Smoke cyclic screening and dedusting method and apparatus

A filter and dust removal device, circulation filter technology, applied in the direction of separation methods, dispersed particle filtration, chemical instruments and methods, etc., to achieve the effects of low temperature resistance, high filtration efficiency, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

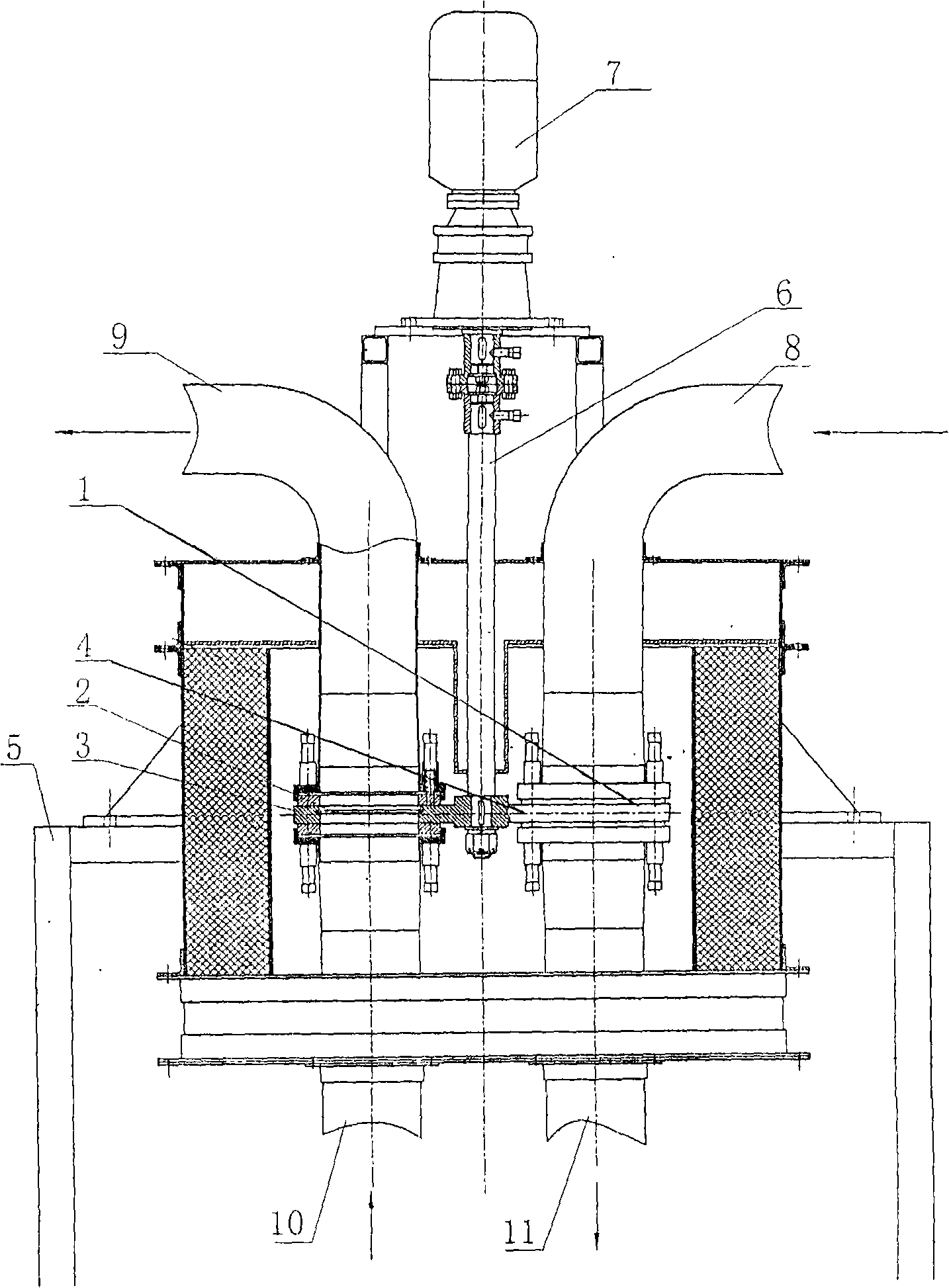

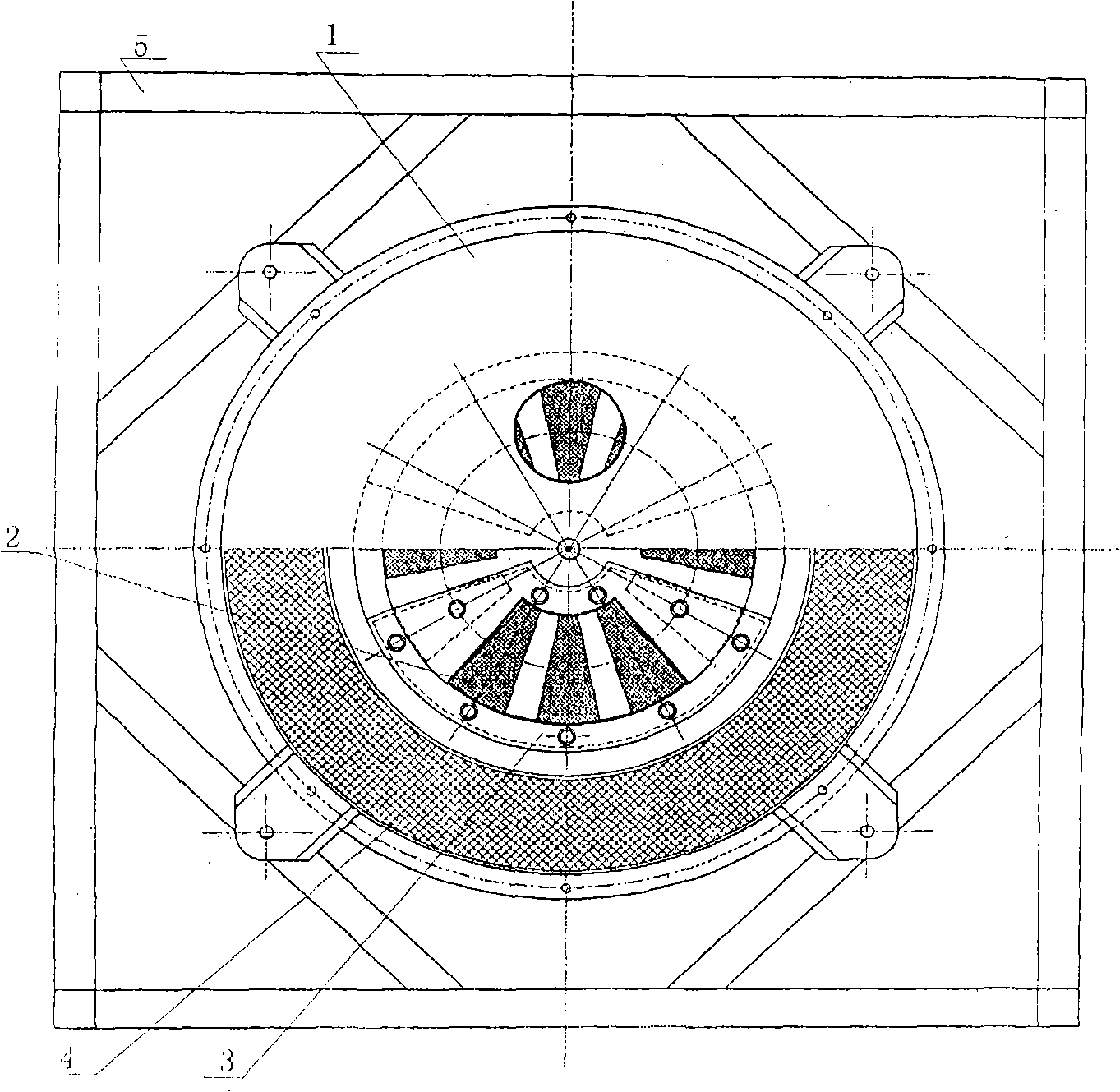

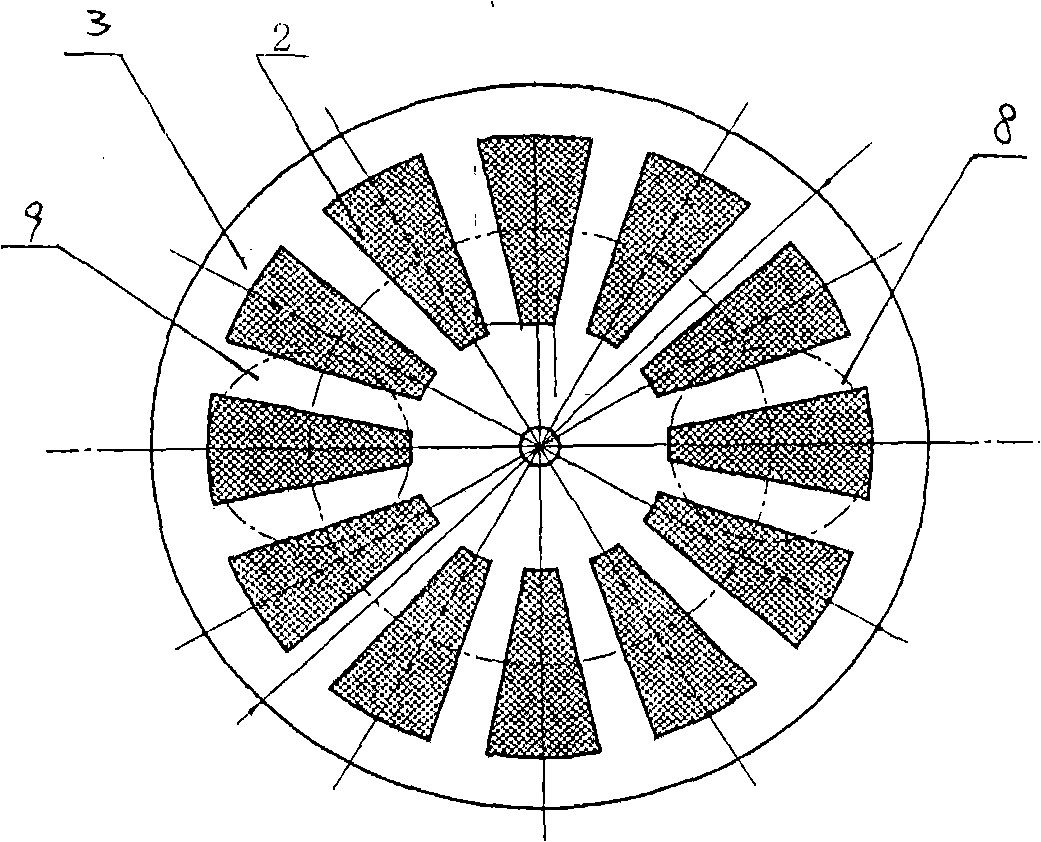

[0012] As shown in Figure 1, the filter and dust removal device body is composed of a filter mechanism 4, a drive motor 7, a dust discharge channel 9 and an airflow recoil channel 8, wherein the filter mechanism 4 is composed of a filter sieve disc 3 and a filter sieve 2 embedded thereon. composition (see image 3 ), and fixed on the frame 5, the middle part of the filter disc 3 is the rotating shaft 6 shaft connected in the sealed connection housing 1, and connected with the drive motor 7 to drive it to rotate, the connection housing 1 is set in the dust discharge On the cross section of the passage 9 and the airflow recoil passage 8, the flow direction of the recoil airflow and the discharge of smoke and dust is formed on the filter mechanism in the opposite direction. The dust discharge channel 9 and the airflow recoil channel 8 are distributed on the disk surface of the filter screen disc 3 with its axis symmetry (see figure 2 ), the flue gas is inhaled from the inlet 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com