Patents

Literature

73results about How to "Vibration up and down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

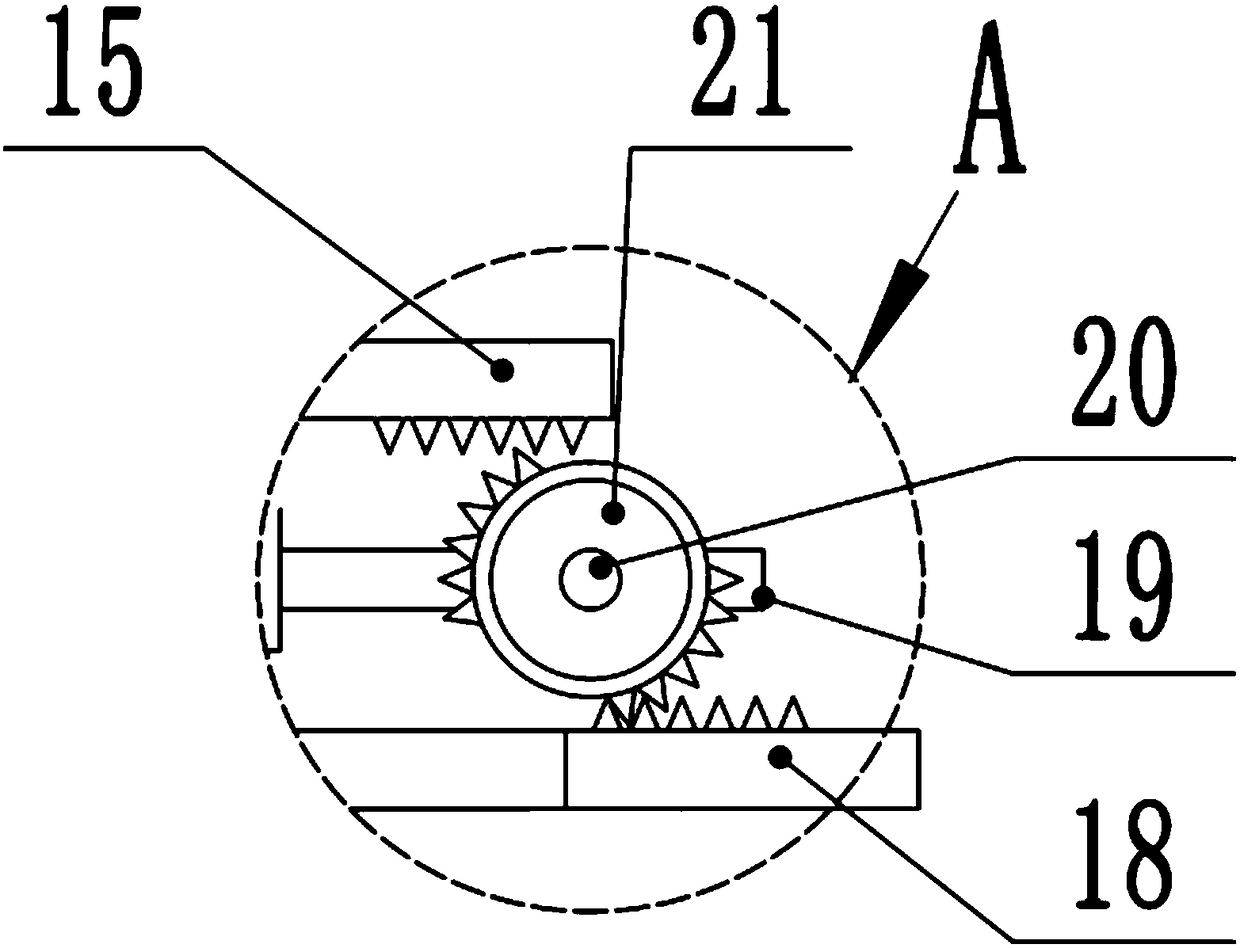

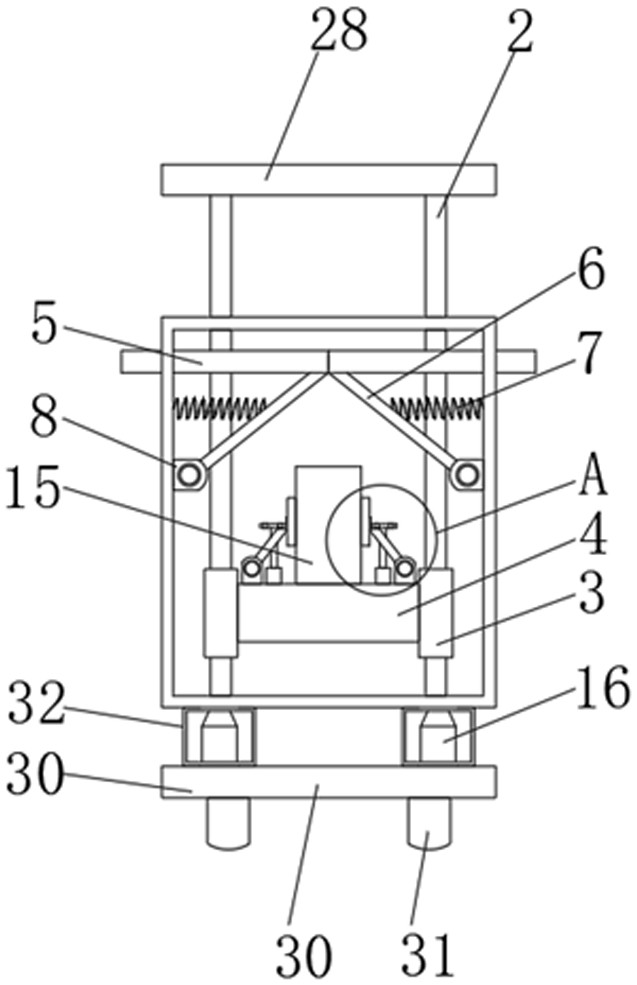

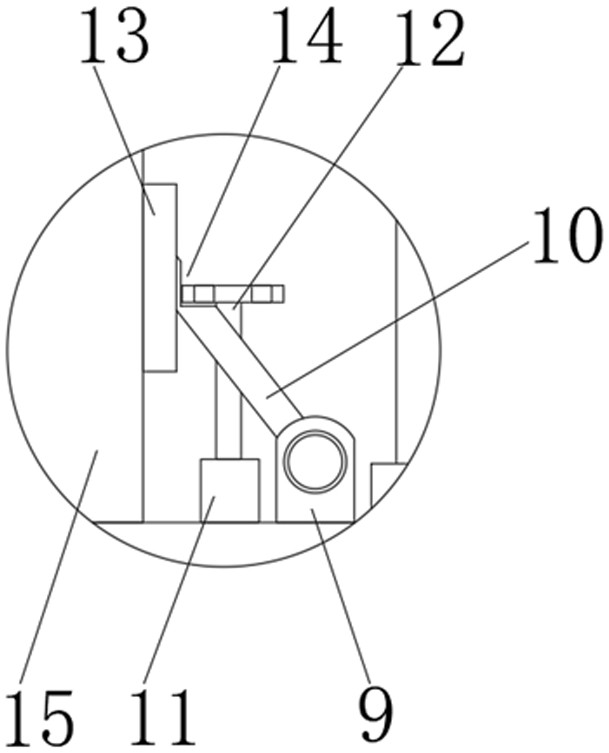

Gear driven vibrating activated carbon grinding screening device

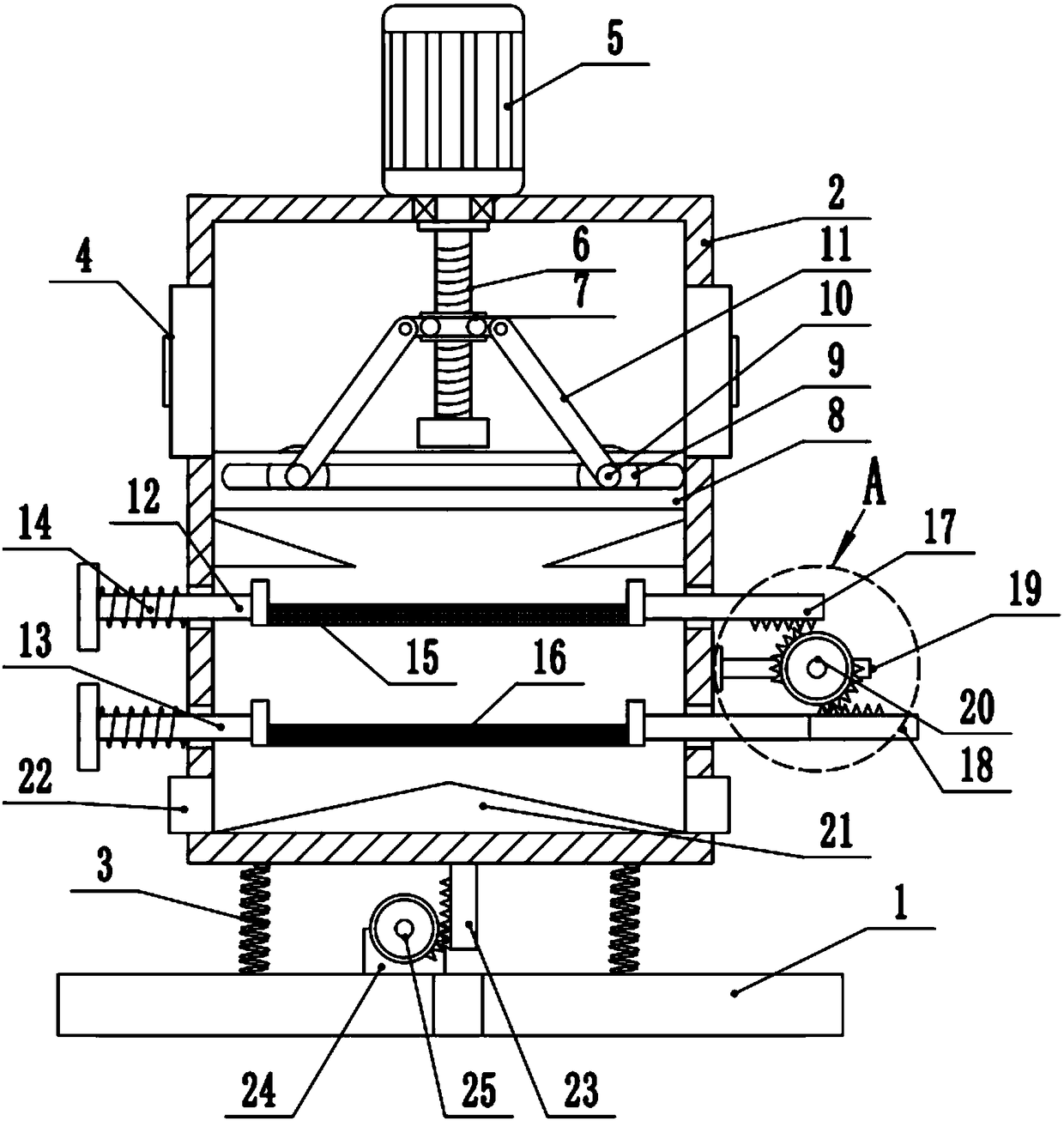

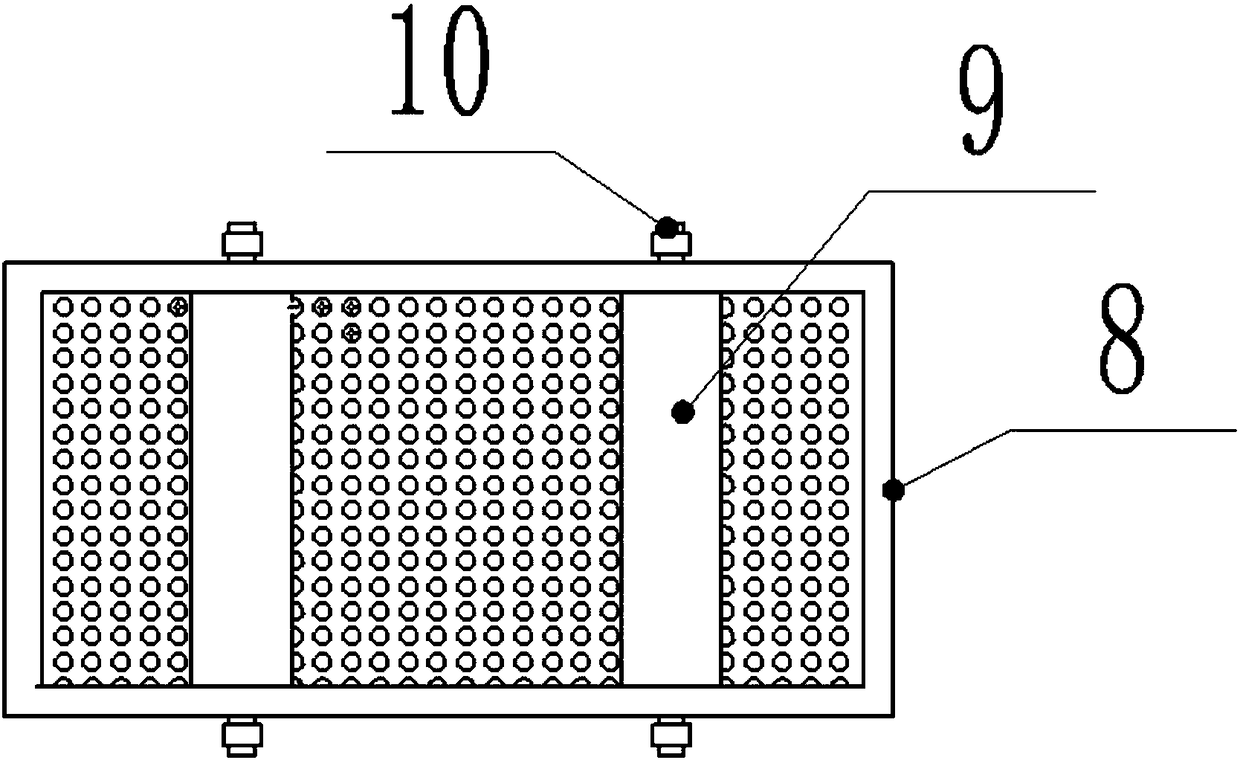

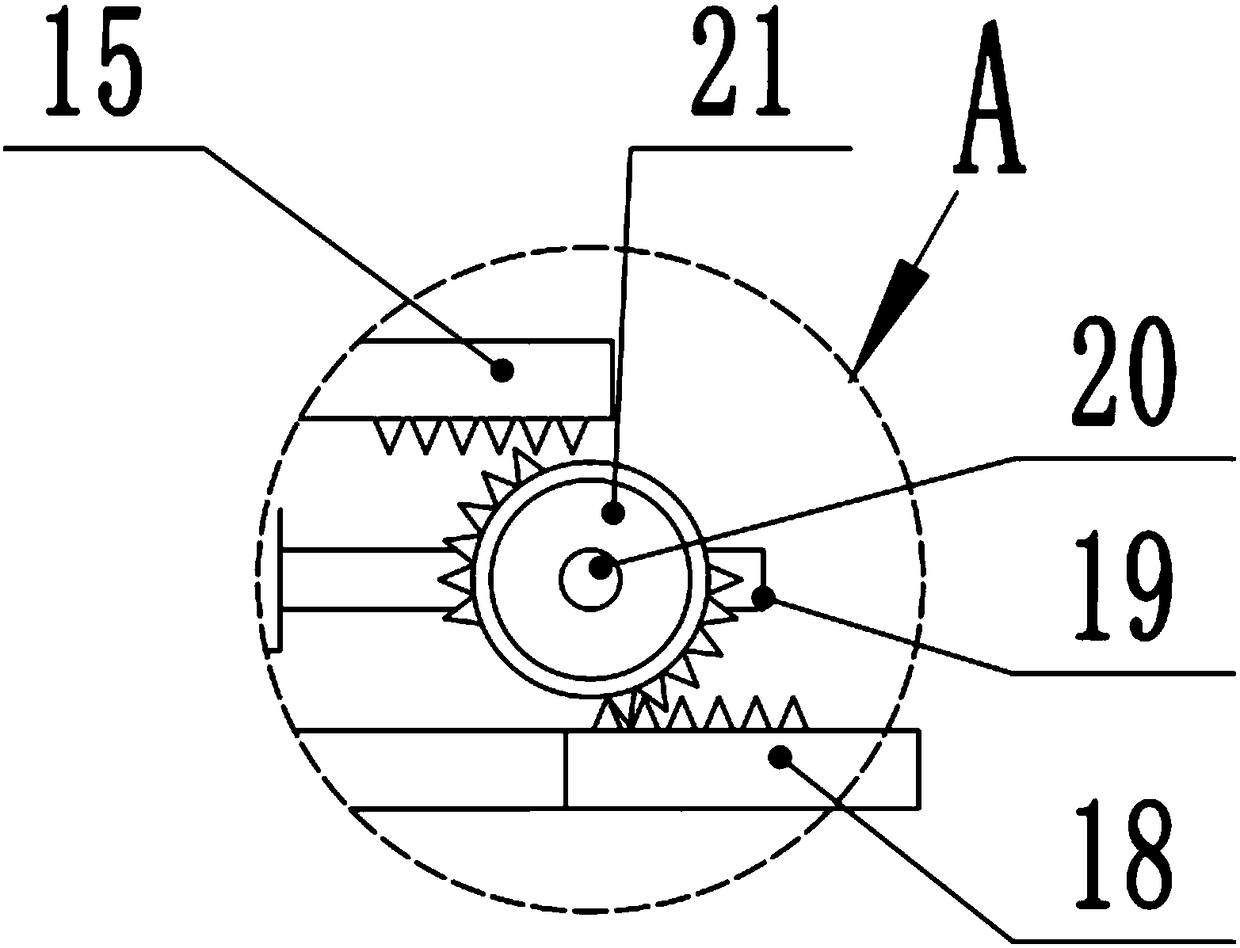

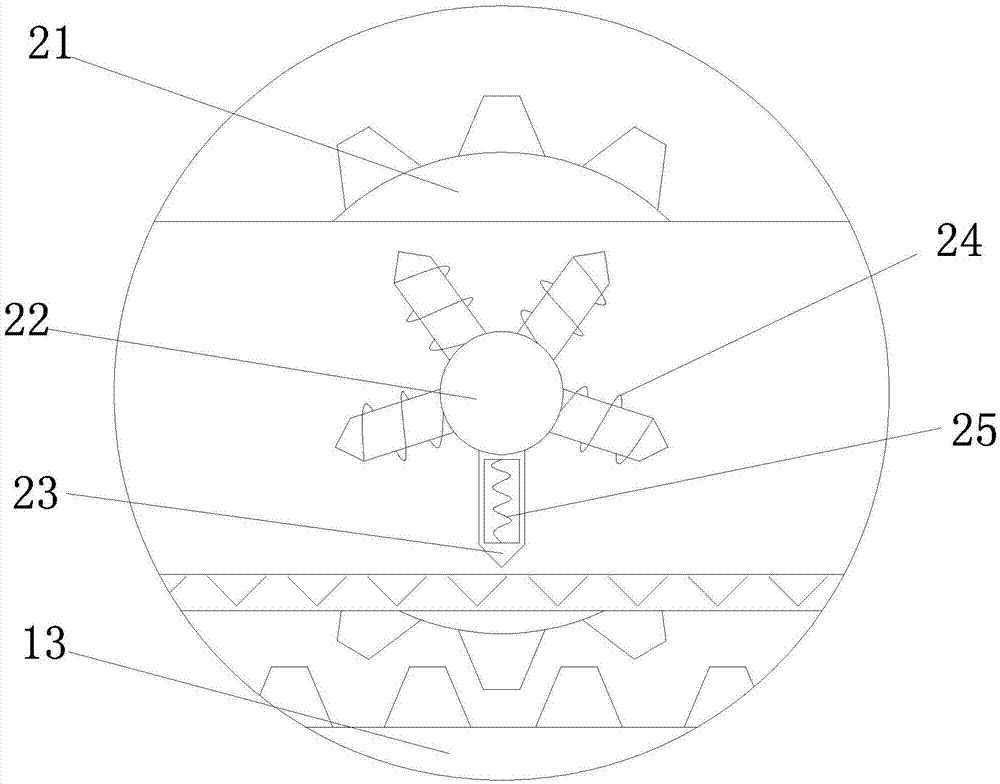

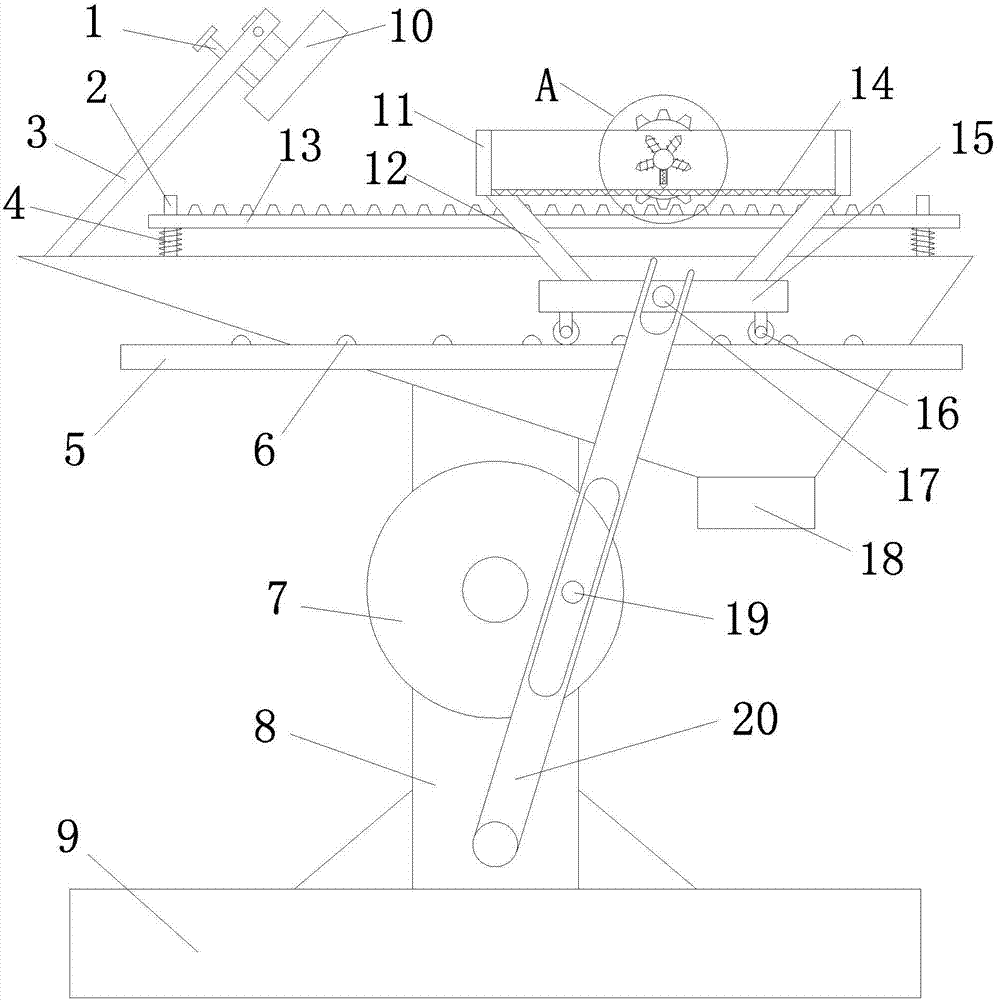

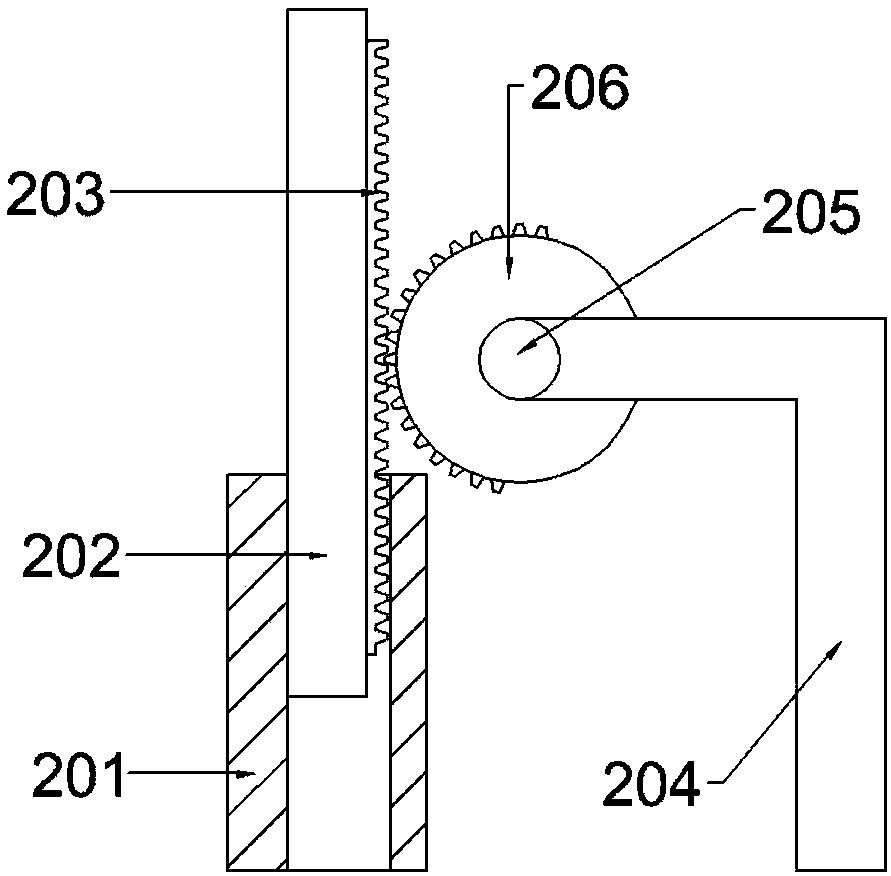

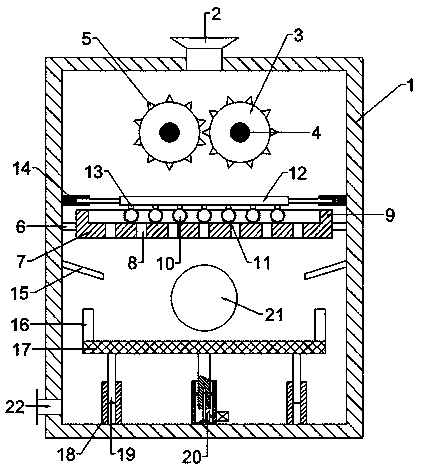

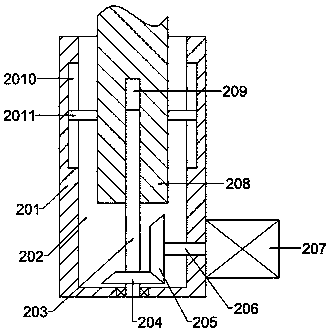

The invention discloses a gear driven vibrating activated carbon grinding screening device. The device consists of a pedestal, a grinding box, a first driving motor, a ball screw, a grinding groove, aprimary screening box and a secondary screening box. The grinding box is arranged above the pedestal, the primary screening box and the secondary screening box are respectively installed on a first slide bar and a second slide bar, the right end of the first slide bar is fixedly connected to a first rack, and the right end of the second slide bar is also fixedly connected to a second rack, and the output shaft of a second driving motor is equipped with a special-shaped rotating wheel. The device provided by the invention utilizes the rotation of the second driving motor to realize left and right swinging of the primary screening box and the secondary screening box at the same time, and the left and right swinging of the primary screening box and the secondary screening box can increase the screening speed, also through multi-dimensional vibration, the activated carbon screening speed is greatly enhanced, at the same time sieve mesh blocking by activated carbon particles can be avoided, and the working efficiency is improved.

