Patents

Literature

147results about How to "Reduce the number of disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

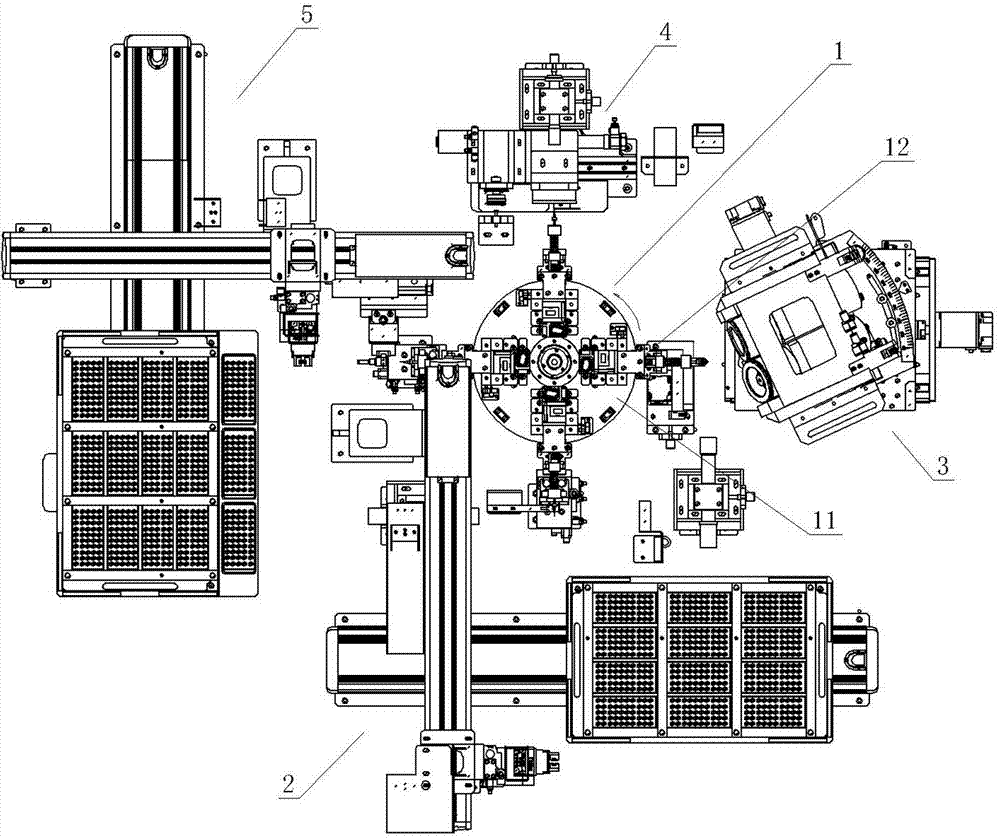

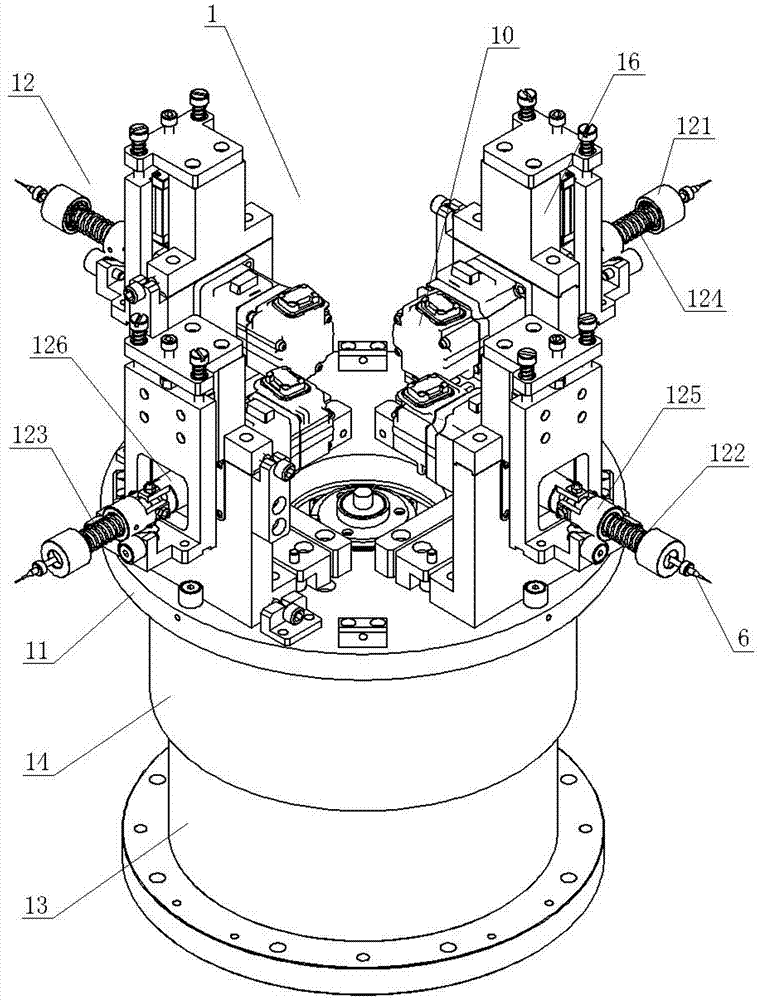

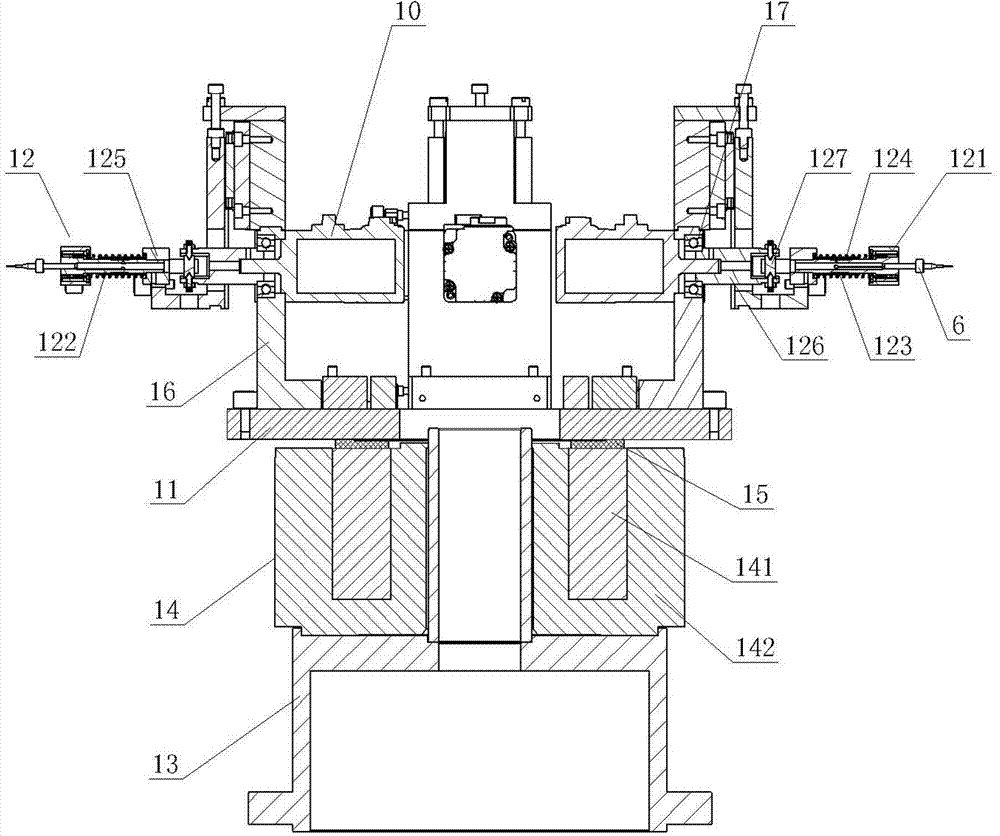

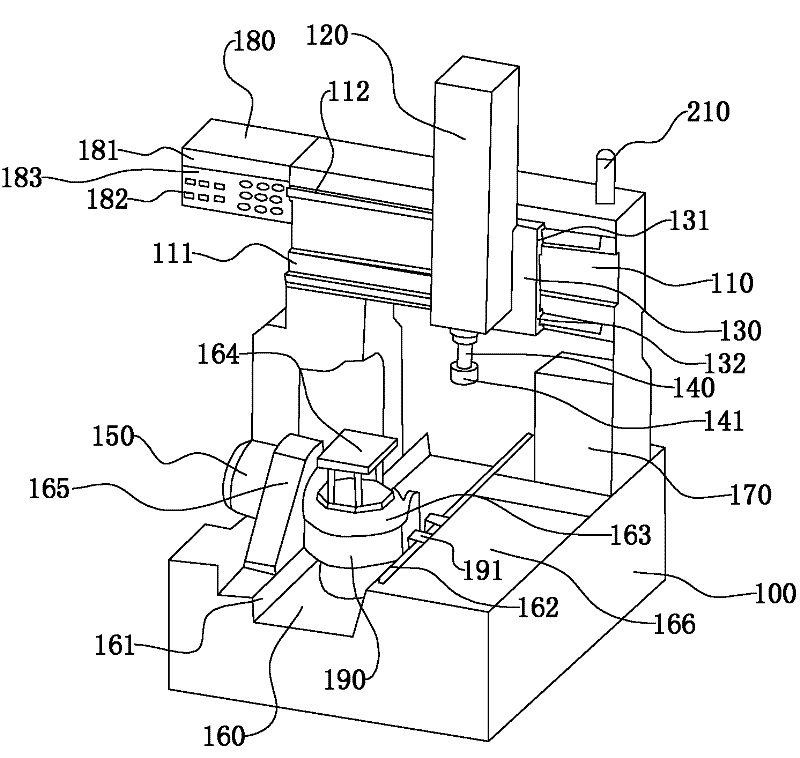

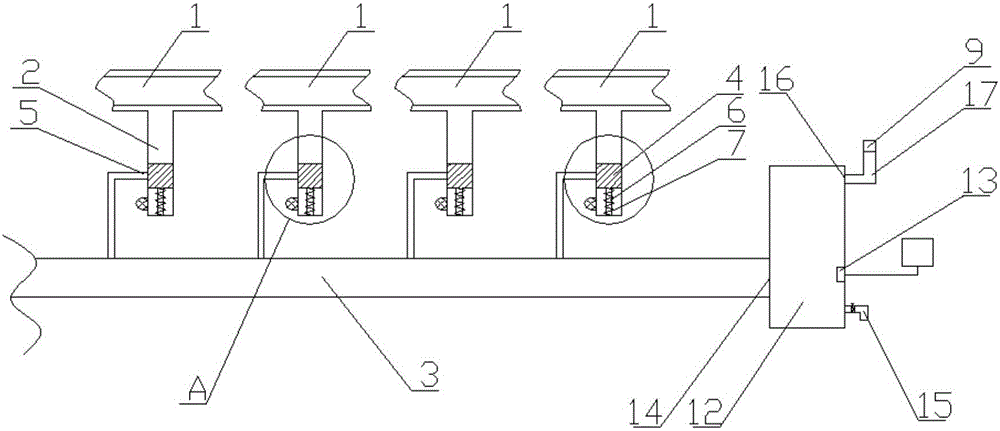

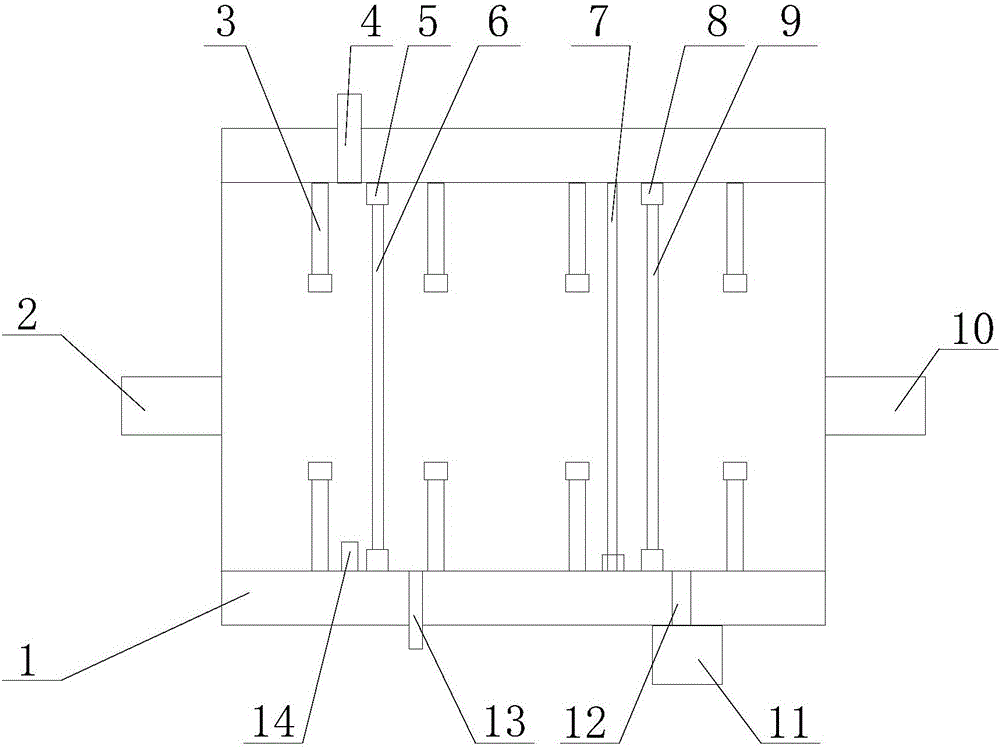

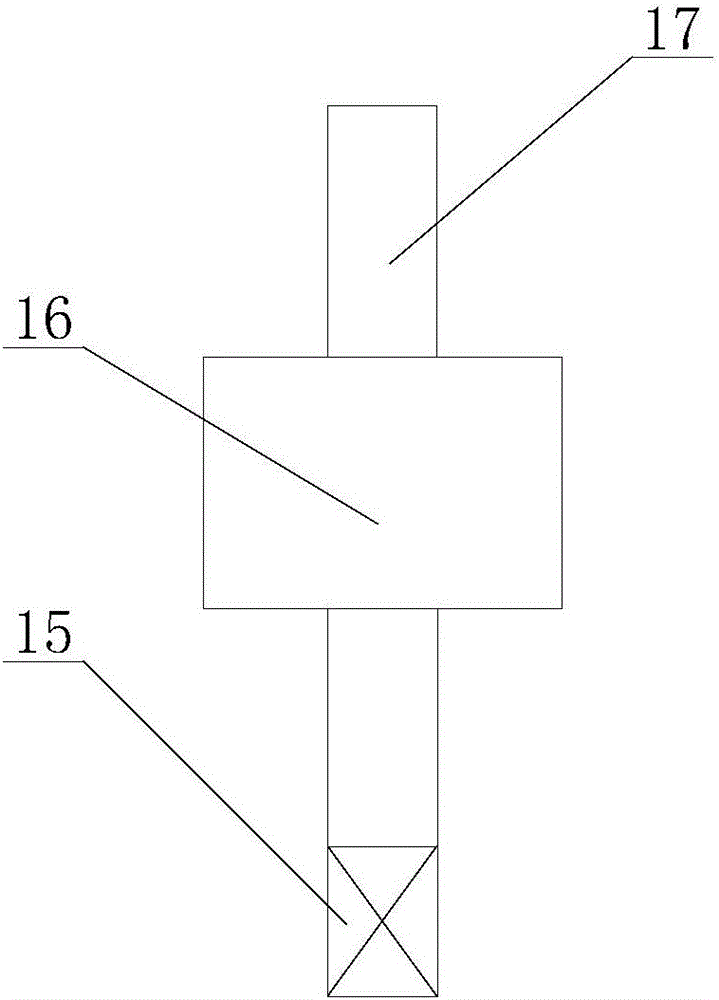

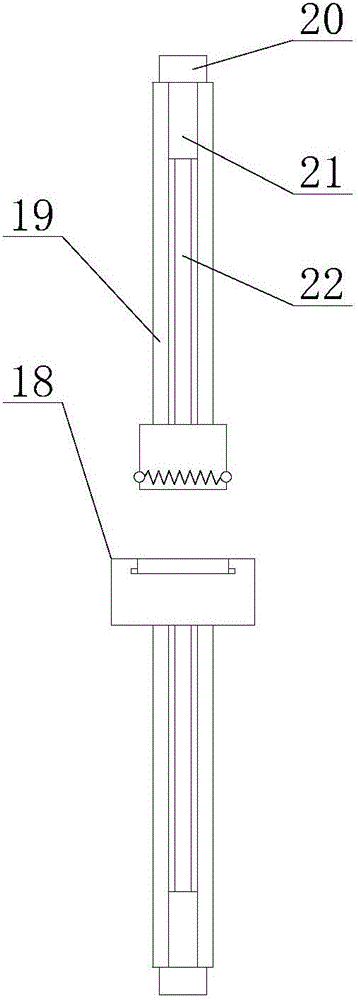

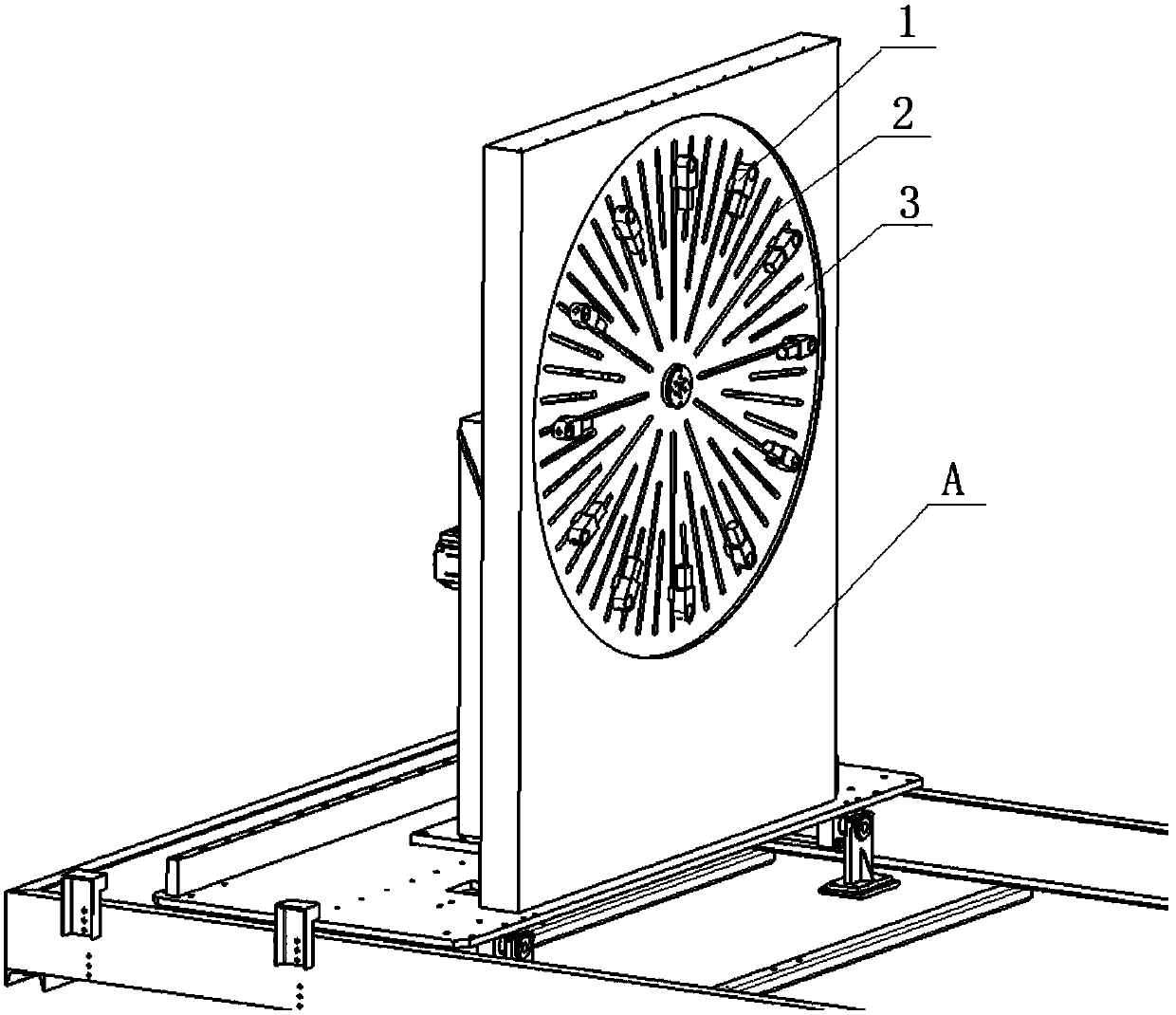

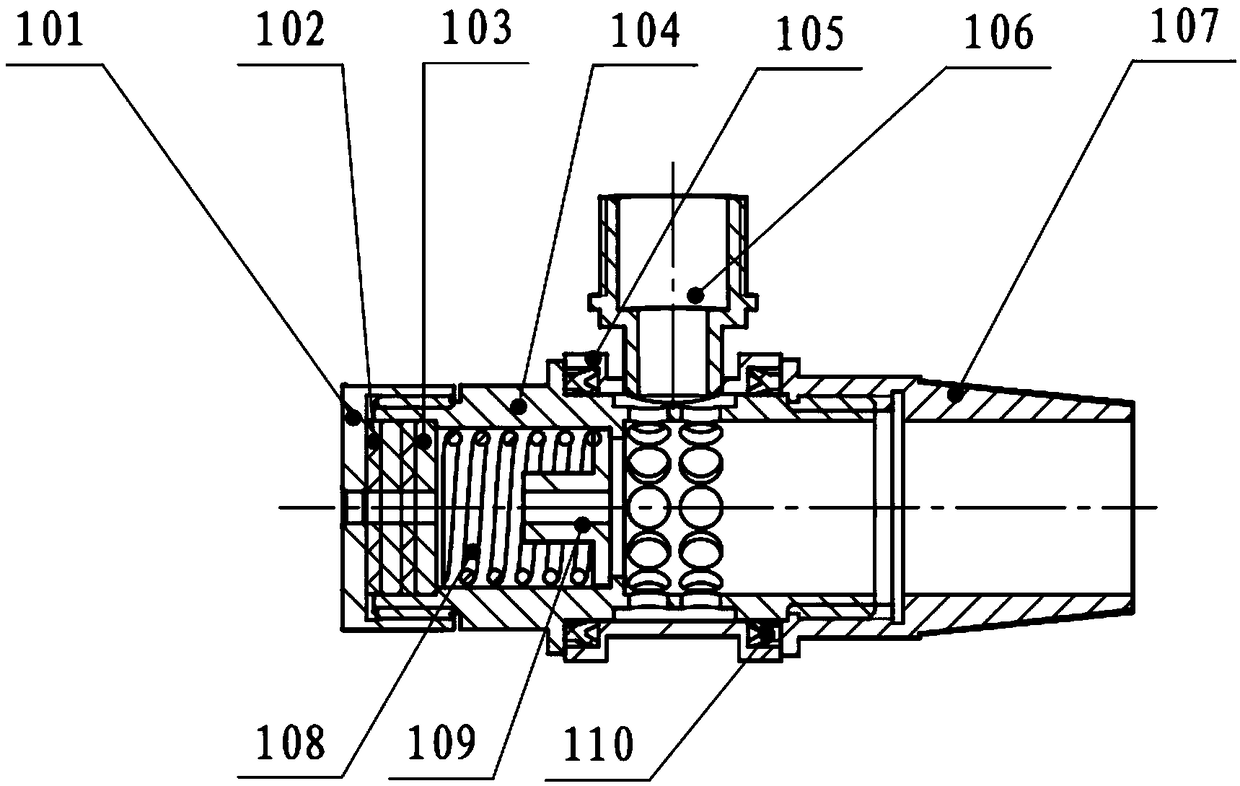

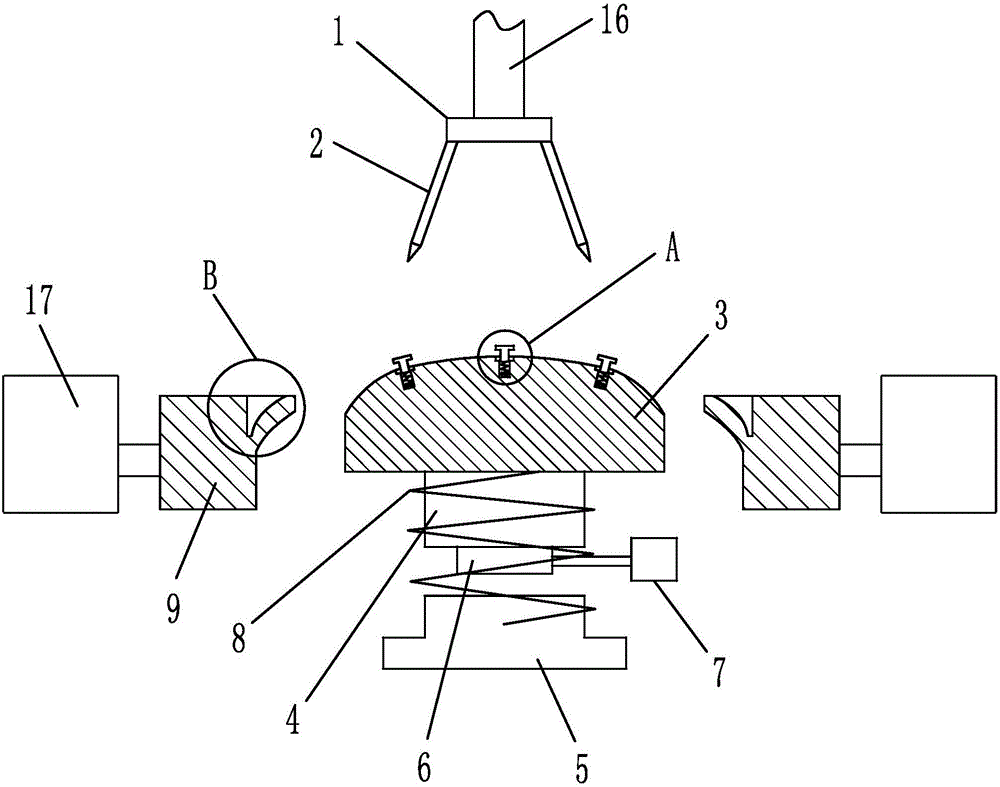

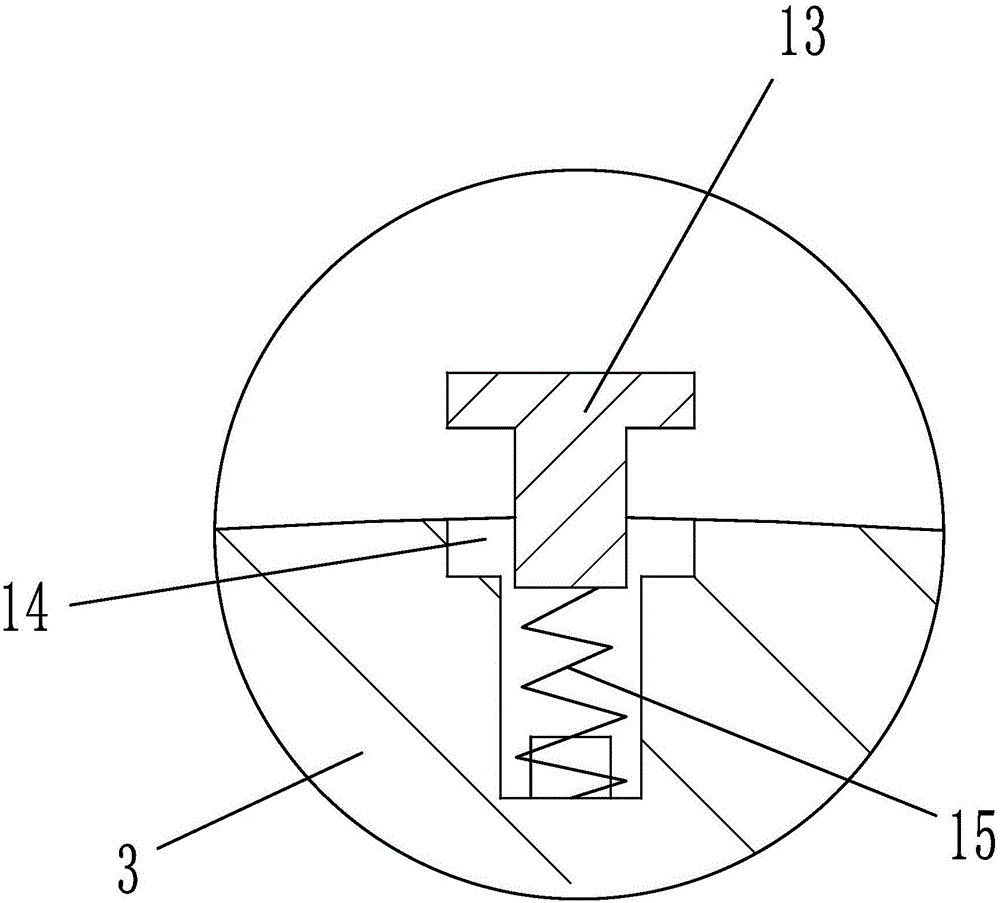

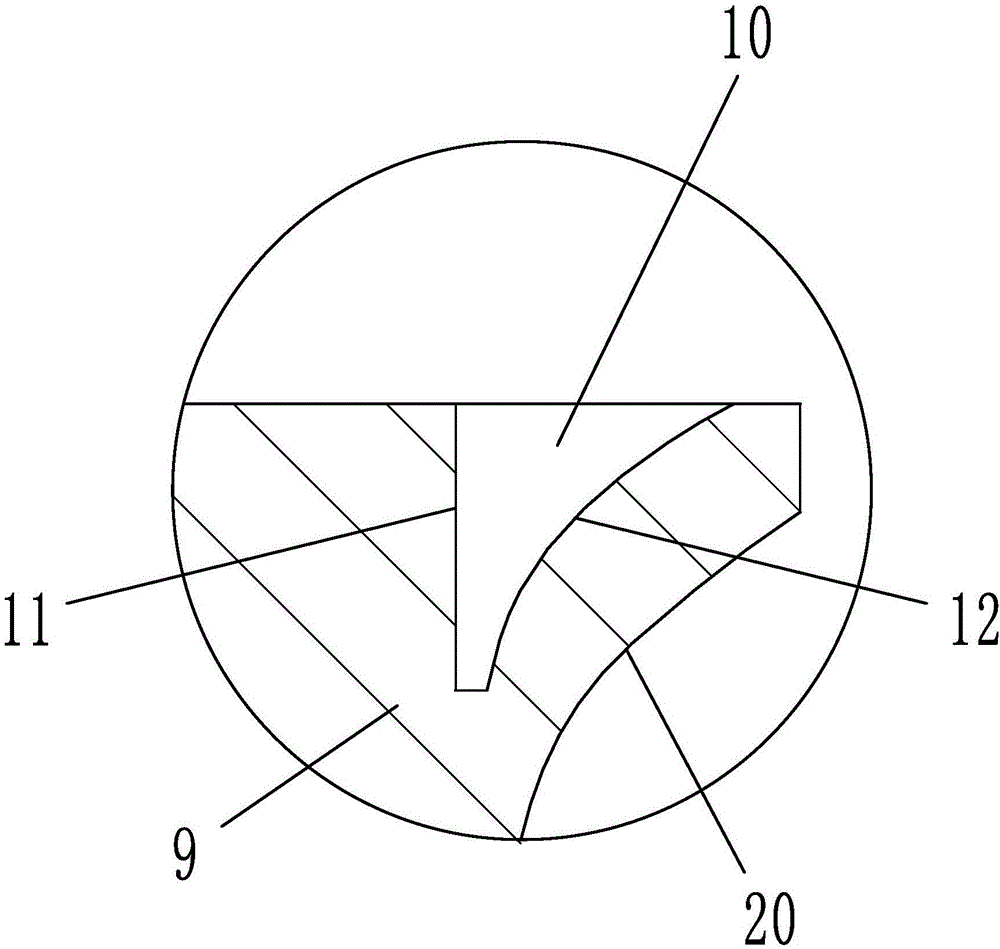

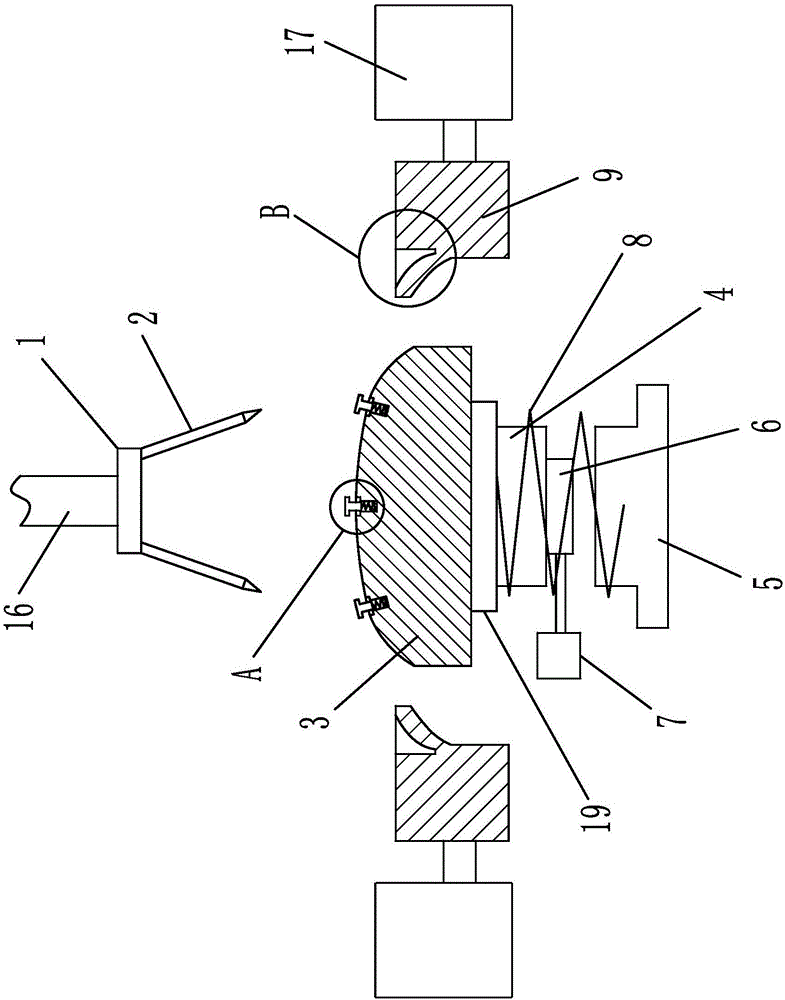

Full-automatic drill grinder

InactiveCN103567821AReduce the number of disassemblyImprove grinding pass rateGrinding feed controlDrilling toolsEngineeringMachining

The invention provides a full-automatic drill grinder. The full-automatic drill grinder comprises a transposition device as well as a feeding device, a grinding device, a detection device and a discharge device which are located around the transposition device, wherein the transposition device comprises a transposition disk and clamping heads arranged on the transposition disk, drills are mounted on the clamping heads through the feeding device, and then the transposition disk is rotated, so that the drills sequentially passes through the grinding device, the detection device and the discharge device for corresponding processing, a whole grinding process can be finished after one-time clamping, both the dismounting time of the drills and errors can be reduced, and the auxiliary time is shortened; servo motors are mounted behind the clamping heads and used for driving the drills on the clamping heads to rotate, so that grinding angles of the drills are adjusted correctly; and the drill grinder is controlled by a program and high in accuracy, the pass percent of the drills is increased, the labor condition is improved, the problems that workers are prone to fatigue and sight losing due to work under microscopes for a long time are solved, and the full-automatic drill grinder is widely applicable to grinding machining of various fine drills.

Owner:刘锦波

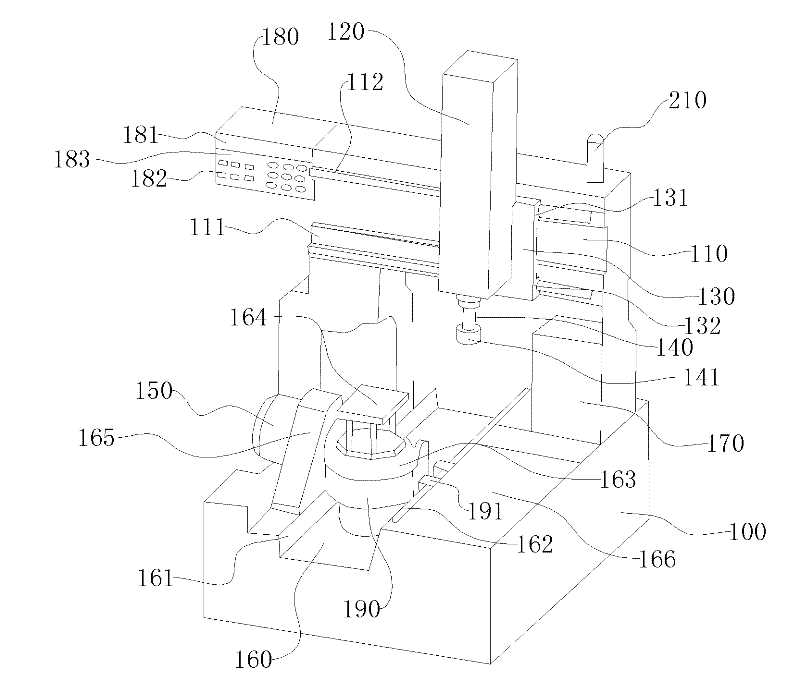

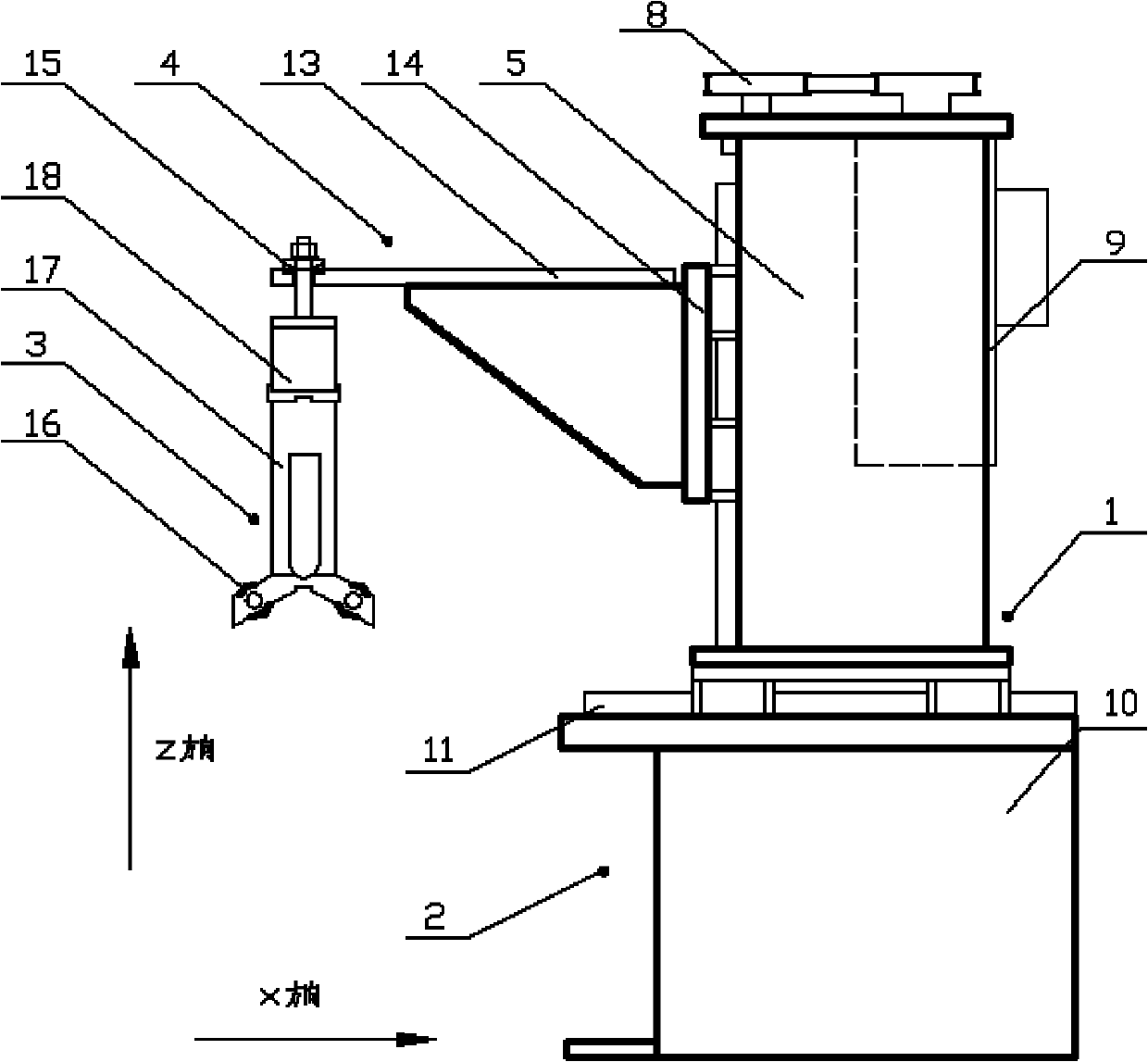

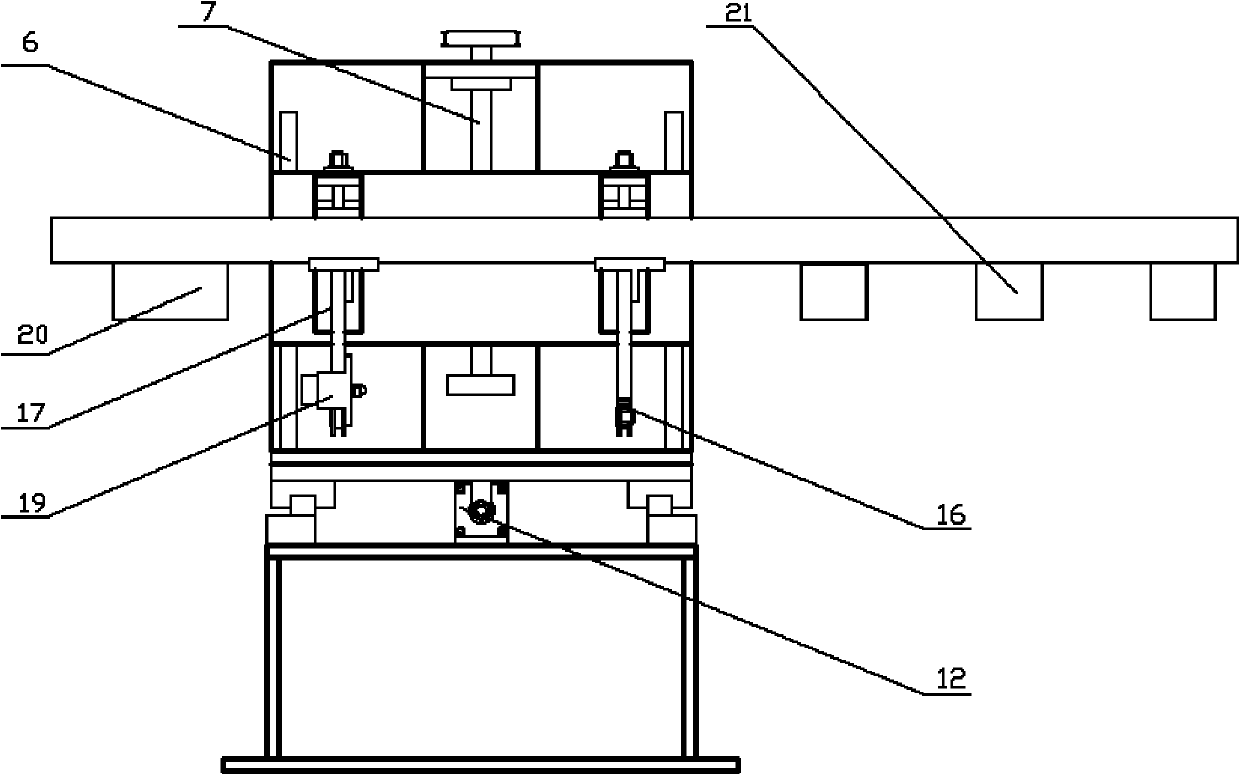

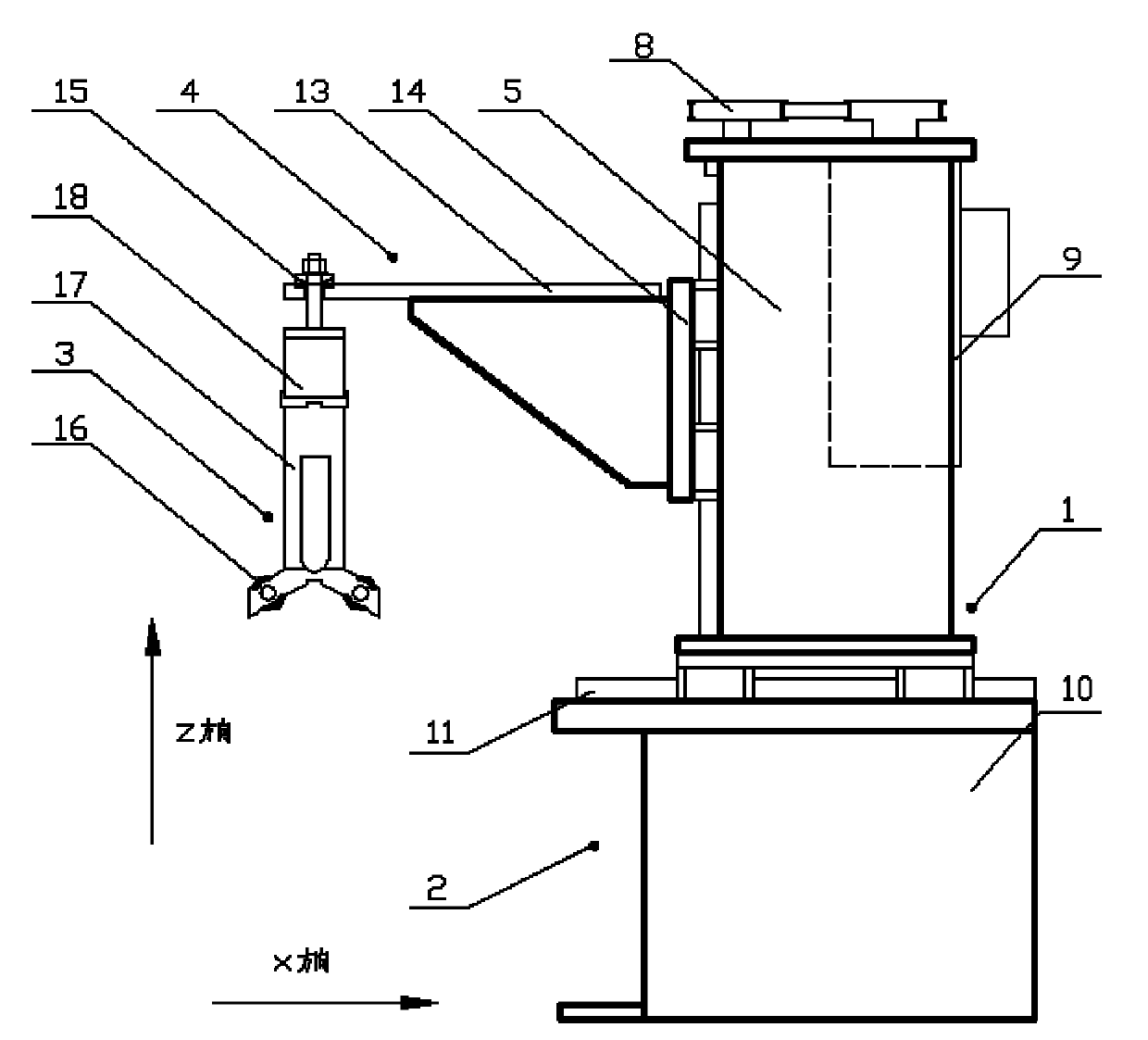

Five-axis linkage numerical control polishing machine

InactiveCN102225528ARealize numerical controlRealize intelligencePolishing machinesGrinding drivesNumerical controlMotor drive

The invention discloses a five-axis linkage numerical control polishing machine which comprises a machine base and a main shaft and is characterized in that one surface of the main shaft is provided with a polishing head; the other side of the main shaft is provided with a Z-axis feeding platform; an X-axis feeding platform is arranged near the main shaft; the X-axis feeding platform and the Z-axis feeding platform are vertical to each other; the machine base comprises a Y-axis feeding platform, a vertically rotary motor and a working table surface; the Y-axis feeding platform is arranged in the middle of the machine base; the vertically rotary motor is arranged at one side of the machine base; the other side of the machine base is provided with the working table surface; the Y-axis feeding platform is provided with a movable table surface; a horizontally rotary motor is arranged at the lower part of the movable table surface; therefore, the machine has the advantages of high location precision and constant polishing effect; the motor drive can achieve the high rotation speed (10000 rpm to 20000 rpm); the machine can be freely switched between the dry polishing and the wet polishing; and the machine can be used for improving the flexibility of working hours, making up for the deficiency of the prior art, improving the production efficiency and realizing complete numerical control and intelligence.

