Combined type male die body for extrusion die

An extrusion die, combined technology, applied in the field of metal pressure processing, can solve the problems of high material consumption, poor stability, increase in the axial dimension of the punch, and achieve the advantages of simplifying the loading and unloading process, fast updating, and reducing the time for changing the mold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

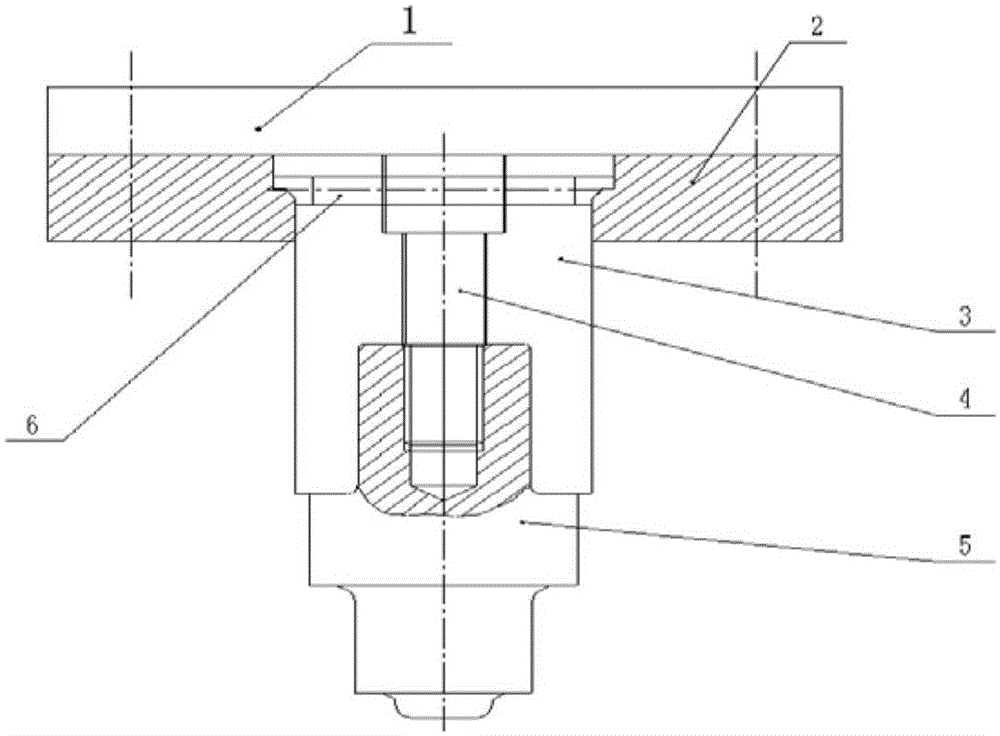

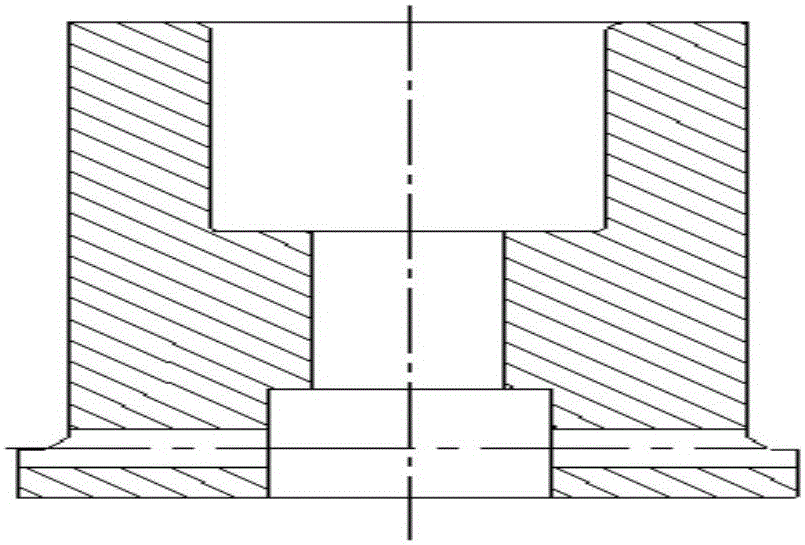

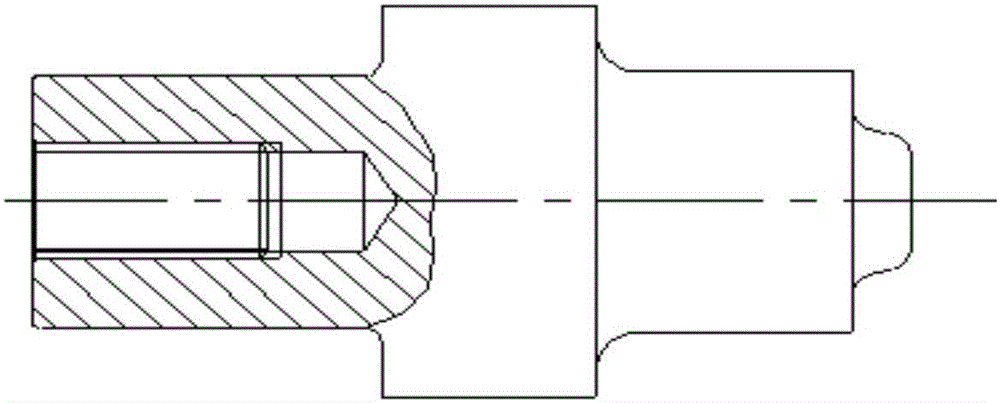

[0014] A combined punch of an extrusion die provided by the present invention includes a backing plate 1, a fixing plate 2, a punch base 3, a working die head 5 of the punch, bolts 4 and pins 6; the punch base 3 is fixed on the fixing plate In 2, the working die head 5 of the punch is installed in the base 3 of the punch through the bolt 4, and the bolt 4 is fixed by the pin 6 to prevent rotation.

[0015] When the punch is initially assembled, the bolt 4 is inserted into the base 3 of the punch, positioned and fixed by the pin 6, and then fixed in the fixed plate 2. The working die head 5 of the punch is built in the cavity of the punch base 3, and is screwed to the axial positioning surface of the punch base 3 by rotation. The diameter must ensure the concentricity to meet the concentricity requirements of the extrusion die for the punch and die. When the punch is extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com