Owner:重庆峰创科技有限公司

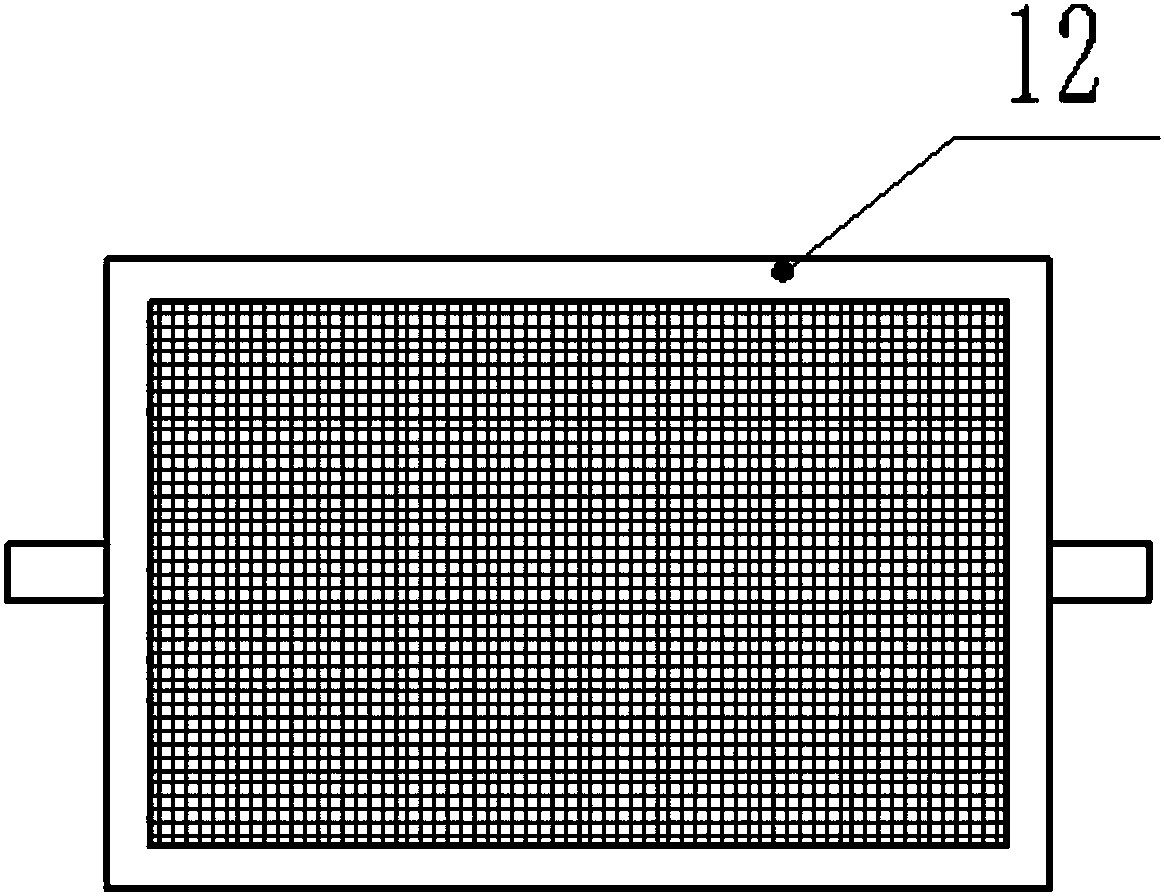

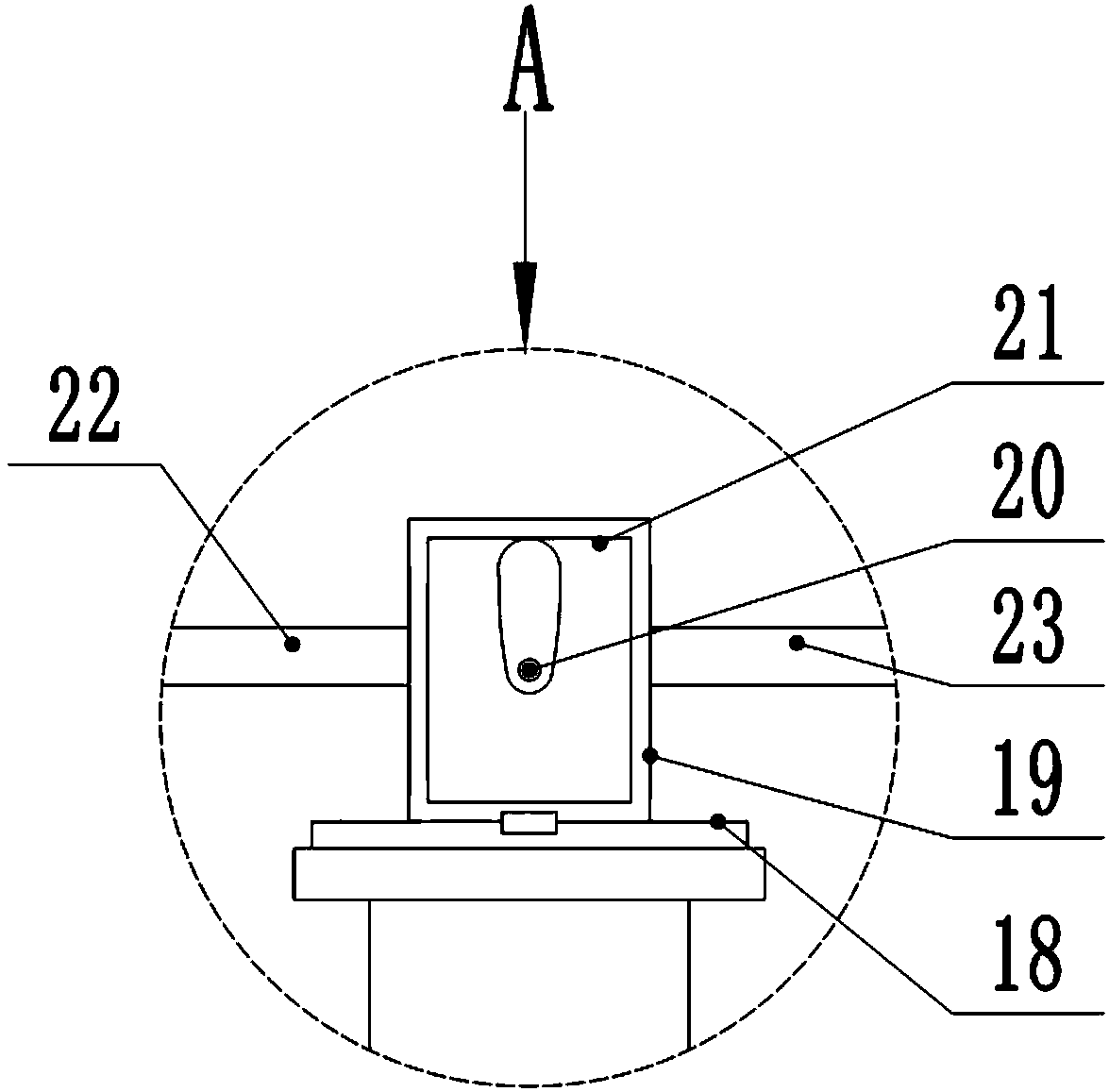

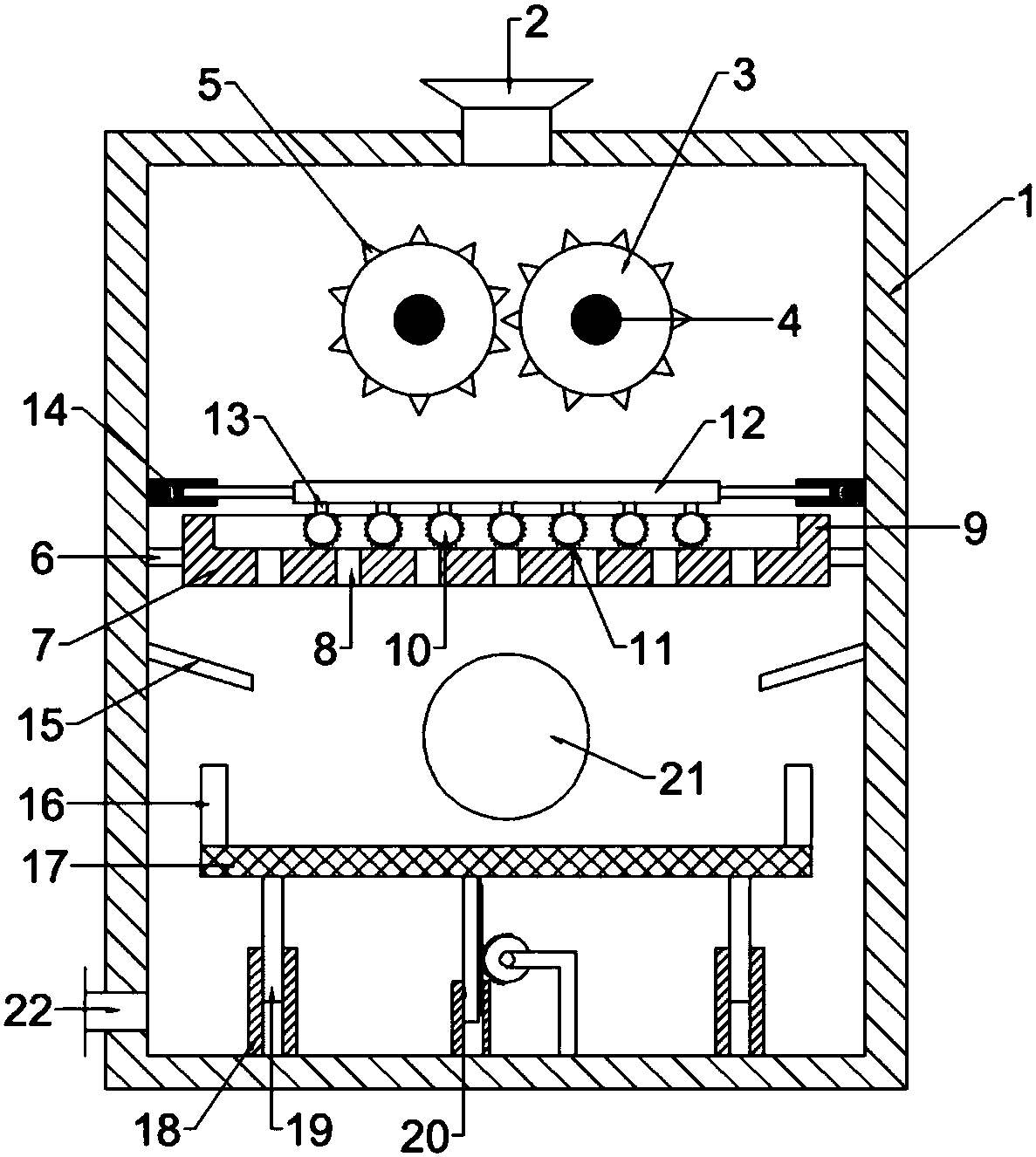

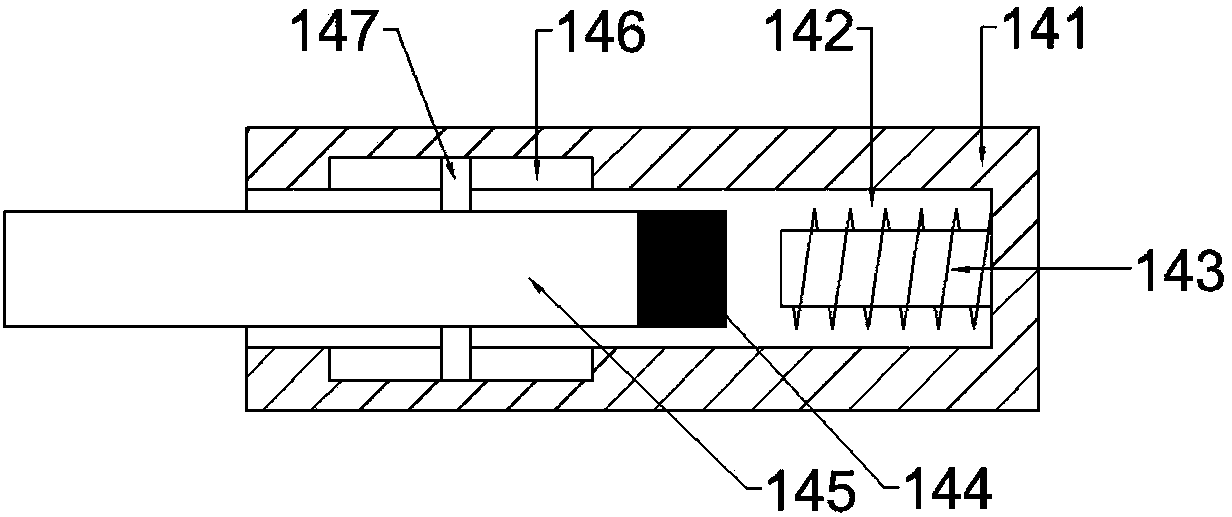

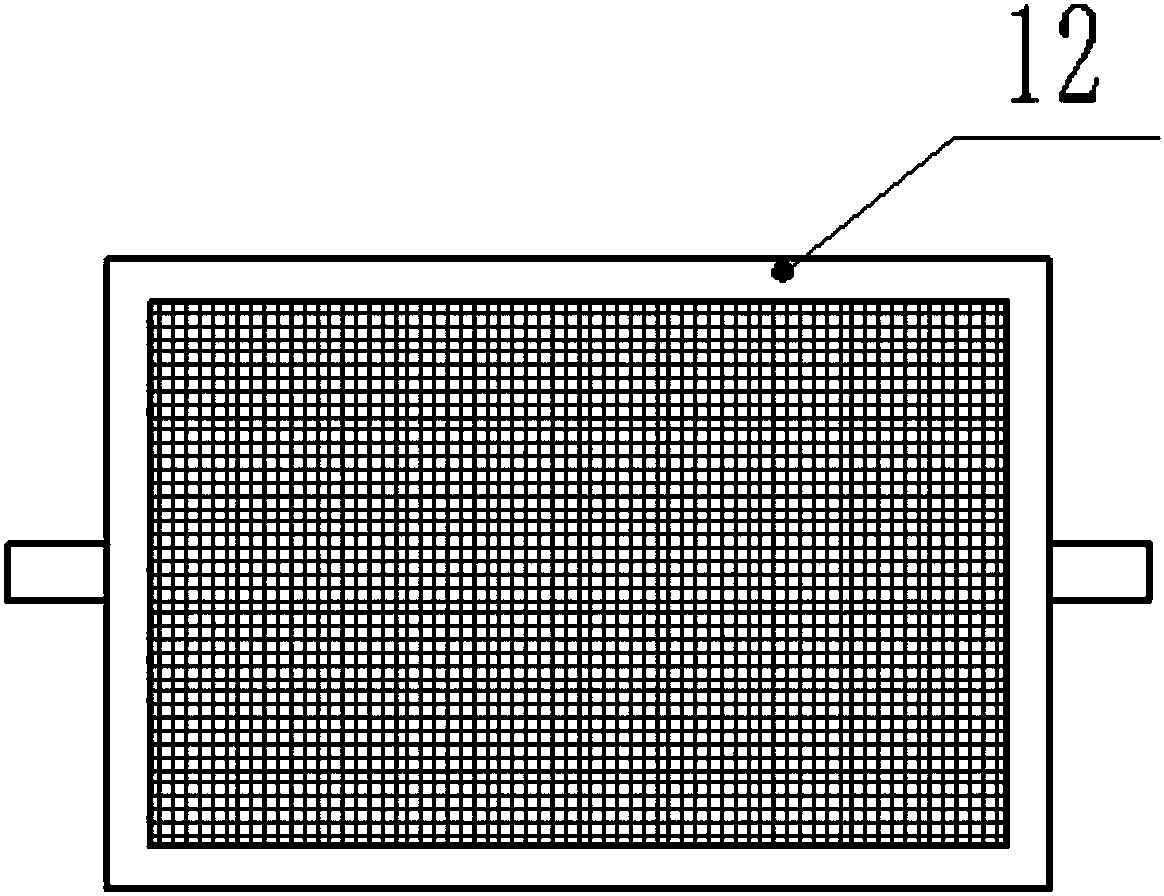

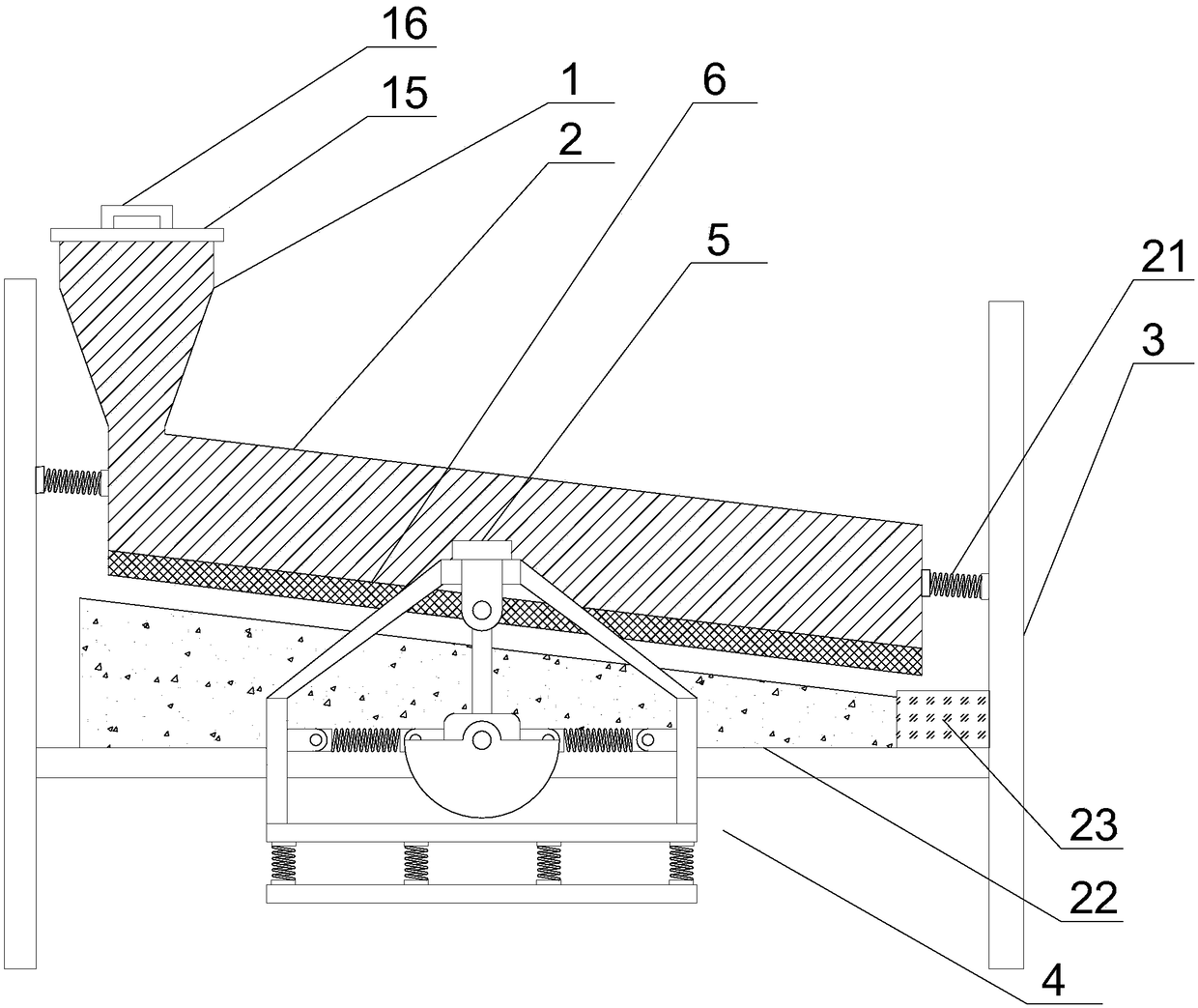

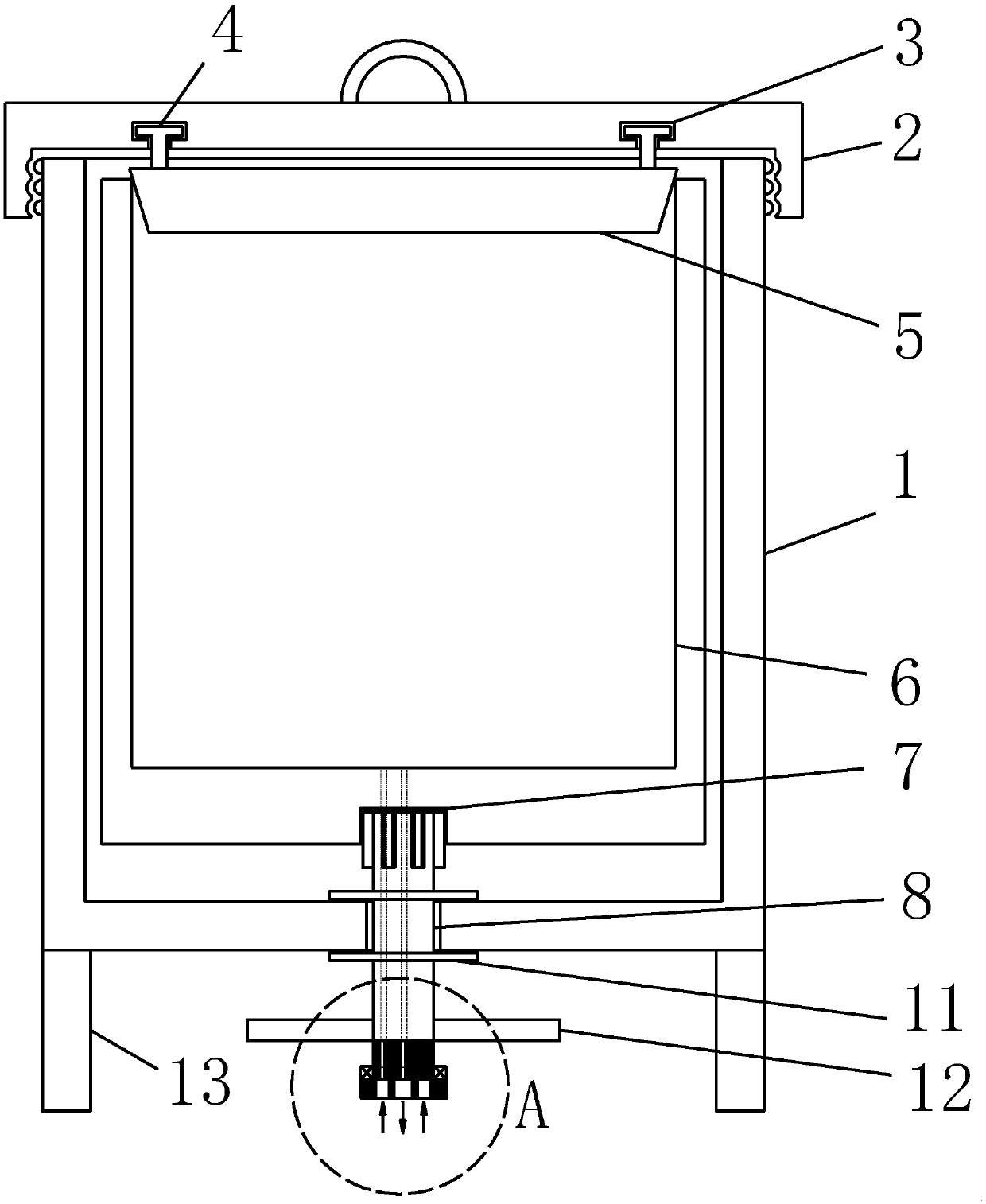

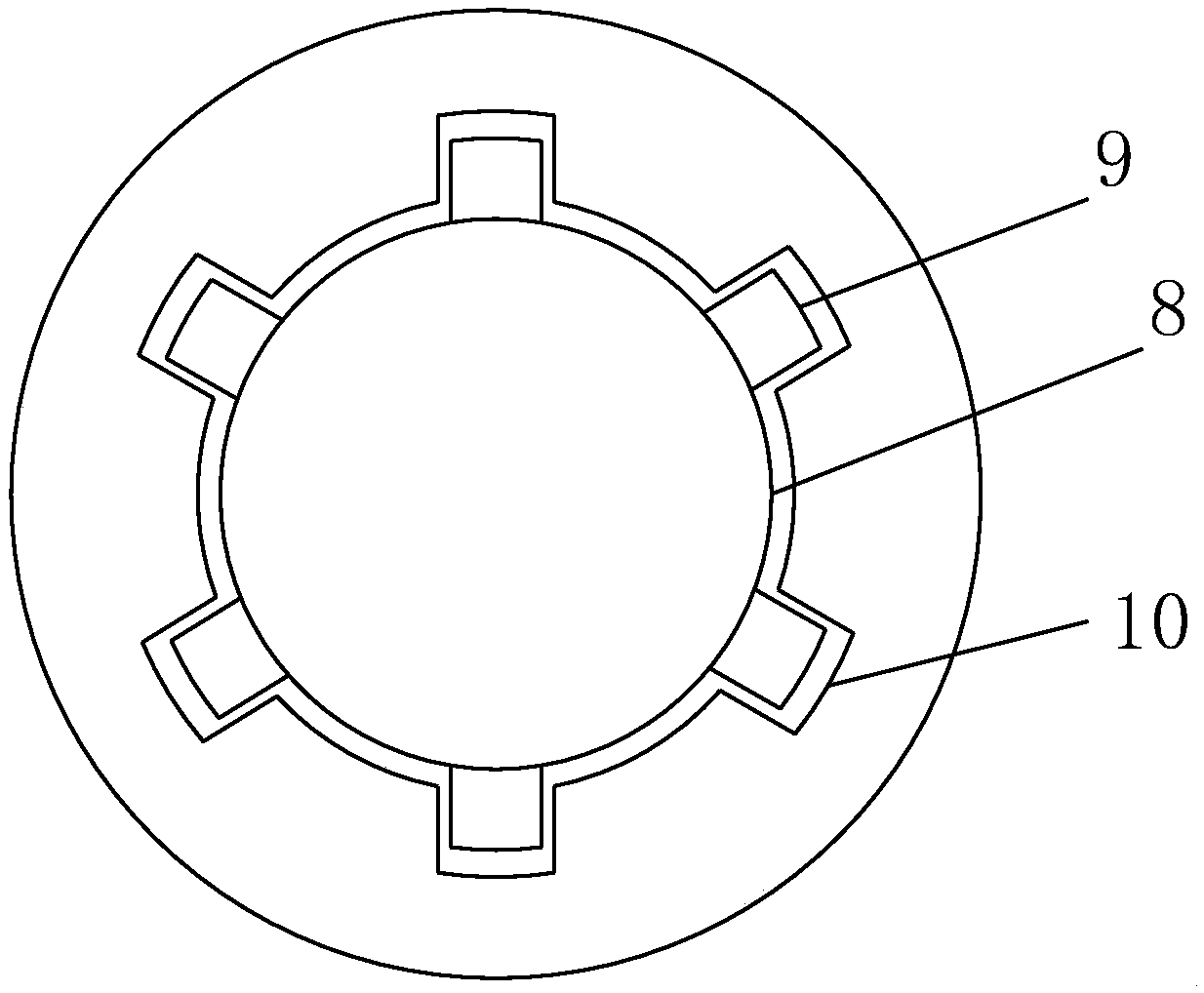

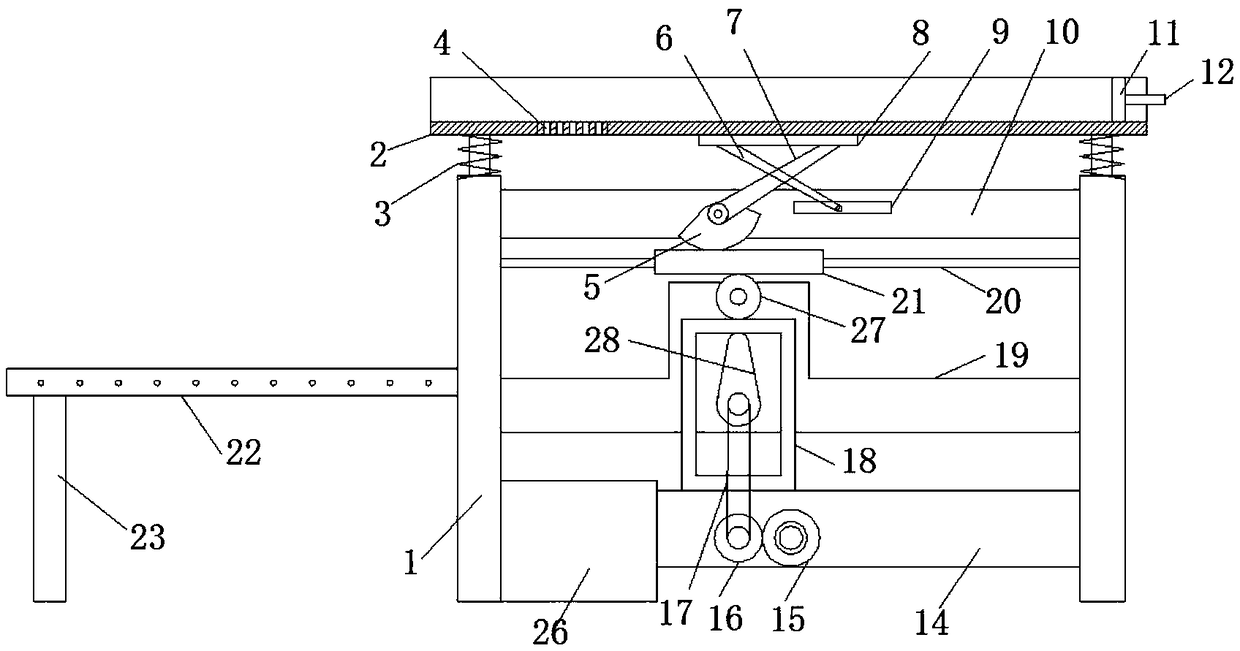

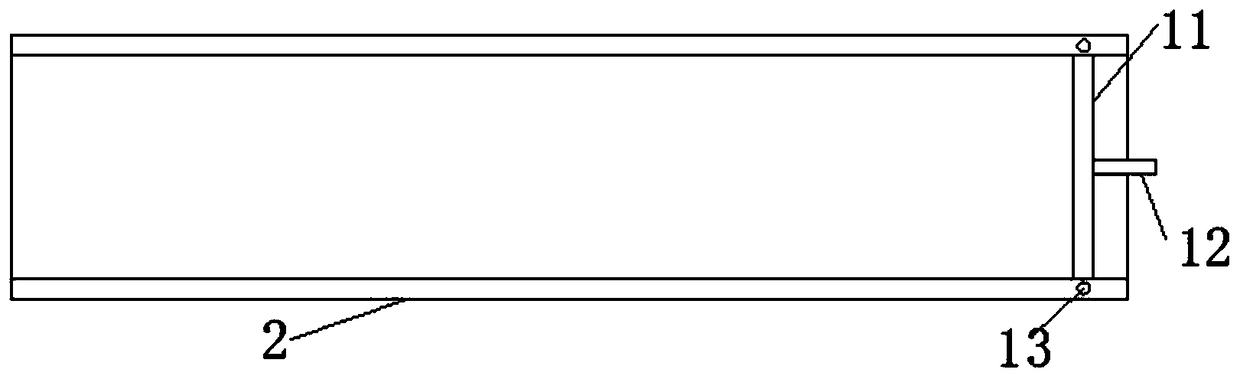

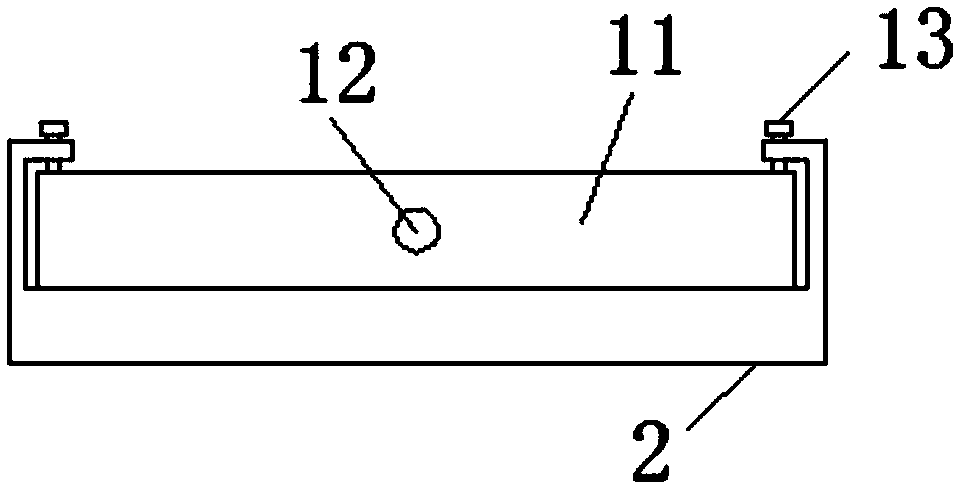

Vibration screening machine

ActiveCN107999387ASimple structureImprove screening efficiencySievingScreeningMotor driveSlide plate

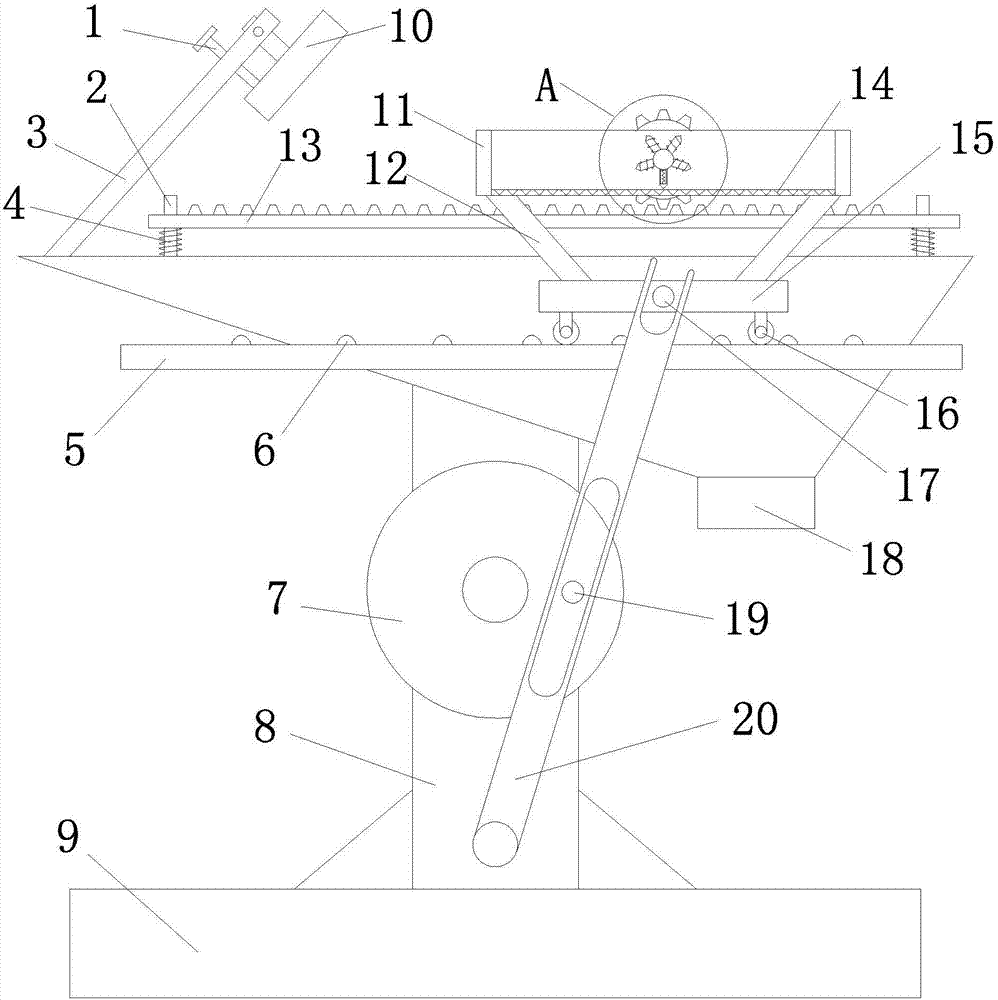

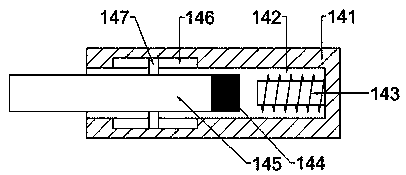

The invention discloses a vibration screening machine. The vibration screening machine comprises a base, a hopper is connected to the top of the base through a vertical rod, a mounting frame is arranged above the hopper, and the inner wall of the mounting frame is connected with a screen and rotationally connected with a rotating shaft. The vibration screening machine is simple in structure, a motor drives a rotating plate to rotate, the rotating plate drives a swinging rod to swing through a second fixing pin, then the swinging rod drives a sliding plate to move left and right through a firstfixing pin, the sliding plate drives the mounting frame and the screen to move left and right through supporting rods so that materials on the screen can shake, the screening efficiency is improved accordingly, idler wheels make contact with arc blocks intermittently when the sliding plate moves so that vertical vibration of the sliding plate can be achieved, vibration of the mounting frame is achieved accordingly, and the screening efficiency is further improved; meanwhile, when the mounting frame moves, a gear and