Owner:赵明杰

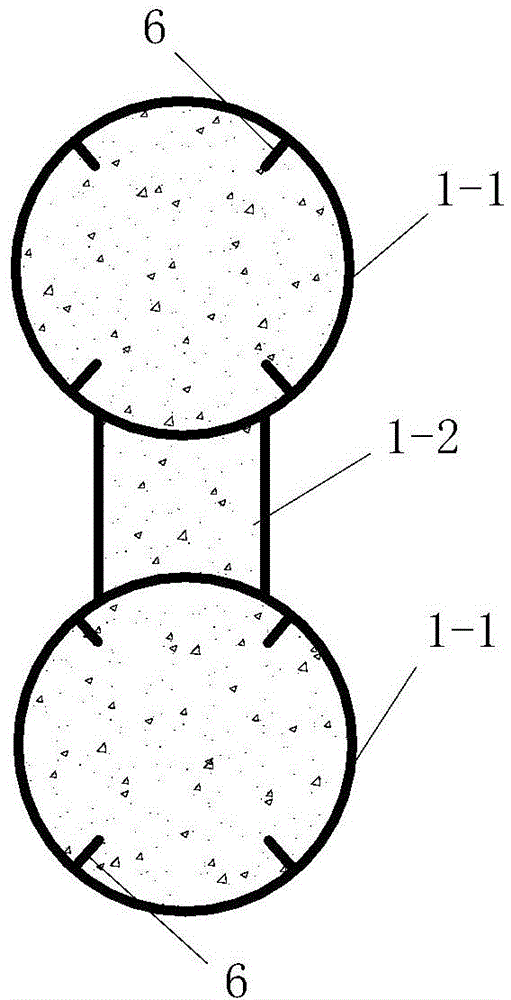

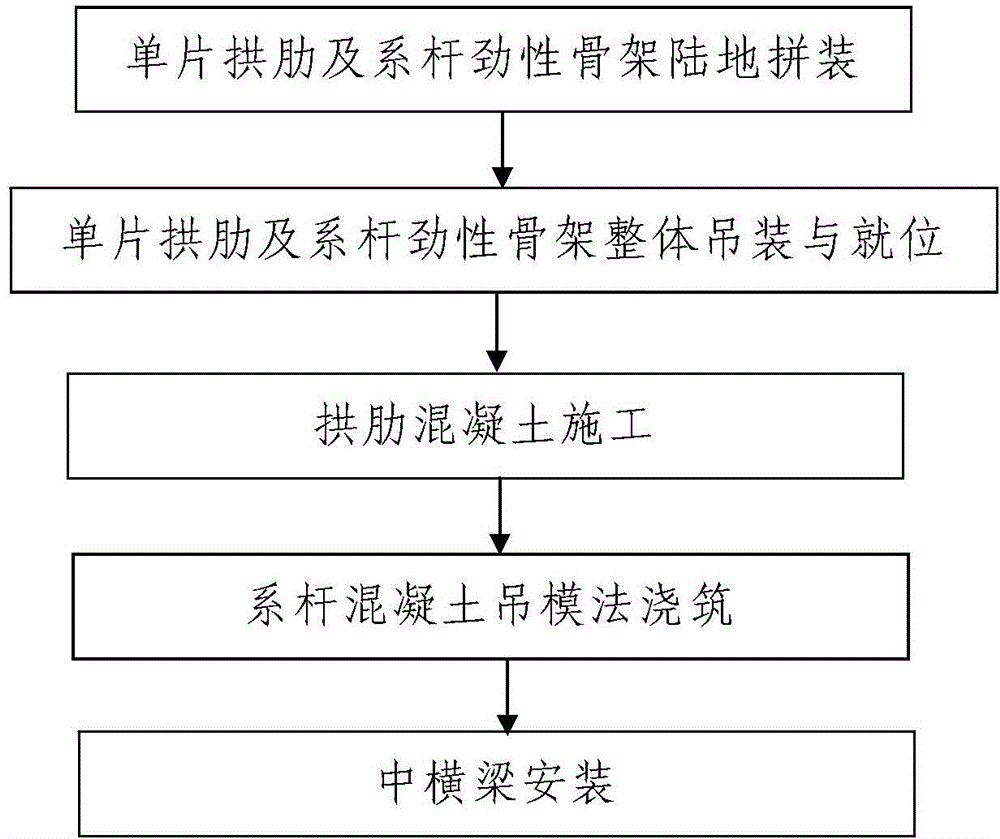

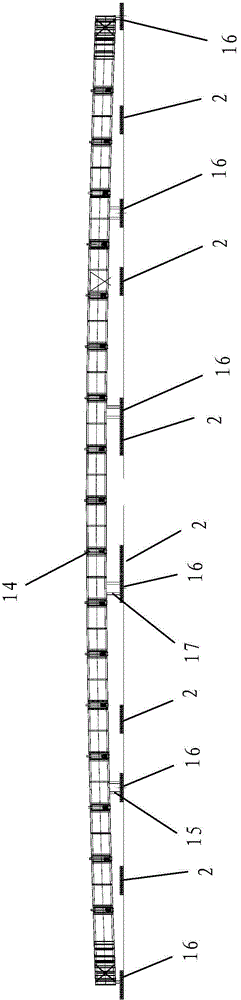

Construction process of large-span steel tube arch bridge without supports

ActiveCN104594197AThe process steps are simpleReasonable designBridge erection/assemblyArch-type bridgeSpandrelMarine navigation

The invention discloses a construction process of a large-span steel tube arch bridge without supports. The constructed large-span steel tube arch bridge is a tied-arch bridge erected on a river channel. A bridge upper structure of the tied-arch bridge comprises arch ribs and tie bars connected between every two arch pins of the arch ribs. Rigid frameworks are arranged in the tie bars. The construction process includes the following steps of firstly, splicing the single-piece arch ribs and the rigid frameworks of the tie rods on the land, wherein arch-shaped steel tube supports of the arch ribs and the rigid frameworks are spliced on a splicing field on a bank side of the river channel; secondly, hoisting the single-piece arch ribs and the rigid frameworks of the tie rods together and placing the arch ribs and the rigid frameworks in place; thirdly, constructing the arch ribs through concrete, wherein the arch pins and end beams are constructed, and concrete is symmetrically pressed and poured for the arch ribs; fourthly, conducting pouring through a tie rod concrete suspended form method; fifthly, installing middle beams. The construction process is simple in process step, reasonable in design, convenient to construct and good in construction effect; the construction process of the large-span steel tube arch bridge without supports can be easily, conveniently and rapidly completed without greatly influencing the navigation of the river channel.

Owner:NO 1 ENG LIMITED OF CR20G

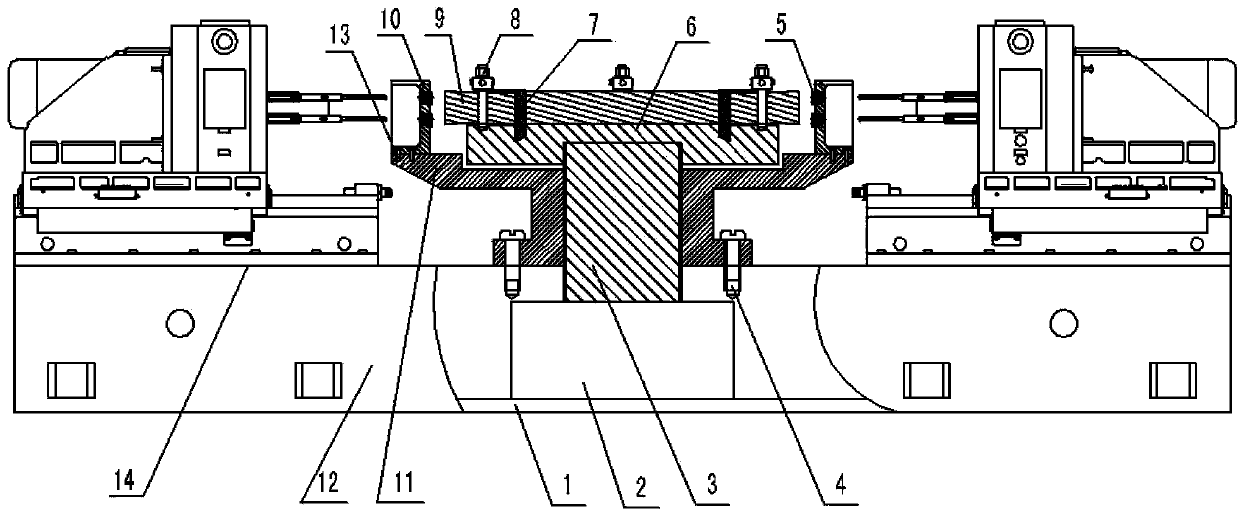

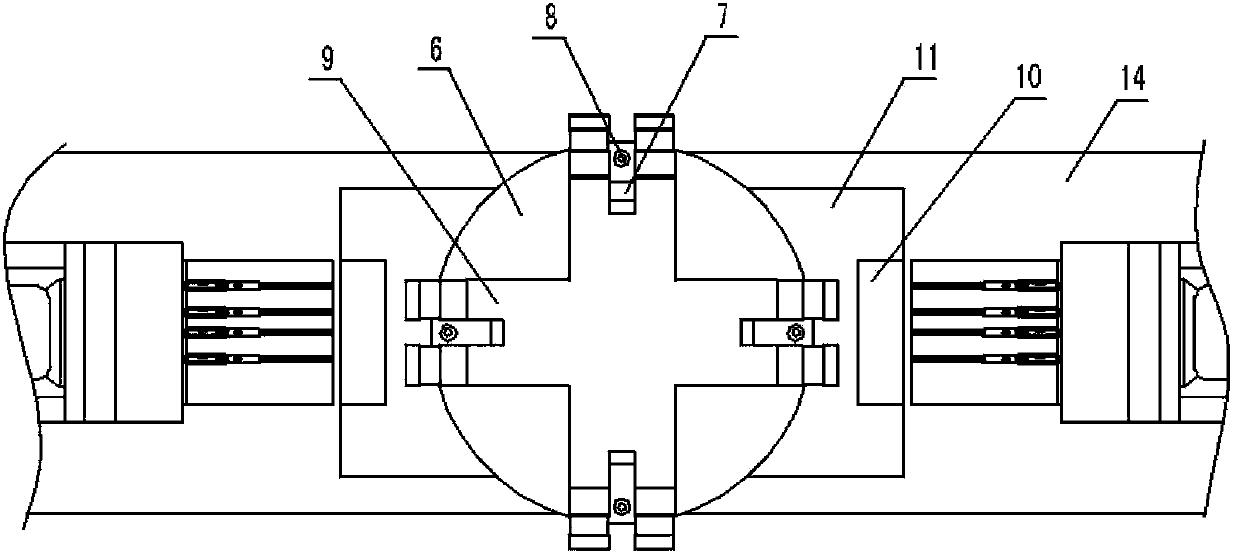

Multi-head drilling equipment comprising rotary table

InactiveCN103418813ARealize multi-face porous processingReduce installationLarge fixed membersBoring/drilling componentsRotary stageIndustrial engineering

The invention discloses multi-head drilling equipment comprising a rotary table. The multi-head drilling equipment comprising the rotary table is characterized in that a motor base is arranged on the bottom face of an inner cavity of a middle machine body of a horizontal-type two-way machine, a rotary motor is fixedly arranged on the motor base, an output shaft of the rotary motor is upward vertically, the rotary table is fixedly arranged at the top end of the output shaft, the rotary table is provided with a plurality of locating grooves with fixing boards inserted and connected, and locking nails penetrate through the fixing boards and process holes of a machined workpiece and fasten the machined workpiece on the rotary table; the output shaft of the motor is sleeved with a tool table which is arranged on the machine body horizontally and is fastened on the machine body through fastening nails; drill die sleeves are arranged on drilling tools, and the drilling tools are fixed to the tool table through fasteners. The multi-head drilling equipment comprising the rotary table aims at machined workpieces with multiple faces and multiple holes, secondary installation is not needed, the requirements for drilling can be met by rotating the rotary table, the efficiency is high, the hole site precision is high, and the structure of the equipment is simple.

