Novel servo positioning device applicable to engine lathe

A technology for servo positioning and ordinary lathes, applied in the field of new servo positioning devices, can solve the problems that ordinary lathes cannot meet new requirements, cannot reach 2um, and cannot adapt to users, etc., and achieves simple structure, fast feed speed, and high rotation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

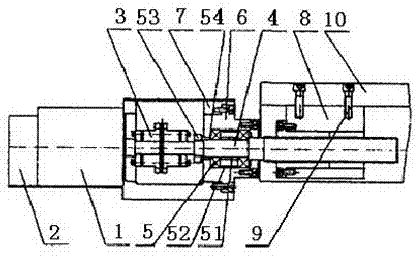

[0012] refer to figure 1 As shown, a new type of servo positioning device suitable for ordinary lathes, including a servo motor 1, the servo motor 1 is connected with a ball screw 4 through an elastic coupling 3, and the ball screw 4 is close to the elastic coupling The end of the ball screw 4 is installed in the bearing seat 6 through the angular contact ball bearing 5, the bearing seat 6 is installed in the connection seat 7, the connection seat 7 is fixed on the bed, and the other end of the ball screw 4 is connected to the screw nut seat 8 , the lead screw nut seat 8 is connected with the workbench carriage 10 through a countersunk bolt 9 , and an encoder 2 is installed on the servo motor 1 .

[0013] Further, an inner bearing spacer 51 is arranged between the angular contact ball bearing 5 and the ball screw 4, and an outer bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com