Pourable vascular tissue engineering reactor having rotating function

A vascular tissue and reactor technology, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, tissue cell/virus culture device, etc., can solve the problem of not carefully considering flow impedance, compliance Flow inertia, inability to provide periodic axial stretching of vascular tissue at the same time, inability to provide a near-physiological flow environment, etc., to achieve the effect of good mass transfer performance and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Embodiment 1 Inner rotation inner perfusion

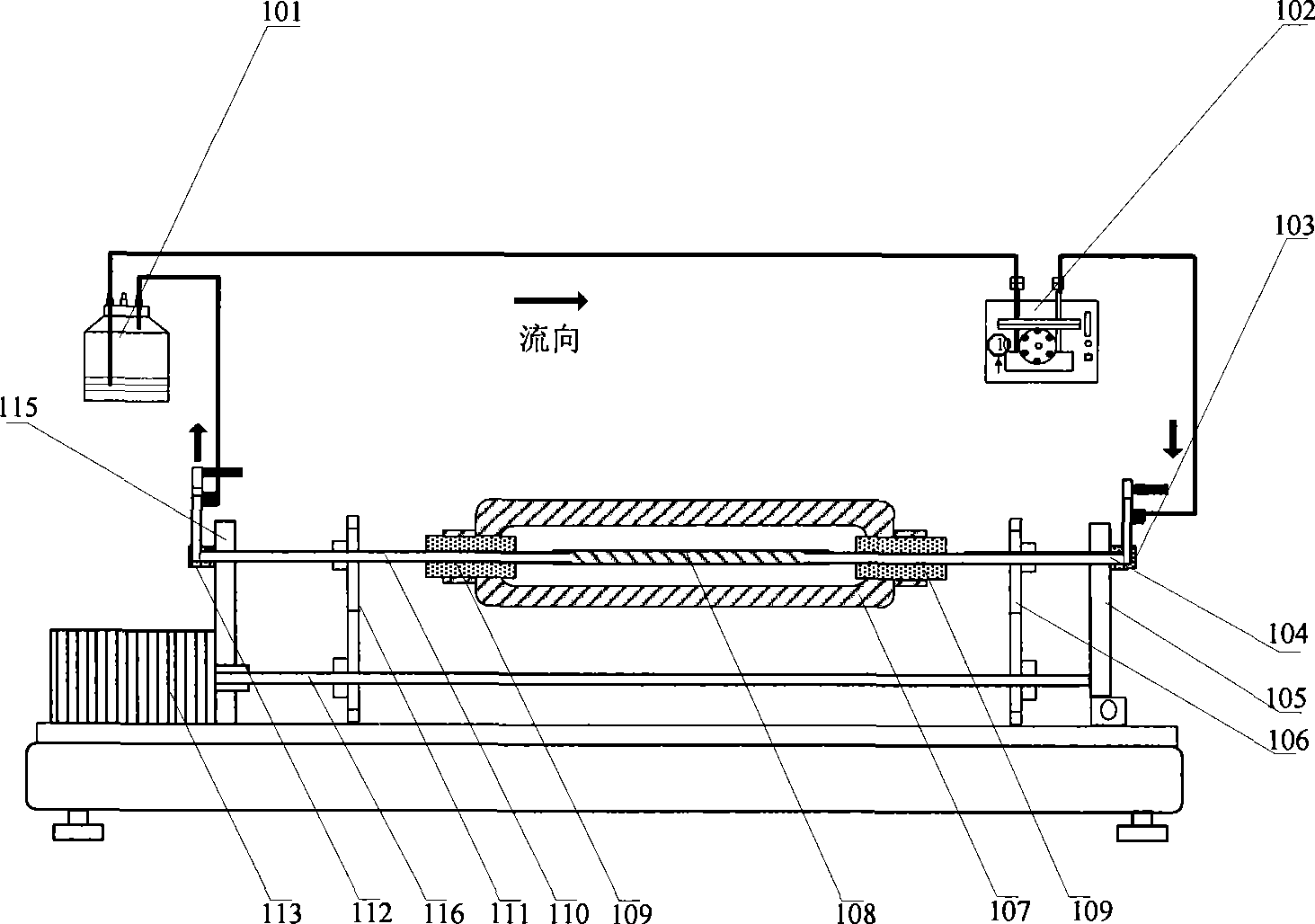

[0115] 1. According to figure 1 The intravascular perfusion circuit is connected as shown, wherein the intravascular perfusion liquid driving device is a peristaltic pump (Cole-Parmer Company, Masterflex series);

[0116] 2. Disinfect the reactor, the disinfection conditions are: 130°C, 3 atmospheres, 1 hour;

[0117] 3. Install the tissue-engineered blood vessel to be cultured on the upstream and downstream pipelines of the intravascular perfusion circuit in the vascular tissue culture cavity under sterile conditions, wherein the inner diameter of the tissue-engineered blood vessel is 2mm, the length is 10cm, and the material is PLGA;

[0118] 4. According to figure 1 The vascular tissue rotation device shown is connected, and the vascular tissue rotation motor is a Haydn 57000 series stepping motor;

[0119] 5. Prepare the medium according to the culture requirements, inject the sterile medium into the intravascular per...