Owner:安徽海川重工科技有限公司

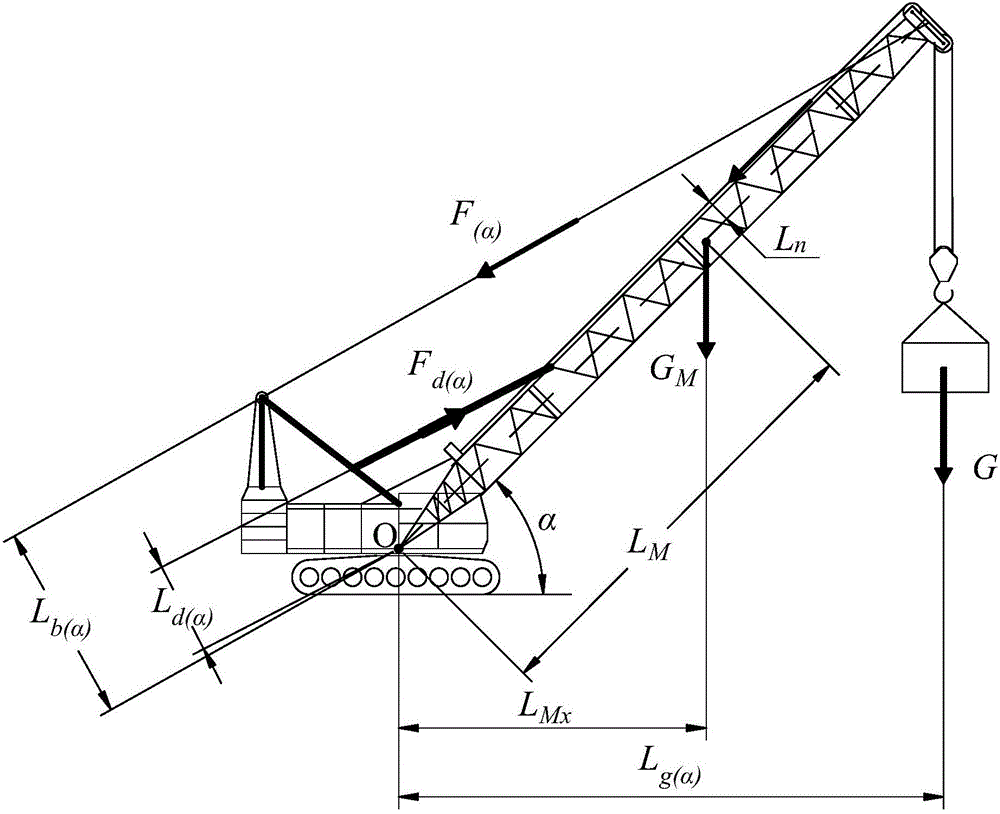

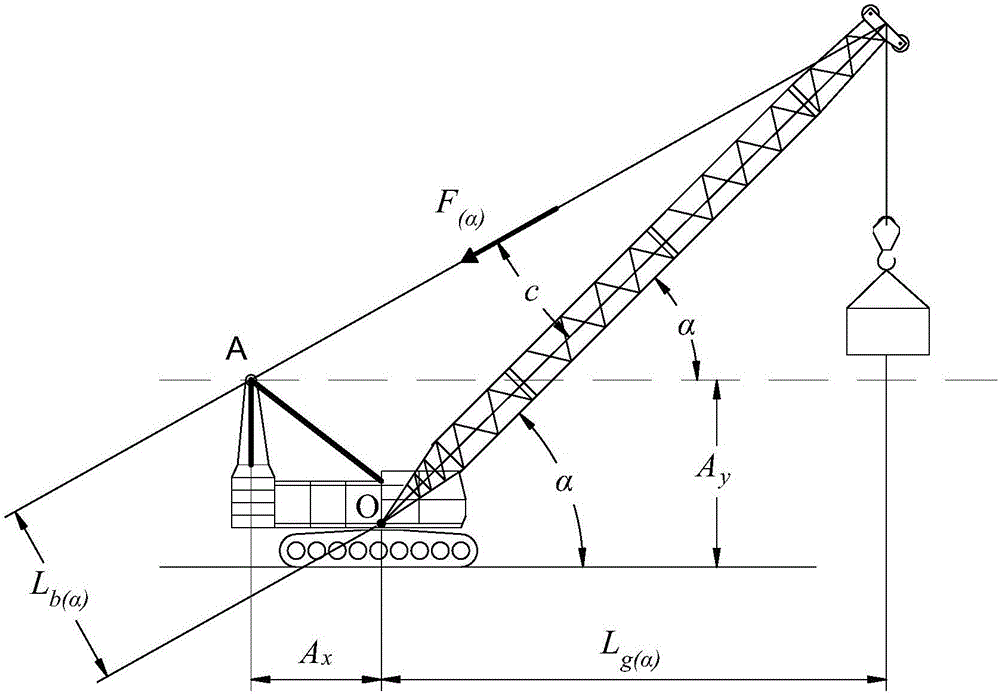

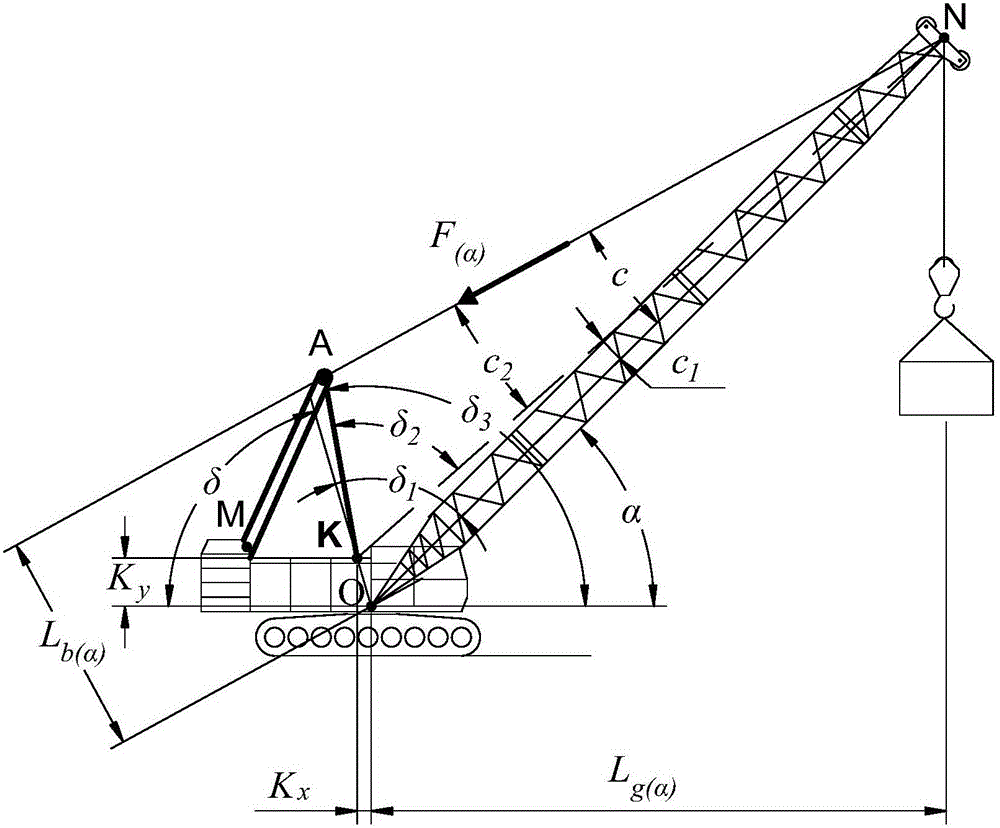

Variable-amplitude rope weighing algorithm

ActiveCN106395630ASolve the swap problemAchieving the need for reuseInformaticsSpecial data processing applicationsMechanical modelsComputer engineering

The invention discloses a variable-amplitude rope weighing algorithm. According to the algorithm, a moment balance theory is utilized to build a mechanical model, and parameters in the mechanical model are calibrated so that the algorithm is capable of solving the problem of interchange of a tensile sensor and realizing the requirement on repeated utilization of debugging data; meanwhile, by adopting the variable-amplitude rope weighing algorithm disclosed by the invention, the weighing measurement under all arm lengths can be realized by replacing only two arm lengths at most and requiring only two times of calibration under each working condition, so the number of mounting and dismounting times of arm levers can be greatly reduced, and the debugging period can be shortened.

Owner:宜昌凯诺电气股份有限公司

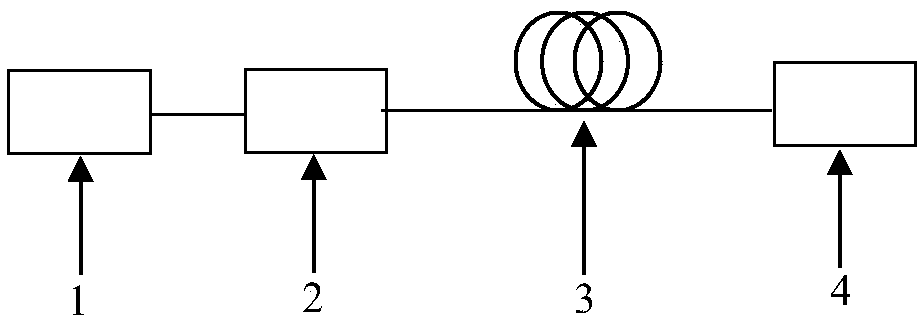

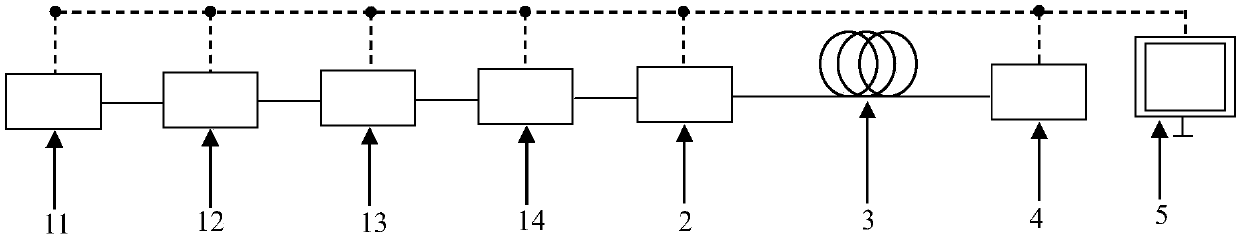

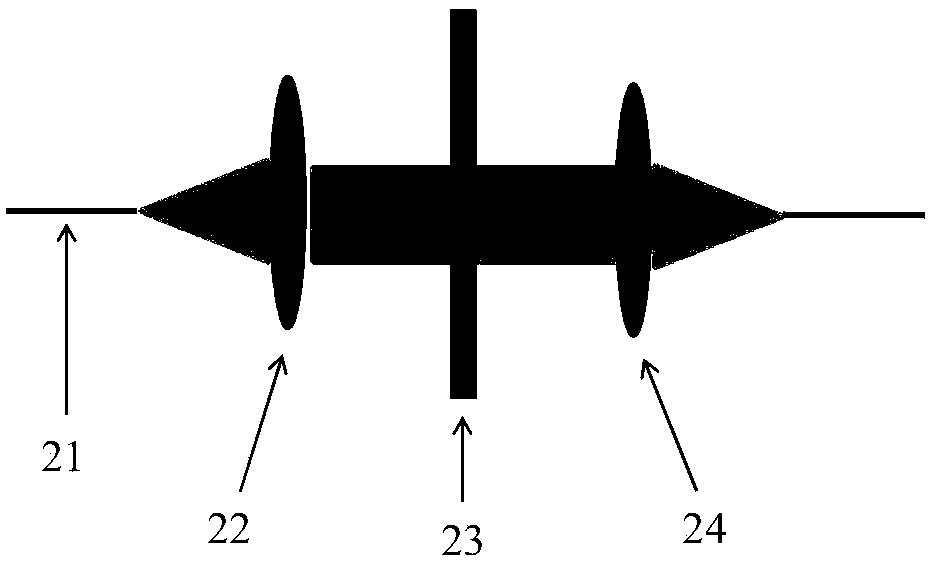

Integrated tester and test method for few-mode fibers

ActiveCN107677452ARealize multiplexingEasy to measureTesting fibre optics/optical waveguide devicesFew mode fiberCombined test

The invention discloses an integrated tester and a test method for few-mode fibers. The tester includes a light source unit, a guide mode selection unit and an oscilloscope arranged in sequence alongthe light path, and further includes a detection unit. The guide mode selection unit includes a narrow-band mode selection module and a wide-band mode selection module. The oscilloscope is used for acquiring the time-domain waveform after a tested few-mode fiber. The detection unit is used for obtaining the time-domain waveforms measured by the oscilloscope in different states according to the detection mode and calculating the differential group delay and dispersion coefficient of the tested few-mode fiber through a pulse delay approach. The method includes the following steps: (1) selectinga tested few-mode fiber, placing the tested few-mode fiber between the guide mode selection unit and the oscilloscope of the tester, and adjusting the light path to make the light path smooth; and (2)comprehensively testing the differential group delay or dispersion coefficient. The tester provided by the invention is simple and reliable, and has a high degree of integration. The test method greatly reduces the workload, and has a high degree of automation.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

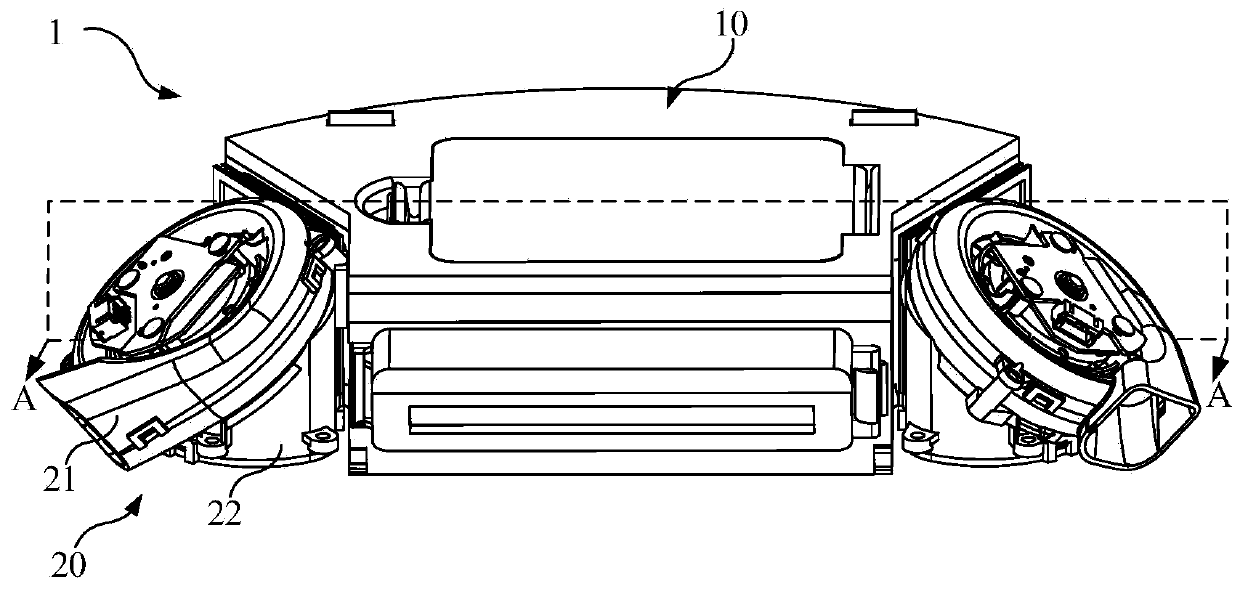

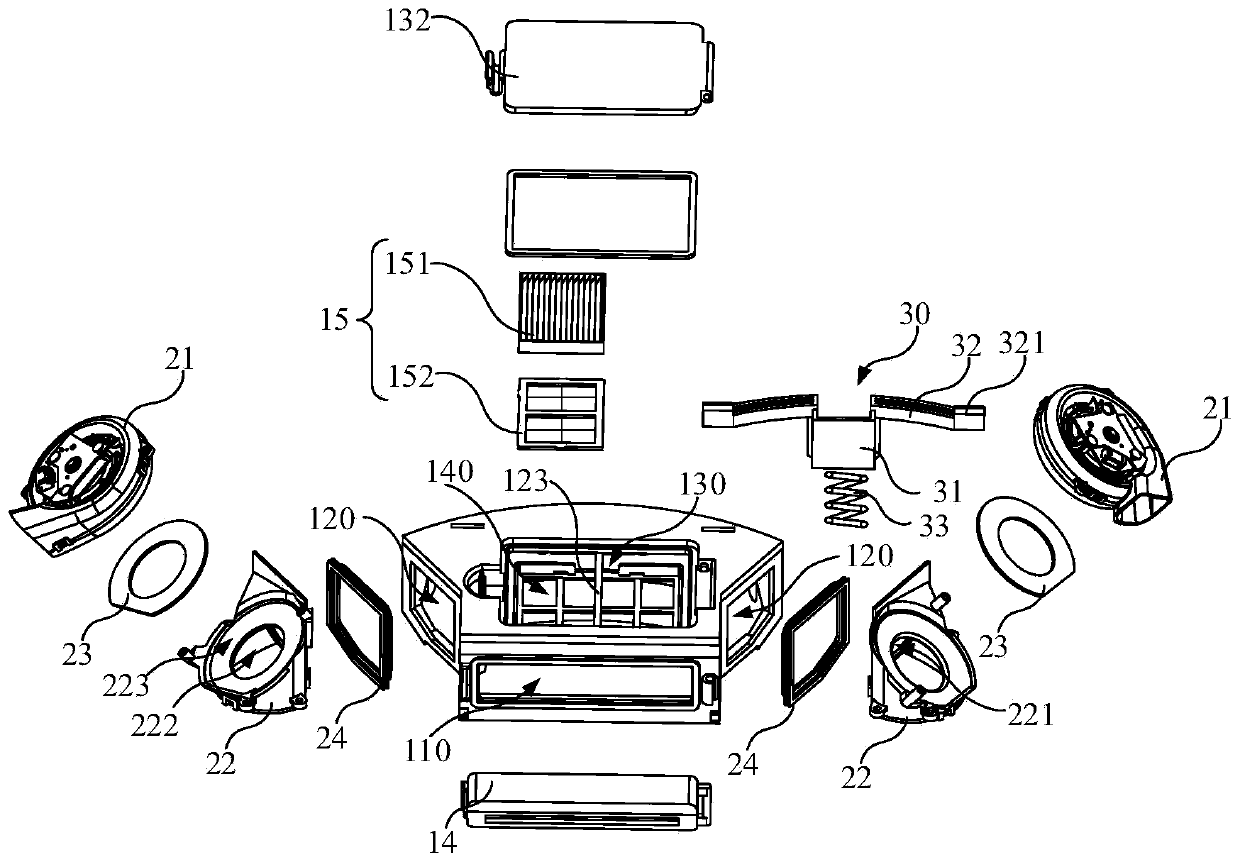

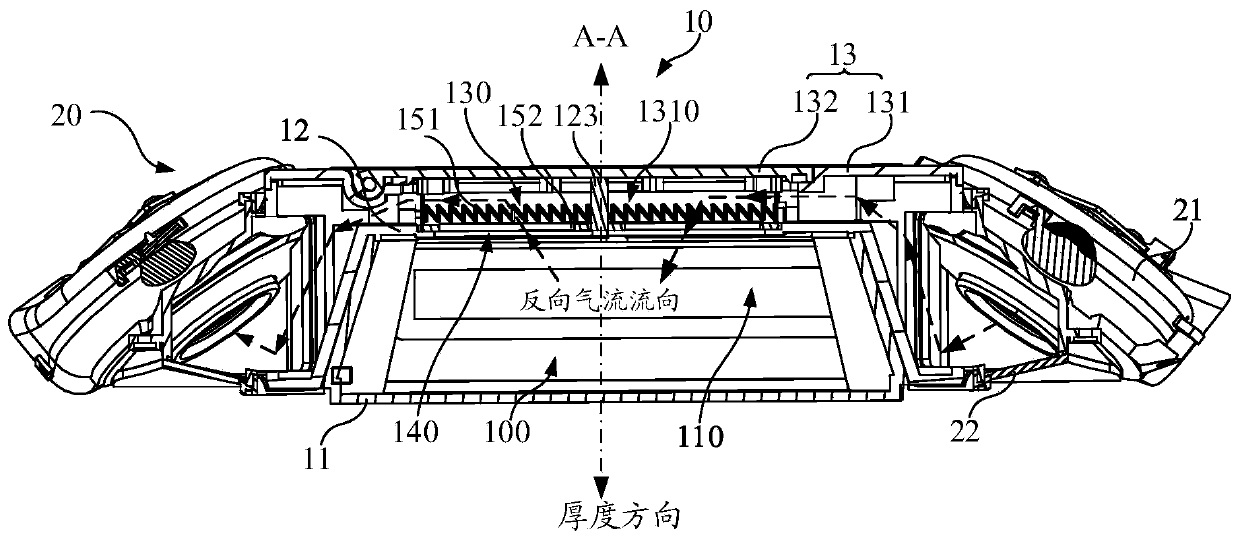

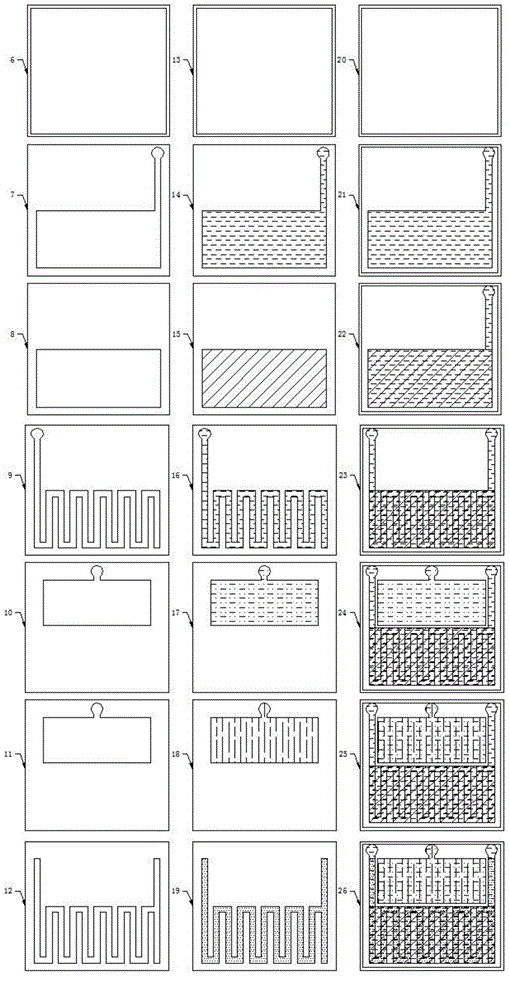

Dust box self-cleaning system, dust box assembly, cleaning device and self-cleaning method

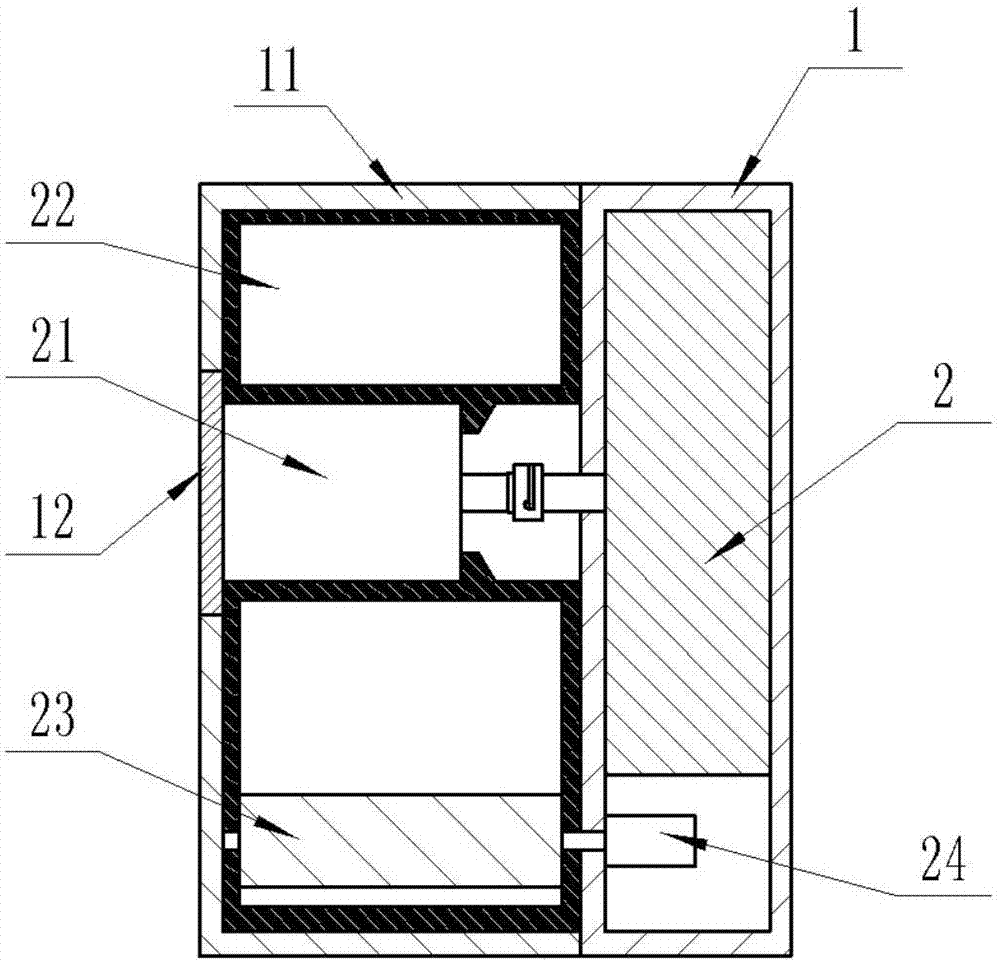

PendingCN111281275ARealize self-cleaningReduce the number of disassemblyCleaning filter meansCarpet cleanersEnvironmental engineeringCleaning methods

The invention discloses a dust box self-cleaning system, a dust box assembly, a cleaning device and a self-cleaning method. The dust box assembly comprises a dust box, at least two filtering pieces and at least two draught fans. A containing cavity and a channel cavity which are arranged at an interval are formed in the dust box; the channel cavity is provided with at least two channel sub-cavities which are independent of each other, at least two communicating openings which are formed at intervals are formed in the dust box, each communicating opening is correspondingly communicated with atleast one channel sub-cavity and the containing cavity, the dust box is further provided with at least two air outlets, and each air outlet is correspondingly communicated with at least one channel sub-cavity; the at least two filtering pieces are arranged corresponding to the at least two communicating openings; and each communicating opening is provided with at least one filtering piece, when part of the fans work and the other fans do not work, reverse airflow sequentially passing through the air outlets corresponding to the other fans, the channel sub-cavities and the communicating openings can be formed in the dust box, and then the filtering pieces corresponding to the other fans which do not work are cleaned. By means of the mode, the filtering pieces can be conveniently and rapidlycleaned.

