Construction process of large-span steel tube arch bridge without supports

A steel pipe arch bridge, the technology of construction technology, applied in the direction of arch bridge, bridge, bridge form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

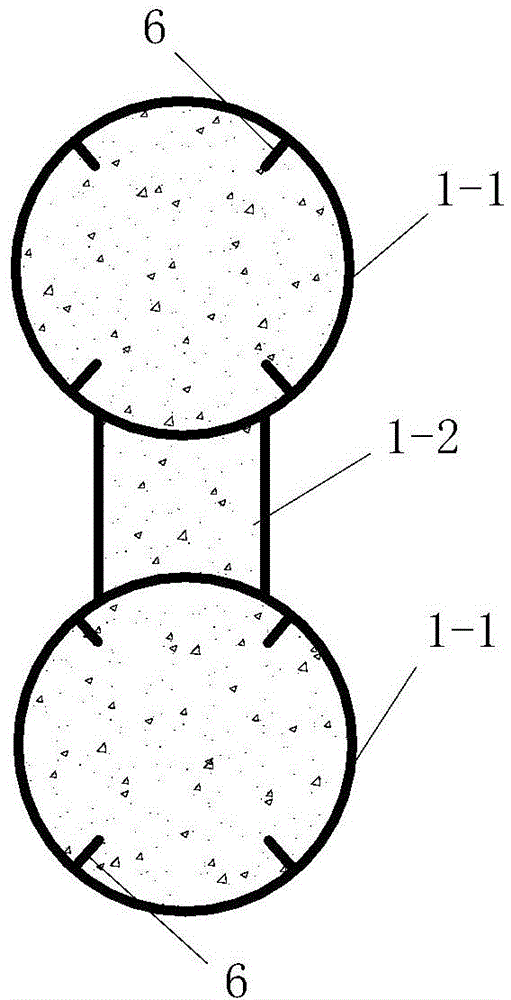

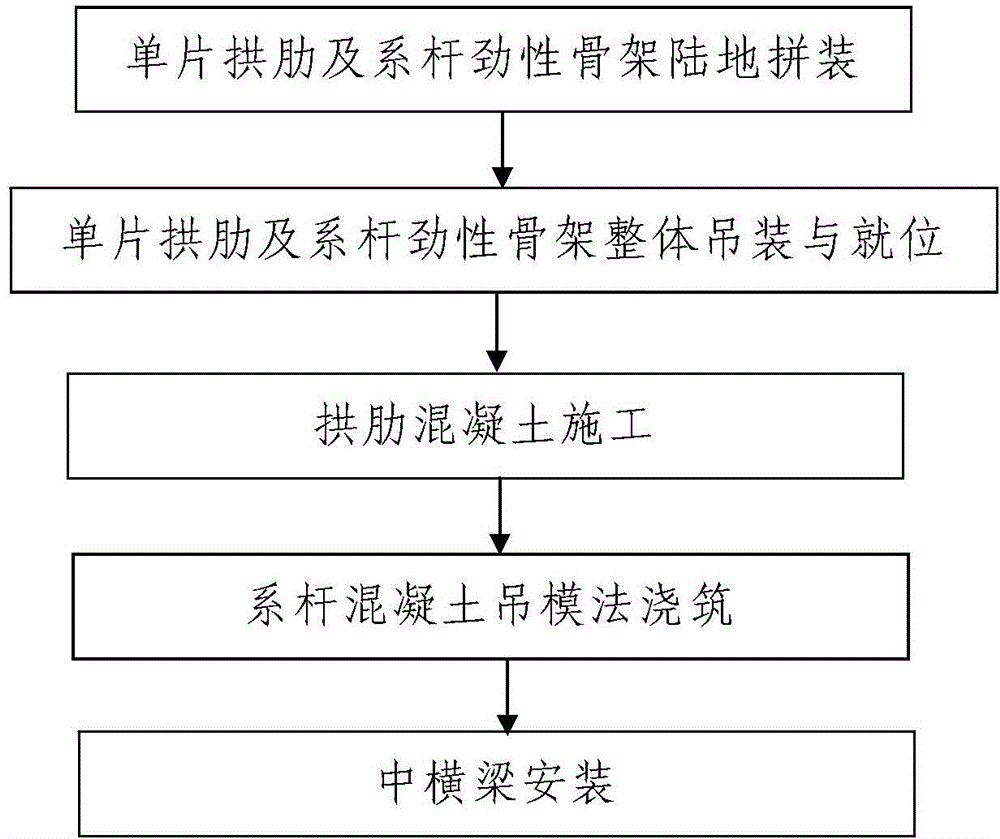

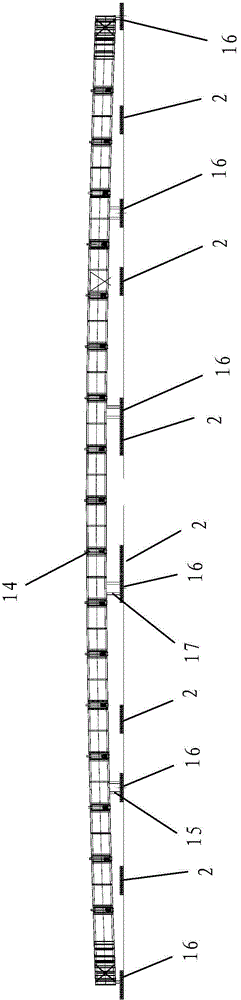

[0112] Such as Picture 1-1 The long-span steel pipe arch bridge has no support construction technology, and the long-span steel pipe arch bridge constructed is a tie-bar arch bridge erected on the river 22, combined with figure 1 , figure 2 , image 3 and Figure 8 , the tied arch bridge includes a bridge lower support structure 23 and a bridge superstructure supported on the bridge lower support structure 23, and the bridge superstructure includes an arch rib 1 and a tie rod connected between the two arch feet of the arch rib 1 19. The tie rod 19 is located directly under the arch rib 1 and has a stiff skeleton 14 inside it. The rigid frame 14 is a rigid frame that reinforces the tie rod 19 and is assembled from a plurality of rods. Both ends of the rigid frame 14 are fastened to the two ends of the arch rib 1 respectively. The arch rib 1 is a steel pipe concrete structure and it is composed of an arched steel pipe support and a concrete structure poured in the arched s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com