Patents

Literature

30results about How to "Realize numerical control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

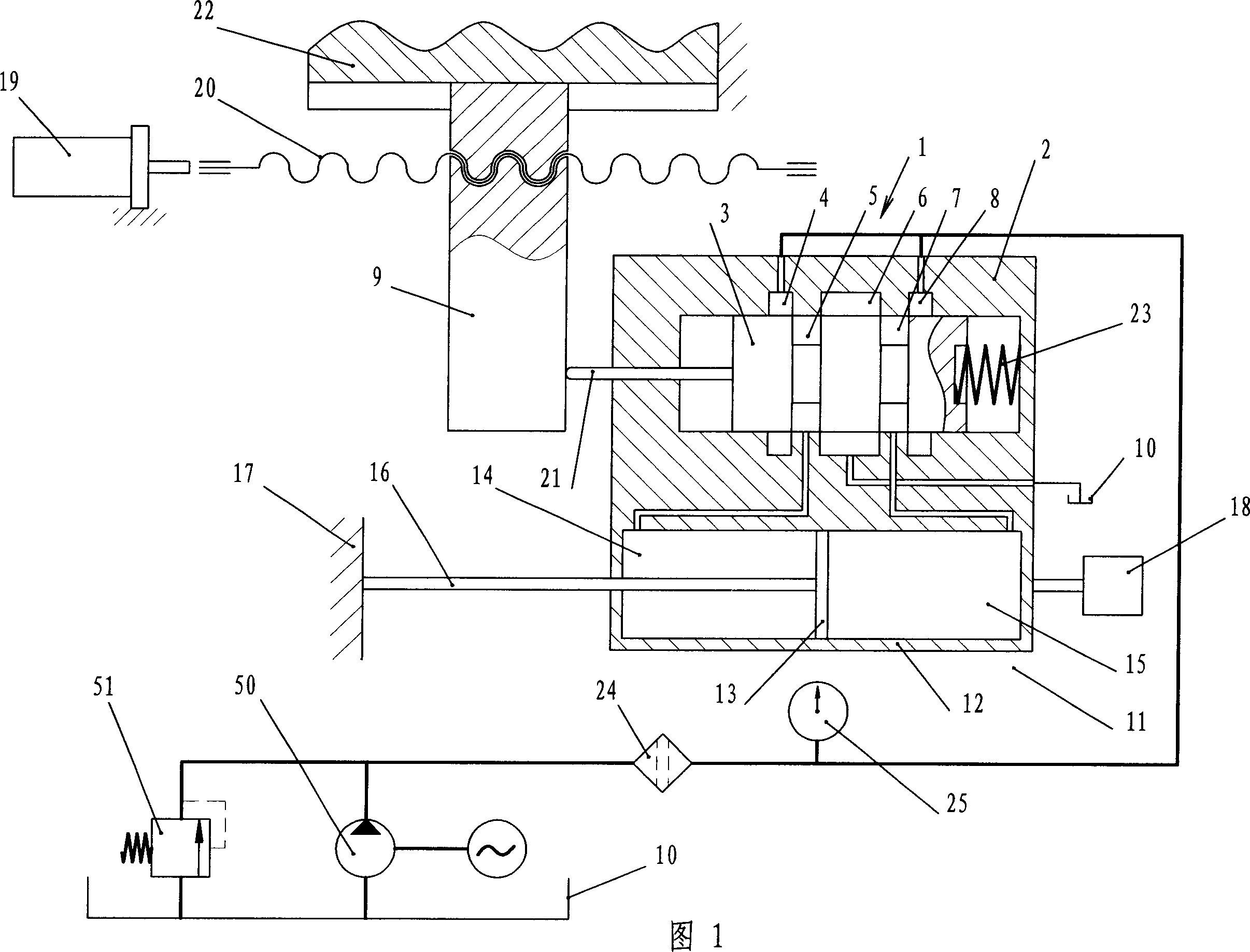

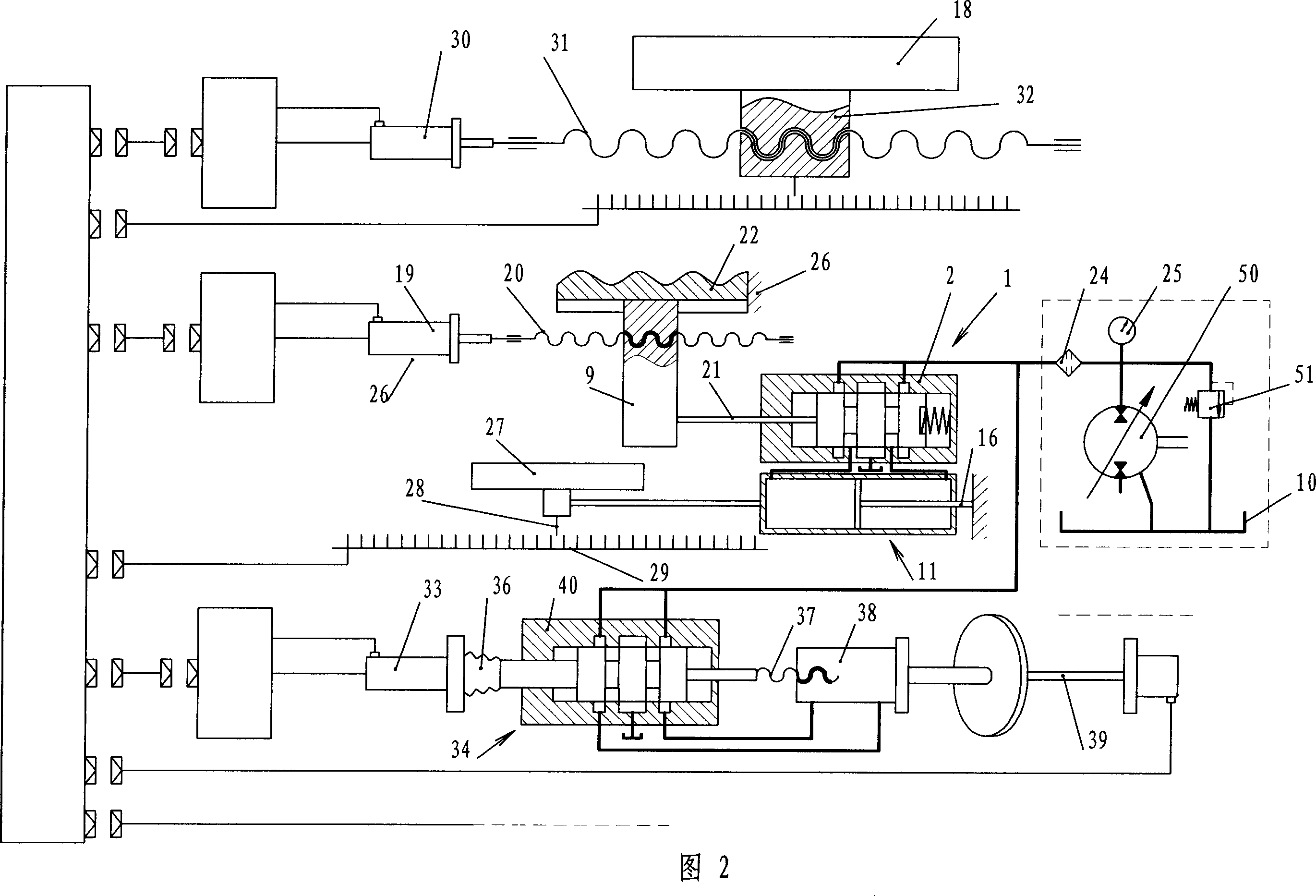

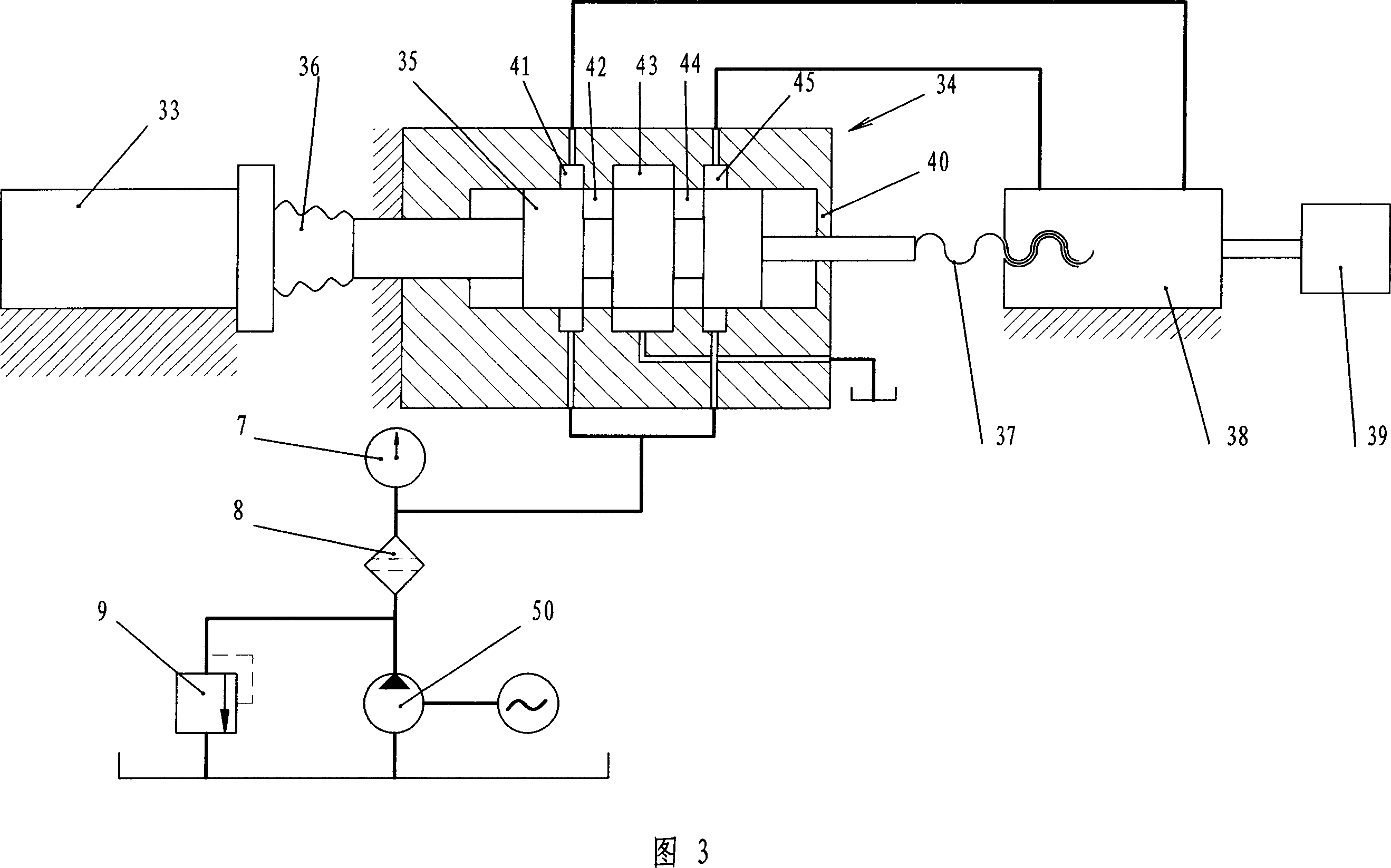

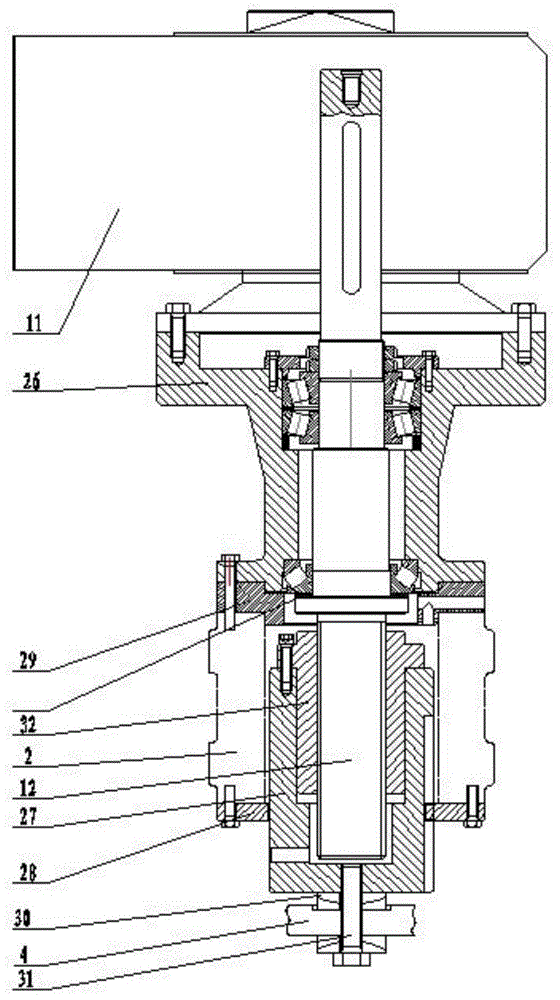

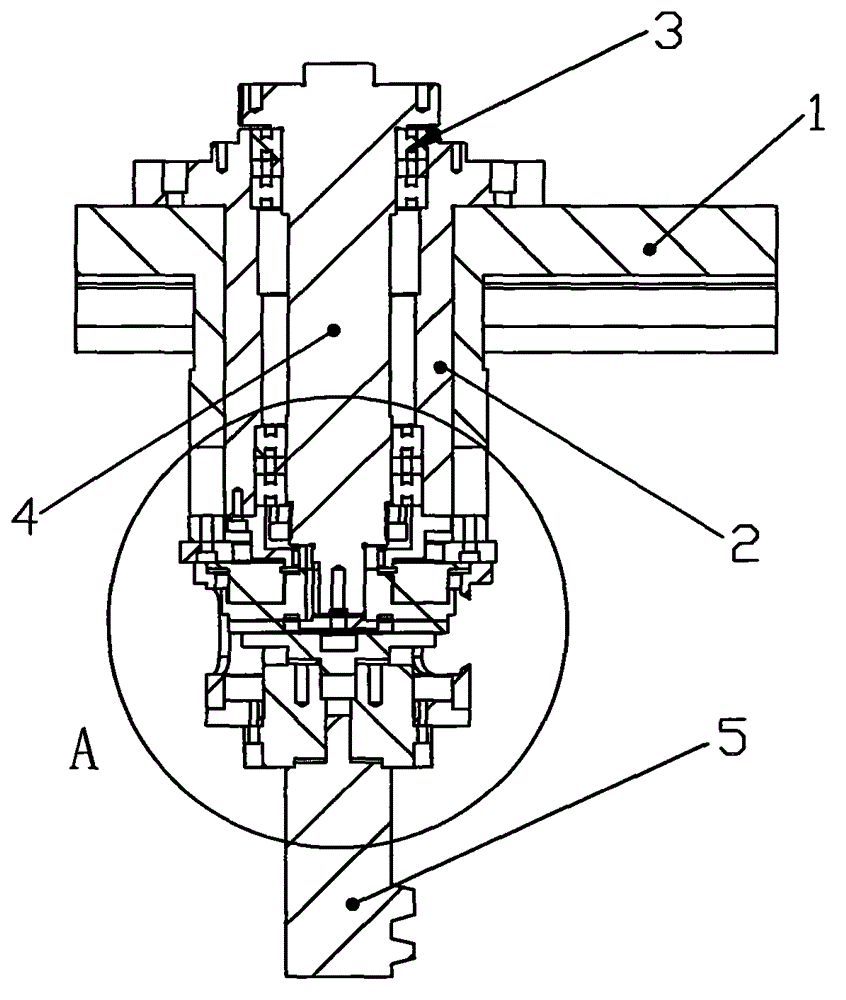

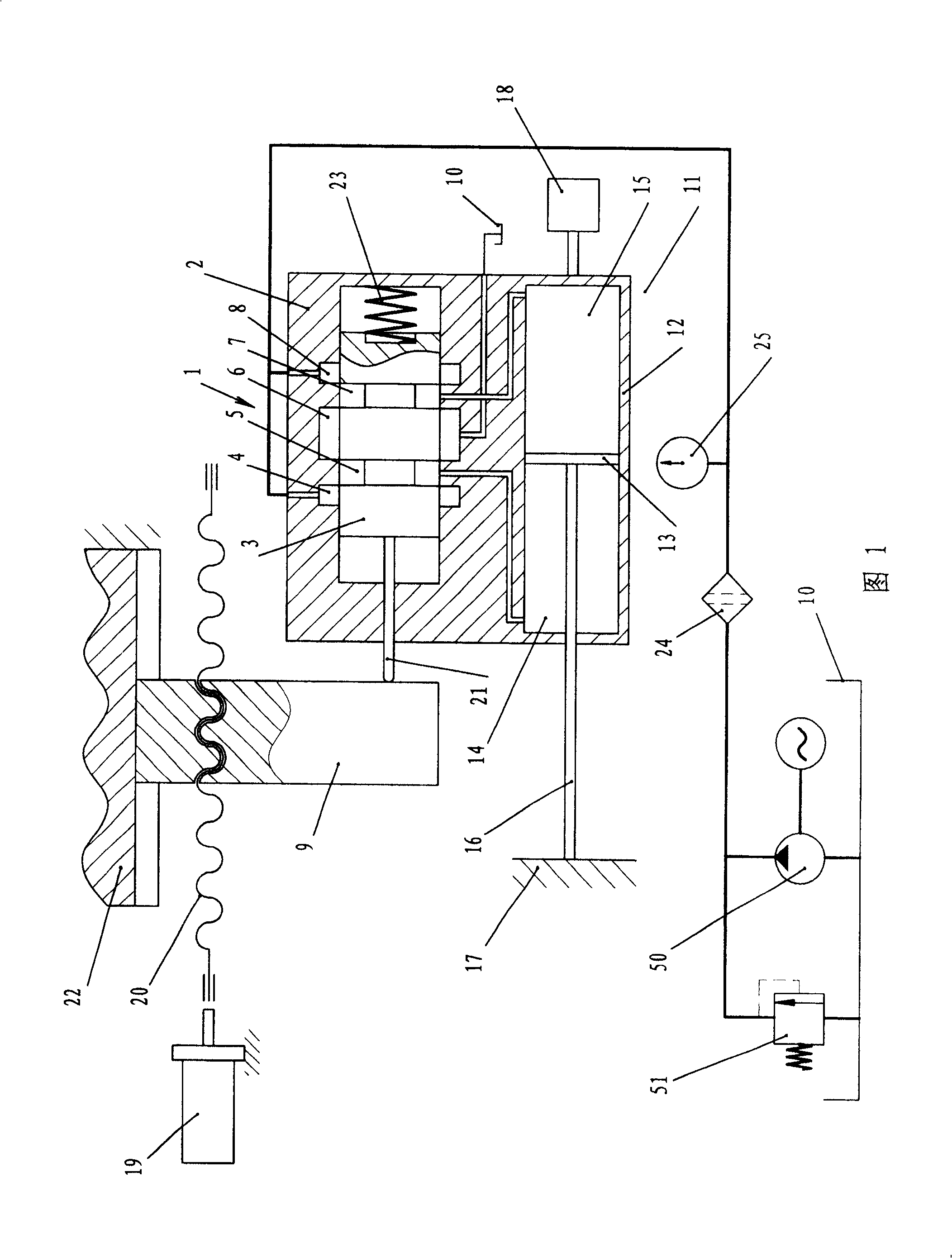

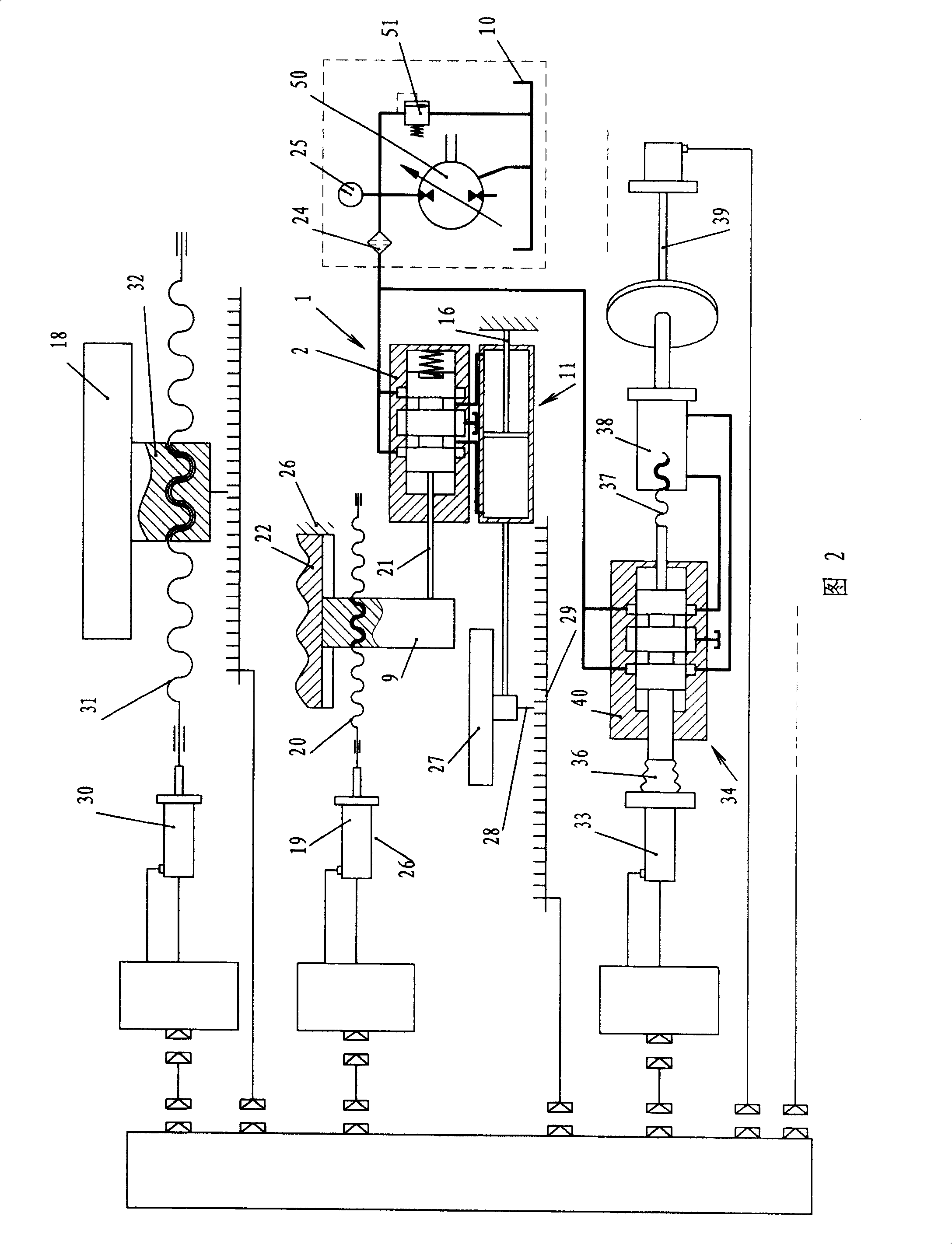

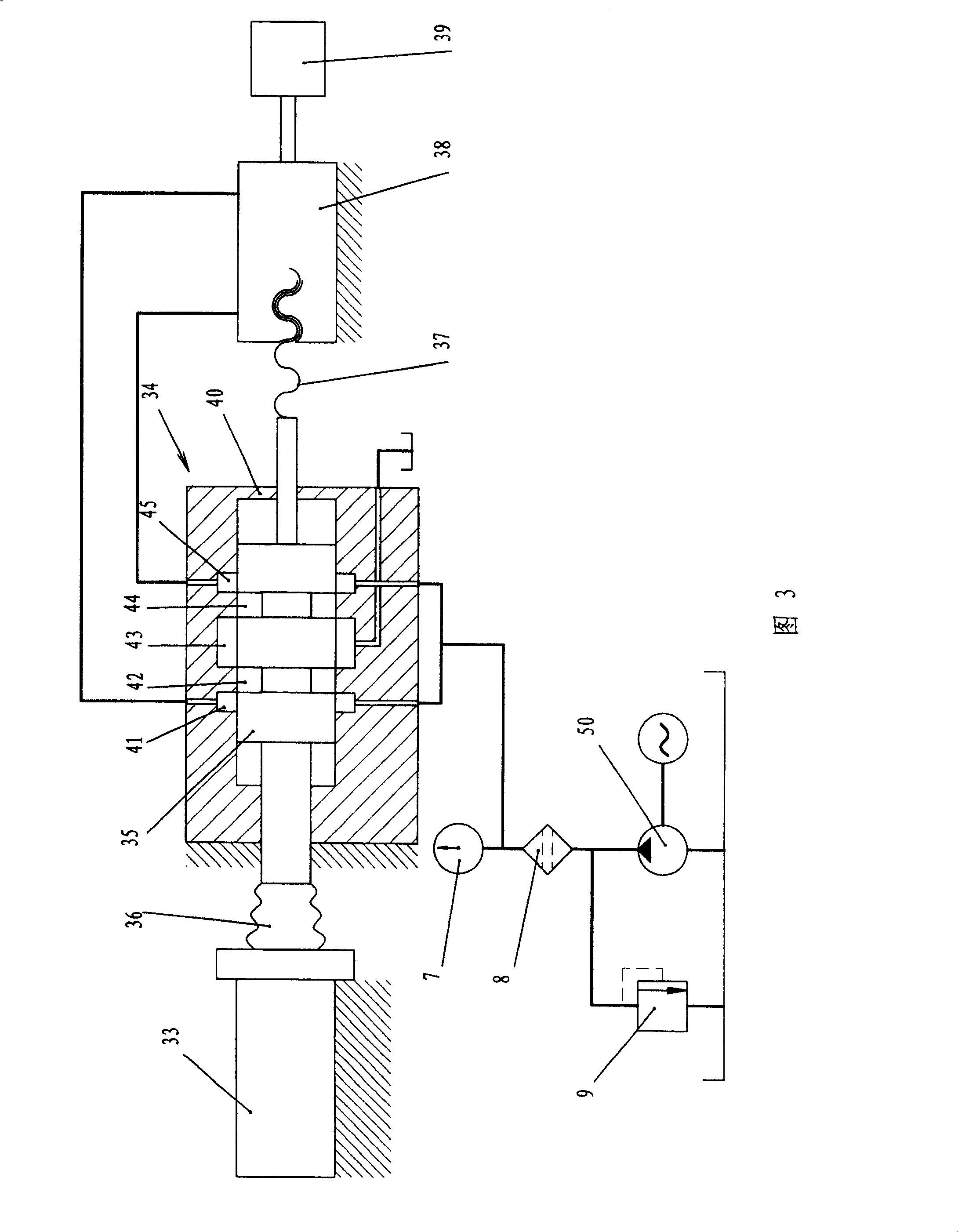

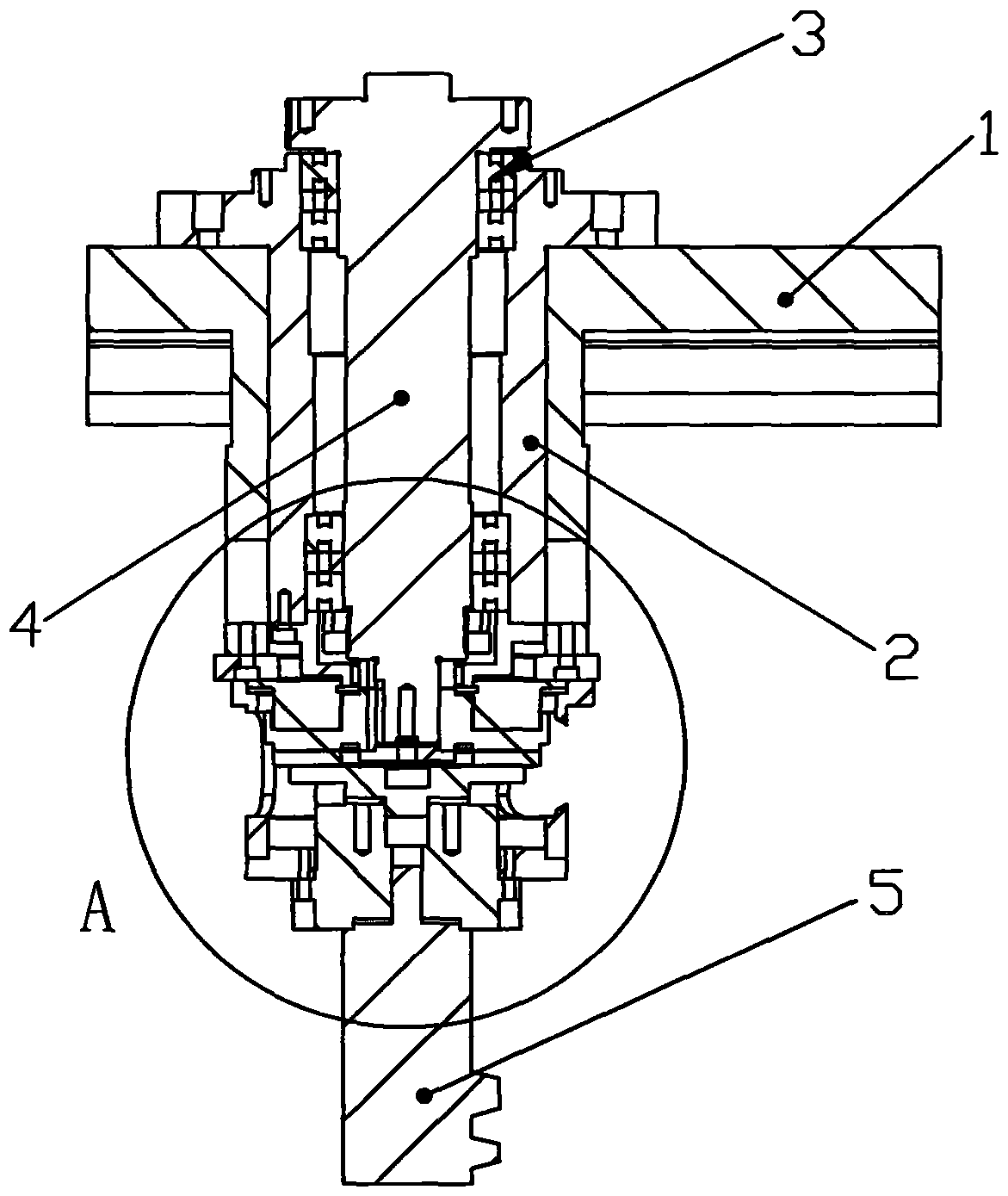

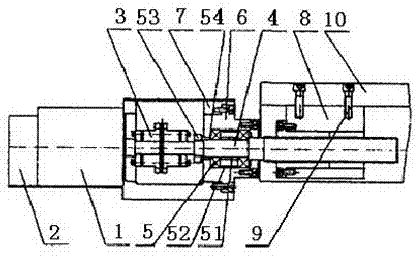

Electrohydraulic servo oil cylinder and numerical control machine tool using same

InactiveCN101008413AServo follow-up motion with high precisionHigh precisionOperating means/releasing devices for valvesServomotor componentsHydraulic cylinderControl system

The invention relates to an electro-hydraulic servo cylinder, comprising a four-edge sliding valve whose base is mounted with a valve element moving left and right. The valve base is fixed on the cylinder whose piston rod is fixed with the frame; the cylinder is connected with the load. The left driving chamber via tube is communicated with the left working chamber, while the right driving chamber via tube is communicated with the right working chamber; one end of valve element is engaged with the dial block mounted on the straight motion output element of straight motion output device. The digit-control machine with said electro-hydraulic servo cylinder comprises a first axle servo driving system, a second axle servo driving system, a third axle servo driving system and a digit-control system, wherein, the second driving system comprises a straight load axle. The invention has high accuracy, quick steering speed, and stable property, which combines the digit control technique with the electro-hydraulic servo motion, with high accuracy in large power.