Embodiment 2

[0124] Example 2 The internal rotation is perfused with a measurement and control device

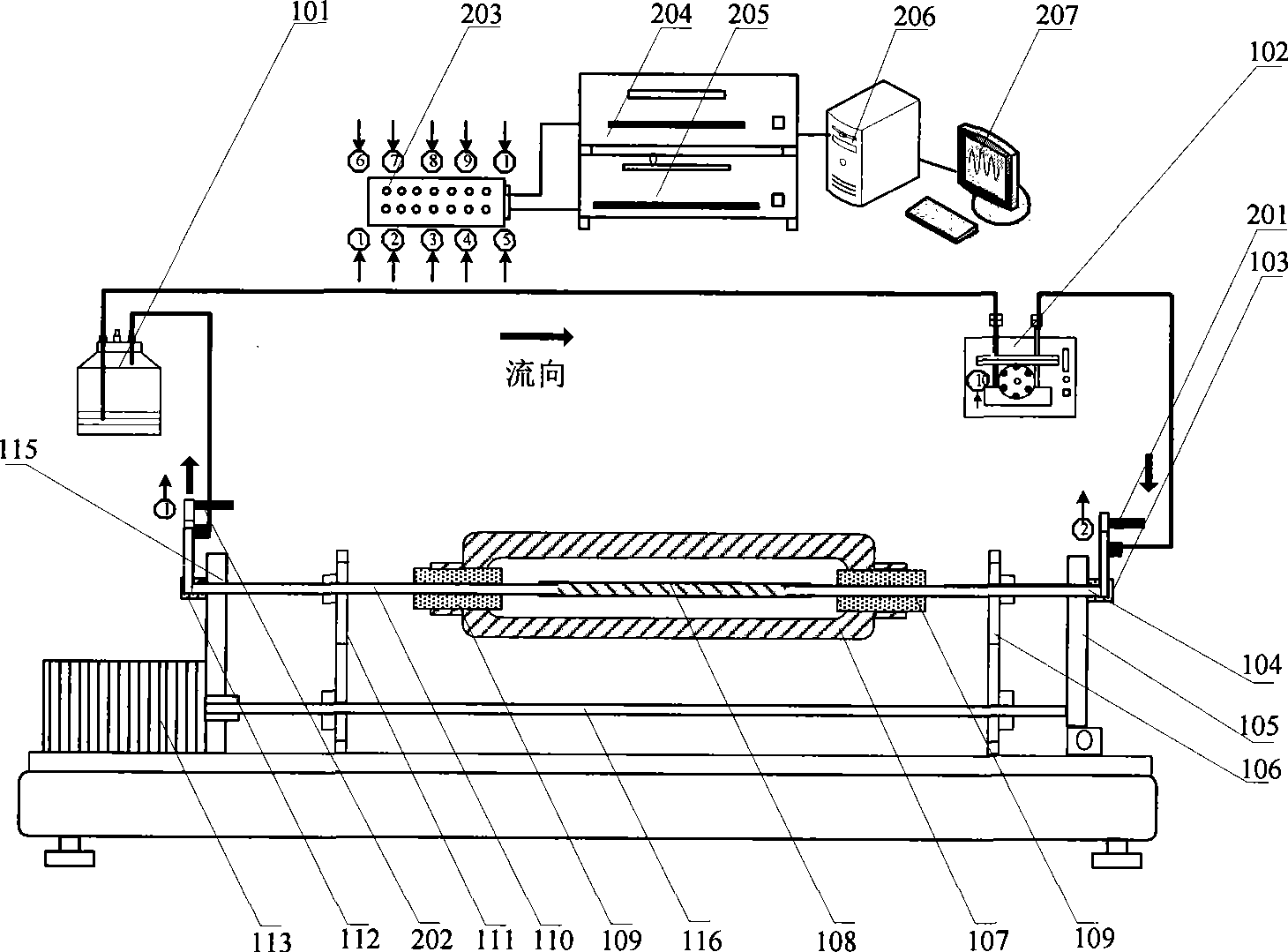

[0125] 1. According to figure 2 The intravascular perfusion circuit is connected as shown, wherein the intravascular perfusion liquid driving device is a peristaltic pump (Cole-Parmer Company, Masterflex series);

[0126] 2. Disinfect the reactor, the disinfection conditions are: 130°C, 3 atmospheres, 1 hour;

[0127] 3. Install the tissue-engineered blood vessels to be cultured on the upstream and downstream pipelines of the intravascular perfusion circuit in the vascular tissue culture cavity under sterile conditions, wherein the inner diameter of the tissue-engineered blood vessels is 4 mm, the length is 15 cm, and the material is PLGA;

[0128] 4. According to figure 2 The vascular tissue rotation device shown is connected, and the vascular tissue rotation motor is a Haydn 57000 series stepping motor;

[0129] 5. According to figure 2 The pressure sensor connected to the inlet...