Owner:ANKER INNOVATIONS TECH CO LTD

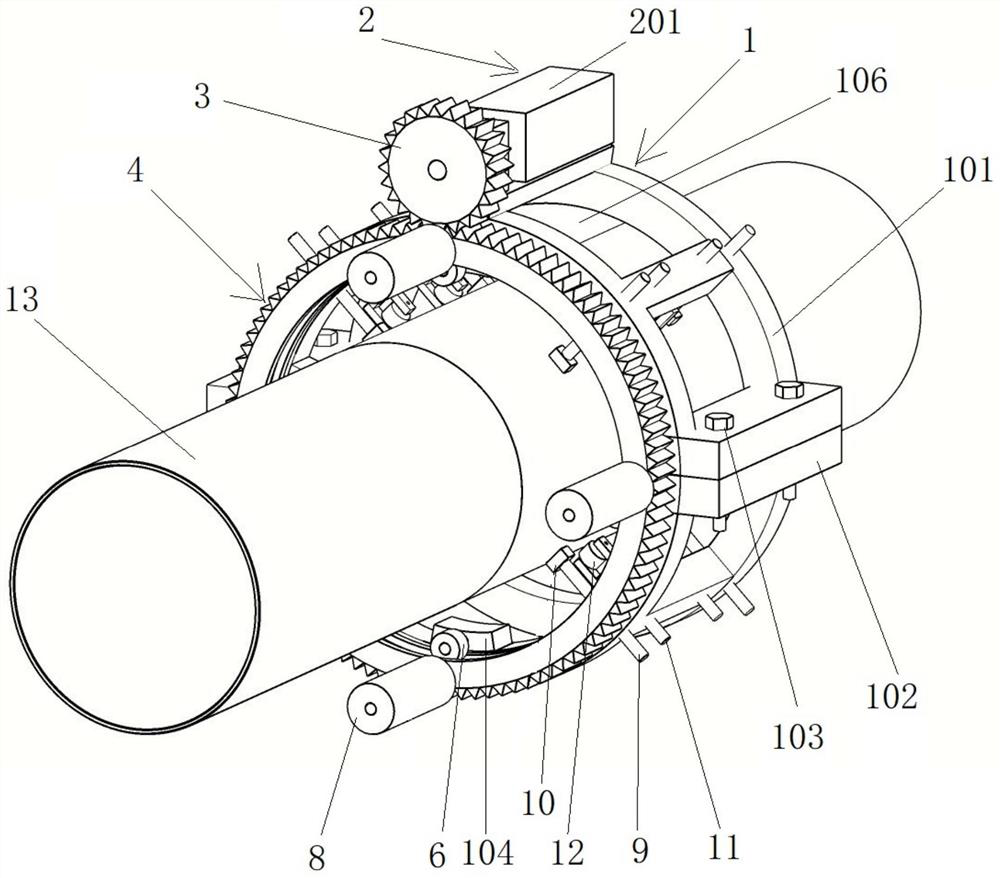

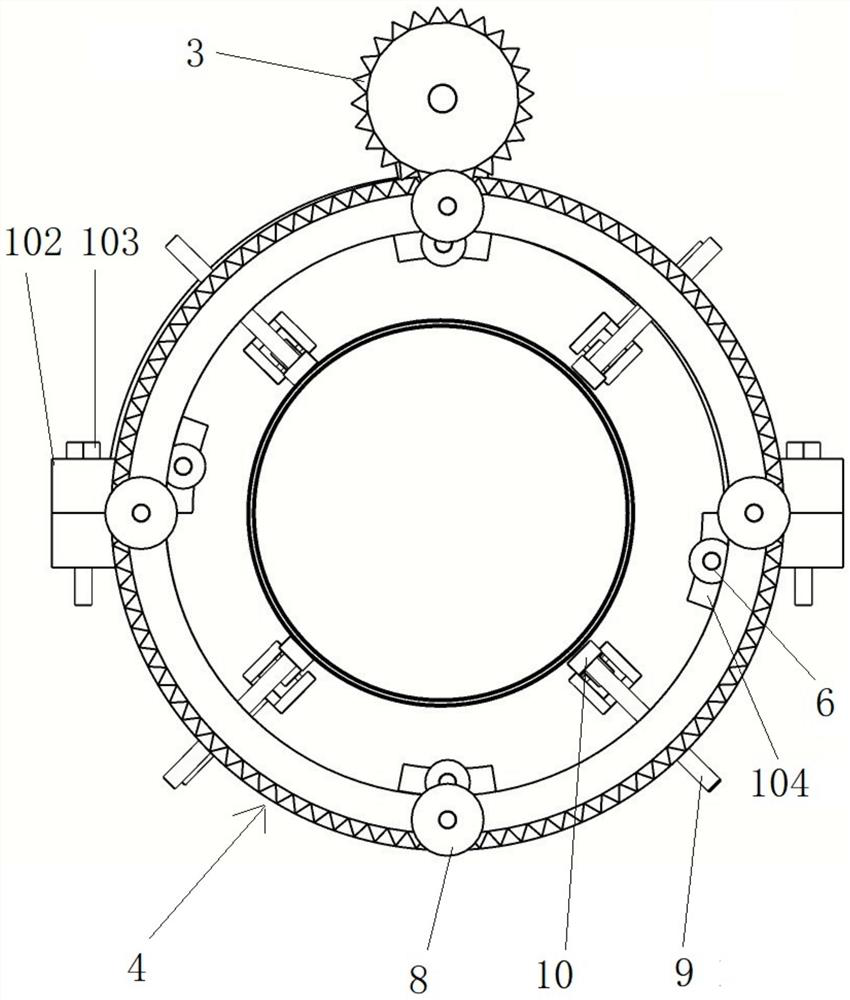

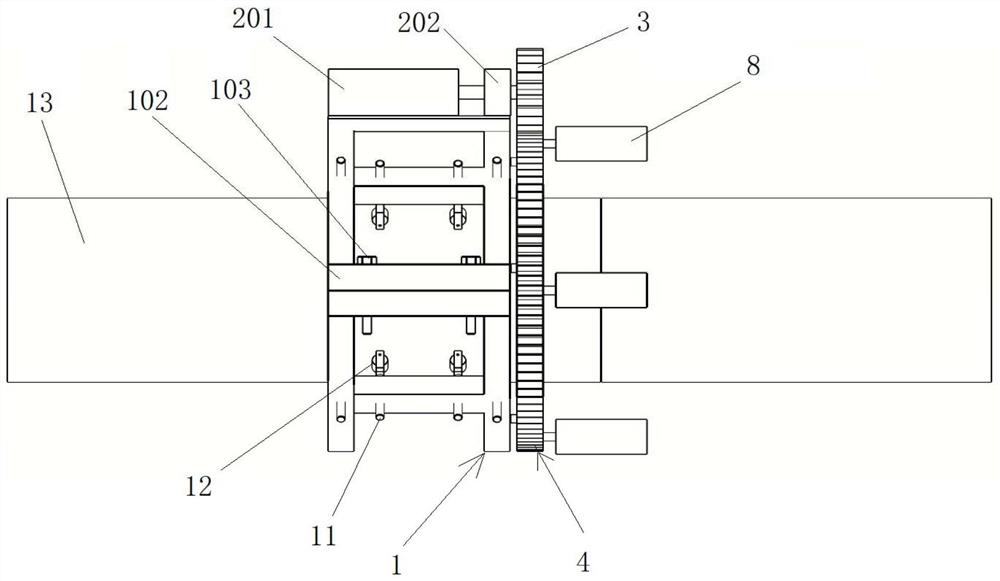

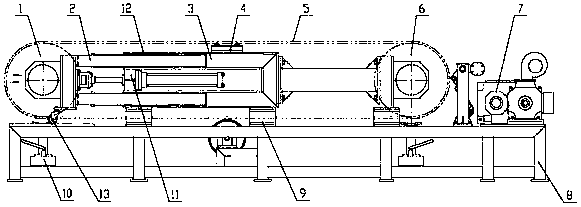

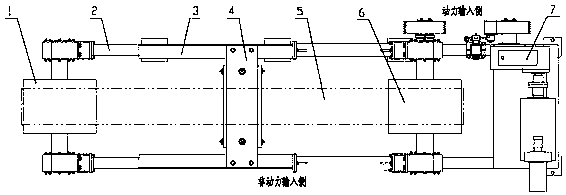

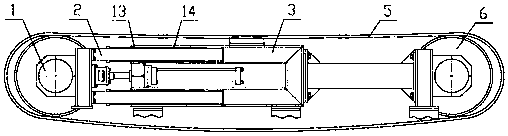

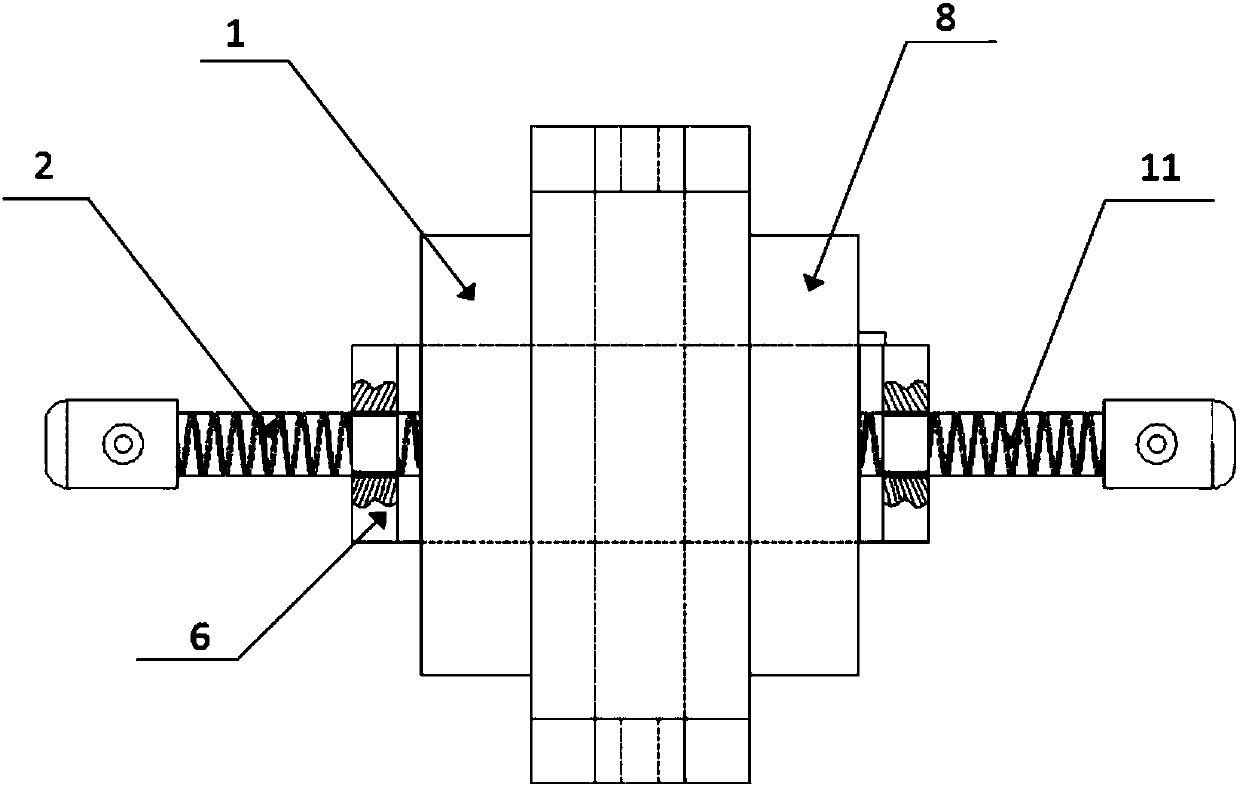

Winding machine for composite reinforced line pipe and use method thereof

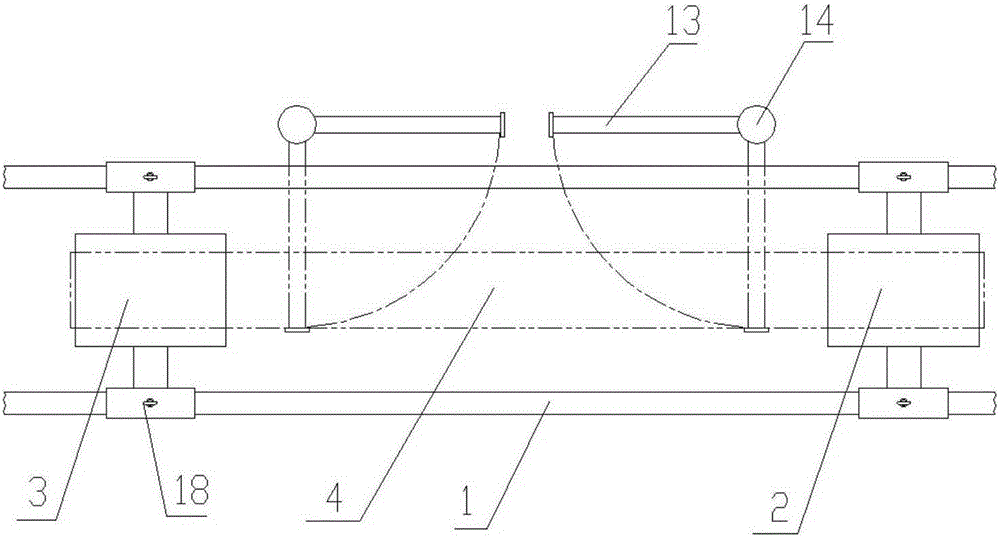

ActiveCN111646327AImprove winding efficiencyImprove winding qualityFilament handlingWinding machineLine tubing

The invention discloses a winding machine for a composite reinforced line pipe and a use method thereof. A positioning device comprises a positioning frame, wherein the positioning frame can fixedly sleeve the to-be-wound steel pipe. A power device comprises a driving mechanism, a gear, an outer gear ring, a positioning bearing and a connecting shaft, wherein the outer gear ring can sleeve the to-be-wound steel pipe, the outer gear ring is located at one end of the positioning frame, the end, away from the positioning frame, of the outer gear ring is provided with a winding roller, an inner circle of the outer gear ring is circumferentially provided with a groove, the positioning bearing is arranged in the groove, the axis of the positioning bearing is parallel to the axis of the outer gear ring, one end of the connecting shaft is matched and connected with a bearing hole of the positioning bearing, the other end of the connecting shaft is fixedly connected with the positioning frame,the driving mechanism is fixed to the positioning frame, the gear fixedly sleeves an output shaft of the driving mechanism, and the gear meshes with the outer gear ring. The winding machine can improve fiber winding efficiency and fiber winding quality and reduce health harm to constructors.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