a rack are engaged, stirring rods are driven by the rotating shaft to rotate,the materials can not only be spread but also be heated for moisture removal, and by means of springs, the effect that the gear is engaged with the rack all the time when the mounting frame is vibrated up and down can be ensured.

Owner:MEISEN IND TECH CO LTD

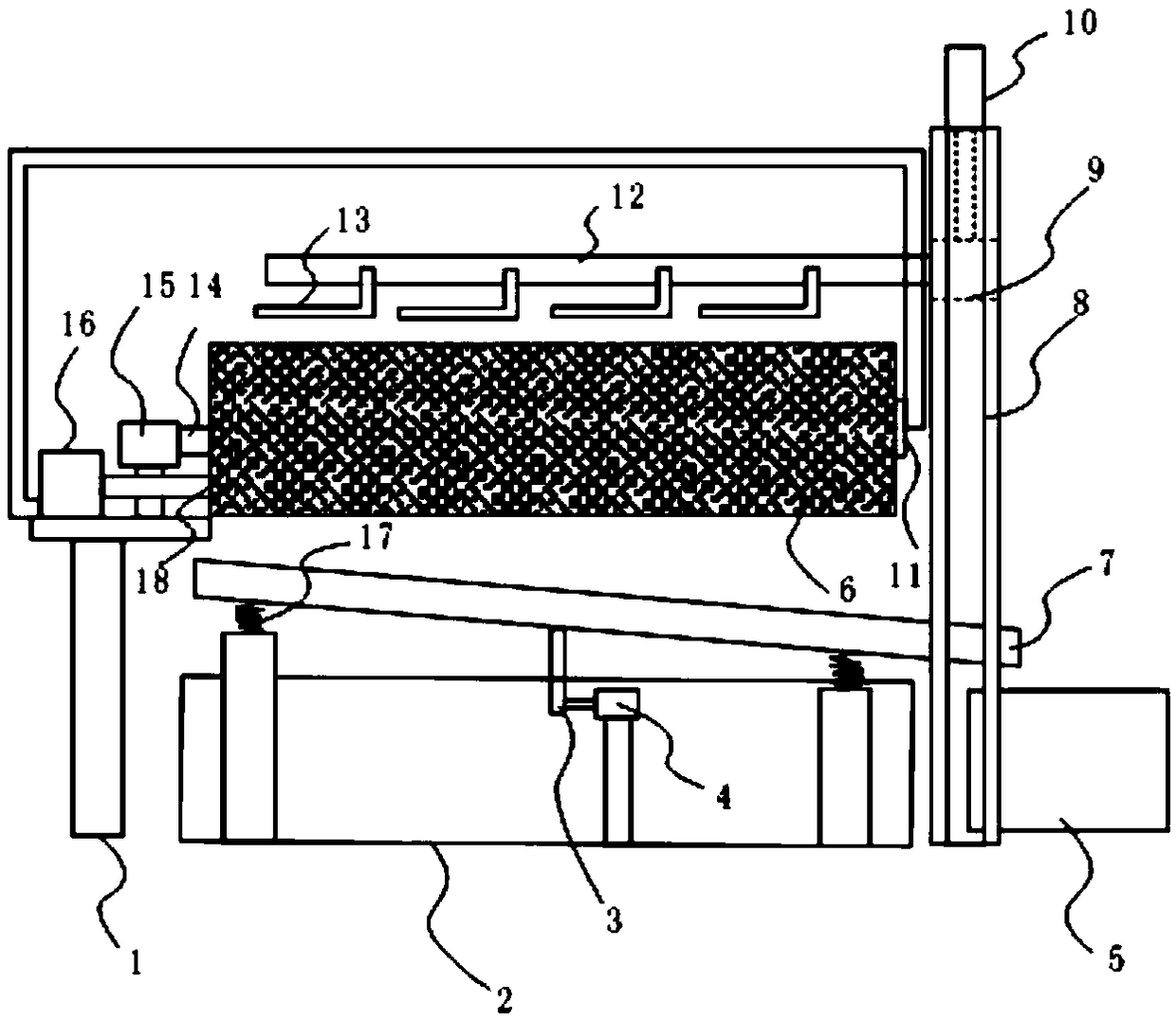

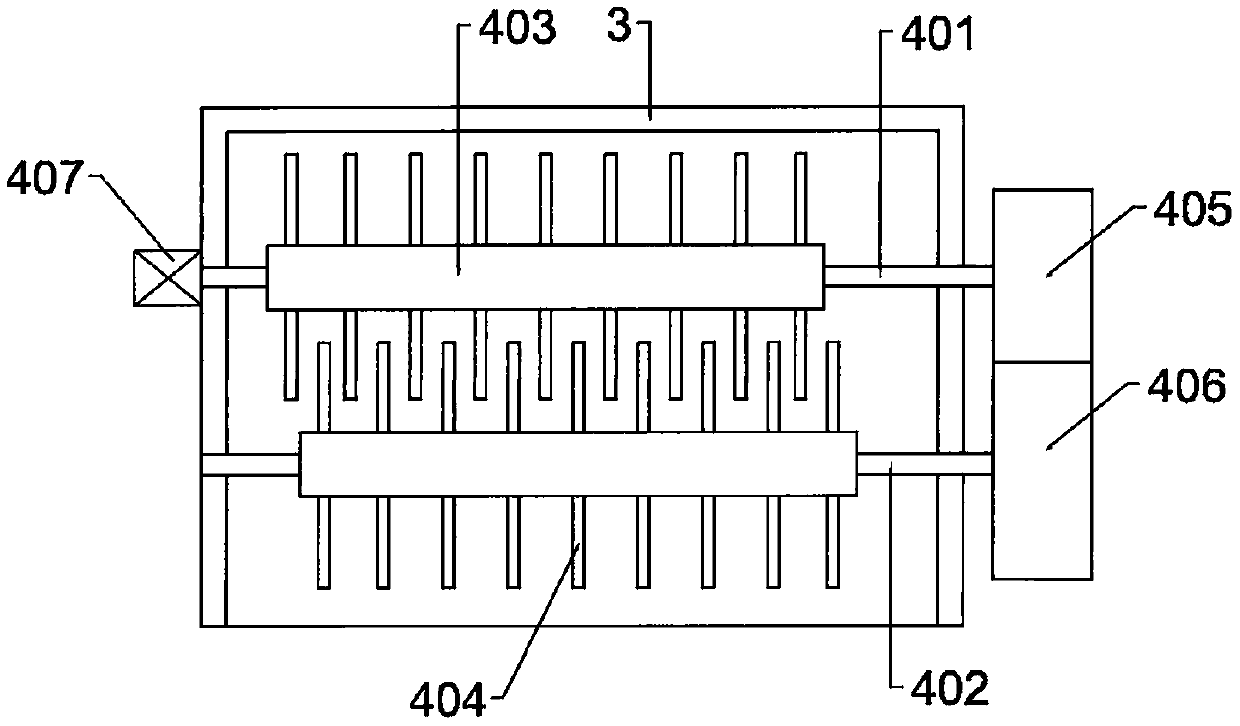

Electromagnetically driven vibration type activated carbon grinding and screening device

The invention discloses an electromagnetically driven vibration type activated carbon grinding and screening device. The device comprises a base, a grinding box, a first driving motor, a ball screw, agrinding groove, a primary screening box and a secondary screening box; and the grinding box is arranged above the base, the primary screening box and the secondary screening box are installed on a first sliding rod and a second sliding rod correspondingly, the right end of the first sliding rod is fixedly connected with a first rack, the right end of the second sliding rod is fixedly connected with a second rack, and a special-shaped rotating wheel is further installed on an output shaft of a second driving motor. According to the device, left-and-right swinging of the primary screening boxand the secondary screening box can be realized at the same time by utilizing the rotation of the second driving motor, the screening speed can be increased through left-and-right swinging of the primary screening box and the secondary screening box, during screening, through multi-dimensional vibration, the activated carbon screening speed is greatly increased, meanwhile, the condition that screening holes are blocked by activated carbon particles is avoided, and the working efficiency is improved.

