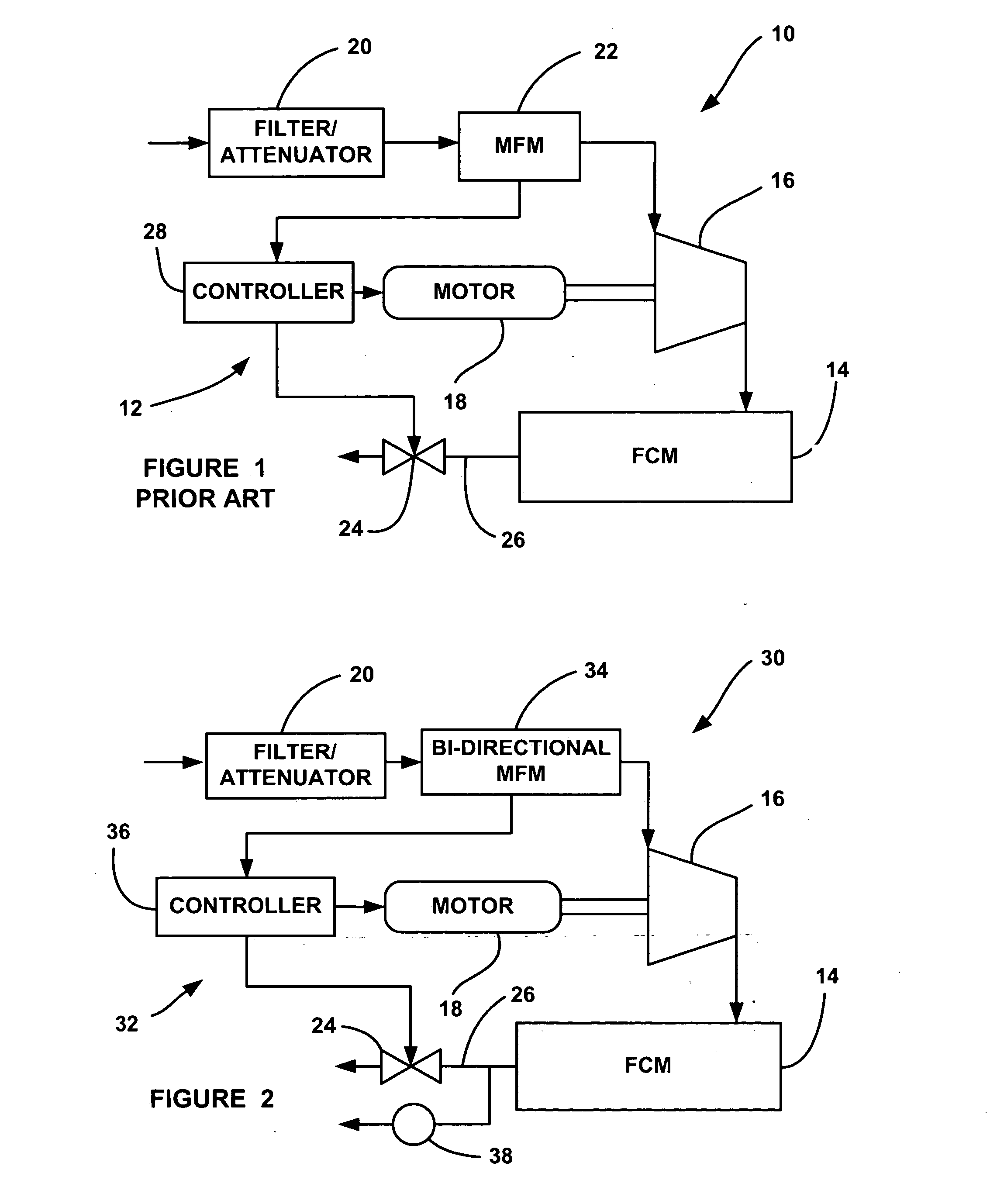

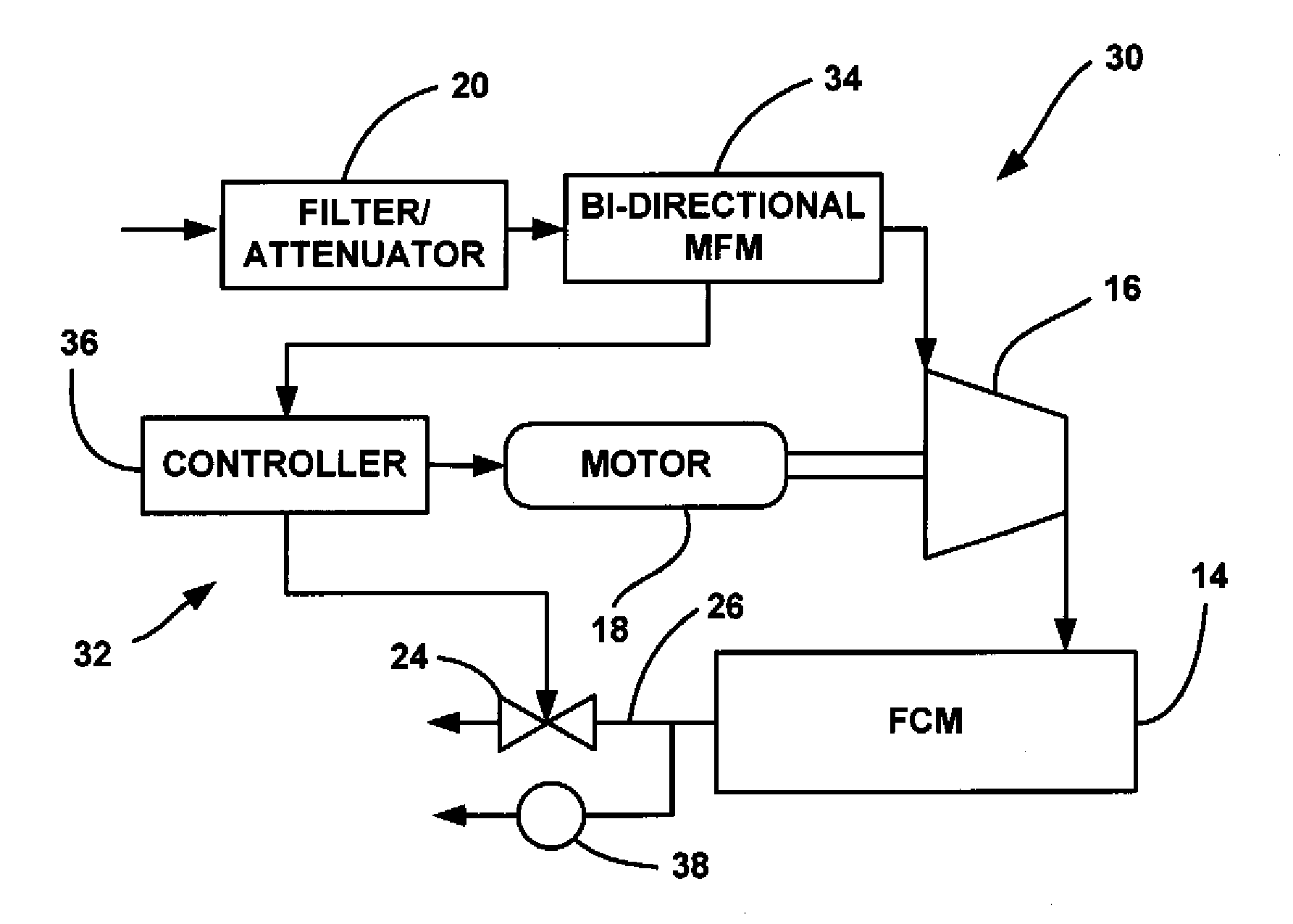

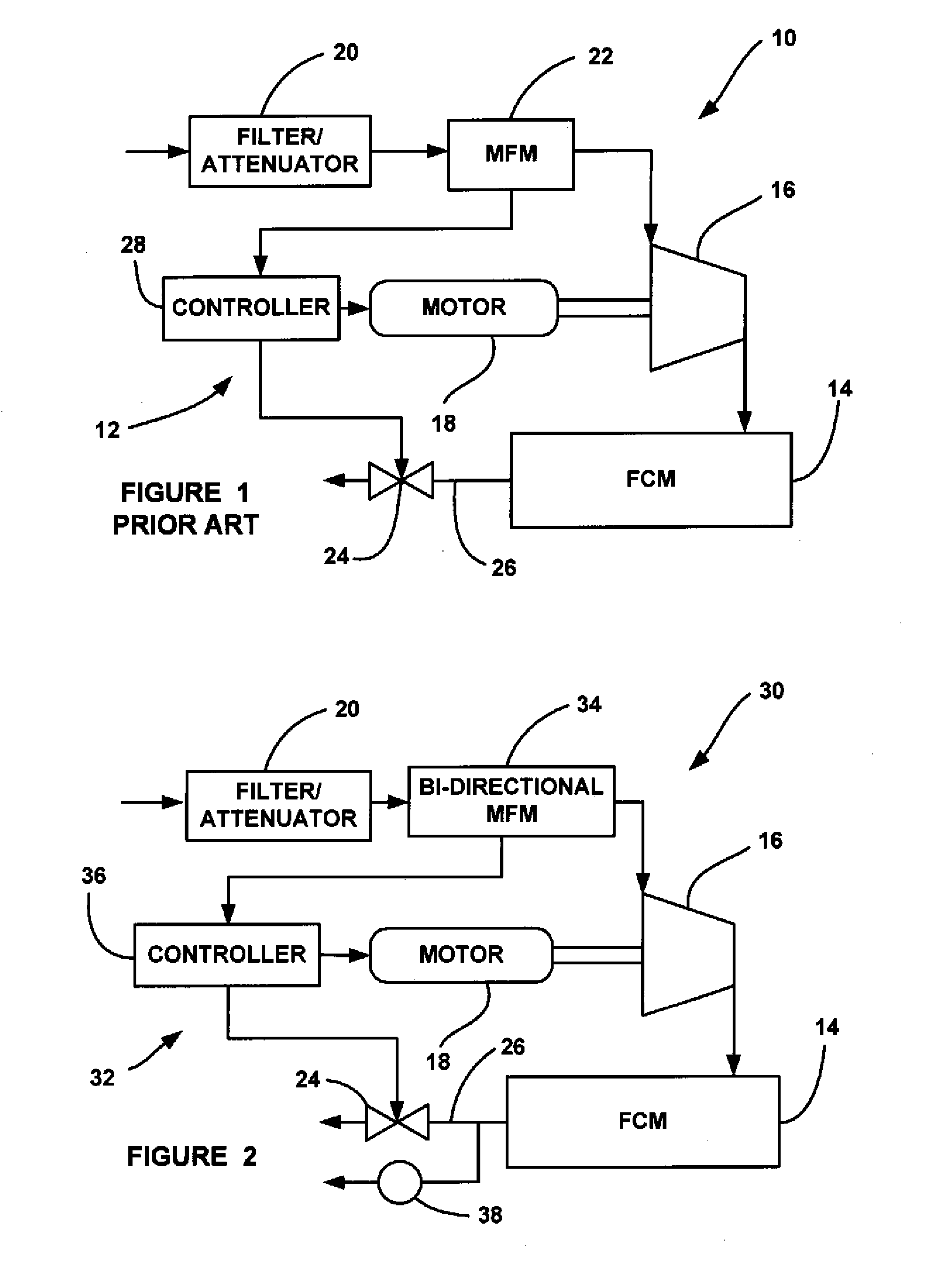

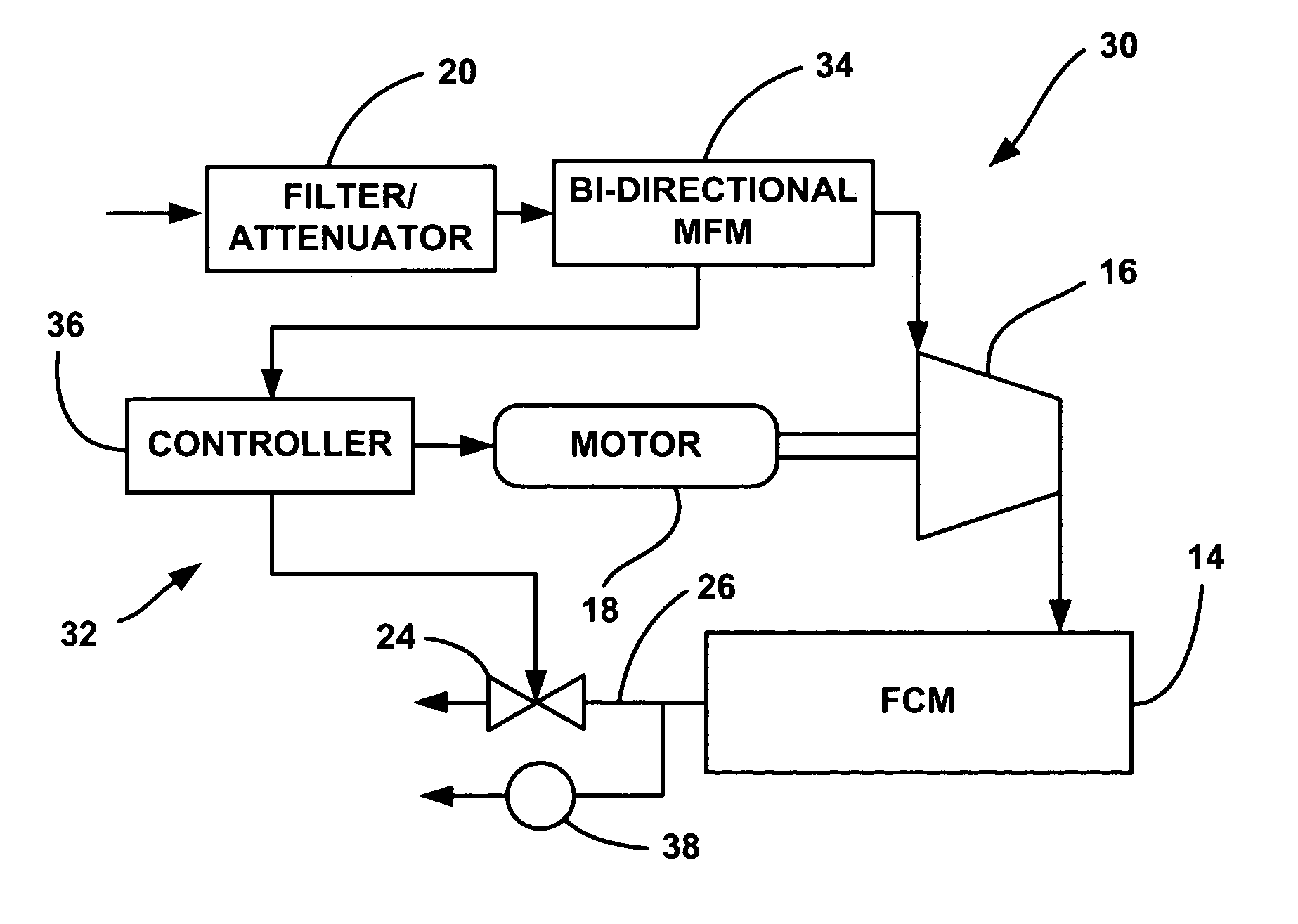

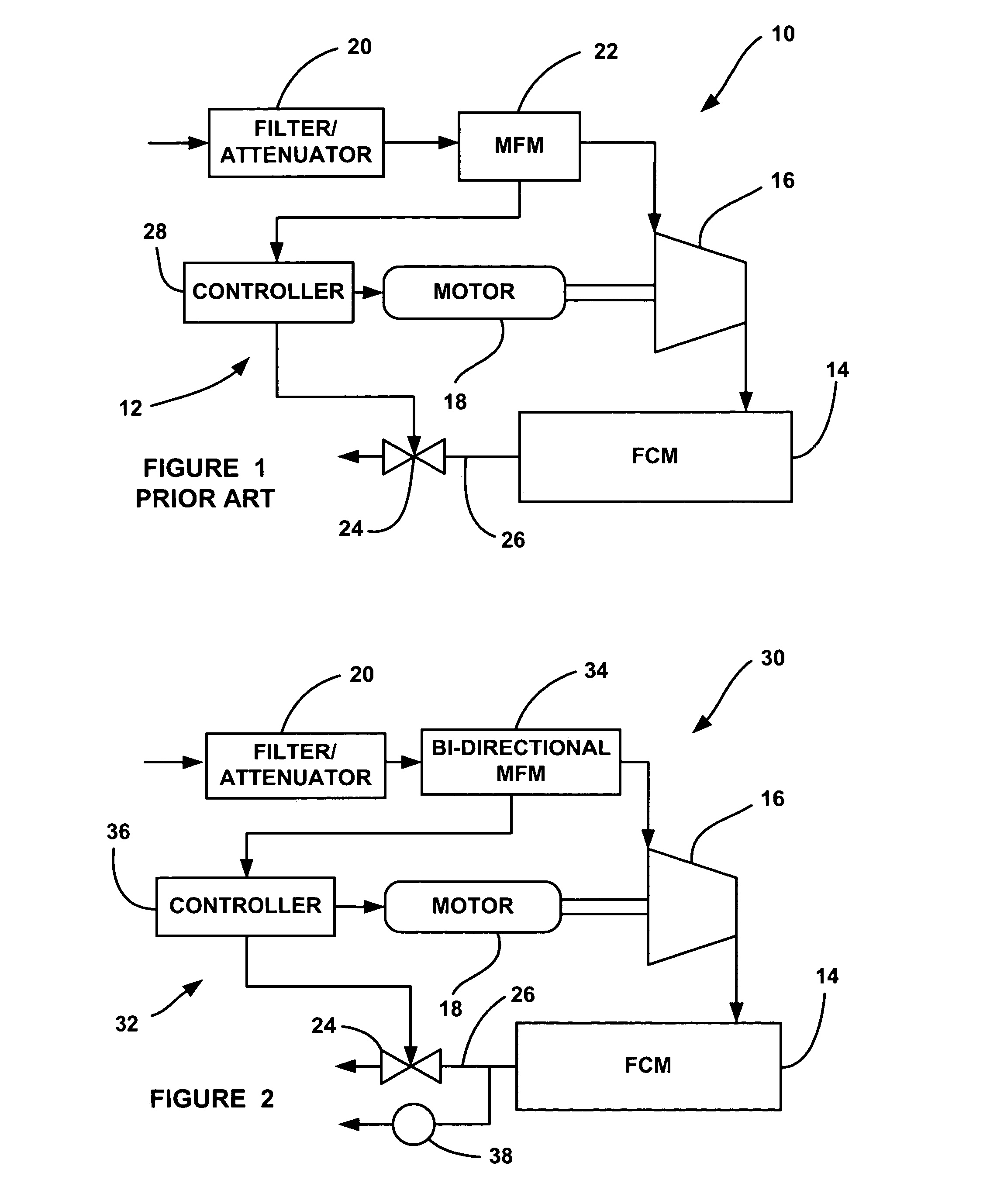

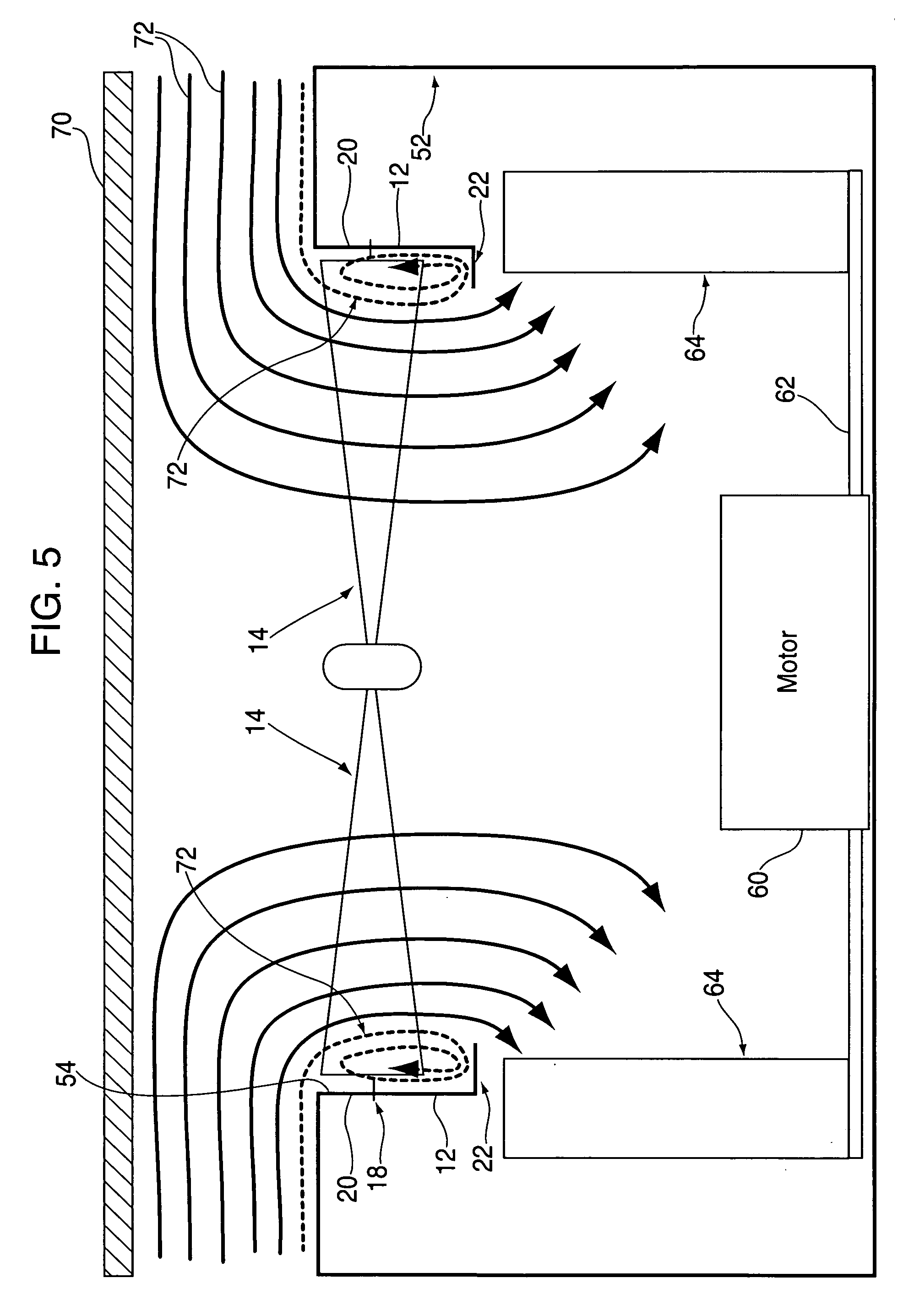

Centrifugal compressor surge detection using a bi-directional MFM in a fuel cell system

A fuel cell system including a turbomachine compressor that delivers charge air to the cathode side of a fuel cell module. A bidirectional mass flow meter measures the airflow through the compressor, and provides an indication of a reverse airflow through the compressor for surge protection. A controller receives a signal from the mass flow meter indicative of the reverse flow. The controller controls a motor driving the compressor and a back pressure valve at the cathode exhaust of the fuel cell module to control the pressure in the fuel cell module to remove the surge condition.

Owner:GM GLOBAL TECH OPERATIONS LLC

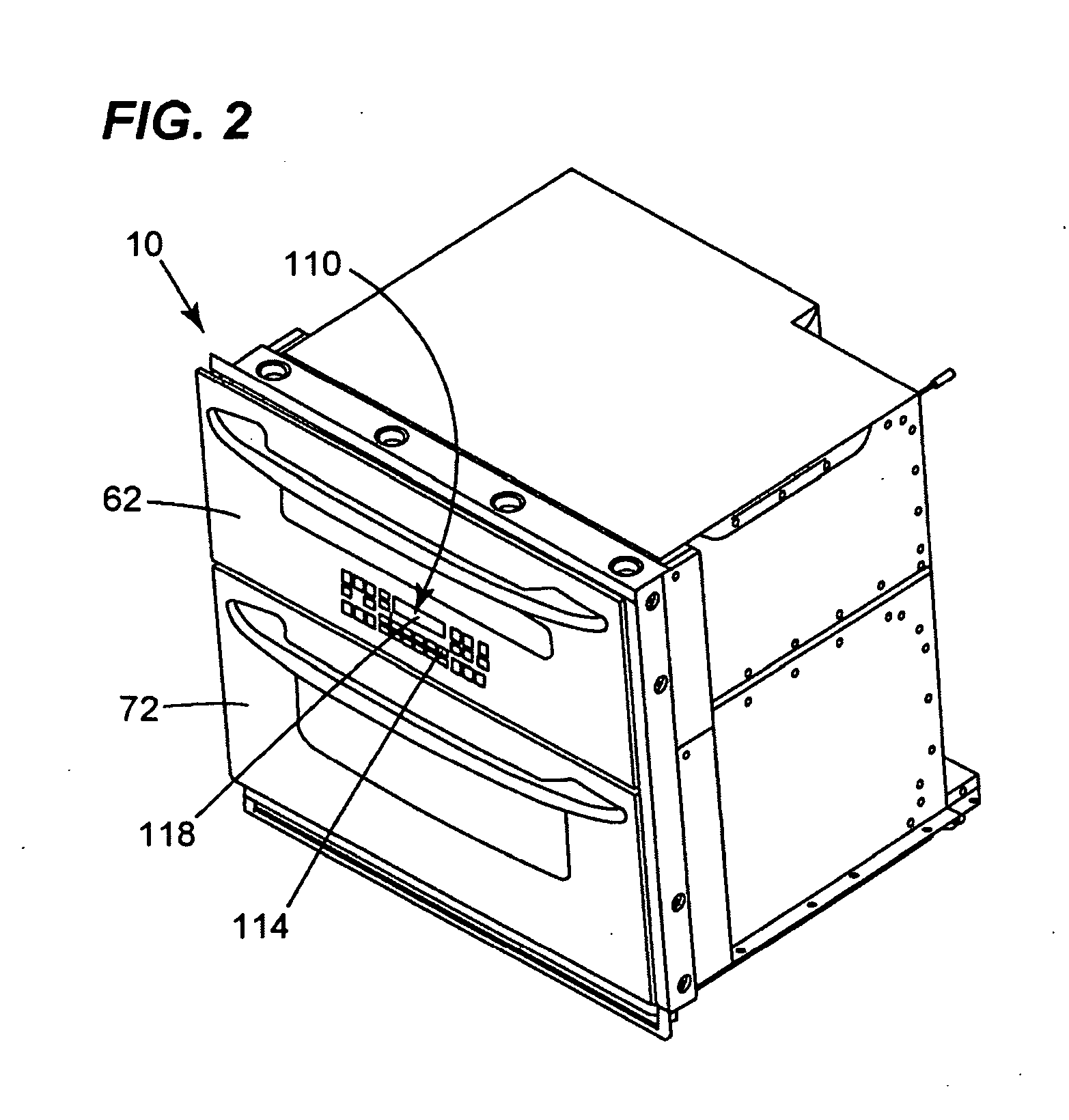

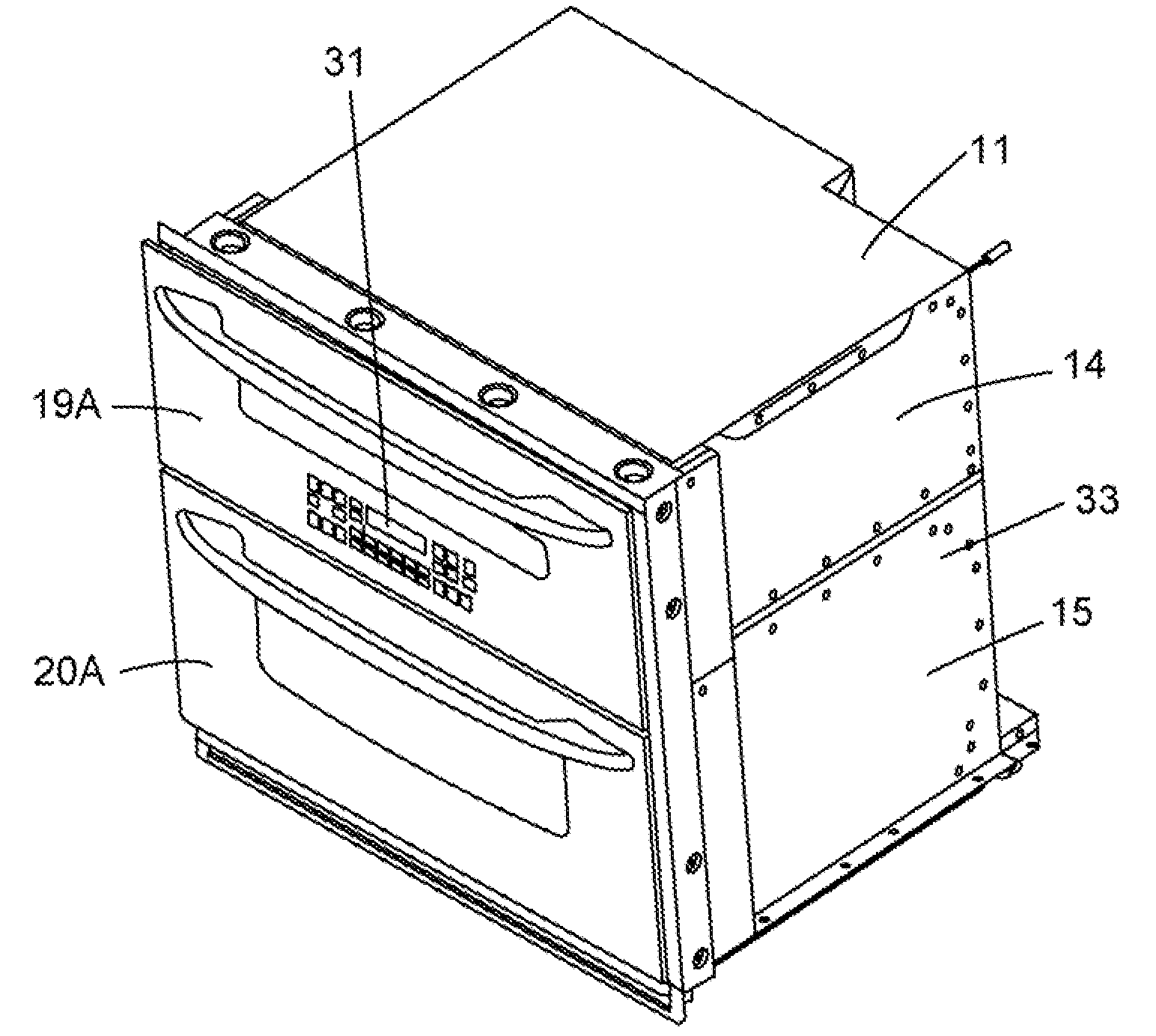

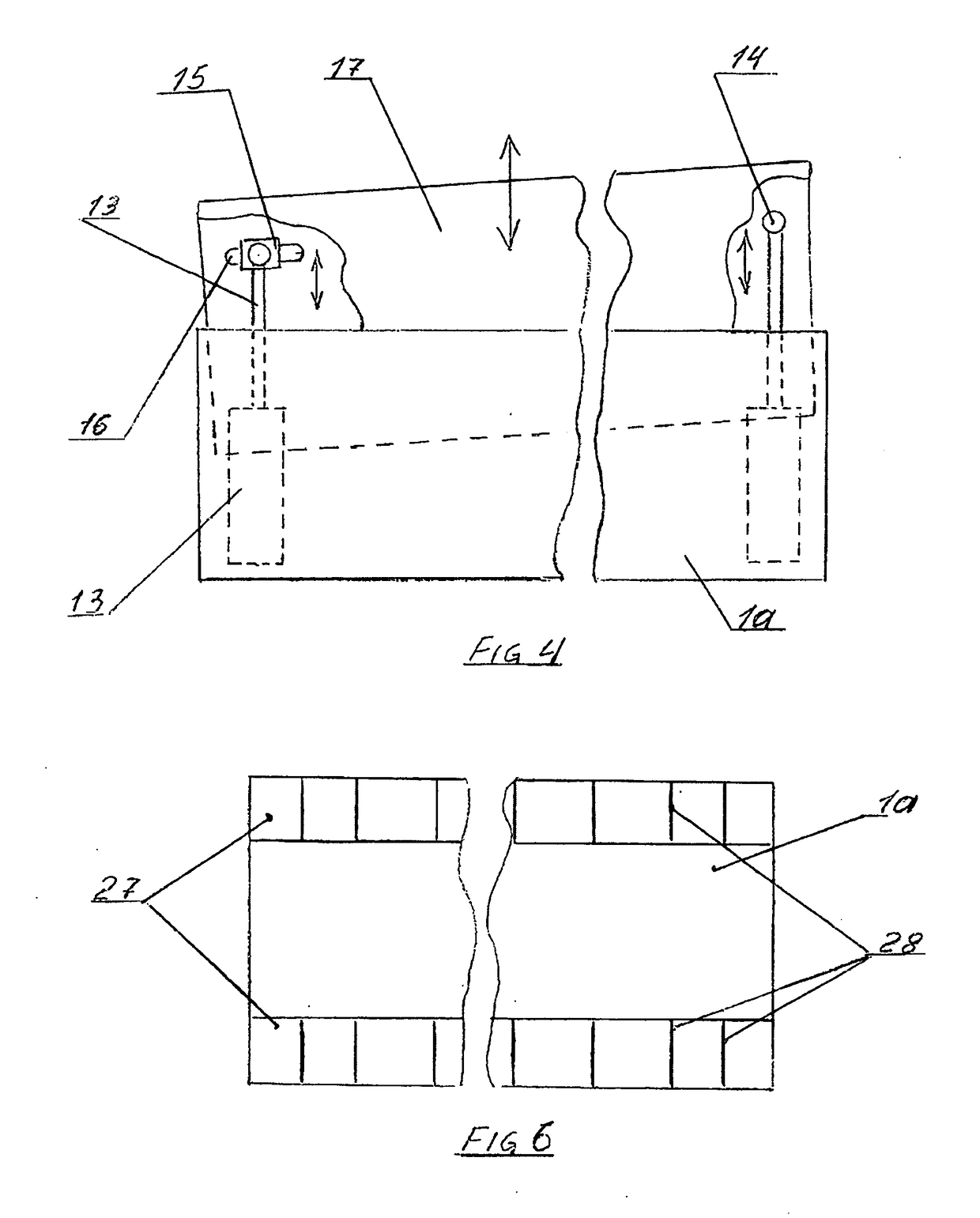

Appliance with a vacuum-based reverse airflow cooling system

An appliance is disclosed. The appliance includes a main body defining a cavity and an air channel which is in flow communication with an outside of the appliance; an access door supported by the main body for selectively closing the cavity, the access door having an airway in flow communication with the outside of the appliance and the air channel; a fan disposed in the air channel; and an Human Machine Interface disposed on or in the access door. When activated, the fan causes ambient air from the outside of the appliance to pass through the airway before entering the air channel so that the access door is cooled off by the ambient air.