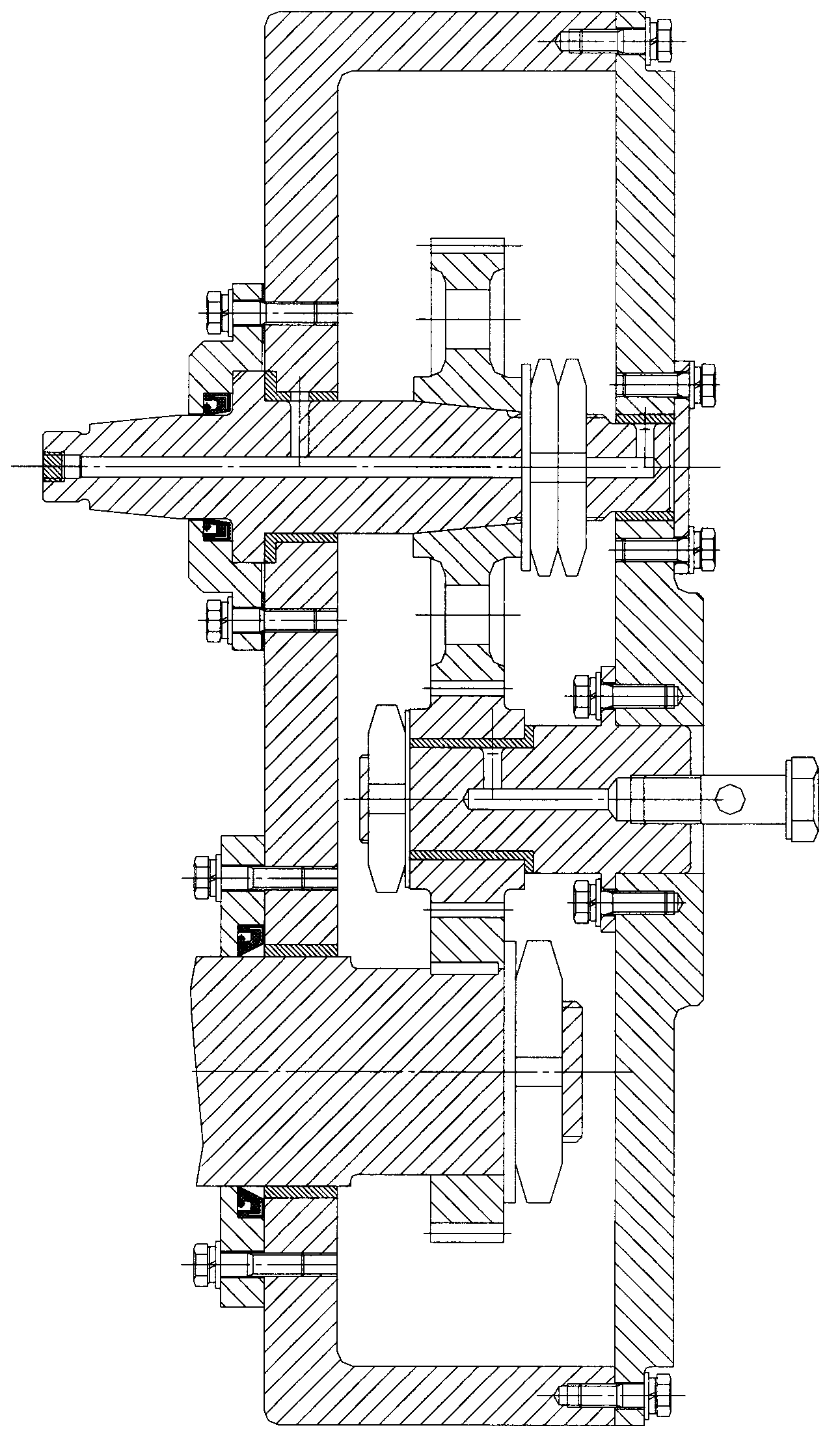

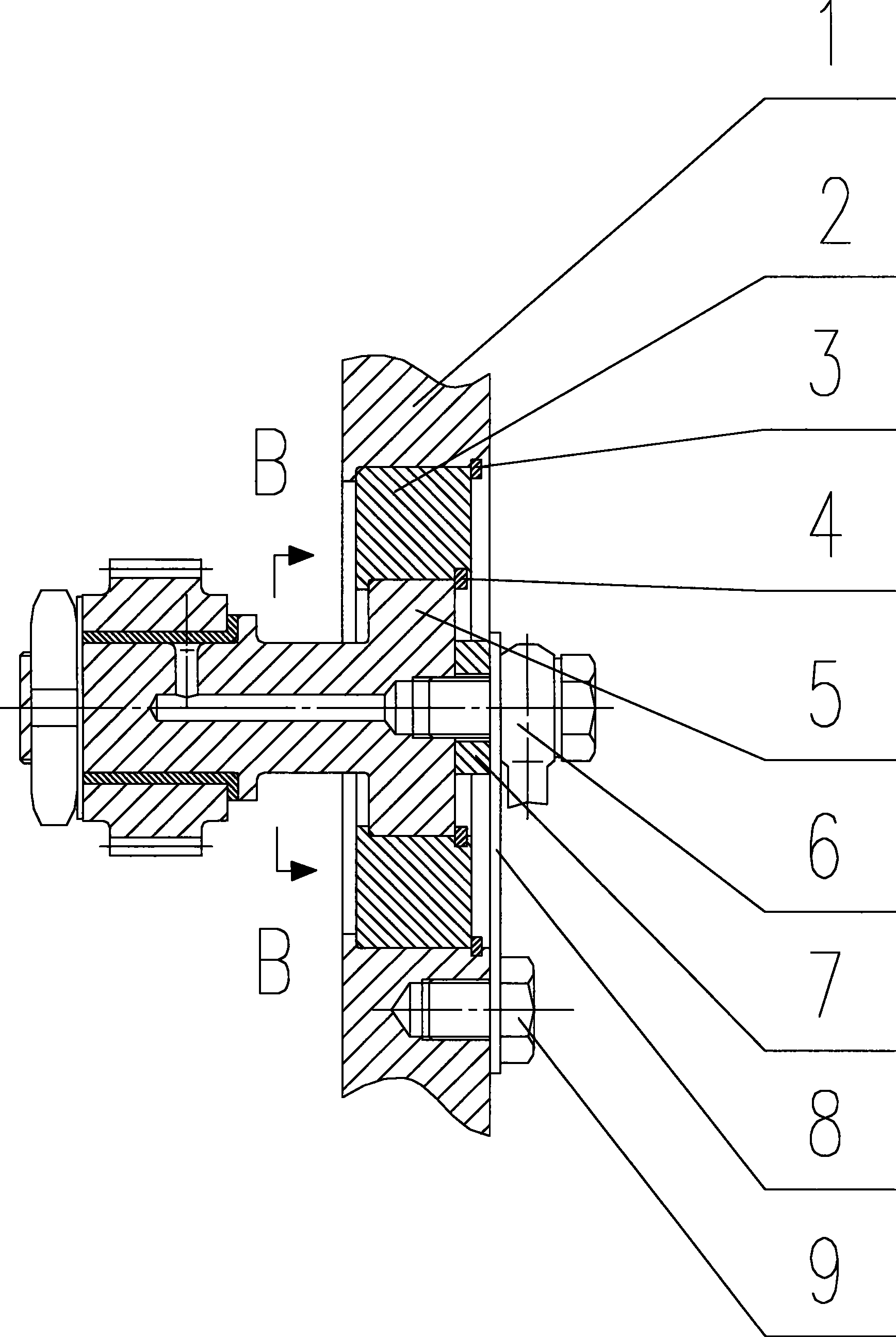

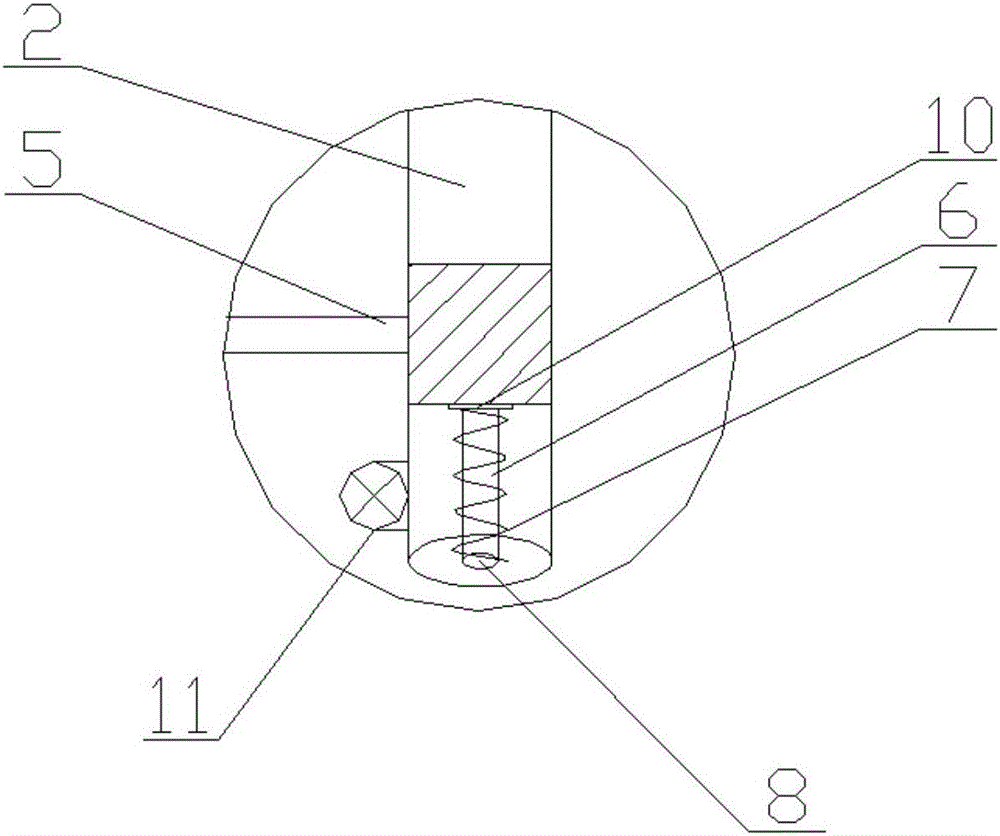

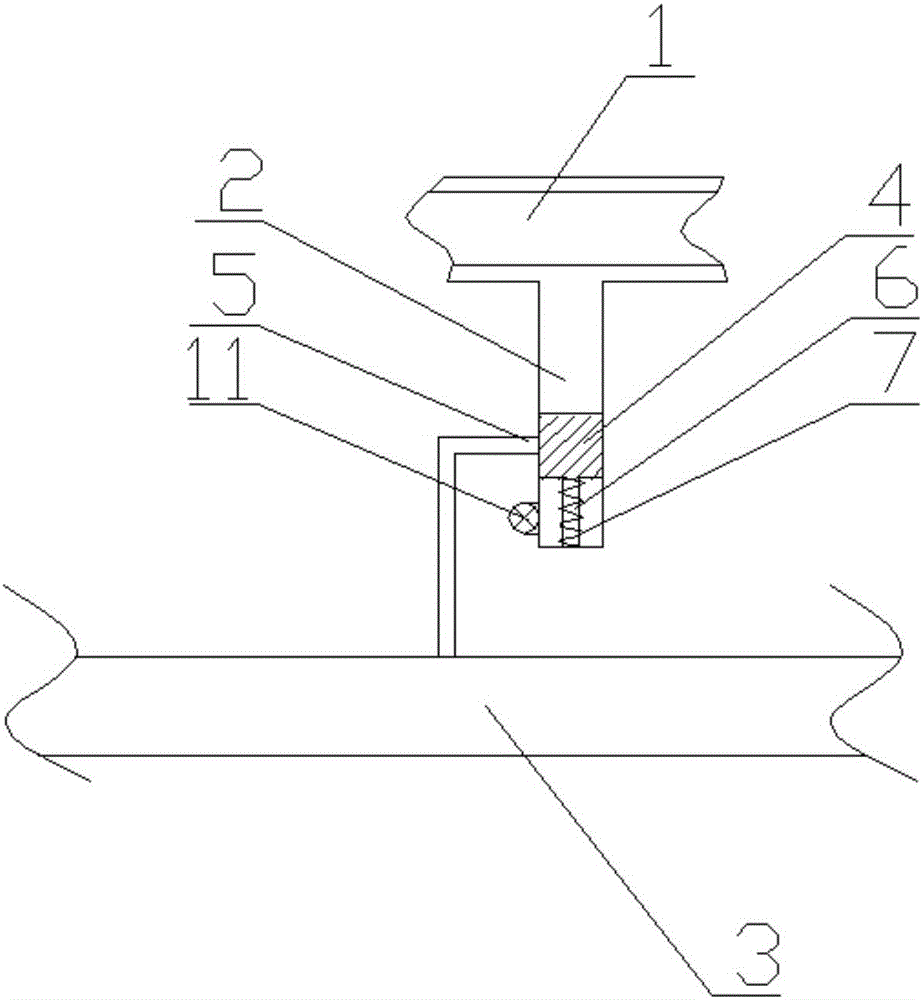

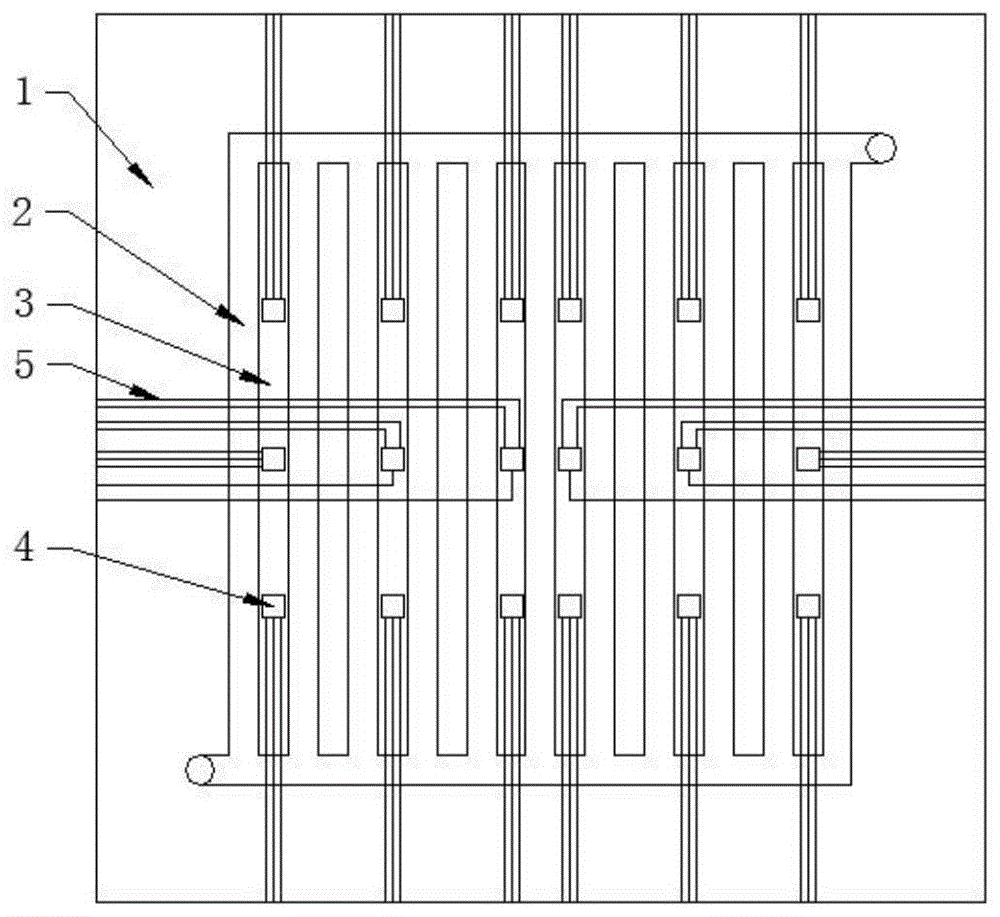

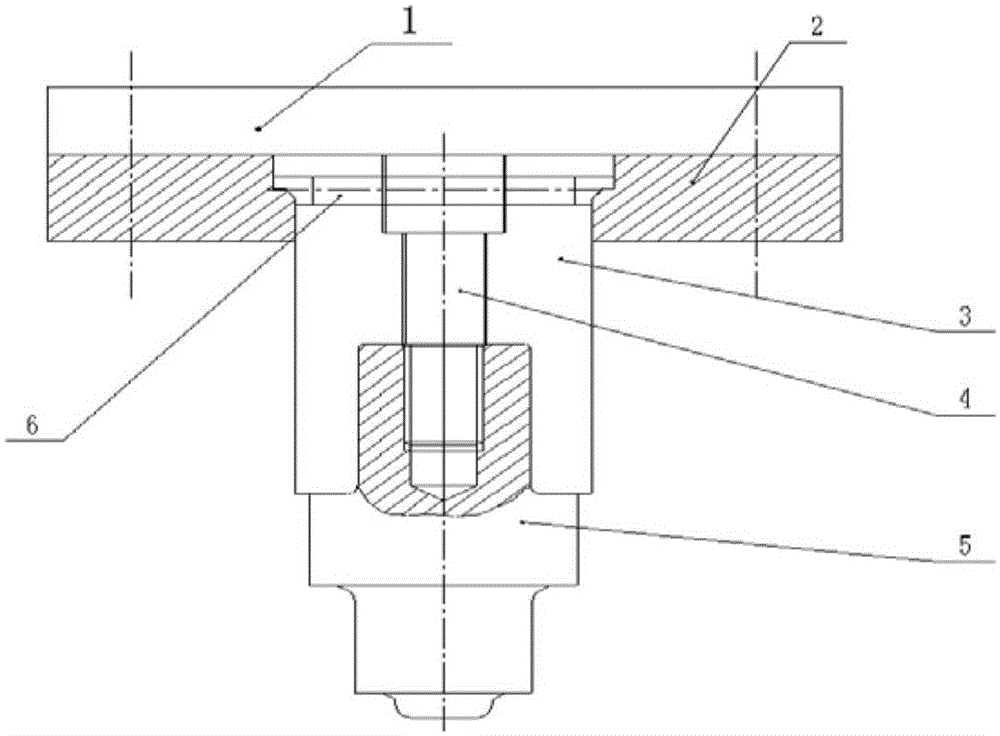

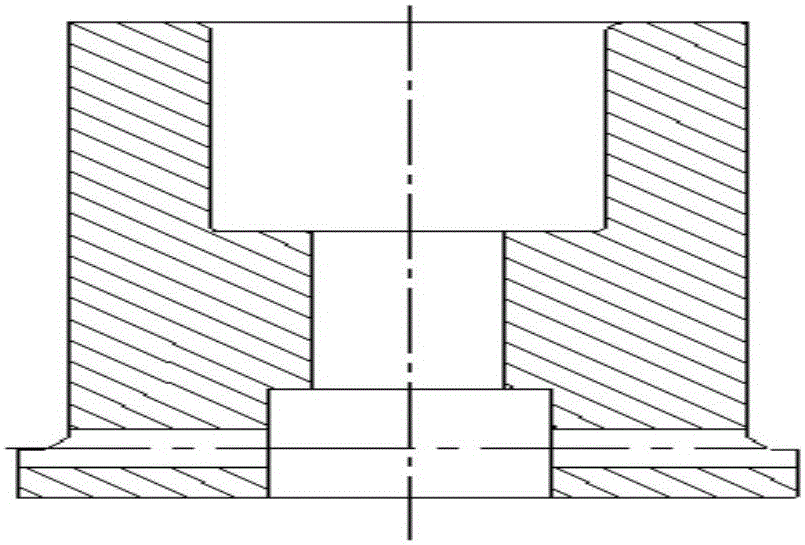

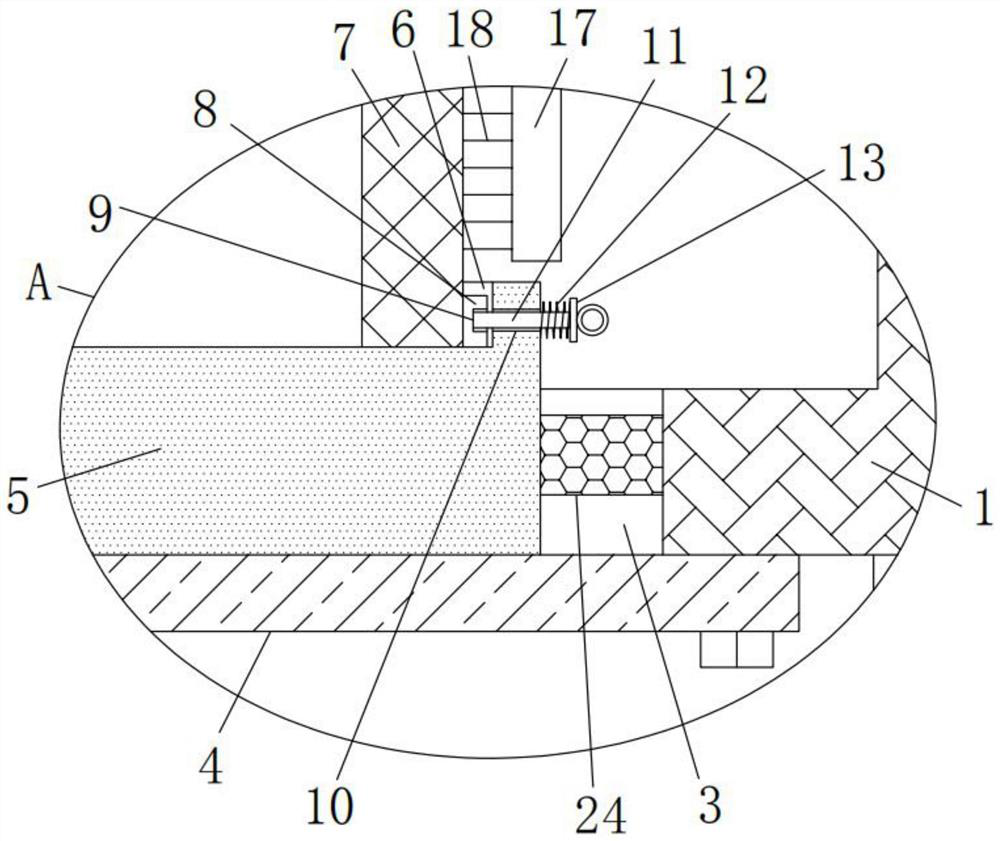

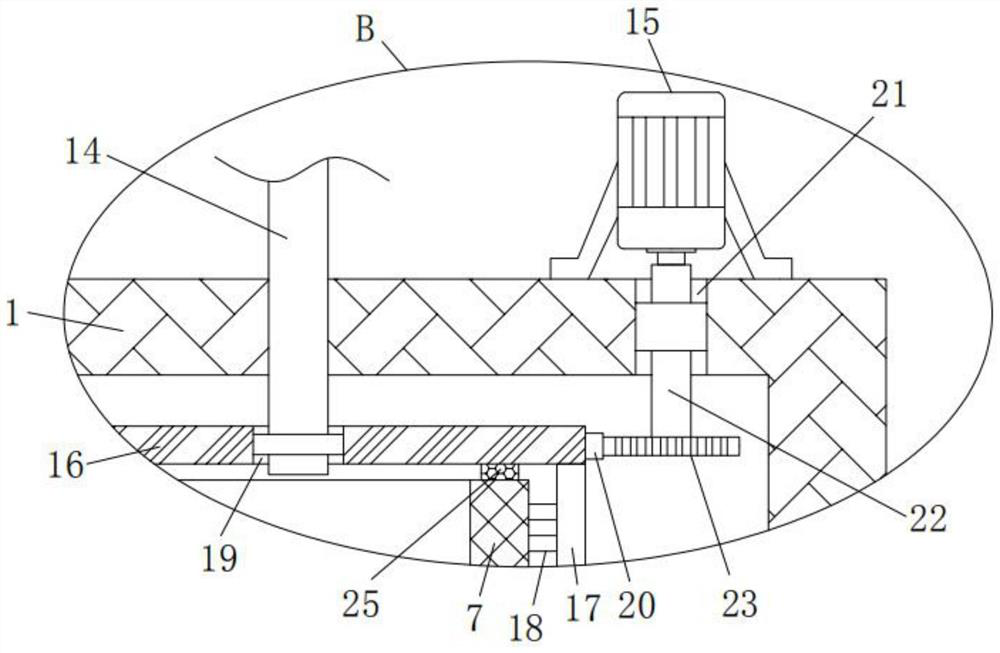

Gear axis position adjustable mechanism

InactiveCN102937178AAchieve fine-tuningImprove assembly accuracyGearing detailsGear wheelDrive shaft

The invention belongs to the transmission field and particularly relates to a gear axis position adjustable mechanism which comprises a gear box cover 1, a large round plate 2, a small round plate 5, an idler shaft, a large check ring 3, a small check ring 4 and a fixing mechanism, wherein a large step through hole is arranged on the gear box cover, the hole diameter of the large step through hole close to the interior of a gear box is small than that of the large step through hole close to the exterior of the gear box, a large check ring groove is arranged on the hole wall of the large step through hole close to the exterior of the gear box, and the large check ring 3 is arranged in the large check ring groove. The gear axis position adjustable mechanism can achieve fine adjustment of the transmission gear axis position, is simple and reliable in action, improves assembling accuracy and transmission accuracy of a transmission gear, and prolongs service life of the transmission gear. For a gear transmission mechanism in research and development, the gear axis position adjustable mechanism enables the gear transmission axis central position to be adjusted randomly in a certain range, can reduce the mounting and demounting times of an engine, and meets requirements of different transmission ratios.

Owner:CHINA NORTH ENGINE INST TIANJIN

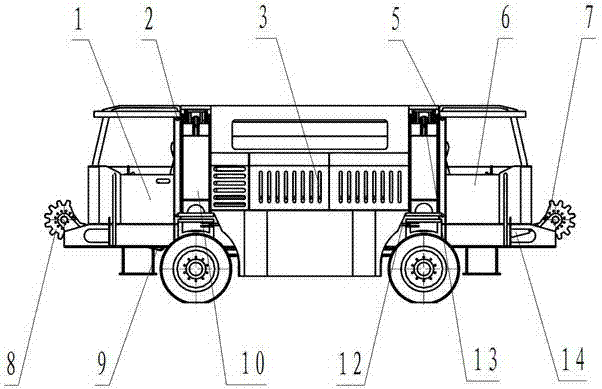

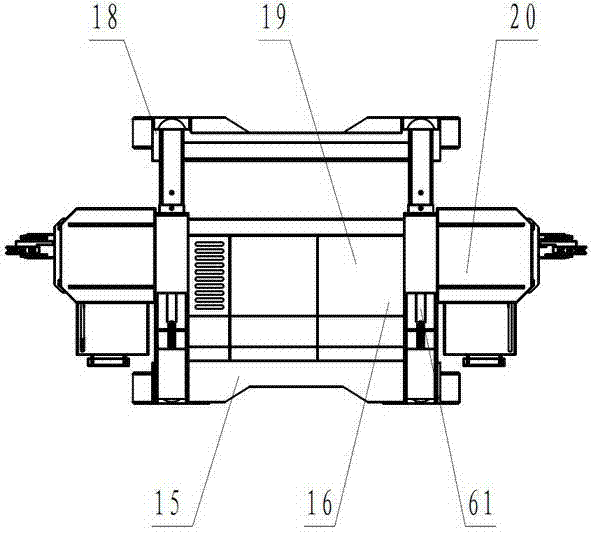

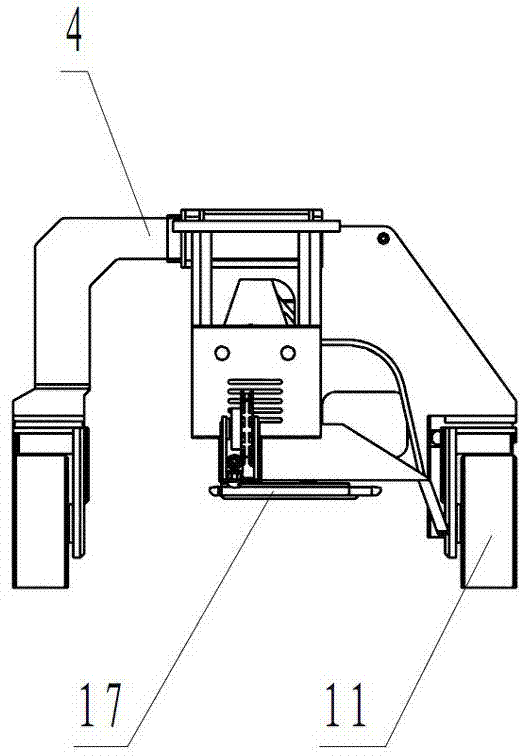

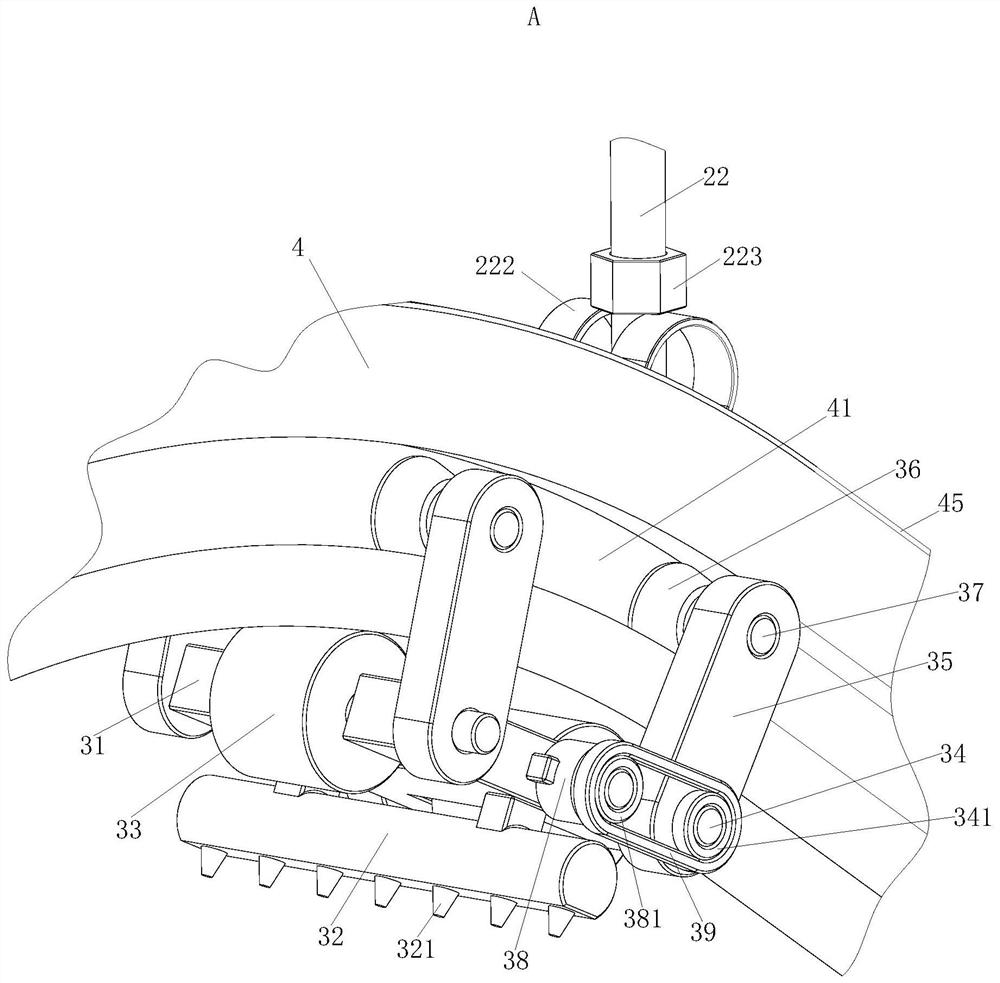

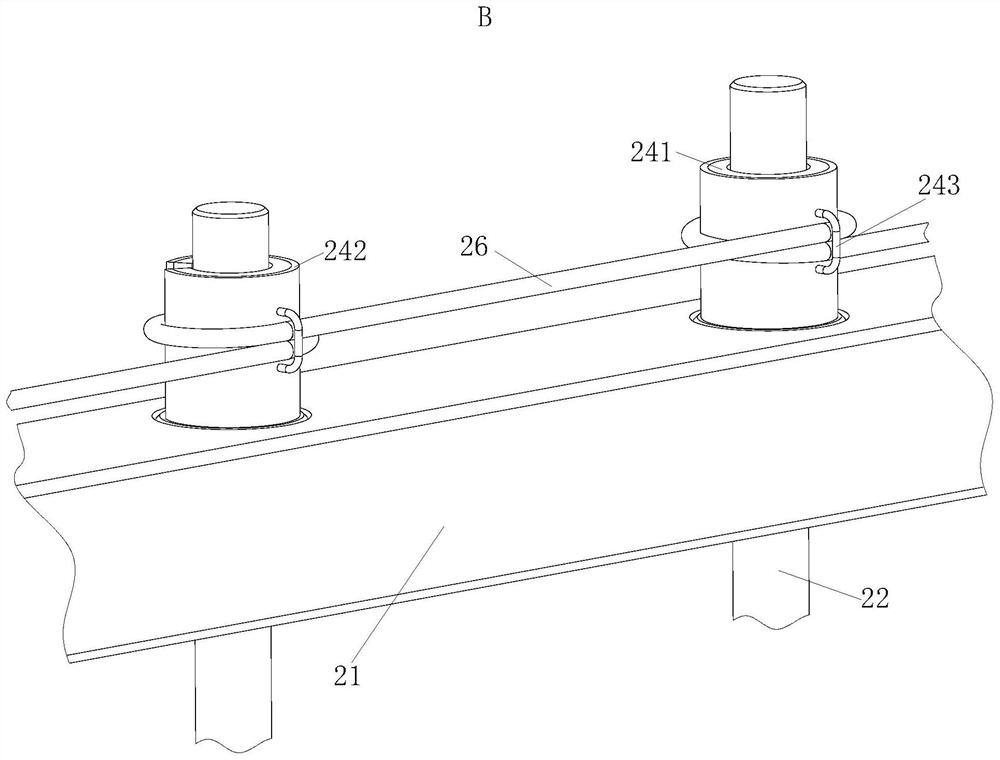

Middle trough moving van

ActiveCN104709152AImprove moving efficiencyIncrease the level of mechanizationItem transportation vehiclesSprocketEngineering

The invention belongs to the technical field of design and manufacturing of coal mine moving equipment, particularly belongs to a middle trough moving van. The problems that the middle trough moving efficiency is low, the process is tedious and certain potential safety hazards exist are solved. The middle trough moving van comprises a gantry type van frame with a telescopic beam, an anti-explosion diesel engine and a hydraulic mechanism, wherein the anti-explosion diesel engine is used for providing mechanical power, the hydraulic mechanism is used for converting the mechanical power into liquid pressure, a front driving cab is arranged at the front side of gantry type van frame, a rear driving cab is arranged at the rear side of the gantry type van frame, wheels capable of independently walking are arranged on the two ends of the front side and the two ends of the rear side of the gantry type van frame respectively, each wheel of the moving van is provided with a steering mechanism and a braking reducing mechanism, a middle trough quick loading and unloading mechanism is arranged on the bottom of the gantry type van frame, chain wheel mechanisms are arranged on the front end and the rear end of the gantry type van frame respectively, and the chain wheel mechanisms are controlled by chain wheel oil cylinders respectively.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

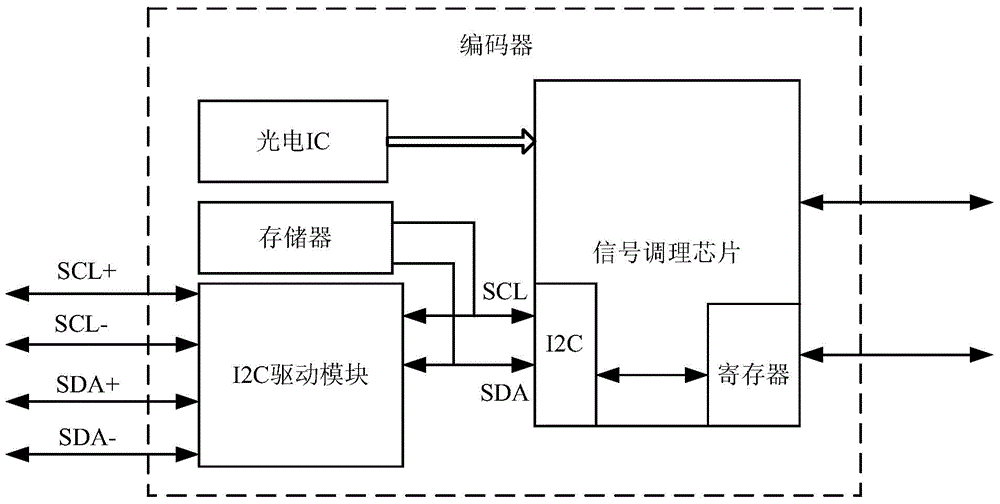

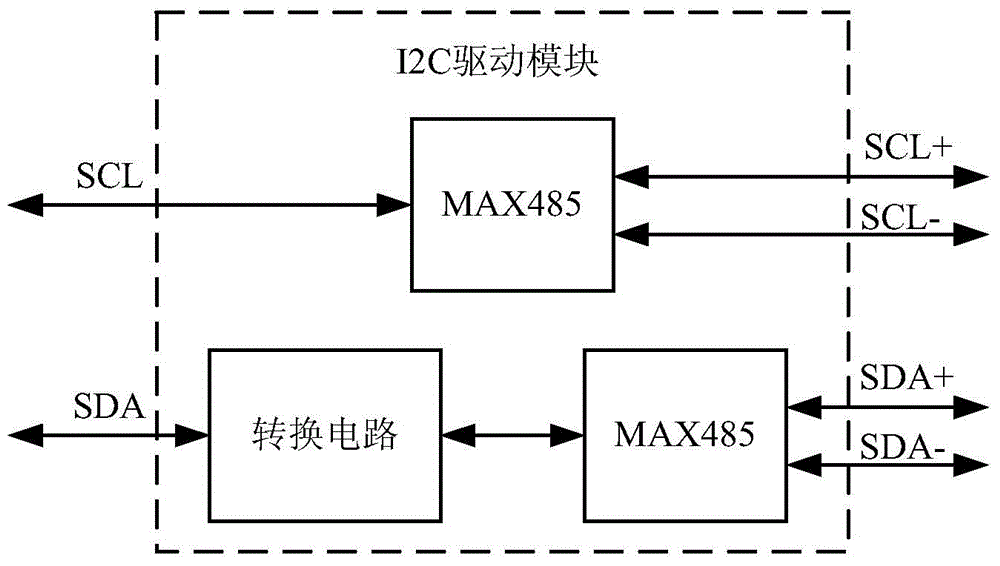

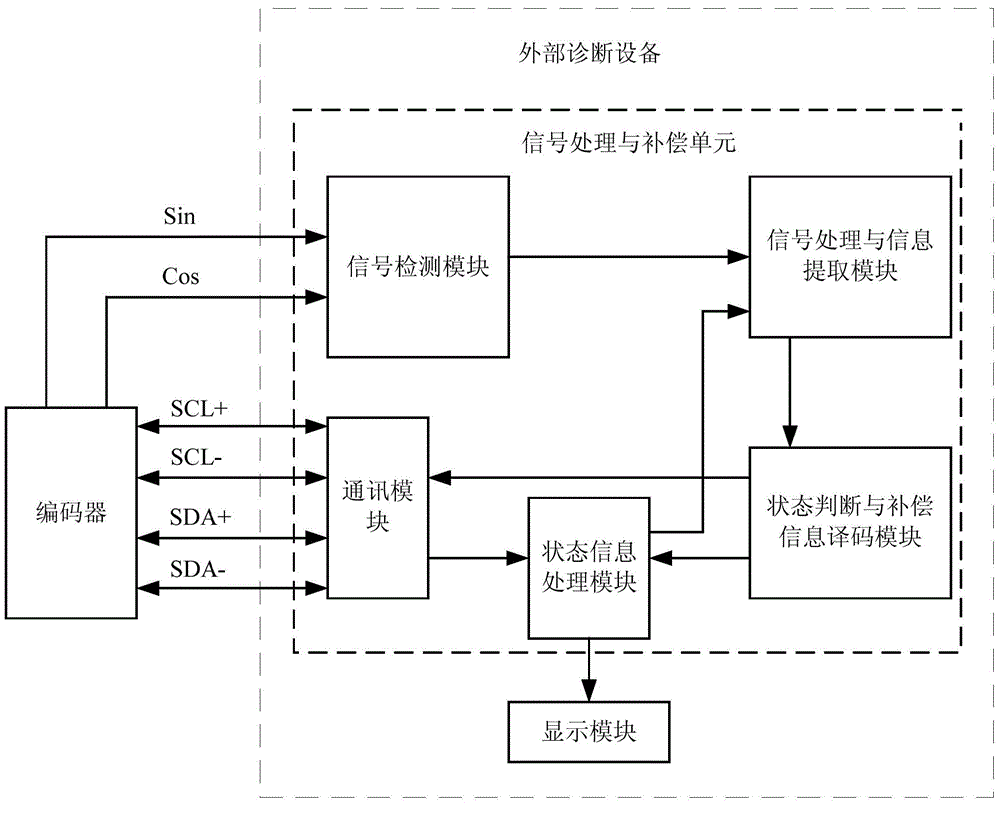

Coder, external diagnosis equipment and on-line diagnosis and adjustment method

ActiveCN104482954AReduce the number of disassemblyImprove service life and maintenance efficiencyElevatorsInstrumentsVIT signalsDependability

The invention relates to the field of communication, and discloses a coder, external diagnosis equipment and an on-line diagnosis and adjustment method. The on-line diagnosis and adjustment method includes the following steps that if the basic state of the coder is normal, the external diagnosis equipment reads operation parameters of the coder from a register in the coder through an I2C interface in the coder, wherein the operation parameters include the amplitude value, direct-current offset and phase of an output signal of the coder; the external diagnosis equipment determines the operation state of the coder according to the operation parameters, and adjusts the operation parameters according to the operation state until the operation parameters are within a preset range, and otherwise it is judged that the coder is abnormal. In this way, the external diagnosis equipment can remotely read the operation parameters in the register in the coder on line through the I2C driving interface and remotely adjust the operation parameters on line, it is unnecessary to repair the coder through disassembling the coder, then the design complexity is lowered, and the adjustment reliability of the coder is improved.

