Mass transfer and reaction equipment for reverse airflow shearing and rotating packed bed

A technology of rotating packed bed and reaction equipment, which is applied in the chemical method of reacting liquid and gas medium, dispersed particle separation, fractionation, etc. The effect of uniform distribution and increased shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

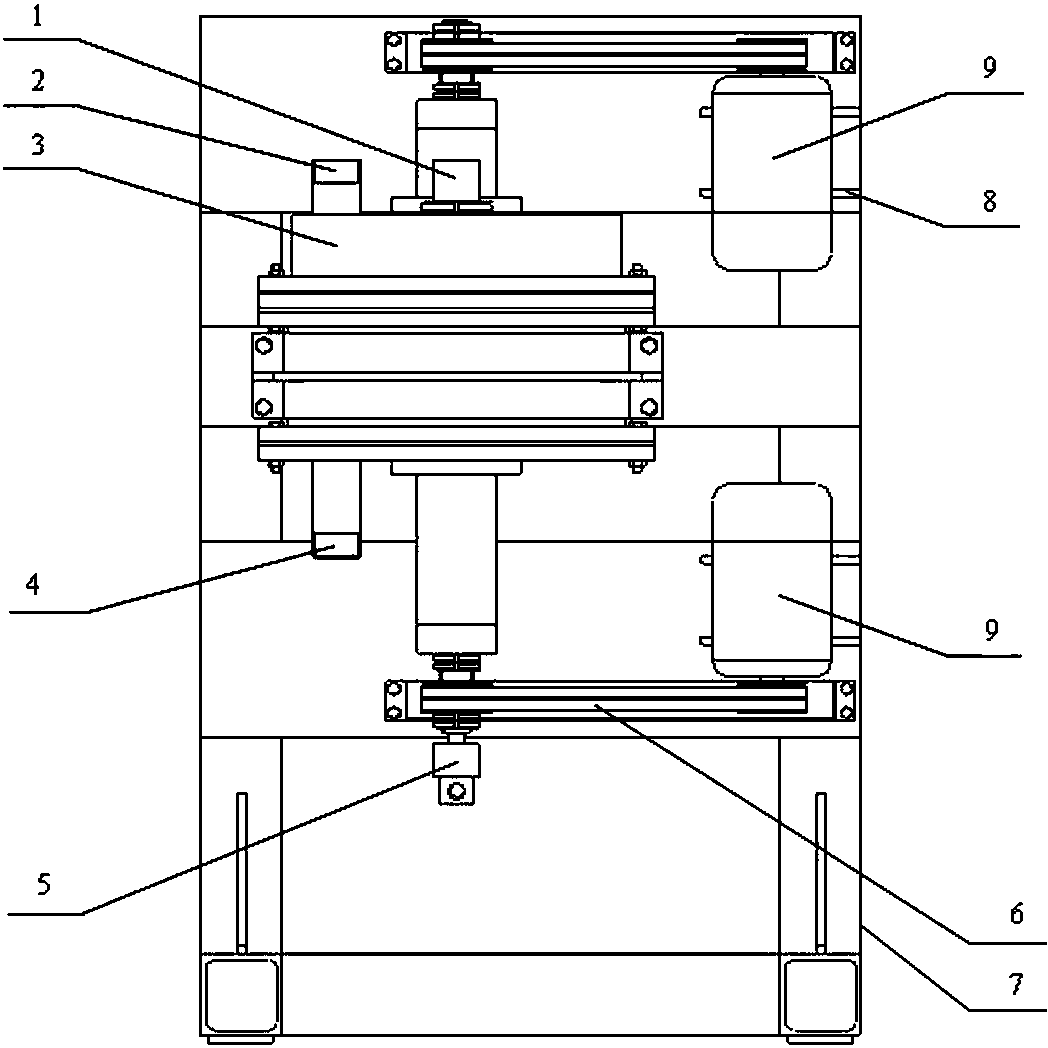

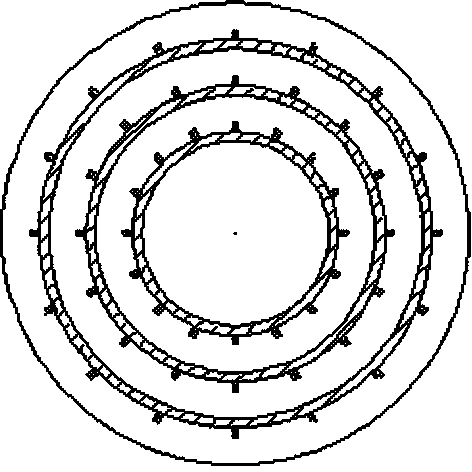

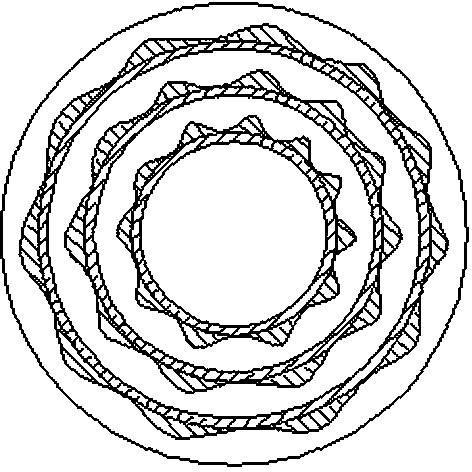

[0024] Air flow reverse shearing rotating packed bed mass transfer and reaction equipment mainly includes rotating bed main body, equipment support and transmission device. The main body of the rotary bed is divided into two parts, the upper air collection chamber and the lower main chamber. The air collection chamber and the main chamber are separated by a partition; the filling rotor is installed in the main chamber and consists of upper and lower turntables that can rotate independently , the distance between the upper and lower turntables is 30mm, each of the turntables is equipped with concentric ring-shaped packing supports, and the interior is filled with wire mesh packing. The packing and packing supports on the upper and lower turntables form mutually nested packing rings. The thickness of the packing rings is 16mm. The distance betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com