Owner:HAIER US APPLIANCE SOLUTIONS INC

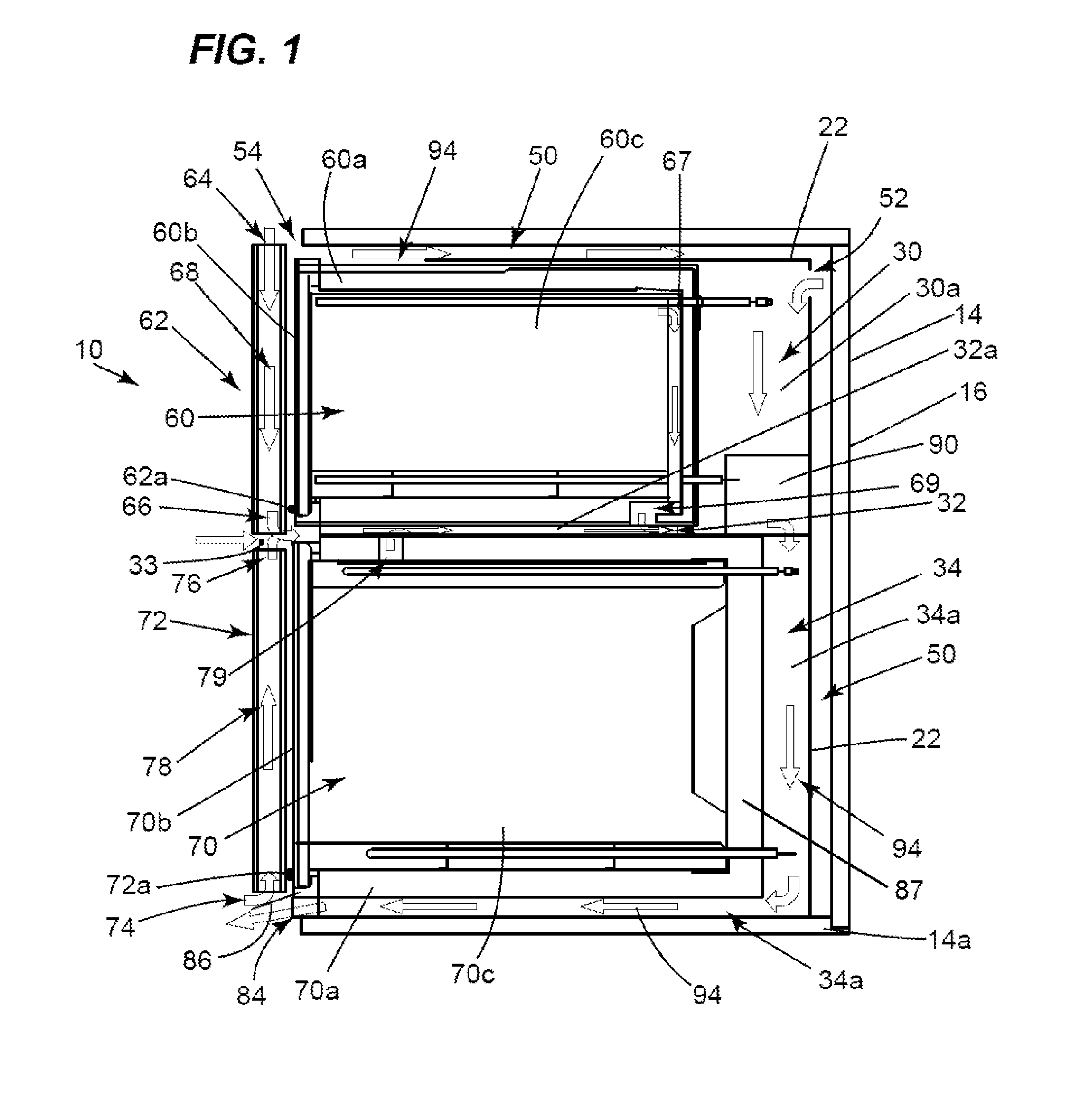

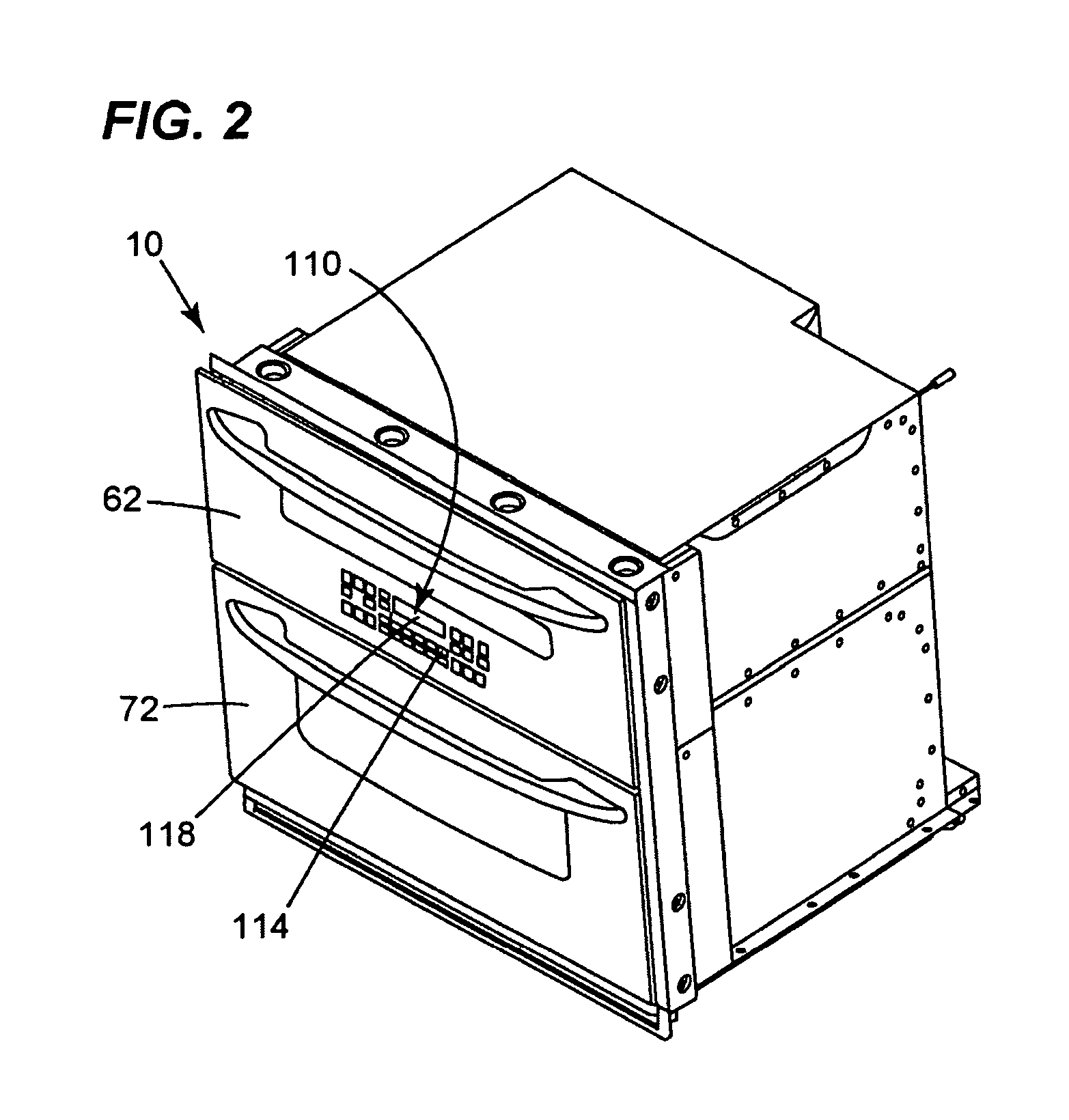

Appliance with a vacuum-based reverse airflow cooling system using one fan

An appliance includes a housing having an airflow channel communicating with outside of the appliance; a first chamber in the housing and having a first opening; a first door for selectively closing the first opening, the first door having a first airway communicating with the outside of the appliance; a second chamber in the housing and having a second opening; a second door for selectively closing the second opening, the second door having a second airway communicating with the outside of the appliance; and a fan in the airflow channel. The airflow channel includes a central segment disposed between the first and second chambers and communicating with the first and second airways. When activated, the fan causes ambient air to pass through the first and second airways before entering the central segment so that the first and second doors are cooled off by the ambient air.

Owner:HAIER US APPLIANCE SOLUTIONS INC

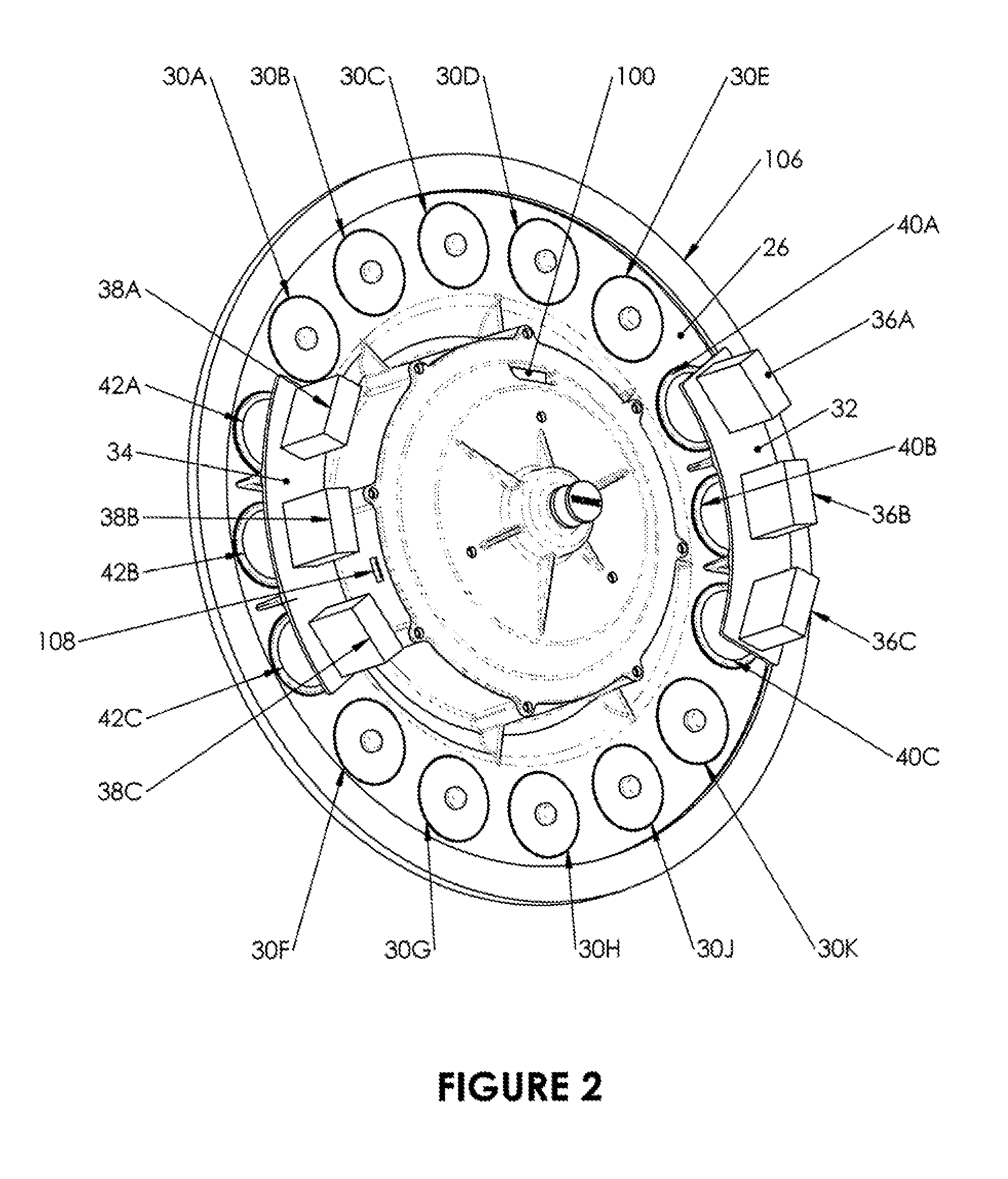

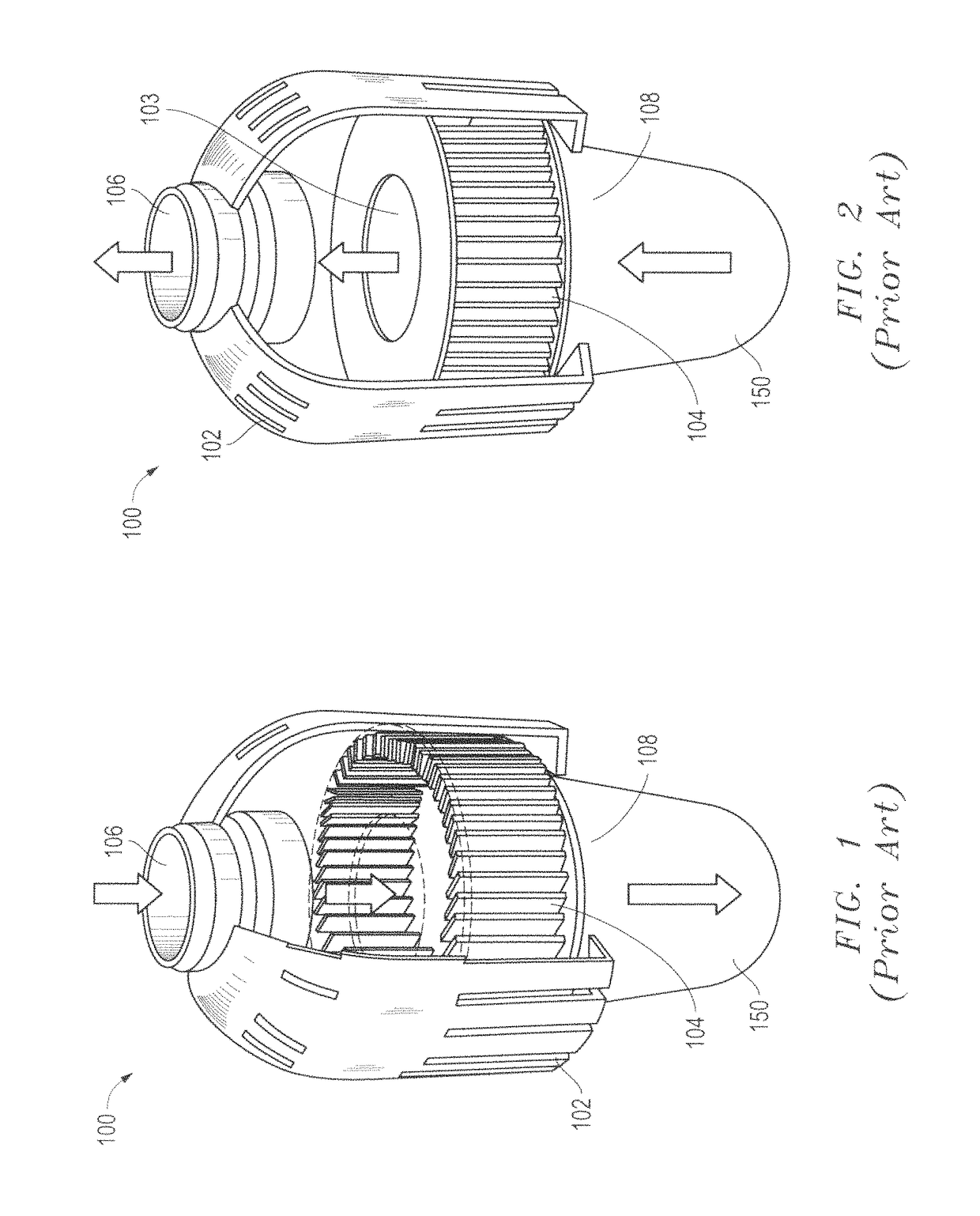

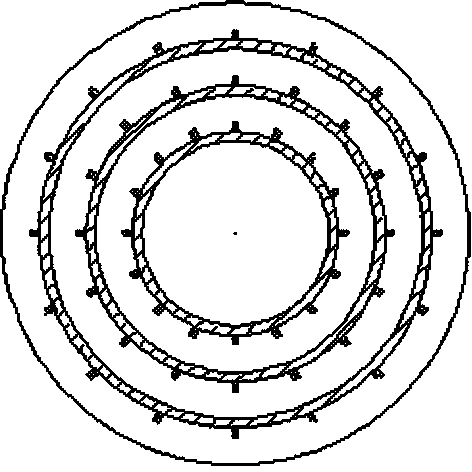

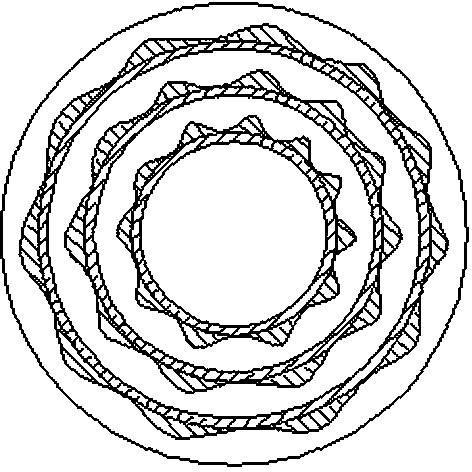

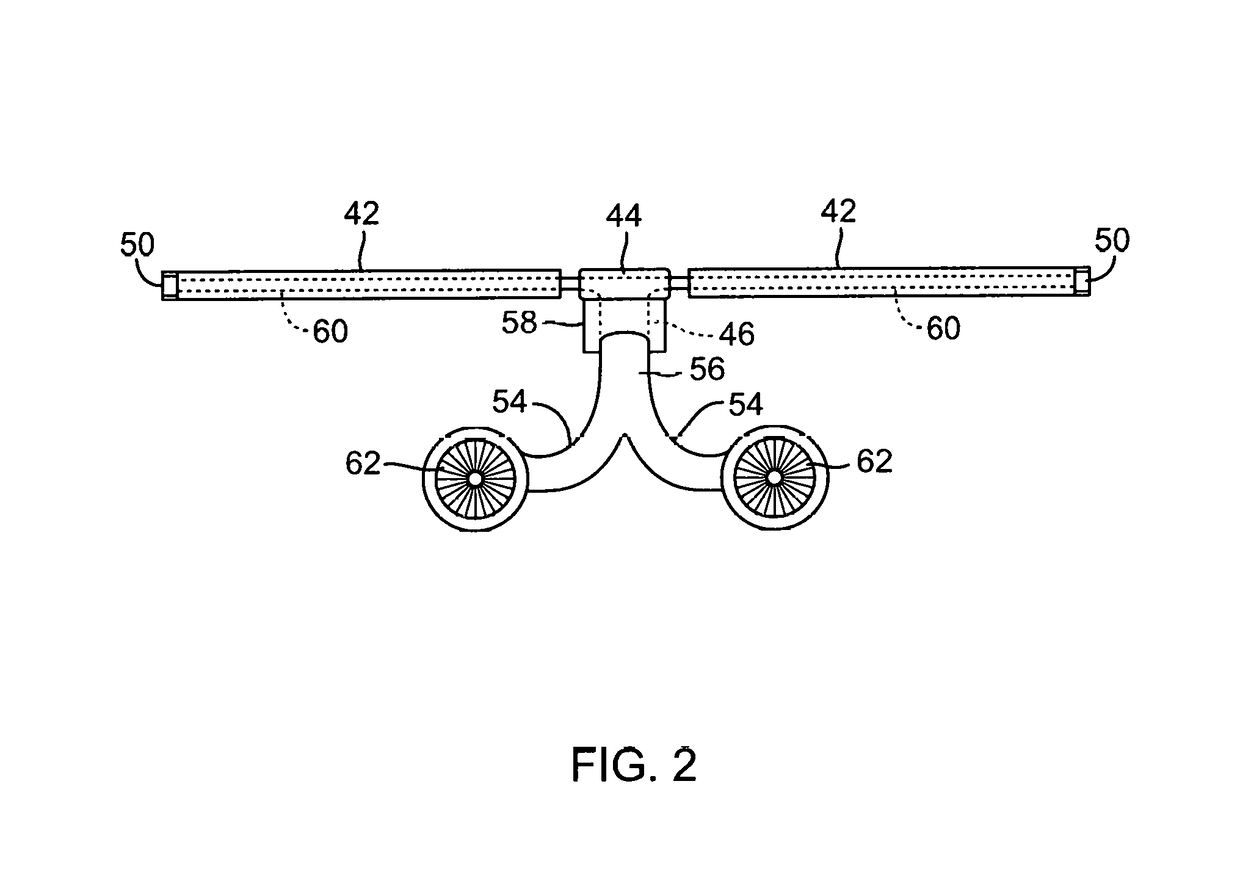

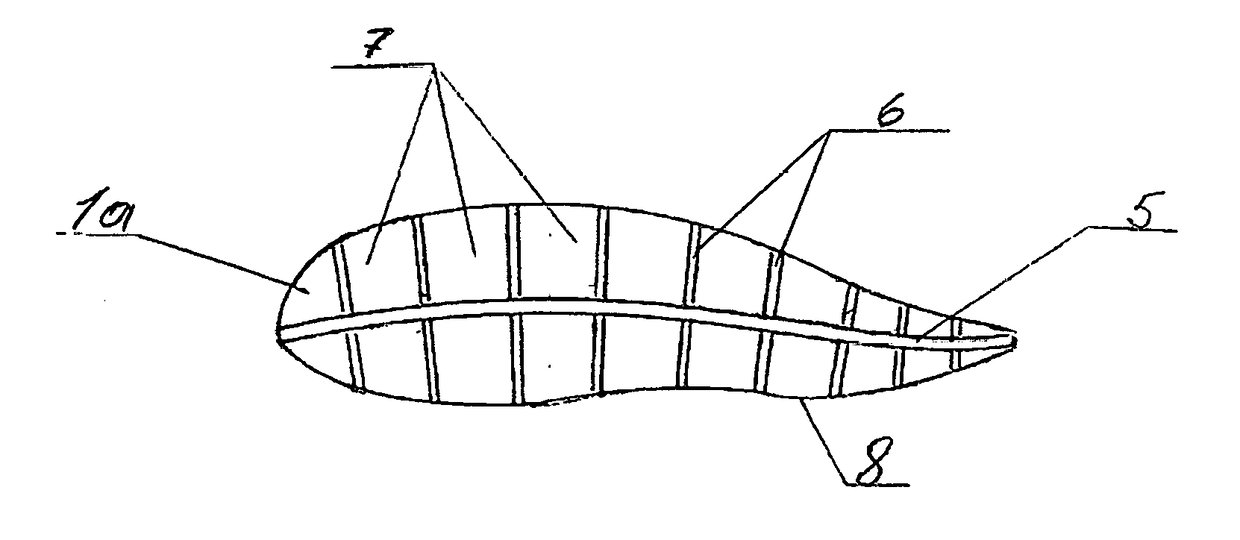

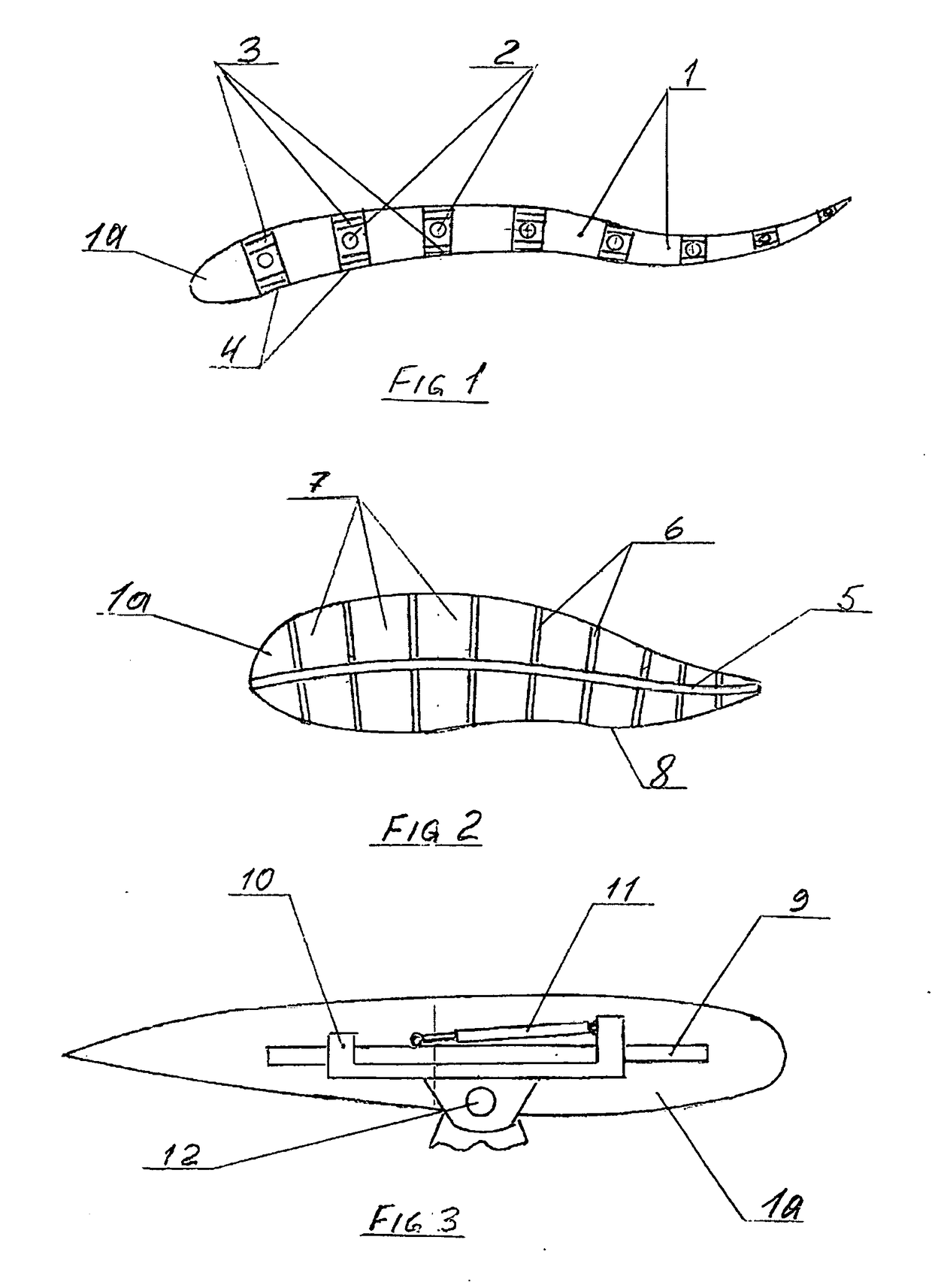

Air Pumping Device

InactiveUS20150336653A1High operating efficiency and power densityLightly appliedPump componentsPiston pumpsStator coilAir pump

An air pumping device for the buoyancy control of a lighter than air craft is presented. The pumping device integrates within a single housing a centrifugal compressor and an axial gap, ironless core, electric motor. All of the rotating components of the compressor and motor are mounted on a single common shaft. The air pumping device includes a valve arrangement which allows for both forward and reverse airflow though the compressor portion of the device. The motor portion of the device features a stator coil and power, communications and sensor electronics, all integrated on a single common printed circuit board. The air pumping device exhibits exceptionally high operating efficiency and power density, which are highly desirable for lighter than air craft applications.

Owner:ANDERSON ROBERT B +1

Appliance with a vacuum-based reverse airflow cooling system using one fan

An appliance includes a housing having an airflow channel communicating with outside of the appliance; a first chamber in the housing and having a first opening; a first door for selectively closing the first opening, the first door having a first airway communicating with the outside of the appliance; a second chamber in the housing and having a second opening; a second door for selectively closing the second opening, the second door having a second airway communicating with the outside of the appliance; and a fan in the airflow channel. The airflow channel includes a central segment disposed between the first and second chambers and communicating with the first and second airways. When activated, the fan causes ambient air to pass through the first and second airways before entering the central segment so that the first and second doors are cooled off by the ambient air.