Owner:SHANGHAI STEP ELECTRIC

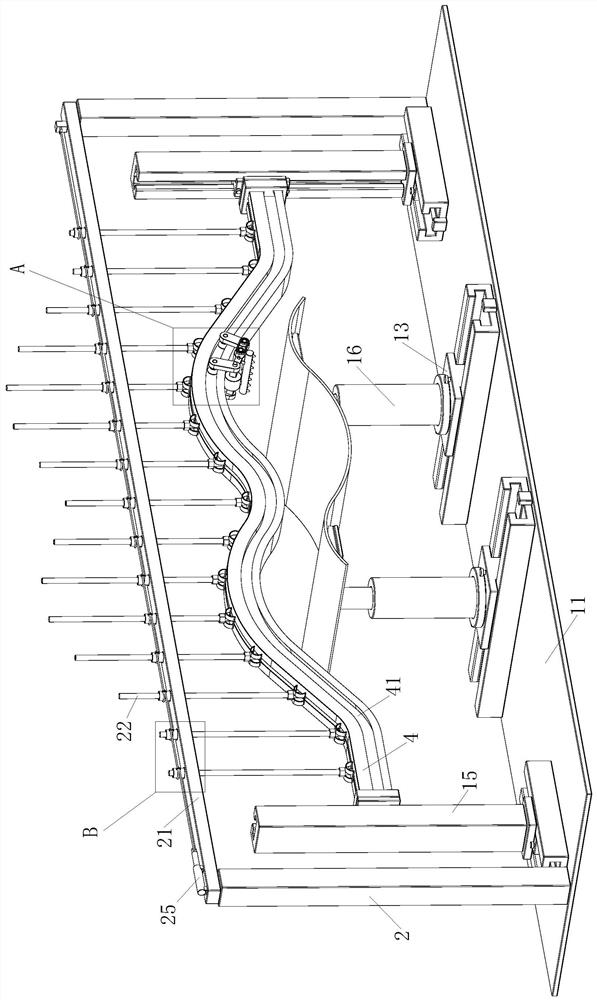

Uniform spraying device for curved-surface plate

The invention belongs to the technical field of spraying equipment, and particularly relates to a uniform spraying device for a curved-surface plate. The uniform spraying device comprises a support part, a suspension part, a spraying mechanism and a rubber guide rail. According to the uniform spraying device for the curved-surface plate, a piston rod of a support cylinder drives the curved-surface plate to move upwards, so that a curved surface matched with the curved-surface plate is formed on the bottom surface of the rubber guide rail, after the matched curved surface is formed, a piston rod of a tensioning cylinder tensions a tension rope, a metal sheet is enabled to be attached to a rubber sheet, the rubber sheet is tightly attached to a hanger rod, the friction force between the rubber sheet and the hanger rod is increased, the hanger rod is locked, the lower end of the hanger rod is connected with the rubber guide rail, the bottom surface of the rubber guide rail is matched with the surface of the curved-surface plate accordingly, after the hanger rod is locked, the piston rod of the support cylinder drives the curved-surface plate to move downwards, the distance between the curved-surface plate and the spraying mechanism is the spraying distance, the vertical distances between the spraying mechanism and all the positions of the curved-surface plate are equal in the spraying process, then uniform spraying of the curved-surface plate is achieved, and the spraying quality is improved.

Owner:SHAOYANG VICTOR HYDRAULICS

Fuel oil leakage positioning system and fuel oil leakage alarm system for marine diesel engine

InactiveCN106523151ARapid positioningRealize leak location functionElectrical controlInternal combustion piston enginesDouble-walled pipeFuel oil

The invention discloses a fuel oil leakage positioning system and a fuel oil leakage alarm system for a marine diesel engine. The positioning system comprises leaked oil branch pipes and leakage directing valves, wherein one end of each leaked oil branch pipe is connected to a position between the inner wall and the outer wall of one high-pressure fuel oil double-wall pipe of a diesel engine, and the other end of each leaked oil branch pipe is equipped with the corresponding leakage indicating valve; indication on a condition whether each leaked oil branch pipe has leaked oil or not is carried out by judging whether the valve element of each leakage indicating valve is ejected out or not, so that positioning for a fuel oil leaking part is realized. The alarm system comprises the positioning system. The invention discloses the fuel oil leakage positioning system and the fuel oil leakage alarm system. The leakage indicating valve is arranged in each branch pipe of each high-pressure fuel oil double-wall pipe, so that the leakage positioning function can be realized; and a leakage alarm device is arranged in a fuel oil recycling device, so that an alarm function is realized.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

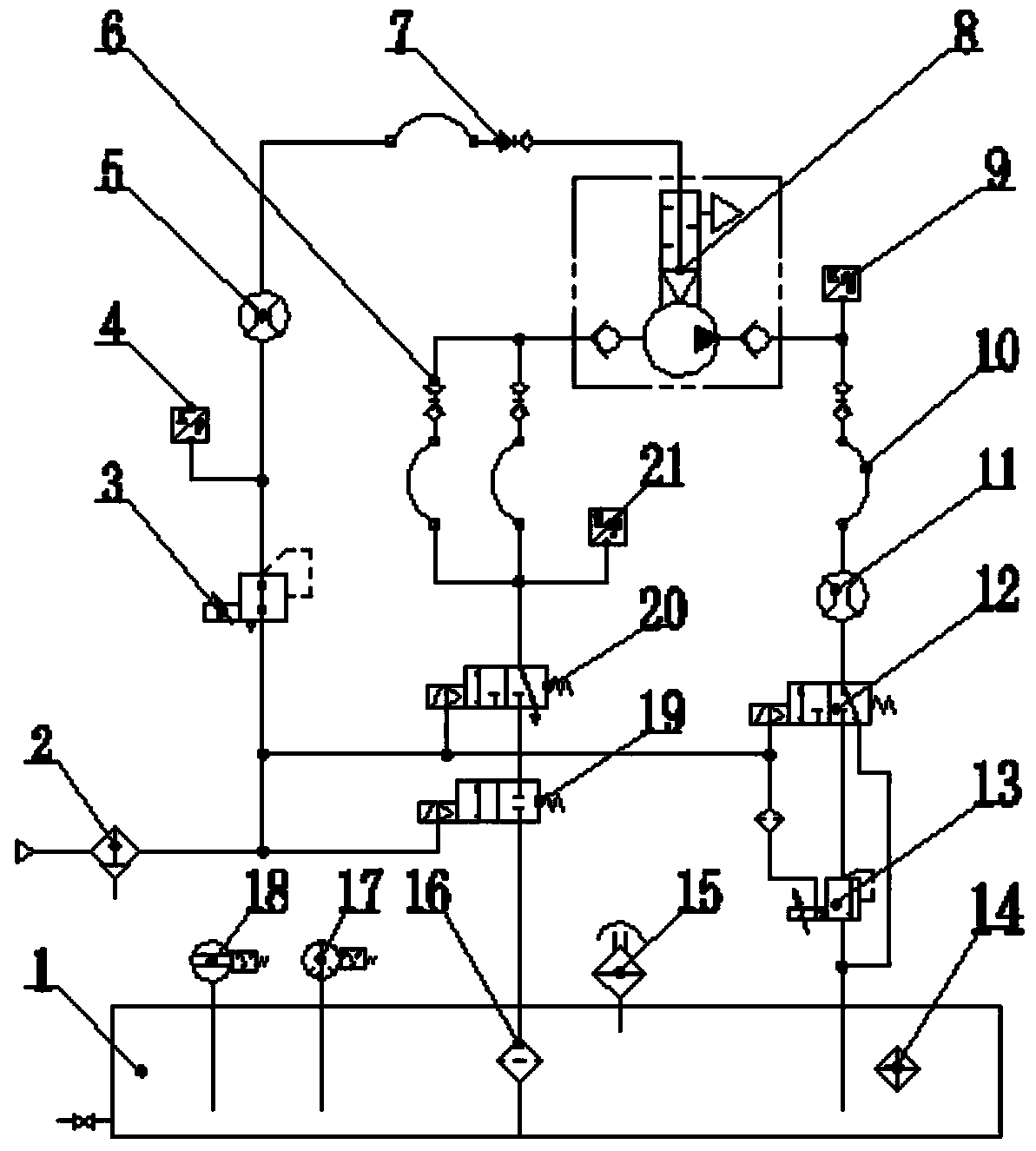

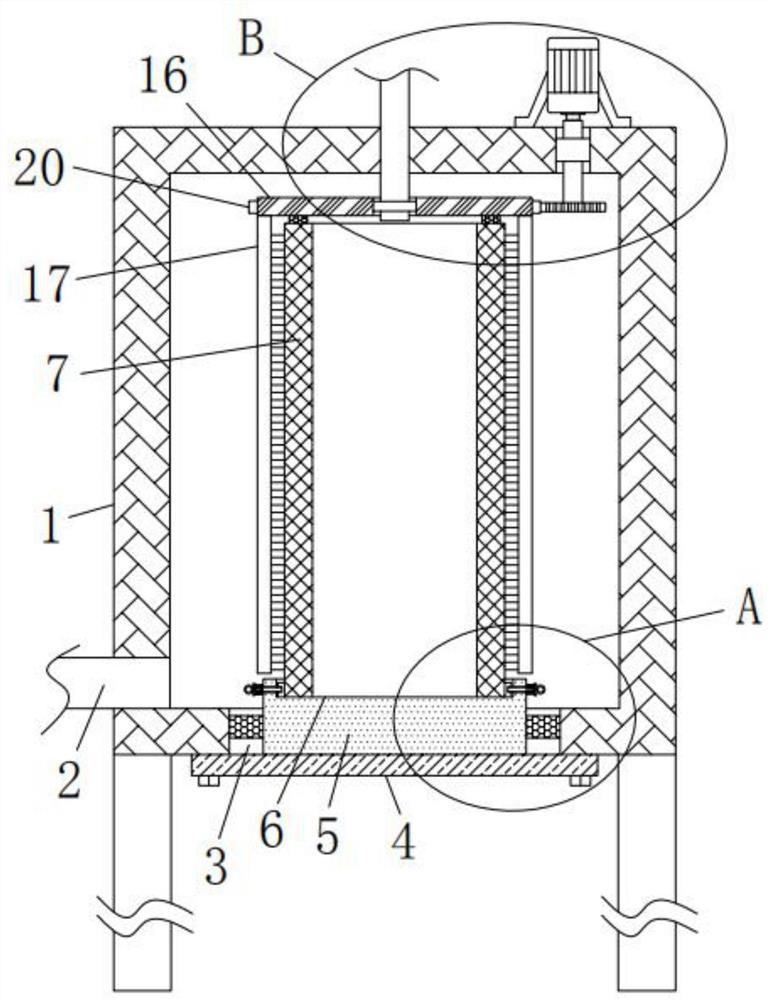

Integrated detection system of performance of gas-liquid booster pump

ActiveCN103644110AReduce the number of disassemblyEasy to disassemblePump testingPositive-displacement liquid enginesData acquisitionDisplay device

The invention discloses an integrated detection system of the performance of a gas-liquid booster pump. The integrated detection system comprises a gas supply testing unit, an oil absorption testing unit, an oil supply testing unit, a data collection and analysis unit and a testing working table; the gas supply testing unit, the oil absorption testing unit and the oil supply testing unit are arranged inside the testing working table in an integrated mode; the operating table surface of the testing working table is provided with a rapid-change joint; a display and a digital display instrument of the data collection and analysis unit are arranged on the front side of the testing working table. According to the integrated detection system of the performance of the gas-liquid booster pump, the use is convenient and rapid, the labor intensity of workers is reduced, the efficiency of the test work is improved, and a test piece is convenient to detach, strong in universality and wide in adaptive range.

Owner:DALIAN REALLY TECH

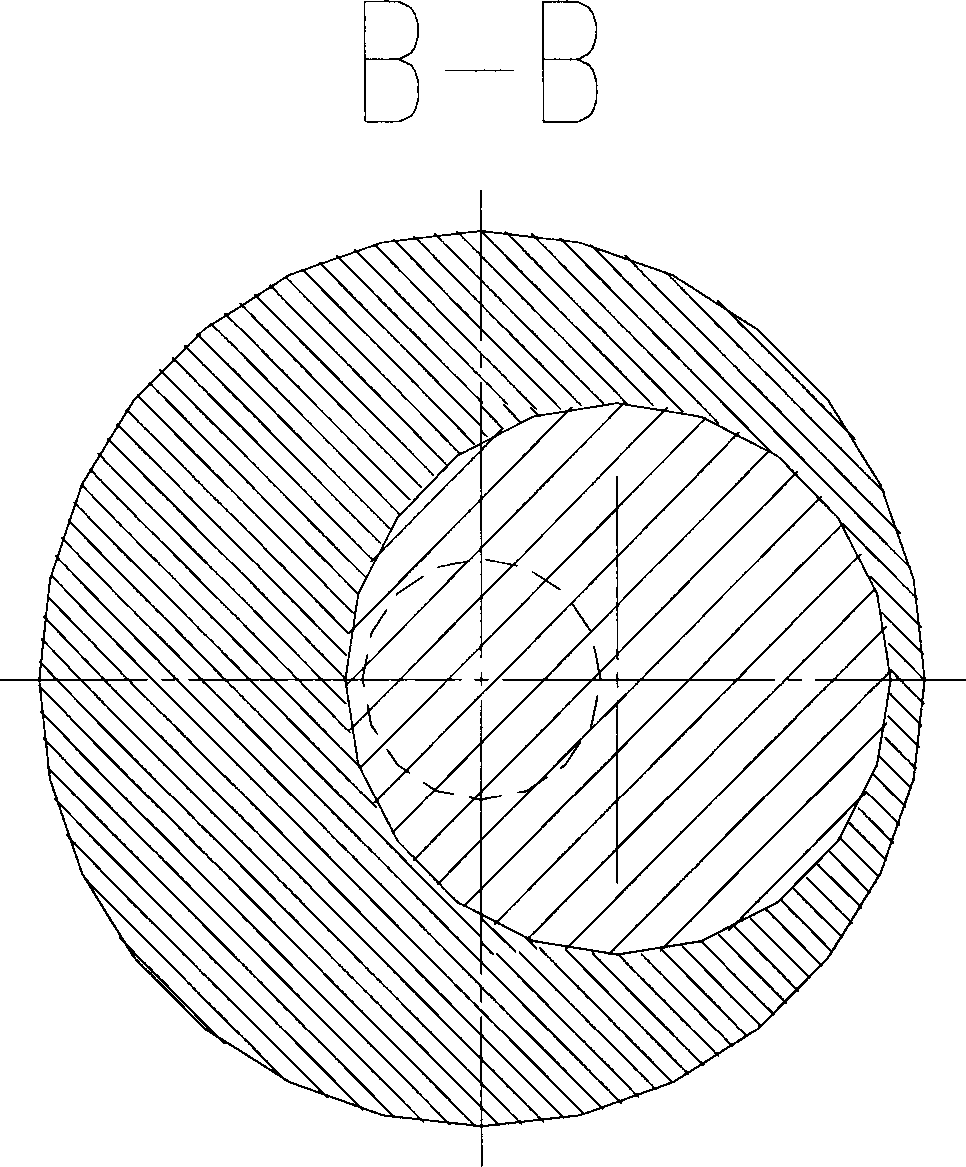

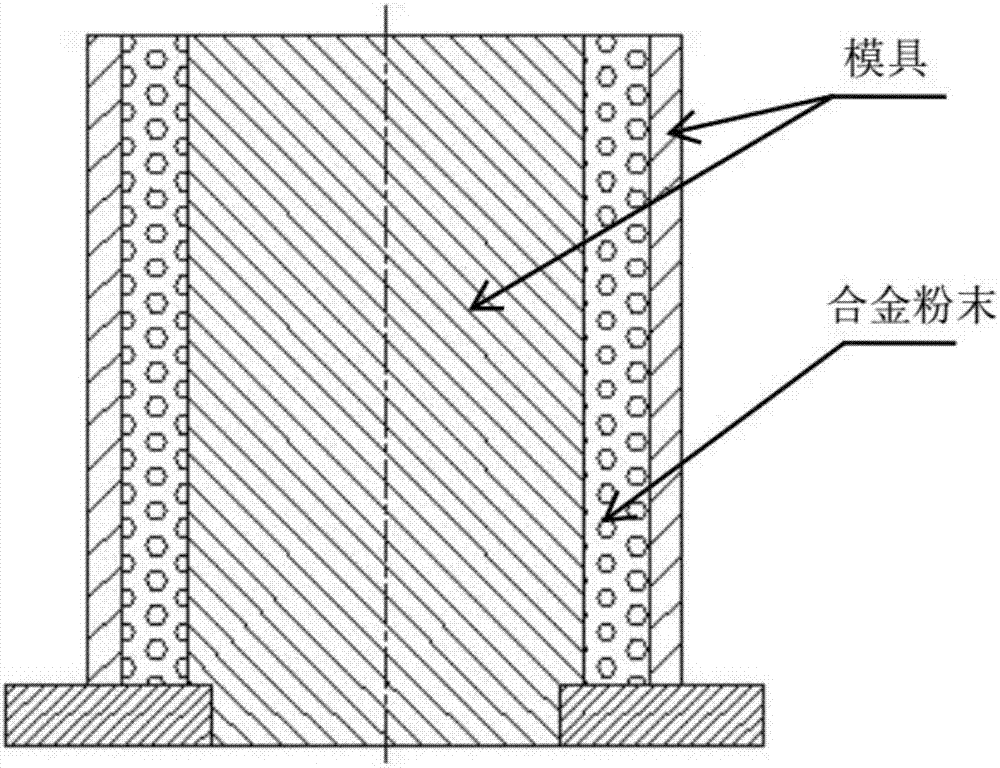

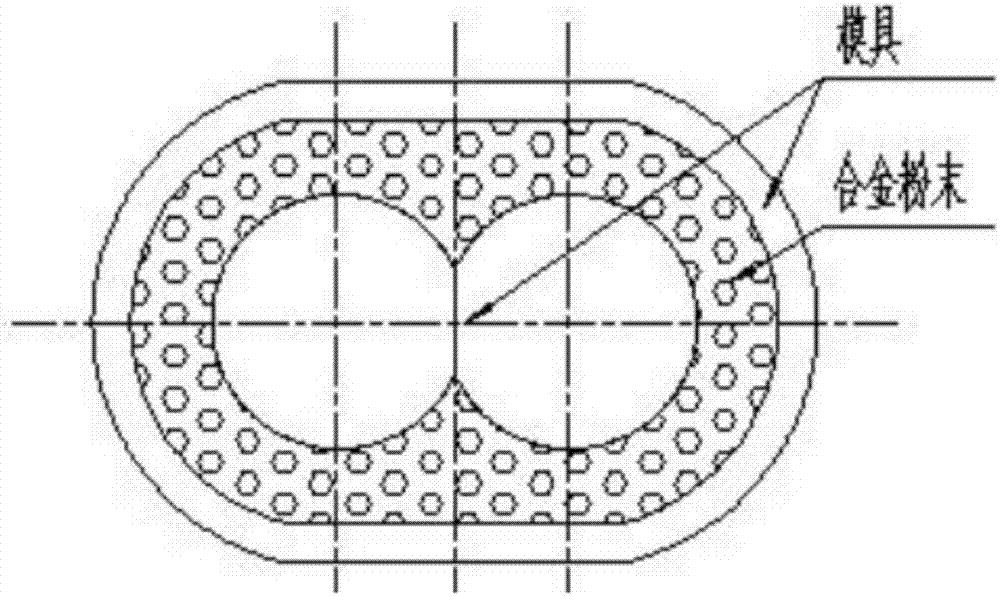

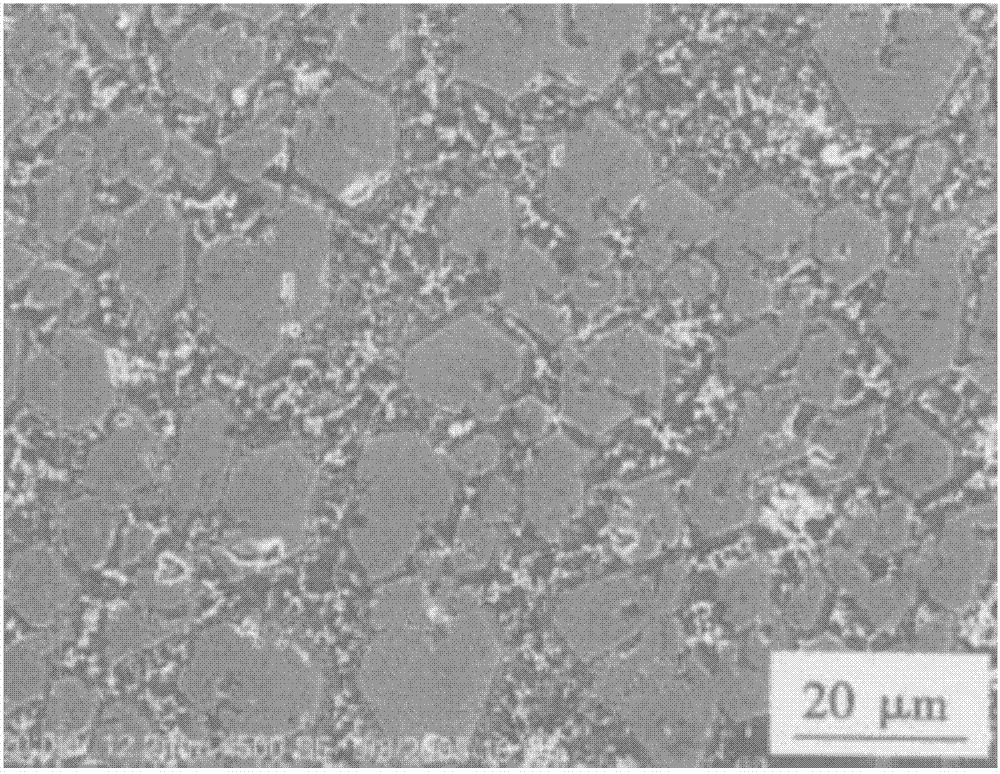

Iron-base alloy double-screw integral alloy lining and preparing method thereof

The invention discloses an iron-base alloy double-screw integral alloy lining and a preparing method thereof. The iron-base alloy double-screw integral alloy lining is formed through integral sintering of cobalt-base alloy powder. The nickel-base alloy powder comprises, by weight percent, 1.50%-3.00% of B, 0.80%-1.60% of C, 6.00%-12.00% of Cr, 8.00%-16.00% of Ni, 2.00%-3.50% of Si, 0.00%-3.00% of W and the balance Fe. The unique machining technology process is adopted in the method, the traditional technology manner of the lining and machine barrel combination is innovated, the hardness of a sintered iron-base alloy lining is HRC58-65, the abrasion resisting performance is 4-7 times of the abrasion resisting performance of 6542 materials, the service life of the lining is effectively prolonged, the production cost is reduced, and the active demand of the market on constant product quality increasing is met.

Owner:苏州艾盾合金材料有限公司

Air purification device good in cleaning effect

ActiveCN106582132ARealize the function of purgingEasy to cleanGas treatmentDispersed particle filtrationDrive shaftAir purification

The invention relates to an air purification device good in cleaning effect. The air purification device comprises a body, a filtering mechanism, a sealing mechanism, a spraying mechanism and a sweeping mechanism. The sealing mechanism comprises two sealing assemblies arranged on the upper inner wall and the lower inner wall of the body correspondingly. Each sealing assembly comprises a first motor, two fixed plates, a first drive shaft and a movable plate. The spraying mechanism comprises a water inlet pipe, a first booster pump and an atomization sprayer. The sweeping mechanism comprises a drive assembly and a sweeping assembly. In the air purification device good in cleaning effect, a first filtering assembly and a second filtering assembly are sealed by adding the sealing mechanism, and respective cleaning is convenient to achieve; through the additional arrangement of the spraying mechanism, spraying cleaning is conducted on dirt on a first filtering net; and through the additional arrangement of the sweeping mechanism, the function of sweeping of dirt on a second filtering net is achieved, the function of cleaning the filtering nets in the device can be achieved without opening the device, the detaching frequency is reduced, and the service life of the device is prolonged.

Owner:GUARDIAN SHANGHAI HYGIENE SERVICE

Welded pipe end straightness online detection device

InactiveCN101769726AMeet the requirements of detection accuracy and efficiencyLower the altitudeUsing optical meansEngineeringVisual inspection

The invention discloses a welded pipe end straightness online detection device, belonging to the technical field of welding control, and comprising a detection mechanism, a detection arm, a pedestal mechanism and a base mechanism, wherein the pedestal mechanism is arranged at the upper part of the base mechanism, the detection arm is arranged at the side surface of the pedestal mechanism, the two ends of the detection arm are respectively connected with the detection mechanism and the pedestal mechanism, the detection mechanism is positioned right above a welded pipe to be detected, and the detection mechanism, the detection arm and the pedestal mechanism are all positioned at the same side of the base mechanism. The invention is the online detection device which can substitute a manual visual inspection method to detect, and realize end straightness online automatic detection of welded pipes with different specifications.

Owner:SHANGHAI JIAO TONG UNIV

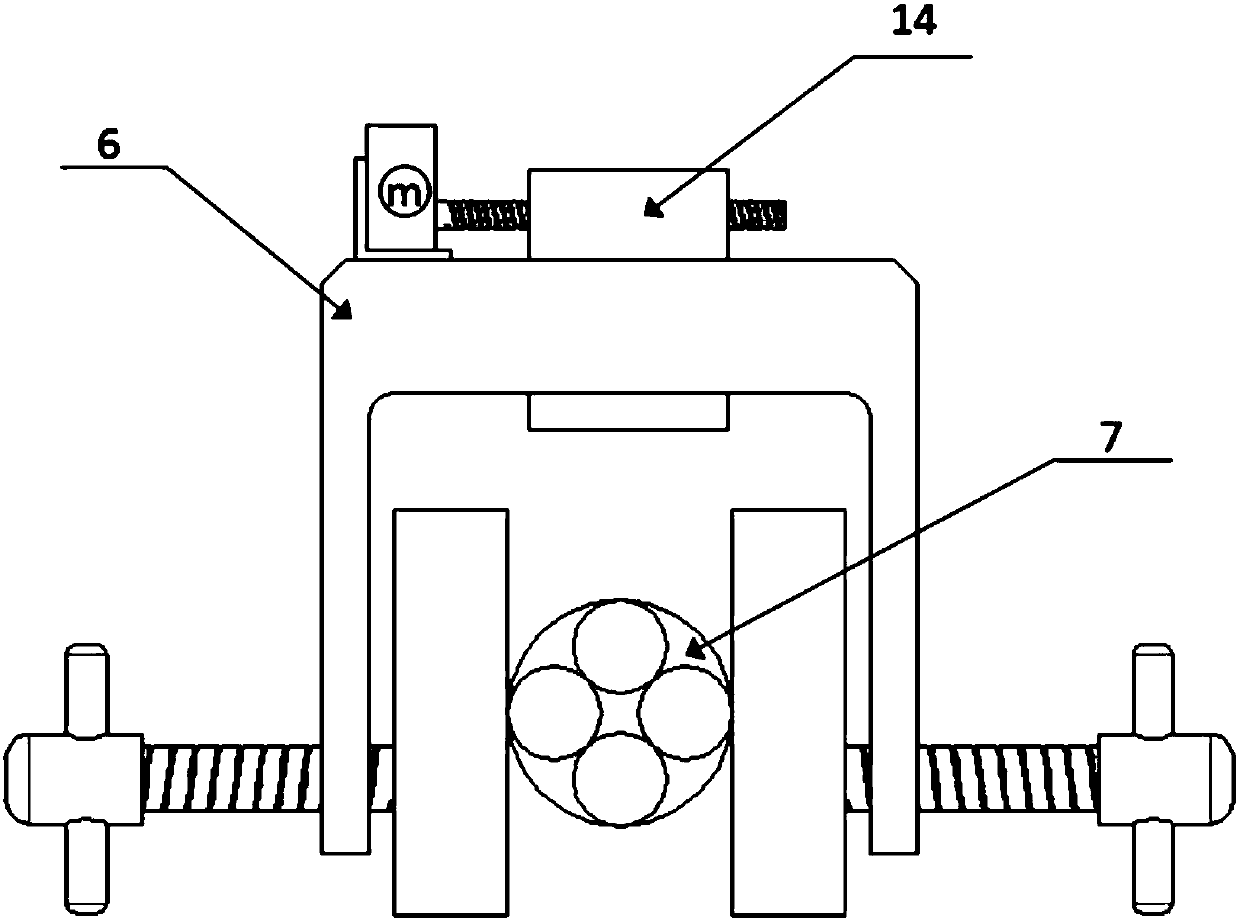

Movable hydraulic automatic reinforcement cage main reinforcement clamping device

ActiveCN107717291ASimple structureLarge clamping forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention discloses a movable hydraulic automatic reinforcement cage main reinforcement clamping device and relates to the field of reinforcement cage automatic production equipment. The problemsthat existing reinforcement cage seam welder main reinforcement clamping devices are insufficient in clamping force, high in workload and low in efficiency are solved. The movable hydraulic automaticreinforcement cage main reinforcement clamping device comprises a clamping body, a hydraulic cylinder of which the outer side of the upper end is fixedly connected with the outer side of the lower endof the clamping body, a pretightening rod which is arranged in the clamping body and fixedly connected with a piston rod of the hydraulic cylinder, a rotation brake screw inserted into the clamping body and fixed to the side face of the upper end of the pretightening rod, a right-angle oil circuit block fixed to the side face of the outer portion of the clamping body, a rotary shaft which extendsinto the right-angle oil circuit block and is fixedly connected with the right-angle oil circuit block, and a hydraulic oil pipeline of which the upper end extends into the right-angle oil circuit block and the rotary shaft, wherein the upper end of the pretightening rod makes contact with a reinforcement cage main reinforcement; the hydraulic cylinder drives the pretightening rod through the piston rod so that the reinforcement cage main reinforcement can be clamped in the clamping body; a hydraulic oil pump is connected with the upper end of the hydraulic oil pipeline; and the lower end ofthe hydraulic oil pipeline communicates with the interior of the hydraulic cylinder through a valve. The movable hydraulic automatic reinforcement cage main reinforcement clamping device is large in clamping force, low in workload and high in efficiency.