Owner:重庆峰创科技有限公司

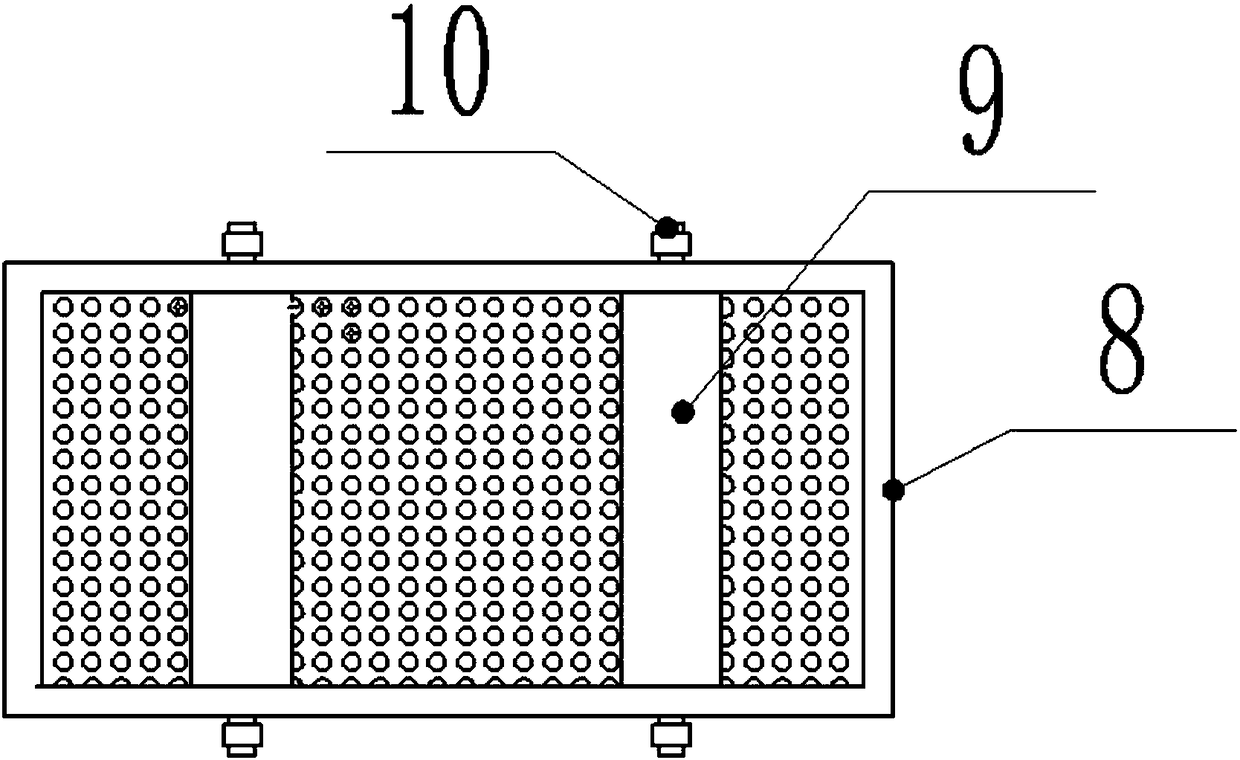

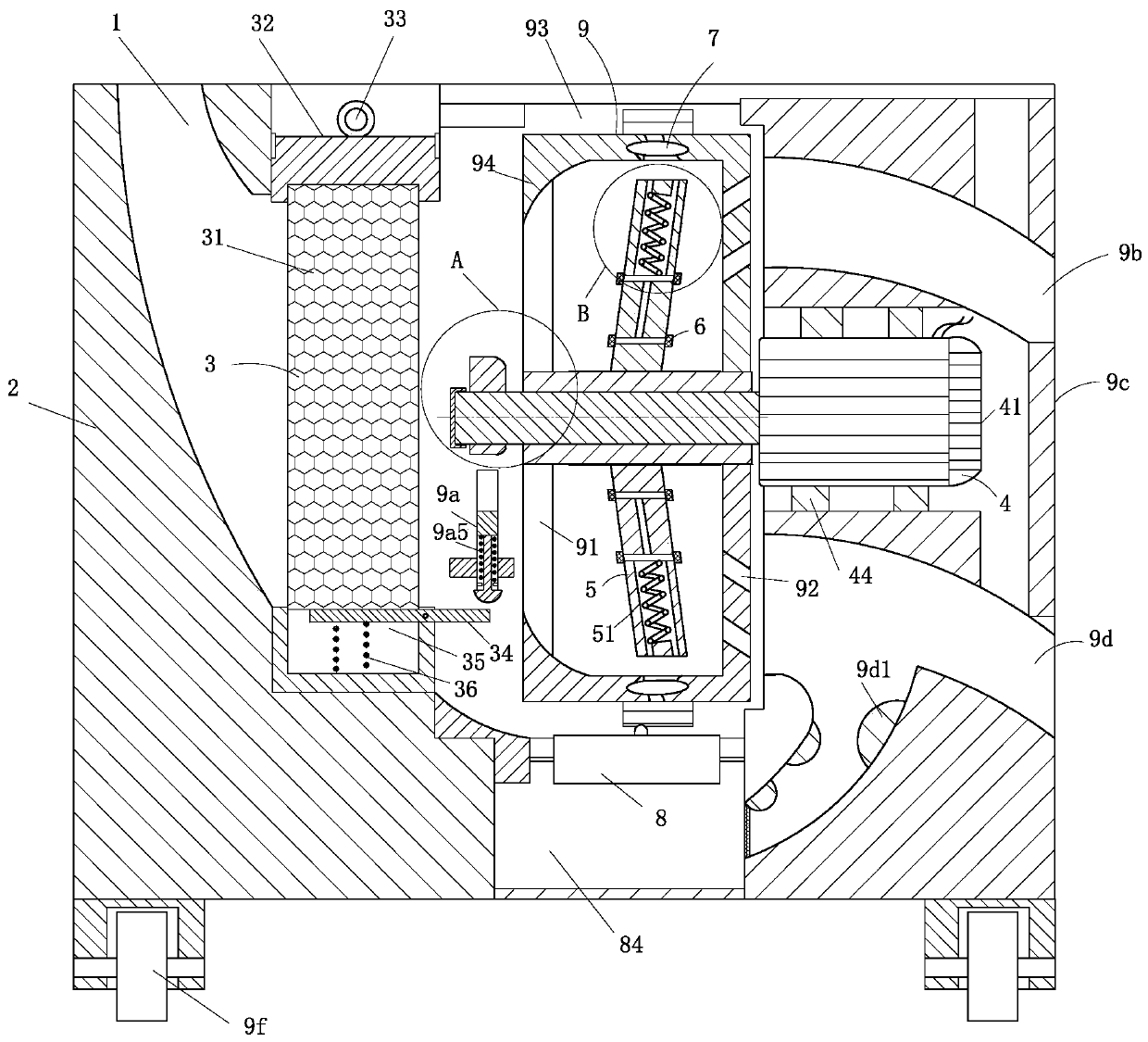

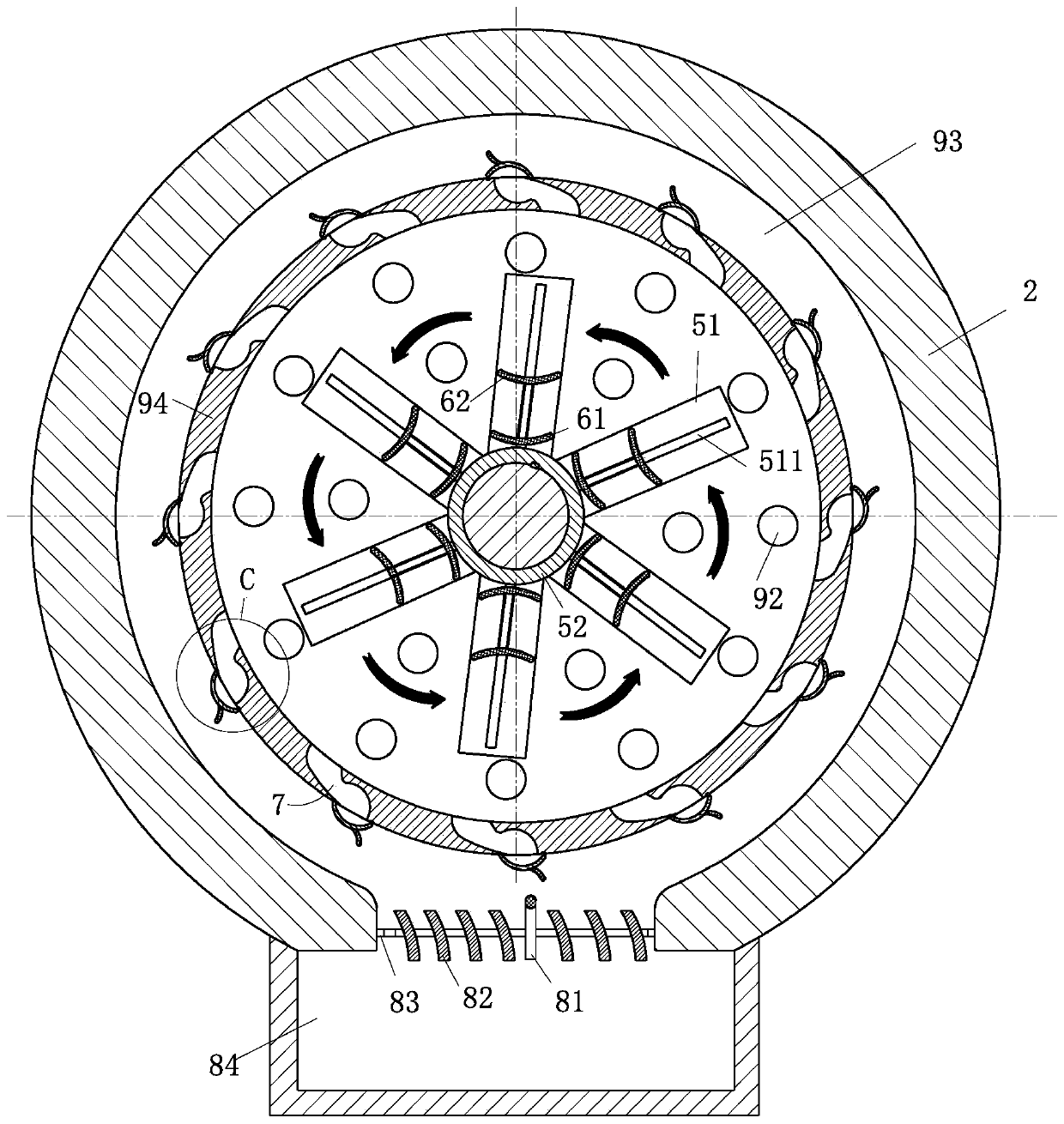

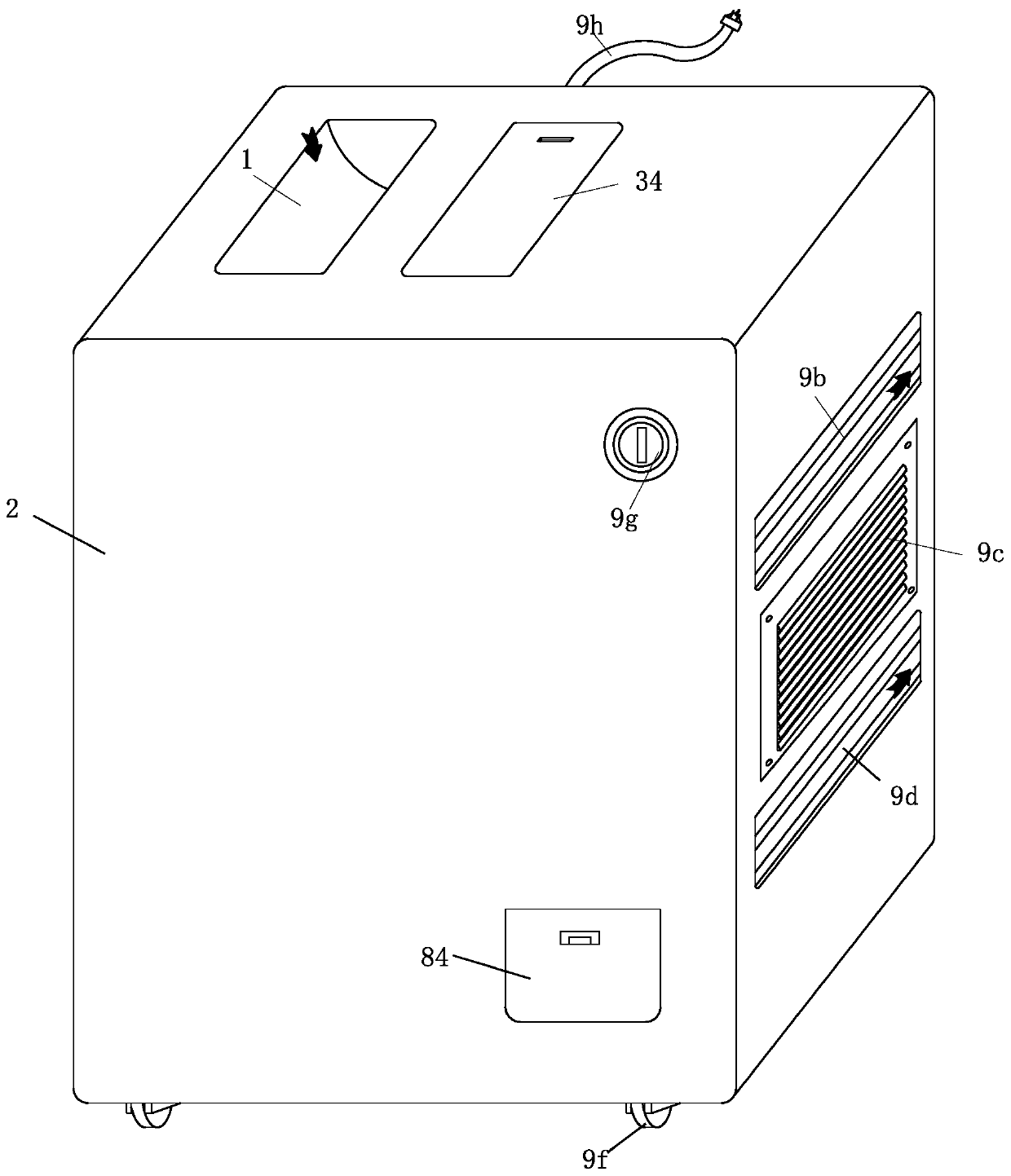

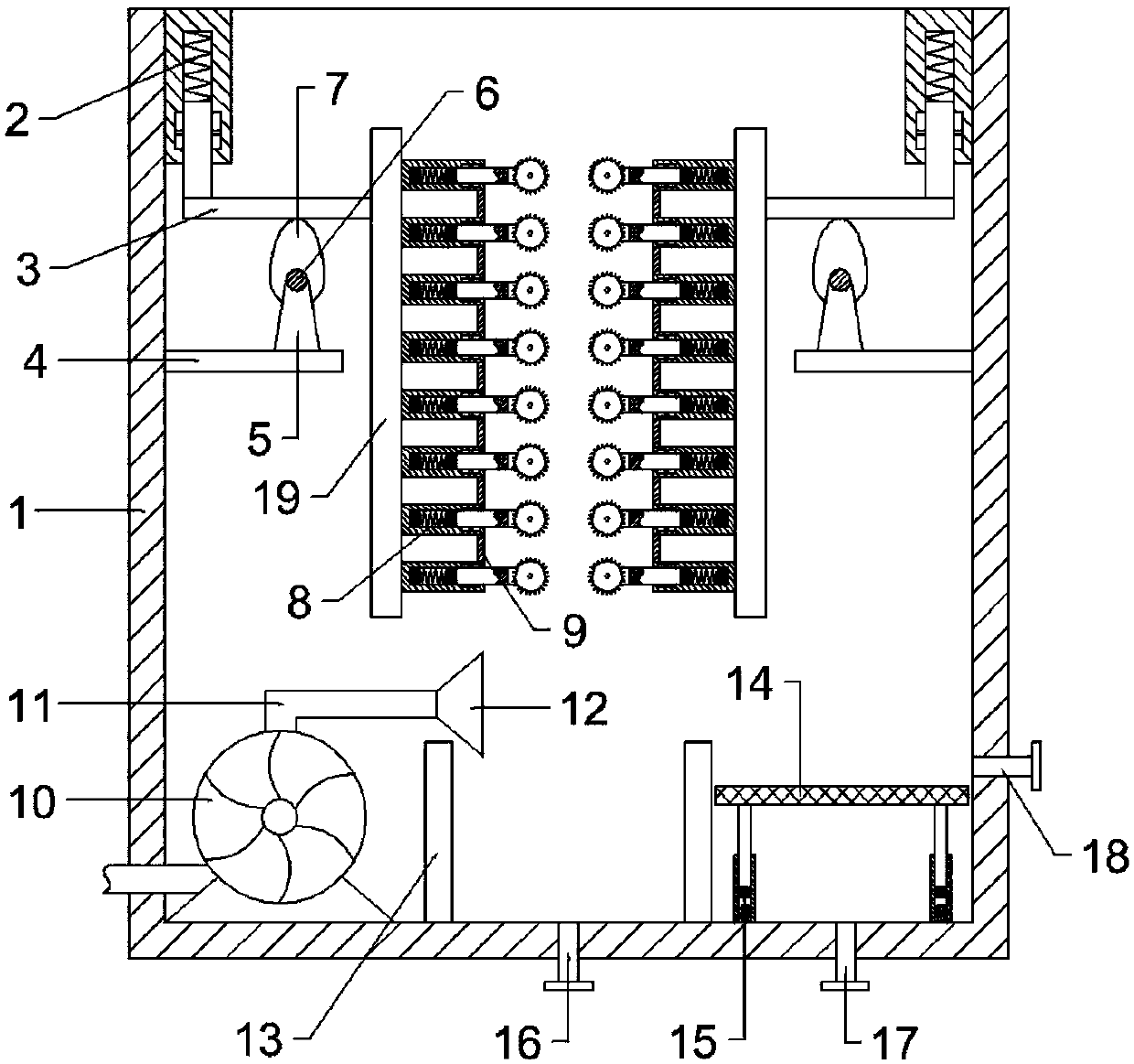

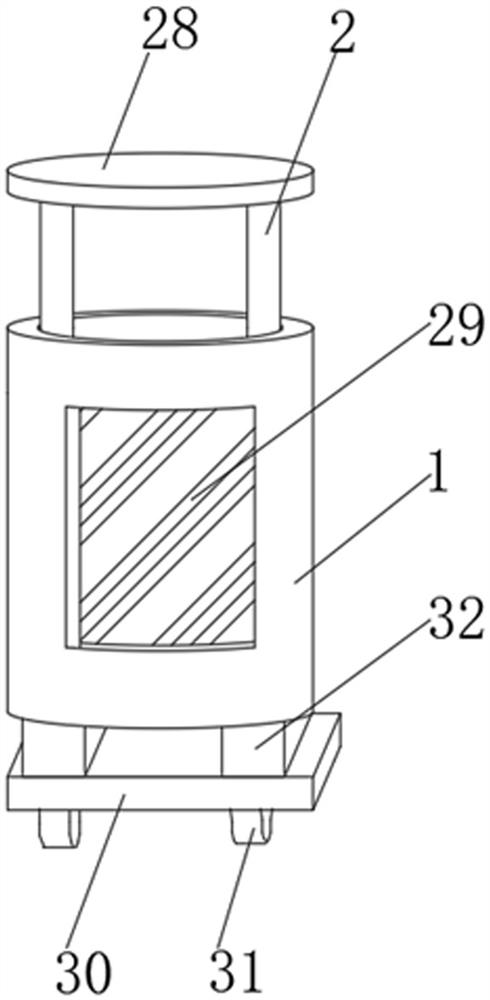

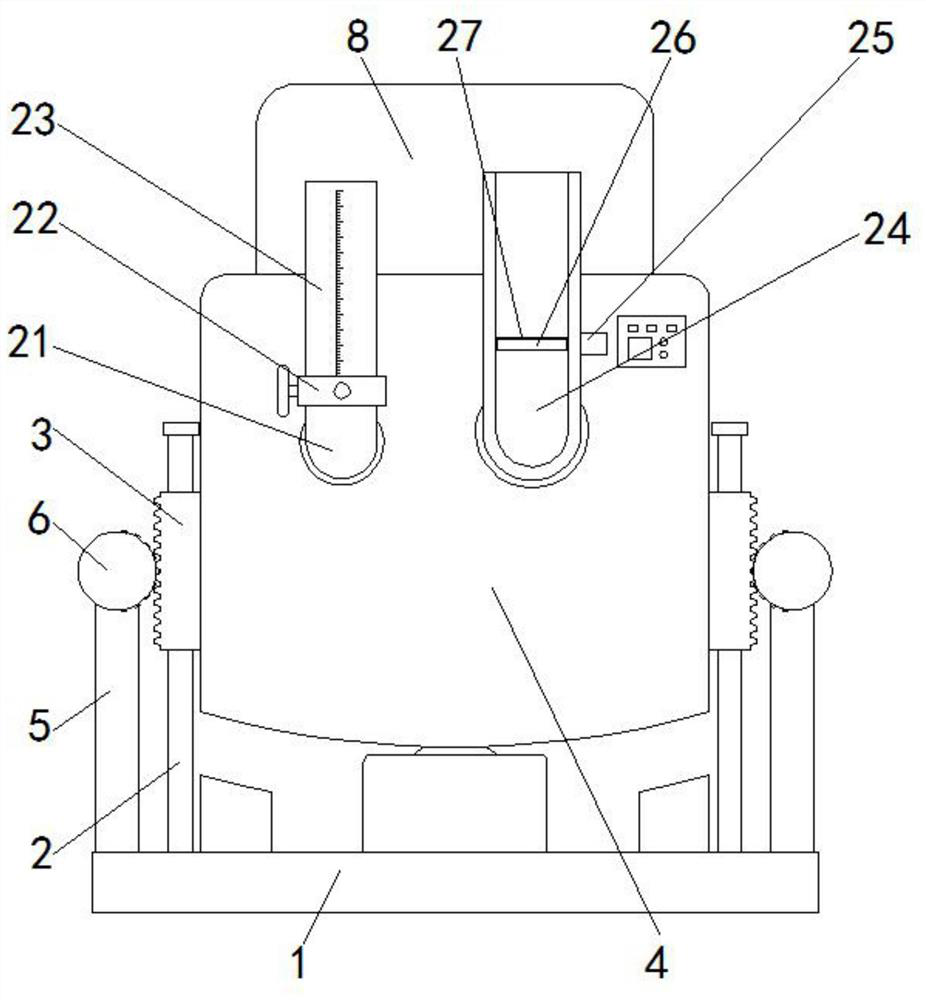

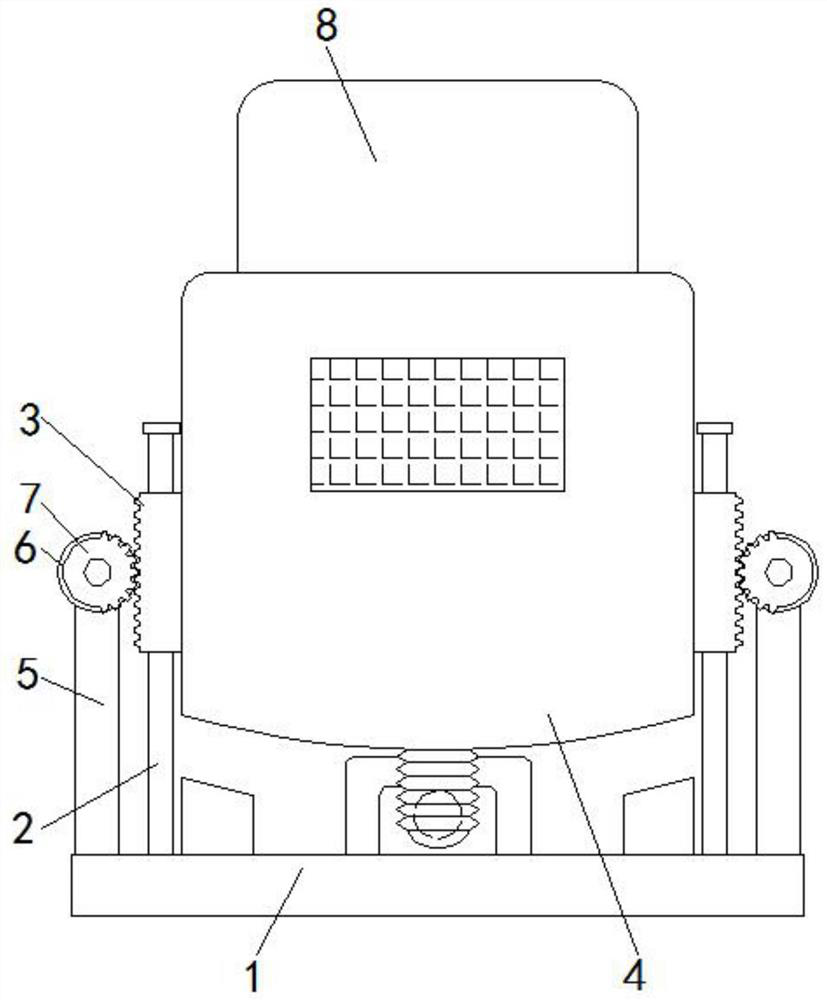

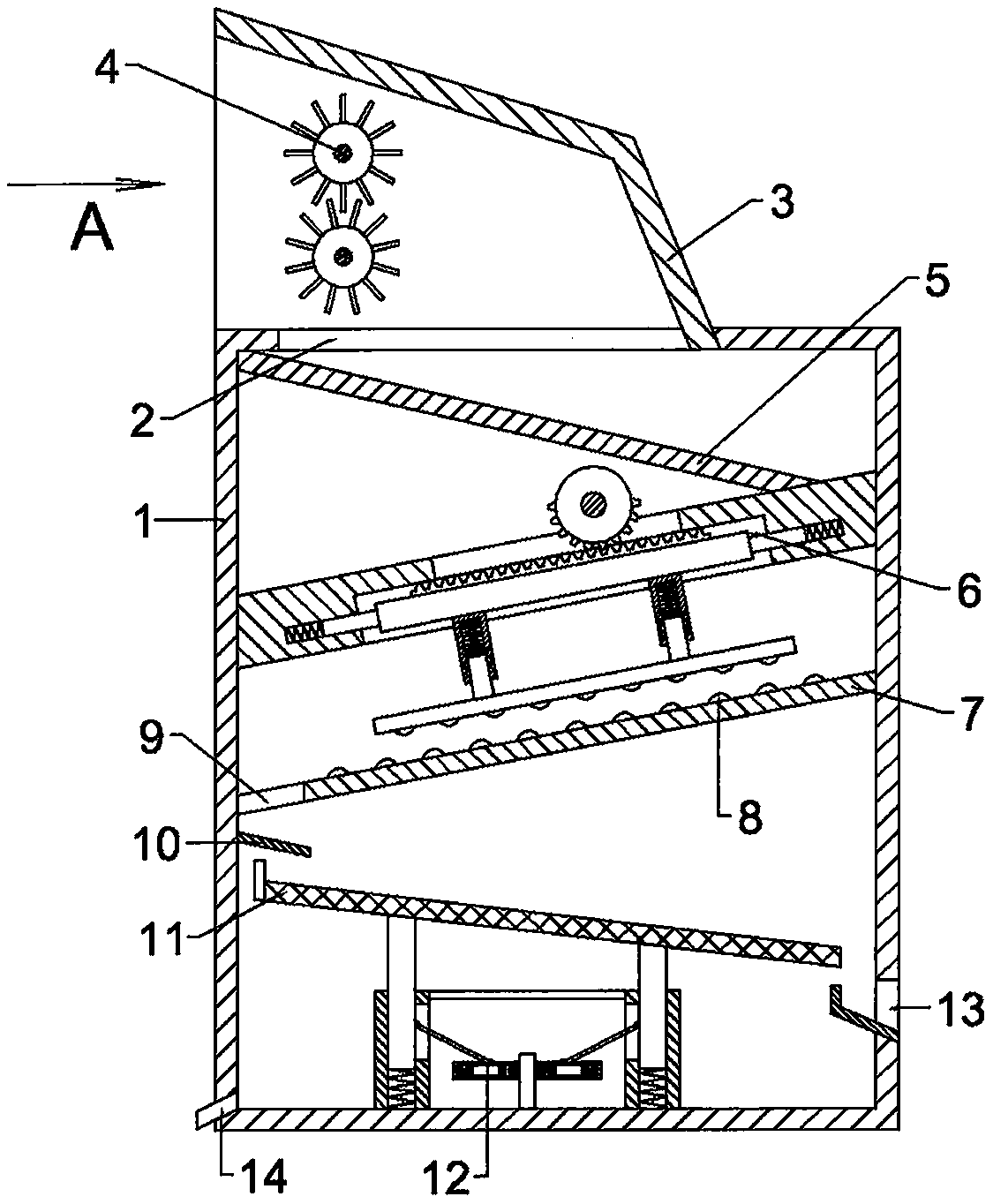

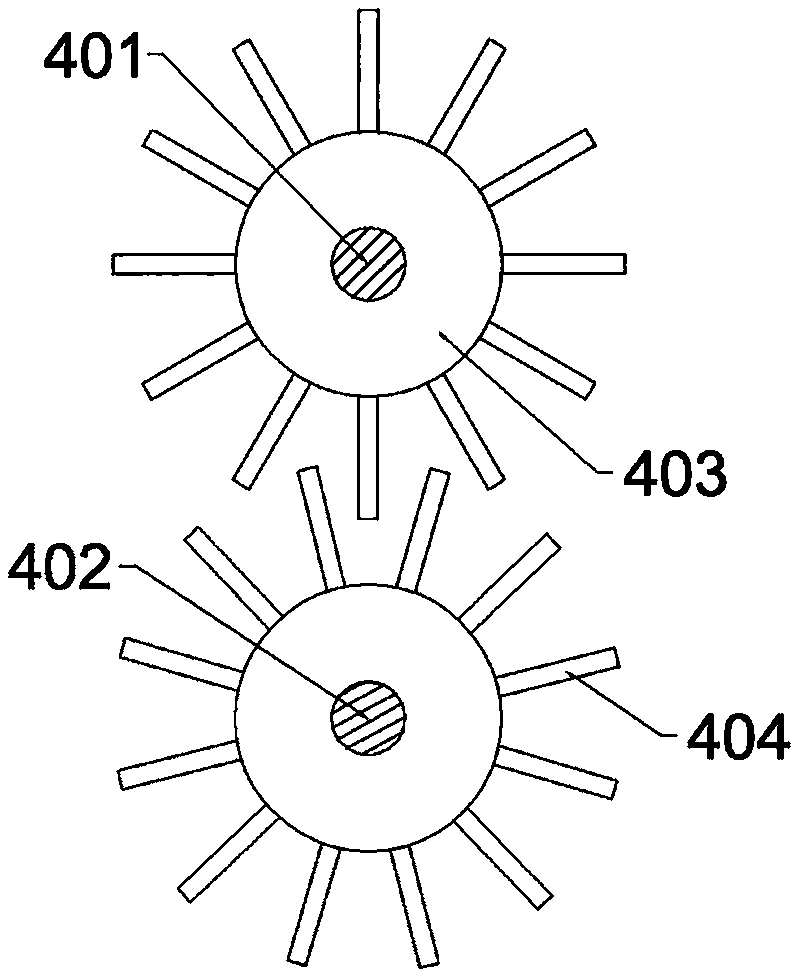

Environmental protection-based air purifier

ActiveCN110354589AImprove purification effectSpeed up circulationDispersed particle filtrationTransportation and packagingInlet channelAir purifiers

The invention relates to the field of purifiers, in particular to an environmental protection-based air purifier. The air purifier comprises a shell, an arc air inlet channel for the entering of the air is arranged in the shell, a filter mechanism for filtering the air is arranged in the shell, a power mechanism for providing power is arranged in the shell, and an air suction mechanism for producing the suction is arranged at one end of the power mechanism; a dust scraping mechanism for scraping the dust is arranged on the air suction mechanism, and a dust processing mechanism for processing the dust is arranged on the power mechanism; a storage mechanism for temporarily storing the dust is arranged on the dust processing mechanism, and a shaking mechanism is arranged on one side of the dust processing mechanism; and a collecting mechanism for collecting the dust is arranged in the shell. The dust cleaning on the blade can be realized without dismounting, the frequency of changing a filter screen is reduced, the air purification effect is better, and the service life of the purifier is prolonged.

Owner:山东同其数字技术有限公司

Iron ore screening device for converter

PendingCN108927336AAvoid cloggingImprove efficiencySievingGas current separationSteelmakingEngineering

The invention relates to the field of steelmaking production, in particular to an iron ore screening device for a converter. The iron ore screening device for the converter comprises a machine frame,material grooves, a vibrating device, a screening device and a crushing machine. The screening device comprises a drum screen and a rotating shaft. A feeding inlet is formed in one end of the drum screen, and a discharging outlet is formed in the other end of the drum screen. The discharging outlet of the drum screen communicates with a feeding inlet of the crushing machine through a pipeline, anda discharging outlet of the crushing machine communicates with the feeding inlet of the drum screen through a pipeline. A filtering net is arranged below the drum screen and is downwards inclined inthe extending direction. The two material grooves are arranged and include the small-particle-size material groove and the large-particle-size material groove, wherein the small-particle-size materialgroove and the large-particle-size material groove are arranged below the filtering net. The vibrating device comprises a vibrating frame, a vibrating connecting plate and a plurality of