Owner:HAIER US APPLIANCE SOLUTIONS INC

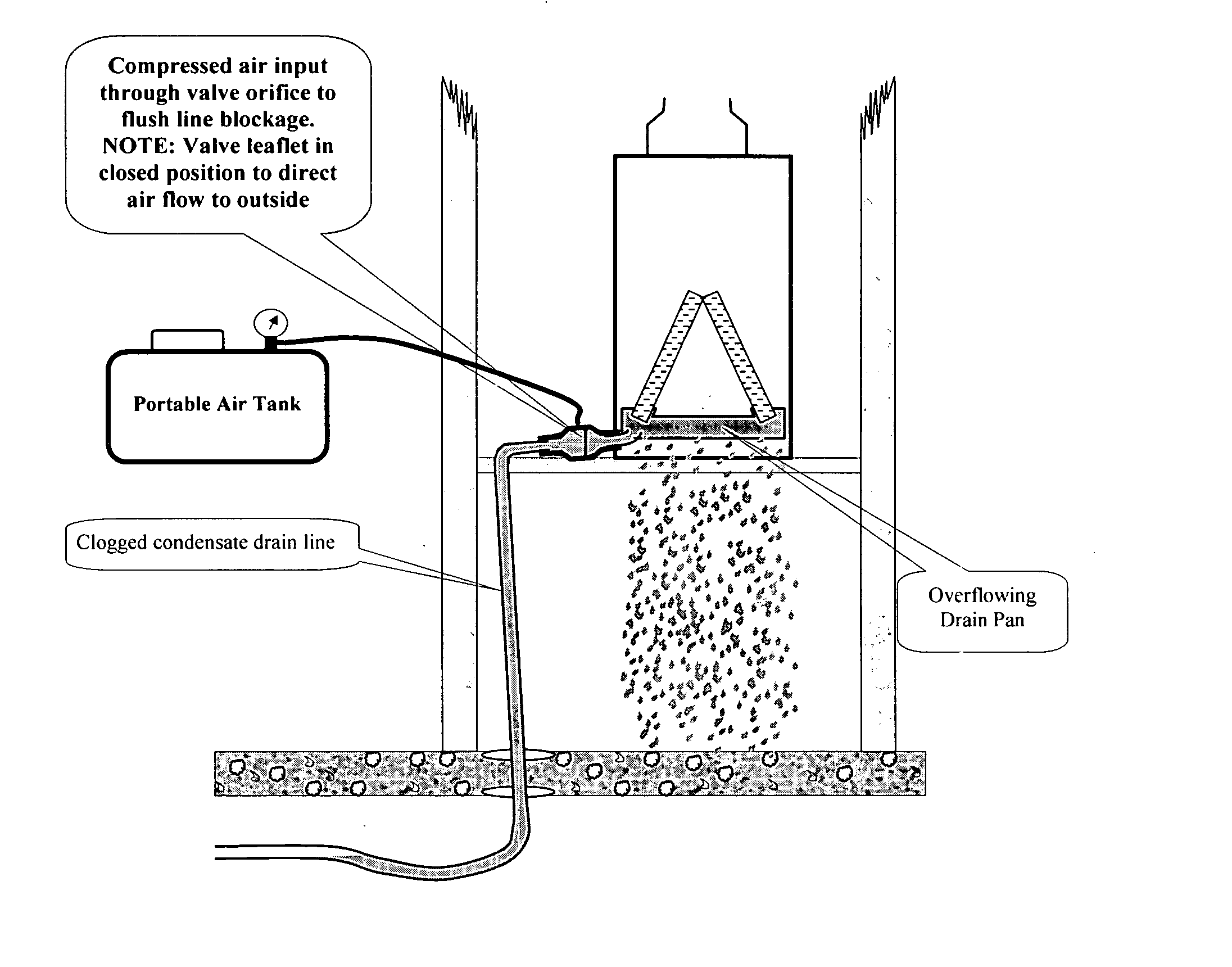

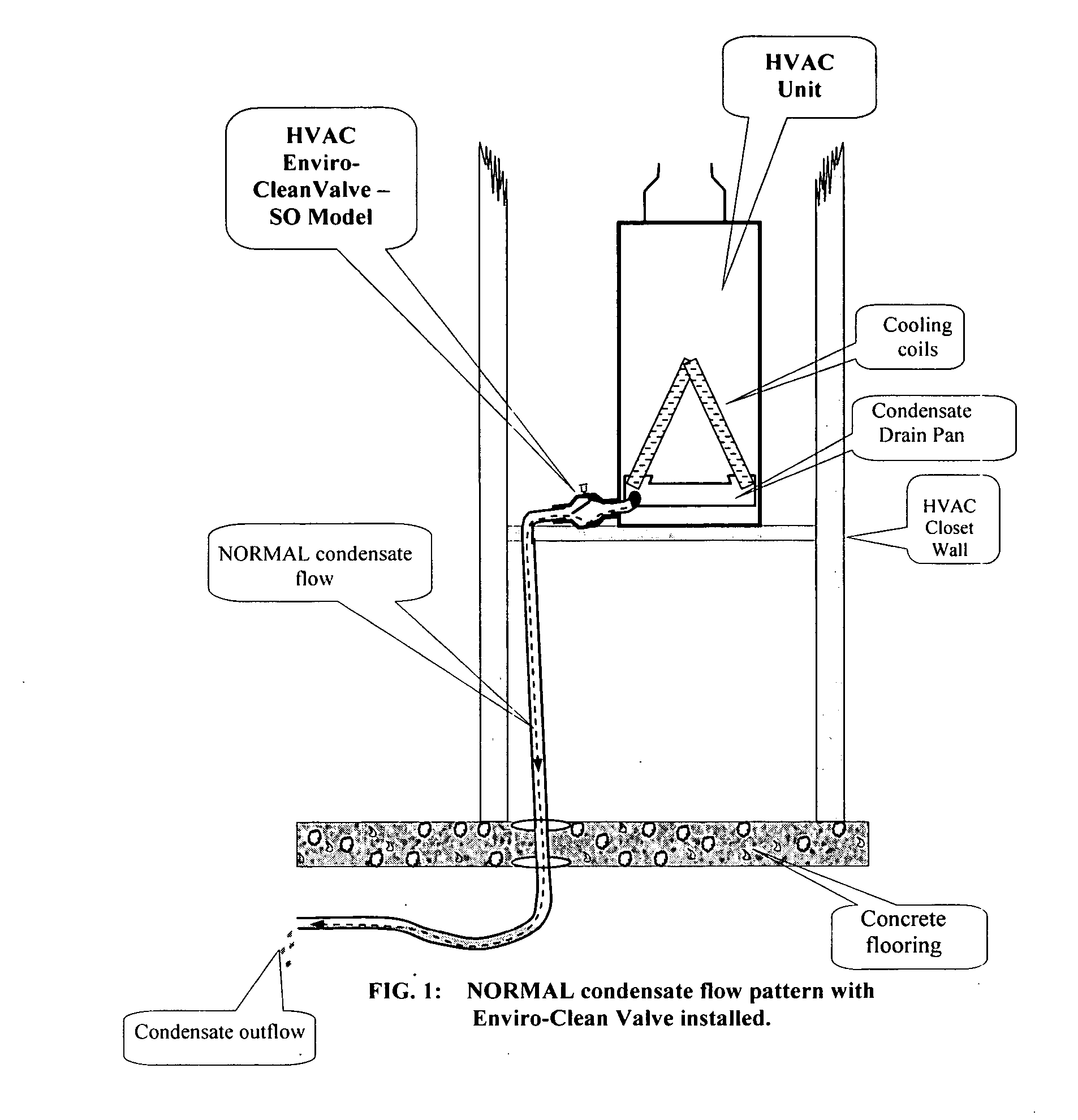

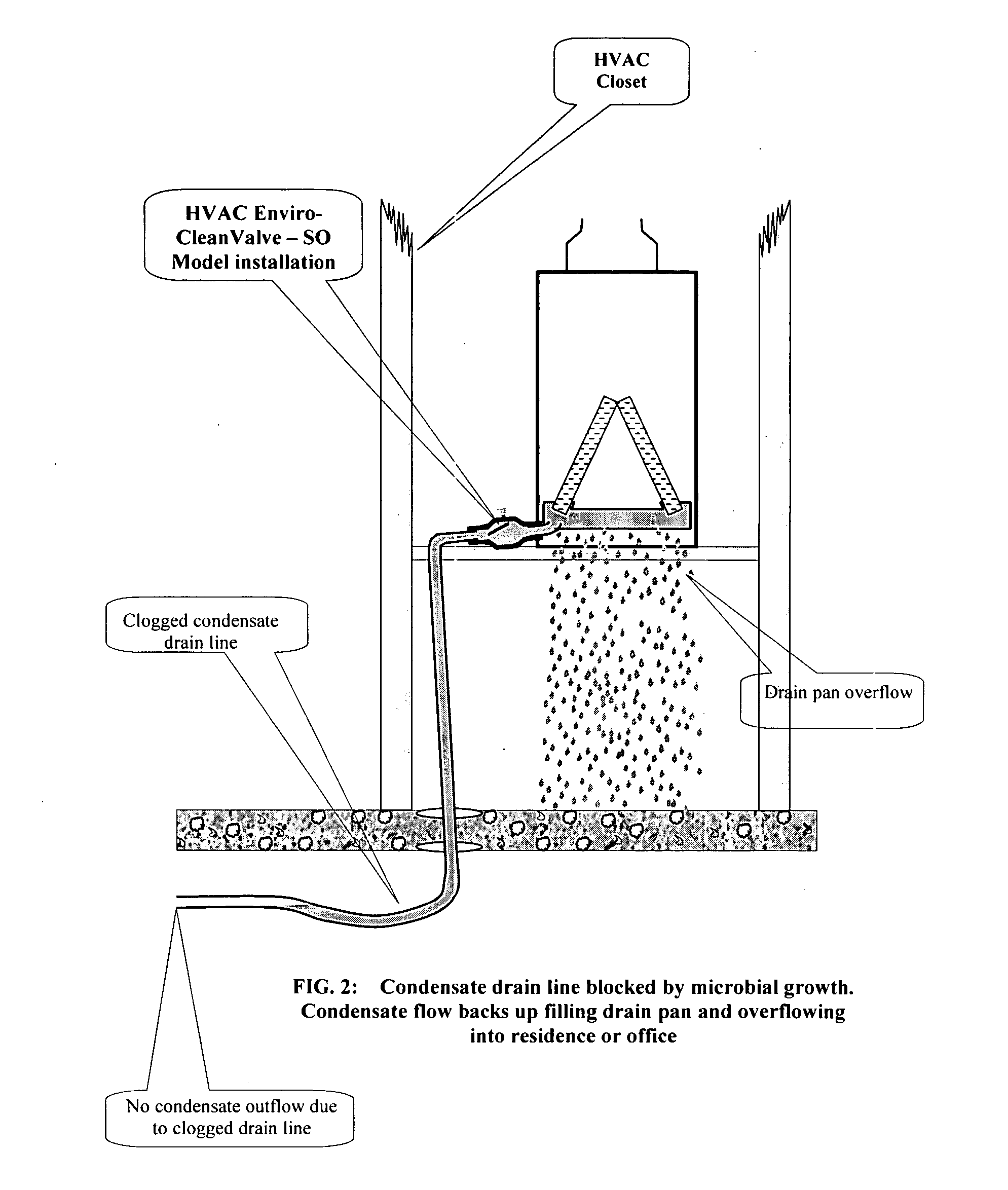

HVAC enviro-clean valve - SO model

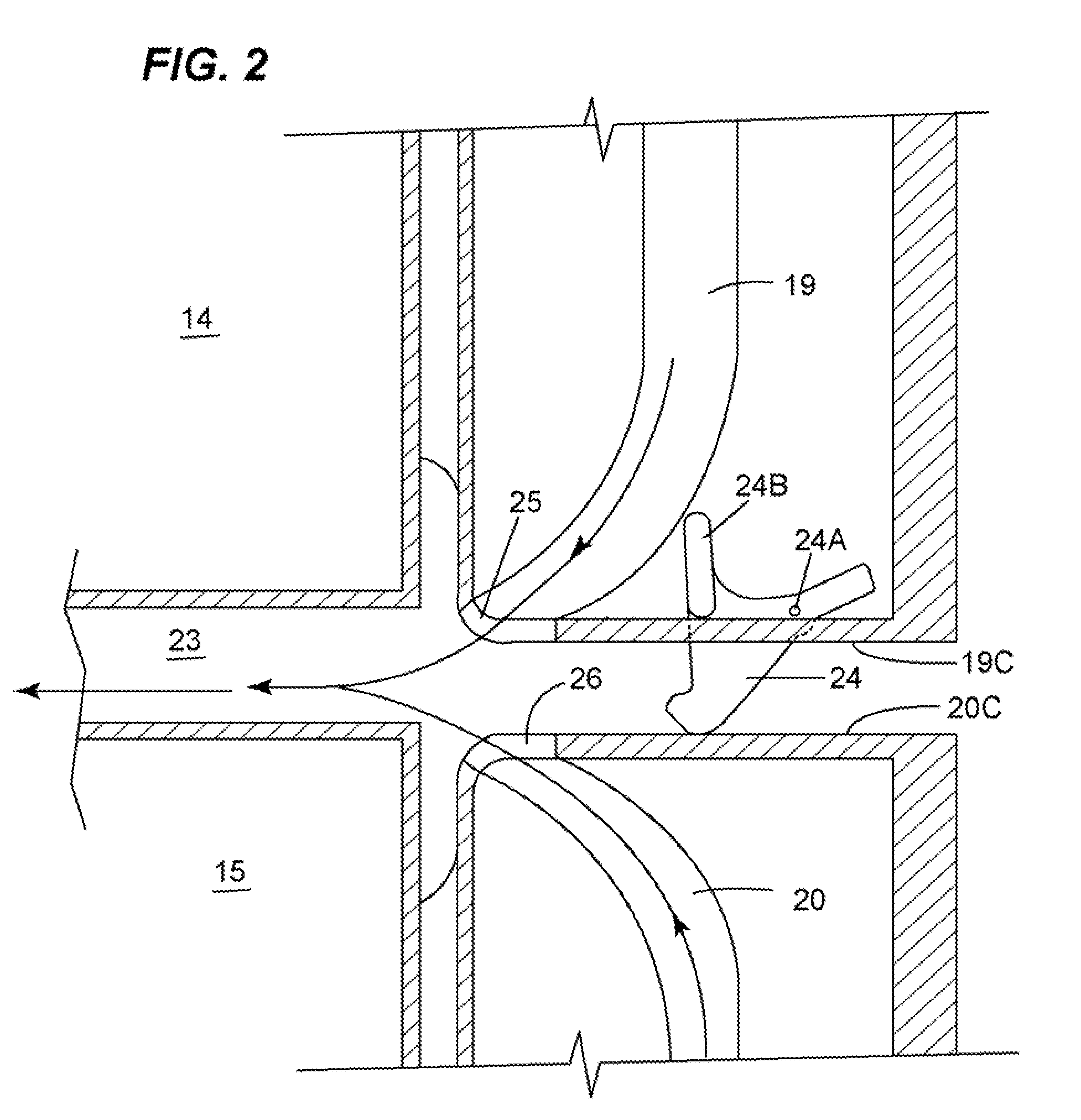

InactiveUS20060042292A1Improve indoor air qualityEnhance IAQLighting and heating apparatusSpace heating and ventilation detailsIndoor air qualityEngineering

Currently, there are no products available which allow a user to solely remove microbial and bacterial growth inside a blocked HVAC condensate drain line using compressed air without cutting into or disassembling the drain line. Our valve is an in-line condensate drain line valve that can be installed easily, quickly and economically, either during new construction or onto existing HVAC systems. The HVAC user can remove microbial and bacterial growths without cutting into or disassembling the drain line by injecting compressed air through the valve. The design of our valve allows the user to perform safe and routine maintenance to the HVAC drainage system without having to resort to expensive and repetitive service call repairs over the lifetime of the HVAC system. The valve is further designed to prevent undesirable reverse airflows into the HVAC system and home or building, caused by a dry trap in the condensate drain. The prevention of reverse airflows and reduction of microbial and bacterial growth will have a positive impact of Indoor Air Quality.

Owner:KIMBROUGH ATWOOD M +1

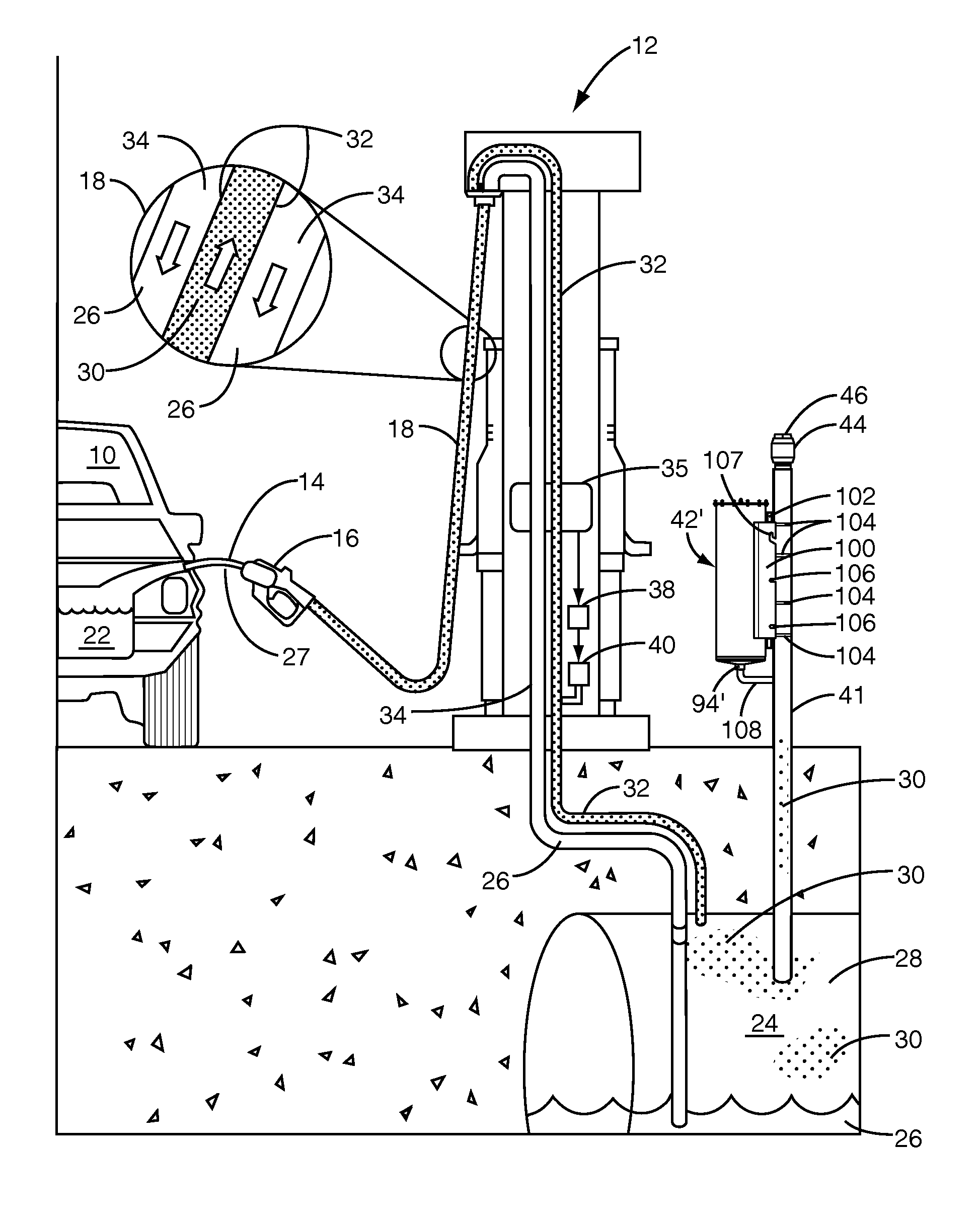

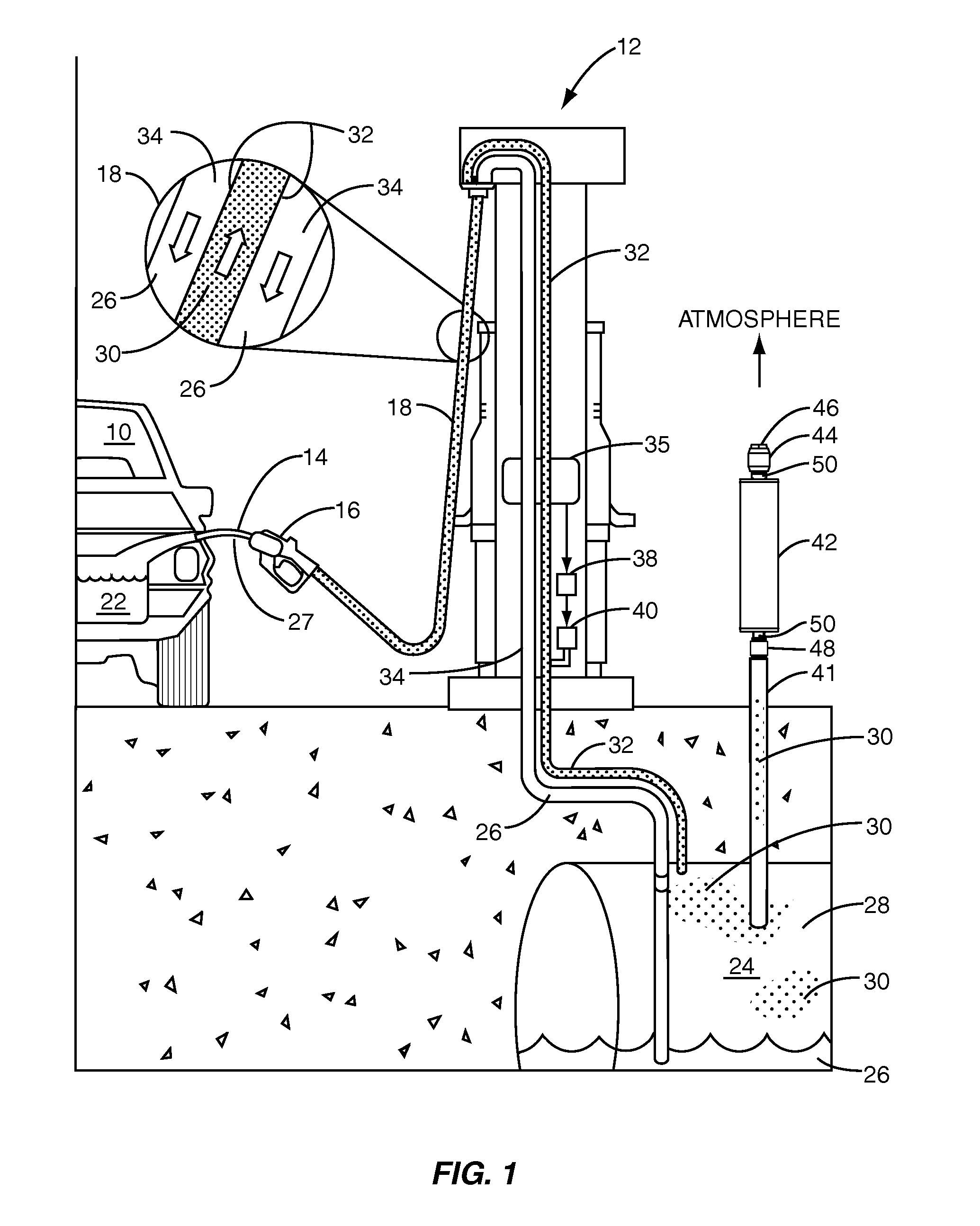

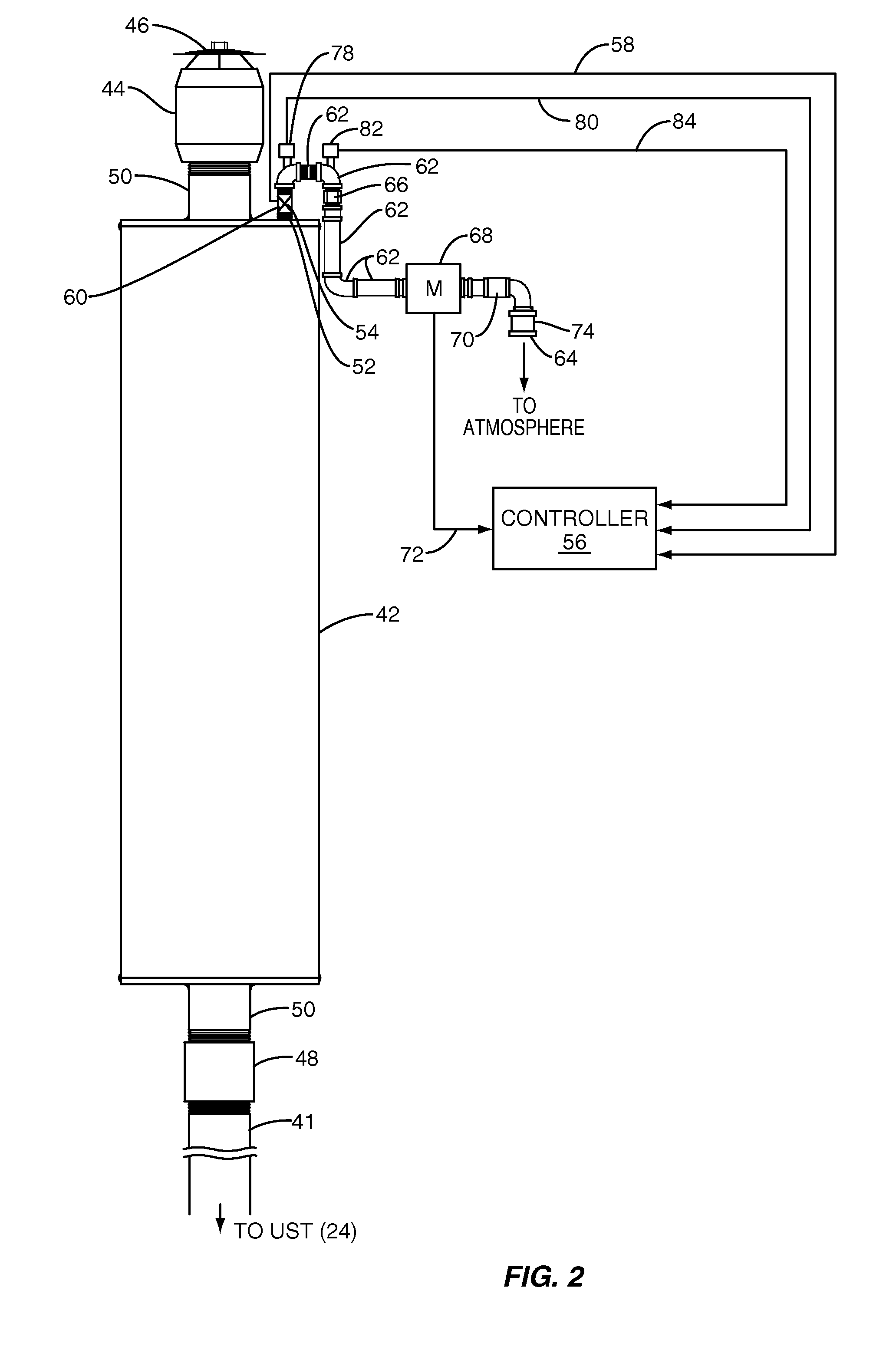

Fuel storage tank pressure management system and method employing a carbon canister

ActiveUS20070131111A1Prevents excessive positive pressureAvoid emissionsCombination devicesGas treatmentPressure risePositive pressure

A carbon canister to adsorb hydrocarbons from a hydrocarbon air mixture in a UST system to prevent fugitive emissions due to overpressurization. The carbon canister has an inlet port at one end coupled to the UST system. An outlet port on the opposite end of the canister is connected to a flow-limiting orifice with a known calibrated flow rate that vents in a controlled fashion to the atmosphere. When UST pressure rises slightly above ambient pressure, fuel vapors and air from the UST system enters, via the inlet port, into the canister, where hydrocarbons are adsorbed onto the surface of the activated carbon. The cleansed air vents through the controlled flow outlet port to atmosphere, thereby preventing excessive positive pressure from occurring in the UST system. The activated carbon is purged of hydrocarbons by means of reverse air flow caused by negative UST pressures that occur during periods of ORVR vehicle refueling.

Owner:VEEDER ROOT

Appliance with a vacuum-based reverse airflow cooling system

ActiveUS20100065036A1Self-cleaning stoves/rangesDoors for stoves/rangesHuman–machine interfaceEngineering

An appliance is disclosed. The appliance includes a main body defining a cavity and an air channel which is in flow communication with an outside of the appliance; an access door supported by the main body for selectively closing the cavity, the access door having an airway in flow communication with the outside of the appliance and the air channel; a fan disposed in the air channel; and an Human Machine Interface disposed on or in the access door. When activated, the fan causes ambient air from the outside of the appliance to pass through the airway before entering the air channel so that the access door is cooled off by the ambient air.

Owner:HAIER US APPLIANCE SOLUTIONS INC

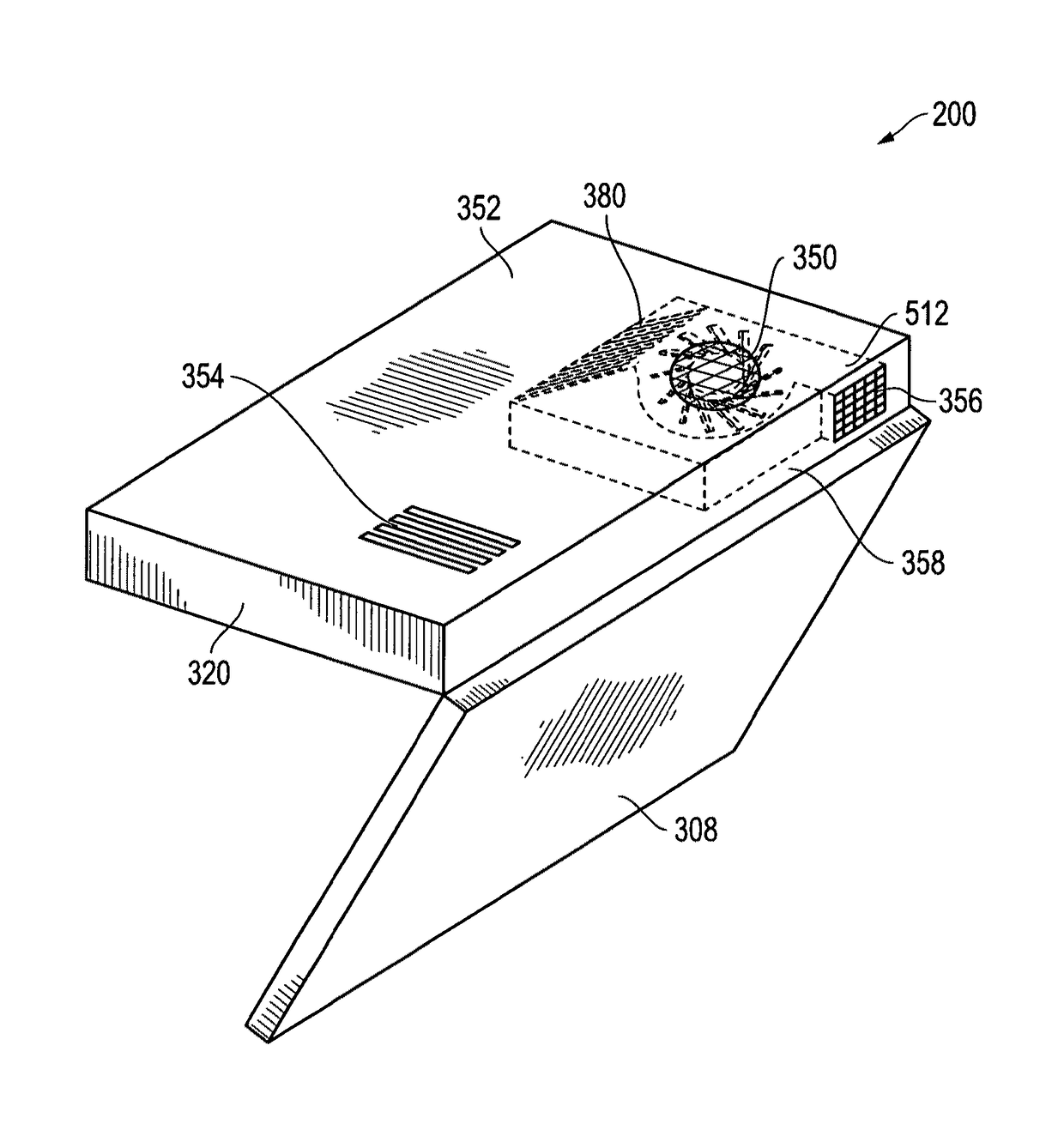

Dual operation centrifugal fan apparatus and methods of using same

Dual operation centrifugal fan apparatus and methods of operating same that may be used, for example, to cool the internal heat-generating components of an information handling system or other device. The dual operation centrifugal fan apparatus may be implemented in one embodiment as a self-cleaning blower apparatus that is operated in a first normal cooling direction to dissipate heat from internal components of an information handling system, and operated in second cleaning direction to reverse airflow and expel accumulated dust from the interior of the information handling system.