Owner:路文忠

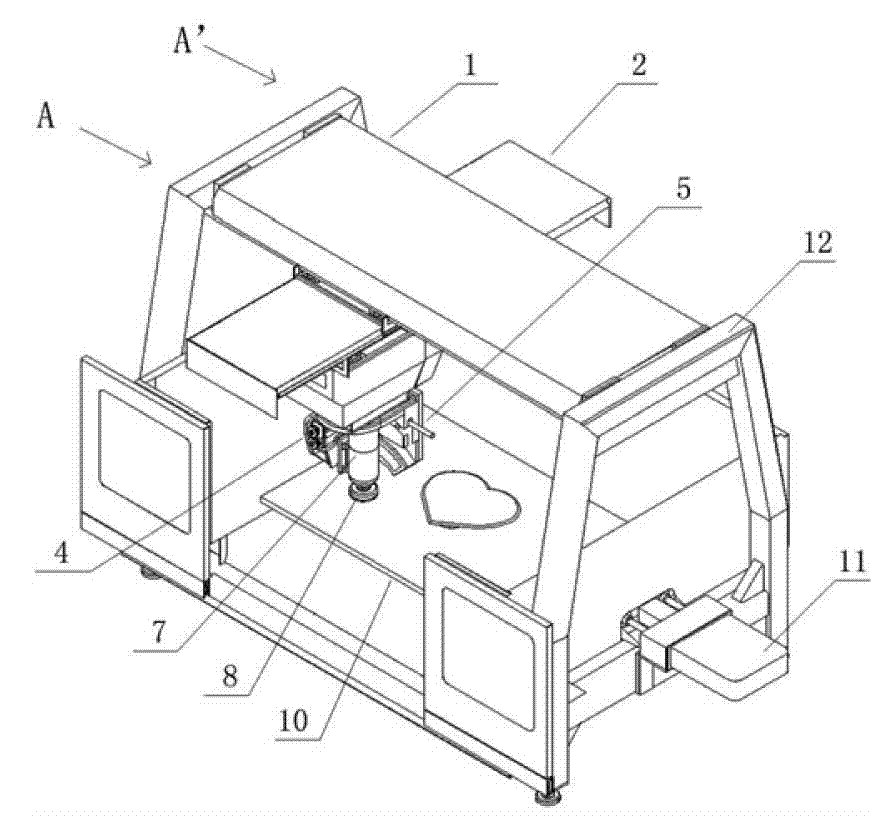

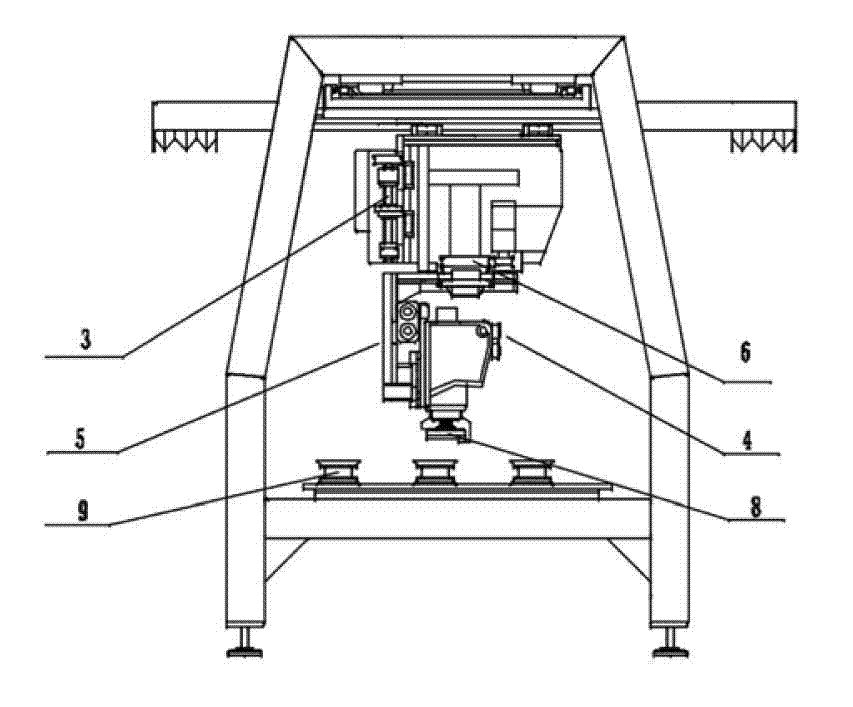

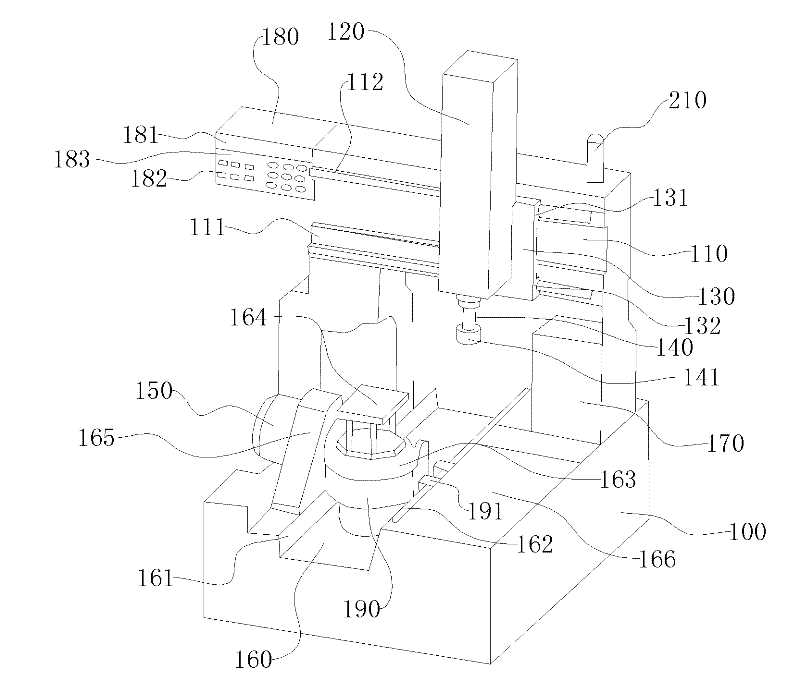

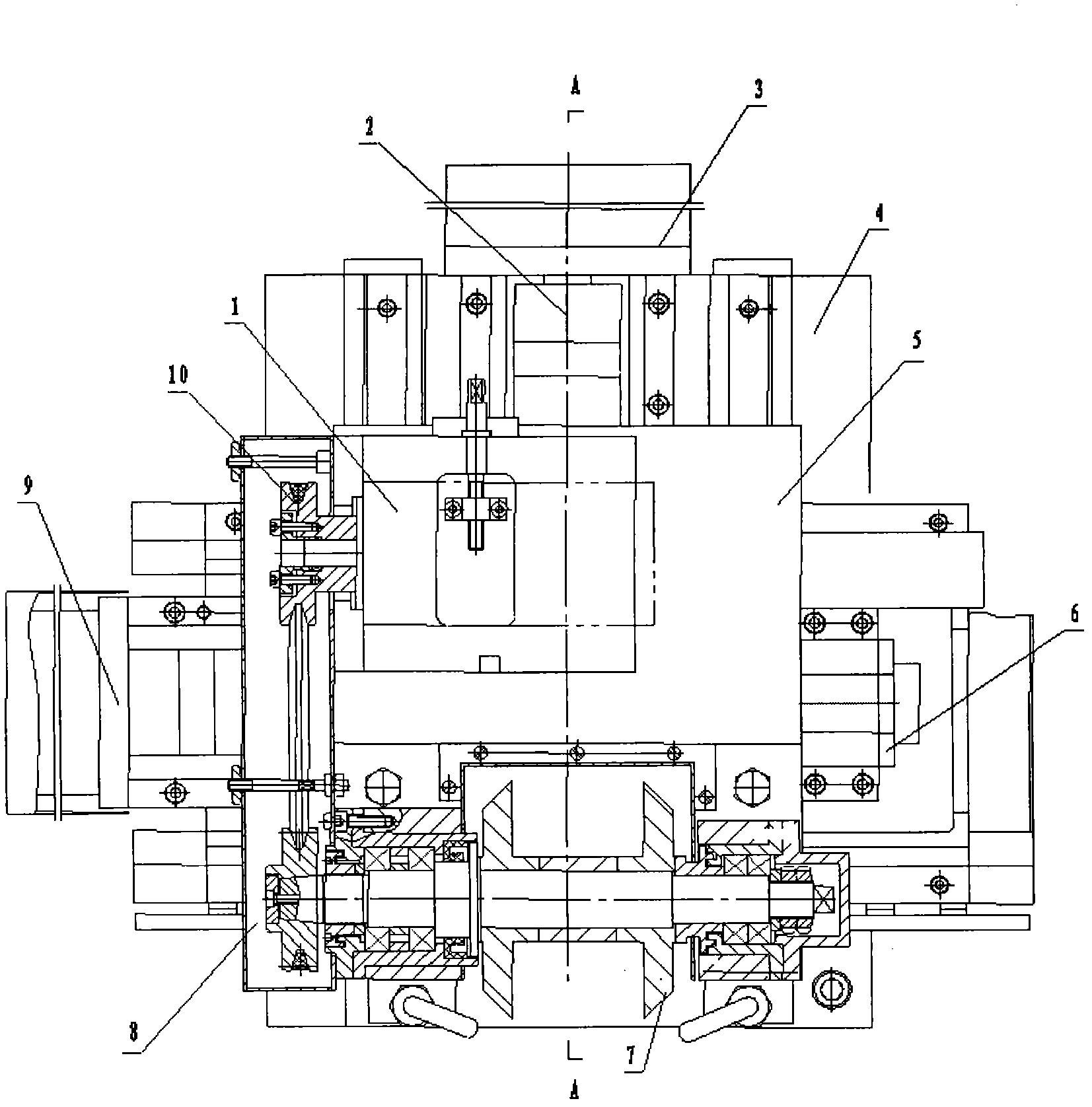

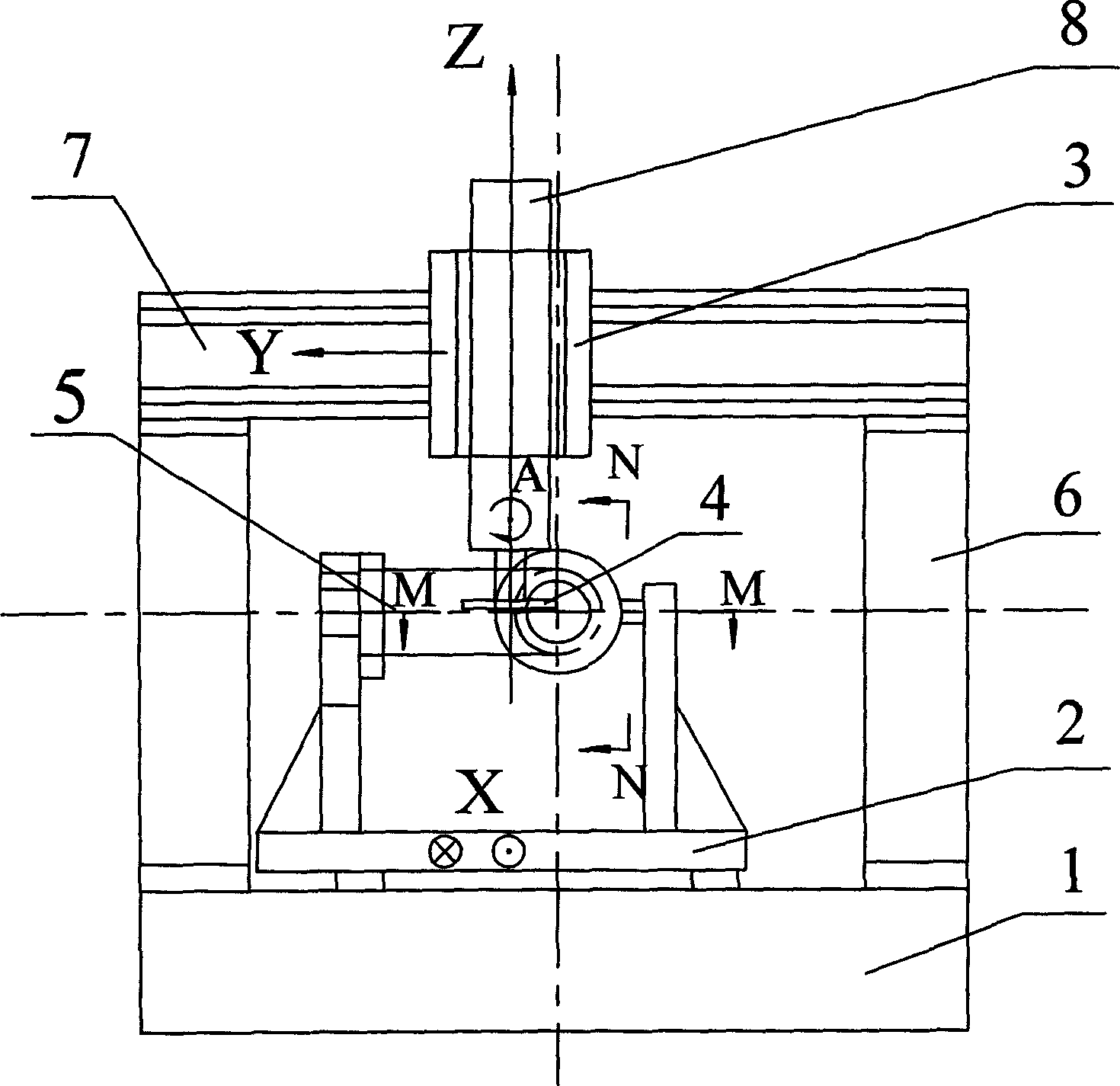

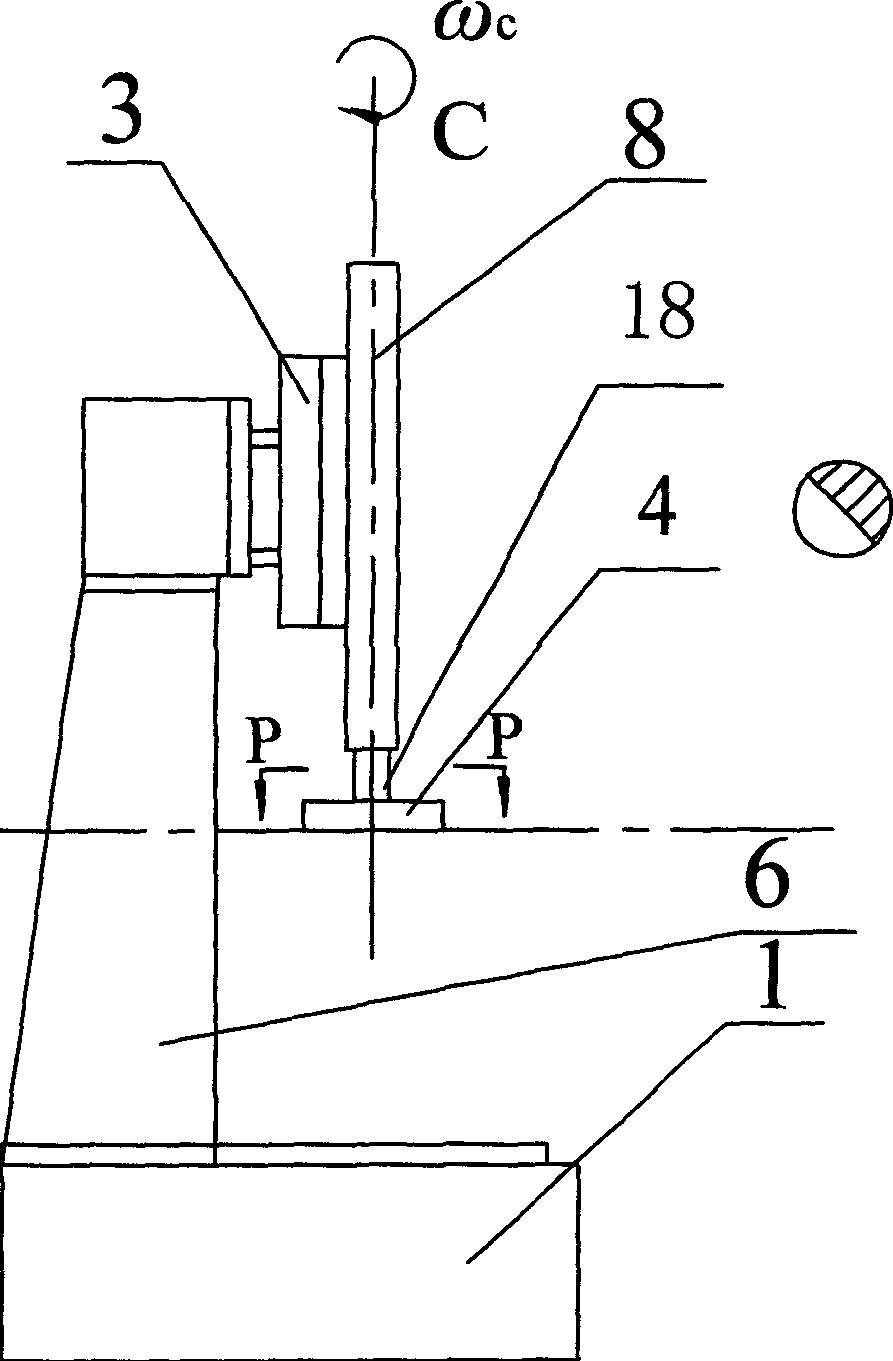

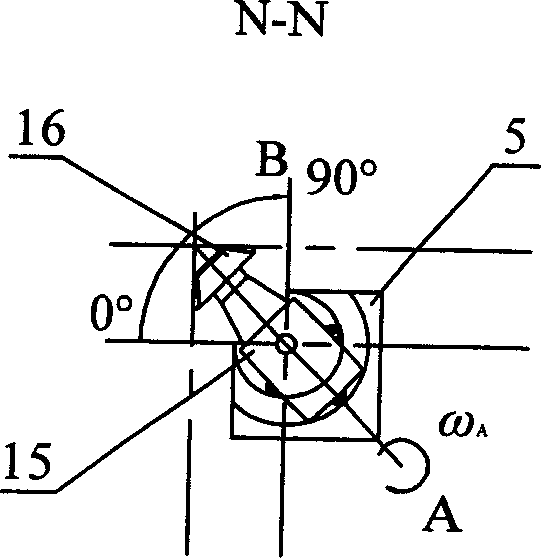

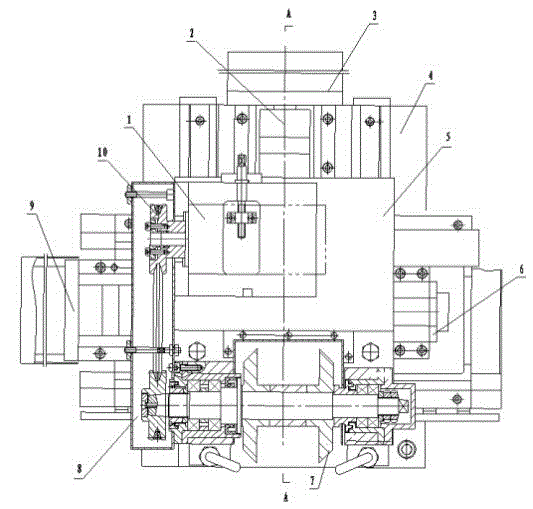

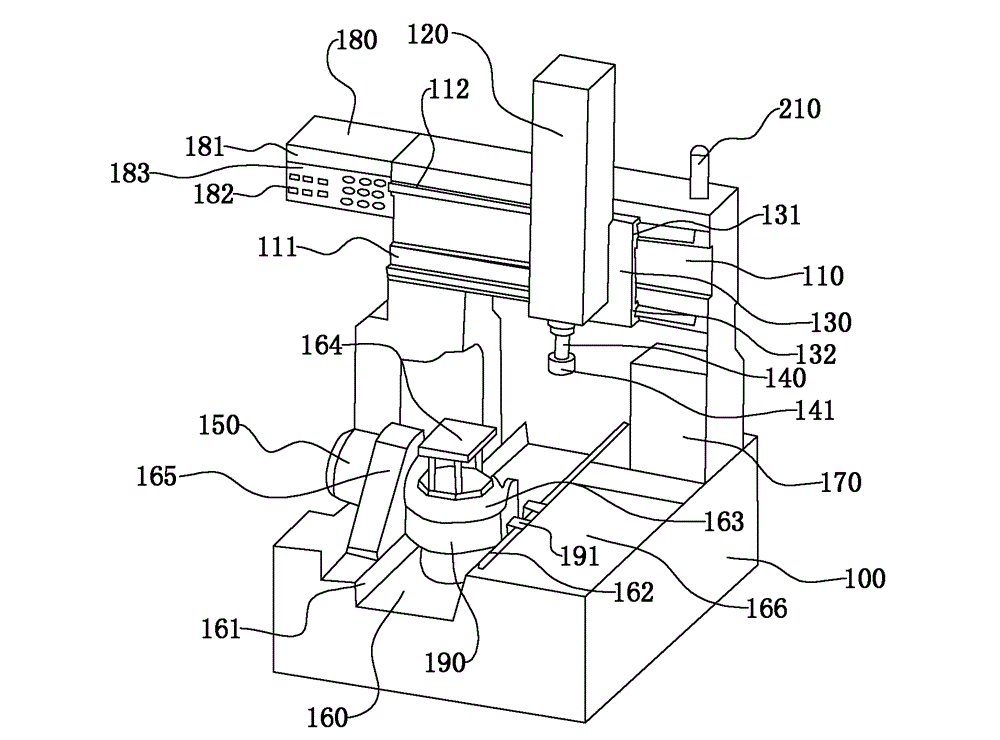

Numerical control irregular glass cutting edging machining center device

InactiveCN103111923ARealize numerical controlRealize intelligenceEdge grinding machinesGrinding machine componentsFlat glassNumerical control

The invention provides a numerical control irregular glass cutting edging machining center device. The numerical control irregular glass cutting edging machining center device comprises an X shaft moving mechanism, a Y shaft moving mechanism, a Z shaft moving mechanism, an A shaft moving mechanism, a B moving mechanism, a C moving mechanism, a grinding head motor, a cutting grinding wheel, a suction disc and a tool changer. The X moving mechanism is located on the top portion of a main rack, the Y shaft moving mechanism is located on the lower portion of the X shaft moving mechanism, the Z shaft moving mechanism is located on the lower portion of the Y shaft moving mechanism, the C shaft moving mechanism is located on one side of the Z shaft moving mechanism, the A shaft moving mechanism and the B moving mechanism are respectively located on the lower portion of the C shaft moving mechanism, the grinding head motor is arranged on the A shaft moving mechanism, the cutting grinding wheel is arranged on the lower portion of the grinding head motor, the suction disc is located on a platform on the lower portion of a host machine, and the tool changer is located on the right lower portion of the host machine. The numerical control irregular glass cutting edging machining center device is capable of achieving plate glass cold machining, diversified cutting, and beveled edge and straight edge grinding of multi-arc and multi-angle combination.

Owner:GLASSMAN MACHINERY BEIJING

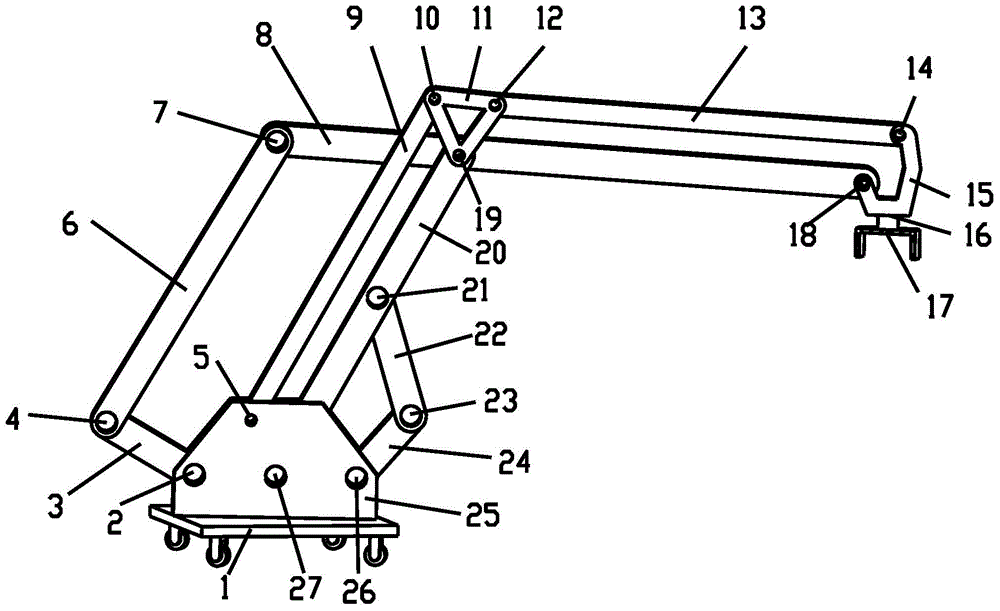

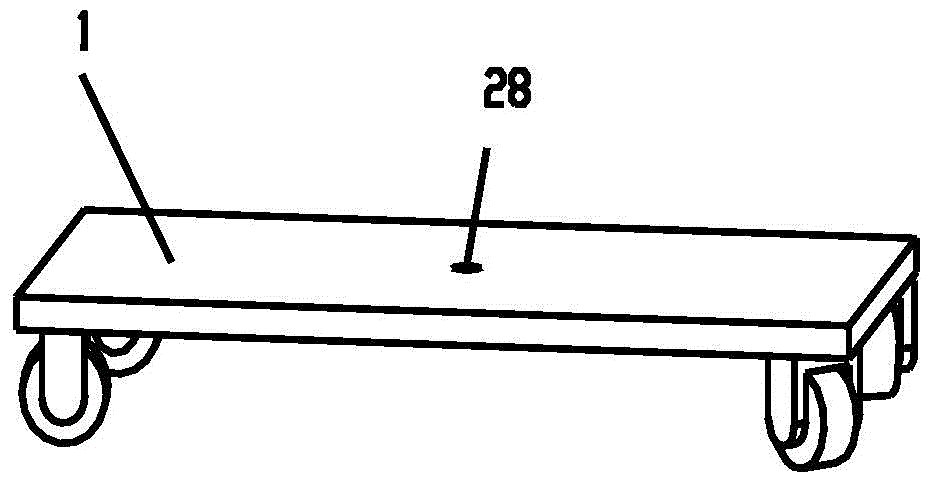

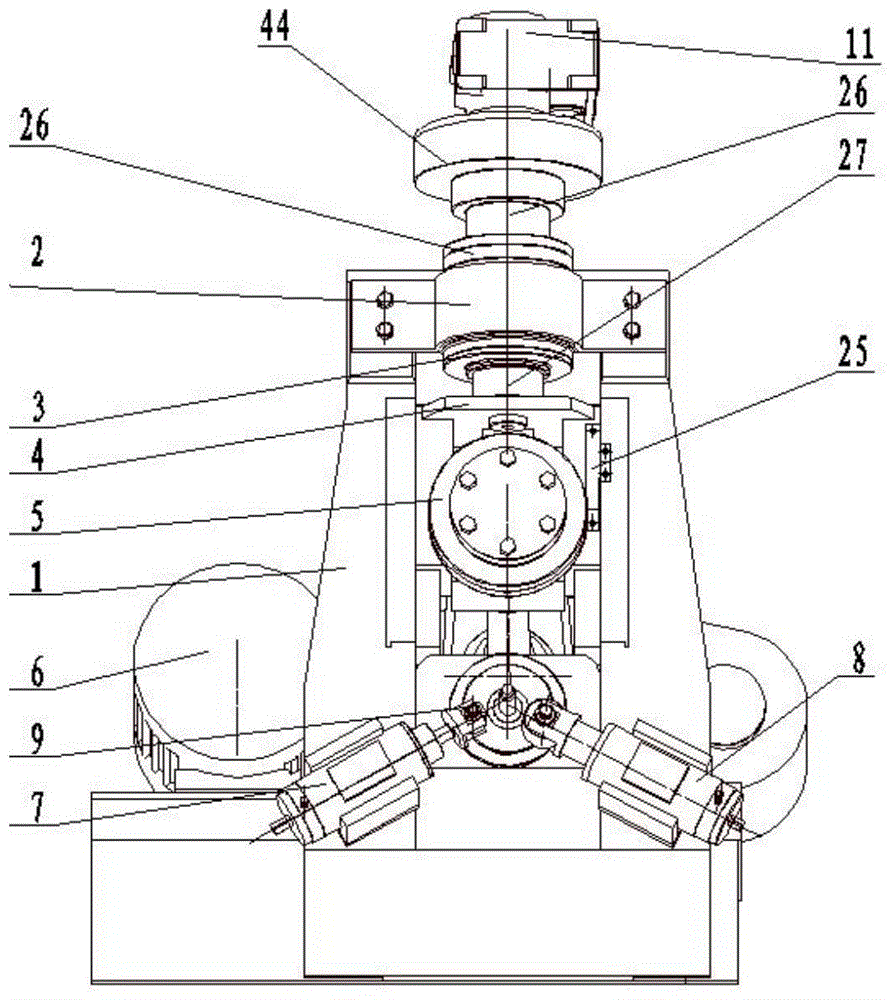

Multi-degree-of-freedom controllable wheel type mobile palletizing robot mechanism

InactiveCN104476535AGuaranteed to always translateInhibition rigidityProgramme-controlled manipulatorMulti degree of freedomActuator

The invention relates to a multi-degree-of-freedom controllable wheel type mobile palletizing robot mechanism. The multi-degree-of-freedom controllable wheel type mobile palletizing robot mechanism comprises an arm lifting mechanism and a movable platform. The arm lifting mechanism is composed of a plane five-bar mechanism and a branched chain. The planar motion of the arm lifting mechanism is realized through the synthetic motion of the plane five-bar mechanism and the branched chain; the spatial motion of the whole mechanism is realized through the motion of the movable platform. Two serial parallelogram structures are utilized for guaranteeing that an end actuator transversely moves all the time. Due to the mechanism, the robot has motion redundancy of almost infinite work space and height, has moving and operating functions at the same time, can realize complicated motion output, preferably realizes various palletizing actions, and is suitable for more occasions.

Owner:GUANGXI UNIV

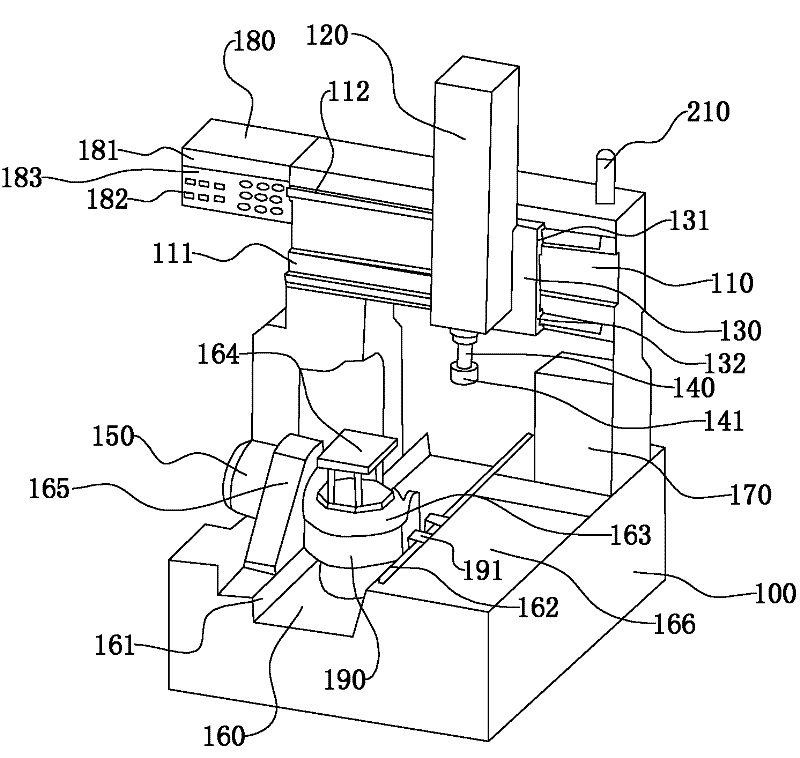

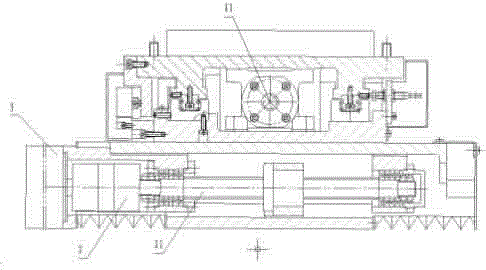

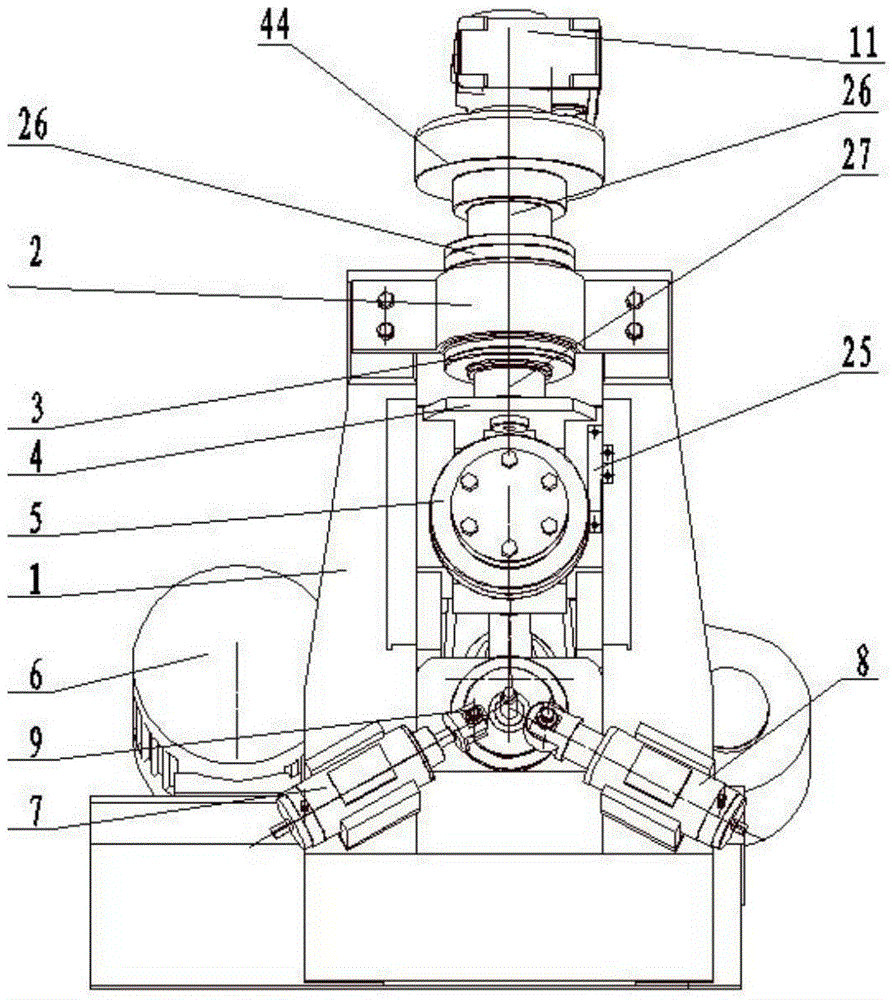

Five-axis linkage numerical control polishing machine

InactiveCN102225528ARealize numerical controlRealize intelligencePolishing machinesGrinding drivesNumerical controlMotor drive

The invention discloses a five-axis linkage numerical control polishing machine which comprises a machine base and a main shaft and is characterized in that one surface of the main shaft is provided with a polishing head; the other side of the main shaft is provided with a Z-axis feeding platform; an X-axis feeding platform is arranged near the main shaft; the X-axis feeding platform and the Z-axis feeding platform are vertical to each other; the machine base comprises a Y-axis feeding platform, a vertically rotary motor and a working table surface; the Y-axis feeding platform is arranged in the middle of the machine base; the vertically rotary motor is arranged at one side of the machine base; the other side of the machine base is provided with the working table surface; the Y-axis feeding platform is provided with a movable table surface; a horizontally rotary motor is arranged at the lower part of the movable table surface; therefore, the machine has the advantages of high location precision and constant polishing effect; the motor drive can achieve the high rotation speed (10000 rpm to 20000 rpm); the machine can be freely switched between the dry polishing and the wet polishing; and the machine can be used for improving the flexibility of working hours, making up for the deficiency of the prior art, improving the production efficiency and realizing complete numerical control and intelligence.