vibrating plates. A sliding rail is installed on the vibrating frame, and a sliding block is installed on the sliding rail. The end of the vibrating connecting plate is fixedly connected with the sliding block, and the multiple vibrating plates are fixedly installed on the vibrating connecting plate. The iron ore screening device for the converter is simple in structure, saves the time and labor, can rapidlyachieve screening of iron ore and cannot cause blocking of the filtering net.

Owner:YANCHENG LIANXIN IRON & STEEL CO LTD

Peanut coat collecting device based on vertically interlaced peeling

ActiveCN107692248AUpward movement achievedRealize reciprocating motionSievingScreeningMotor driveReciprocating motion

The invention provides a peanut coat collecting device based on vertically interlaced peeling. The peanut coat collecting device comprises a frame body, wherein the top of the frame body is in an openshape, two suspension devices are symmetrically fixedly connected on the two inner side walls of the frame body, the bottom of each suspension device is fixedly connected with a horizontal plate, oneend of each horizontal plate is fixedly connected with an interlacing plate, and a plurality of peeling devices are uniformly arranged on the sidewalls of the interlacing plates. The peanut coat collecting device has the following advantages: firstly, a motor drives a rotation shaft, the rotation shaft drives the rotation of a cam, and the horizontal plates in contact with the cam move upwards todrive the interlacing plates to move upward, and when the cam continues to rotate, the interlacing plates, under the action of a first spring and gravity, move downwards so that the upward movement of the interlacing plates is realized, thus the reciprocating motion of the interlacing plate can be realized repeatedly; secondly, as a second spring, a first magnetic pole, and a second magnetic poleare arranged to adapt to different sizes of peanuts so as to play a full peeling effect, the peanut coat collecting device has a good application value.

Owner:曹县万基商砼有限公司

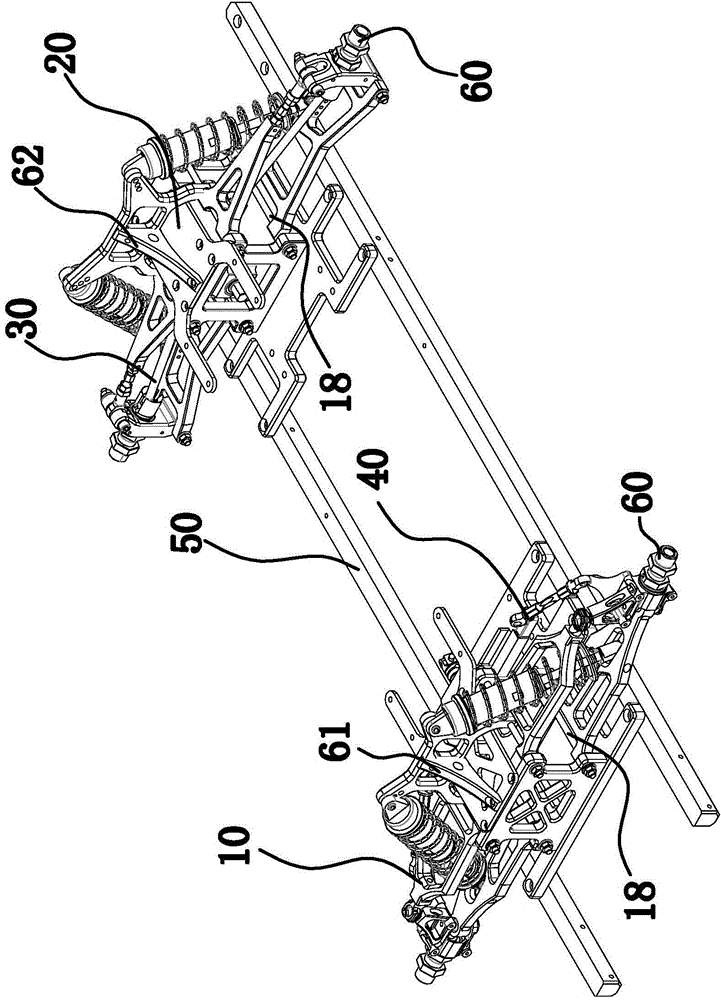

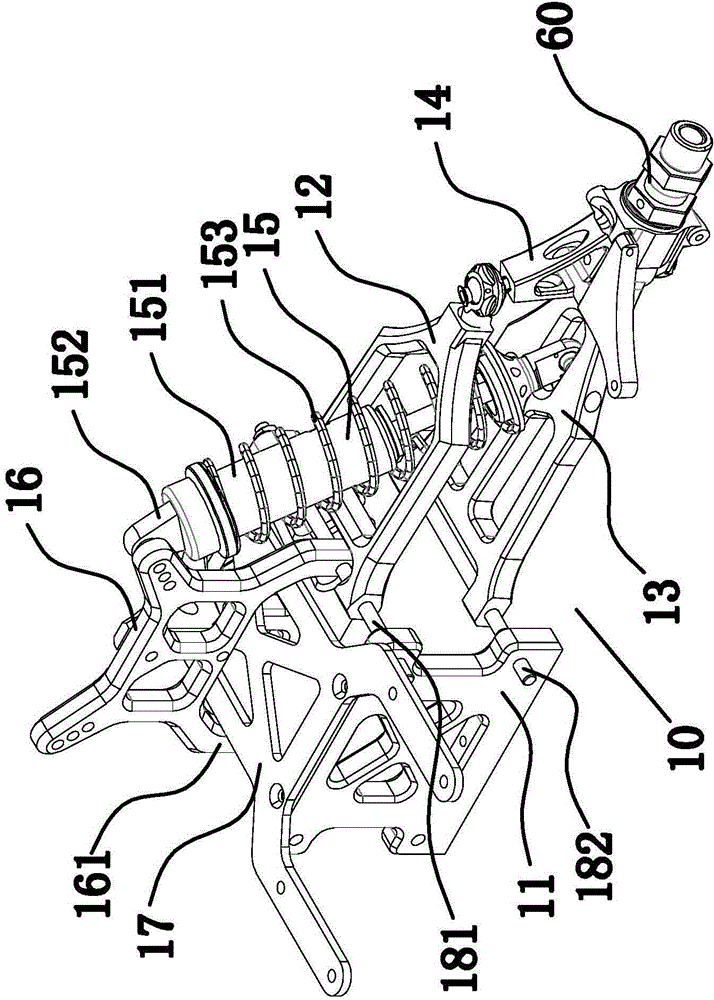

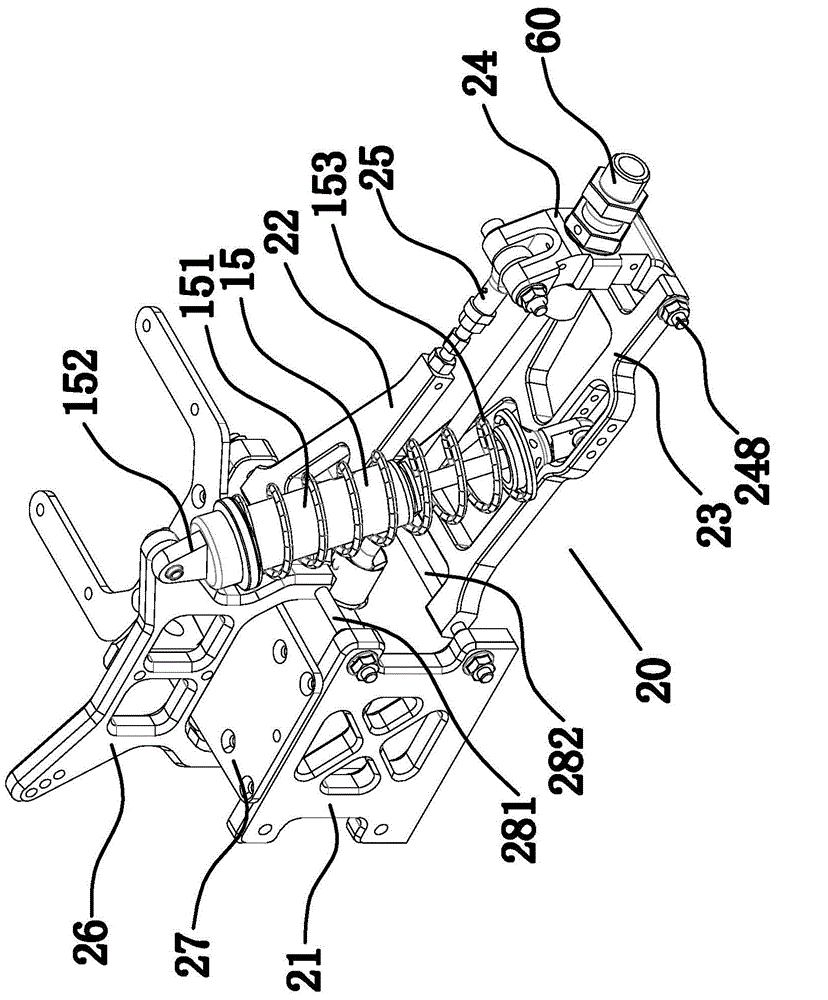

Suspension system for child automobile

ActiveCN103979057AVibration up and downEven by forceAxle suspensionsTransmission systemRolling chassis

The invention provides a suspension system for a child automobile, belongs to the technical field of child automobiles and solves the problems of complex structure and high cost of the conventional suspension system for toy automobiles. The suspension system for the child automobile comprises a front suspension system and a rear suspension system which are fixedly connected to a chassis, wherein the front suspension system is arranged at one end of the chassis, and is connected with a steering system; the rear suspension system is arranged at the other end of the chassis and the connected with the transmission system. The suspension system has the advantages of simple structure, high damping property and clear wheel motion locus.