Owner:DELL PROD LP

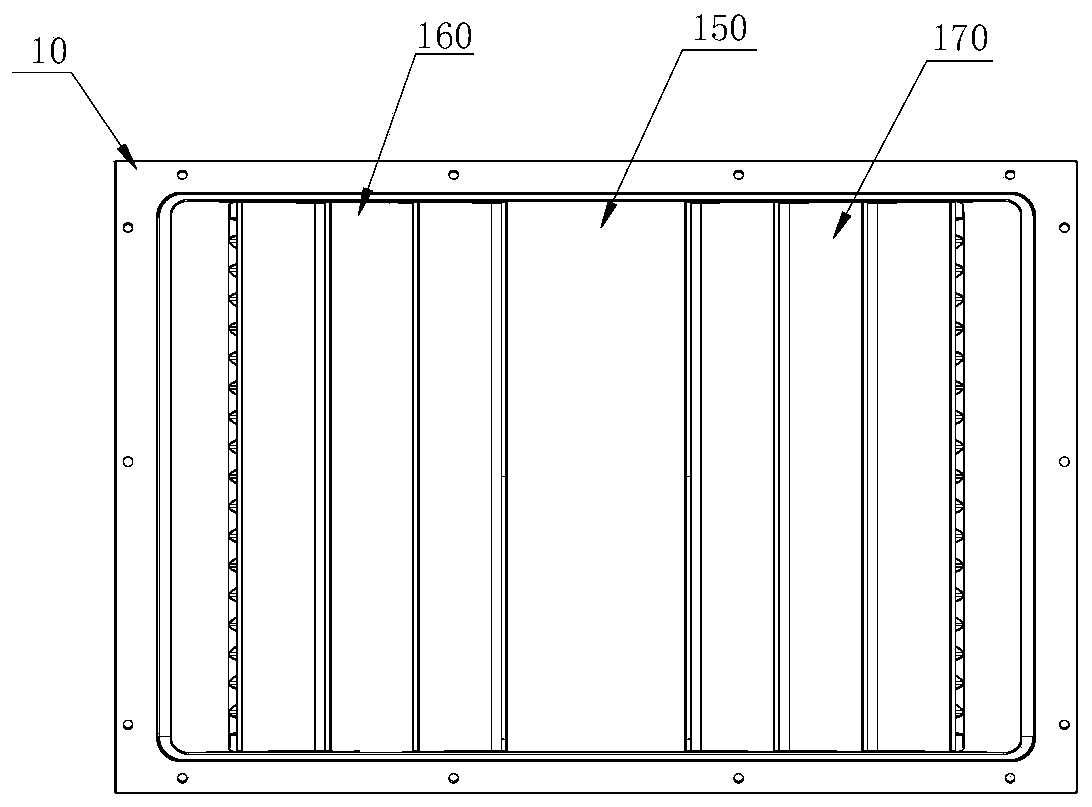

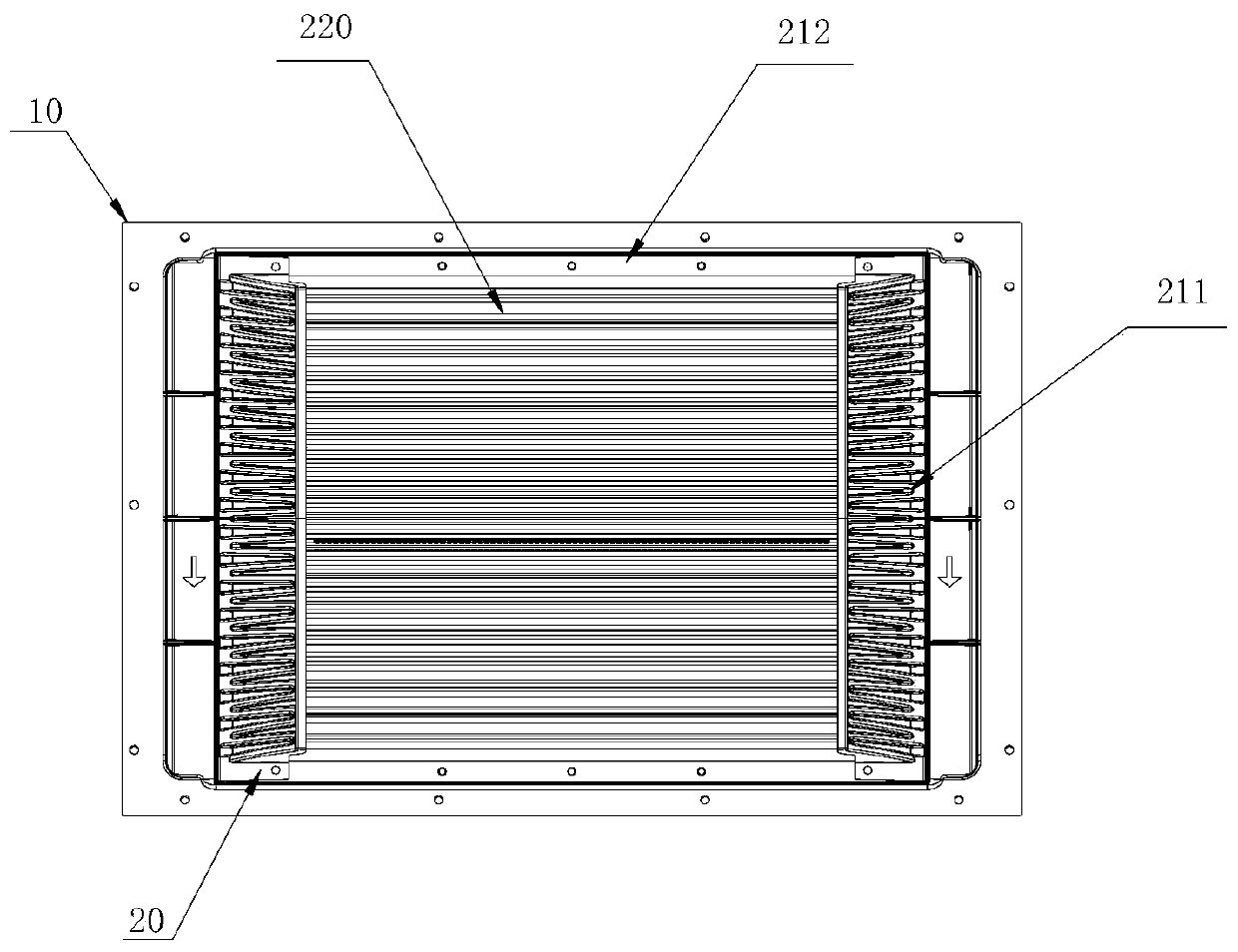

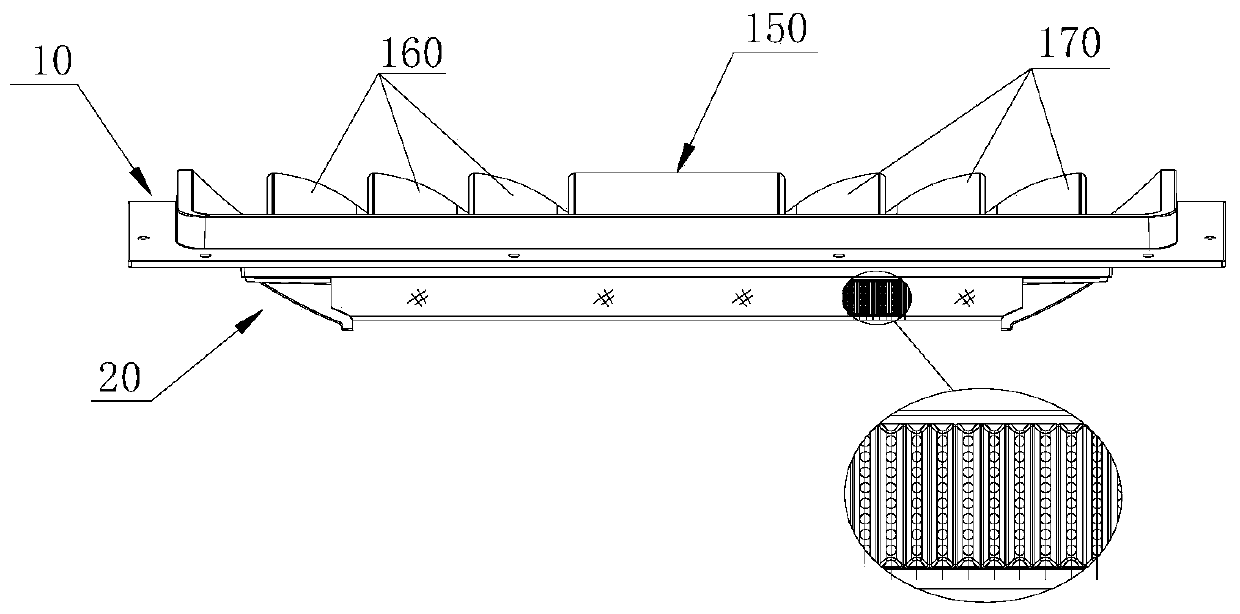

Equipment compartment dust removal and ventilation device for transport machine

PendingCN110281733AGuaranteed stabilityImprove stabilityCombination devicesAir-treating devicesWave shapeHigh pressure

The invention discloses an equipment compartment dust removal and ventilation device for a transport machine. The equipment compartment dust removal and ventilation device comprises a baffle frame assembly and a filter net assembly. The baffle frame assembly comprises an inner frame and a mounting plate. A middle lower guide plate, an air inflow lower guide plate and an air outflow lower guide plate are arranged in the inner frame. The inner frame is divided into two ventilation regions through the middle lower guide plate, one ventilation region is an air inflow region, and the other ventilation region is an air outflow region. A middle upper guide plate, an air inflow upper guide plate and an air outflow upper guide plate are fixedly mounted above the middle lower guide plate, the air inflow lower guide plate and the air outflow lower guide plate separately. The filter net assembly comprises a filter net frame and a wave-shaped filter net. By means of strong reverse airflow generated at the position of an air inlet of a skirt board when a bullet train unit runs, floating objects and air inflow airflow are voluntarily separated, and the separated floating objects are exhausted back to the atmosphere under coercing of airflow of a main ventilation duct; and meanwhile, under the effect of the guide surfaces of the guide plates, the air pressure at the position of the filter net is increased, a high-pressure region is formed, and active air supply to an equipment compartment is achieved.

Owner:ZHONGCHE TIANJIN RAIL TRANSIT EQUIP CO LTD

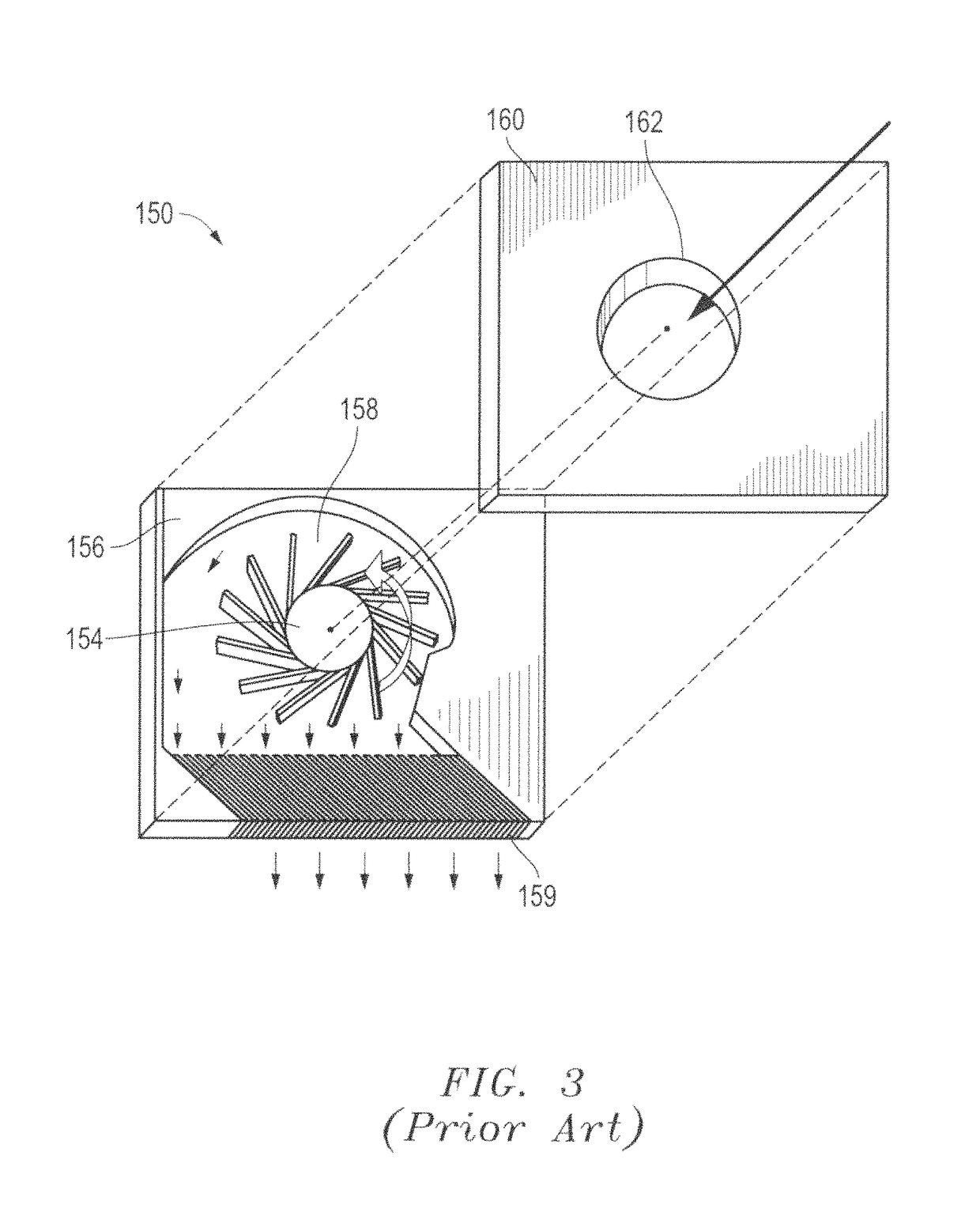

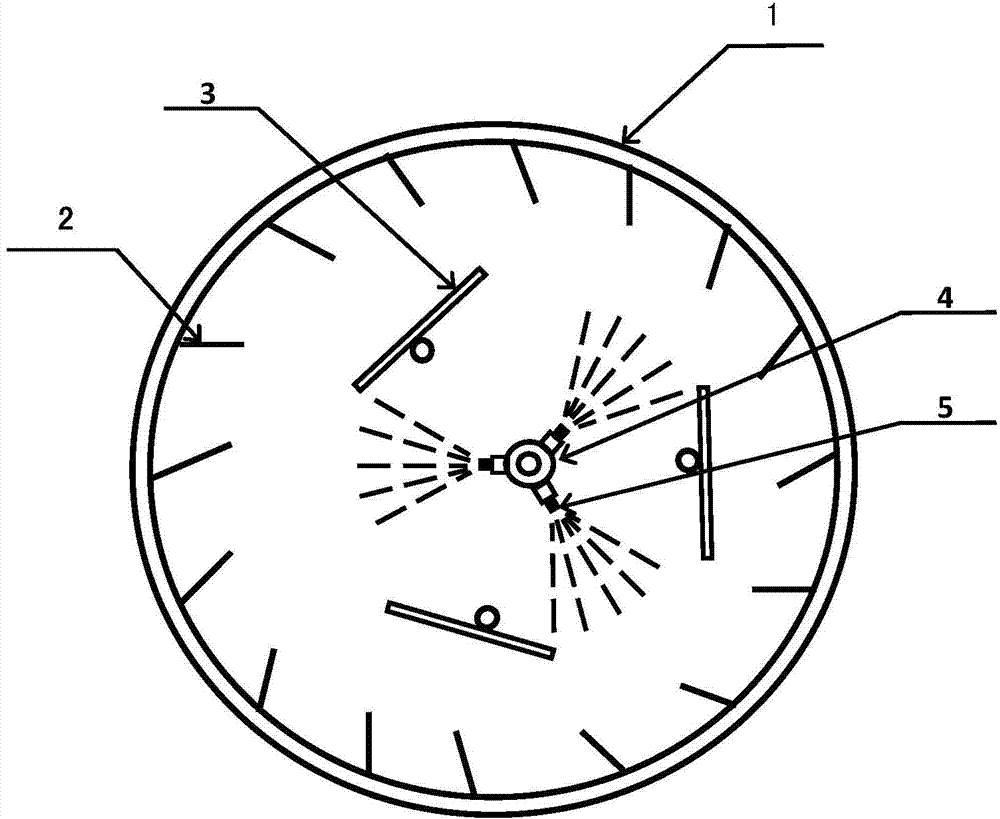

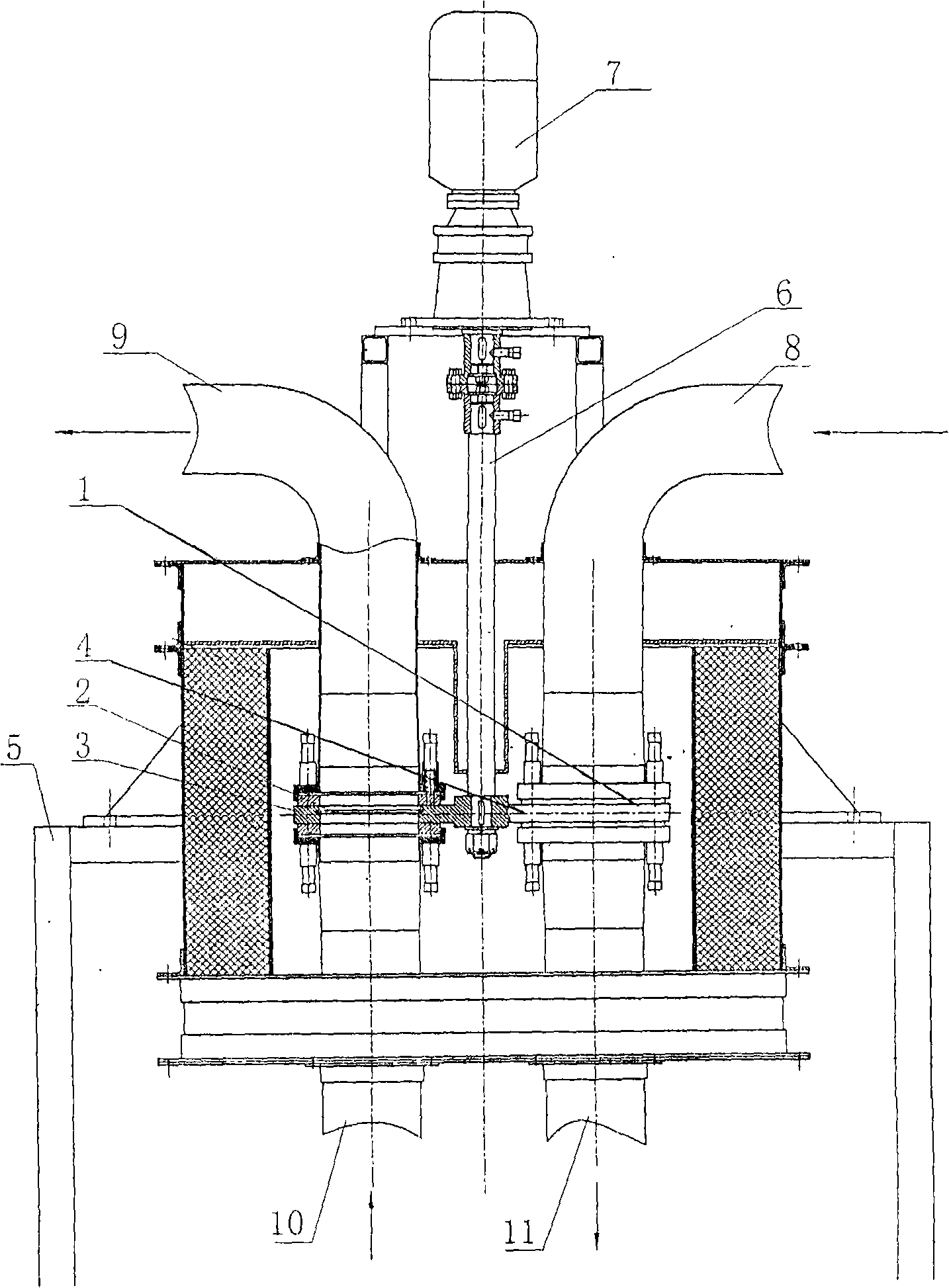

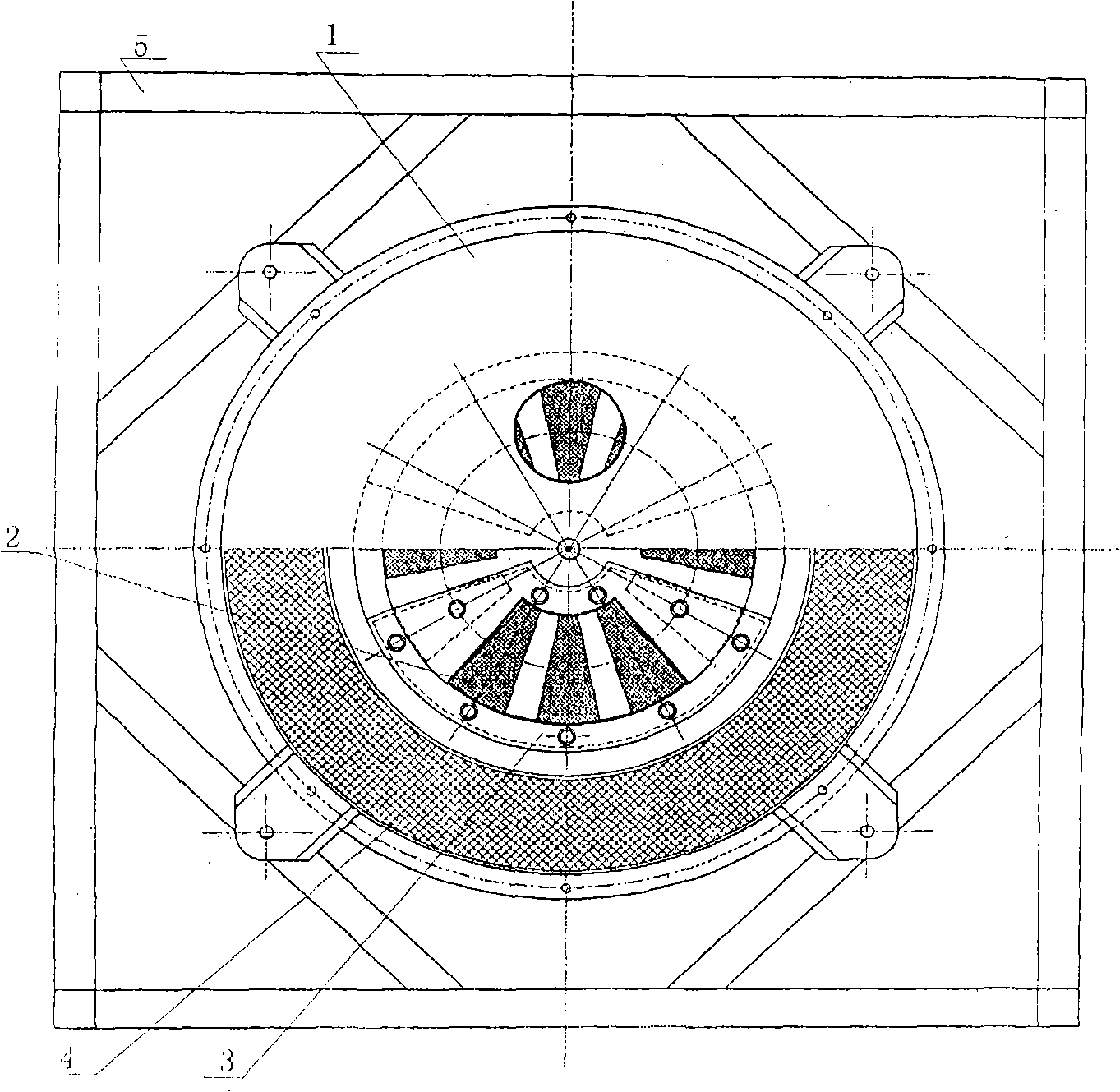

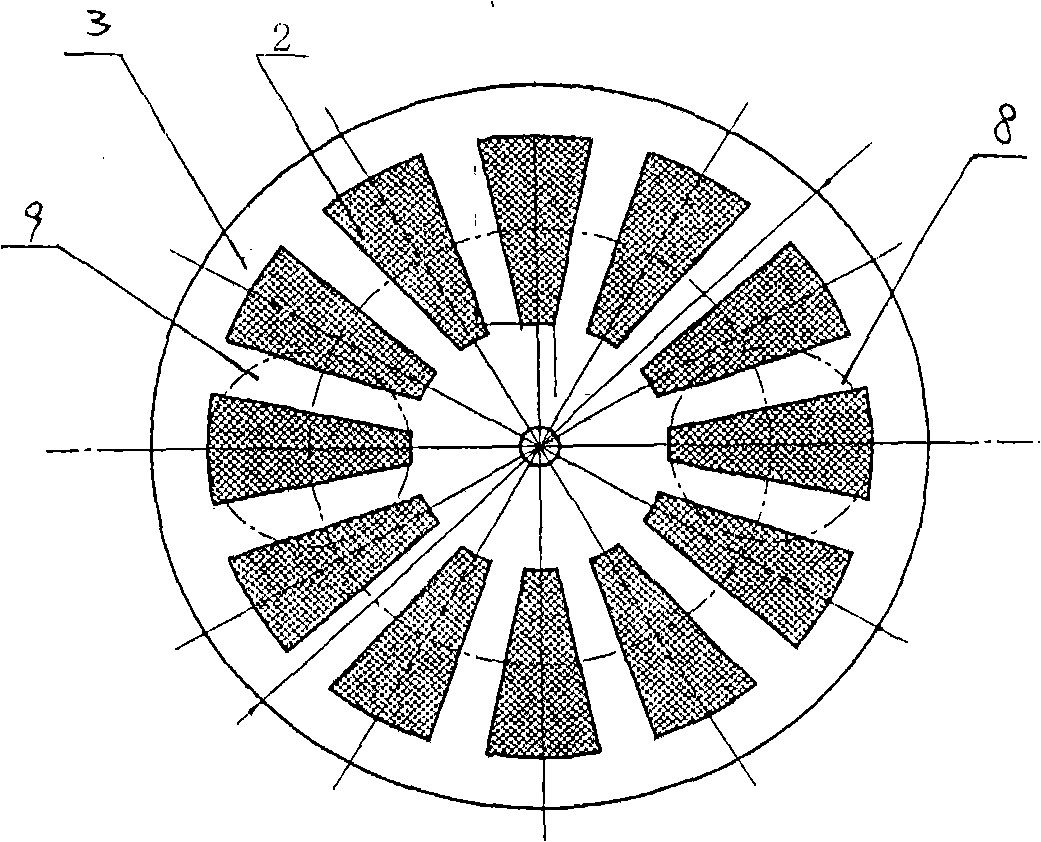

Mass transfer and reaction equipment for reverse airflow shearing and rotating packed bed

ActiveCN103463829AIncrease shear stressEasy to separateDispersed particle separationLiquid-gas reaction processesAir liquid interfaceShear stress

The invention belongs to the technical field of mass transfer reaction equipment, and particularly relates to mass transfer and reaction equipment for a reverse airflow shearing and rotating packed bed which solves the problems of the existing ultragravity equipment in the aspect of air phase mass transfer. The mass transfer and reaction equipment comprises a rotating bed main body, an equipment bracket and a transmission device, wherein the rotating bed main body comprises an upper part and a lower part which are an air collection chamber and a main cavity; the main cavity is internally provided with a packing rotor capable of rotating at a high speed; the upper part of the main cavity is connected with an air inlet pipe; the bottom of the main cavity is connected with a drainage pipe; the center of the packing rotor is provided with a liquid distributor; the liquid distributor is connected with a liquid inlet pipe; the top of the air collection chamber is connected with an exhaust pipe; an opening in the top of the packing rotor is communicated with the air collection chamber. The mass transfer and reaction equipment has the beneficial effects that the shearing stress for fluid can be increased, more momentum is transferred to interior fluid by packing, the boundary layer separation of air liquid is promoted, the degree of turbulence is increased, and the update rate of air liquid interface is increased, and thus the purpose of strengthening the air phase mass transfer is achieved; the operation stability is improved, and the equipment is suitable for high throughput occasions; the air collection chamber effectively inhibits the influences on operation balance caused by entrainment and flooding.

Owner:ZHONGBEI UNIV

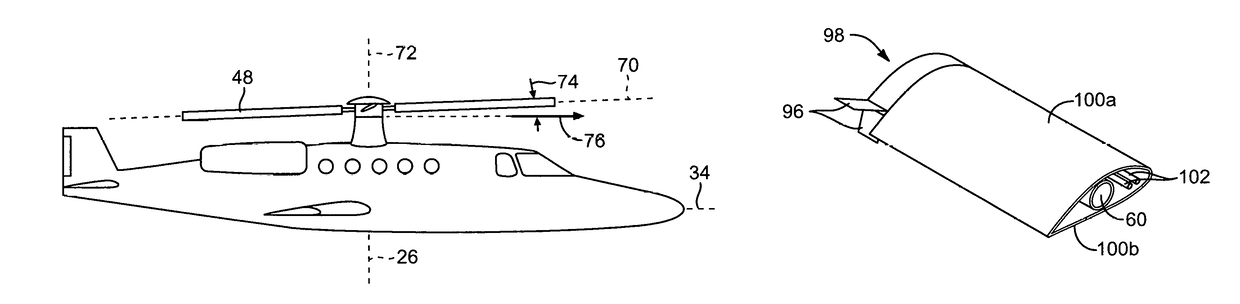

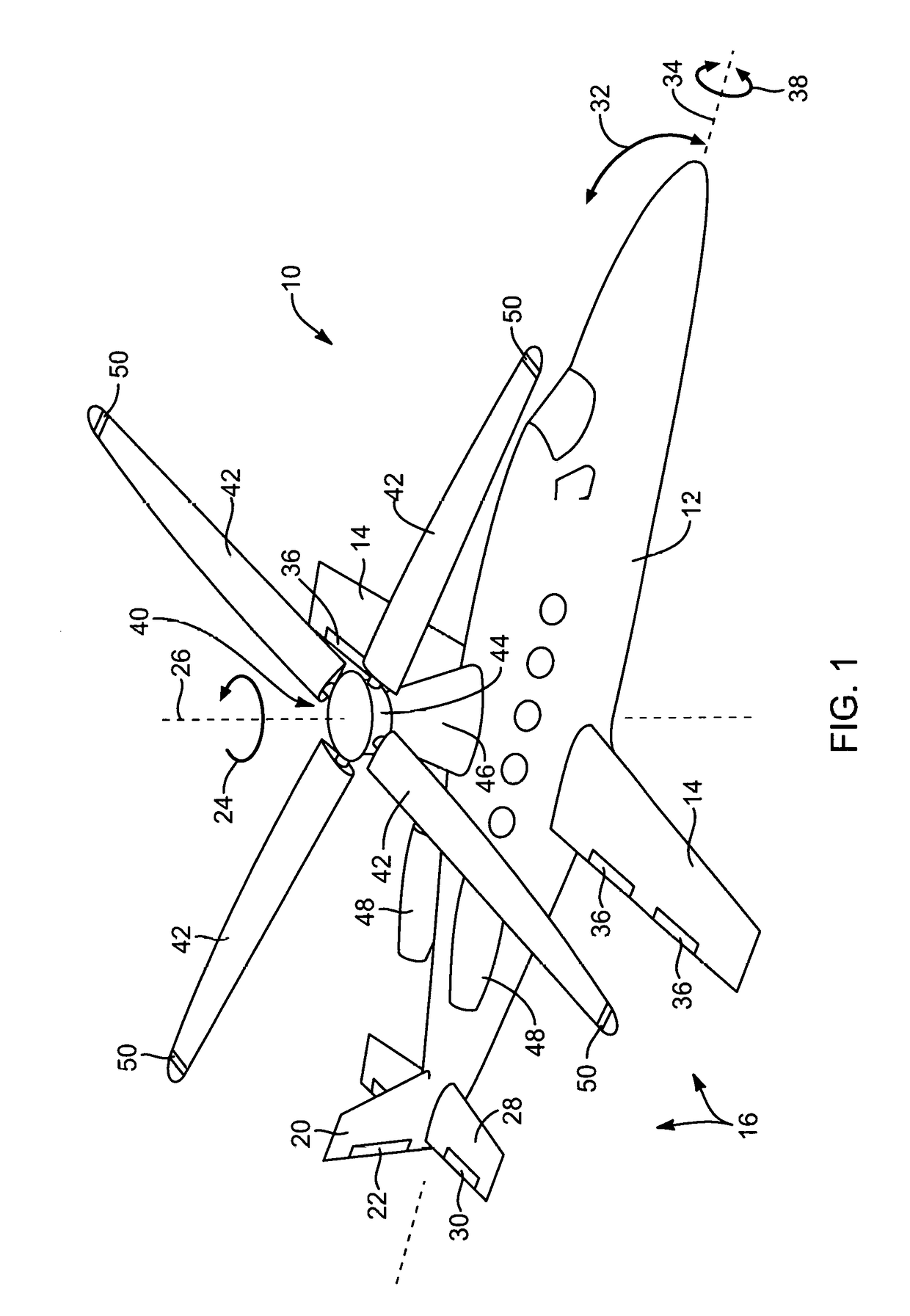

Apparatus and method for roll moment equalization at high advance ratios for rotary wing aircraft

A method for equalizing rolling moments at high advance ratios is disclosed including impelling an aircraft in a forward direction at an airspeed by means of a thrust source and rotating a rotor of the aircraft at an angular velocity with respect to the airspeed effective to cause a positive total lift on each blade due to air flow over the blades in the retreating direction when the blade is moving in the retreating direction. The rotor includes an even number of blades placed at equal angular intervals around the rotor hub. One or both of cyclic pitch and rotor angle of attack are adjusted such that a rolling moment of the retreating blade due to reverse air flow is between 0.3 and 0.7 times a rolling moment on the advancing blade due to lift.