Owner:赵明杰

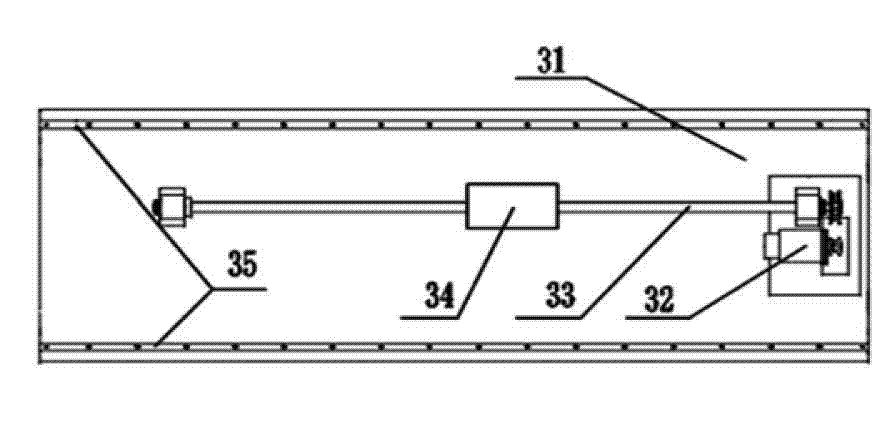

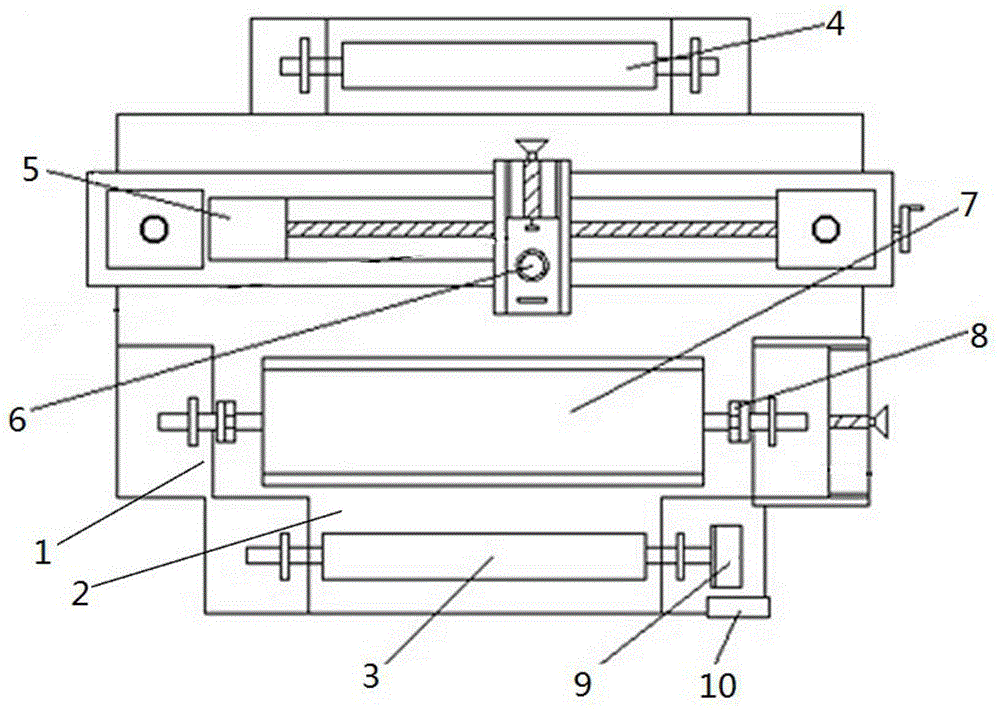

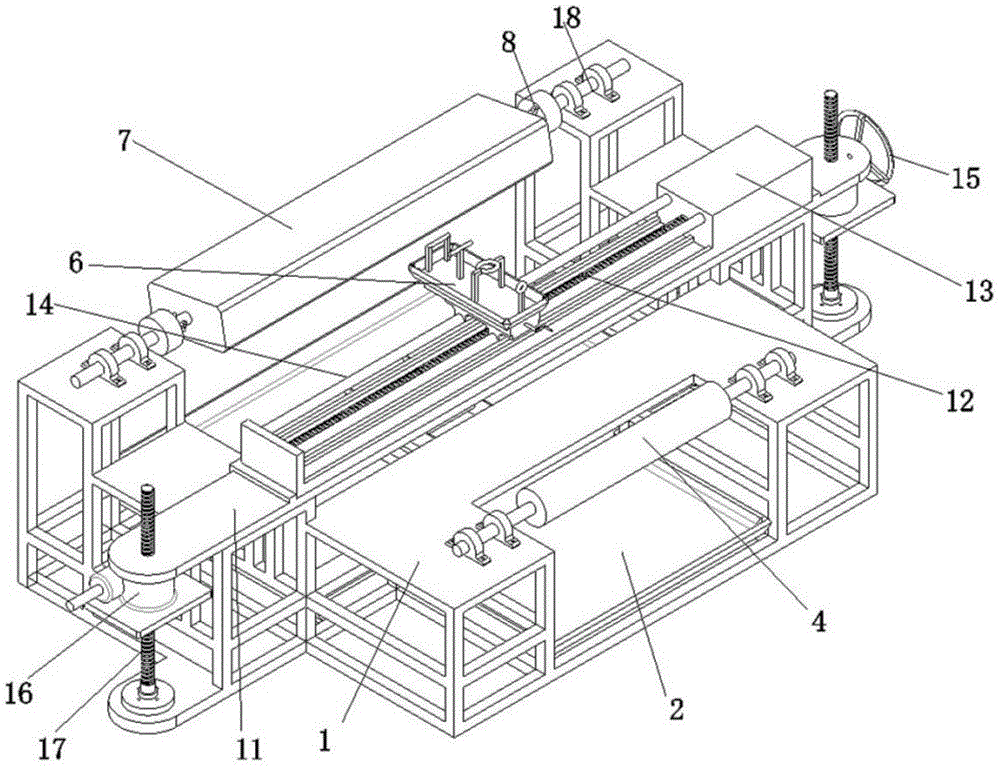

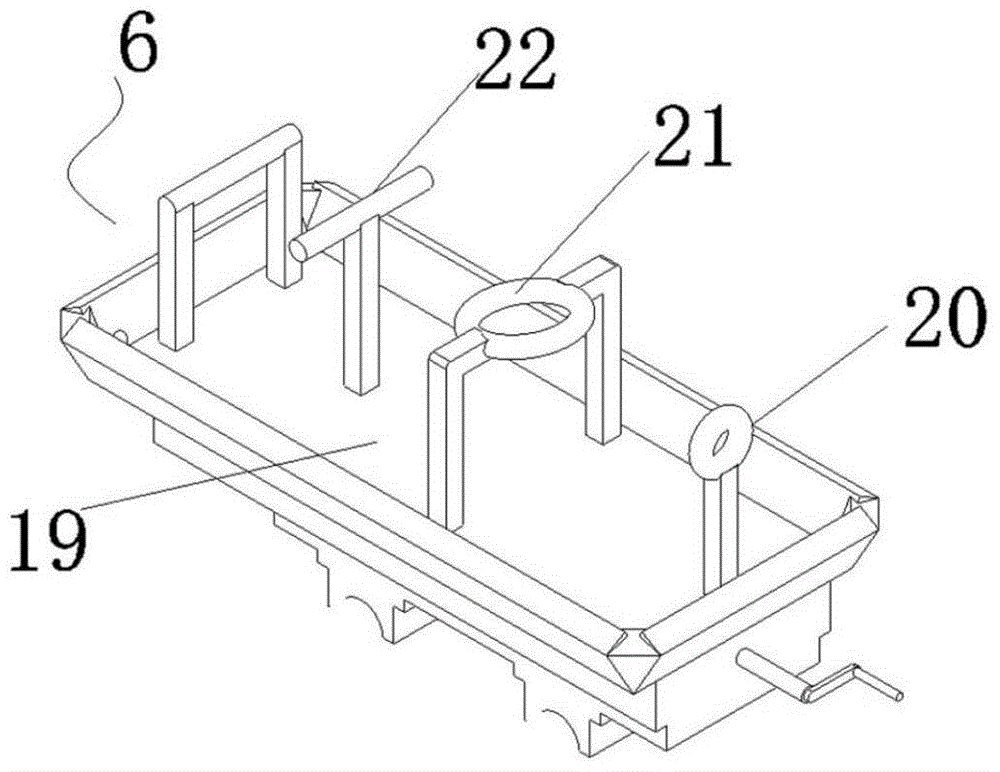

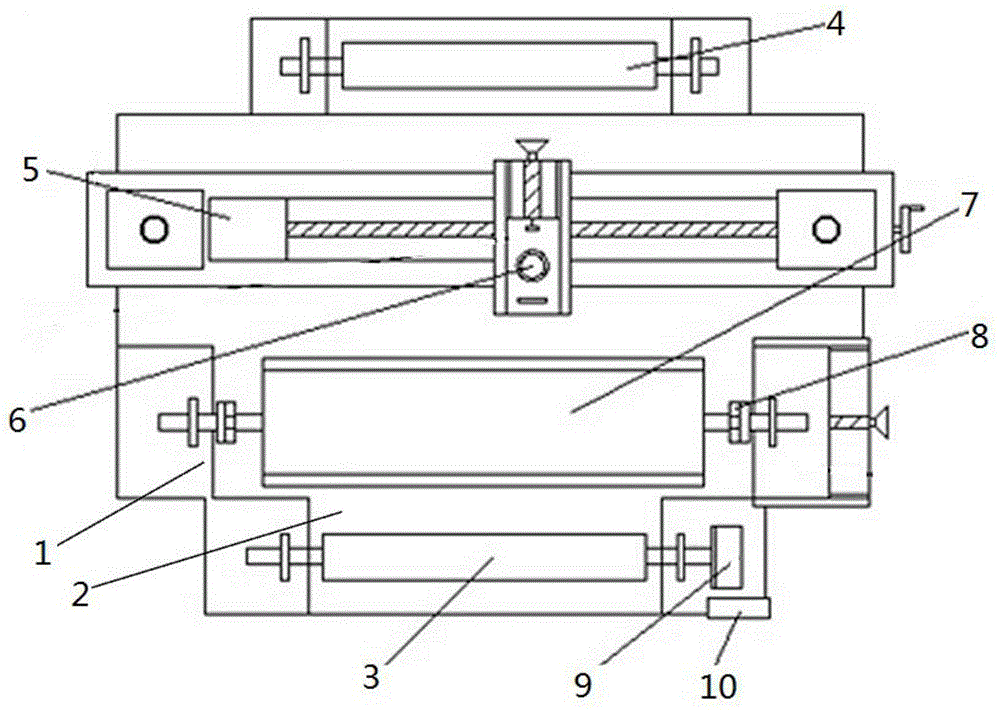

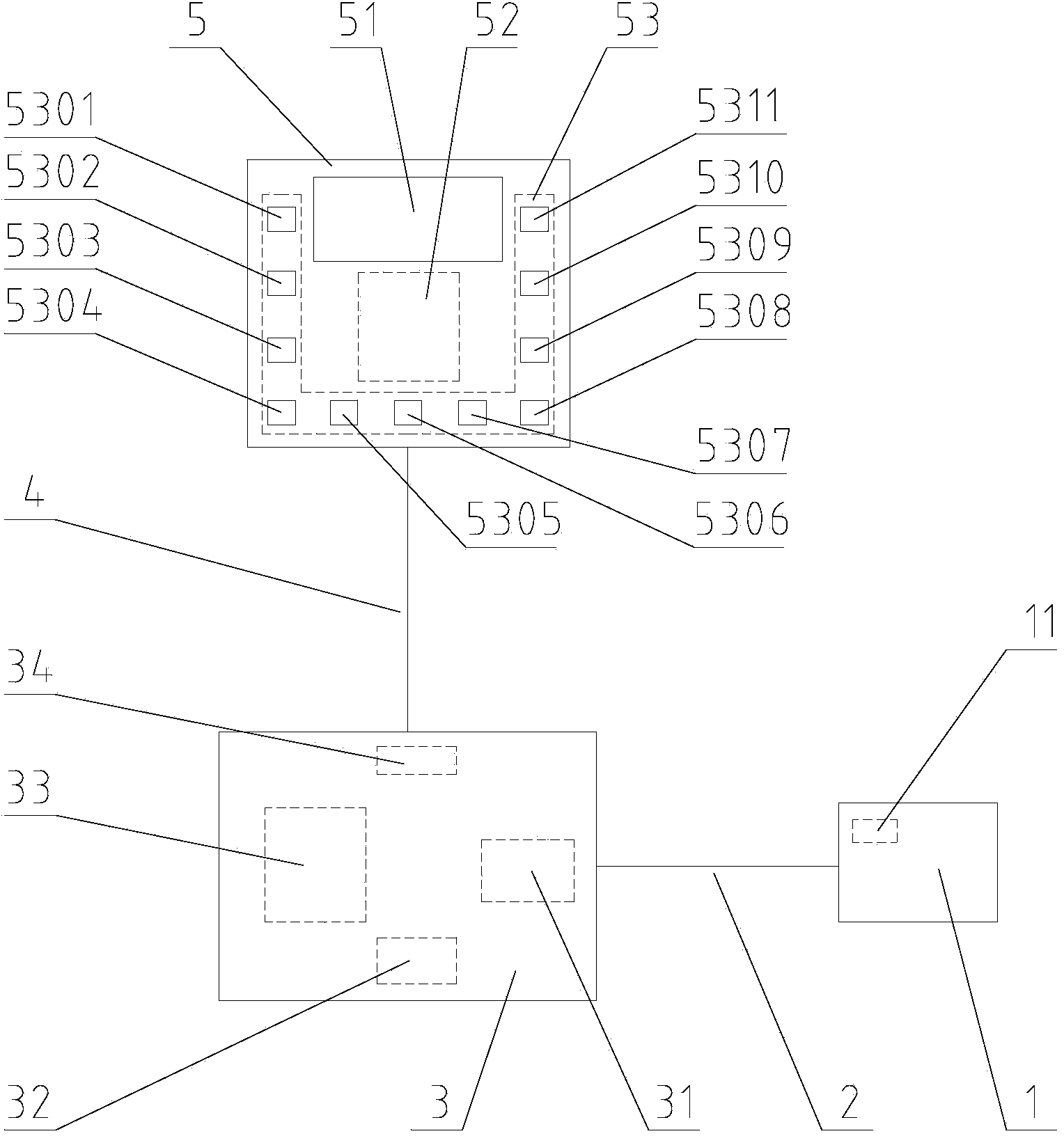

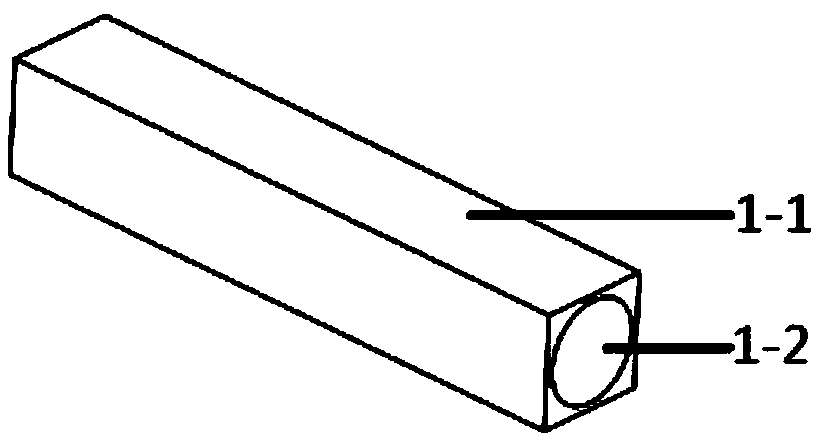

Numerical control winding apparatus and method for square glass fiber reinforced plastic air pipe

The invention discloses a numerical control winding apparatus for a square glass fiber reinforced plastic air pipe. The numerical control winding apparatus comprises a rack, a pay-off roller, a guide device, a yarn arranging device, a square mandrel winding device and a numerical control system. The pay-off roller, the guide device, the yarn arranging device, the square mandrel winding device and the numerical control system are arranged on the rack and sequentially connected through glass fiber yarn. The yarn arranging device comprises a base arranged on the rack. A servo motor, a lead screw and a guide rail which are connected with the servo motor, and a yarn nozzle installed on the guide rail and connected with the lead screw. The numerical control system is connected with the servo motor. The invention further discloses a numerical control winding method for the square glass fiber reinforced plastic air pipe. By the adoption of the numerical control winding apparatus for the square glass fiber reinforced plastic air pipe, the yarn arranging device and the square mandrel winding device are synchronously controlled through the numerical control system to move, the winding angle of the square glass fiber reinforced plastic air pipe is controlled, the glass fiber yarn is provided through the yarn arranging device, the tension of the fiber yarn can be adjusted at any time to control the quality of a product, numerical control is achieved, and the machining quality and efficiency of the square glass fiber reinforced plastic air pipe are improved.

