Combined sliding block forming mechanism of cavity die

A technology of combining sliders and cavities, applied in the field of combined slider forming mechanisms, can solve the problems of increasing mold development costs, unbalanced forming pressure, and the influence of the number of slider forming cavities, saving mold development costs and ensuring assembly. Accuracy, the effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

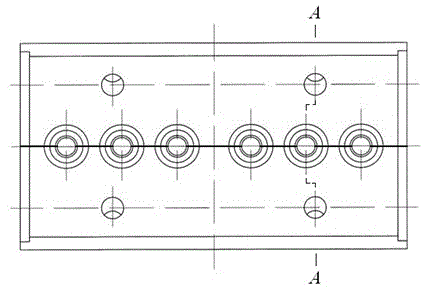

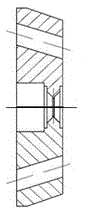

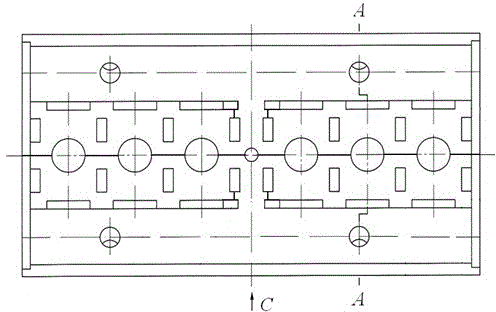

[0046] A combined slide block forming mechanism of a cavity mold of the present invention is shown in the appendix image 3 to attach Figure 11 , on the slider seat 1 corresponding to the two sides of the cavity block 2, the mounting holes for the positioning blocks 3 on both sides are opened, and the mounting holes for the positioning block 4 at the end are opened at the end, and the positioning blocks are lightly fitted with the corresponding mounting holes, and the cavity The block and slider seat are installed and positioned through the positioning block. The shape of the cavity block and the positioning block adopt H7 / k7 transition fit. Since the slider only bears the lateral parting force when the mold is opened and closed, the cavity block and the slider The light press fit of the seat eliminates the need for screw fixing and pin positioning.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com