Owner:SKYWORKS GLOBAL INC

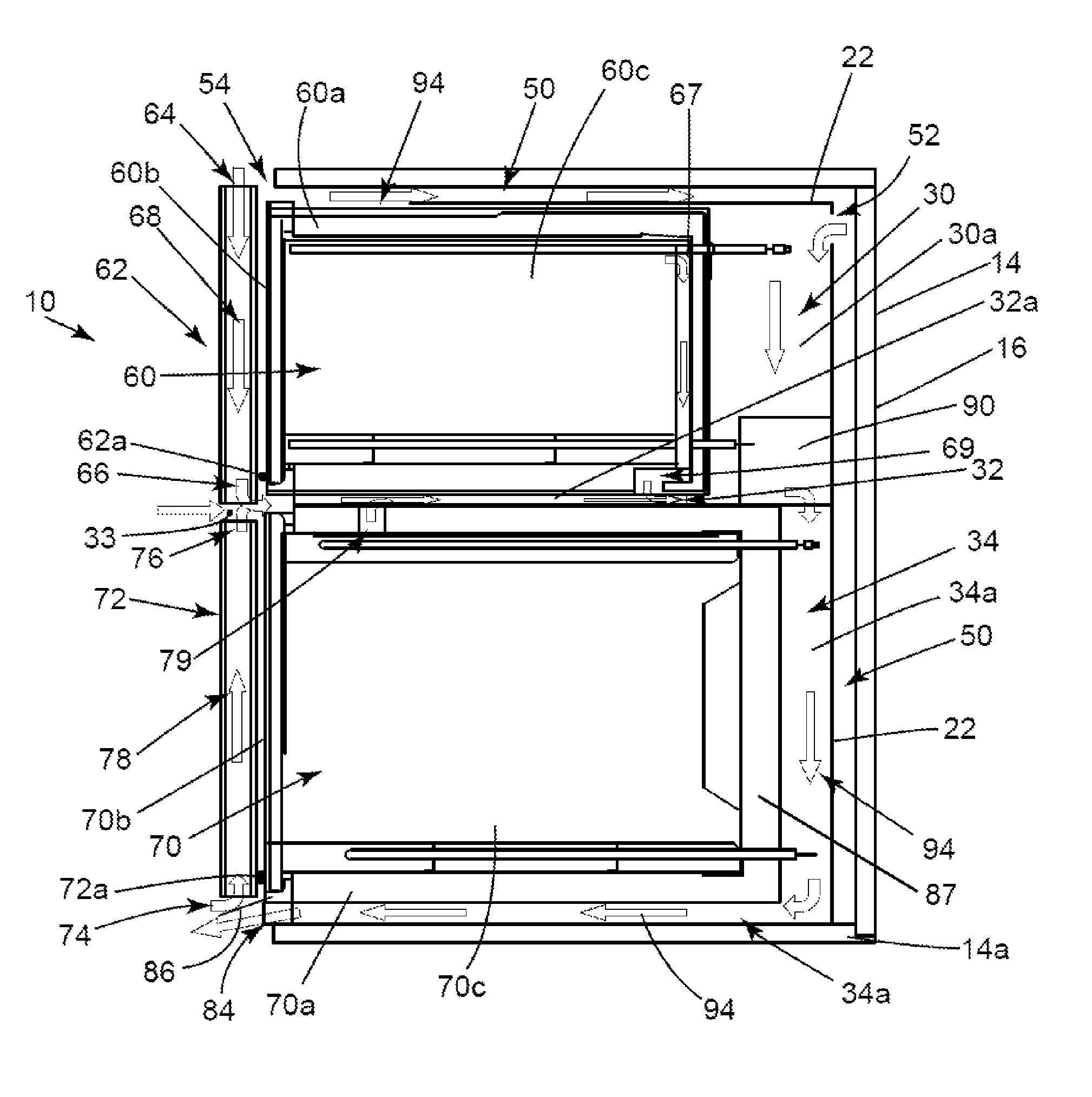

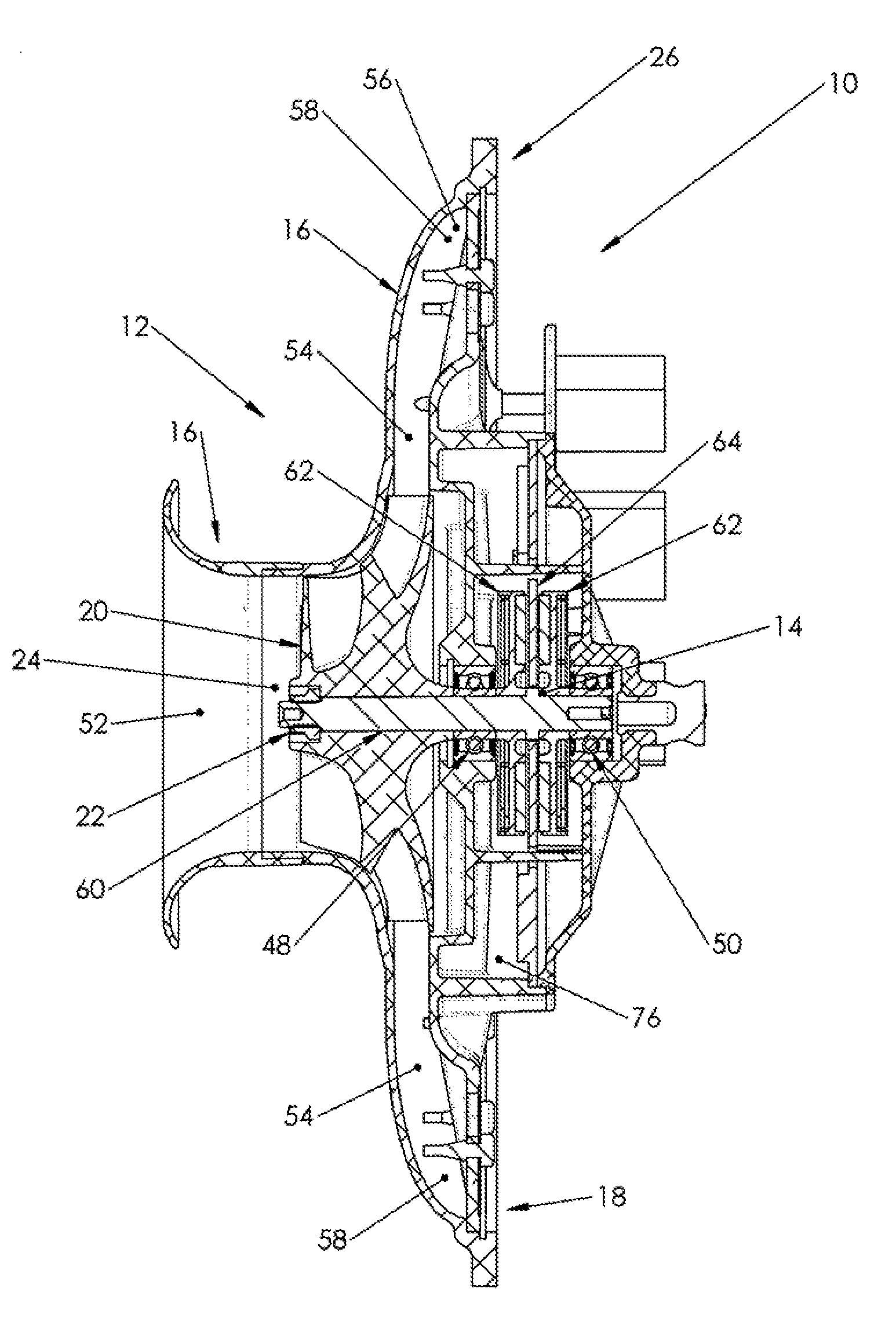

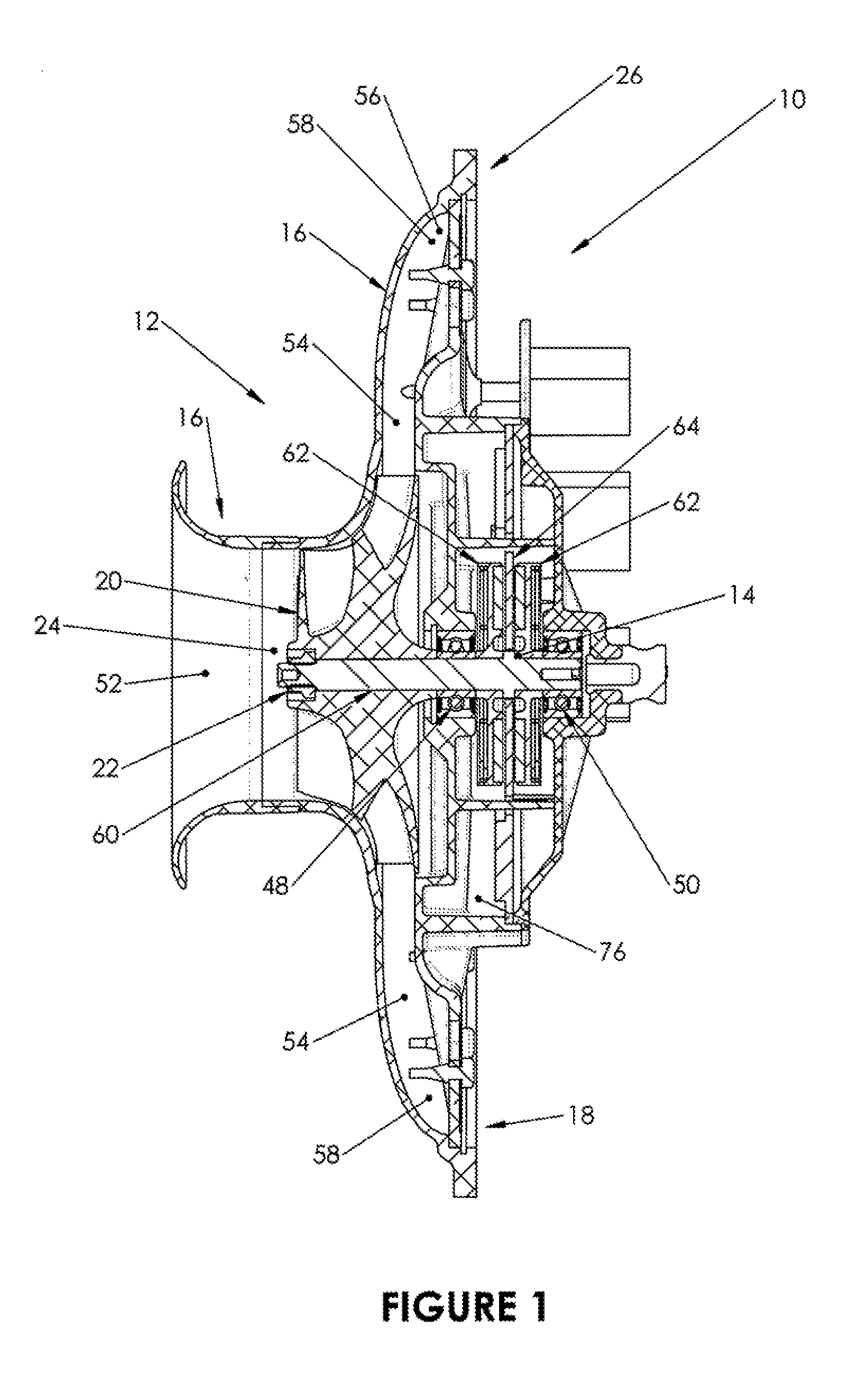

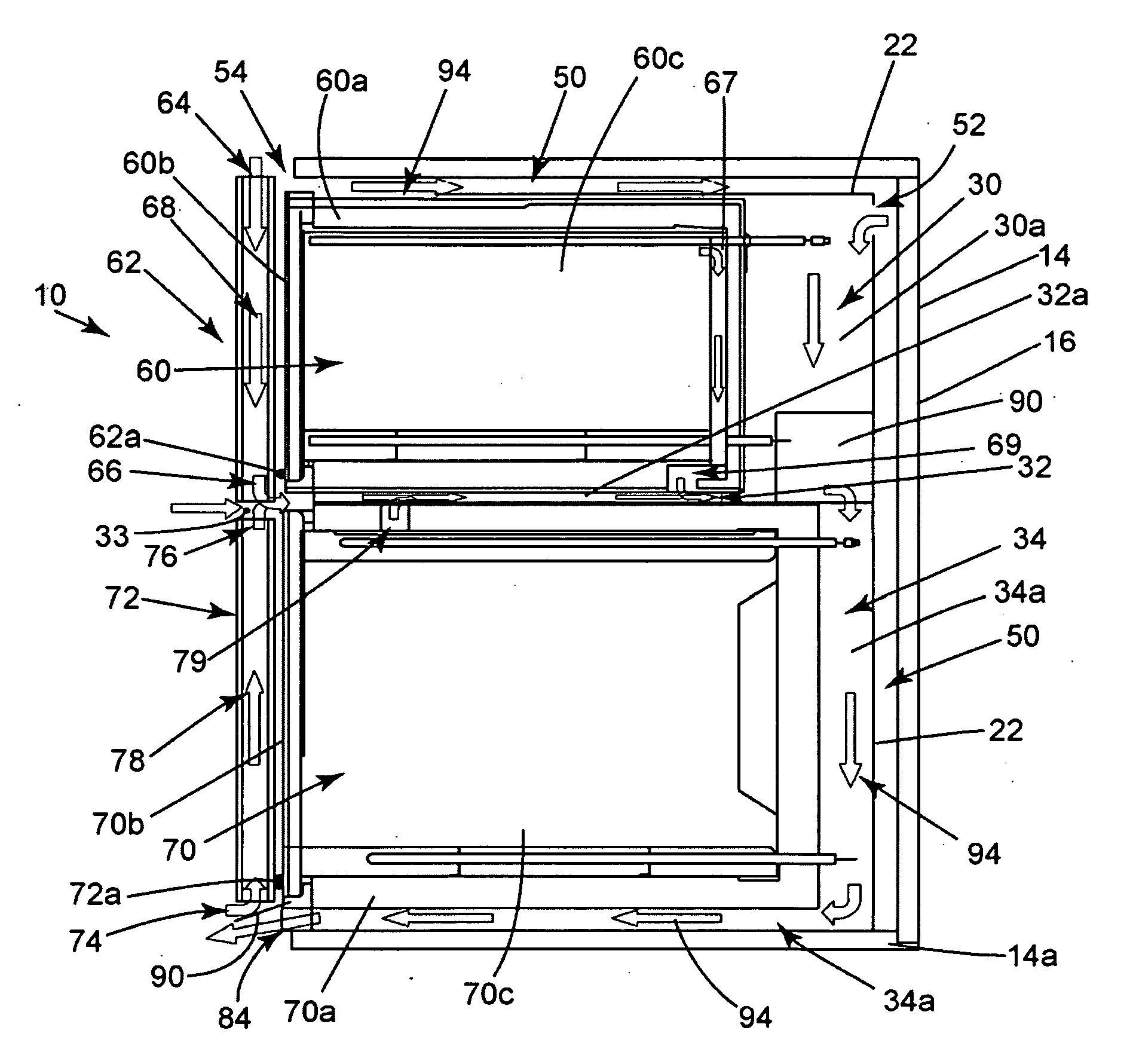

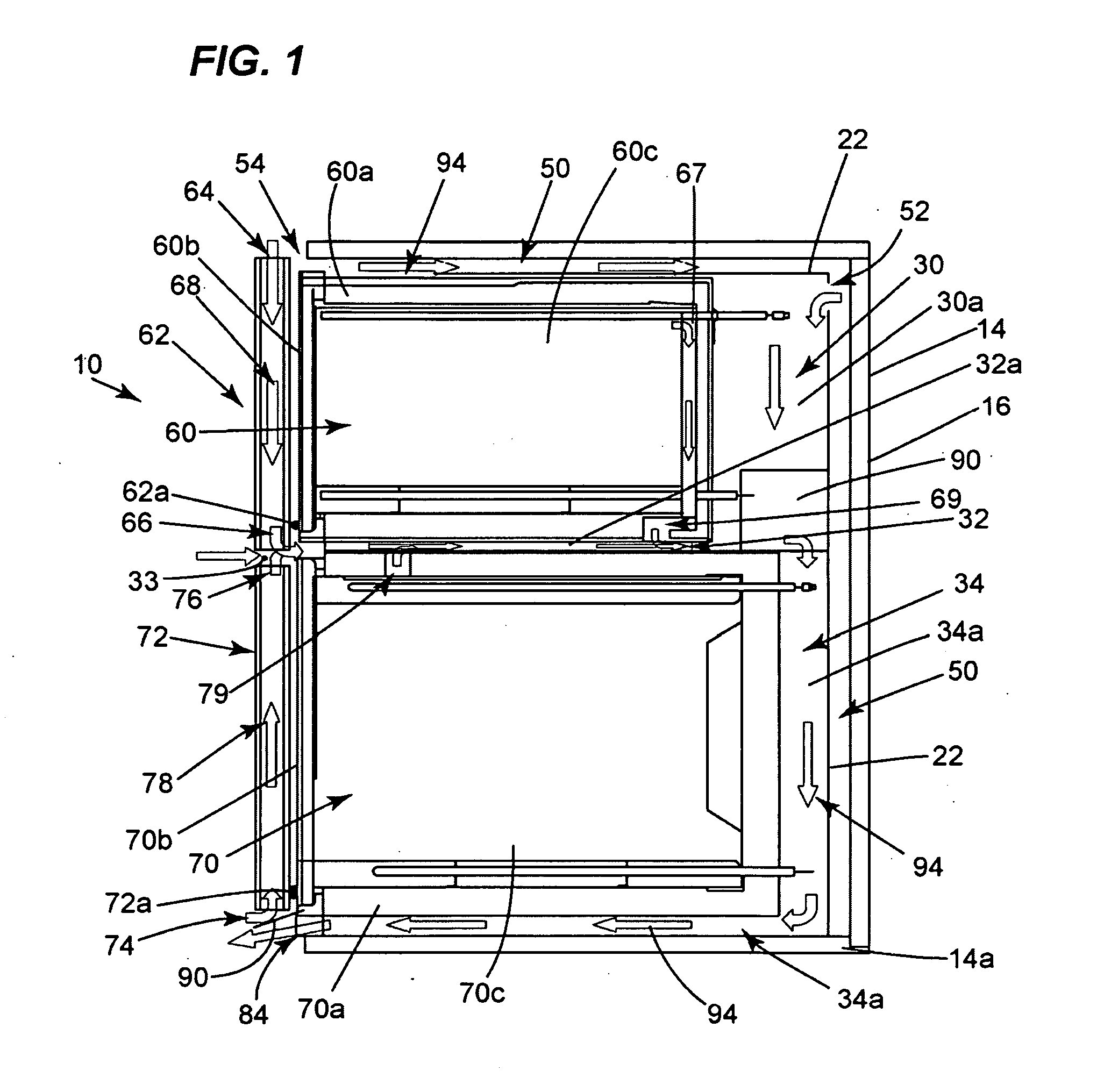

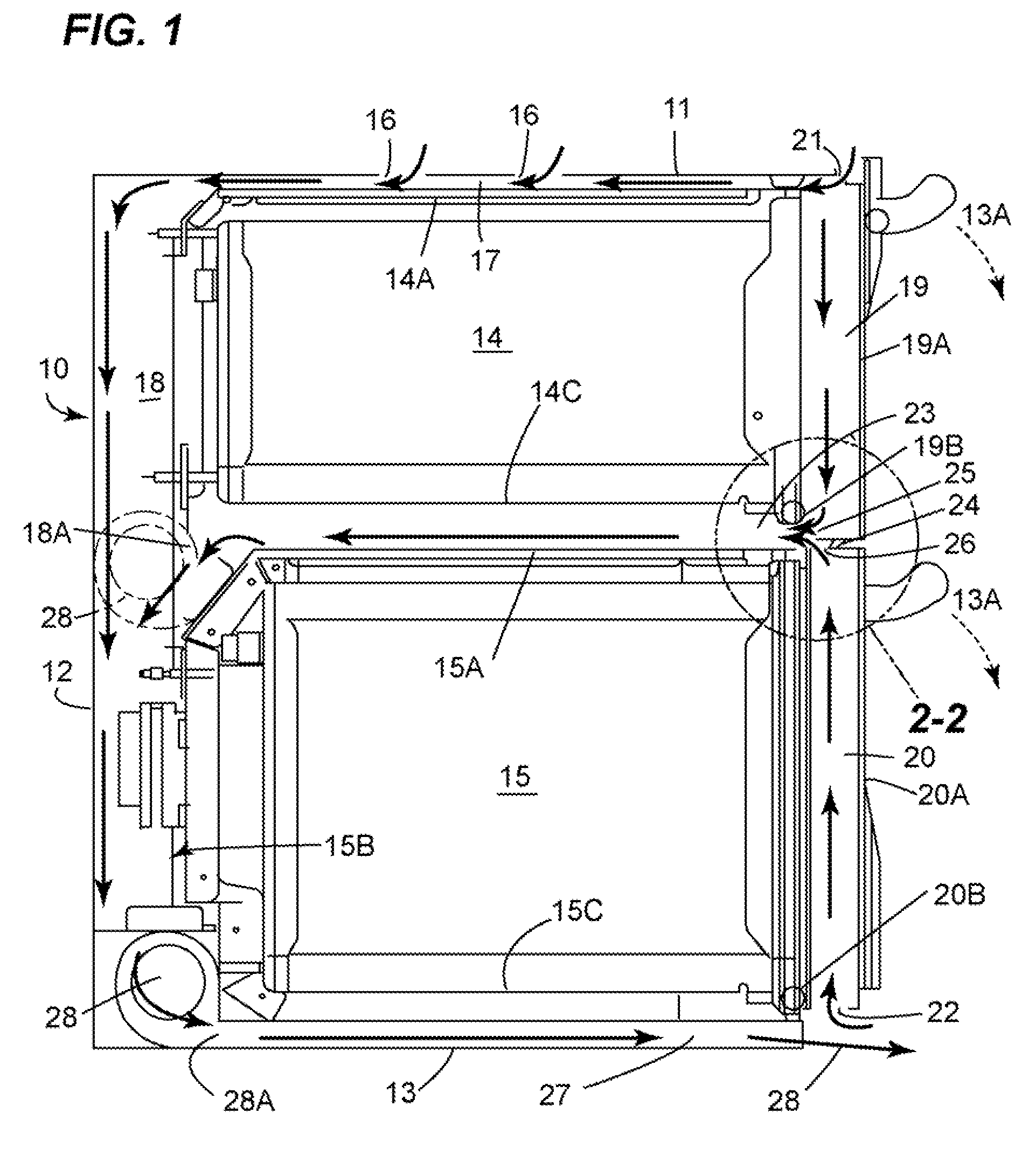

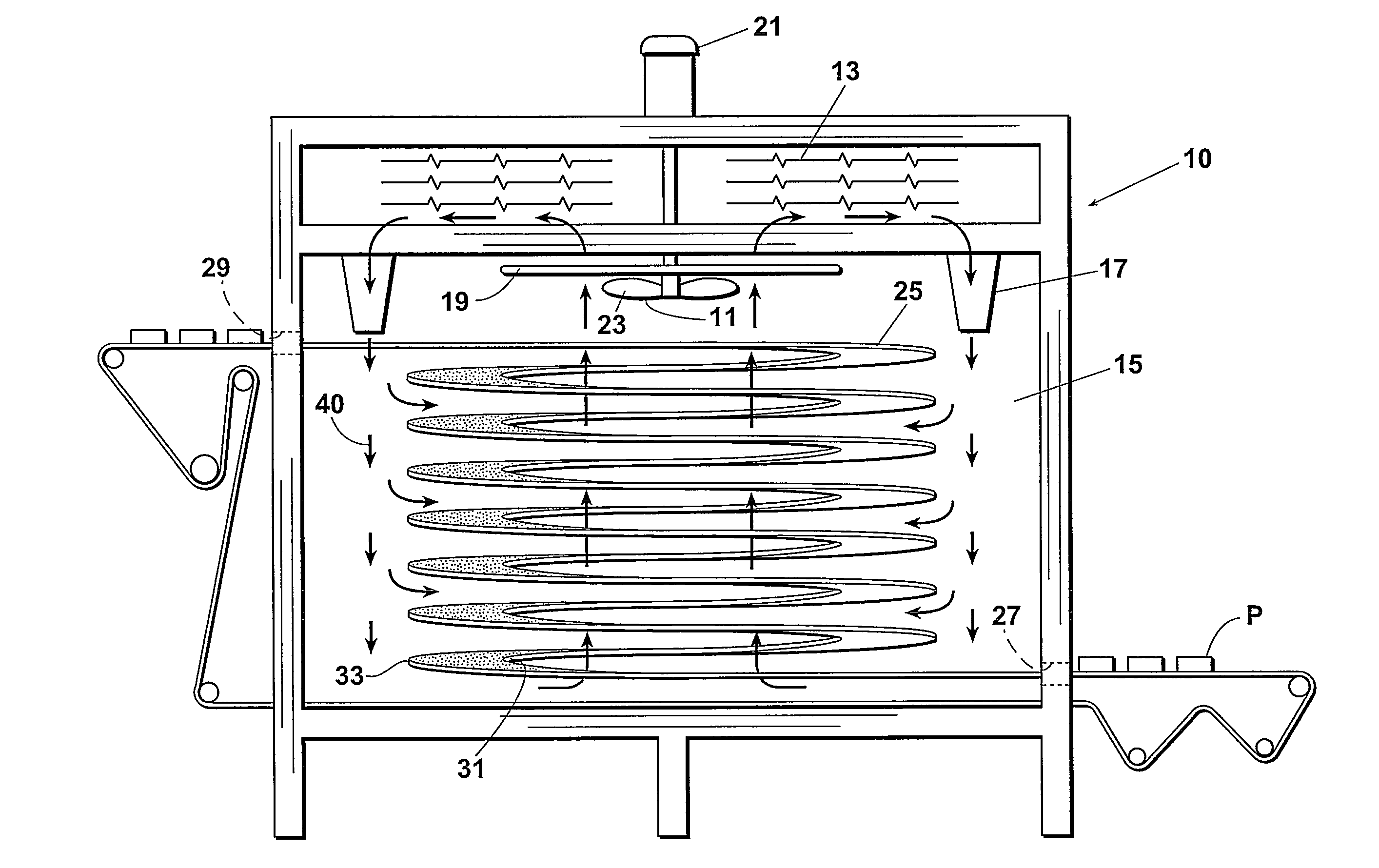

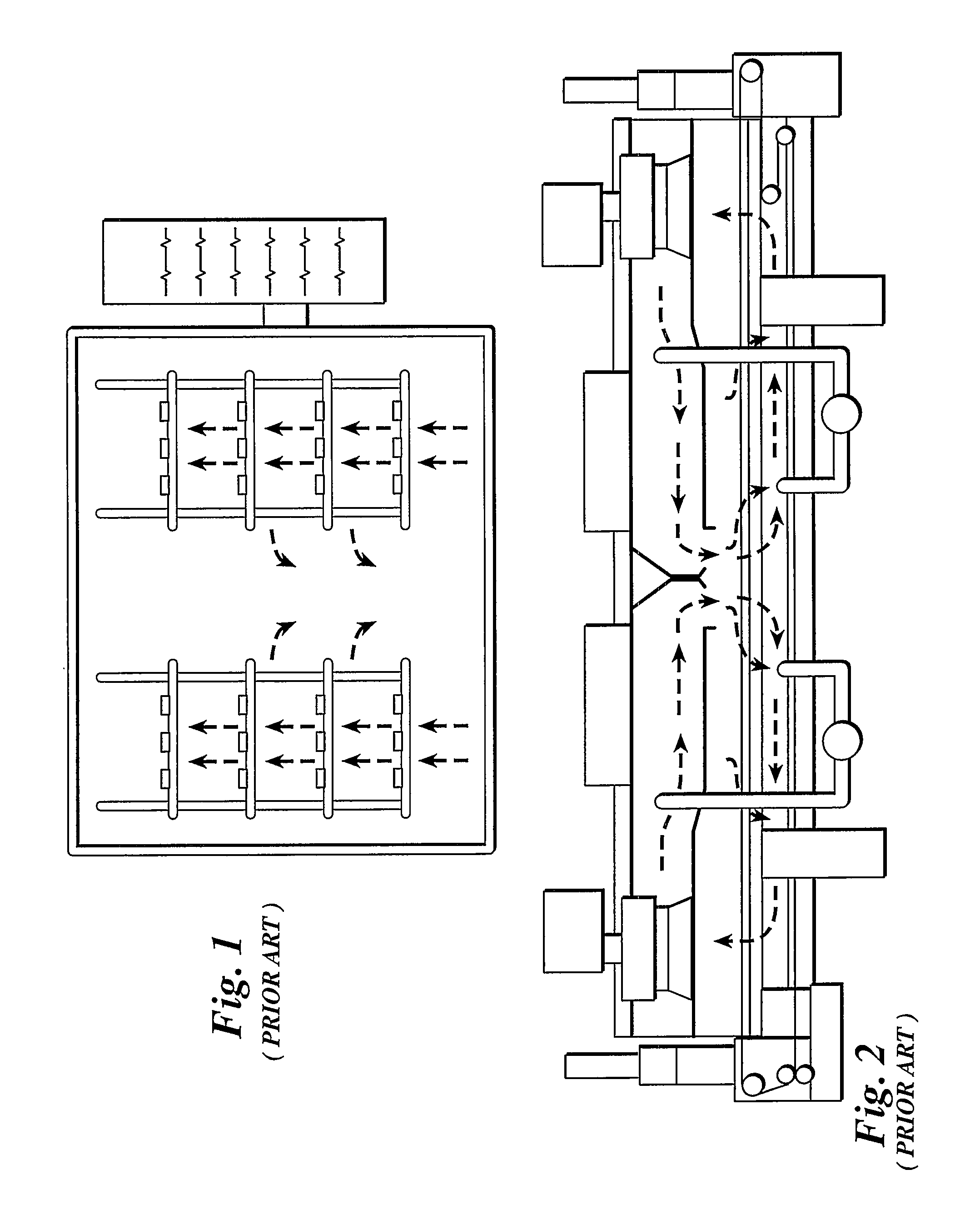

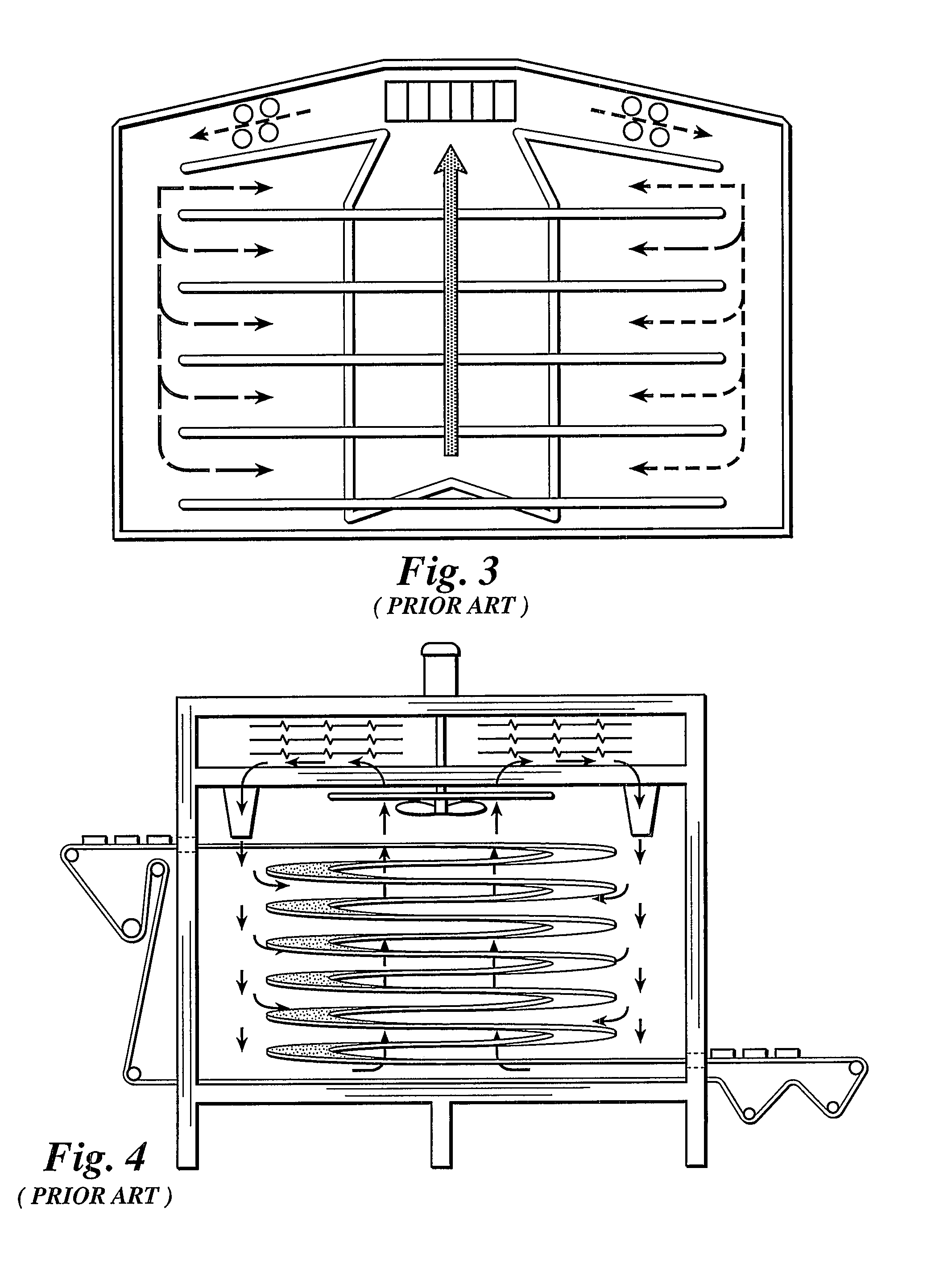

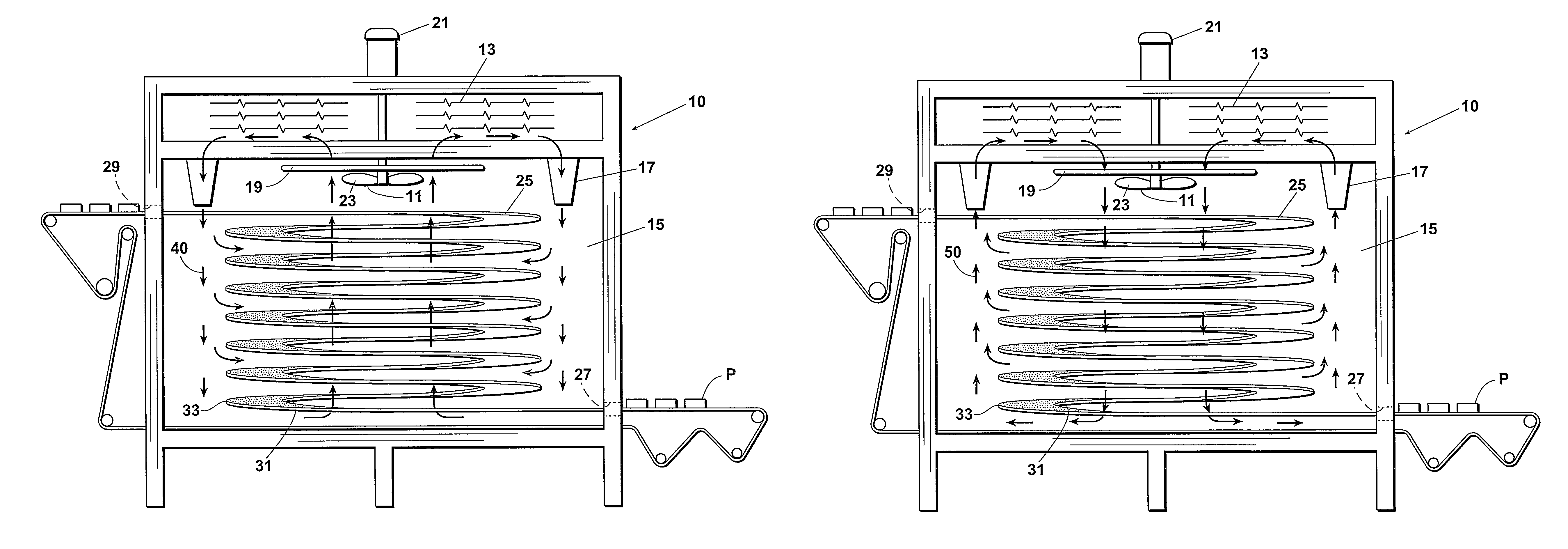

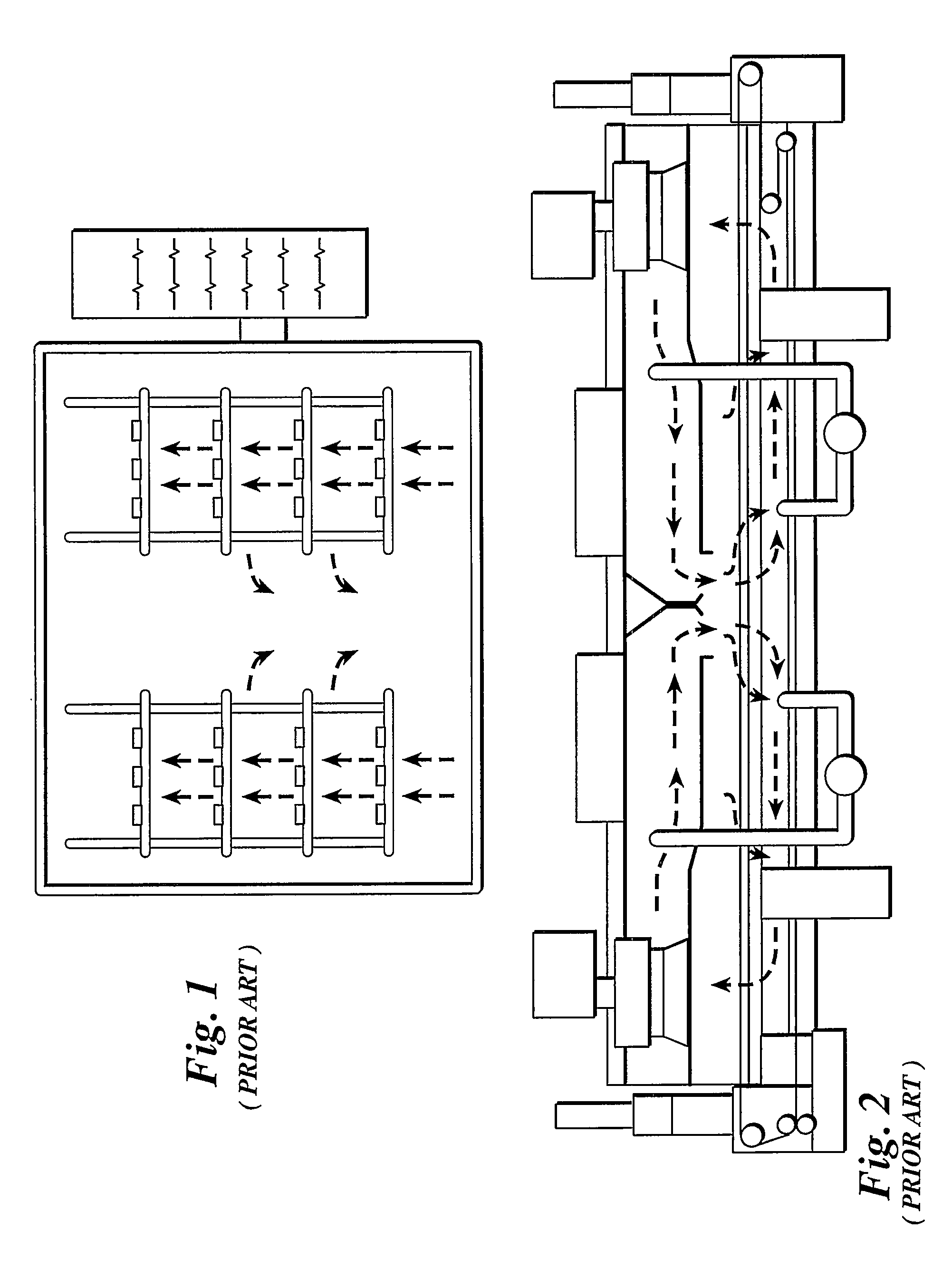

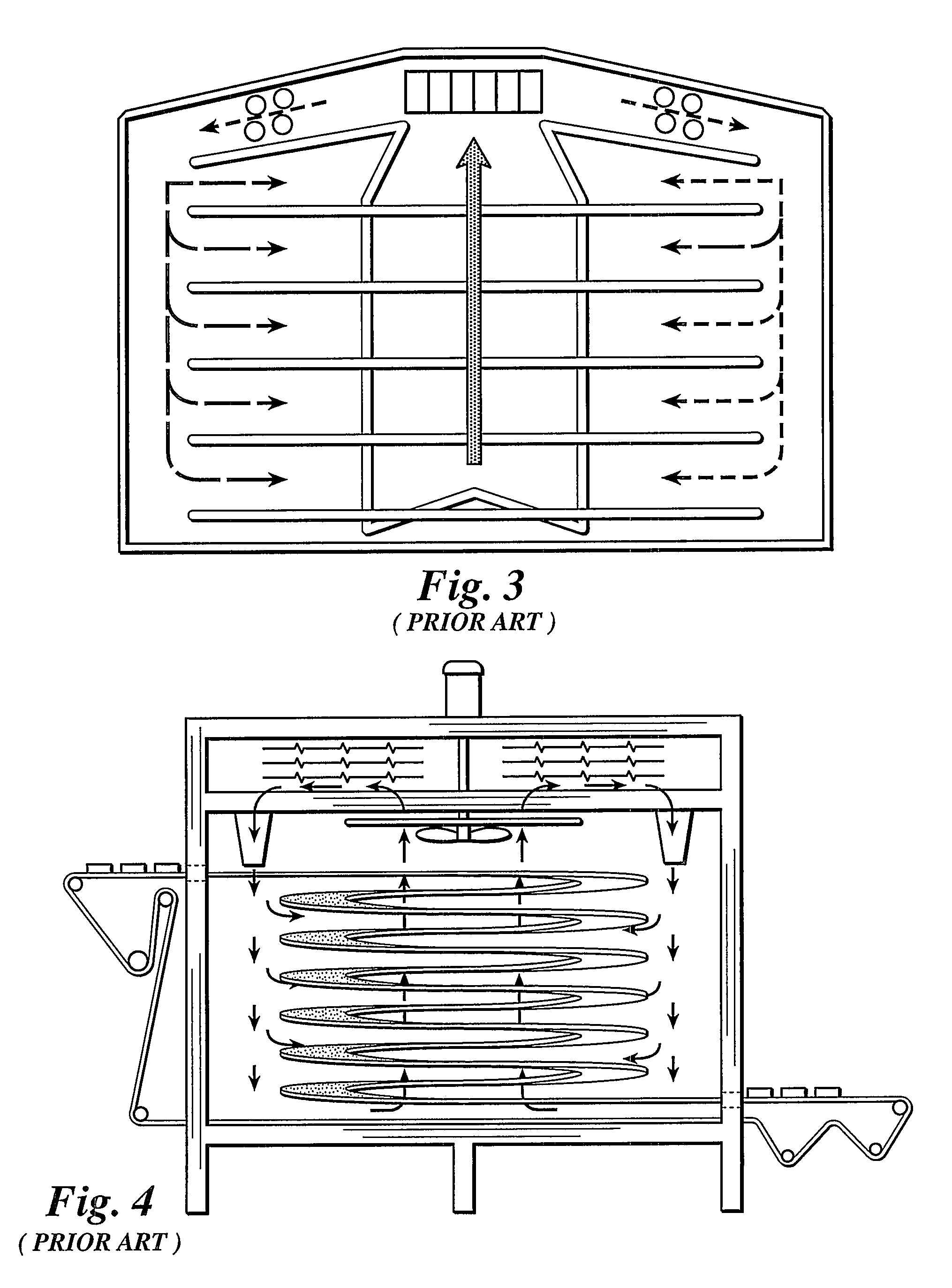

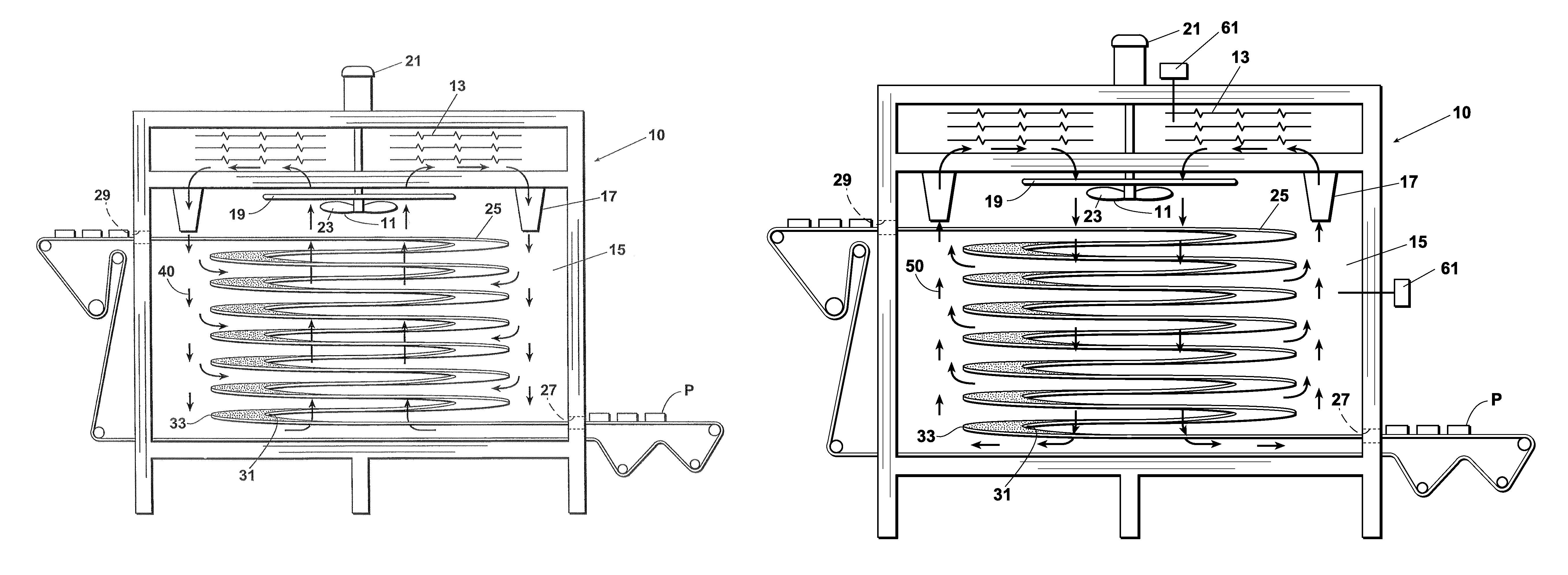

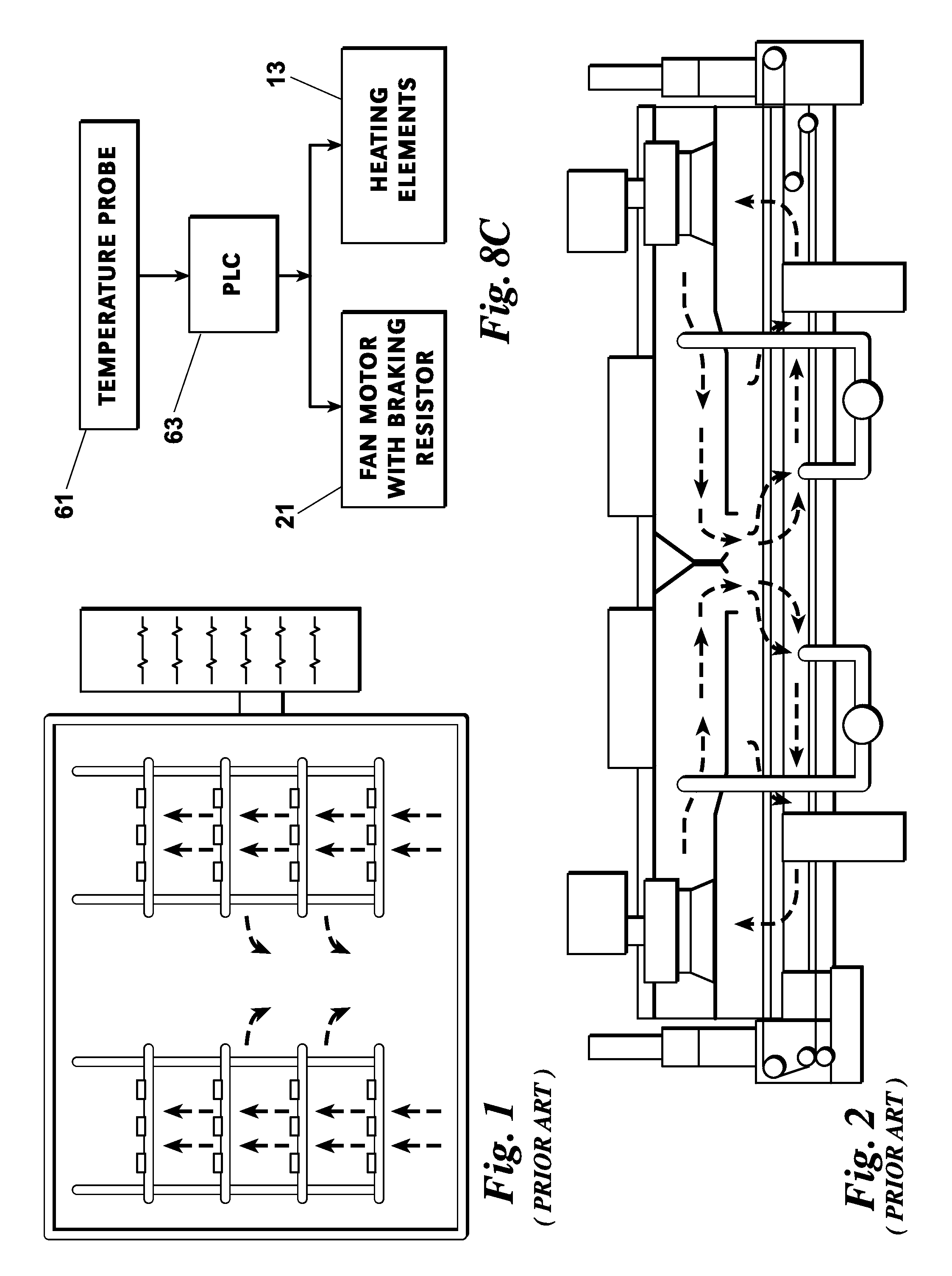

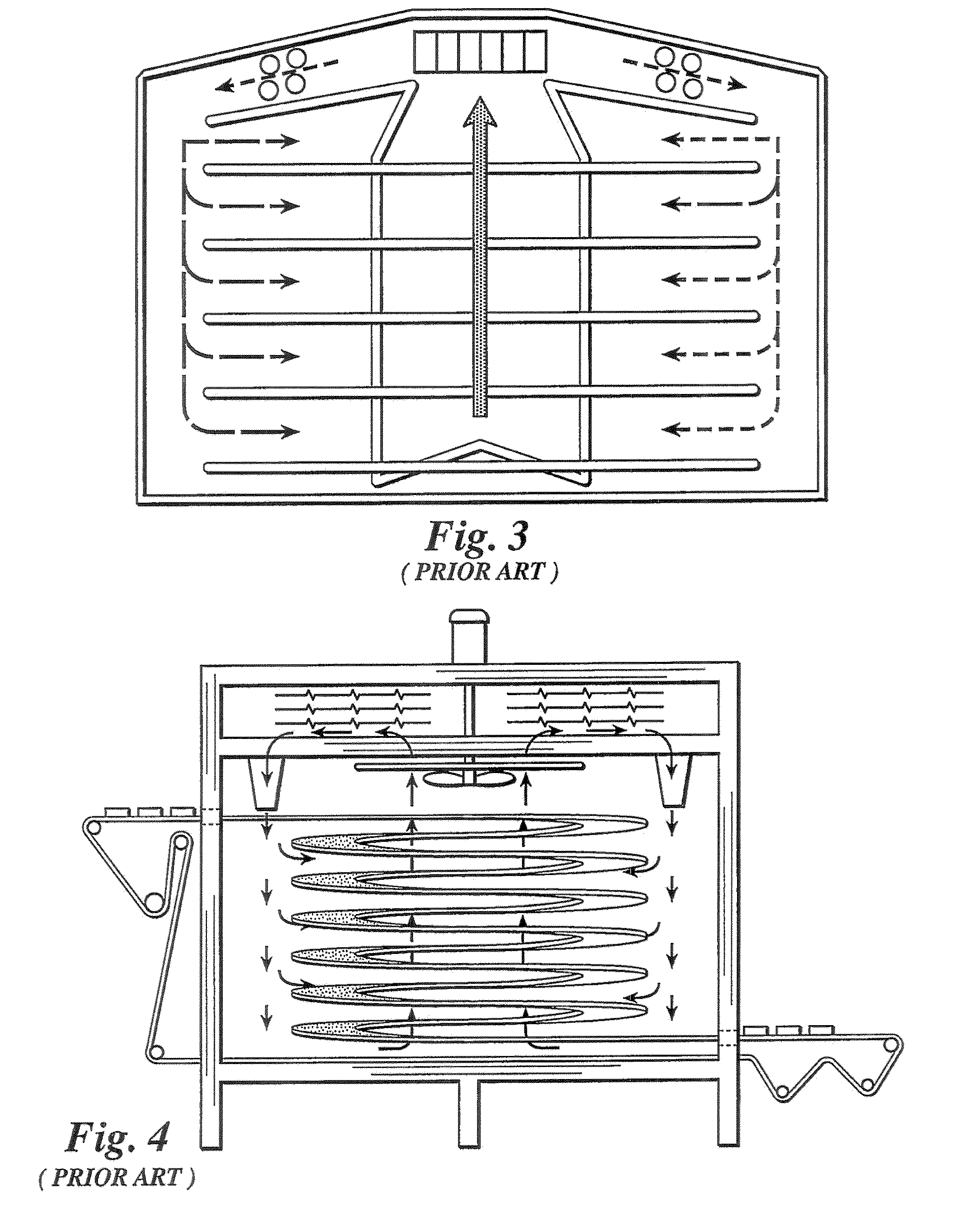

Airflow Pattern for Spiral Ovens

ActiveUS20120318254A1Reduce and eliminate temperature differenceLow costDomestic stoves or rangesLighting and heating apparatusResidence timeReverse airflow

An improved spiral oven and method for its use includes the step of using a forward / reversing fan to produce a first airflow and a second inverted airflow in the cooking chamber. The proportion of time each airflow occurs may be unbalanced within an oven residence time or cook cycle, and either airflow may begin the cycle. The first airflow creates a flow across the cook belt predominantly at the top and bottom tiers, whereas the second airflow creates this flow predominantly in the middle tiers. A braking resistor allows the fan to quickly changeover between full-forward and full-reverse directions. Because of the reversing airflow pattern, the product cooks more evenly across the cook belt.

Owner:MARLEN INT

Method for Detecting Compressor Surge in a Fuel Cell System Using a Mass Flow Meter

A method for detecting compressor surge in a fuel cell system. The system includes a turbomachine compressor that delivers charge air to the cathode side of a fuel cell module. A bi-directional mass flow meter measures the airflow through the compressor, and provides an indication of a reverse airflow through the compressor for surge protection. A controller receives a signal from the mass flow meter indicative of the reverse flow. The controller controls a motor driving the compressor and a back pressure valve at the cathode exhaust of the fuel cell module to control the pressure in the fuel cell module to remove the surge condition.

Owner:GM GLOBAL TECH OPERATIONS LLC

Rotor or propeller blade with dynamically variable geometry and other properties

A blade is provided for the cycloidal marine propellers or cycloidal aerial rotors. Said blade is provided with the capabilities, in response to the control system commands to dynamically and in real time; flex itself along its chord in any required way, vary its relative pivot point position, change its planform by extending or retracting a trailing edge extension, differentially if needed on the right and left, turn the flap along the trailing edge in either direction or allow it to be turned by the flows. Said blade is also optionally provided with one or more elastic trailing edges whose stiffness is dynamically, and possibly differentially along the blade span, variable by the control system. For the reversal of the leading and trailing edges for operation in reverse airflow and other conditions the blades are provided with edges that can be made rigid when functioning as the leading edge and flexible if needed when functioning as the trailing edge. Also the blades are provided with the capability of varying their cross-sectional profile thickness and reshaping it. Finally the blades are given on command flow permeability along much of their surface. These capabilities will enable each control system controlled blade to continually optimally adjust to and make the best use of its immediate operating environment as it travels along its trajectory within each revolution.