Owner:安徽萨克赛斯服装有限公司

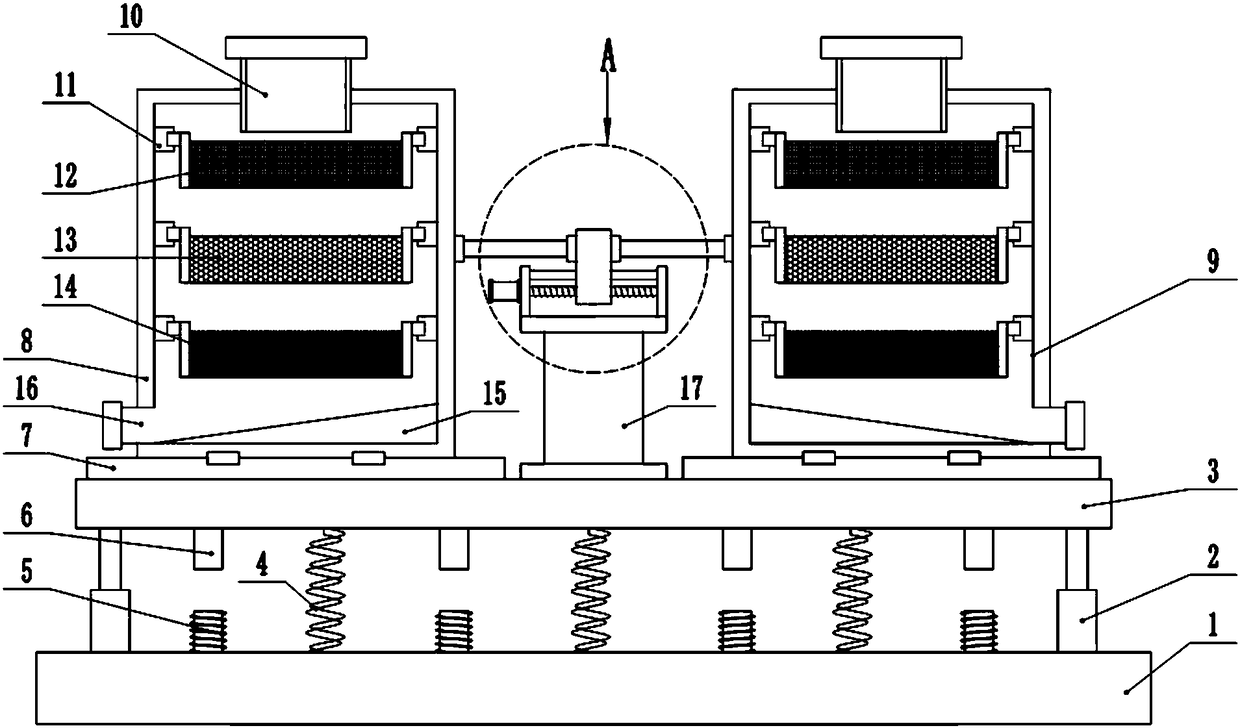

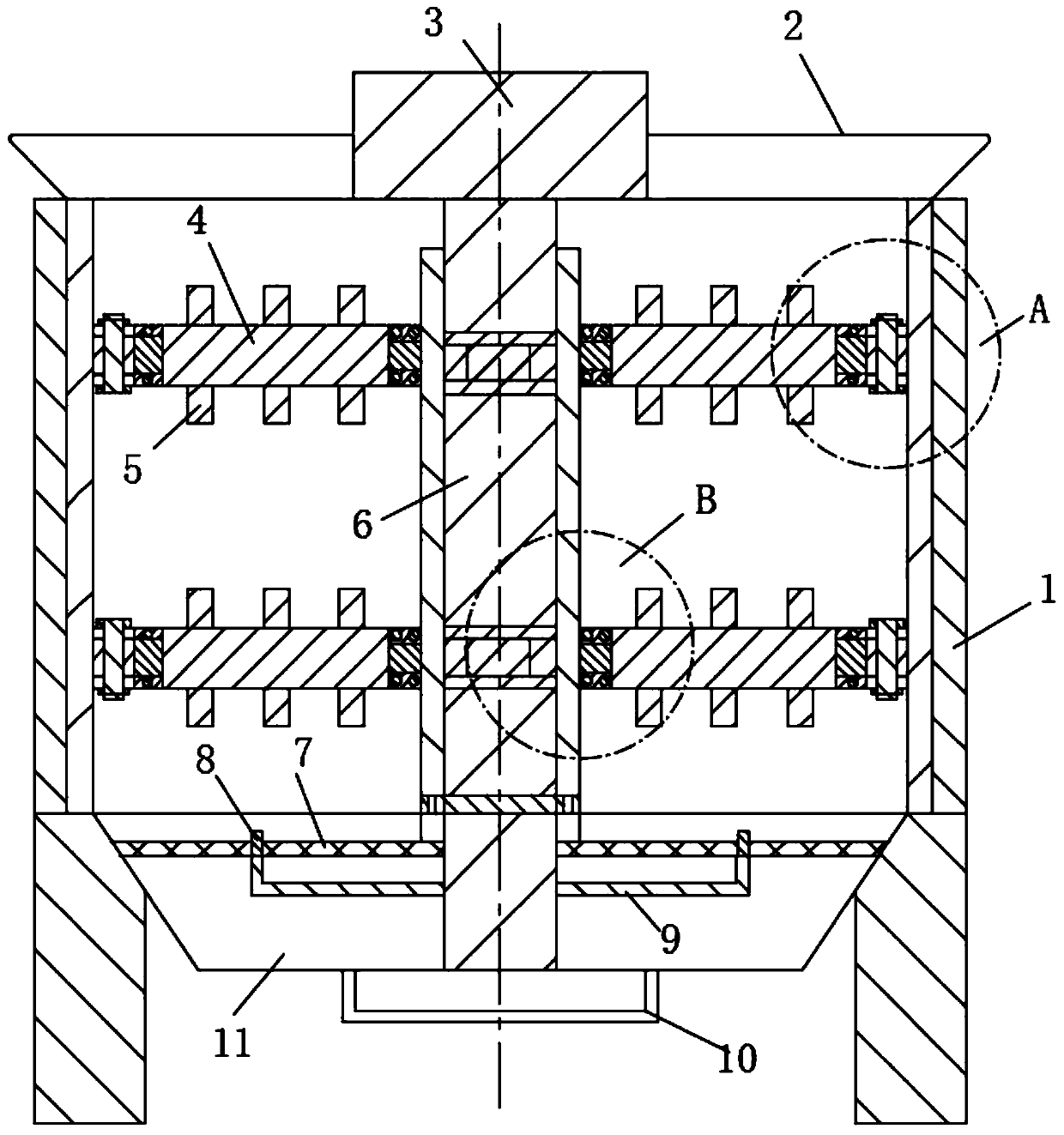

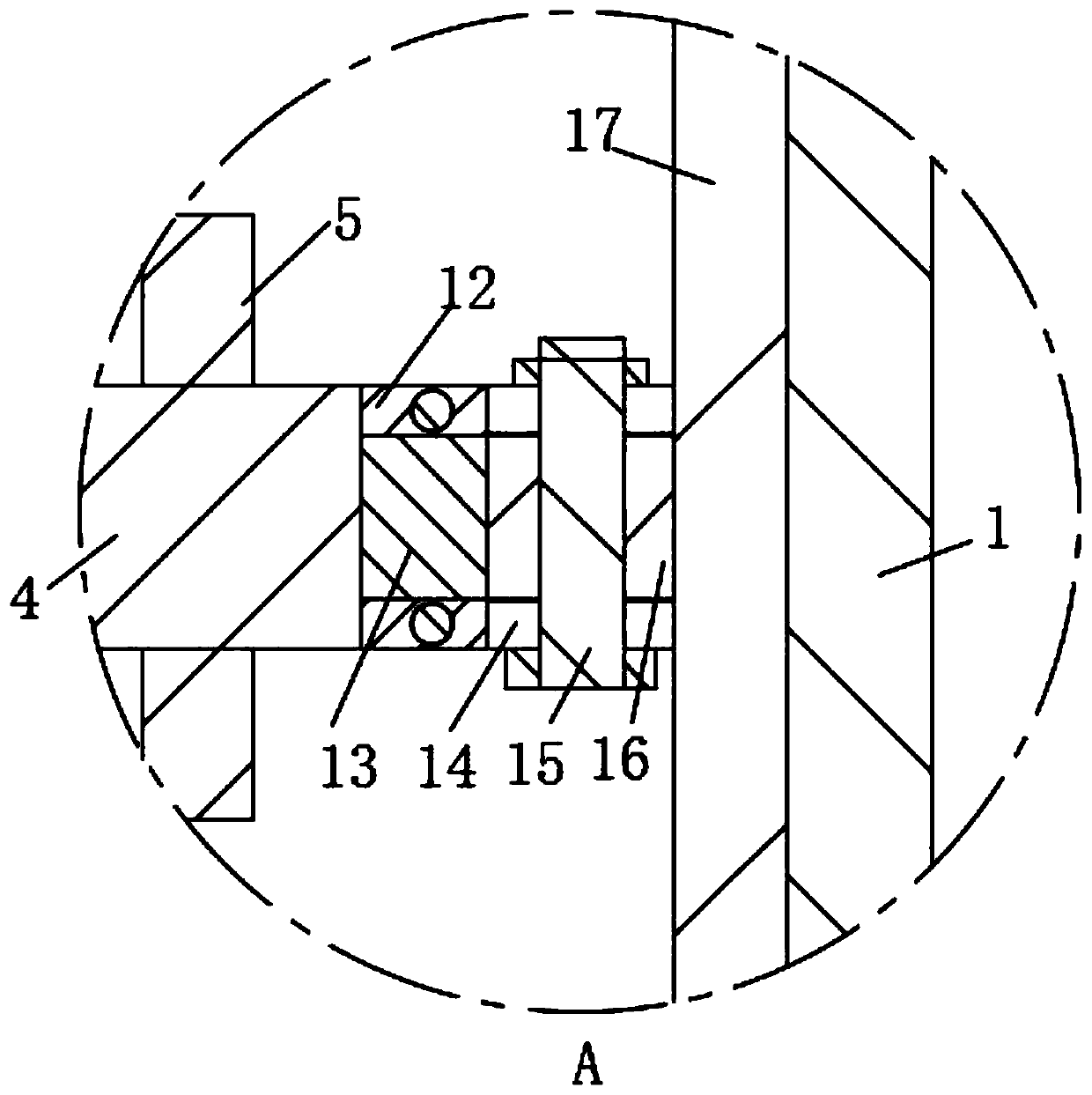

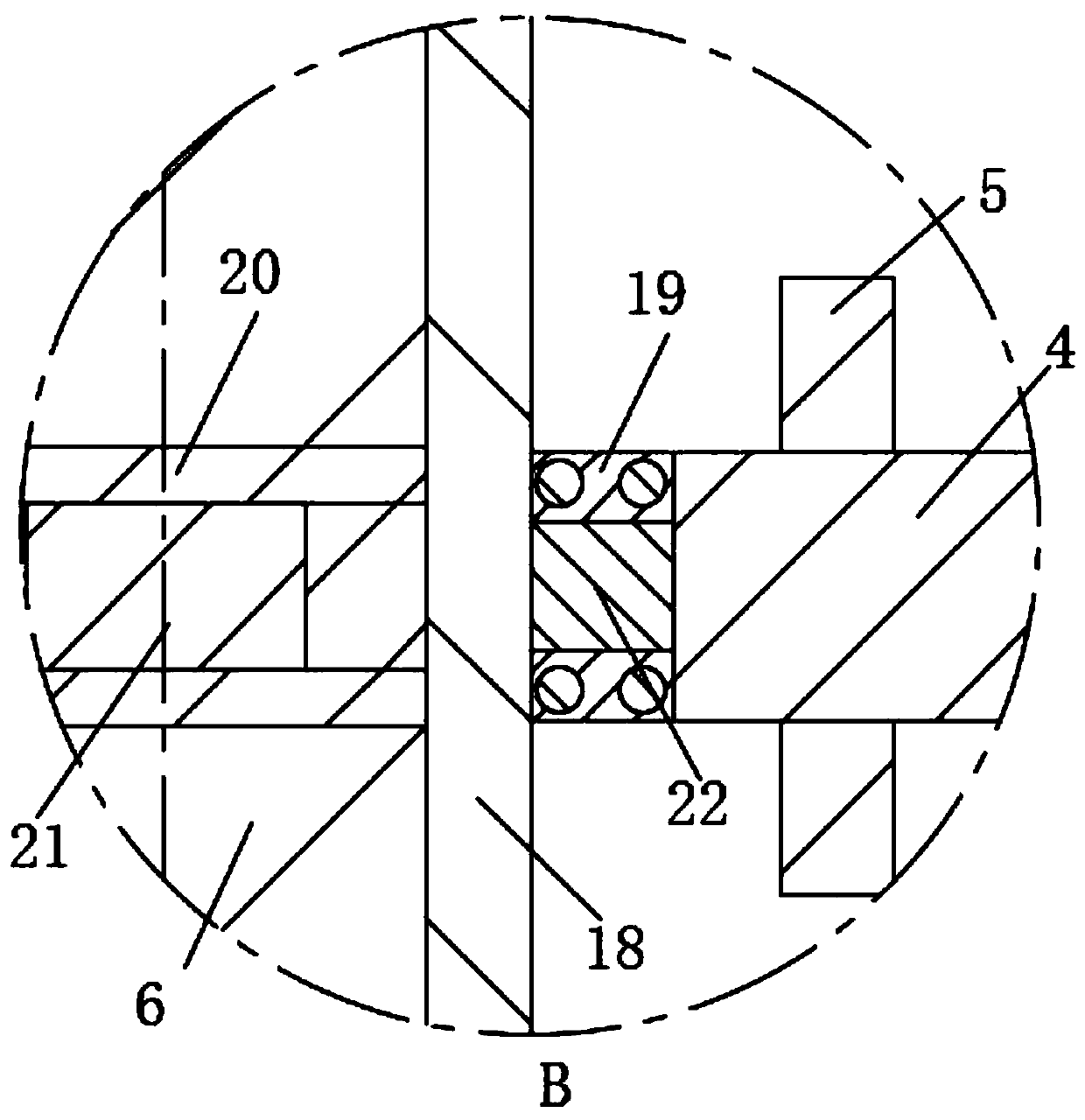

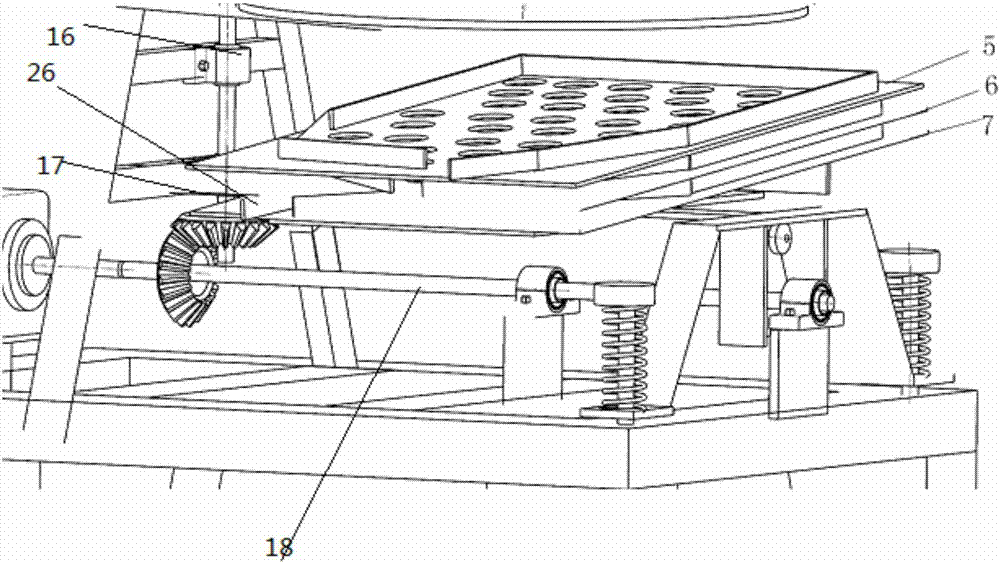

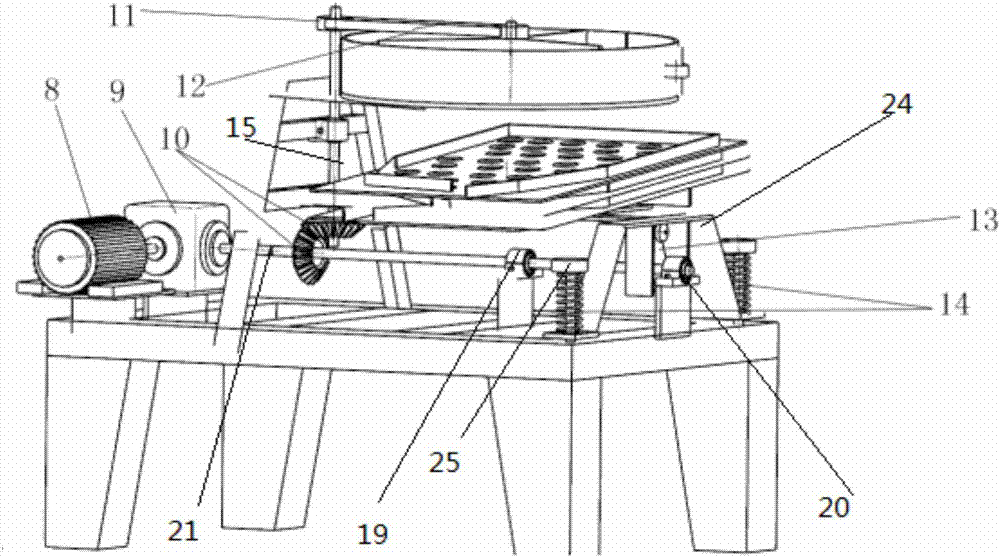

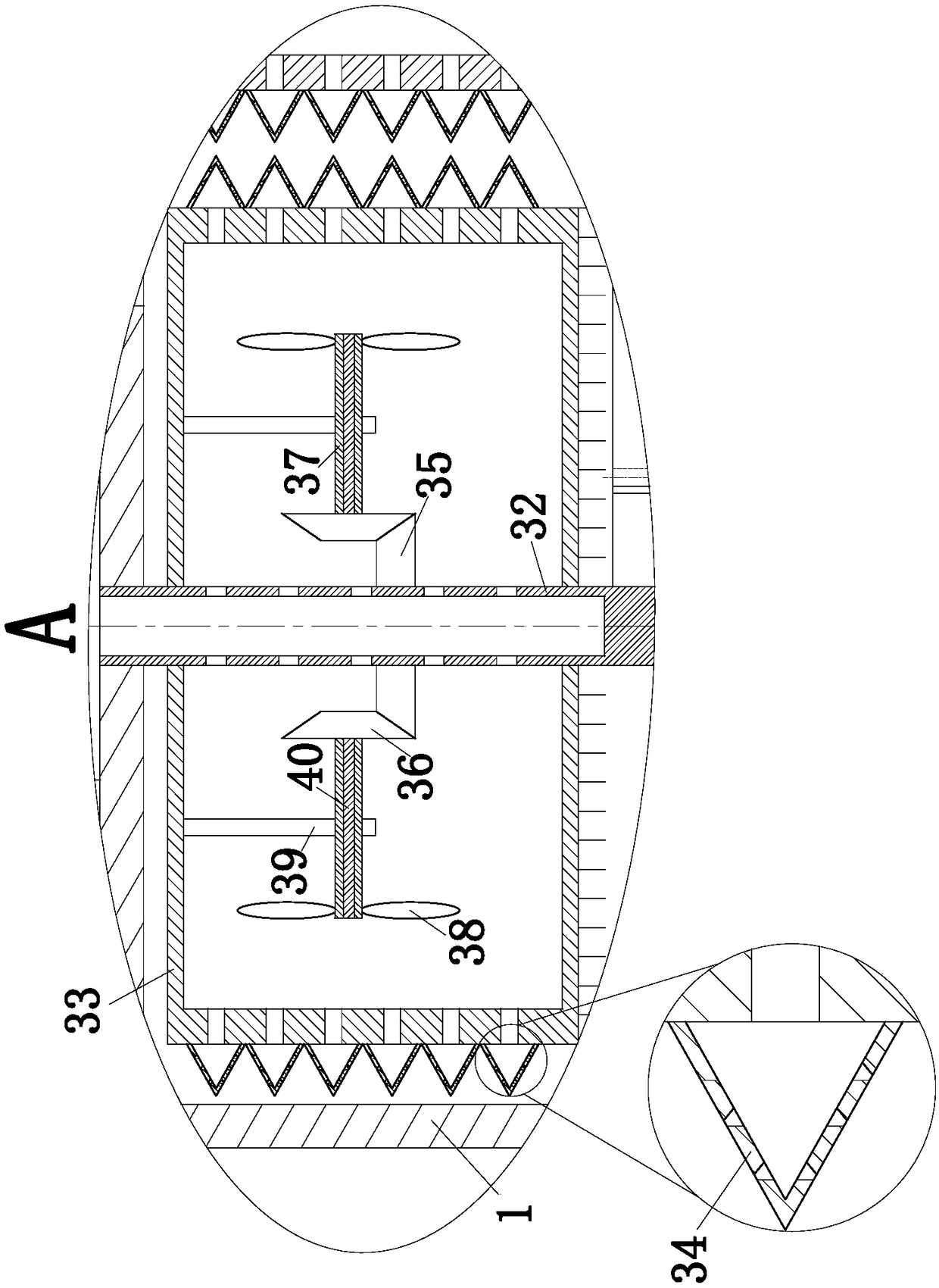

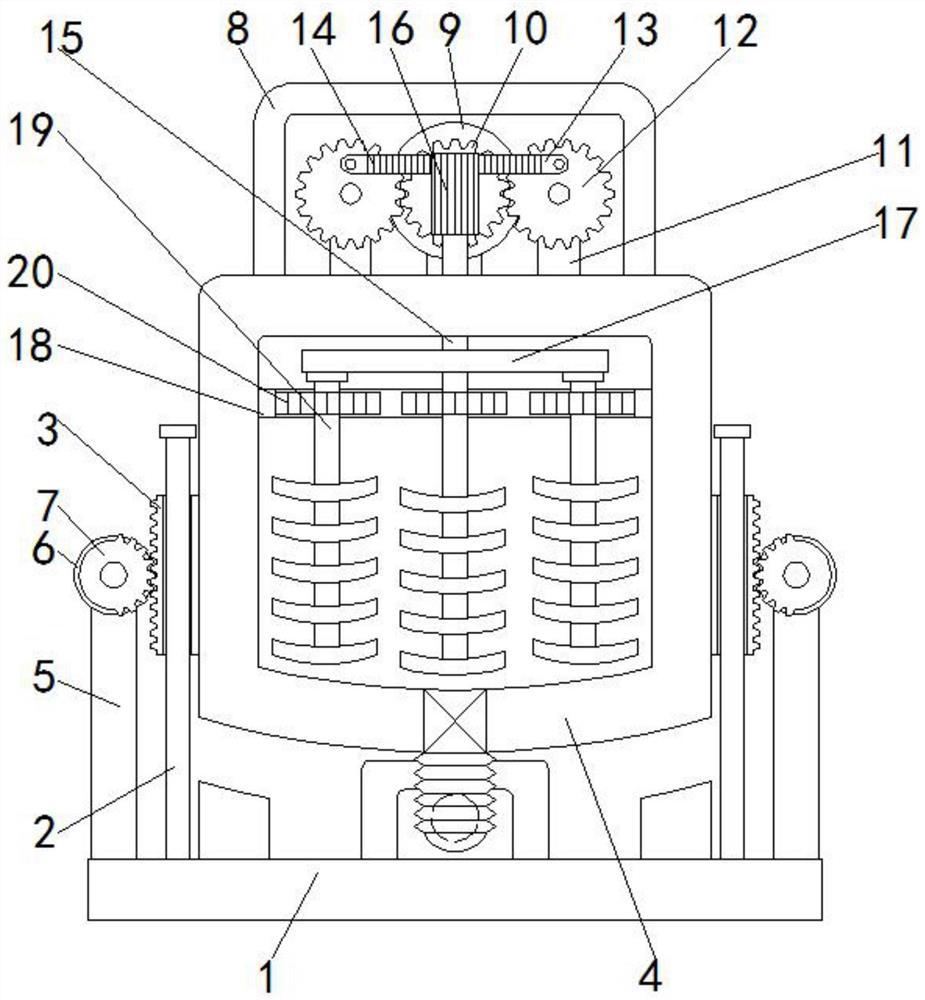

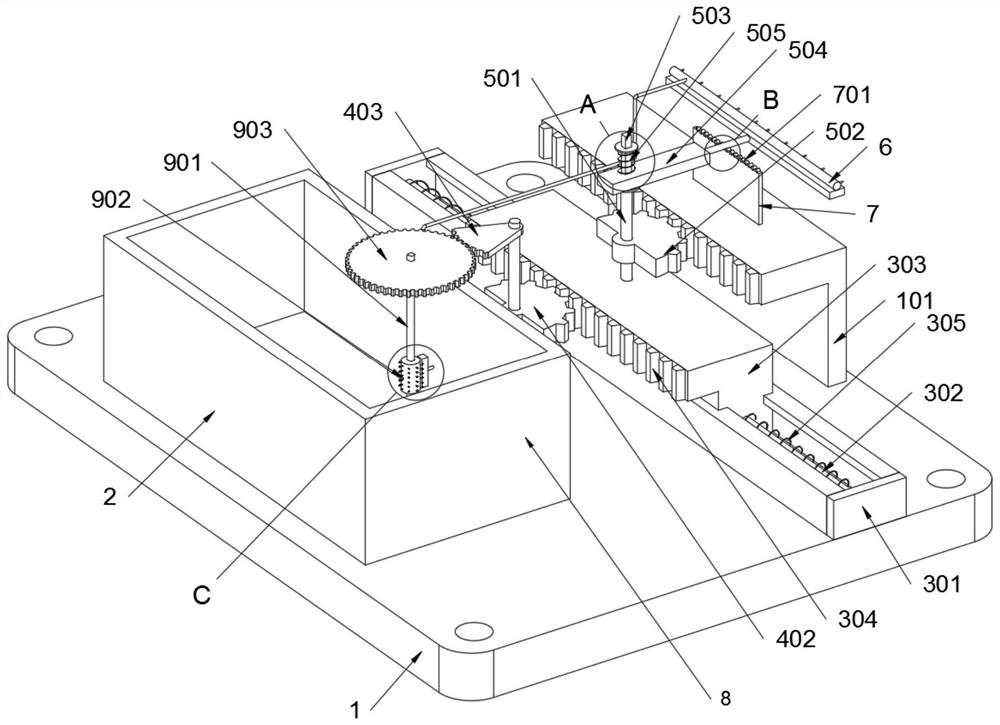

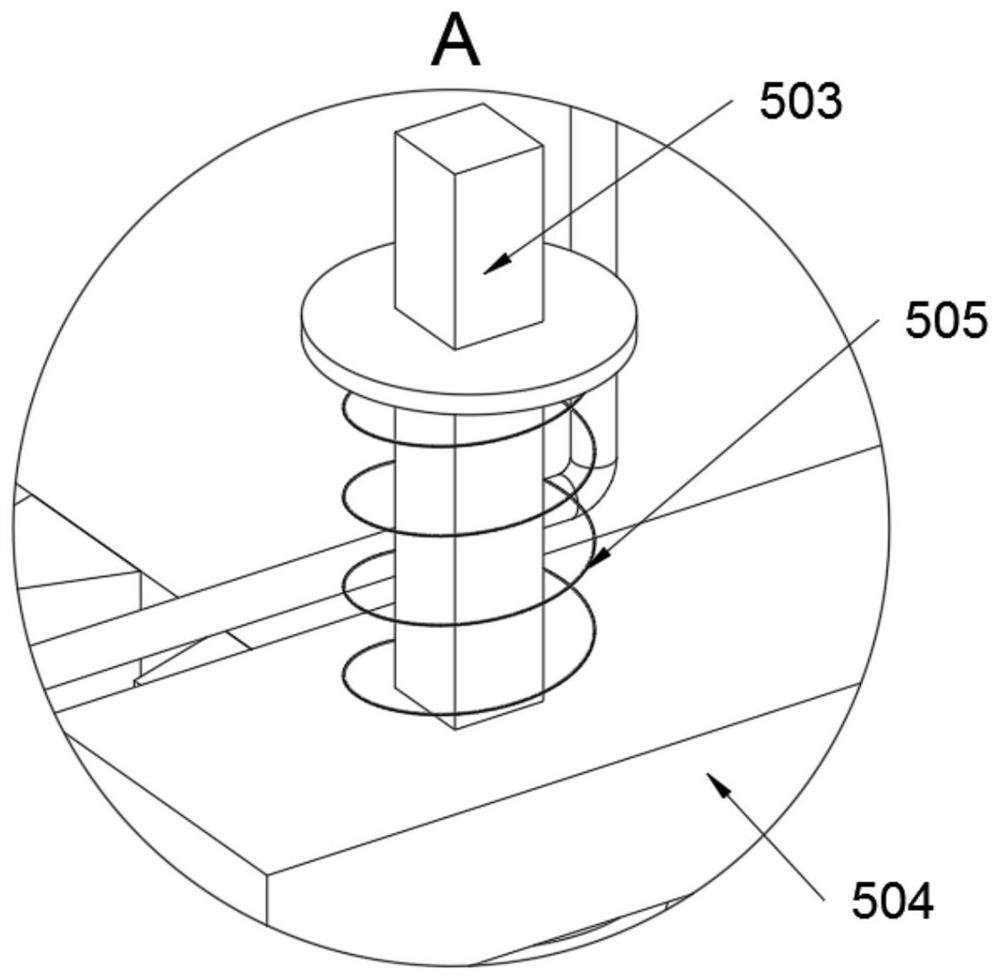

Cam-driving-type Maojian tea double-station multidimensional screening device

InactiveCN108554779AImprove efficiencyImprove work efficiencySievingScreeningAgricultural engineeringCam

The invention discloses a cam-driving-type Maojian tea double-station multidimensional screening device which comprises a base, a supporting table, a first screening box, a second screening box, first-stage screening grooves, second-stage screening grooves and third-stage screening grooves. A plurality of sets of electromagnets are arranged on the upper surface of the base, a plurality of sets ofmagnets are arranged on the lower side of the supporting table, and the magnets and the electromagnets correspond mutually. The first screening box and the second screening box are slidably mounted onfirst sliding rails located on the left side and right side correspondingly. During tea screening, the efficiency of tea screening in the first screening box and the second screening box is improvedgreatly through leftward and rightward sliding of the first screening box and the second screening box; and large-particle tea is left in the first-stage screening grooves, small-particle tea is leftin the third-stage screening grooves, impurities in the tea are discharged from impurity outlets, thus the tea is automatically sorted, manual sorting is not needed, and the working efficiency is greatly improved.

Owner:张春分

Integrated crushing and filtering equipment for food detection

InactiveCN108152098AAchieve left and right movementEfficient screeningPreparing sample for investigationMagnetic polesElectromagnet

The invention relates to integrated crushing and filtering equipment for food detection. The integrated crushing and filtering equipment comprises a casing, wherein a material feeding hopper is arranged at the top part of the casing; a pair of crushing rolls is arranged under the material feeding hopper, and is supported by crushing roll shafts, the crushing roll shafts are arranged onat the innerside wall of the casing, and a plurality of crushing teeth are uniformly arranged on each crushing roll; the inner side wall of the casing under each crushing roll is symmetrically and fixedly connected with two fixed rods, the two fixed rods are fixedly connected with a crushing disc, and a plurality of material falling holes are formed in the crushing disc; an installation plate is arranged above the crushing disc. The integrated crushing and filtering equipment has the beneficial effect that when current is led into an electromagnet, the magnetism which is the same with magnetic poles is produced, the magnetic poles are repelled to drive a horizontal rod to move out, so repeatedly, the installation plate is moved left and right is realized, then crushing balls are driven to move left and right when the installation plate is moved left and right, and the material on the crushing disc is crushed by crushing bulges on the crushing balls.

