Novel numerical control grinding wheel dressing device

A new type of grinding wheel dressing technology, used in abrasive surface adjustment devices, parts of grinding machine tools, metal processing equipment, etc., can solve problems such as high requirements for operator experience, low efficiency, and unstable quality of grinding workpieces. Achieve the effect of automation and numerical control, high efficiency and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

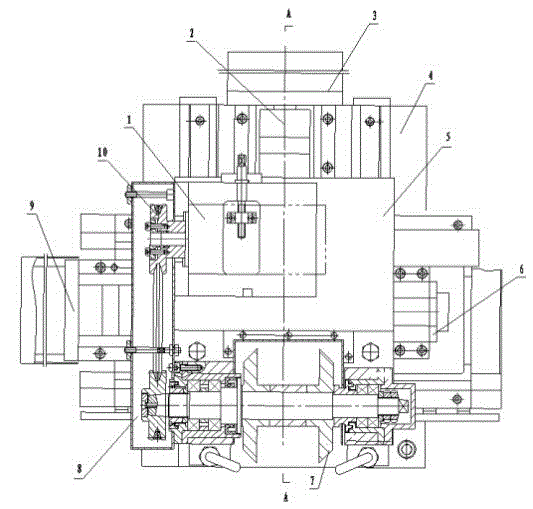

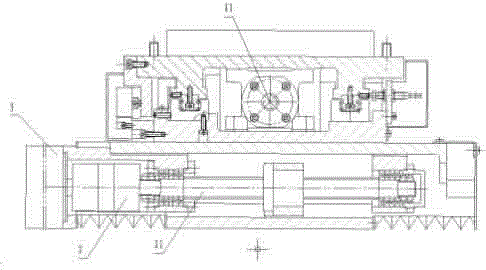

[0019] Such as figure 1 with figure 2 , a new type of CNC grinding wheel dressing for a screw rotor grinder, including a motor 1, two couplings 2, a servo motor I 3, a vertical guide rail 4, an upper carriage 5, a horizontal guide rail 6, and two diamond wheels 7, a lower carriage 8, a servo motor II 9, a pulley mechanism 10 and two ball screw mechanisms 11.

[0020] The new CNC grinding wheel dressing of the screw grinder adopts a two-coordinate feed mechanism perpendicular to each other, which is divided into horizontal feed and vertical feed. Servomotor 1 3 and shaft coupling 2 and ball screw mechanism 11 drag lower carriage 8 to realize that lower carriage 8 is vertically fed together with the horizontal feed mechanism installed thereon. Servomotor II 9 and shaft coupling 2 and ball screw mechanism 11 drag upper carriage 5 to realize that upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com