Owner:CHONGQING UNIV

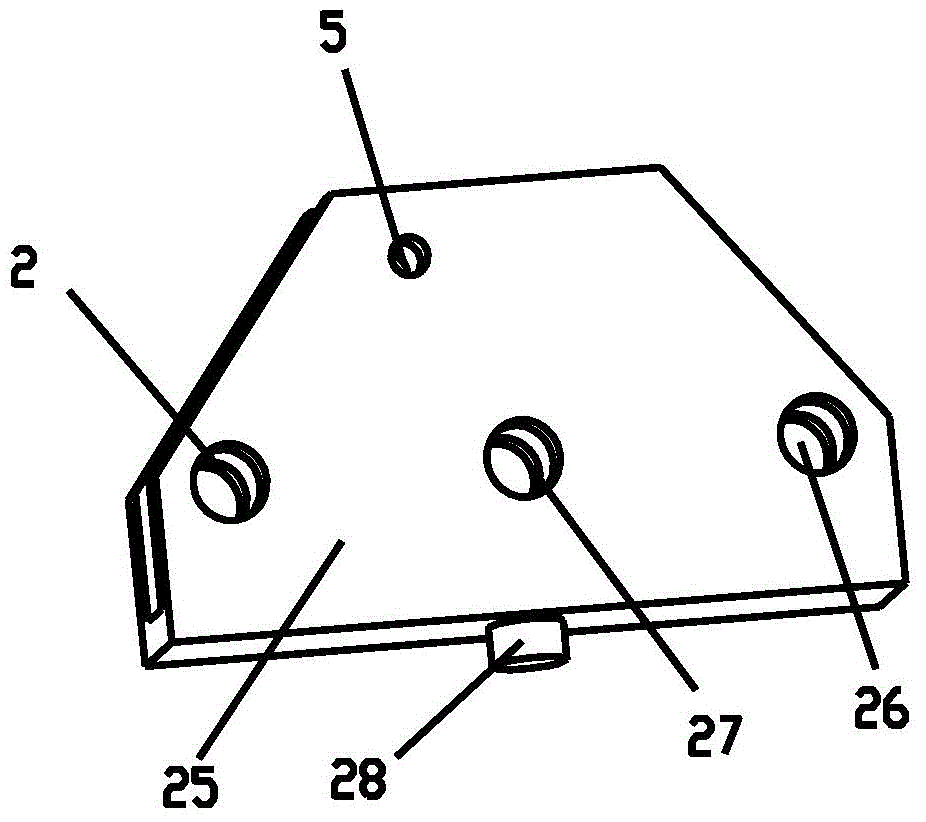

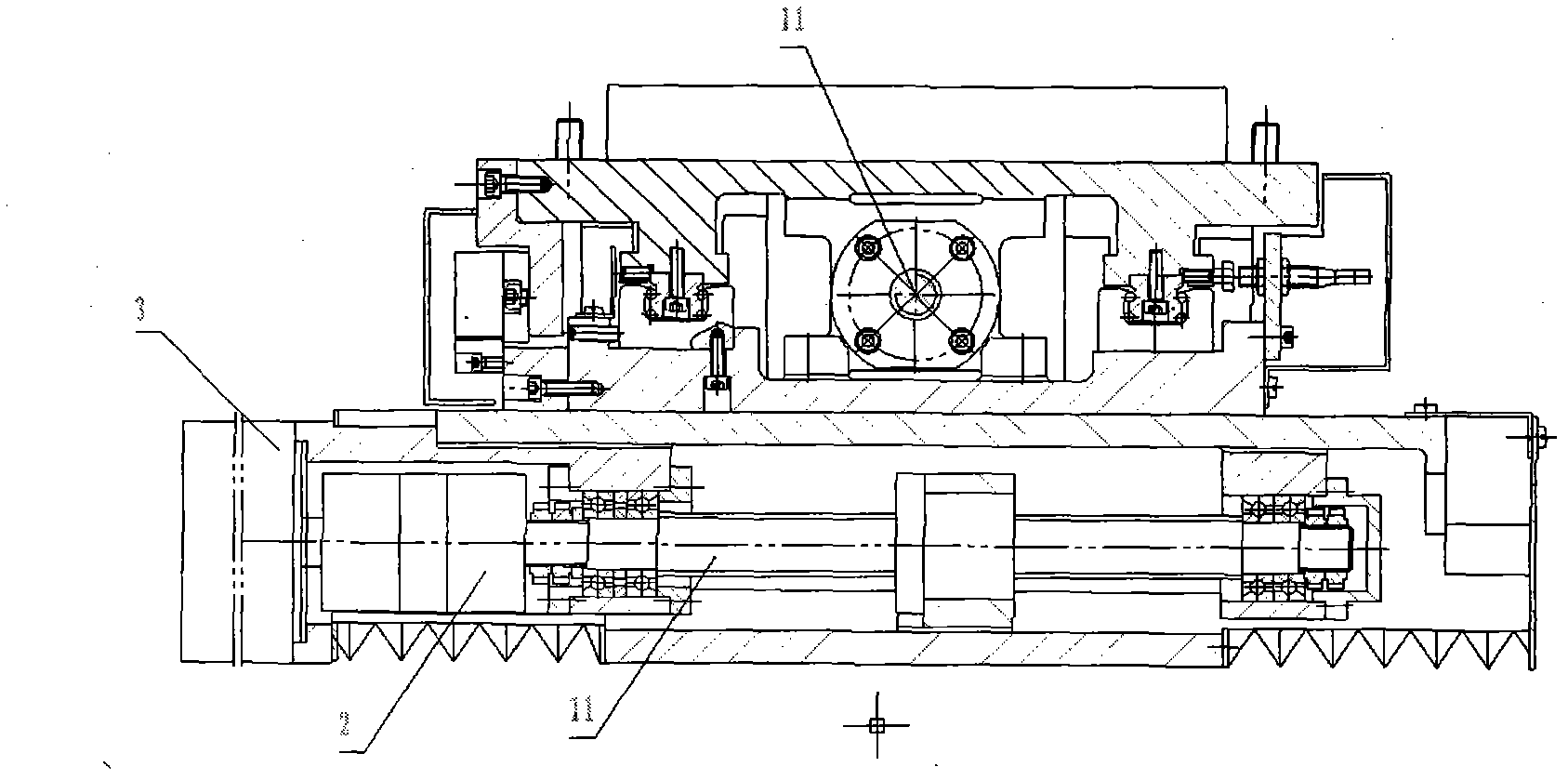

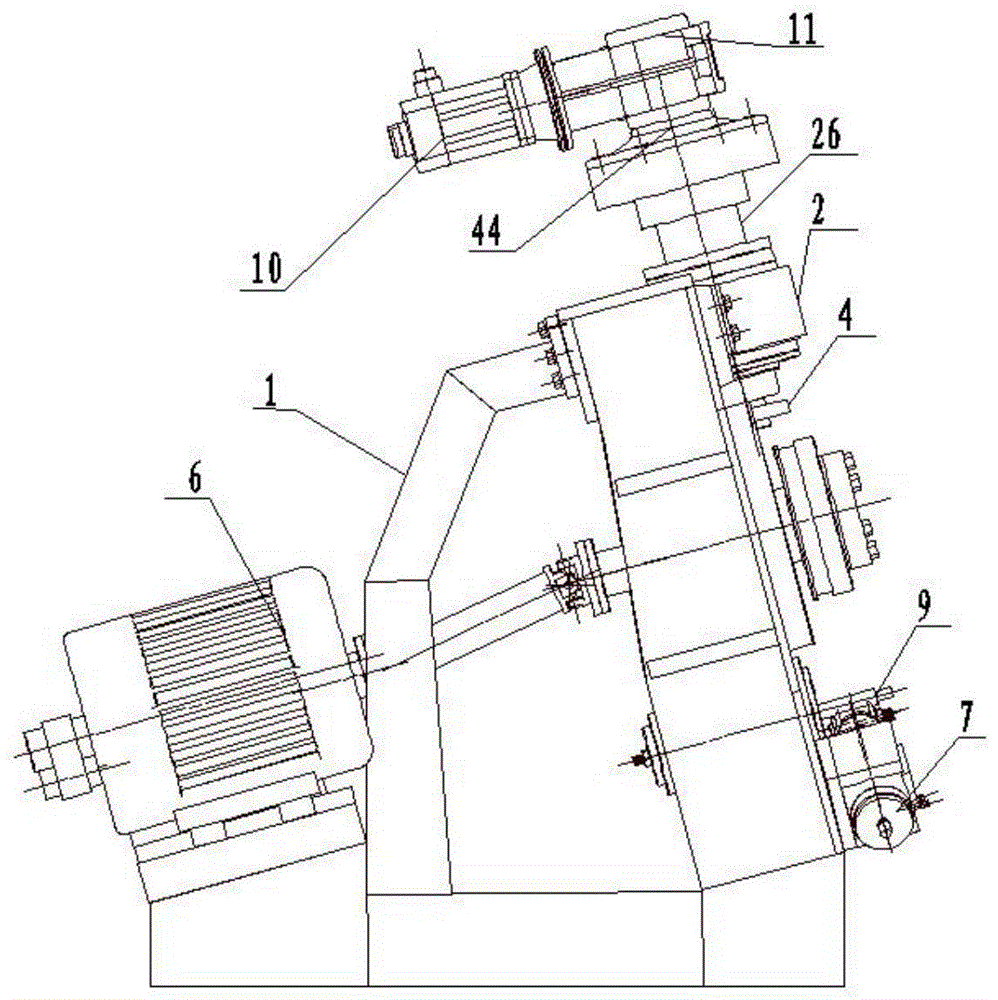

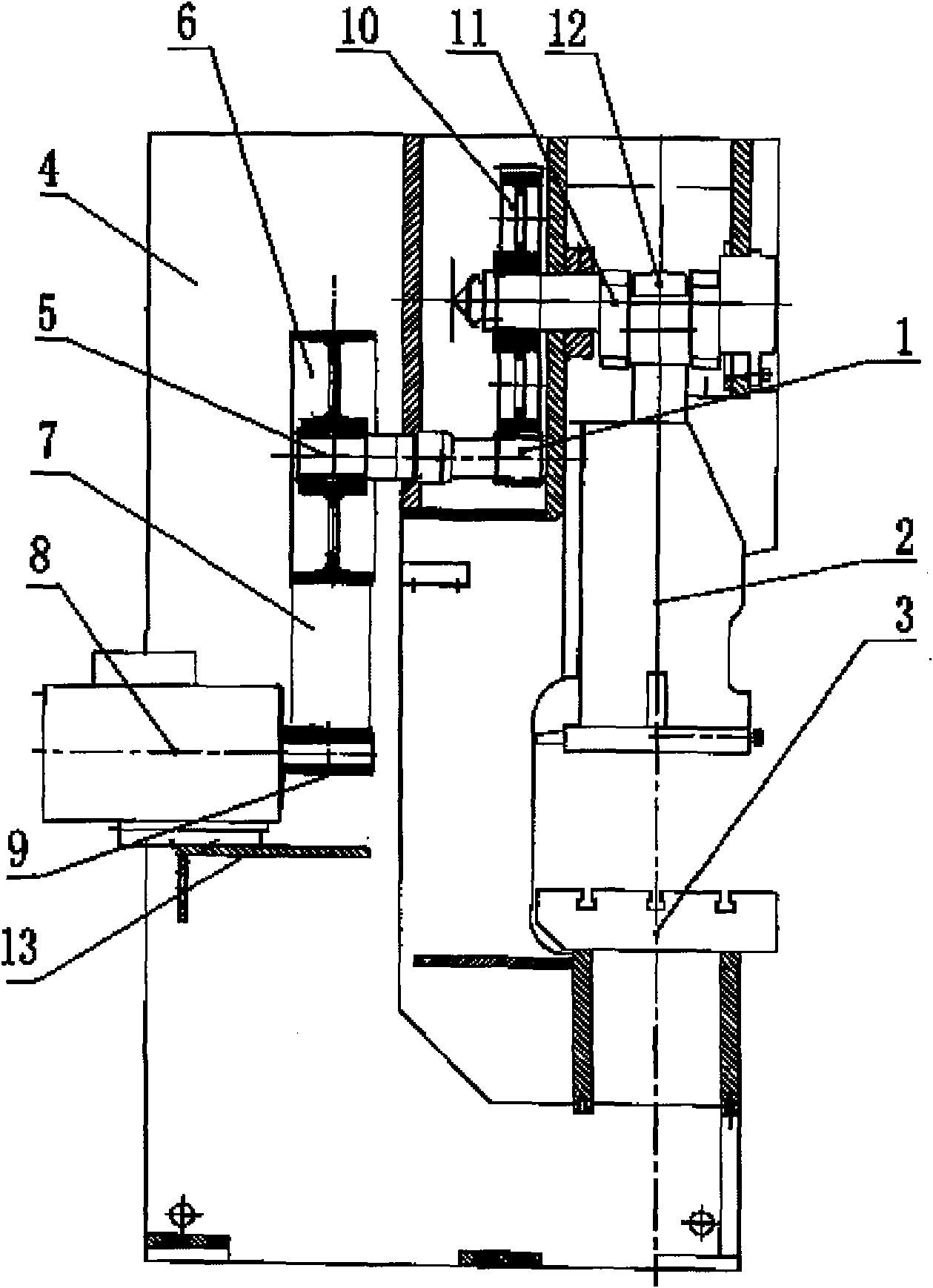

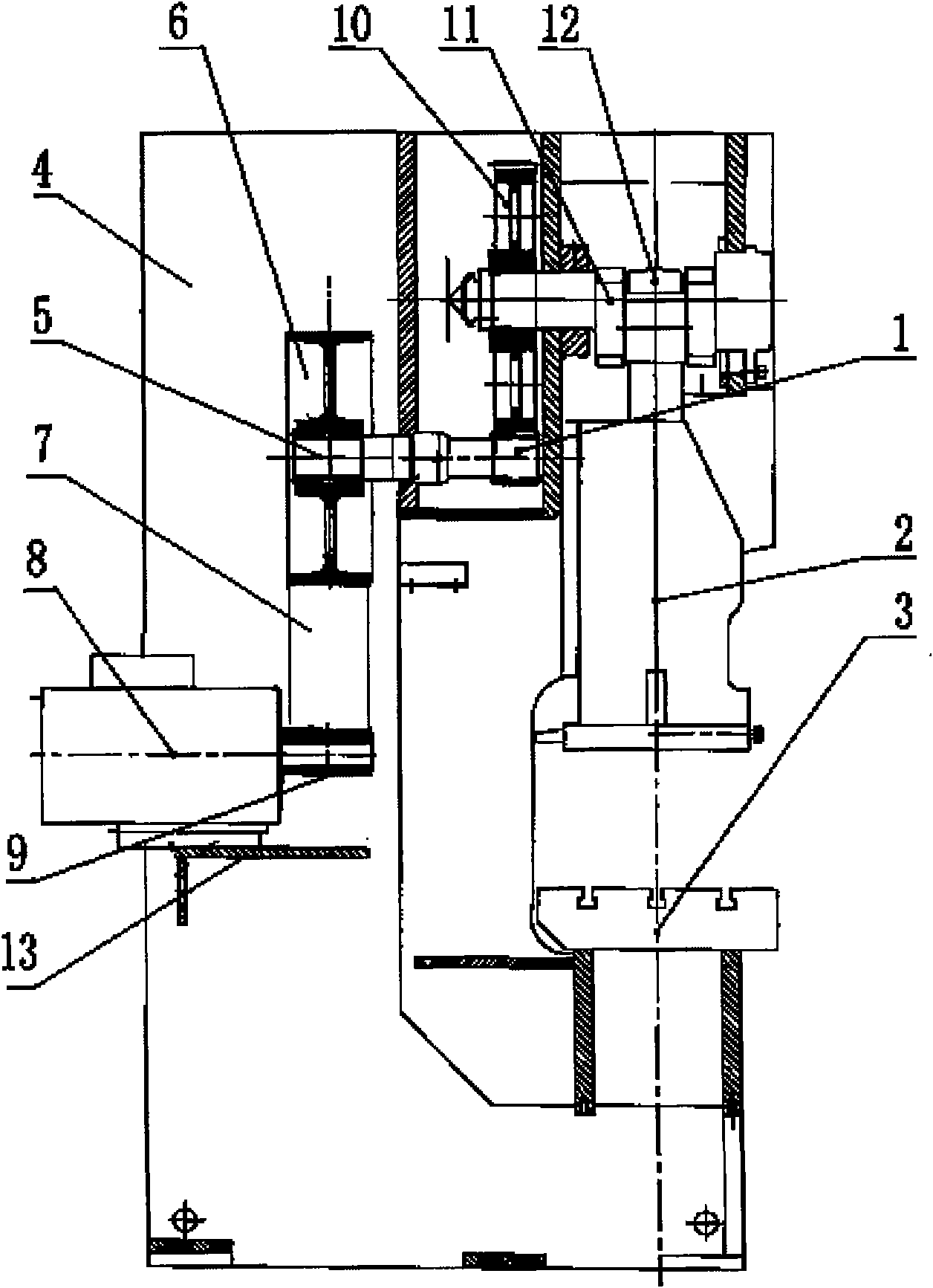

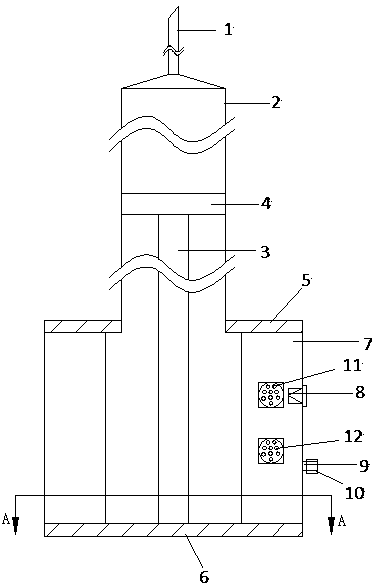

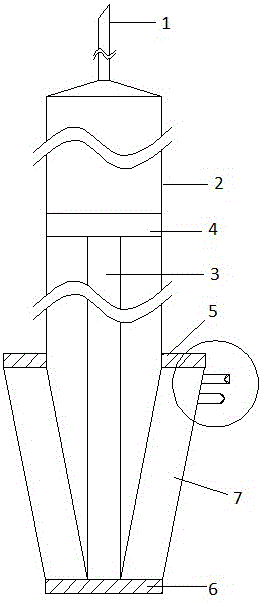

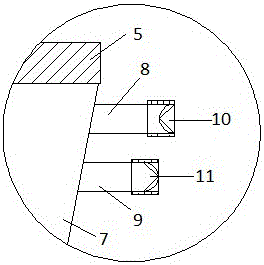

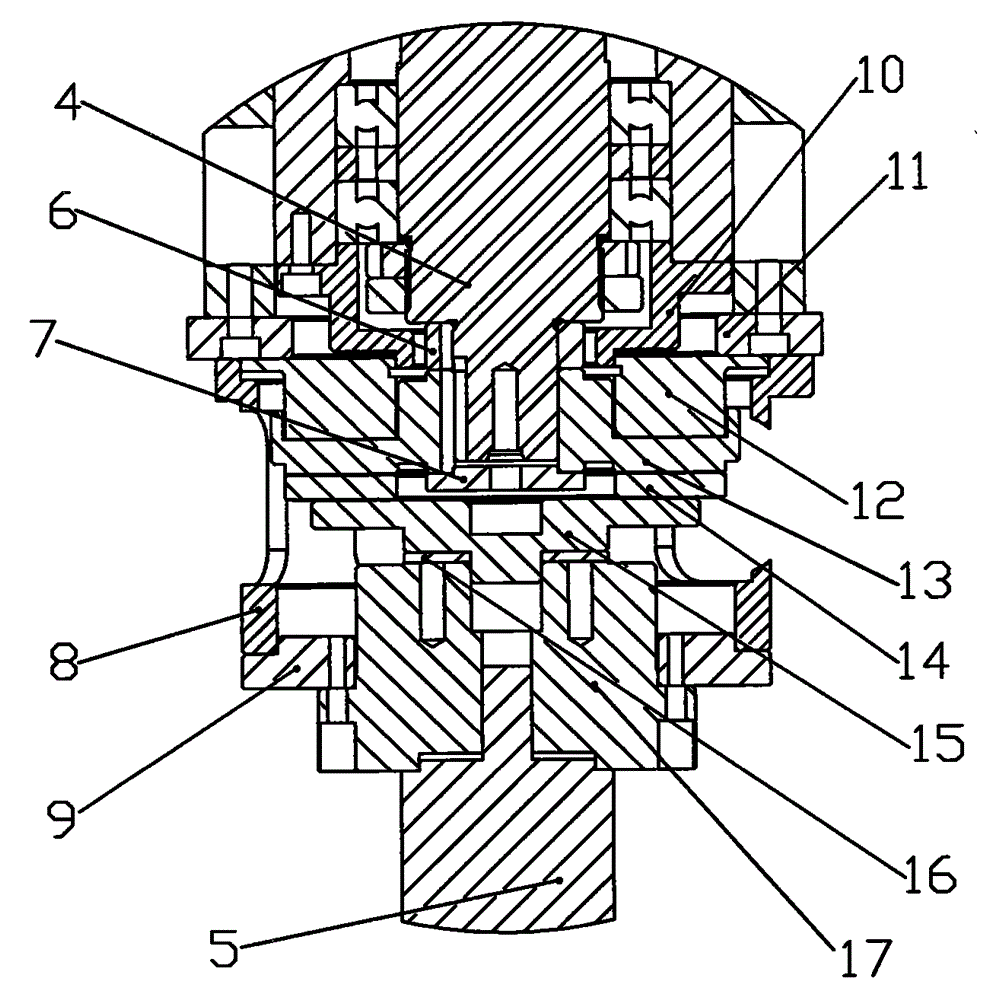

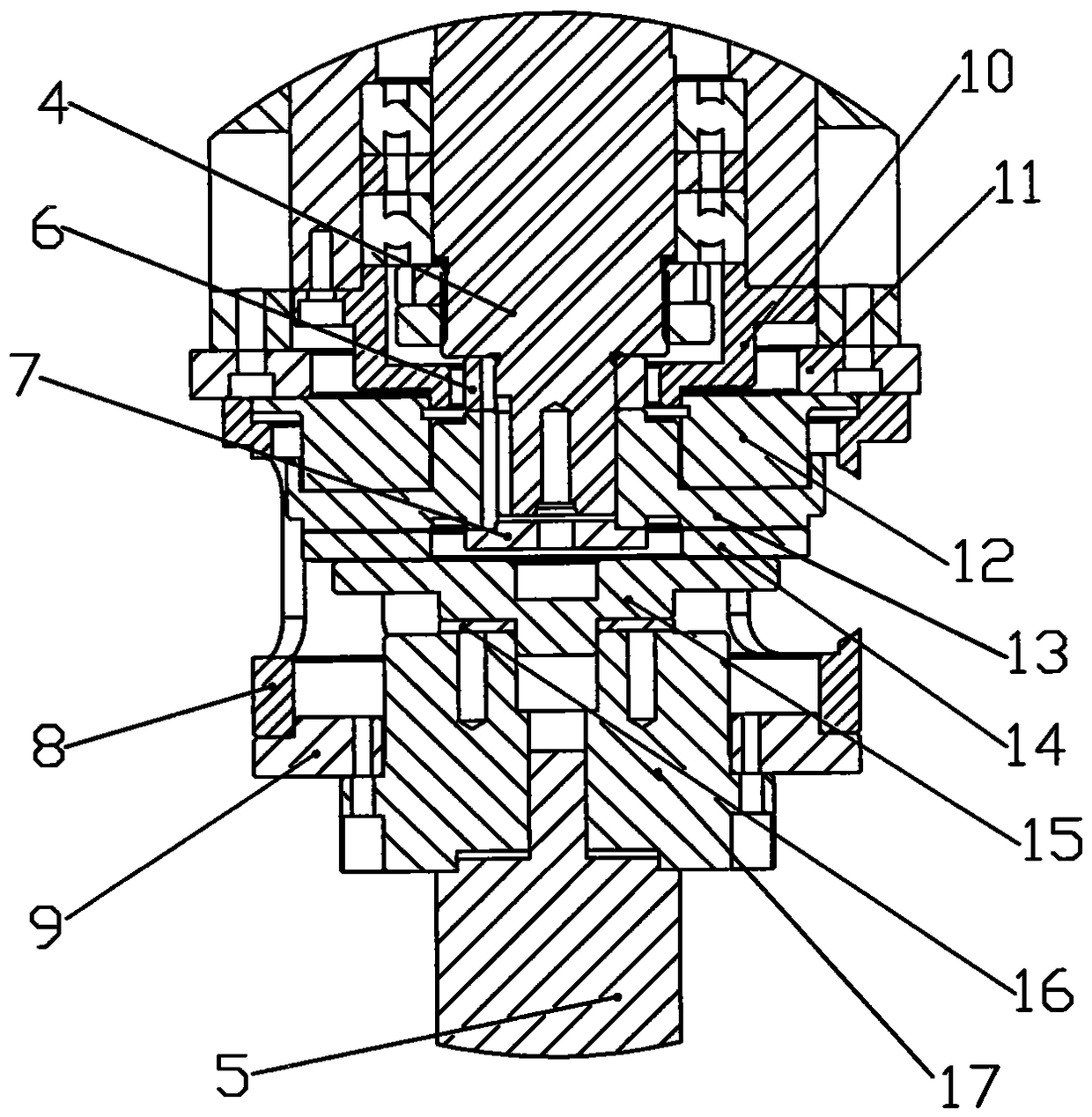

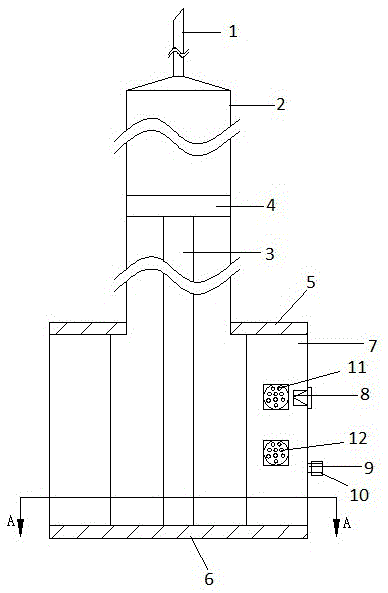

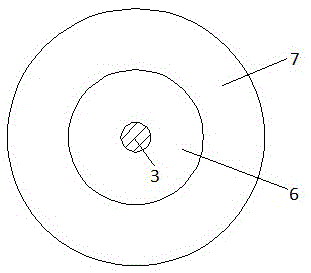

Novel numerical-control grinding wheel dressing device

InactiveCN102528665ATimely trimmingHigh cut-off accuracyAbrasive surface conditioning devicesNumerical controlCoupling

The invention discloses a novel numerical-control grinding wheel dressing device, which comprises a motor (1), two couplers (2), a servo motor I (3), a vertical guide track (4), an upper carriage (5), a horizontal guide track (6), two diamond wheels (7), a lower carriage (8), a servo motor II (9), a belt pulley mechanism (10) and two ball screw mechanisms (11). Two plane rectangular coordinate feeding mechanisms which are mutually perpendicular are formed, and numerical-control interpolation of the diamond wheels in the same plane is realized. Accordingly, automatic and numerical-control shape modification of grinding wheels in screw grinding machines is realized, precision of section shapes of dressed grinding wheels is high, efficiency is high, a shape modification process is simple and convenient in operation without limitation of experience.

Owner:陕西汉江机床有限公司

Numerical control vertical hot ring rolling mill and control method

InactiveCN104368734AHigh forming precisionReduce the amount of processingRoll mill control devicesMeasuring devicesNumerical controlBall screw

The invention provides a numerical control vertical hot ring rolling mill and a control method. The numerical control vertical hot ring rolling mill comprises a rack, a roller mechanism, a measuring roll mechanism, a guide roll mechanism, a core roll mechanism, a feed mechanism and a control device. A ball screw is driven by a servo motor to drive a rolling wheel to move. The measuring roll mechanism is a follow-up measuring roll mechanism provided with a displacement sensor. The position can be adjusted through a lead screw to adapt to measuring of ring pieces of different dimensions and specifications in the rolling process. Parameters are input into a PLC, and numerical control of the vertical hot ring rolling process is achieved. By means of the numerical control vertical hot ring rolling mill and the control method, manpower can be saved, materials can be saved, the part forming accuracy can be improved, and the subsequent machine machining amount and the rejection rate can be reduced.

Owner:WUHAN UNIV OF TECH

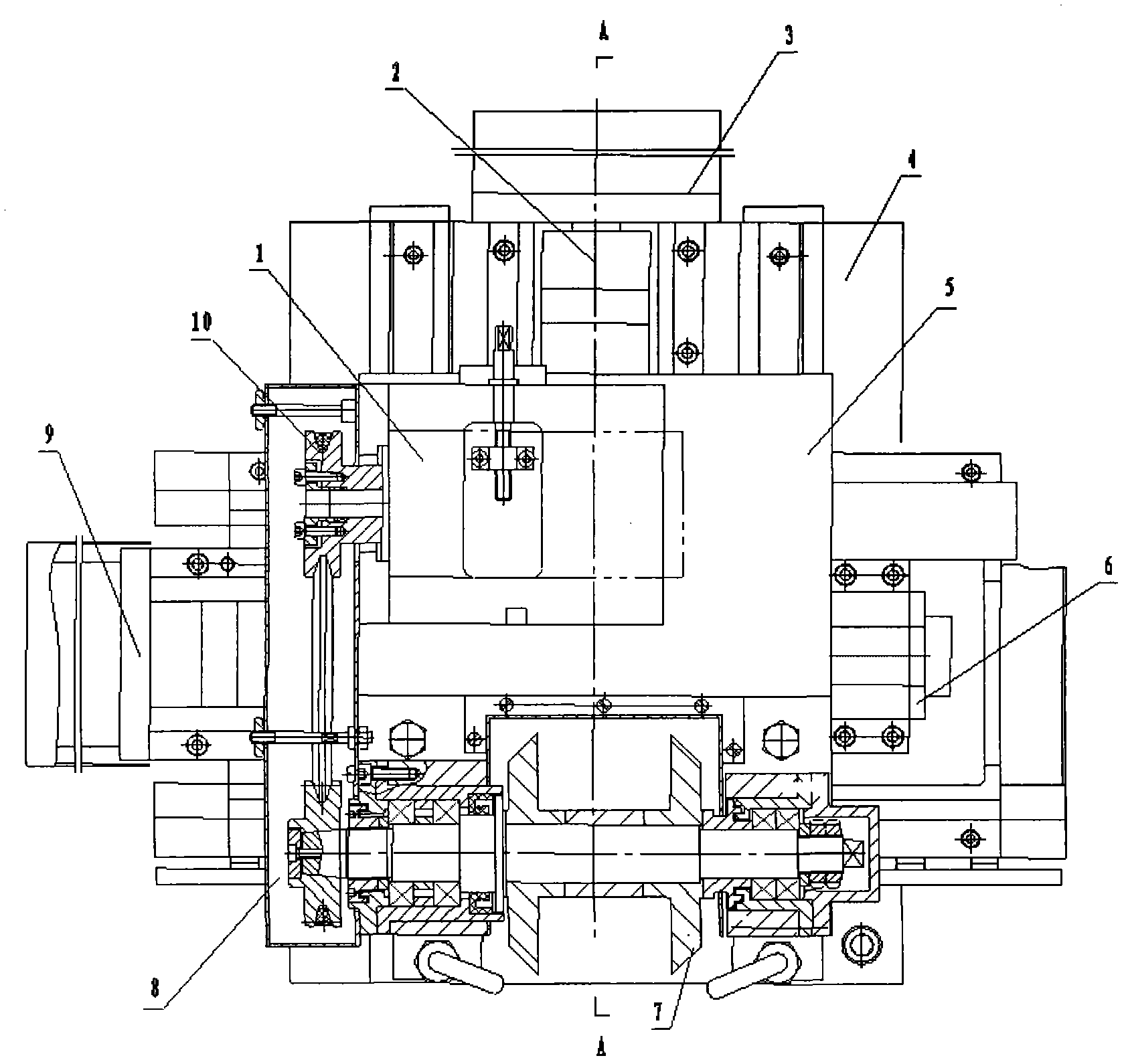

Machining tool and process for addendum chamfer in outer cone of curved-cog bevel gear

The machining tool for addendum chamfer in outer cone of curved-cog bevel gear includes machine bed, work bench, transverse slide carriage, grinding disc, saddle part, etc. The transverse slide carriage can move on the horizontal guide track of the portal frame in Y direction, and has one ram capable of moving in Z direction. The grinding discs on the ram has one or two grinding heads on it and grinding disc sliding plate set between the grinding head and the grinding disc for regulating the distance between the central axis of the grinding wheel and the central axis of the grinding disc. There are also spring, limiting screw, and grinding wheel contact with the workpiece. The work bench with saddle part and on the guide track moves in the X direction. The method of machining addendum chamfer in outer cone of curved-cog gear in the said machining tool is also disclosed.

Owner:TIANJIN UNIV

Automatic servo driving press machine

InactiveCN101837647APrecisely control where you areAchieve speed controlPress ramDrive wheelGear wheel

The invention relates to an automatic servo driving press machine, which comprises that: a sliding block is arranged above a worktable of the press machine, is connected with a connecting rod and can slide vertically; the other end of the connecting rod is hinged to a crankshaft; the crankshaft is connected with a driven gear supported on a frame; the driven gear is externally meshed with a driving gear; the center of the driving gear is fixed with a gear shaft; a shaft end of the gear shaft is provided with a driven wheel; a rear opening gear of the frame is provided with a motor base; a servo motor is arranged on the motor base; a shaft end of the servo motor is provided with a driving wheel; and the driving wheel and the driven wheel are connected by a synchronous belt. In working time, the servo motor rotates, a torque is transmitted to the gear shaft through the transmission of the driving wheel, the synchronous belt and the driven wheel, the gear shaft further drives the driving gear, the driven gear and the crankshaft to rotate, and the crankshaft drives the sliding block to move up and down when rotating. Relative sliding does not exist among the driving wheel, the synchronous belt and the driven wheel, so the position of the sliding block and an angle over which a rotor of the servo motor rotates correspond to each other.

