An Automatic Cutting Mechanism for Side Gate of Laminated Injection Mold

An injection mold and side gate technology, which is applied in the field of automatic side gate removal mechanism, can solve the problems of high precision control requirements, low appearance quality, complex mold mechanism, etc., and achieves simple overall structure, saving injection cycle, precision Effects with low control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

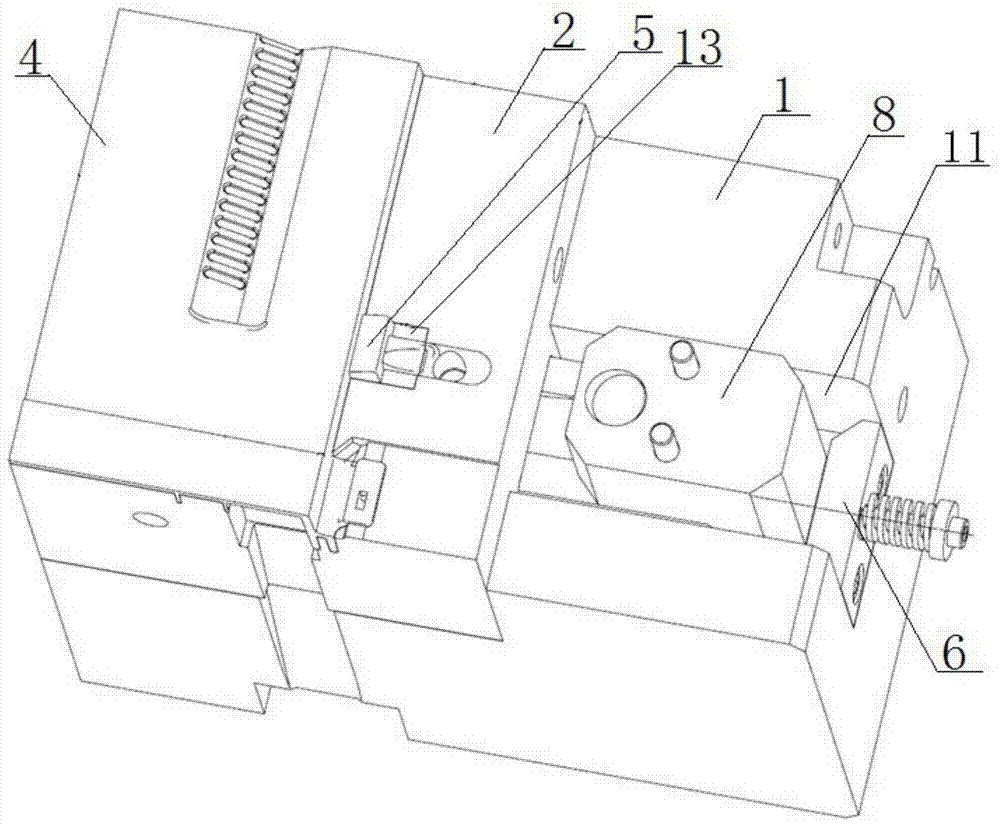

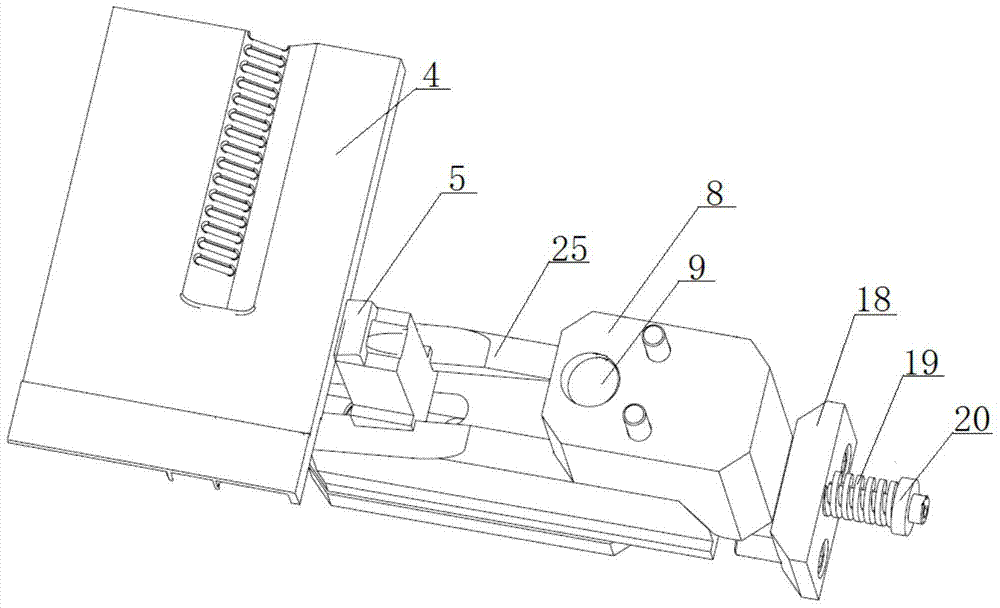

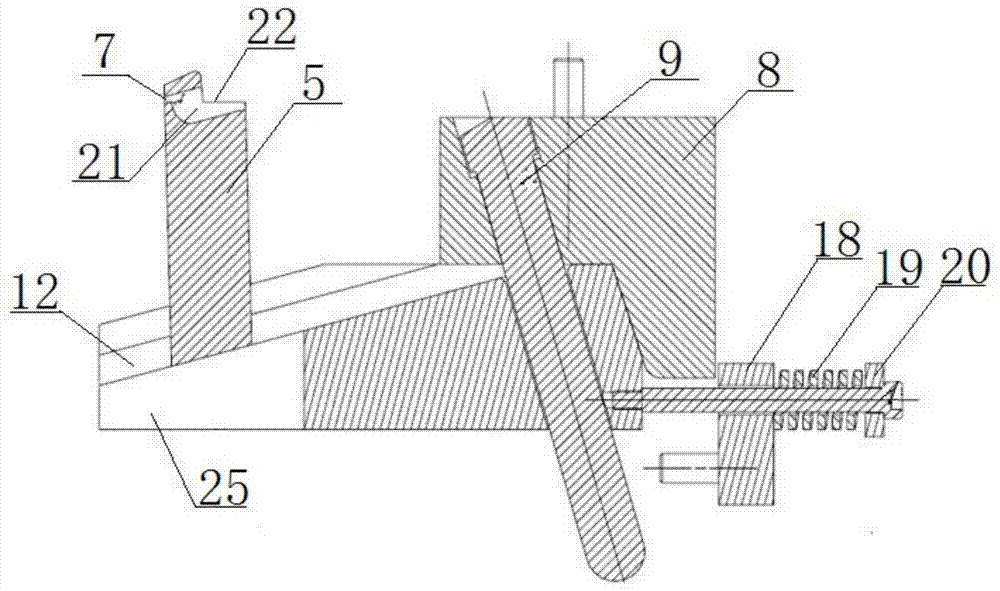

[0031] Such as Figure 1 to Figure 7 As shown, the present invention provides a laminated injection mold side gate automatic cutting mechanism, including a front mold (not shown in the figure) and a rear mold 1. The front mold and the rear mold 1 are provided with front mold molding inserts (Not shown in the figure), the back mold forming insert 2, the runner 3, the front mold forming insert and the rear mold forming insert 2 are fixedly installed on the front mold and the rear mold 1 by screws, and the front mold forming insert After being matched with the back mold molding insert 2 to form a cavity (not shown in the figure), the hot melt plastic enters the cavity through the runner 3, and forms a plastic product 4 after cooling. Under the action of the ejection mechanism, the back mold 1 Separate from the front mold and take out the product 4.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com