Owner:OPTIVECTOR LTD

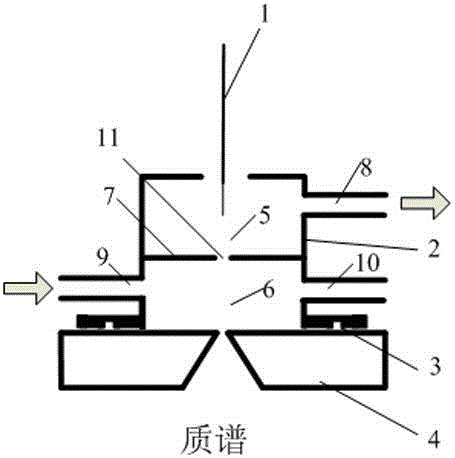

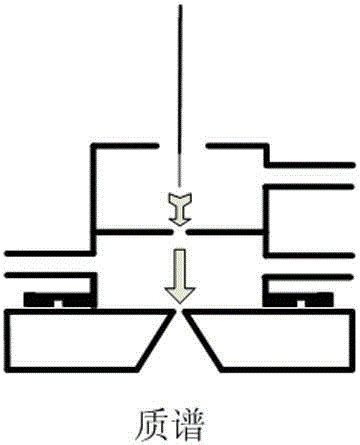

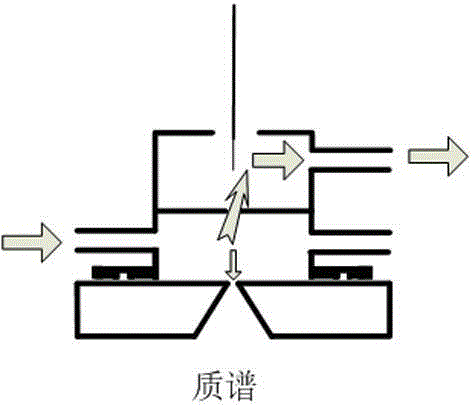

Two-area reverse airflow atmospheric pressure chemical ionization source

InactiveCN105206499AReduce ionization effectsReduce formationMaterial analysis by electric/magnetic meansIon sources/gunsMass spectrometryIonization

A two-area reverse airflow atmospheric pressure chemical ionization source comprises an ionization source cavity, a discharge needle, a sample inlet and a mass spectrum sample entering conical port and is characterized in that the ionization source cavity is divided by a partition board into an upper part and a lower part, the upper part is a discharging area, the lower part is an ionization area, the two areas are communicated through a center small hole of the partition board, a gas exhaust port is formed in the discharging area, and a gas blowing inlet is formed in the ionization area. The ionization process includes the steps that sample gas enters the ionization area from the sample inlet, part of the sample gas reaches the discharging area through the small hole formed in the middle of the ionization source cavity and then is exhausted through the gas exhaust port, and the other part of the sample gas enters an online mass spectrum through the conical port. Discharging happens between the discharging needle and the small hole of the ionization source cavity, reagent ions generated during discharging are introduced into the ionization area through a strong electric field, and the sample gas and the reagent ions are ionized in the ionization area. Neutral products generated during discharging can be easily blown by airflow of the small hole of the ionization source cavity, and therefore the neutral products flowing to the ionization area are reduced, and influences of the neutral products generated in the discharging process on ionization of sample molecules are reduced.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

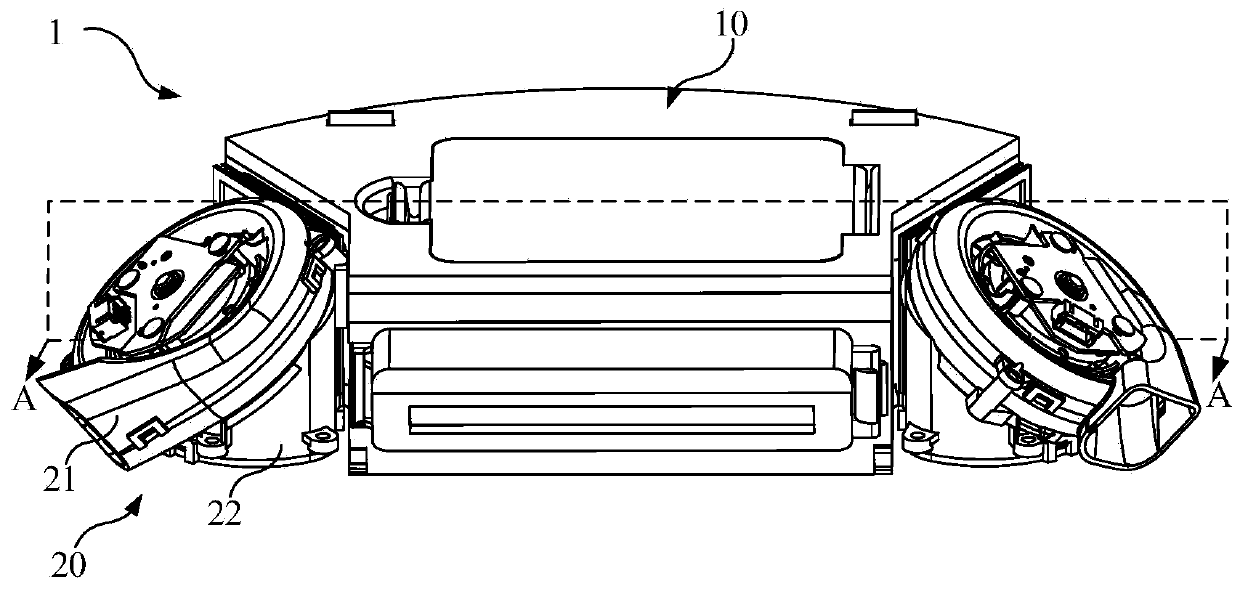

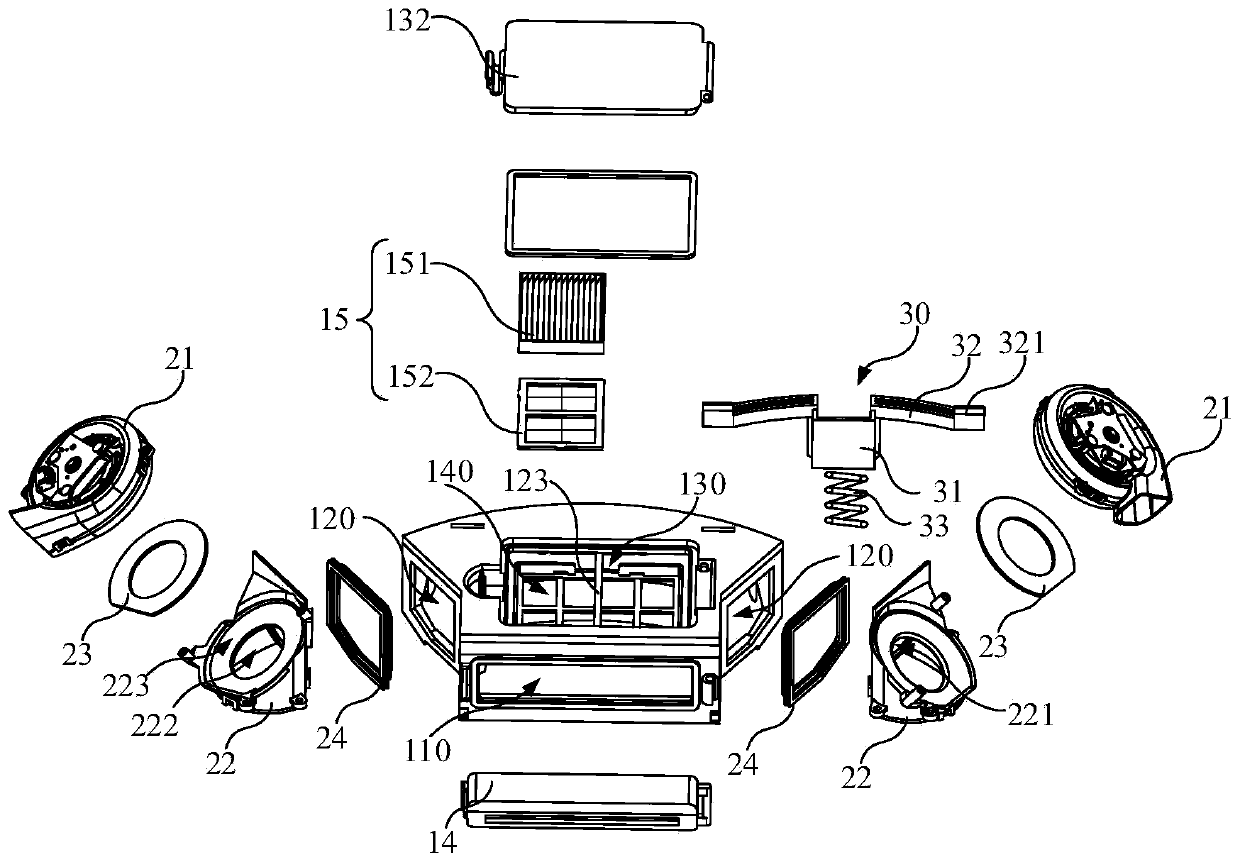

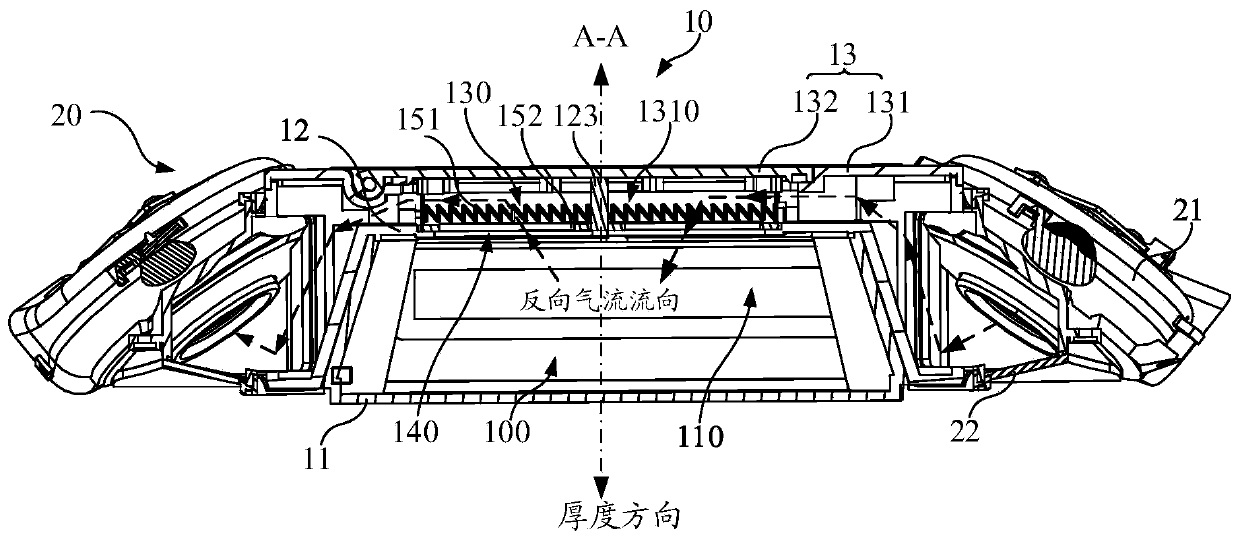

Dust box self-cleaning system, dust box assembly, cleaning device and self-cleaning method

PendingCN111281275ARealize self-cleaningReduce the number of disassemblyCleaning filter meansCarpet cleanersEnvironmental engineeringCleaning methods

The invention discloses a dust box self-cleaning system, a dust box assembly, a cleaning device and a self-cleaning method. The dust box assembly comprises a dust box, at least two filtering pieces and at least two draught fans. A containing cavity and a channel cavity which are arranged at an interval are formed in the dust box; the channel cavity is provided with at least two channel sub-cavities which are independent of each other, at least two communicating openings which are formed at intervals are formed in the dust box, each communicating opening is correspondingly communicated with atleast one channel sub-cavity and the containing cavity, the dust box is further provided with at least two air outlets, and each air outlet is correspondingly communicated with at least one channel sub-cavity; the at least two filtering pieces are arranged corresponding to the at least two communicating openings; and each communicating opening is provided with at least one filtering piece, when part of the fans work and the other fans do not work, reverse airflow sequentially passing through the air outlets corresponding to the other fans, the channel sub-cavities and the communicating openings can be formed in the dust box, and then the filtering pieces corresponding to the other fans which do not work are cleaned. By means of the mode, the filtering pieces can be conveniently and rapidlycleaned.

