Mechanism used for cutting off side gate in mold automatically and suitable for injection mold

An automatic cutting and injection mold technology, which is applied in the field of injection molds, can solve the problems of high mold cost, easy cutting marks of separated products and gates, and complicated overall structure, so as to avoid procedures, ensure injection molding processing efficiency, and avoid cutting scar effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

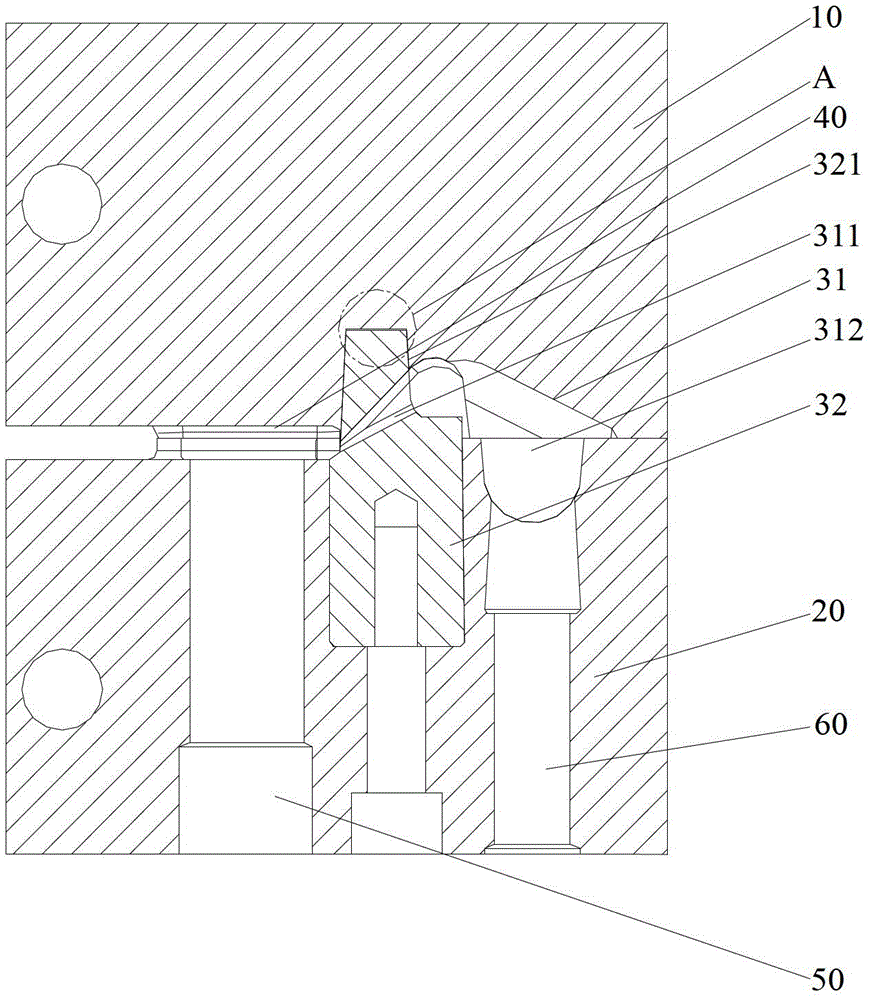

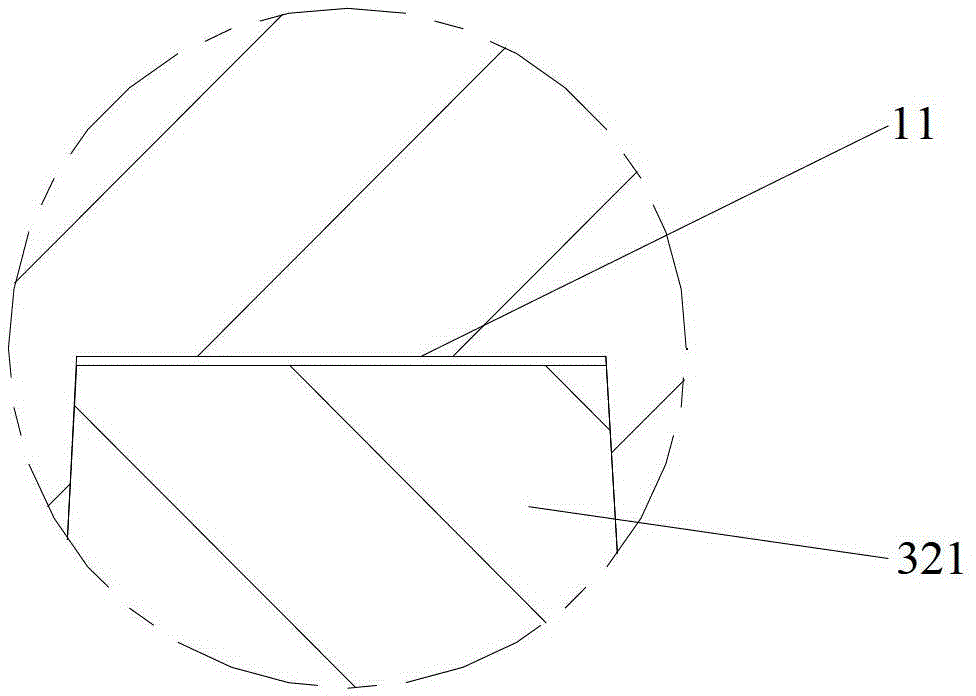

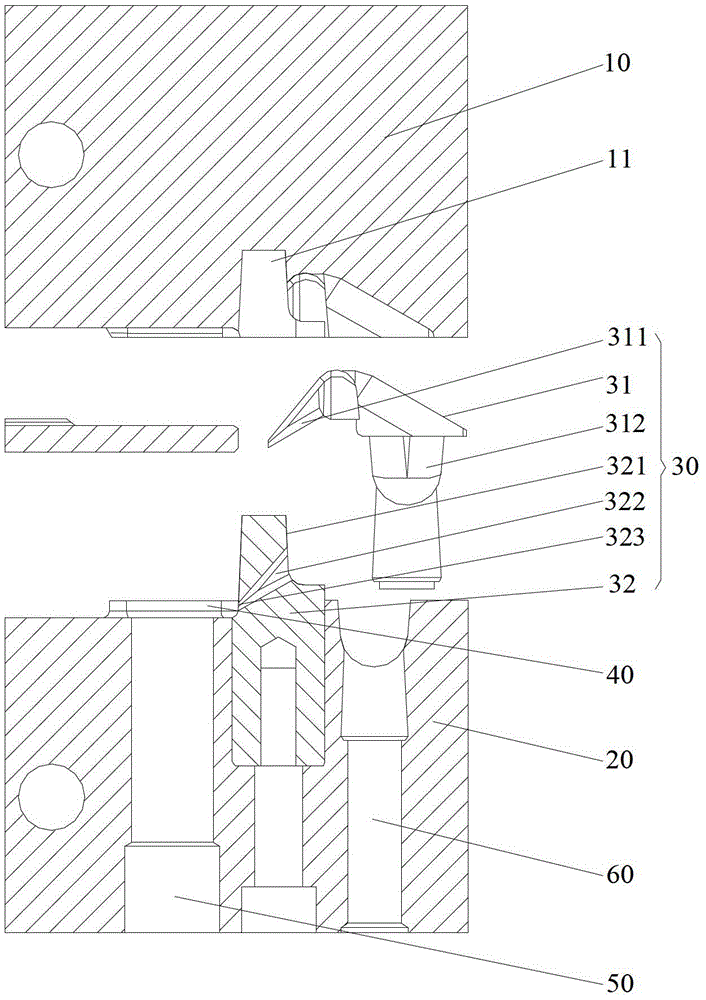

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] see Figure 1 to Figure 3 As shown, the present invention provides a kind of automatic cut-off side gate mechanism 30 in the mold that is suitable for injection mold, and injection mold comprises front mold 10 and rear mold 20, and front mold 10 and rear mold 20 cooperate to form a mating body and this mating body A mold cavity 40 for plastic products is provided. Specifically, the injection mold used in this case is a water-cooled injection mold, that is, after the rubber material is sprayed into the mold cavity 40, the rubber material is cooled rapidly by cooling water, so that the rubber material is in the Solidification molding in the mold cavity 40 . The in-mold automatic cut-off side gate mechanism 30 includes a side gate 31 and a gate insert 32 located in the mating body. The side gat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com