Owner:杨茂召

Syringe capable of pumping automatically

InactiveCN104337523ANo resistanceRealize numerical controlInfusion syringesPharmaceutical containersAutomatic controlSyringe needle

The invention discloses a syringe capable of pumping automatically. The syringe comprises a syringe needle, a cylinder, a piston rod and a round piston rod pressing handle, wherein the piston rod pressing handle and a blocking edge serve as concentric circles with the identical diameter; an air bag is arranged between the piston rod pressing handle and the blocking edge; the two ends of the air bag are respectively fixed with the piston rod pressing handle and the blocking edge; the air bag encircles the piston rod; a reverse valve and an aeration nozzle are arranged on the surface of the air bag; a sealing cover is arranged on the aeration nozzle; the reverse valve allows gas to flow from outside to inflate the gas bag. According to the syringe disclosed by the invention, the gas bag is inflated to push the piston rod to move, so as to allow the syringe needle to pump liquid, realize automatic control, and control the pumping speed through the inflation speed.

Owner:吴燕霞 +5

High-frequency induction heating chemical dressing device for brazed diamond abrasive router

ActiveCN107900924AReduce oxidation lossExtend the life cycleIncreasing energy efficiencyGrinding devicesNumerical controlMaterials science

The invention provides a high-frequency induction heating chemical dressing device for a brazed diamond abrasive router. According to the high-frequency induction heating chemical dressing device, real-time high-temperature graphitization chemical dressing of the brazed diamond abrasive router on a machine can be realized, the air in a dressing area can be effectively isolated under pure nitrogenprotection or the isolation atmosphere, the oxidation loss of an ultrahigh-strength steel high-temperature dressing base body in a high-temperature environment is greatly reduced, and the use period and the use stability of the ultrahigh-strength steel high-temperature dressing base body are improved; a nitrogen protection connector or an isolation atmosphere connector and a high-frequency induction heating coil are all connected with a control valve of a numerical control machine tool, and therefore all PLC data can be read by a PLC while the pressure, the flow as well as the start and stop can be controlled, the numerical control machining program and the start-stop control of the dressing device can be built in, and the numerical control is completely realized; and a built-in type thermocouple is used for measuring heat deformation before the use of the ultrahigh-strength steel high-temperature dressing base body and the use process of the ultrahigh-strength steel high-temperature dressing base body and for controlling the environment temperature in the dressing process.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Polyester resin impregnating agent

InactiveCN101654336AStrong solubilityThe accuracy of feeding and temperature control is improvedChemistrySolubility

The invention relates to a polyester resin impregnating agent which is widely suitable for glass fiber enterprises. The polyester resin impregnating agent is prepared by the following raw materials inparts by weight: 100-200 of dicyclopentanediol, 90-180 of neopentyl glycol, 90-200 of trimethylolpropane, 120-200 of dihydromethyl propionic acid and 70-160 of tetrafluorophthalic anhydride. The invention has high hardness, toughness, tensile strength, bending strength and dissolubility in styrene, trends to refinement in the synthesizing process, improves the feed and temperature control precision and realizes numerical control; the synthesizing process is carried out by from a one-step method to a multistep method so as to enable a molecule chain structure of a polyester film forming agentto be more reasonable and regular, and the molecular weight is as high as more than ten thousand; and the polyester resin impregnating agent is widely applied to the impregnating agent of chopped strand mat, jet, BMC and SMC yarns.