Embodiment 3

[0135] Example 3 Perfusion with internal rotation and internal pulsating flow

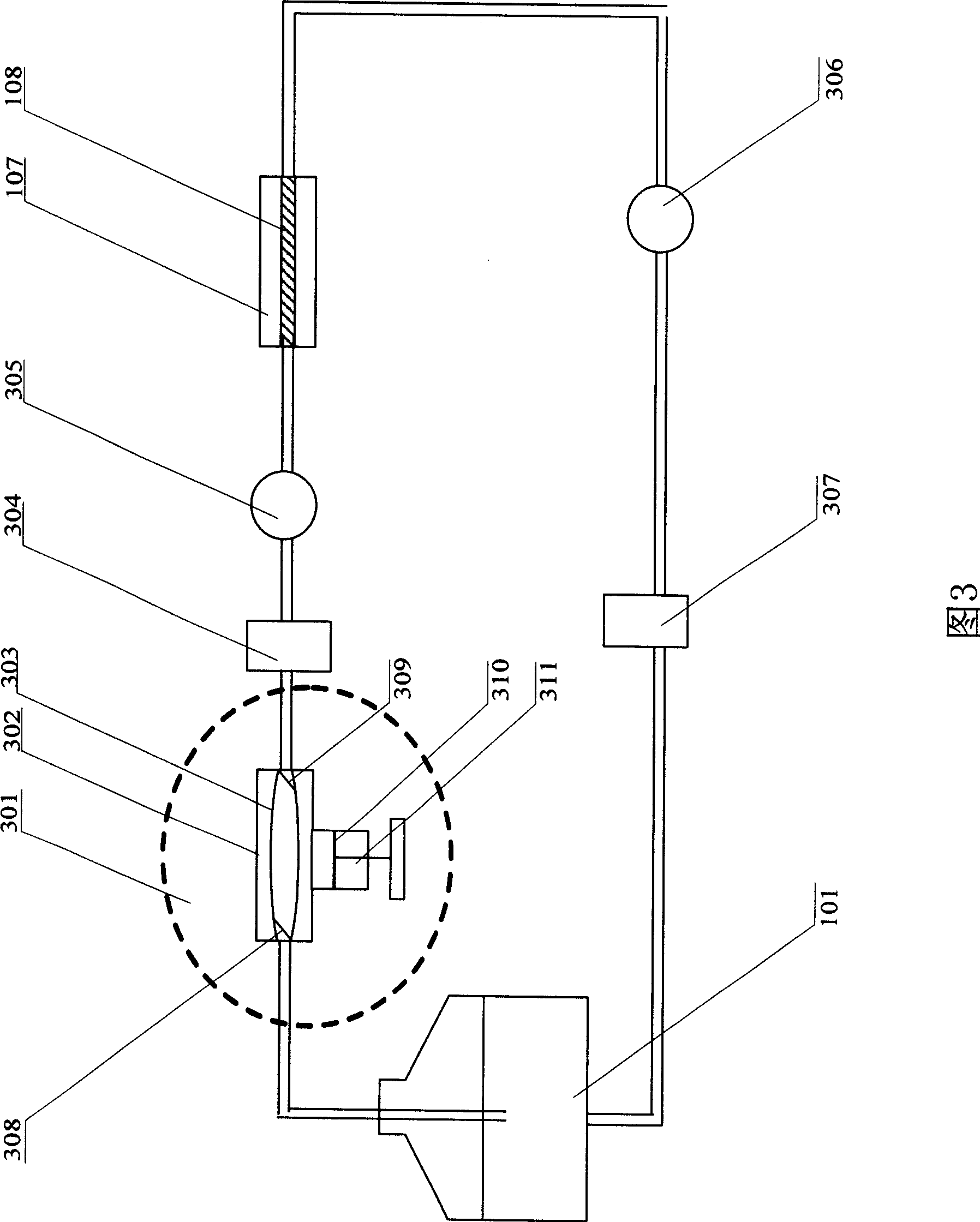

[0136] 1. Connect the intravascular perfusion circuit as shown in Figure 4, where the intravascular perfusion liquid drive device is the pulse source;

[0137] 2. Disinfect the reactor, the disinfection conditions are: 130°C, 3 atmospheres, 1 hour;

[0138] 3. Install the tissue engineering blood vessel to be cultured on the upstream and downstream pipelines of the intravascular perfusion circuit in the vascular tissue culture cavity under sterile conditions, wherein the inner diameter of the tissue engineering blood vessel is 4 mm, the length is 10 cm, and the material is collagen;

[0139] 4. Connect the vascular tissue rotation device as shown in Figure 4, wherein the vascular tissue rotation motor is a Haydn 57000 series stepping motor;

[0140] 5. Connect the pressure sensor at the inlet and outlet of the vascular tissue culture chamber in the intravascular perfusion line as shown in Figure 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com