Owner:ANKER INNOVATIONS TECH CO LTD

Airflow pattern for spiral ovens

ActiveUS9220276B2Quick conversionCook evenlyDomestic stoves or rangesLighting and heating apparatusEngineeringResidence time

An improved spiral oven and method for its use includes the step of using a forward / reversing fan to produce a first airflow and a second inverted airflow in the cooking chamber. The proportion of time each airflow occurs may be unbalanced within an oven residence time or cook cycle, and either airflow may begin the cycle. The first airflow creates a flow across the cook belt predominantly at the top and bottom tiers, whereas the second airflow creates this flow predominantly in the middle tiers. A braking resistor allows the fan to quickly changeover between full-forward and full-reverse directions. Because of the reversing airflow pattern, the product cooks more evenly across the cook belt.

Owner:MARLEN INT

Airflow pattern for spiral ovens

ActiveUS9107422B2Quick conversionCook evenlyDomestic stoves or rangesLighting and heating apparatusEngineeringResidence time

An improved spiral oven and method for its use includes the step of using a forward / reversing fan to produce a first airflow and a second inverted airflow in the cooking chamber. The proportion of time each airflow occurs may be unbalanced within an oven residence time or cook cycle, and either airflow may begin the cycle. In addition, the fan velocity may vary so that the speed of the first airflow is different from the speed of the second airflow. A braking resistor allows the fan to quickly changeover between full-forward and full-reverse directions, while a programmable delay limits adjustments to the heat output control method until temperature variations caused by alternating between the first direction of rotation and the second direction of rotation have stabilized. Because of the reversing airflow pattern, the product cooks more evenly across the cook belt.

Owner:MARLEN INT

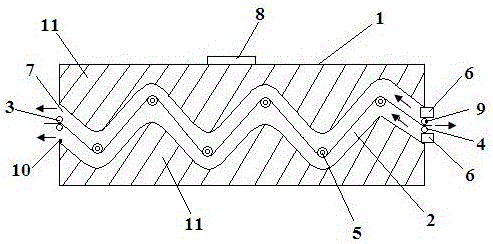

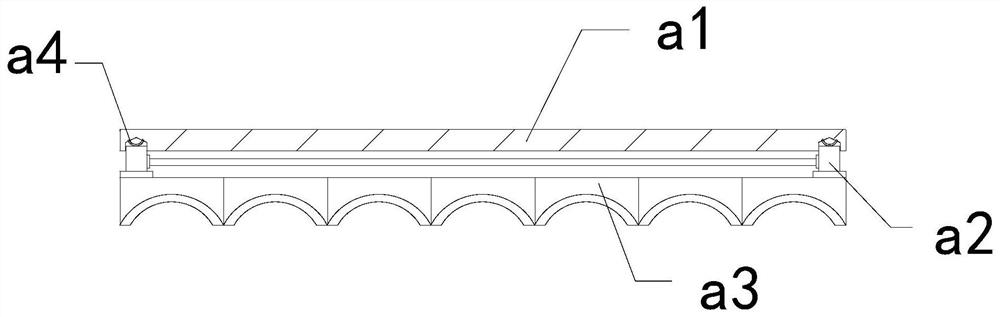

Intelligent hot air/electric heating dryer of textile fabric

InactiveCN106017025AAvoid deformationSmooth circulationDrying gas arrangementsDrying chambers/containersAutomatic controlAssembly line

An intelligent hot air / electric heating dryer for textile fabrics, comprising an oven body, a wavy cloth passage is arranged inside the oven body, and a plurality of cloth passages arranged in the same wave shape as the cloth passage are arranged in the middle of the oven body and have The material guide roller with heating function forms a cloth feeding line, the cloth feeding roller is arranged at the entrance of the cloth passage, the pulling roller is arranged at the outlet of the cloth passage, and the hot air blowing device is arranged at the cloth outlet of the cloth passage, and the cloth is The entrance is an air outlet; a humidity detector is arranged outside the pulling roller, and a temperature detector is arranged at the air outlet. The invention adopts wave-shaped cloth conveying and reverse airflow drying design, intelligently and automatically controls the drying program, realizes high-quality drying of cloth, improves drying efficiency, saves energy and reduces emissions.

Owner:WUXI ANG YIDA MACHINERY

Centrifugal compressor surge detection using a bi-directional MFM in a fuel cell system

A fuel cell system including a turbomachine compressor that delivers charge air to the cathode side of a fuel cell module. A bi-directional mass flow meter measures the airflow through the compressor, and provides an indication of a reverse airflow through the compressor for surge protection. A controller receives a signal from the mass flow meter indicative of the reverse flow. The controller controls a motor driving the compressor and a back pressure valve at the cathode exhaust of the fuel cell module to control the pressure in the fuel cell module to remove the surge condition.

Owner:GM GLOBAL TECH OPERATIONS LLC

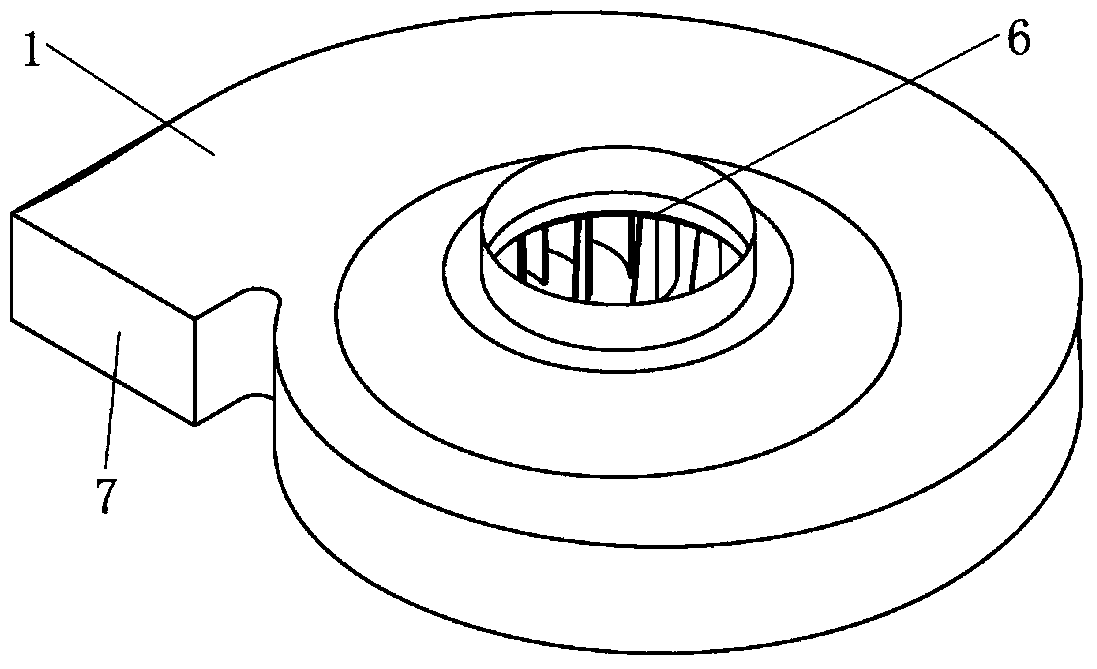

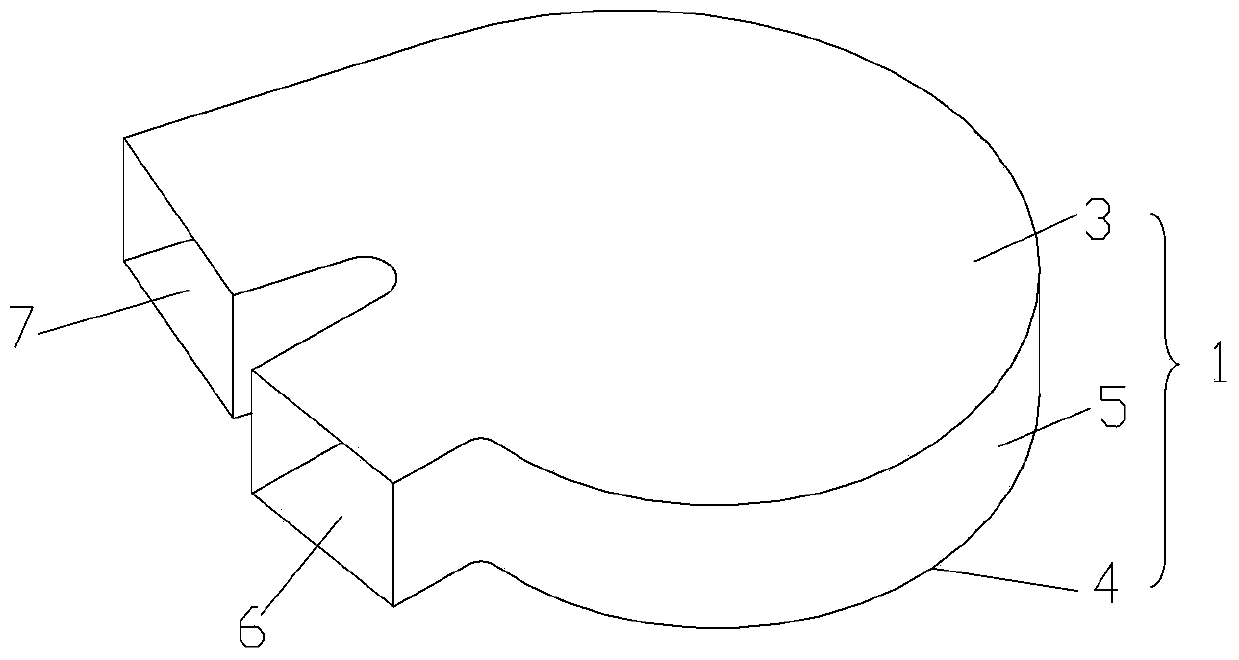

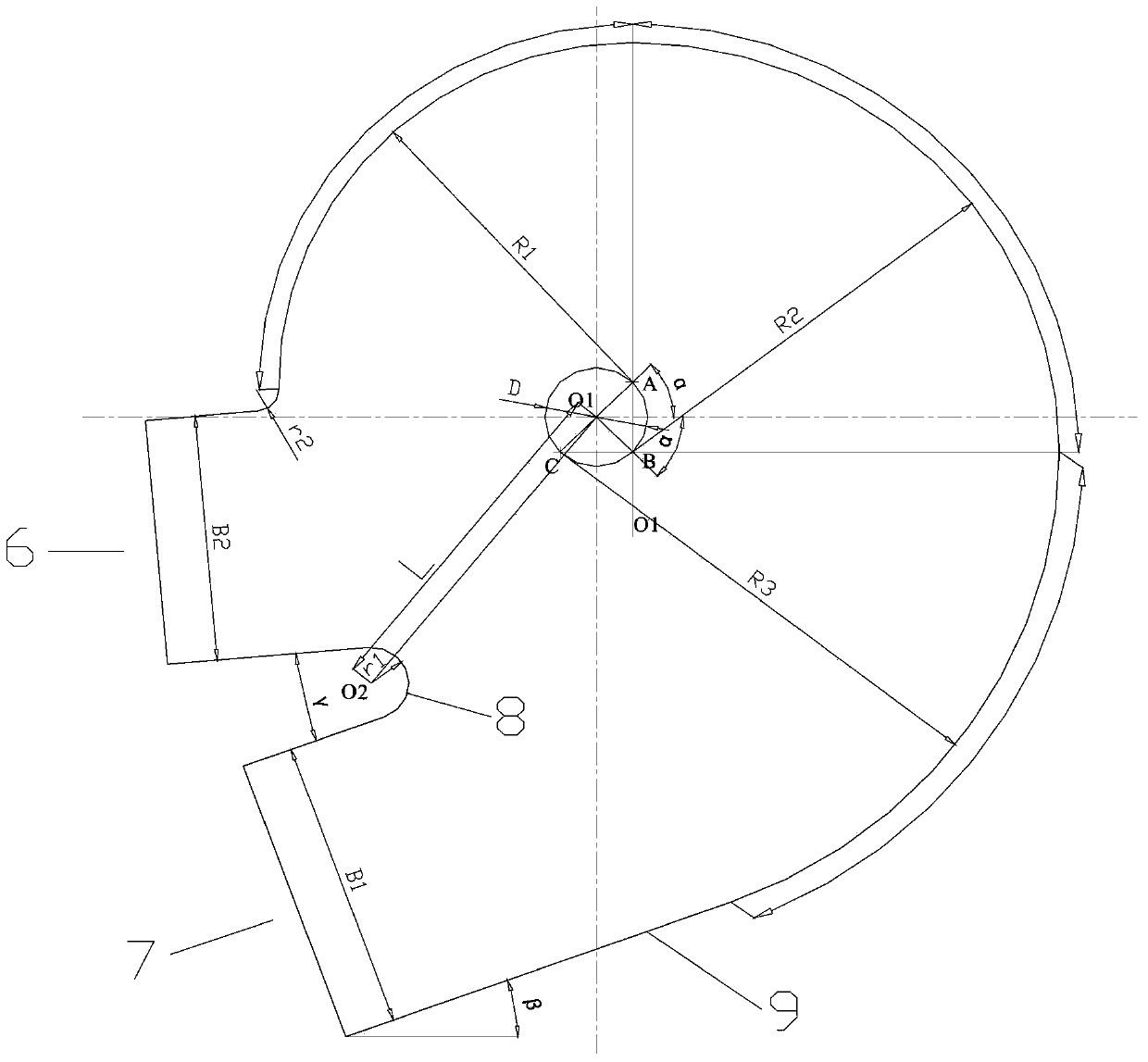

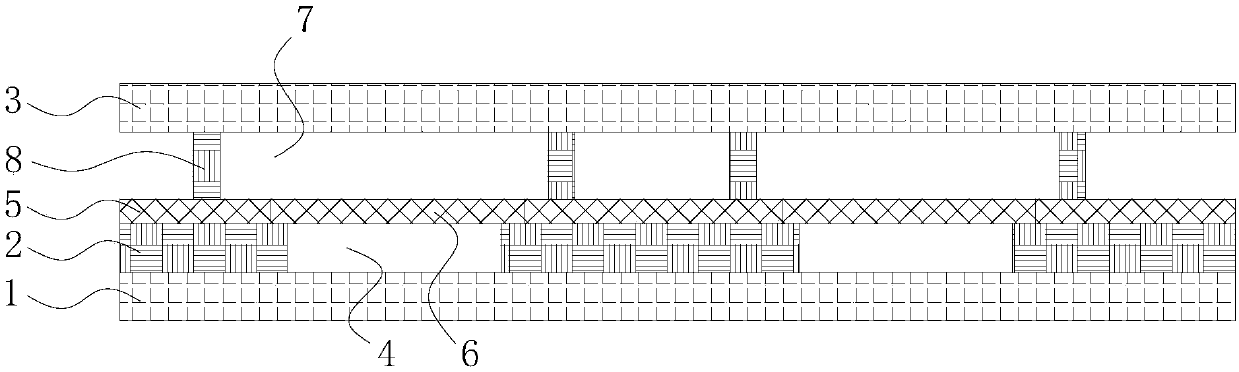

Centrifugal fan and road sweeper

The invention discloses a centrifugal fan and a road sweeper. The centrifugal fan comprises a volute and an impeller arranged in the volute. The volute comprises an air inlet, an air outlet, a front disk, a rear disk and a connecting part, wherein the front disk and the rear disk are arranged in parallel; the connecting part is arranged between the front disk and the rear disk; and both the air inlet and the air outlet are formed on the connecting part along the parallel direction of the front disk and the rear disk. The road sweeper comprises the centrifugal fan. When the centrifugal fan disclosed by the invention is applied to a certain specific equipment, for example, when the centrifugal fan is used in the road sweeper of which an air inlet pipeline and an air outlet pipeline are both in parallel to the front disk and the rear disk of the volute, a reversing elbow does not need to be specially arranged to reverse airflow in the volute and the airflow can directly enter the volute from the air inlet through the air inlet pipeline without being reversed, and thus, the space structural layout is simplified, pressure loss is avoided and noise is also reduced.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

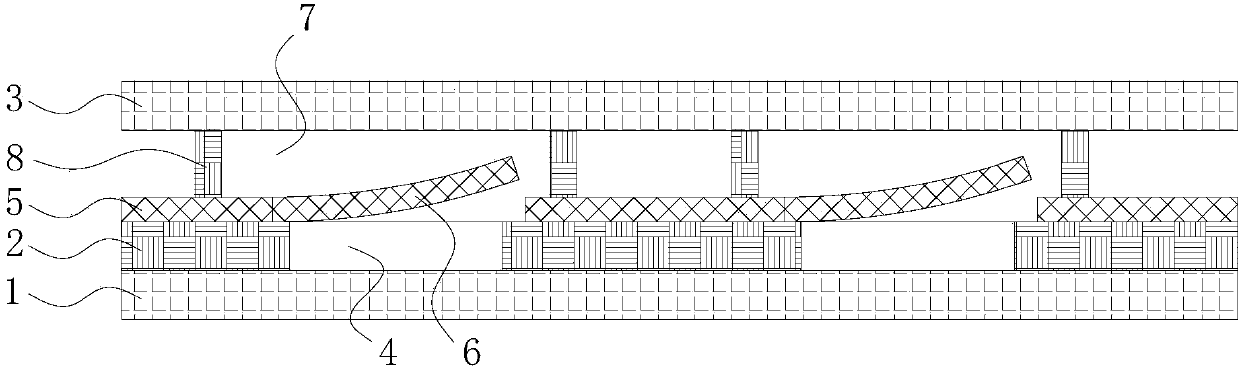

Unidirectional breathable cloth

PendingCN107696602AFeel goodGuaranteed to open normallySynthetic resin layered productsClothingsBlocking layerReverse airflow

The invention discloses unidirectional breathable cloth. The unidirectional breathable cloth comprises an inner layer, a base layer and an outer layer, wherein the inner layer is a breathable layer, aplurality of vent holes are formed in the base layer, a blocking layer is arranged on the base layer, valves corresponding to each breathable hole are arranged on the blocking layer and cover the vent holes, the areas of the valves are more than the areas of the breathable holes, the valves are rotatably connected with the blocking layer, the outer layer is arranged on the blocking layer, and a gap is formed between the outer layer and the valves. The unidirectional breathable cloth has the advantages that the inner layer can be manufactured from breathable cloth, so that the contact hand feel between the inner layer and a human body is improved; the blocking layer is covered by the base layer, the valves of the blocking layer serve as the valves of the vent holes and cover the vent holes, and the areas of the valves are more than the areas of the breathable holes, so that the valves can be unidirectionally opened to enable internal gas to flow out through the vent holes; and the valves cling to the vent holes so as to close the vent holes while meeting reverse airflow, so that the unidirectional breathable cloth in proper sense is realized.

Owner:嘉兴佳达实业股份有限公司

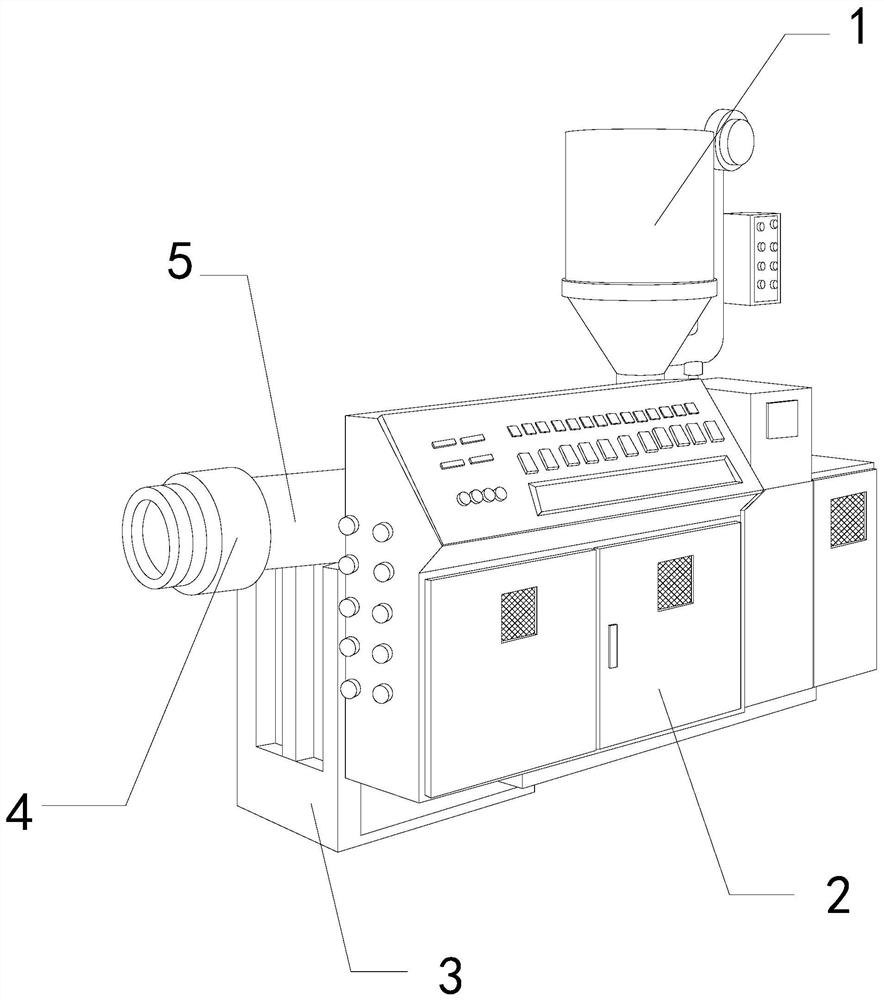

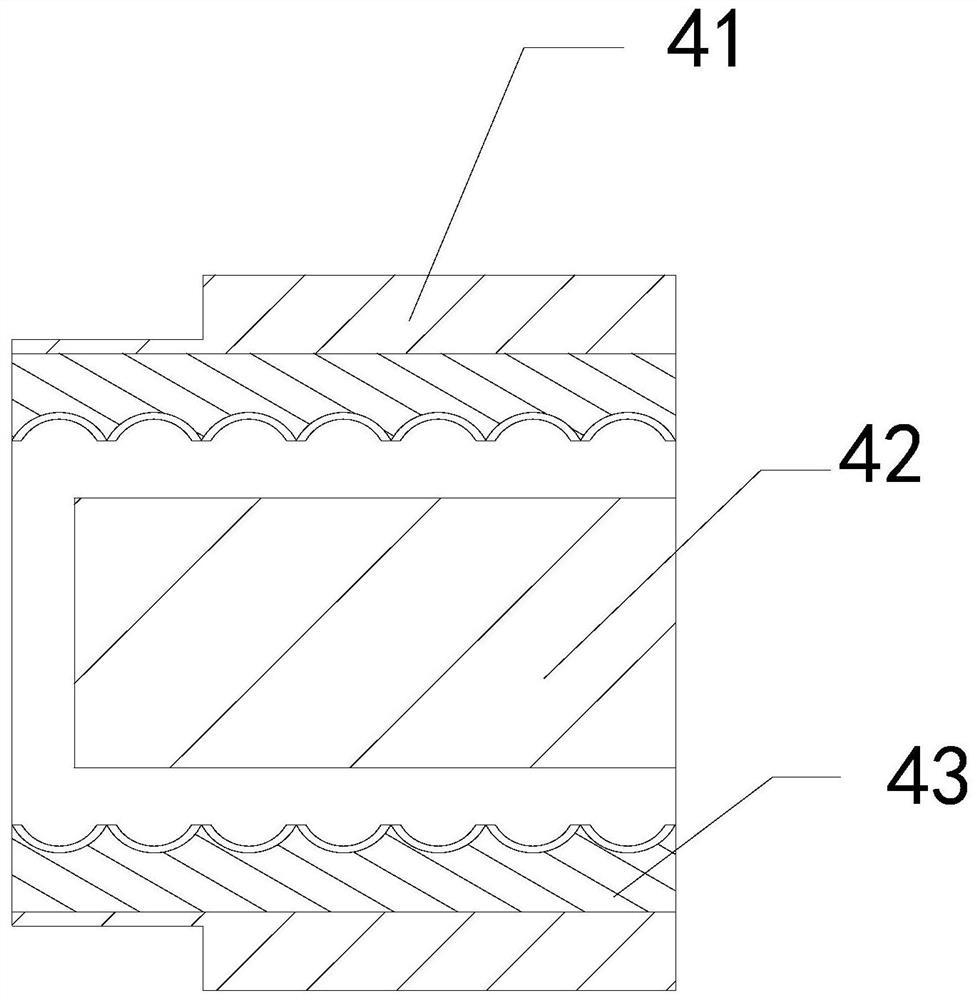

Extrusion forming equipment for PVC pipe production

InactiveCN112277284AAvoid air drying and solidificationEasy fall offEngineeringMechanical engineering

The invention discloses extrusion forming equipment PVC pipe production. The extrusion forming equipment structurally comprises a heating hopper, a machine body, a support seat, a forming head and anextrusion pipe, and the heating hopper is fixedly embedded at the upper end of the extrusion pipe; the machine body is welded on the support seta, and the extrusion pipe is fixedly embedded in the machine body; and the forming head and the extrusion pipe are of an integrated structure. Upon completion of extrusion of PVC plastic, a telescopic block can be quickly pushed to slide downwards throughan elastic piece, so that a lower swing plate can be quickly swung downwards along a plate body; thus, the PVC plastic at the bottom of a lower connecting plate can be loosened, and bounced off downwards through the lower swing plate; and an extending block can be pushed to extend forwards along a combining plate through airflow in an air guide cavity. When a contraction plate loses extrusion of molten PVC plastic, the contraction plate can be pushed to reset upwards through a rebounding strip, so that the extending block can be attracted by reverse airflow to slide backwards; and thus, a PVCplastic layer on the outer surface of a front plate can fall off easily.