Owner:朱继业

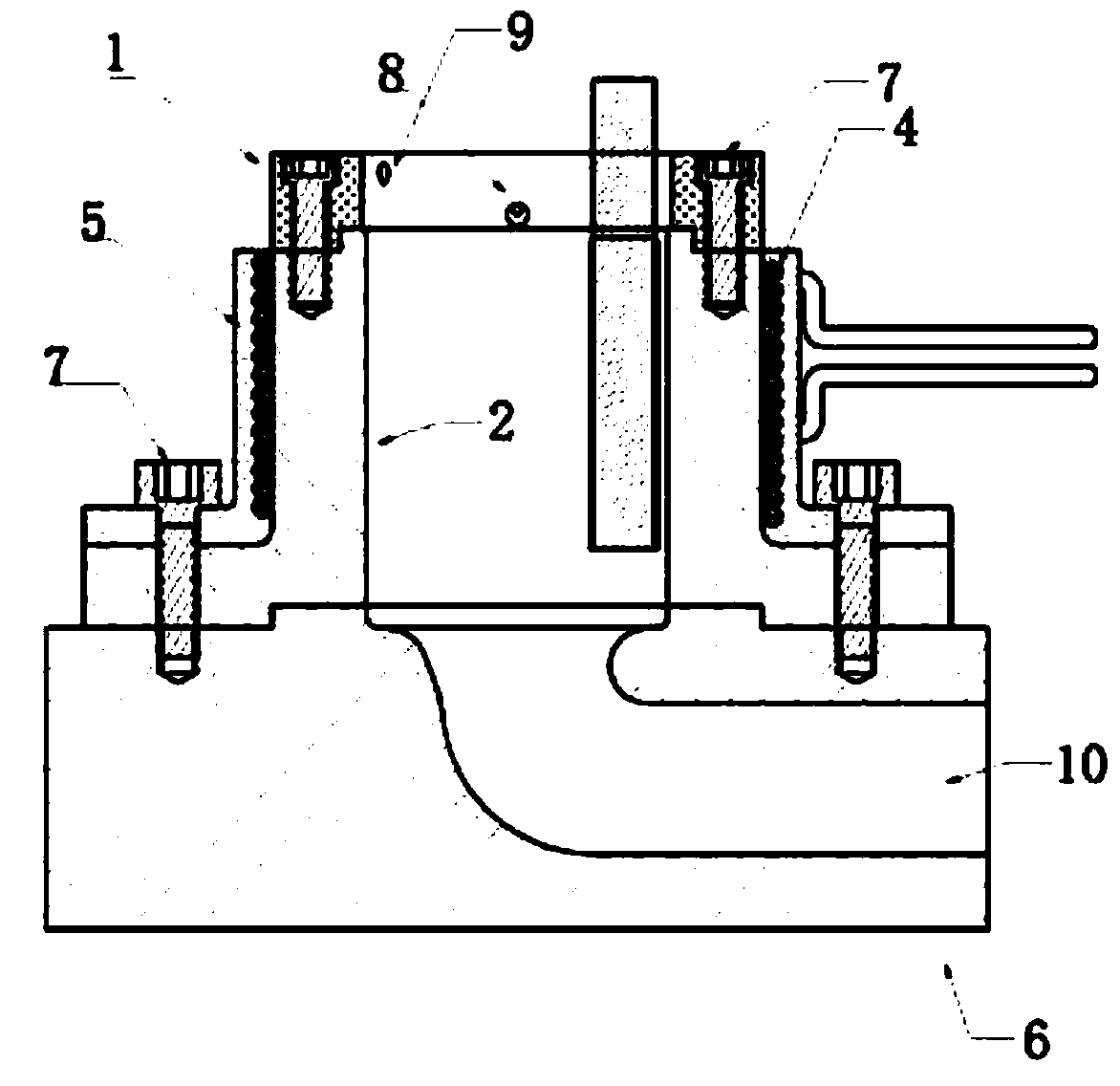

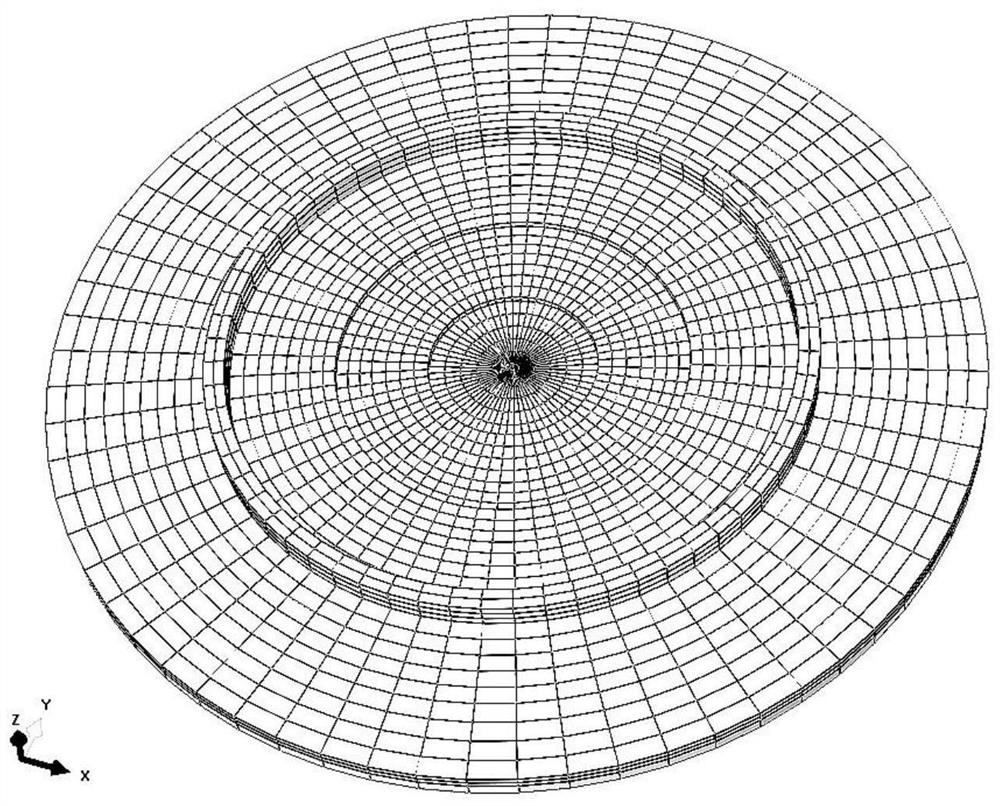

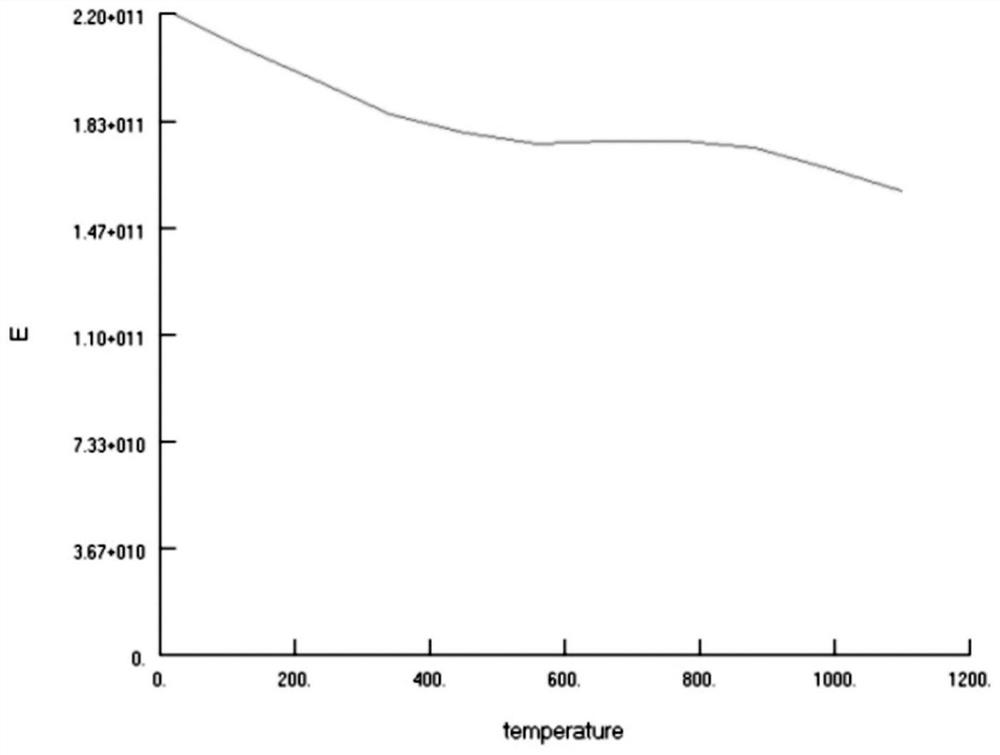

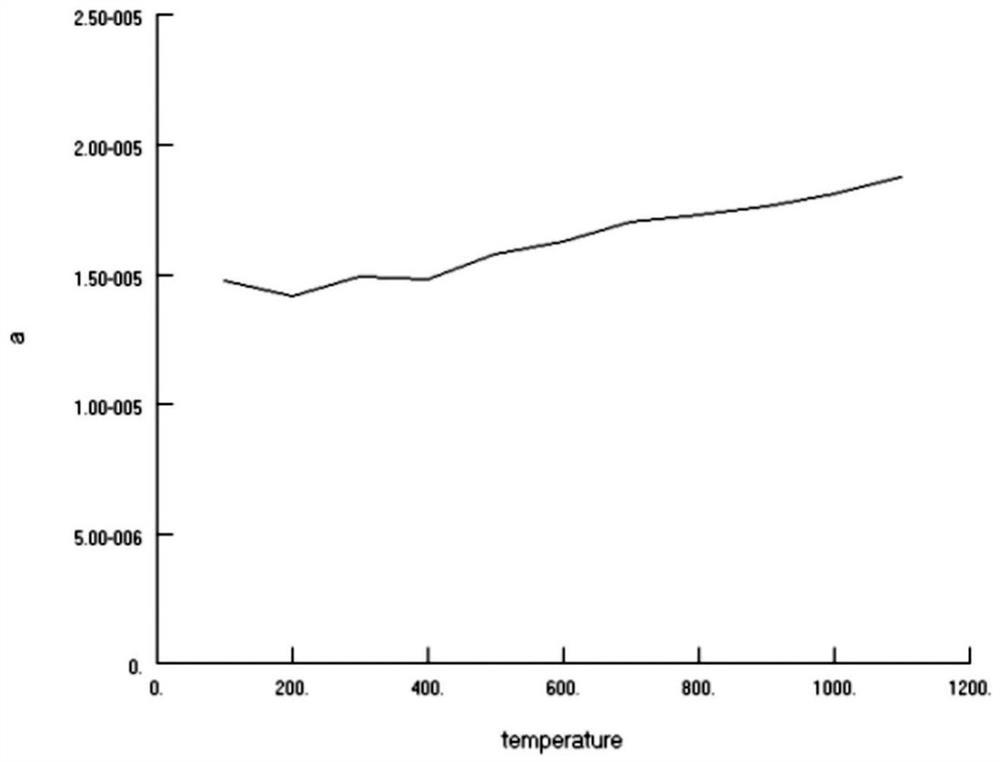

Dissimilar material brazing gap control method and system

ActiveCN113510327AImprove boundary conditionsGood capillary actionWelding/soldering/cutting articlesMetal working apparatusNumerical controlStructure analysis

The invention provides a dissimilar material brazing gap control method and system. The dissimilar material brazing gap control method comprises the steps of: presetting assembly gap values according to the actual structures of all workpieces to be assembled; determining performance parameters of all the workpieces; according to the brazing structures of all the workpieces and the brazing filler metal joint filling requirements, determining the positions of brazing seams and the boundary conditions of thermal structure analysis; according to the boundary conditions of thermal structure analysis and the performance parameters of all the workpieces, analyzing thermal displacement changes of all the workpieces, and working out brazing gap values among all the workpieces; performing comparison and re-calculation according to the brazing gap values among all the workpieces and a preset brazing gap range of a brazing material to obtain an optimal assembly gap range among the workpieces; and performing a process test according to the optimal assembly gap range to determine the actual assembly gap among the workpieces. According to the method, the initial assembly gap of the workpieces and the brazing gap are linked through simulation analysis, so that numerical control over the brazing gap of the dissimilar materials is achieved, and the brazing quality of products is guaranteed.

Owner:SHANGHAI INST OF SPACE PROPULSION

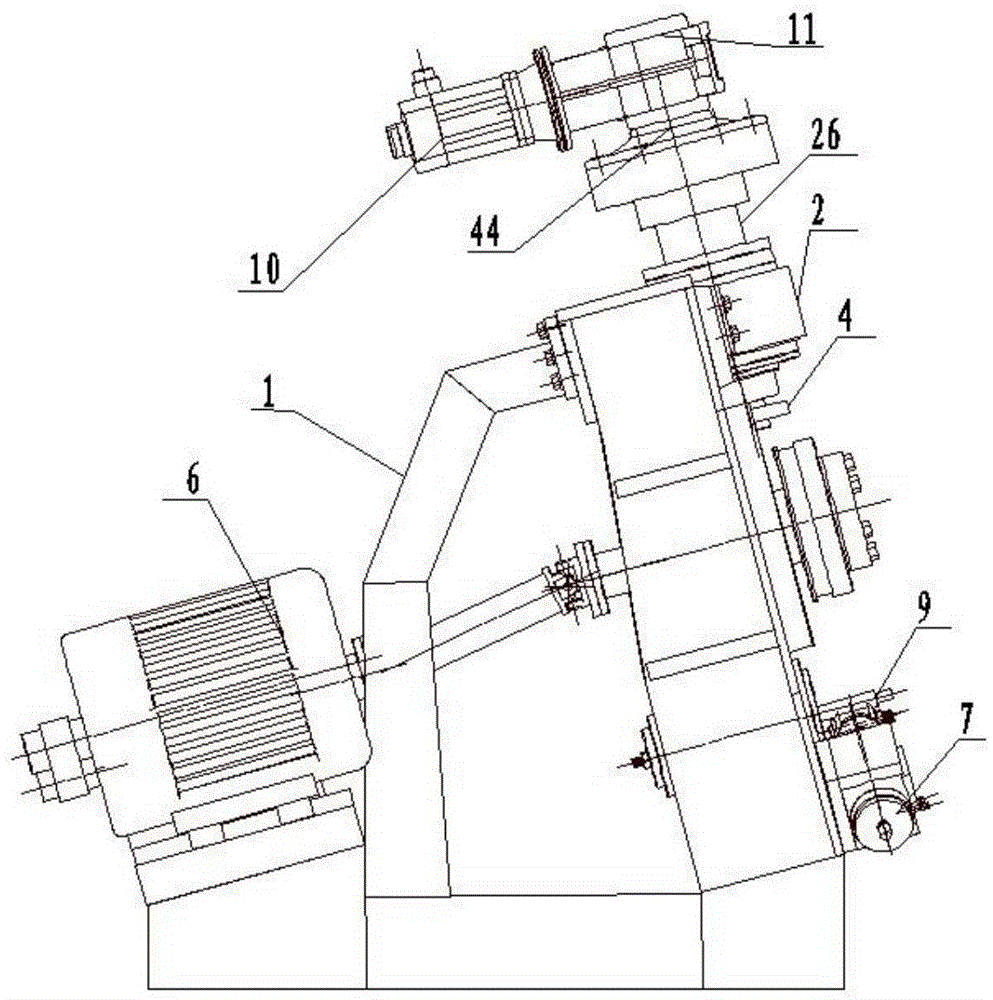

Novel numerical control grinding wheel dressing device

InactiveCN104416465ATimely trimmingHigh cut-off accuracyAbrasive surface conditioning devicesNumerical controlEngineering

The invention discloses a novel numerical control grinding wheel dressing device for a screw grinding machine. The novel numerical control grinding wheel dressing device comprises a motor (1), two couplers (2), a servo motor I (3), a vertical guide rail (4), an upper dragging plate (5), a horizontal guide rail (6), two diamond wheels (7), a lower dragging plate (8), a servo motor II (9), a belt wheel mechanism (10) and two ball screw mechanisms (11), so that a flat square two-coordinate feeding mechanism mutually vertical is formed, and numerical control interpolation of the diamond wheels in the same plane is realized. The automation and the numerical control of grinding wheel dressing in the screw grinding machine are realized, a dressed grinding wheel is high in sectional profile accuracy, high in efficiency, simple and convenient to operate during the dressing process, and not limited by experiences.

Owner:XI AN BANGHE ELECTRICAL EQUIP

A syringe with quantitative rapid suction

InactiveCN104382738BRealize numerical controlEasy to operatePharmaceutical containersMedical packagingAutomatic controlSyringe needle

The invention relates to an injector capable of realizing quantitative and fast suction. The injector comprises a needle cylinder provided with a needle head and a piston rod, wherein the end part of the piston rod is provided with a piston rod press handle, a retainer ring which is vertical to the needle cylinder and outwards extends is arranged around the needle cylinder, the retainer ring surrounds the needle cylinder for a circle, the piston rod press handle is in a round shape by using the piston rod as the circle center, an air bag is arranged between the piston rod press handle and the retainer ring, each of the two ends of the air bag is fixed with the one opposite side of the piston rod press handle and the retainer ring, the air bag surrounds the periphery of the piston rod, and is provided with an air inlet pipe and an air outlet pipe which extend to the outside, a positive-installation reverse valve is arranged in the air inlet pipe, an opposite-installation reverse valve is arranged in the air outlet pipe, the air inlet pipe only allows air to flow into the air bag, and the air outlet only allows the air to flow out of the air bag. The injector has the advantages that the air is inflated into the air bag, the effect of pushing the piston rod to move is achieved, further, the effect of sucking liquid by the needle head is achieved, the automatic control is realized, in addition, the suction speed is controlled through controlling the air inflating speed, the structure is light, ingenious and simple, and natural damage is avoided during storage.

