Electric spark deposition mechanism for functional coating on inner wall of slender pipeline

A technology of EDM deposition and pipeline, applied in coating, metal material coating process and other directions, can solve the problems of poor deposition quality, low efficiency, and difficulty in manual EDM deposition, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

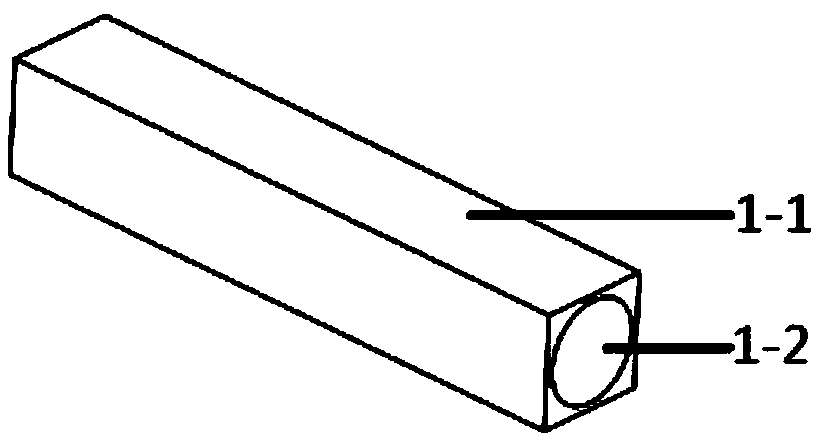

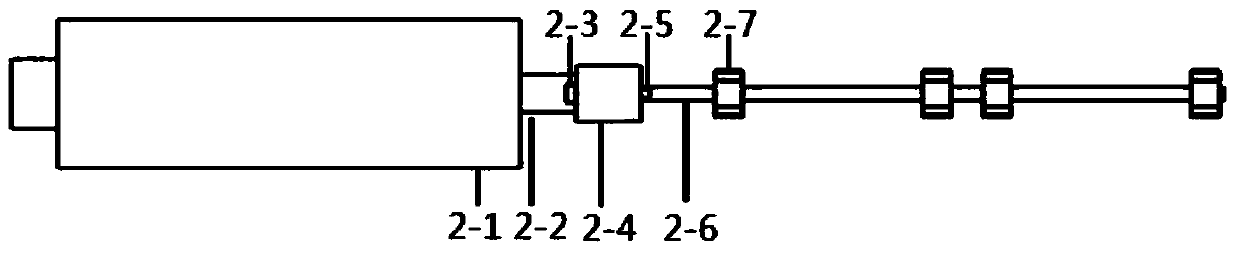

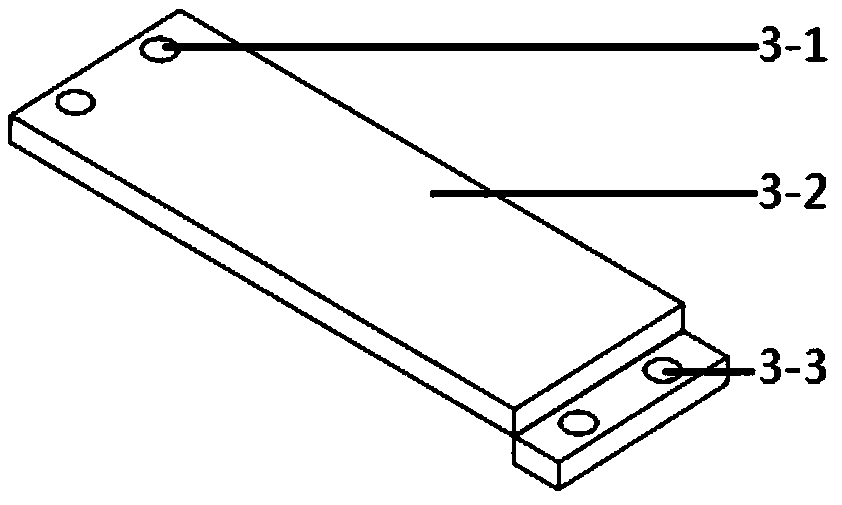

[0033] Specific embodiment 1: This embodiment is a kind of electrospark deposition mechanism of functional coating on the inner wall of a slender pipeline, which includes a support shaft (1), a cam rotation device (2), a primary supporting plate (3), and an electrode rotary vibration device (4). ), a shielding gas pipeline (5), a secondary pallet (6); the support shaft (1) includes a support shaft body (1-1) and a motor mounting part (1-2); the cam rotation device (2 ) including motor (2-1), motor rotating shaft (2-2), motor rotating shaft key (2-3), coupling (2-4), camshaft key (2-5), camshaft (2 -6) and cam (2-7); said primary pallet (3) includes threaded hole (3-1) connecting support shaft (1), primary pallet body (3-2) and fixed bracket ( 4-7) threaded hole (3-3); the electrode rotary vibration device (4) includes an electrode (4-1), a deposition power supply positive pole bearing (4-2), an electrode holder (4-3), Insulation sleeve (4-4), bolt (4-5), spring (4-6), bracket...

specific Embodiment approach 2

[0061] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the outer contour of the support shaft (1) is square, the inner contour is circular, and the material is aluminum alloy with good rigidity and light weight . Others are the same as the first embodiment.

specific Embodiment approach 3

[0062] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the motor rotating shaft (2-2) and the camshaft (2-6) are connected by a shaft coupling (2-4) , the coupling (2-4) is connected to the motor rotating shaft (2-2) through the motor rotating shaft key (2-3), and the coupling (2-4) and the camshaft (2-6) are connected through the cam The shaft key (2-5) is connected, and the cam (2-7) is fixed on the camshaft (2-6) by the camshaft key (2-5). Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com