Owner:北京林远商贸有限公司

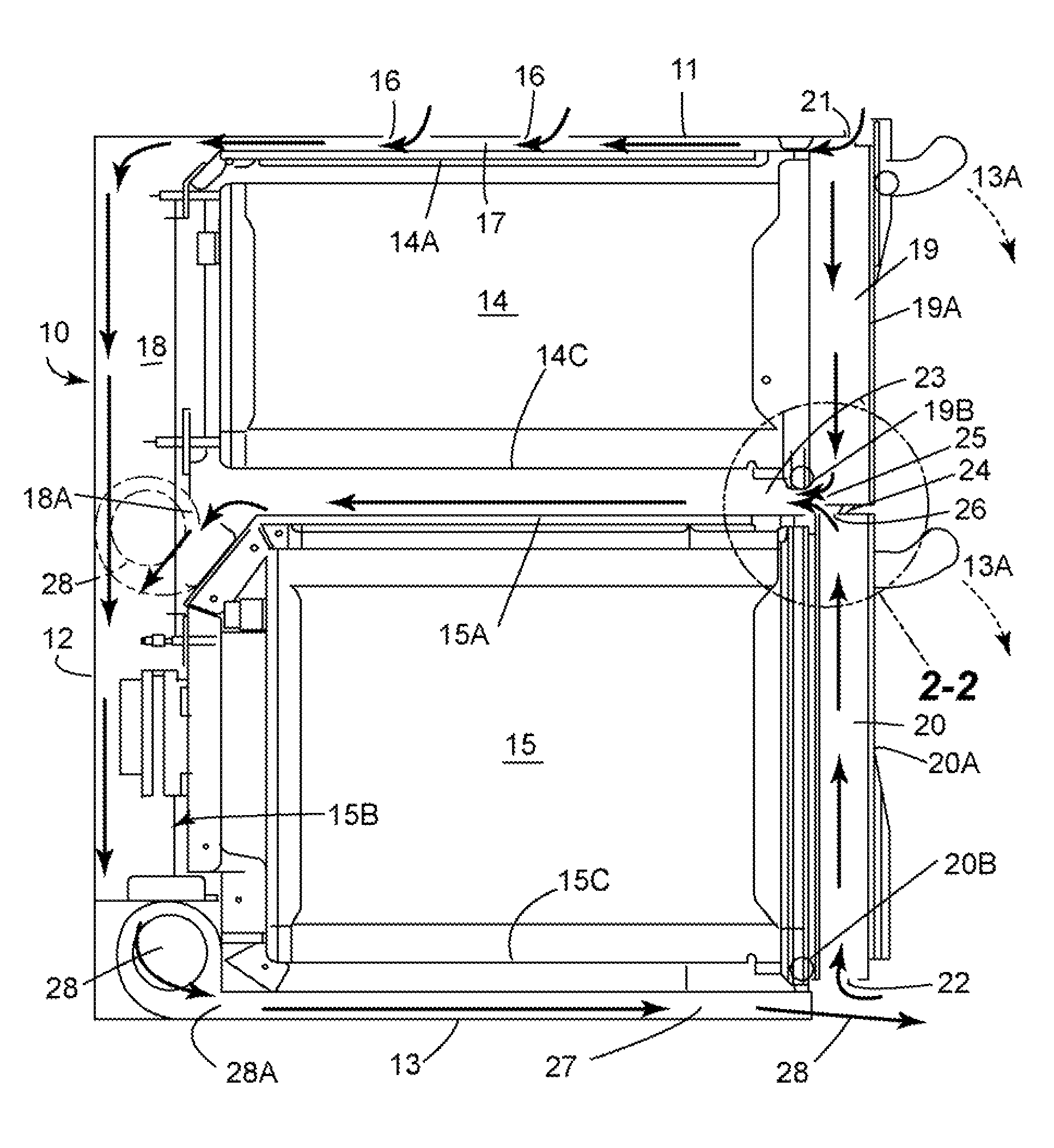

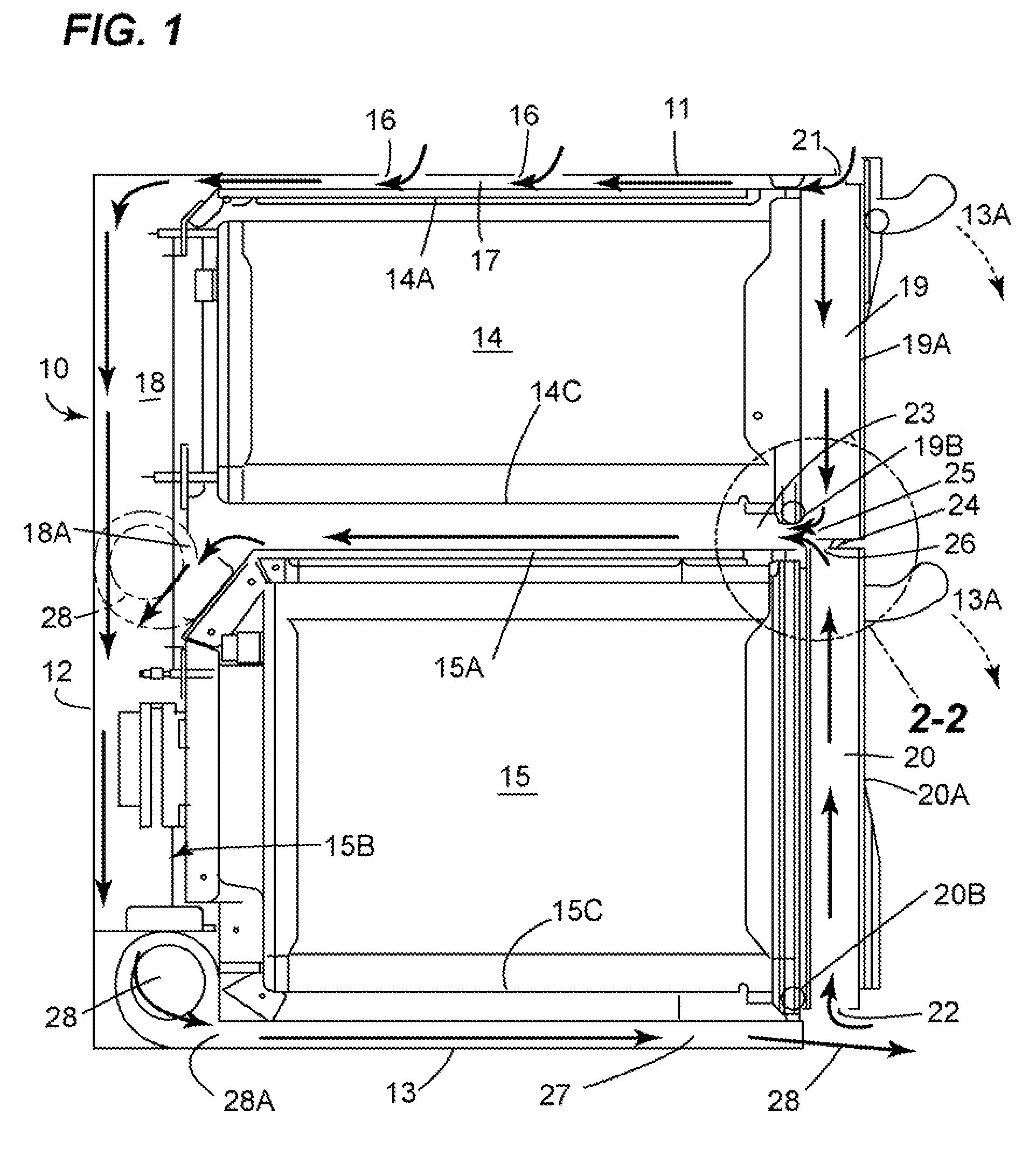

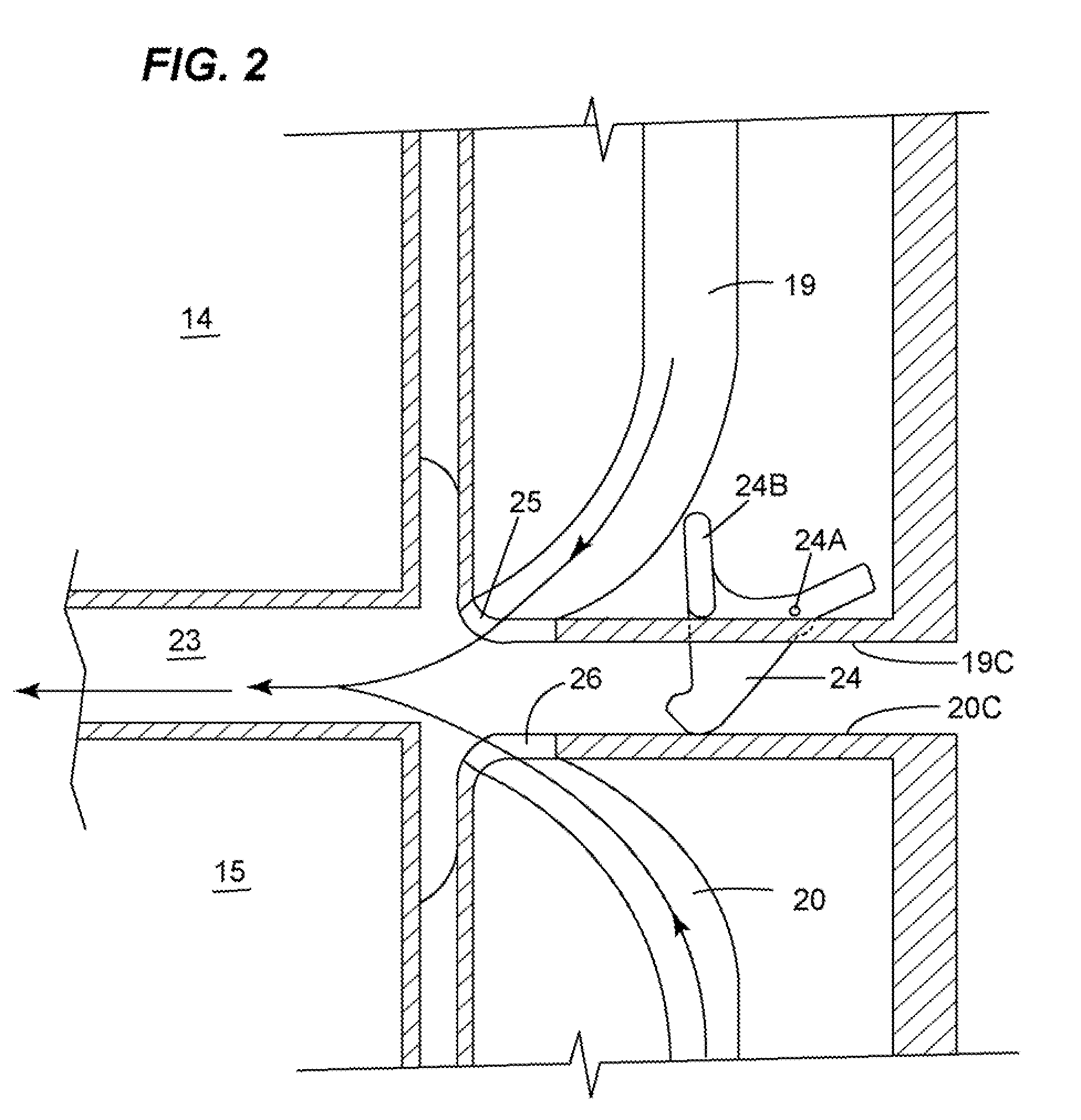

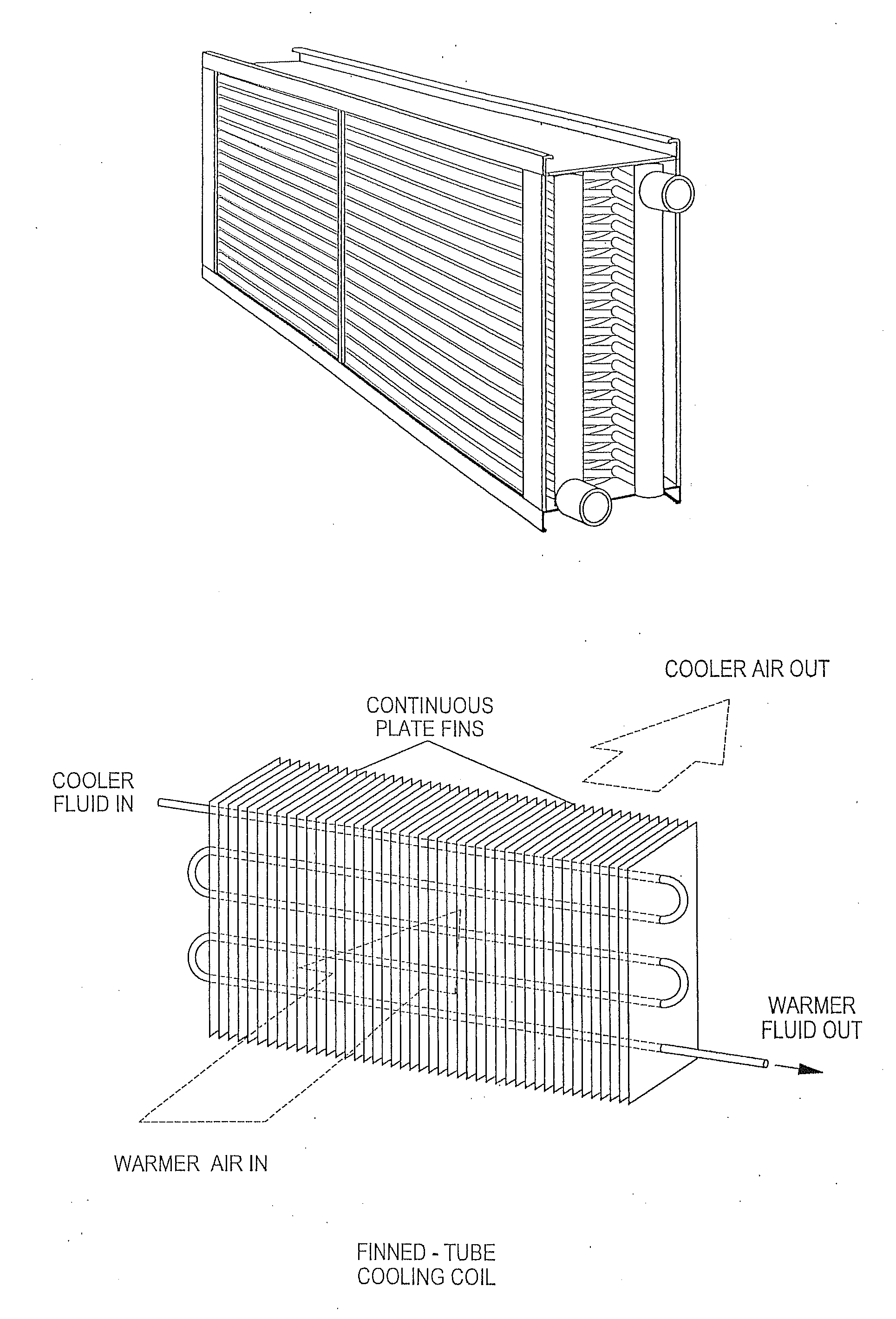

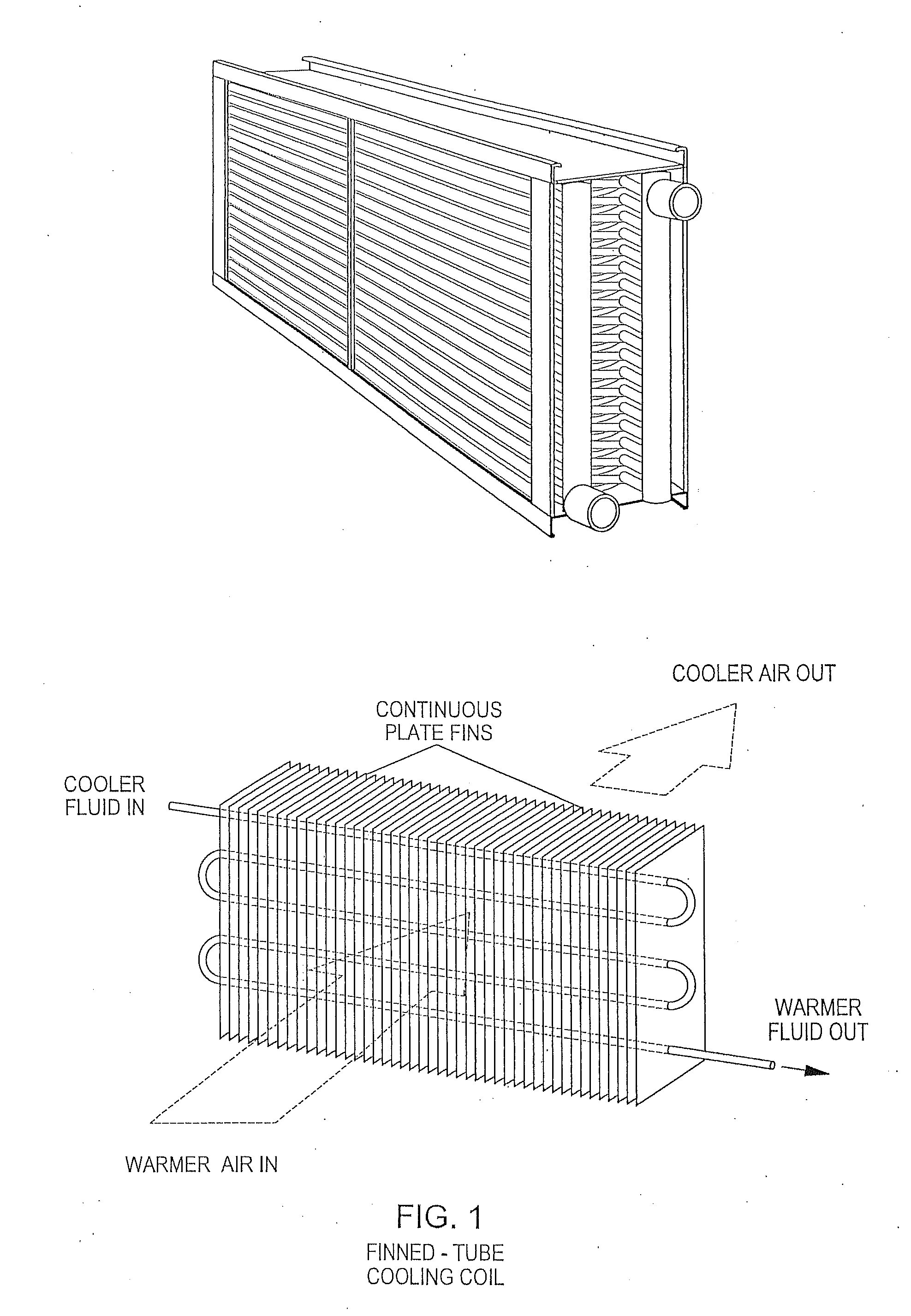

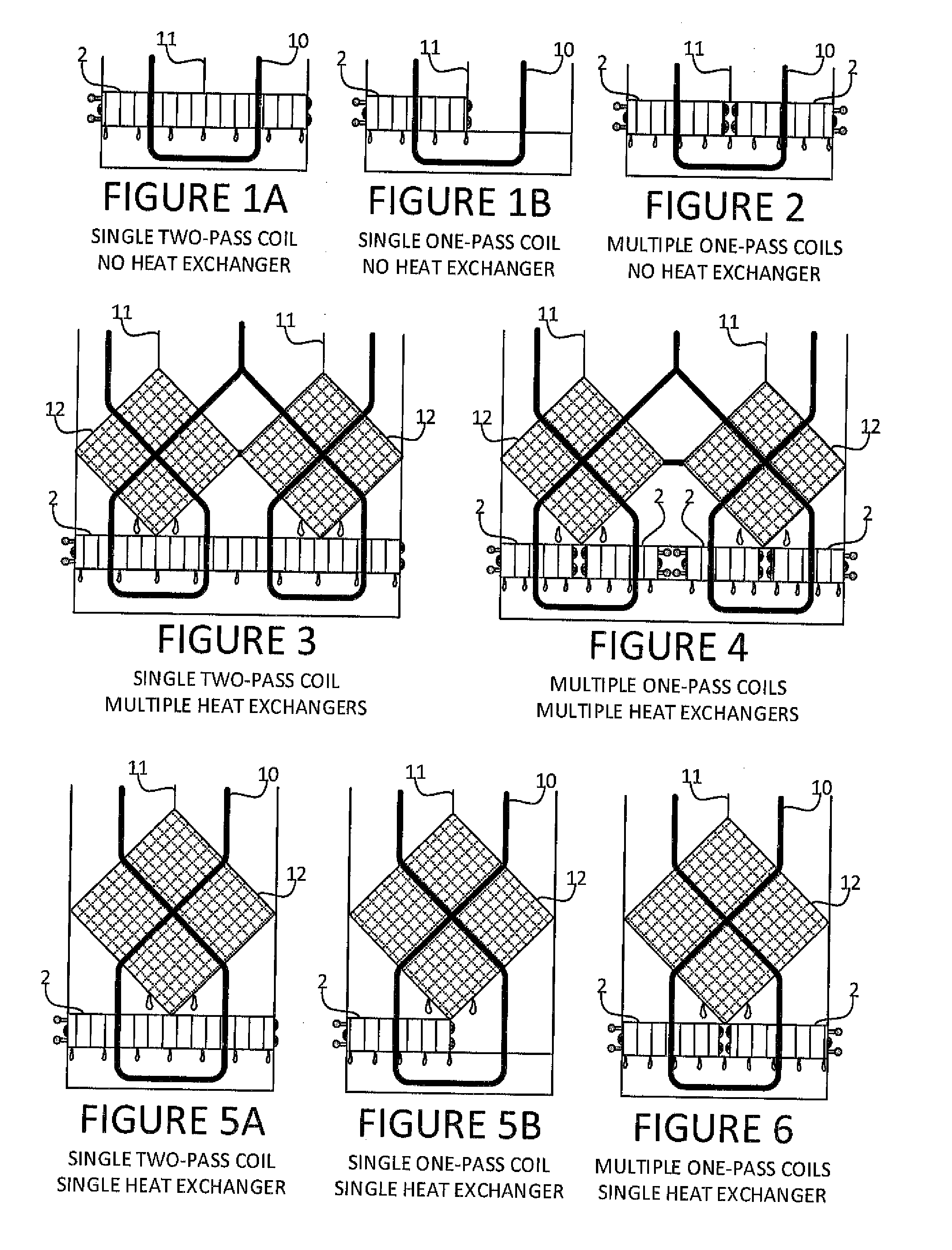

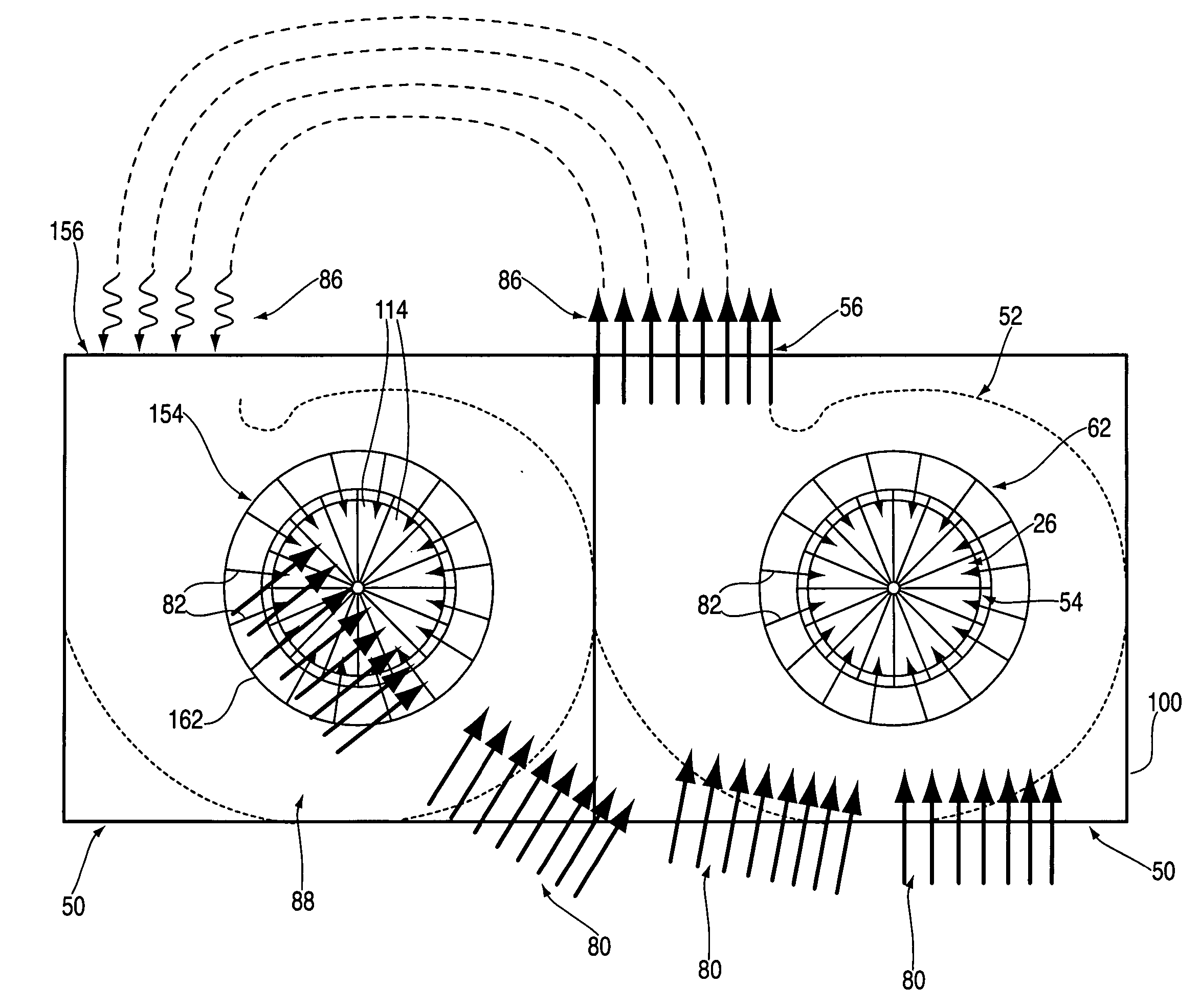

Low temperature cooling and dehumidification device with reversing airflow defrost for dehumidification and water generation applications where cooling coil inlet air is above freezing

ActiveUS20150082817A1Avoiding air restrictionAvoid frostEnergy recovery in ventilation and heatingMechanical apparatusFrostActive cooling

A low temperature cooling and dehumidification system uses a reverse airflow arrangement to defrost a frosted cooling coil while not interrupting operation. Automatic air dampers are used to reverse the airflow at the proper time to initiate defrost of that section of frosted cooling coil. This system is useful for low temperature cooling and dehumidification in situations where the inlet air is above freezing, however exiting air below freezing can be supplied if desired. It is advantageous for operation if the coolant flow and temperature internal to the cooling coil are regulated to create the conditions for frost formation to begin closer to the air leaving side of the active cooling coil. The dehumidified generated condensate can be collected and used as grey water and / or potable water.

Owner:KENTUCKIANA CURB

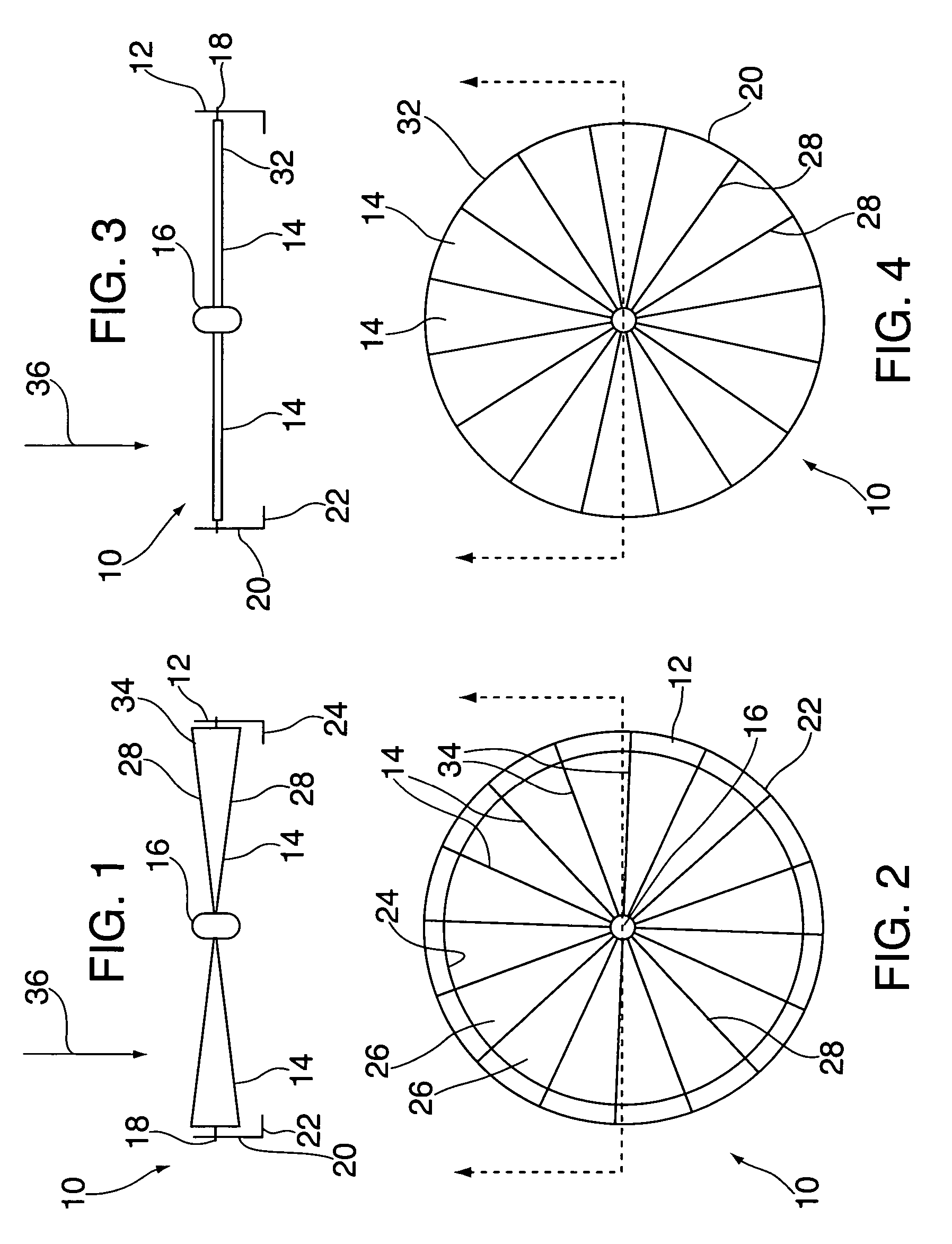

Method and apparatus for a low impedance anti-recirculation air moving inlet device

InactiveUS20060084374A1Reduce airflowElectrical apparatus contructional detailsElectrical apparatus casings/cabinets/drawersReverse airflowLow impedance

An inlet recirculation apparatus for an air moving device includes a housing defined by a wall extending from a base. The base includes an aperture therethrough receptive to alignment with an inlet of the air moving device. A plurality of flaps each pivotally extends radially outwardly from a center pivot to another corresponding pivot disposed around a perimeter of the wall. The center pivot is coaxial with a center of the aperture. Each flap moves to an open position due to air pressure from the air moving device causing air to flow into the inlet wherein each flap pivotally rotates about the center pivot and corresponding pivot at the wall, and moves to a closed position when air pressure from the air moving device ceases wherein a space between contiguous flaps is eliminated when each flap pivotally rotates to the closed position about the center pivot and corresponding pivot at the wall to prevent reverse airflow through the air moving device.

Owner:IBM CORP

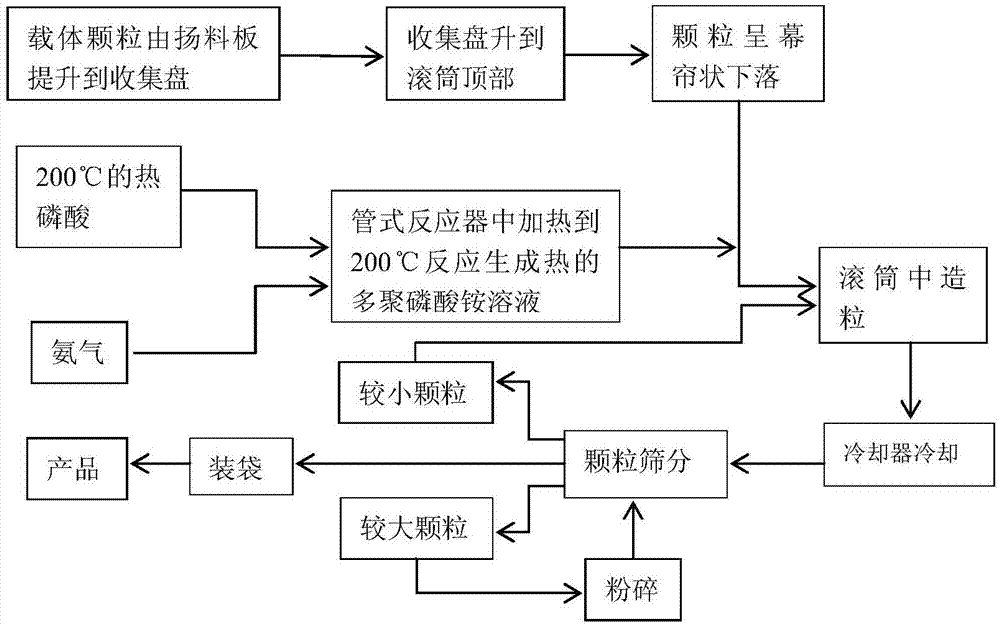

Ammonium polyphosphate agricultural fertilizer granulating technology

InactiveCN103787695AReduce moisture contentImprove qualityPhosphatic fertiliser granulation/pelletisationParticulatesPrill

The invention belongs to the field of fertilizer, and particularly relates to an ammonium polyphosphate agricultural fertilizer granulating technology. The ammonium polyphosphate agricultural fertilizer granulating technology comprises the following steps: adding phosphoric acid into a tubular reactor, introducing ammonia under turbine stirring, and reacting, so as to obtain an ammonium polyphosphate solution; regulating the falling speed of granules in a collecting plate, then spraying the ammonium polyphosphate solution onto the falling granules, carrying out cooling action of reverse airflow in a roller so as to form particulate matters, discharging the particulate matters from the roller, feeding the particulate matters into a rotating cooler and cooling; screening the cooled particulate matters in a screening device, thus finally obtaining the product. The ammonium polyphosphate agricultural fertilizer granulating technology has the characteristics of being low in energy consumption, pollution-free, and easy to operate; the prepared agricultural fertilizer is excellent in granule quality, hard in texture, low in moisture content, and good in granule structure and maintains more polyphosphate content.

Owner:山东泰宝生物科技股份有限公司

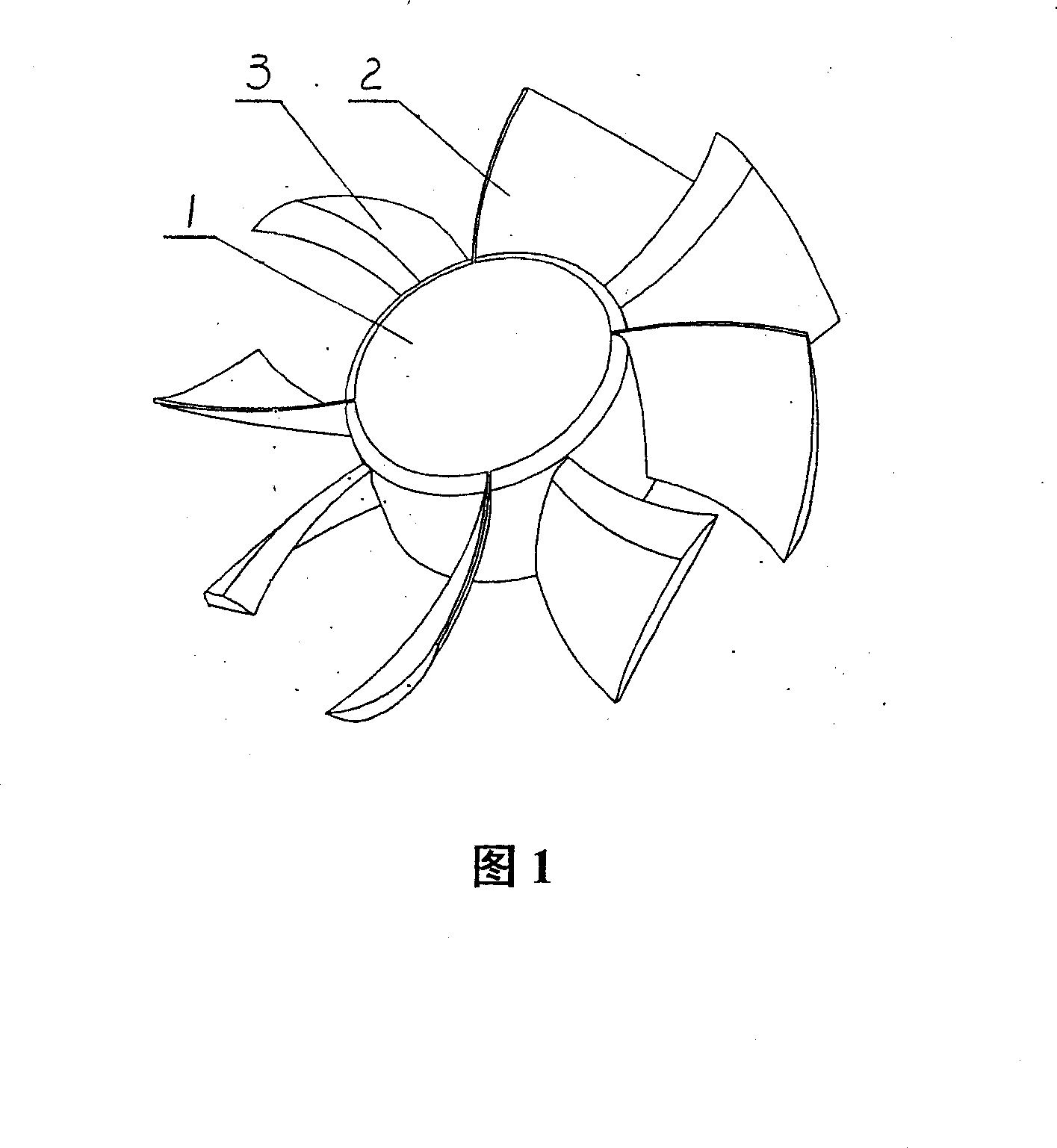

Oscillating air flow combined type fan blade with low noise

The invention relates to a vibration airflow low-noise composite blade of fan, comprising hub and even blades distantly arranged on the edge of hub. The invention is characterized in that: each blade is symmetry arranged with reverse blade, to utilize their reverse airflow to impact the positive blade, to output vibrated worm which can be used to cool and radiate heat of radiating plate. The generated vibrated airflow can impact the stable air film at the face of radiating plate to accelerate the heat transmission and improve the radiating efficiency, with low cost.

Owner:赵汉高

Smoke cyclic screening and dedusting method and apparatus

InactiveCN101322893ASolve the shortcomings of low temperature resistance, high energy consumption, and secondary pollutionImprove temperature resistanceDispersed particle filtrationEmission channelingSoot

Owner:苏忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com