Owner:冯伟明 +18

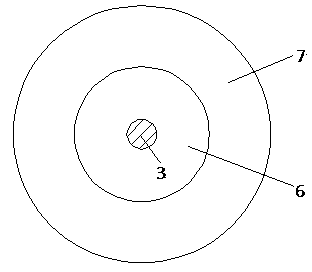

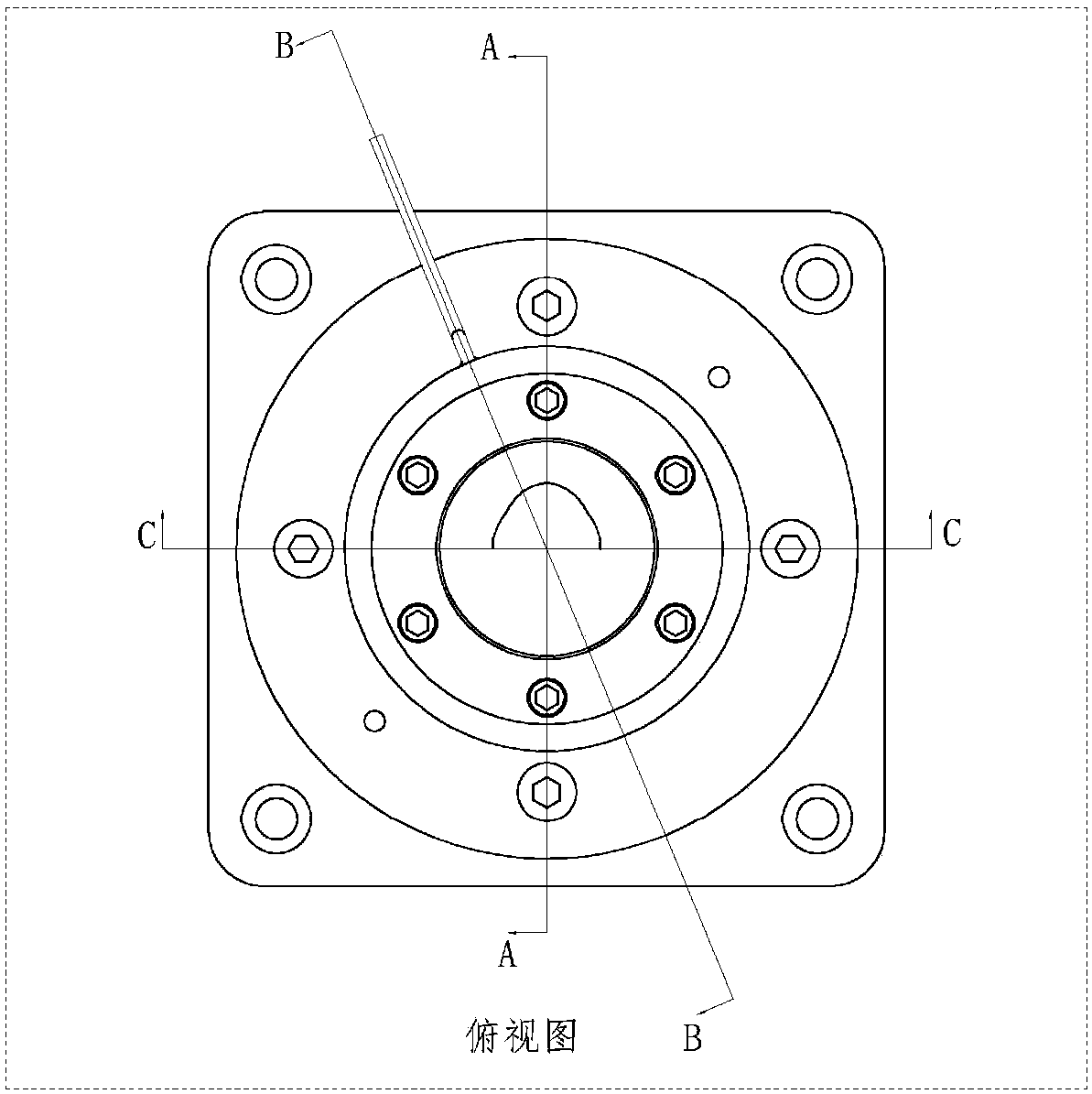

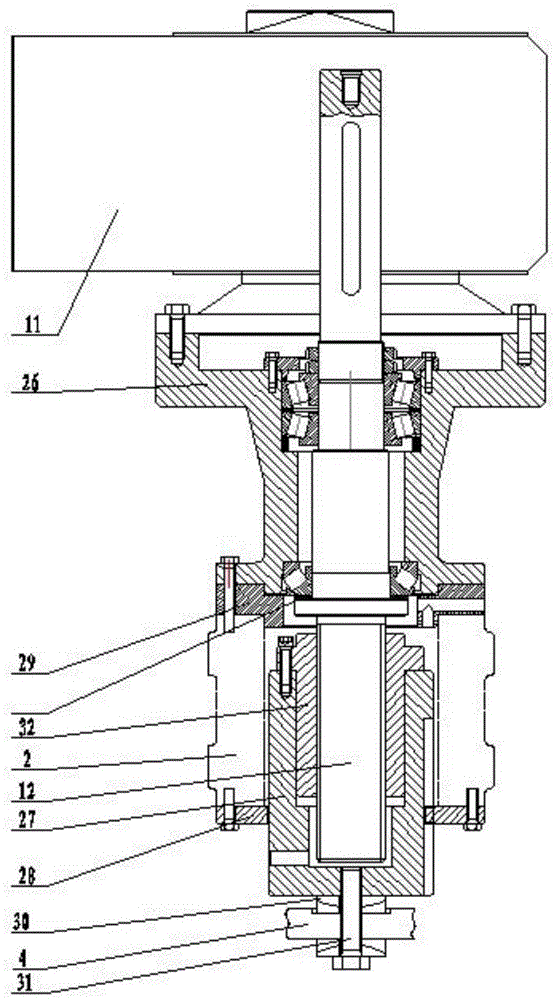

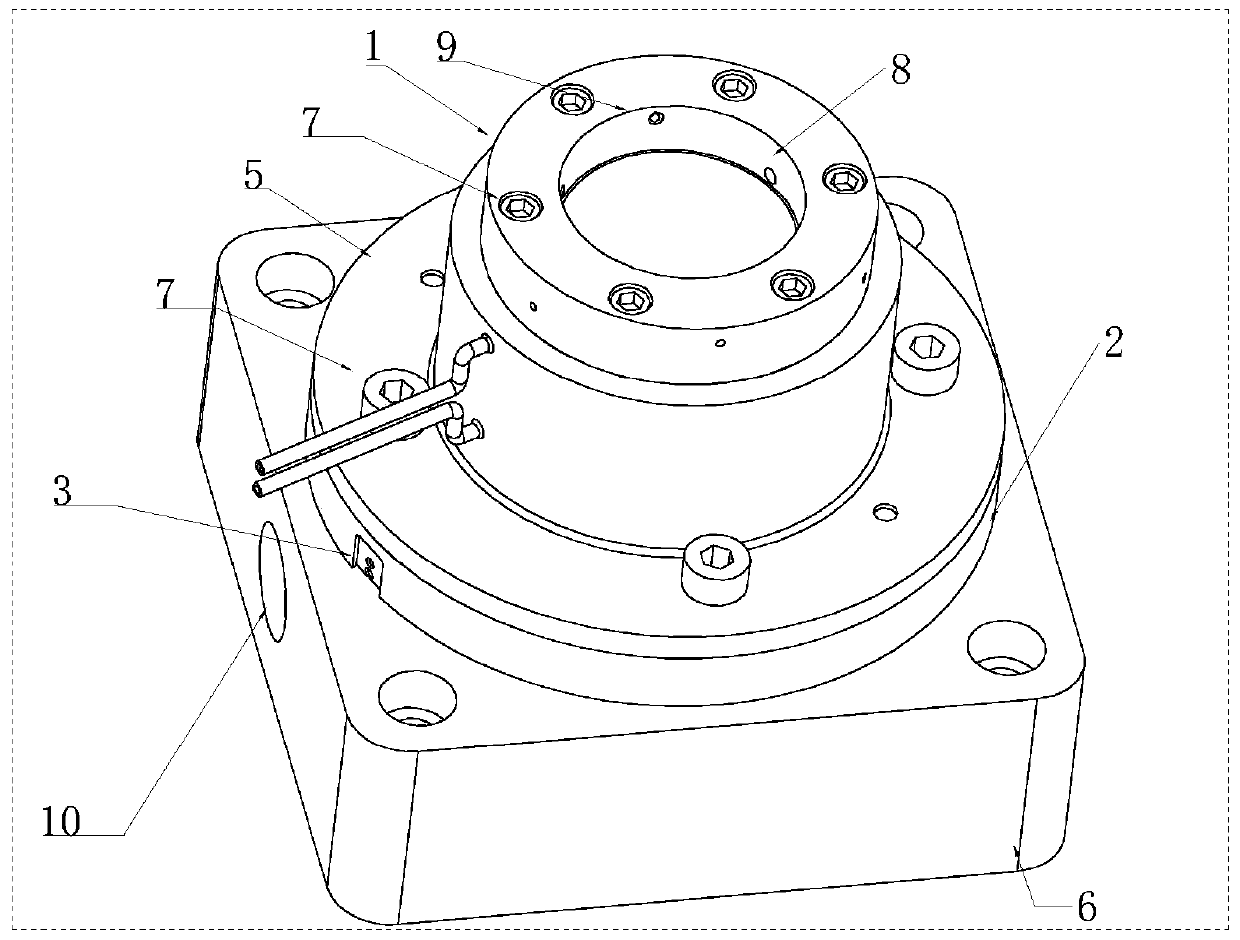

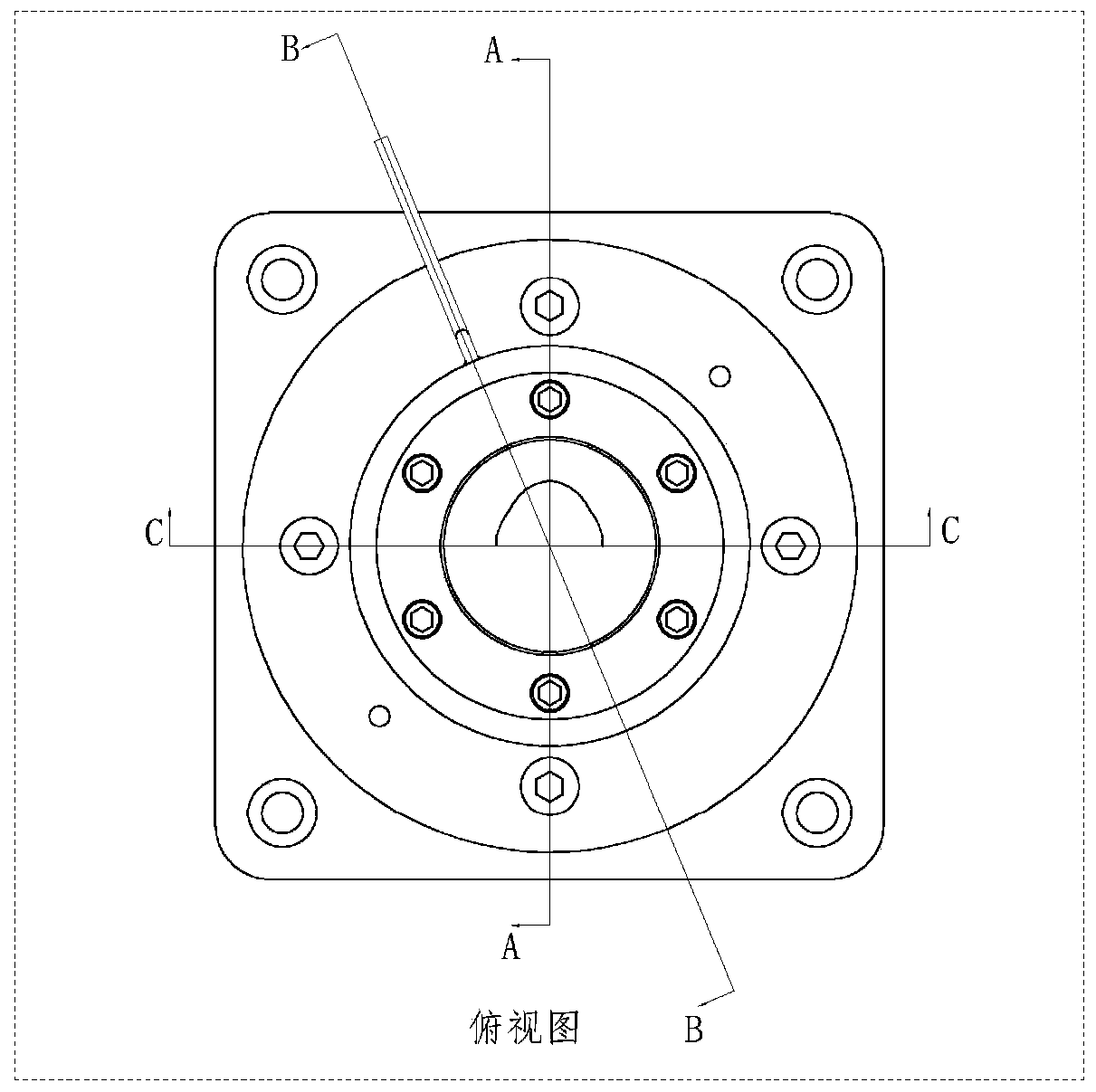

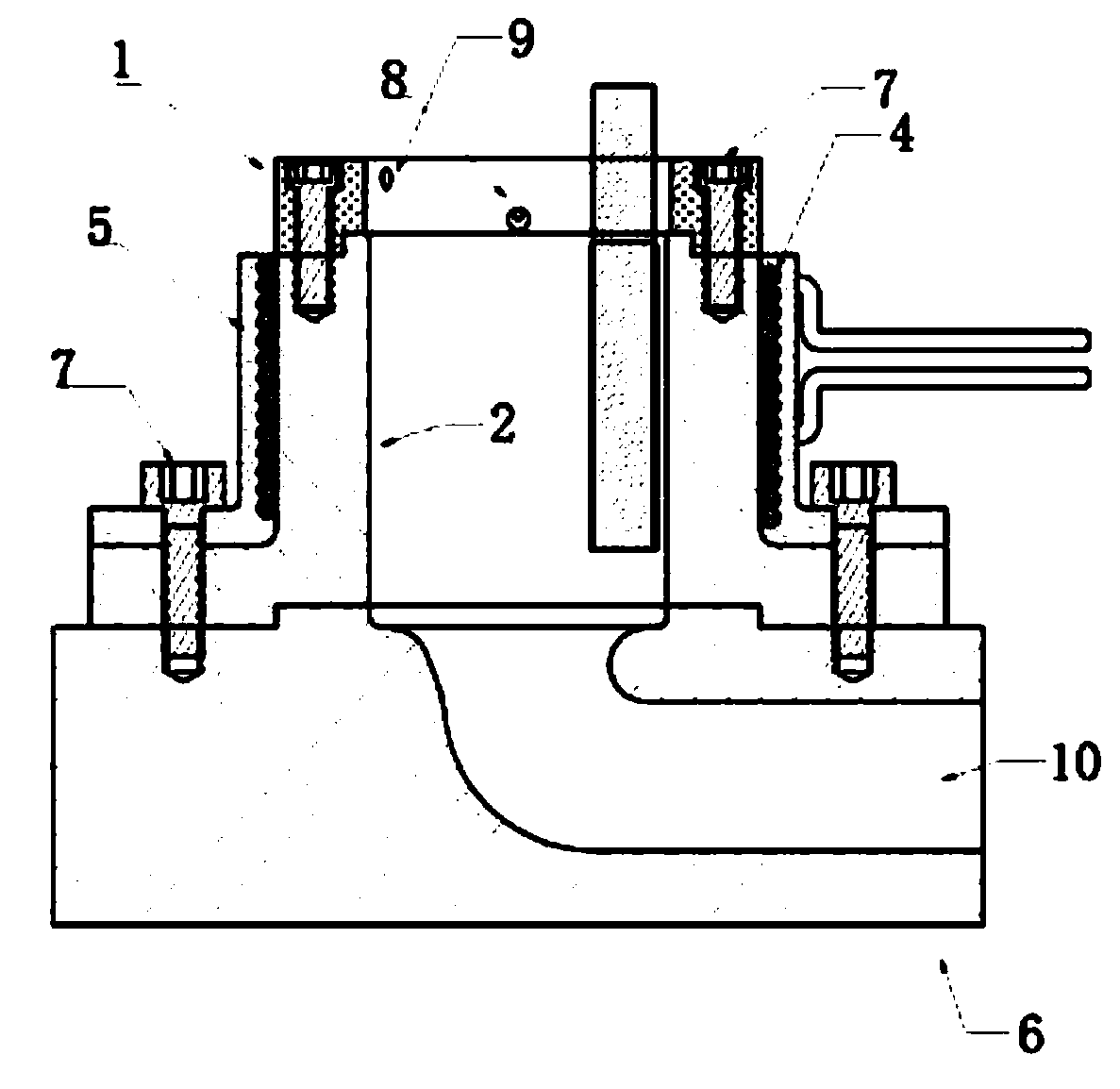

Rotary workbench

ActiveCN105881112ASimple structureRealize numerical controlOther manufacturing equipments/toolsControl theoryEngineering

The invention relates to a rotary workbench, comprising a feed slide table, a cylindrical convex part with a through hole inside is arranged on one side of the feed slide table, a vertical shaft is arranged in the through hole, a vertical shaft sleeve is arranged outside the vertical shaft, and the vertical shaft is connected to the The two ends of the vertical shaft sleeves are respectively provided with bearing groups, and the lower end of the vertical shaft is provided with a reducer and a servo motor in turn. An inner spacer is set between the lower end cover, a transition plate is set at the lower end of the convex part, a clutch stator and a clutch rotor are set at the end of the vertical shaft, and a clutch armature is set under the clutch rotor, and the clutch armature passes through the armature connecting plate It is connected with the reducer, an adjusting pad is arranged between the armature connection plate and the reducer, and a gland is arranged at the center of the end of the vertical shaft. The beneficial effect of the present invention is that the present invention provides a rotary table with simple structure, safe and reliable operation and convenient operation.

Owner:BEIJING DEMINA PRECISION MACHINERY

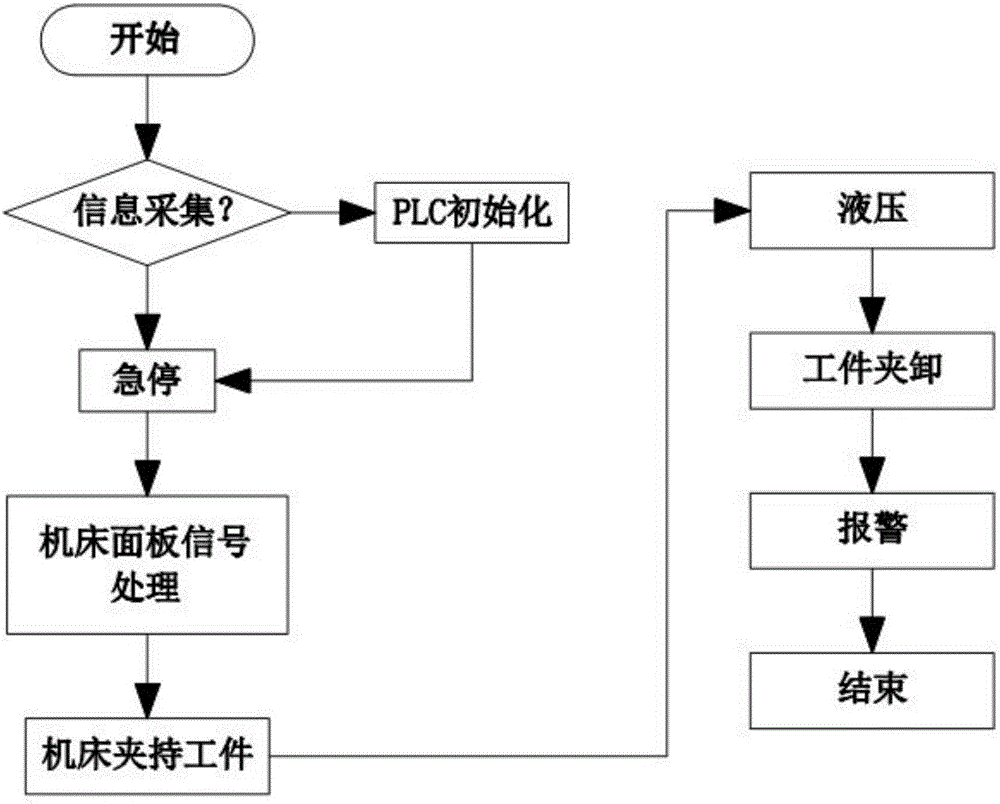

Electrical transformation technology for machine tool

InactiveCN106597994AAchieve accuracyAchieve effectivenessNumerical controlMachine controlProcessor register

The invention, which belongs to the technical field of machine tool transform, discloses an electrical transformation technology for a machine tool. The electrical transformation technology is implemented as follows: S1, information of an output terminal of an electrical appliance is collected by using a PLC technology; S2, after storage of the information, the PLC technology is applied to an execution process; S3, with the PLC technology, data information stored into a register is arranged; S4, all independent circuits are designed in an electrical appliance of a machine tool; and S5, data in a latching device are analyzed and adjusted reasonably and randomly. On the basis of the PLC technology, the register is in an independent state all the time during the operating process, so that no conflict with any operation change exists and no contact is caused; and with PLC servo control, numerical controlling and intelligence of machine tool control can be improved and problems of contact point losses and high equipment fault probability can be solved. Meanwhile, various faults during the machine tool operation process can be dealt with timely and effectively; and the work efficiency of the machine tool can be improved.

Owner:王全亮

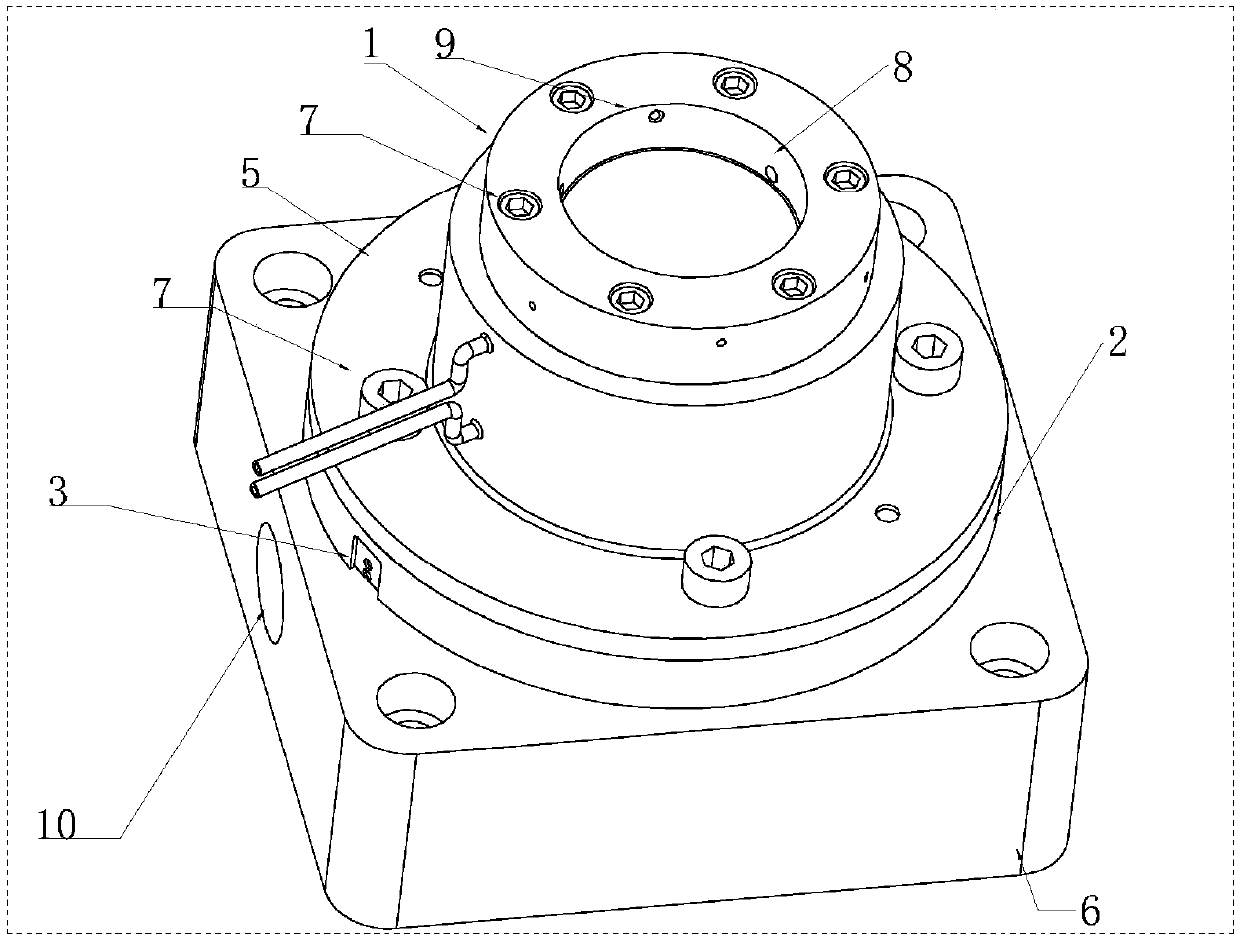

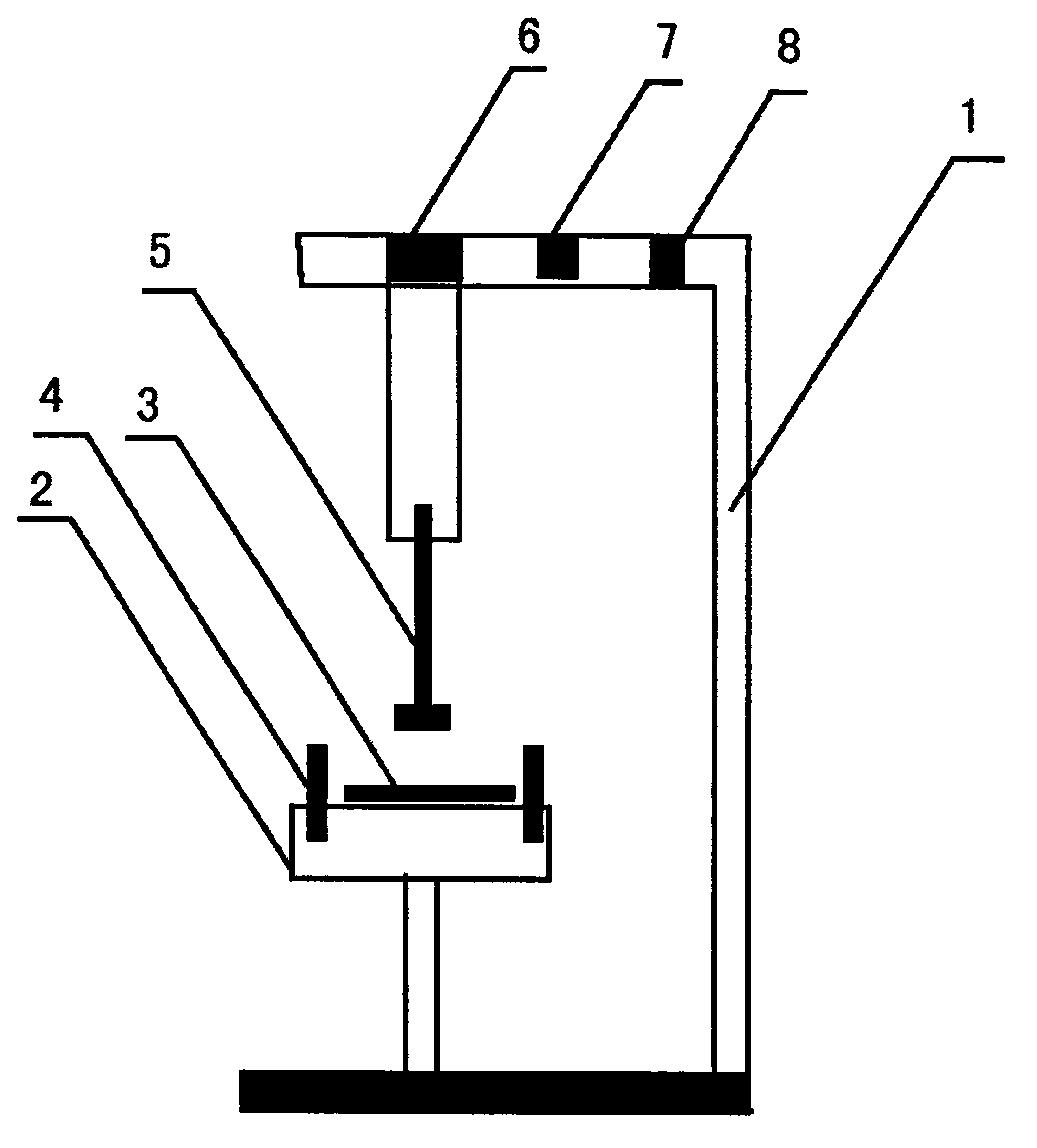

Beating machine for producing prepared Chinese ink

A beating machine for producing prepared Chinese ink comprises a support (1) and is provided with a beating pallet (2), and an ink stick (3) gathering device (4) is arranged on the beating pallet (2); the beating machine is provided with a beating rod (5) which is driven by electric power, and corresponding speed, strength, frequency and other parameters can be adjusted. When the beating machine is used, an ink stick (3) is put on the beating pallet (2), when the beating rod (5) beat once, the ink stick gathering device (4) automatically gathers beaten ink sticks for another-time beating; the beating pallet (2) possesses a base layer prepared from hard rubber, so that the beating pallet (2) has elastic and necessary beating can be performed; a corresponding control module (6) is arranged for controlling beating rhythm and strength; a corresponding prompt module (7) is arranged for emitting prompt information when the beating machine finishes set beating; and a video monitoring device (8) is arranged for observing appearance characteristics of prepared Chinese ink. By employing the beating machine, automation and numerical control of a beating link for producing prepared Chinese ink for traditional calligraphy are realized, and the production efficiency is improved.

