Oscillating air flow combined type fan blade with low noise

A low-noise, composite technology, applied in non-variable pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problem of increasing fan speed, increasing power consumption and noise, and not complying with environmental protection The trend and requirements of the company, to achieve the effects of accelerating heat transfer, reducing operating noise, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

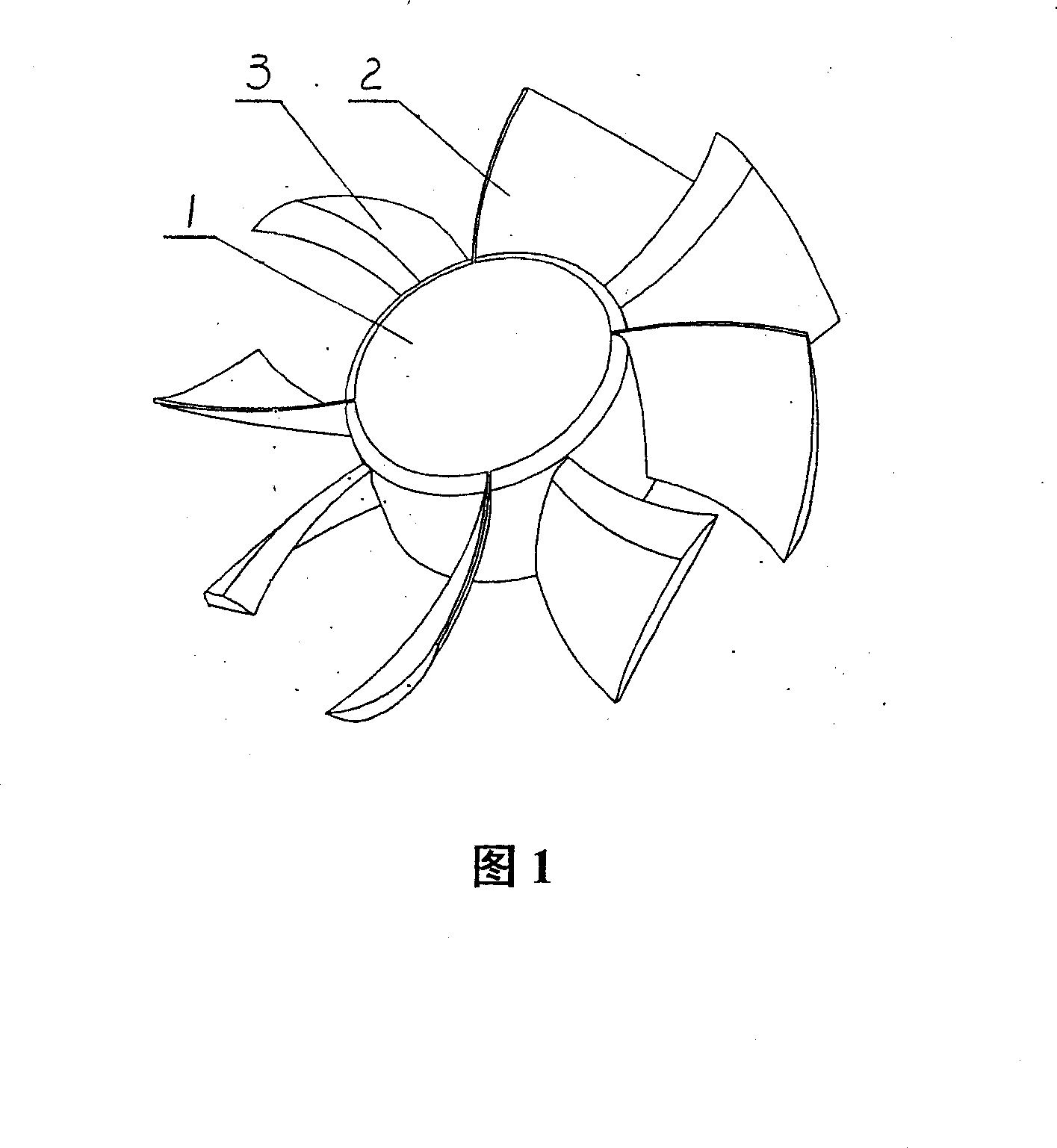

[0009] Embodiment: It can be clearly seen from Fig. 1 that this is an oscillating air flow low-noise composite fan blade used by a radiator. Composition towards blade 3. The wheel hub 1 is provided with a motor assembly assembly cavity; the four forward blades 2 are equidistantly arranged on the periphery of the wheel hub 1; the reverse blades 3 are respectively symmetrically arranged on the periphery of the wheel hub 1 between the forward blades 2 .

[0010] The air supply principle of the oscillating airflow low-noise composite fan blades: when the blades rotate, the reverse blades and forward blades arranged on the periphery of the hub also rotate synchronously, and the two sets of blades with the windward curved surfaces facing oppositely cut the air respectively. The lift works, and the two kinds of wind pressure and flow in the opposite direction are discharged axially. The two airflows collide with each other during the discharge process, forming the oscillating output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com