Owner:CHANGCHUN UNIV OF SCI & TECH

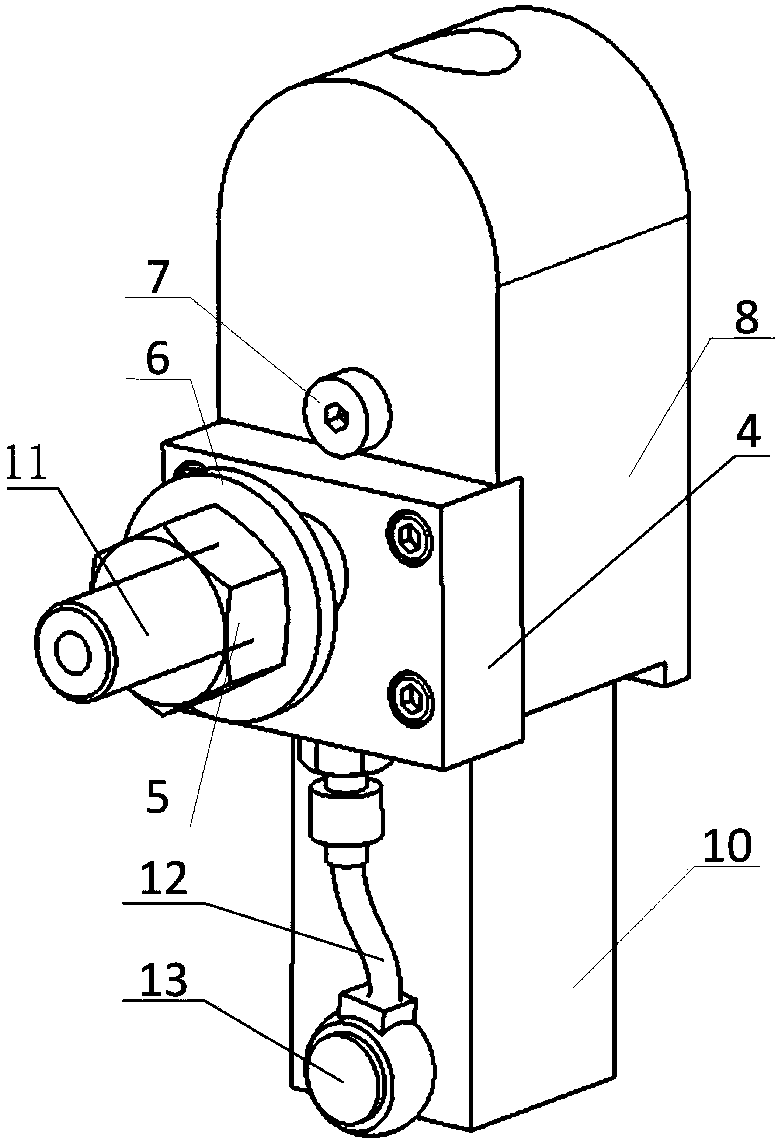

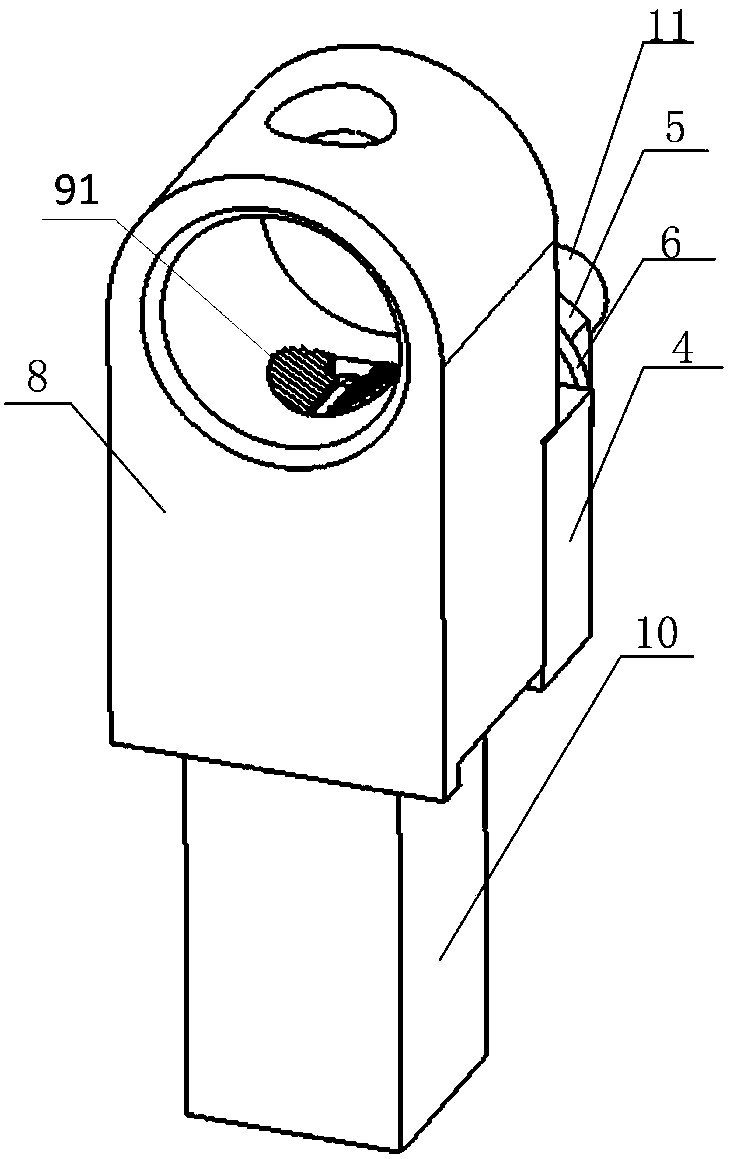

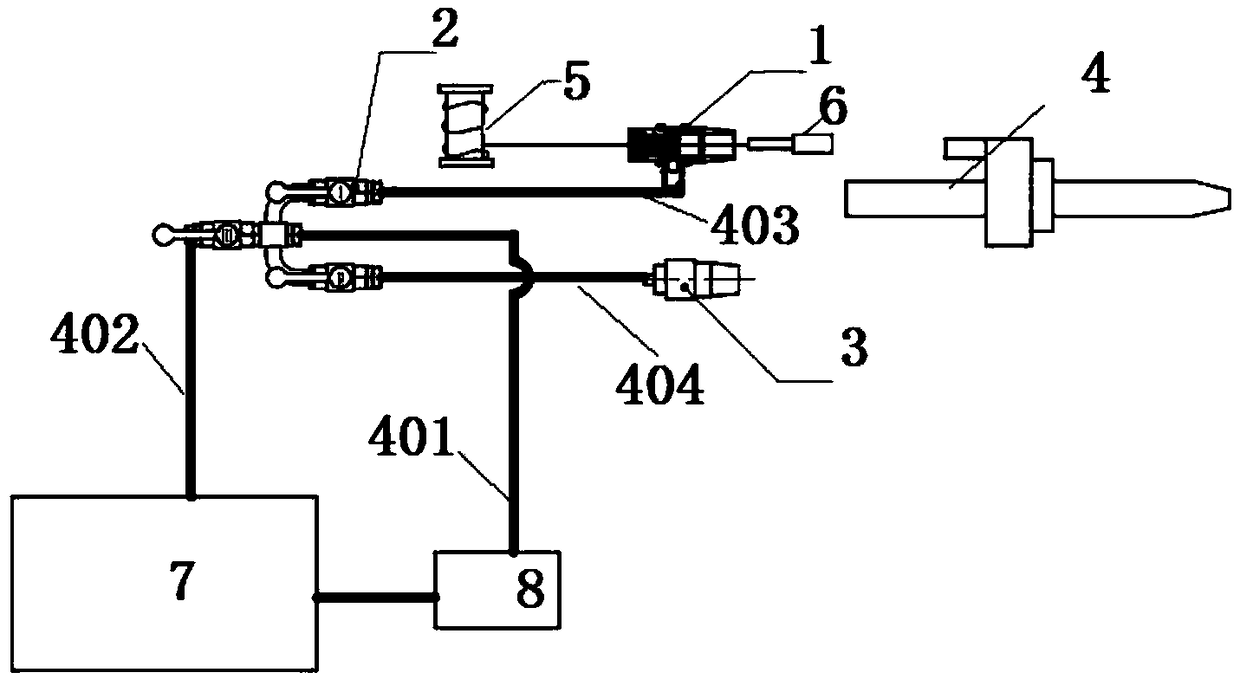

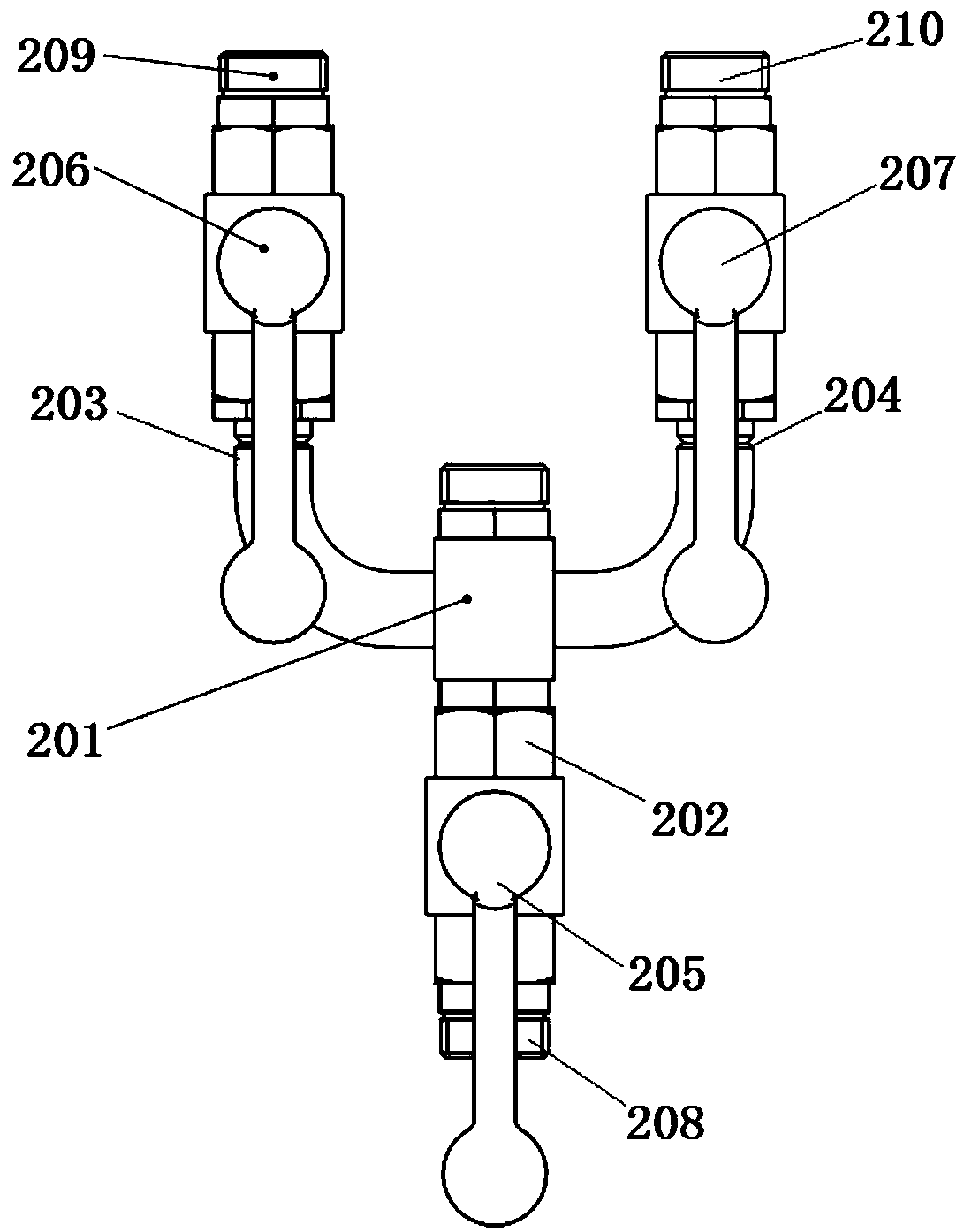

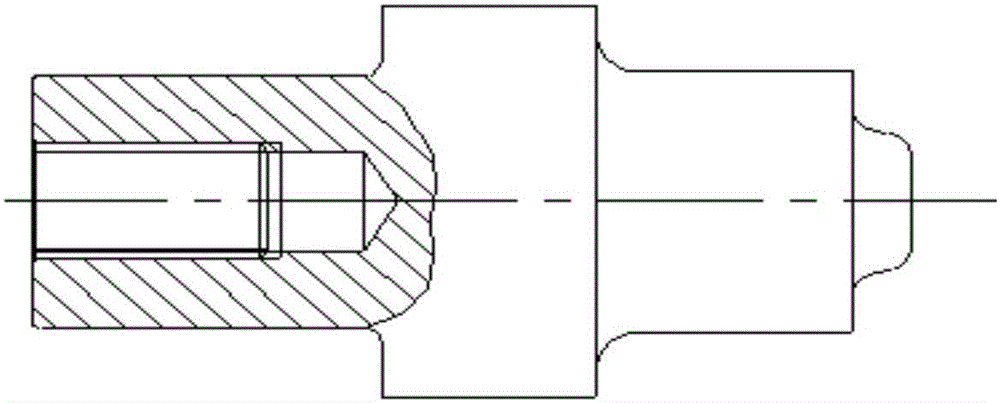

Waterway control assembly and method for rope core drilling rig

ActiveCN108756794AReduce connectivityReduce the number of disassemblyDrilling rodsFlushingControl valvesUltimate tensile strength

The invention discloses a waterway control assembly and method for a rope core drilling rig. The waterway control assembly comprises a rotatable through-cable water connector, a waterway control valveset, a conventional water connector and a connecting pipeline. The waterway control valve set is an intercommunication-type four-way pipe, corresponding three connecting openings are provided with two-way ball valves, the three two-way ball valves are opened and closed to control the connecting and disconnecting relation among the four connecting openings, and thus a waterway is controlled. The rotatable through-cable water connector comprises an end cover, a water sealing ring, a retaining ring, a mandrel, a rotating sleeve, a water pipe connector and a transition connector; the tail end ofthe mandrel is provided with a groove for allowing the water sealing ring and the retaining ring to be mounted in a spaced mode; the rotating sleeve is sleeved with the middle of the mandrel; and thewater pipe connector radially extending is connected to the rotating sleeve in a penetrating mode. Thus, according to the waterway control assembly and method, the structure is simple, operation is convenient, and the problems that in the prior art, the waterway control auxiliary time is long, and the labor intensity of workers and the personnel cost are high can be solved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

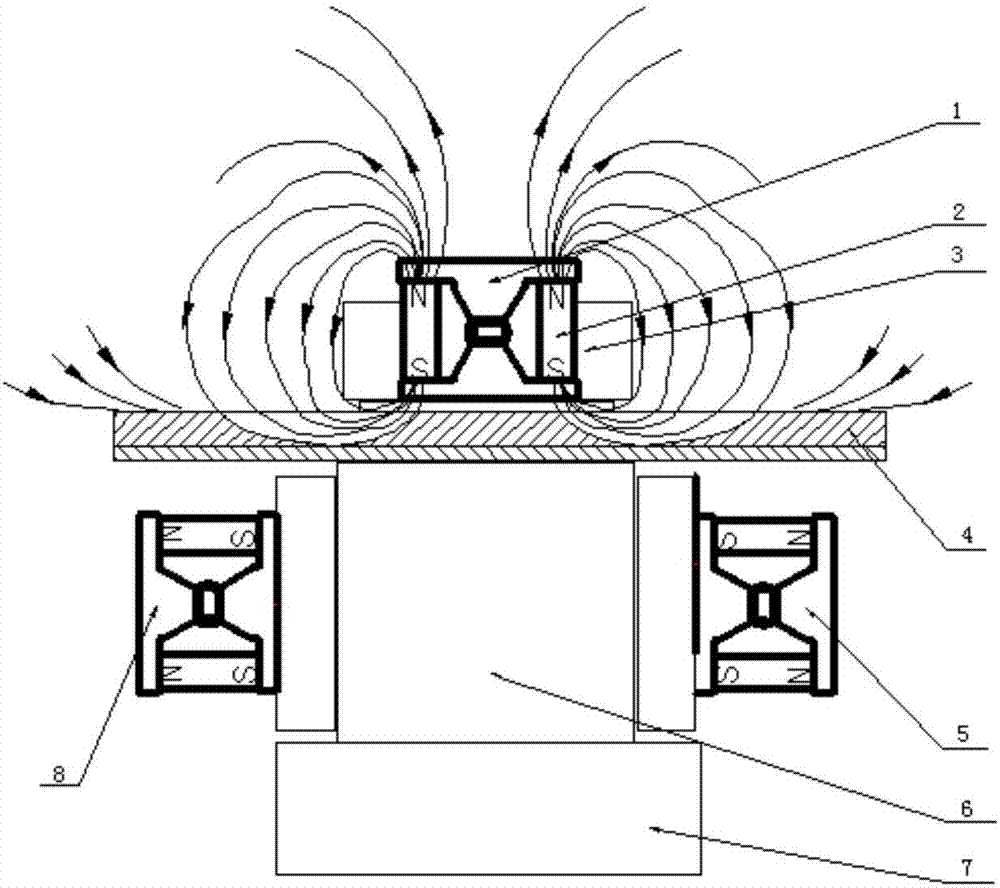

Rapid magnetizing and demagnetizing method for triple redundant servo valve

The invention belongs to the technical field of hydraulic control, and specifically relates to a rapid magnetizing and demagnetizing method for a triple redundant servo valve. The rapid magnetizing and demagnetizing method comprises the following steps: step one, mounting the integral triple redundant servo valve on a test board, wherein the triple redundant servo valve comprises a second pre-stage, a third pre-stage and a first pre-stage; step two, carrying out magnetizing and demagnetizing on the second pre-stage to adjust flow gain; step three, recording demagnetizing voltage after the second pre-stage is demagnetized, drawing a non-load flow curve, and calculating the flow gain of the second pre-stage; and step four, carrying out magnetizing and demagnetizing and flow gain calculationon the first pres-stage and the third pre-stage in sequence according to the method in the third step. According to the method, the flow gain of the single pre-stage can be rapidly adjusted through mutual isolation of tools in a space magnetic field under the premise of without dismounting any pre-stage.

Owner:北京实验工厂有限责任公司 +1

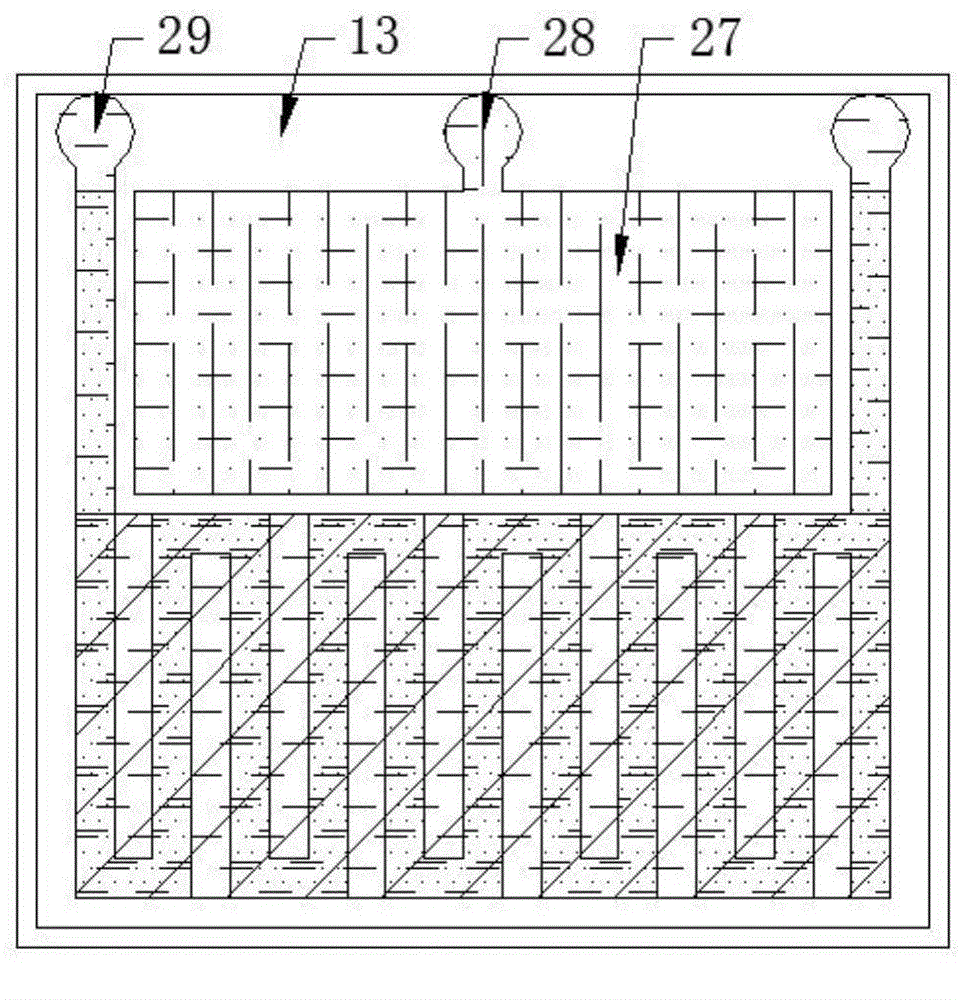

Fuel cell internal humidity-current density combined measurement sensor

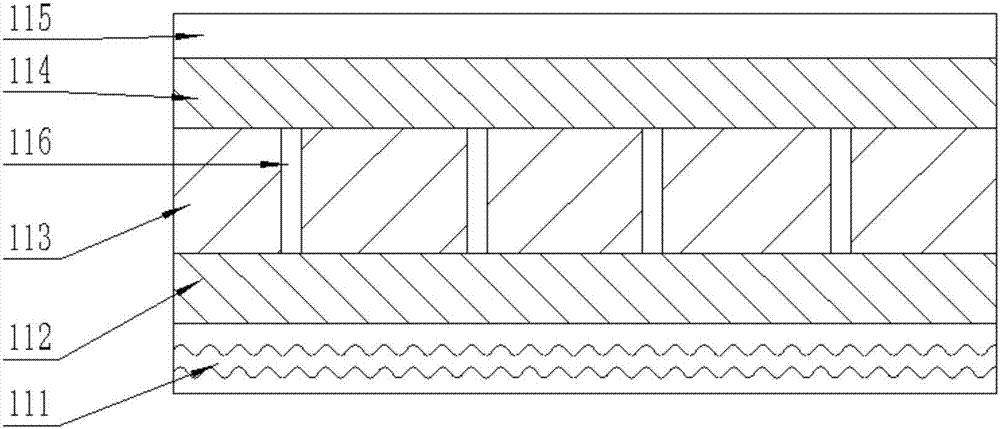

ActiveCN104409754AImprove performanceReduce the number of disassemblyFuel cell auxillariesCurrent density measurementsCopper platingSilicon oxide

The invention discloses a fuel cell internal humidity-current density combined measurement sensor, which belongs to the field of fuel cell internal parameter measurement, comprises seven layers of films, and is prepared by a vacuum evaporation coating method; a first layer is a silicon dioxide insulating layer, a second layer is a lower electrode aluminum coating, a third layer is a polymer coated humidity sensing dielectric layer, a fourth layer is an upper electrode aluminum coating, a fifth layer and a sixth layer are respectively a current density measurement copper plating and a current density measurement gold plating which are deposited on the silicon dioxide insulating layer by vapor deposition, and a seventh layer is a silicon oxide protective layer. The fuel cell internal humidity-current density combined measurement sensor is arranged on a ridge of a fuel cell flow field plate, one end of a leading wire is connected with the humidity-current density combined measurement sensor, and the other end of the leading wire extends to the edge of the flow field plate. The fuel cell internal humidity-current density combined measurement sensor has the advantages of simple structure and small volume, can be conveniently arranged on fuel cell flow field plates in various shapes, and can realize the synchronous combined measurement of fuel cell internal humidity and current density.

Owner:BEIJING UNIV OF TECH

Conveyer belt test device and method for loading and unloading samples on annular conveyer belt

PendingCN107121280AEasy to installSimple structureConveyorsMachine gearing/transmission testingEngineeringCushion

The invention relates to a conveyer belt test device, which comprises a base, a driving roller, a driven roller, a conveyer belt arranged on the driving roller and the driven roller, and a test system arranged below the conveyer belt. A telescopic rack is arranged on the base. The telescopic rack is composed of a fixed part and a movable part. The fixed part is fixedly provided with the driving roller. The movable part is provided with the driven roller. The movable part is capable of sliding left and right relative to the fixed part. A detachable supporting device is arranged on at least one side below the fixed part and the movable part of the telescopic rack. A jack is arranged below the driving roller and the driven roller and on the base. A cushion block arranged between the fixed part of the telescopic rack and the base is used for supporting the fixed part of the telescopic rack and the base. A hydraulic jack is arranged below the rollers. In this way, an annular sample can be placed on the test device and can also be unloaded from the test device. The disassembly and assembly number of parts is reduced, and the accuracy of the entire test device is ensured.