Owner:XINCHANG COUNTY YULIN STREET YUQUAN MACHINERY FACTORY

A numerical control vertical hot rolling ring machine and its control method

InactiveCN104368734BHigh forming precisionReduce the amount of processingRoll mill control devicesMeasuring devicesNumerical controlBall screw

Owner:WUHAN UNIV OF TECH

High-frequency induction heating chemical dressing device for brazing diamond milling and grinding tools

ActiveCN107900924BReduce oxidation lossExtend the life cycleIncreasing energy efficiencyGrinding devicesNumerical controlMilling cutter

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

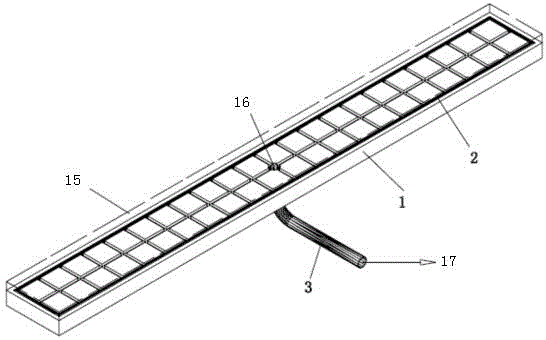

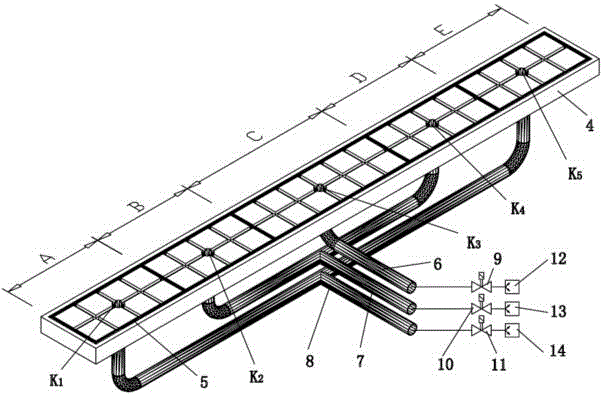

Vacuum adsorption device for processing antique grooves on wooden floor surface and floor clamping method

InactiveCN104191488BRealize vacuum adsorption clampingRealize numerical controlWood working apparatusSolenoid valvePulp and paper industry

The present invention is a vacuum adsorption device and a floor clamping method for processing antique grooves on the surface of wooden floors. A Solenoid Valve 9, B Solenoid Valve 10, C Solenoid Valve 11, A Vacuum Pump 12, B Vacuum Pump 13, C Vacuum Pump 14; the method of floor clamping is to gradually pass the vacuum from the middle part of the solid wood composite floor to the two ends of the area. adsorption. Advantages: 1) The vacuum adsorption table is divided into five adsorption areas, and the vacuum is gradually passed from the middle part to the two ends, so that the curved solid wood composite floor is gradually absorbed, gradually becomes flat, completely absorbed and flattened, without manual or other 2) It is beneficial to realize the numerical control, automation and continuous production of the antique groove processing on the surface of the solid wood composite floor.

Owner:GUANGDONG YIHUA TIMBER IND +1

Electrohydraulic servo oil cylinder and numerical control machine tool using same

InactiveCN100451355CServo follow-up motion with high precisionHigh precisionOperating means/releasing devices for valvesServomotor componentsSpool valveControl system

The invention relates to an electro-hydraulic servo cylinder, comprising a four-edge sliding valve whose base is mounted with a valve element moving left and right. The valve base is fixed on the cylinder whose piston rod is fixed with the frame; the cylinder is connected with the load. The left driving chamber via tube is communicated with the left working chamber, while the right driving chamber via tube is communicated with the right working chamber; one end of valve element is engaged with the dial block mounted on the straight motion output element of straight motion output device. The digit-control machine with said electro-hydraulic servo cylinder comprises a first axle servo driving system, a second axle servo driving system, a third axle servo driving system and a digit-control system, wherein, the second driving system comprises a straight load axle. The invention has high accuracy, quick steering speed, and stable property, which combines the digit control technique with the electro-hydraulic servo motion, with high accuracy in large power.

Owner:路文忠

a rotary table

ActiveCN105881112BSimple structureRealize numerical controlOther manufacturing equipments/toolsReduction driveEngineering

The invention relates to a rotary workbench. The rotary workbench comprises a feeding sliding table. A cylinder protruding portion internally provided with a through hole is arranged on one side of the feeding sliding table. A vertical shaft is arranged in the through hole and sleeved with a vertical shaft sleeve. Bearing sets are arranged at the two ends of the portion between the vertical shaft and the vertical shaft sleeve. A reducer and a servo motor are sequentially arranged at the lower end of the vertical shaft. The servo motor is arranged at the lower end of the reducer. A lower end cover is arranged at the lower end of the vertical shaft sleeve. The vertical shaft penetrates the lower end cover. An inner spacer bush is arranged between the lower end of the vertical shaft and the lower end cover. A transition plate is arranged at the lower end of the protruding portion. The tail end of the vertical shaft is sleeved with a clutch stator and a clutch rotor which are matched with each other. A clutch armature is arranged below the clutch rotor and connected with the reducer through an armature connecting disc. An adjusting pad is arranged between the armature connecting disc and the reducer. A gland is arranged in the center of the end of the vertical shaft. The rotary workbench has the beneficial effects that the rotary workbench is simple in structure, safe and reliable in operation and convenient to operate.

Owner:BEIJING DEMINA PRECISION MACHINERY

CNC Winding Equipment and Method for Square FRP Air Duct

The invention discloses a numerical control winding apparatus for a square glass fiber reinforced plastic air pipe. The numerical control winding apparatus comprises a rack, a pay-off roller, a guide device, a yarn arranging device, a square mandrel winding device and a numerical control system. The pay-off roller, the guide device, the yarn arranging device, the square mandrel winding device and the numerical control system are arranged on the rack and sequentially connected through glass fiber yarn. The yarn arranging device comprises a base arranged on the rack. A servo motor, a lead screw and a guide rail which are connected with the servo motor, and a yarn nozzle installed on the guide rail and connected with the lead screw. The numerical control system is connected with the servo motor. The invention further discloses a numerical control winding method for the square glass fiber reinforced plastic air pipe. By the adoption of the numerical control winding apparatus for the square glass fiber reinforced plastic air pipe, the yarn arranging device and the square mandrel winding device are synchronously controlled through the numerical control system to move, the winding angle of the square glass fiber reinforced plastic air pipe is controlled, the glass fiber yarn is provided through the yarn arranging device, the tension of the fiber yarn can be adjusted at any time to control the quality of a product, numerical control is achieved, and the machining quality and efficiency of the square glass fiber reinforced plastic air pipe are improved.

Owner:CHONGQING UNIV

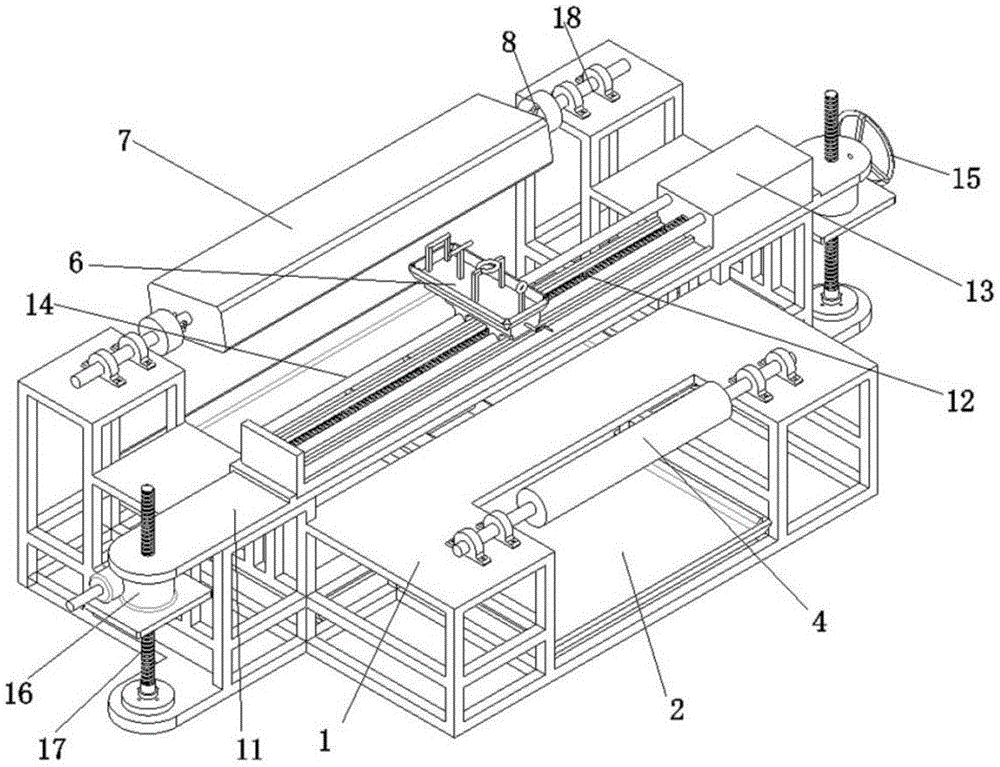

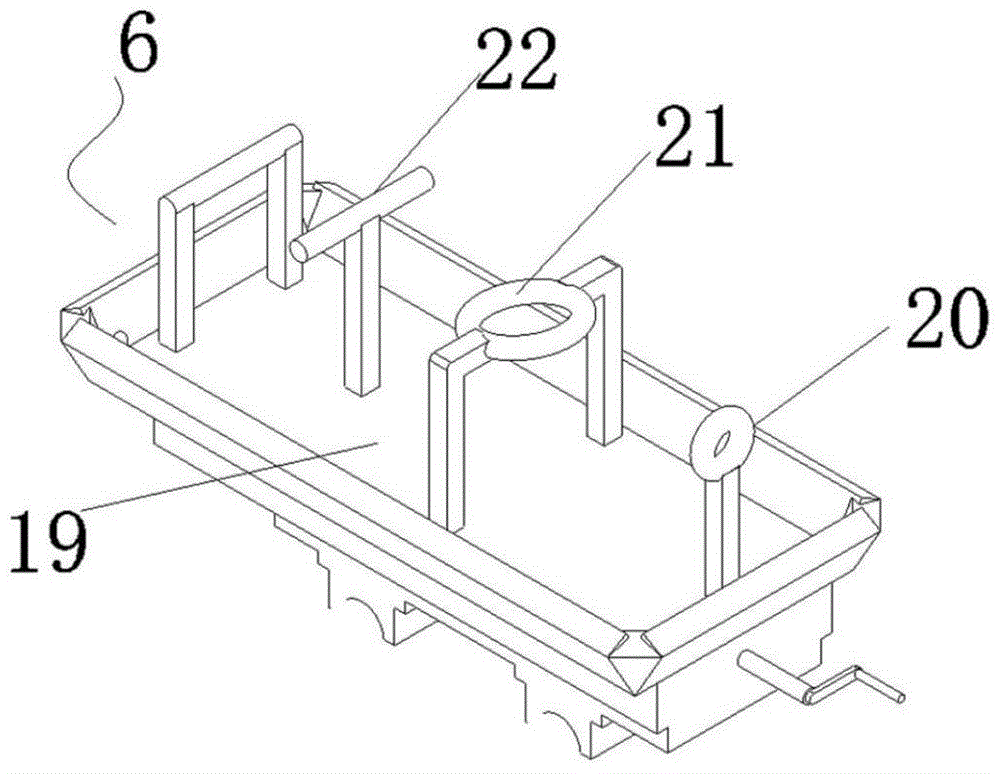

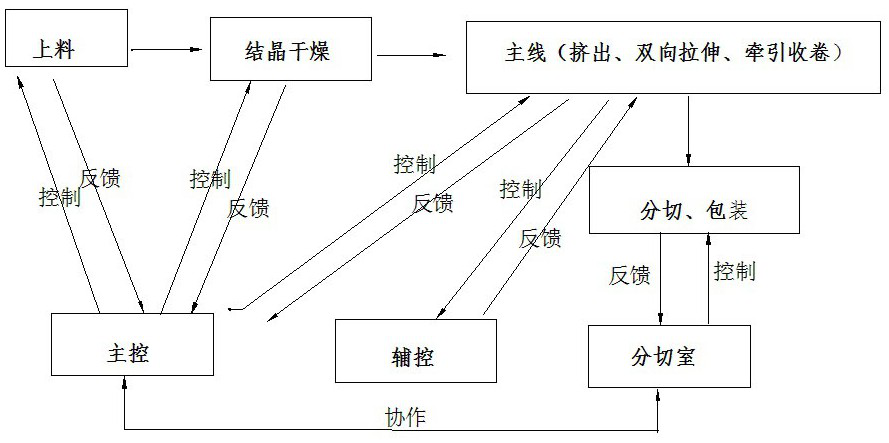

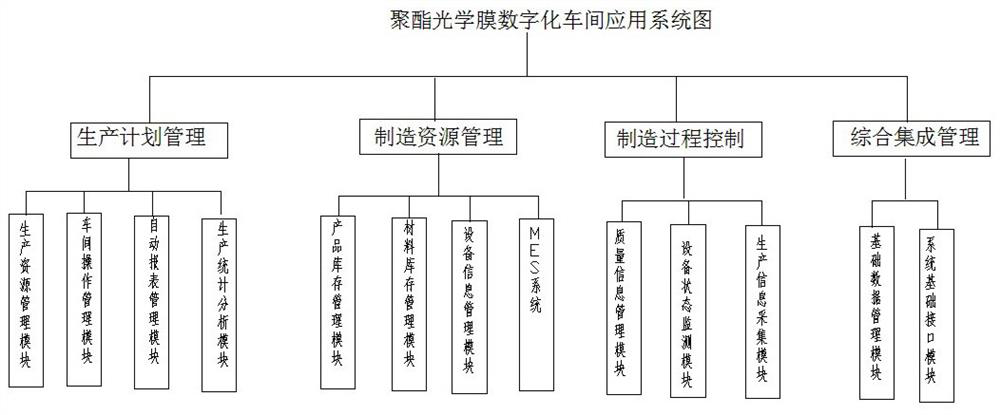

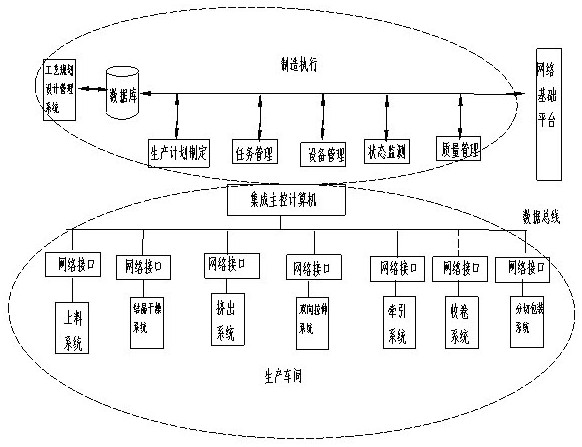

Polyester optical film digitization workshop

PendingCN112318905ARealize numerical controlRealize intelligenceOptical articlesTotal factory controlPolyesterNumerical control

The invention belongs to the field of polyester optical film production, particularly relates to a polyester optical film digitization workshop, and aims to solve the problem that the thickness uniformity and flatness of an existing produced film cannot meet the technical requirements, and in production line operation, once some flaws are found on the surface of a thin film, position coordinates on the surface of the thin film and the overall defect condition of the thin film are difficult to find. The following scheme is proposed: the system comprises a workshop application system and an execution system; the workshop application system is connected with a central control system; the workshop application system comprises a production management module, a manufacturing resource managementmodule, a manufacturing process control module and a comprehensive integration management module; and the production management module comprises a production resource management module, a workshop operation management module and an automatic report management module. By adopting the polyester optical film digitization workshop, workshop equipment numerical control, intelligentization, production control informationization and workshop networks are realized; and perfect unification of production, technology, quality and the like is ensured.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

Novel servo positioning device applicable to engine lathe

InactiveCN103481105ARealize numerical controlIncrease rotation speedAutomatic control devicesFeeding apparatusBall bearingCoupling

The invention relates to a novel servo positioning device applicable to an engine lathe. The novel servo positioning device comprises a servo motor which is connected with a ball screw through an elastic coupling; the end, close to the elastic coupling, of the ball screw is mounted on a bearing seat through an angular contact ball bearing; the bearing seat is mounted in a connecting base fixed on a lathe bed; the other end of the ball screw is connected with a screw nut seat which is connected with a workbench dragging plate through countersunk bolts, and an encoder is mounted on the servo motor. The novel servo positioning device is convenient for encoding, high in rotation speed, fast in feeding, simple in structure, convenient to maintain and high in positioning accuracy.

Owner:苏州凯欧机械科技有限公司

self-aspirating syringe

InactiveCN104337523BRealize numerical controlEasy to controlInfusion syringesPharmaceutical containersAutomatic controlEngineering

The invention discloses a syringe capable of pumping automatically. The syringe comprises a syringe needle, a cylinder, a piston rod and a round piston rod pressing handle, wherein the piston rod pressing handle and a blocking edge serve as concentric circles with the identical diameter; an air bag is arranged between the piston rod pressing handle and the blocking edge; the two ends of the air bag are respectively fixed with the piston rod pressing handle and the blocking edge; the air bag encircles the piston rod; a reverse valve and an aeration nozzle are arranged on the surface of the air bag; a sealing cover is arranged on the aeration nozzle; the reverse valve allows gas to flow from outside to inflate the gas bag. According to the syringe disclosed by the invention, the gas bag is inflated to push the piston rod to move, so as to allow the syringe needle to pump liquid, realize automatic control, and control the pumping speed through the inflation speed.

Owner:吴燕霞 +5

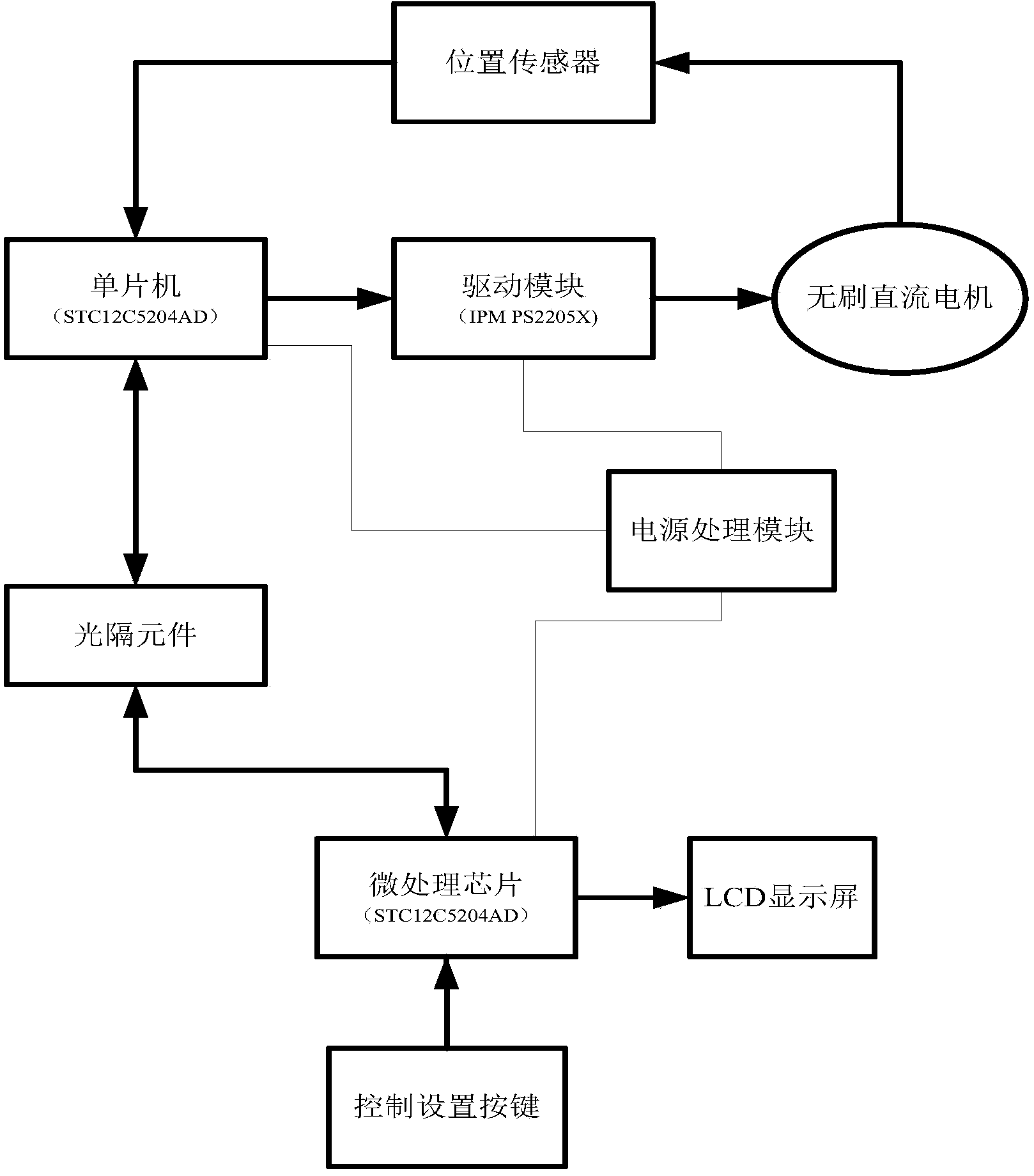

Brushless direct current motor controlling device for tapping

InactiveCN104270048AImprove processing efficiencyFully automatedSingle motor speed/torque controlElectronic commutatorsControl setNumerical control

The invention relates to the technical field of machining, in particular to a brushless direct current motor controlling device for tapping. The brushless direct current motor controlling device for tapping comprises a brushless direct current motor with a position sensor, a control main board, a display operation panel, a transmission cable A and a transmission cable B. The control main board comprises a driving module, a power source processing module, a single-chip microcomputer and an optical isolation element; the display operation panel comprises an LCD screen, a micro processing chip and control setting keys. By arranging the eleven control setting keys on the display operation panel, tapping parameters are reasonably and corporately set through the control setting keys, the manual tapping motion of a technician is simulated, and an optical tapping technical scheme is realized. The LCD screen can display related information of control setting and prompt fault self-diagnosis information. The functions of an existing brushless direct current motor controlling device are expanded, automation and numerical control of tapping equipment can be realized on a matched motor controller, machining efficiency is improved, and the quality of mechanical products is guaranteed.

Owner:FENGHUA XINGYU SPECIAL MOTOR MFG

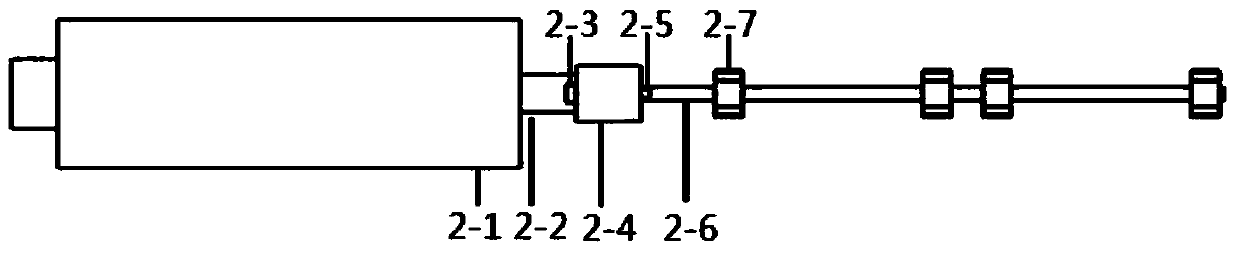

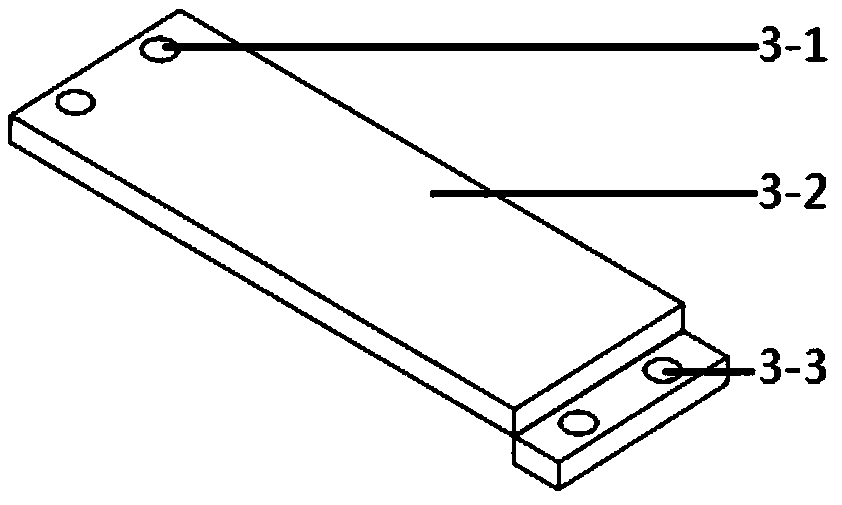

Electric spark deposition mechanism for functional coating on inner wall of slender pipeline

PendingCN111321406AAchieve precise controlRealize numerical controlMetallic material coating processesPhysicsGas pipeline

The invention relates to a mechanism, in particular to an electric spark deposition mechanism for a functional coating on the inner wall of a slender pipeline. The purpose is to solve the problems that manual electric spark deposition for the functional coating on the inner wall of the slender pipeline is difficult to carry out, the deposition quality is poor, and the efficiency is low. The electric spark deposition mechanism is based on modular design, and includes a supporting shaft, a cam rotating device, a primary supporting plate, an electrode rotating vibration device, a protective gas pipeline and a secondary supporting plate. Combined with a numerical control technology and an electric spark deposition surface strengthening technology, an electro spark deposition process platform for the functional coating of the inner wall of the slender pipeline is built, so that the numerical control and automatic deposition for the functional coating on the inner wall of the slender pipeline is realized. The electric spark deposition mechanism for the functional coating on the inner wall of the slender pipe is obtained.

Owner:LANZHOU JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com