Owner:青岛中化新材料实验室检测技术有限公司

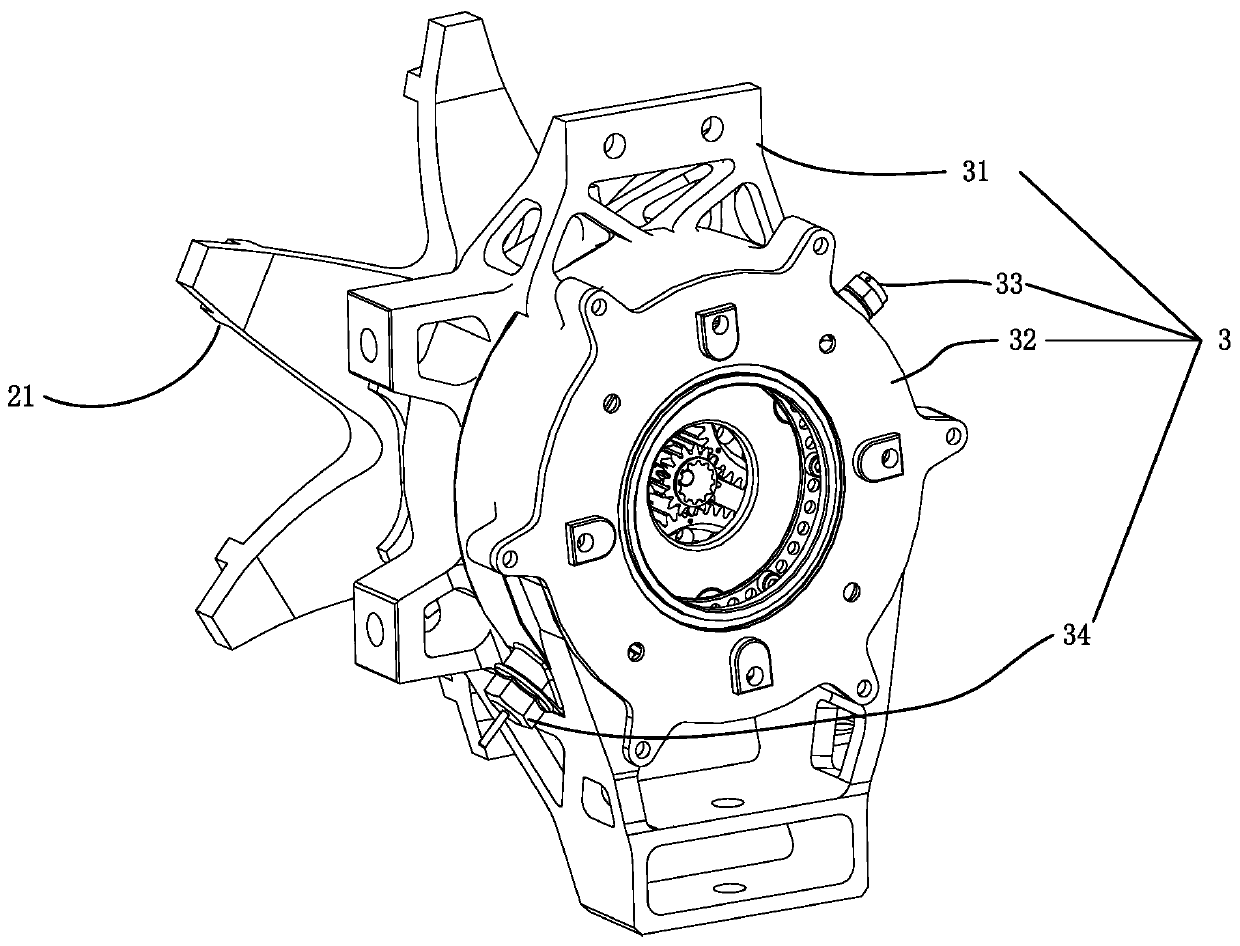

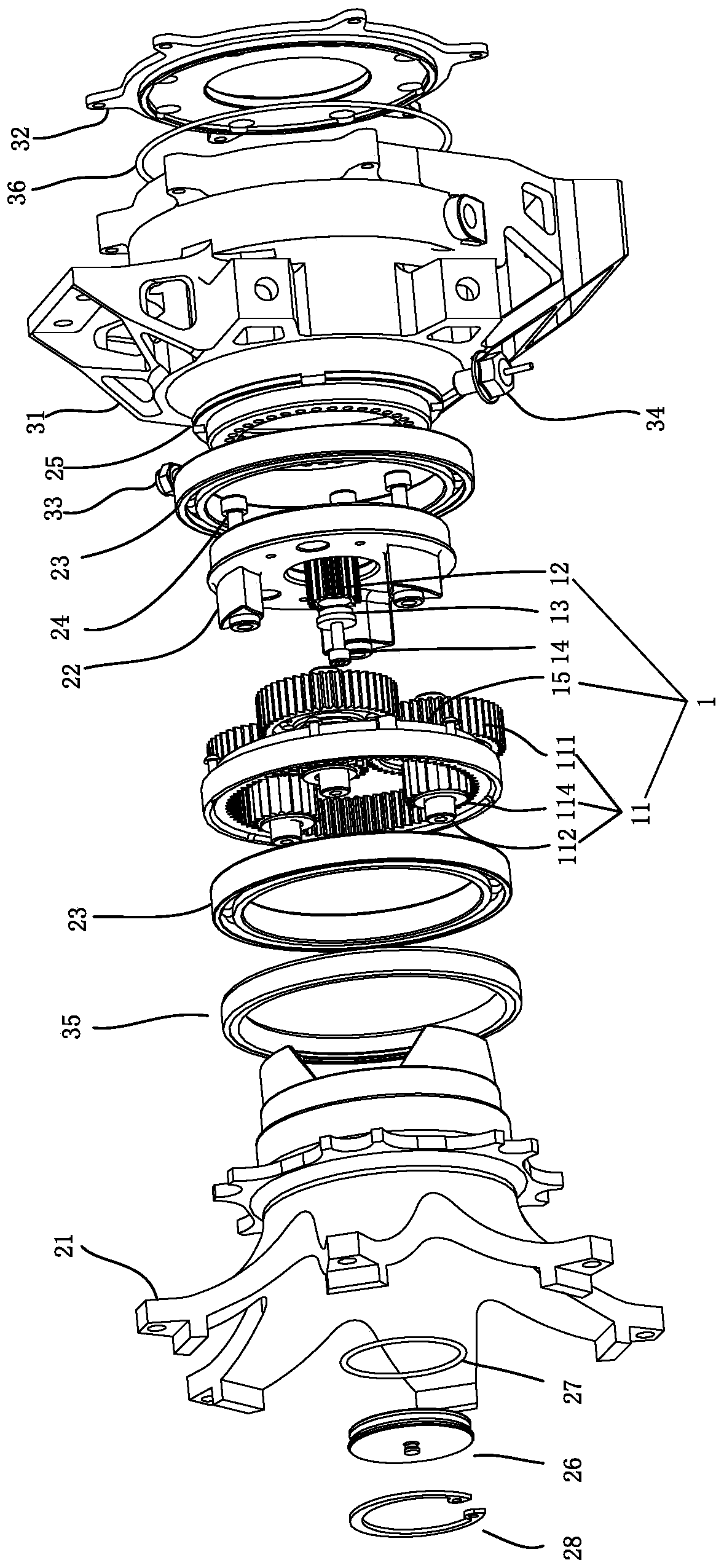

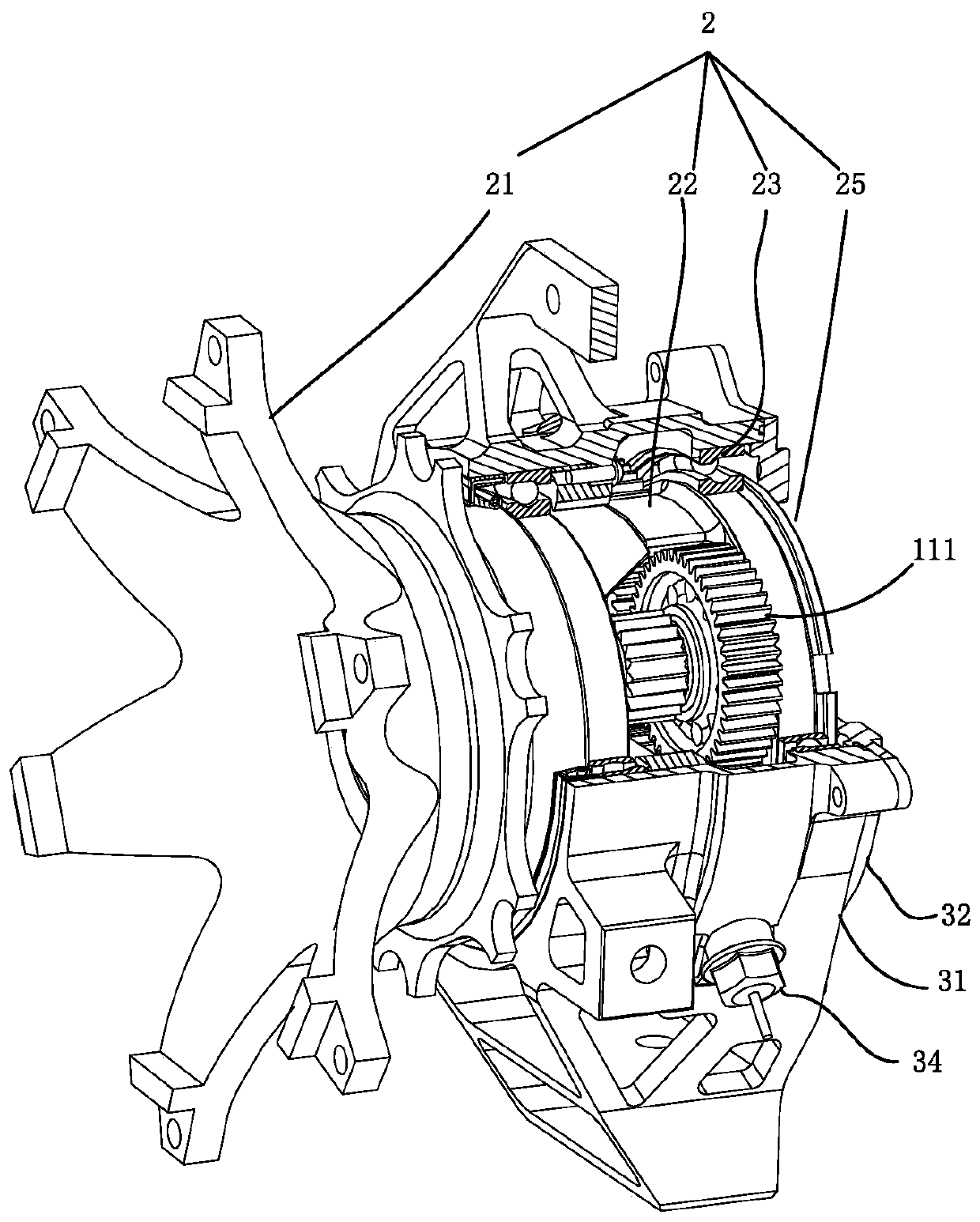

Wheel edge planetary gear speed reducer for electric formula racing car

The invention relates to a wheel edge planetary gear speed reducer for an electric formula racing car. The wheel edge planetary gear speed reducer for the electric formula racing car comprises a planetary gear mechanism, a double-web planet carrier mechanism and a gear box mechanism. According to the wheel edge planetary gear speed reducer for the electric formula racing car, the form of planetarygear sets arranged in series is used to replace the form of a single planetary row or a plurality of planetary rows in the prior art, so that the structure of the speed reducer is simplified, and therequirement on a large speed ratio of the speed reducer in a limited wheel edge installation space of the electric formula racing car is realized.

Owner:BEIHANG UNIV

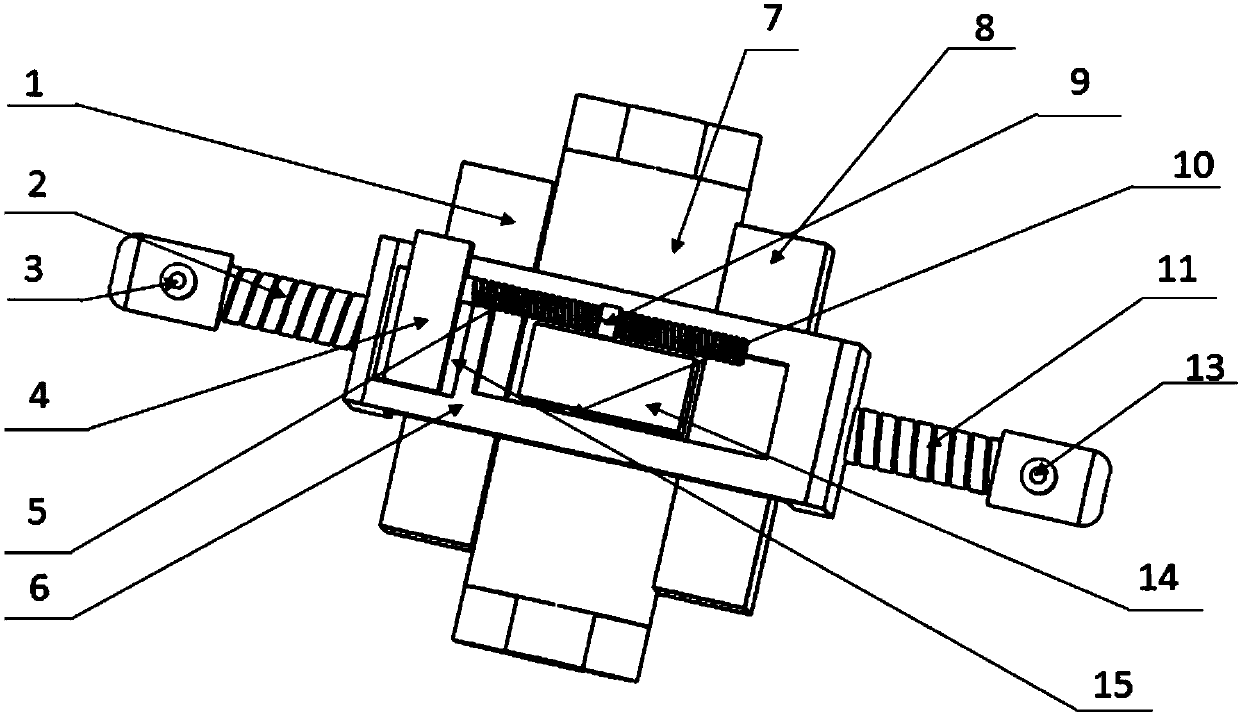

Current measurement device and method facing three-phase four-wire system balanced load

ActiveCN107765058ARealize non-contact measurementReduce the number of disassemblyVoltage/current isolationMeasurement instrument housingReciprocating motionElectric machine

The invention relates to a current measurement device and method facing a three-phase four-wire system balanced load, and belongs to the field of measurement. A rectangular stop block is fixedly connected with one end of a threaded guide rod, the other end of the threaded guide rod is sleeved with a manual rotating handle, a U-shaped frame is in threaded connection with the threaded guide rod, a linear motor is fixedly connected with the U-shaped frame through a motor supporting base, a sensor module is arranged in a sensor adjusting table, the lower end of the sensor adjusting table is fixedly connected with two slidable keys, a pair of linear keyways are arranged in the U-shaped frame, the linear motor drives a threaded lead screw to rotate, the threaded lead screw is provided with two-directional threads and can drive a nut arranged on the threaded lead screw to do reciprocating motion, and the nut is connected with the sensor adjusting table through a screw. Accordingly, an effective value of a three-phase alternating-current current connected with the balanced load can be measured in a passive and non-contact mode, and the device has the advantages of being small in size, simple in structure, low in cost, wide in application range and the like.

Owner:JILIN UNIV

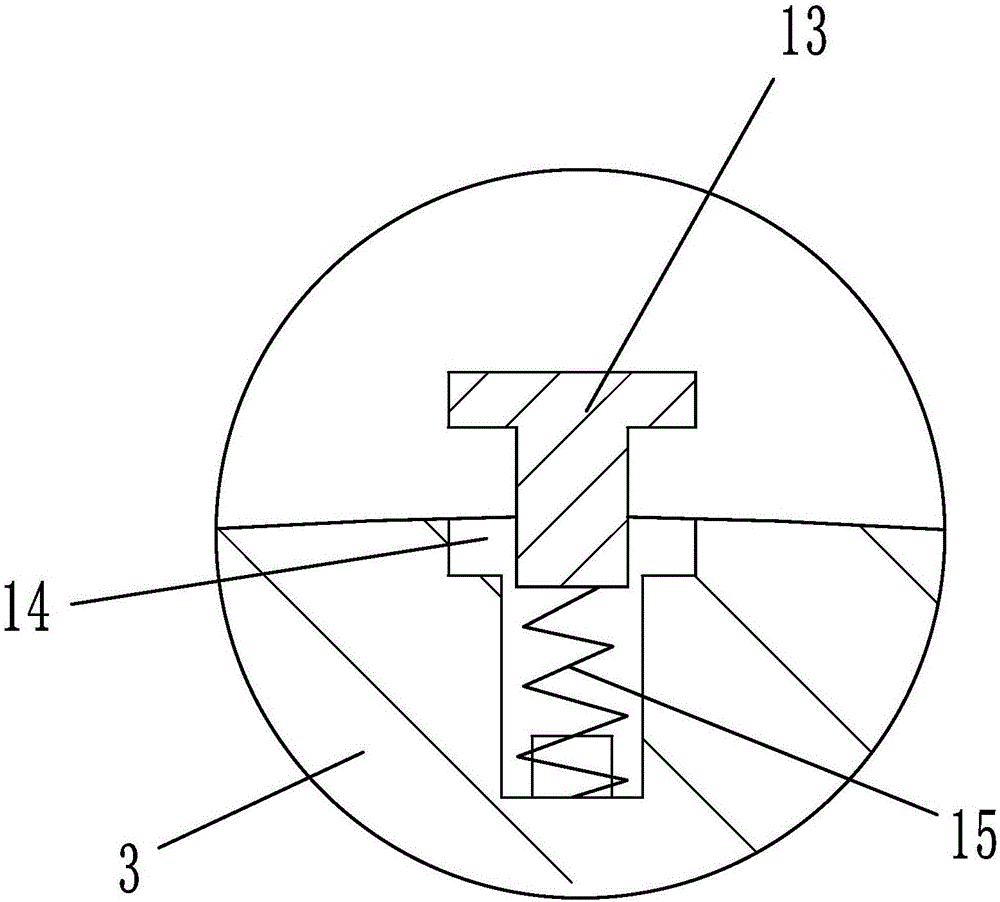

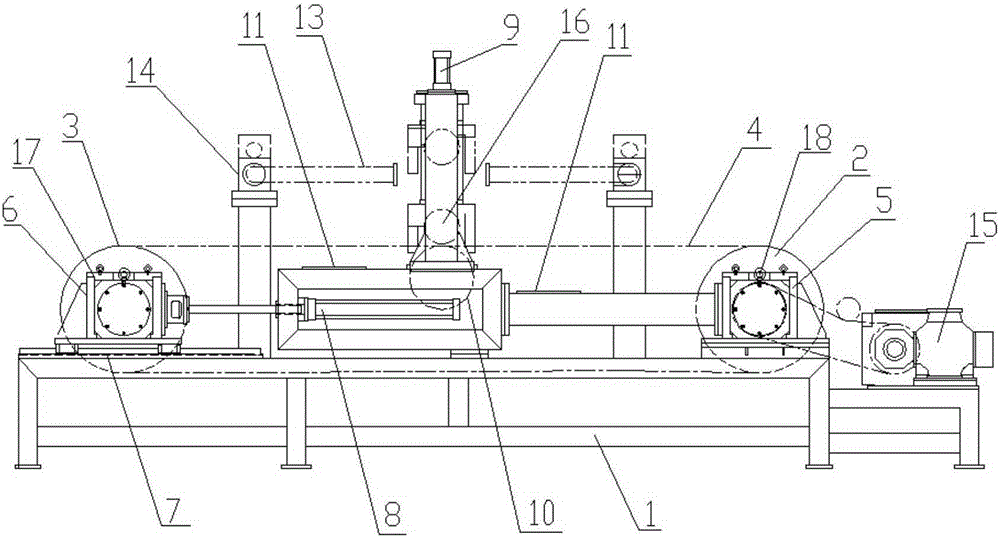

Machine leg welding equipment for compressor and use method of machine leg welding equipment

ActiveCN106553016AQuick disassemblyHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to processing of compressor parts, in particular to machine leg welding equipment for a compressor and a use method of the machine leg welding equipment. The machine leg welding equipment for the compressor comprises a positioning head matched with the inner surface of a case, jack catches positioned on two sides of the positioning head and a welding mechanism positioned above the positioning head, wherein a guiding face matched with the shape of the outer surface of the positioning head is formed on the end surface of the end, close to the positioning head, of each jack catch, and the end, far away from the positioning head, of each jack catch is connected with a driving cylinder; the welding mechanism comprises a positioning base and welding guns positioned on the positioning base, and an adjustment cylinder used for controlling the positioning base to ascend or descend is arranged on the positioning base; and T-shaped adjustment heads are uniformly distributed on the outer surface of the positioning head, adjustment holes for accommodating the adjustment heads are formed in the outer surface of the positioning head, and adjustment springs are arranged between the adjustment holes and the adjustment heads. The machine leg welding equipment has the beneficial effects that the clamping frequency can be effectively reduced, the positioning precision can be effectively improved, the welding frequency can be effectively reduced, multi-point simultaneous welding is effectively realized and the production efficiency is effectively improved.

Owner:杭州瀚真电器制造有限公司

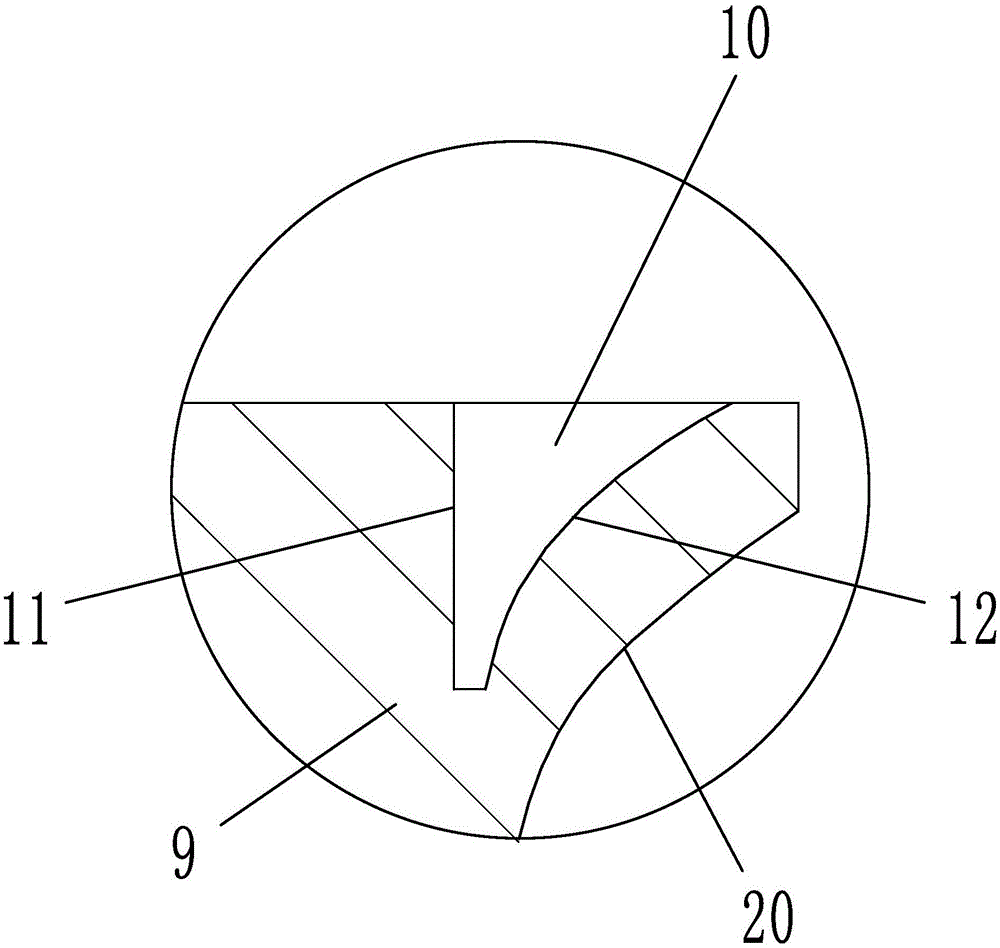

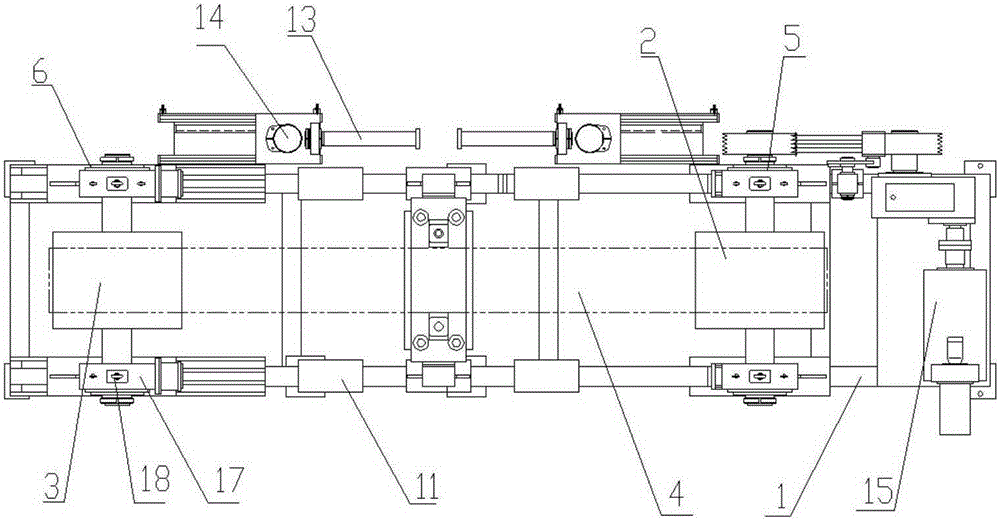

Compressor silencer assembling equipment and use method thereof

ActiveCN106563886AHigh precisionImprove product qualityWelding/cutting auxillary devicesAuxillary welding devicesMultiple pointEngineering

The invention relates to production of a compressor part, in particular to compressor silencer assembling equipment and a use method thereof. The compressor silencer assembling equipment comprises a positioning head matched with the inner surface of a machine enclosure, clamping claws located on two sides of the positioning head and a welding mechanism located above the positioning head, wherein a stand column is arranged on the axis of the lower end surface of the positioning head; the outer side of the stand column is sleeved with an electromagnetic attraction sleeve; the upper end surface of the electromagnetic attraction sleeve is attached to the lower end surface of the positioning head; a guide surface matched with the outer surface of the positioning head in shape is arranged on the end surface of the end, close to the positioning head, of each clamping claw; the welding mechanism comprises a positioning seat and a welding gun located on the positioning seat; the positioning seat is provided with an adjustment air cylinder used for controlling the positioning seat to ascend and descend; and adjustment heads are uniformly distributed on the outer surface of the positioning head. The compressor silencer assembling equipment and the use method thereof have the beneficial effects of being capable of effectively reducing the clamping frequency, increasing positioning accuracy, reducing the welding frequency, realizing simultaneous welding at multiple points, improving productivity and the like.

Owner:杭州瀚真电器制造有限公司

Conveyer belt energy saving property testing device and sample loading and unloading method

ActiveCN105157978AEasy to installSimple structureMachine gearing/transmission testingConveyor beltEnergy analysis

The invention relates to a conveyor belt energy saving property testing device, including a frame, an active roller mounted on the frame, a driven roller, and a conveyor belt mounted on the active roller and the driven roller. The active roller and the driven roller are detachably mounted on the frame. The active roller and the driven roller can slide relatively. Inners sides of installation positions of the active roller and the driven roller on the frame are fixedly provided with a platform for dismounting the active roller and the driven roller. A roller hoisting device is arranged beside the frame. According to the invention, an annular conveyor belt sample can be conveniently mounted, and the structure of the testing device is simplified as much as possible. The invention adopts the method for hoisting the active roller and the driven roller of the testing device, adopts special-purpose rotary supports and movable holding rods, can mount the annular sample on the testing device and dismount the annular sample from the testing device according to predetermined steps, reduces the number of dismounted parts, and guarantees the precision of the overall testing device.

Owner:青岛中化新材料实验室检测技术有限公司

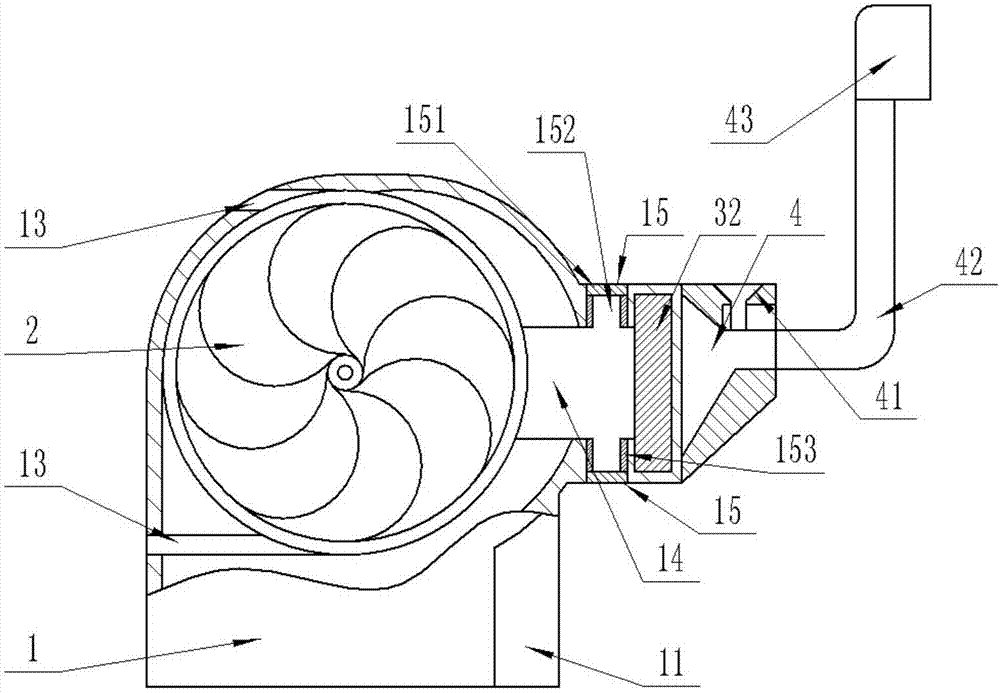

Household medical oxygen inhaler having oxygen separation function

The invention belongs to the technical field of household oxygen inhalers, and in particular relates to a home medical oxygen inhaler with oxygen separation function, including a casing, an air pump and an oxygen-enriched separation membrane. The side of the casing is shaped like a volute, and the The air pump is a scroll compressor, which is arranged horizontally on the inner wall of the casing side, and the oxygen-enriched separation membrane is arranged in a fixed frame, and the fixed frame is fixed on the inner wall at one end of the casing circumferential surface through a mounting slot, and Perpendicular to the horizontal plane, the upper and lower parts of the circumferential surface of the casing relative to the other end of the oxygen-enriched separation membrane are respectively provided with air inlets, and the gas outlet is arranged on the outer wall of the circumferential surface of the casing. The present invention has the advantages of simple operation and low cost. Oxygen production is stable, and as a home medical device, it is suitable for people who need oxygen inhalation in ordinary families.

Owner:SHENZHEN WOHAISEN TECH CO LTD

Combined type male die body for extrusion die

InactiveCN105080986ASimplify loading and unloading processImprove reliabilityExtrusion diesEngineeringCushion

The invention discloses a combined type male die body for an extrusion die and belongs to the technical field of pressurized metal working. The combined type male die body comprises a cushion plate, a fixed plate, a male die base, a male die working die head, a bolt and a pin. The male die base is fixed in the fixed plate. The male die working die head is installed in the male die base through the bolt, and the bolt is fixed through the pin to be prevented from rotating. The male die body is of a combined structure, so that combination of the die head and the base of the extrusion male die is achieved, and extrusion is achieved through direct contact between the die head and a workpiece during male die extrusion forming. When the die head of the male die body is abraded and needs to be replaced, dismounting and mounting can be achieved quickly. By the adoption of the combined type male die body, quick replacement of the extrusion die can be achieved, production efficiency is improved, loss of the die is reduced, and cost is reduced.

Owner:安徽工业大学科技园有限公司

Electronic dust remover with conveniently-replaced filter element

InactiveCN112717573AEasy to replaceImprove filtering effectDispersed particle filtrationTransportation and packagingStructural engineeringFilter effect

The present invention discloses an electronic dust remover with a conveniently-replaced filter element. The electronic dust remover comprises an electronic dust remover body, an air inlet pipe is fixedly installed on one side of the electronic dust remover body and communicates with the interior of the electronic dust remover body, and an installation hole is formed in the bottom of the electronic dust remover body; and a cover plate is fixedly mounted at the bottom of the electronic dust remover body through bolts, a mounting base is fixedly mounted at the top of the cover plate, and the top of the mounting base penetrates through the mounting hole and is provided with a mounting groove. The electronic dust remover is reasonable in design and good in practicability, dust and particle impurities adhering to the surface of the filter element can be swept down through rotation of the bristles, the filtering effect of the filter element can be improved, the filter element does not need to be frequently disassembled for cleaning or replacement, the disassembling frequency of the filter element is reduced, and the labor amount of workers is reduced; in addition, the filter element can be conveniently and rapidly disassembled and assembled, the filter element can be conveniently replaced, operation is convenient and fast, and time and labor are saved.

Owner:HANGZHOU KUANFU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com