Owner:BEOSON JIANGSU FOOD SAFETY TECH CO LTD

Bevel gear transmission type facility for food pesticide residue detection

A bevel gear transmission type facility for food pesticide residue detection comprises a shell. A feeding hopper is arranged on the top of the shell. A pair of smashing rollers are arranged below thefeeding hopper and arranged in the mode of being supported by smashing roller shafts, the smashing roller shafts are erected on the inner side wall of the shell, and multiple smashing teeth are evenlyarranged on the smashing rollers. Two fixing rods are symmetrically and fixedly connected to the portion, located below the smashing rollers, of the inner side wall of the shell, a smashing disc is fixedly connected between the two fixing rods together, and multiple material falling holes are evenly formed in the smashing disc. An installation plate is arranged above the smashing disc. The bevelgear transmission type facility for food pesticide residue detection has the beneficial effects that when the current is led to electromagnets, the electromagnets can generate the magnetism same to the magnetism of magnetic poles and repel the magnetic poles, the magnetic poles can drive horizontal rods to move outwards, the left-and-right movement of the installation plate can be achieved throughthe repeated operation, smashing balls are driven to move leftwards and rightwards when the installation plate moves leftwards and rightwards, and smashing protrusions on the smashing balls conduct smashing treatment on materials on the smashing disc.

Owner:陈建文

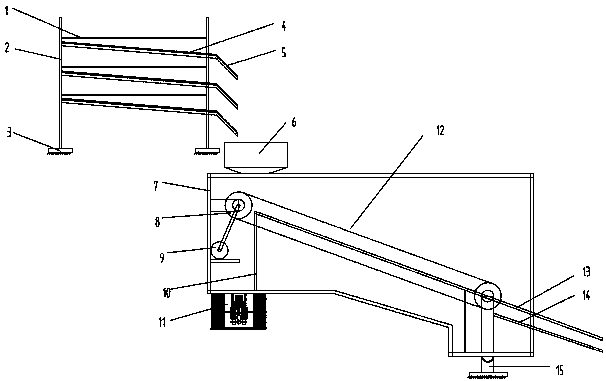

Raw coal conveying method

ActiveCN107555195AEasy to installExtend sieving timeLoading/unloadingJigging conveyorsUltimate tensile strengthConveyor belt

Sundry screens are arranged through supports, holes are formed in the sundry screens, slide way grooves are formed under the holes, raw coal is conveniently collected, the raw coal which is separatedout can be further subjected to washing processing to be used as fuel, the pollution degree of the environment is decreased, the effect of the fuel is better brought into play, and waste utilization for shaft backfilling and the like can also be achieved for sundries. By means of the arrangement, the structure is simple and efficient. By means of the invention, reverse operation is achieved whilescreening is conducted through a conveyor belt so that the screening time can be prolonged; separation processing can be effectively conducted for the raw coal, the raw coal which is separated out canbe collected after being conveyed, and therefore the separation and utilization efficiency of the raw coal is effectively improved, pollution and waste caused by the raw coal are reduced, the whole device is convenient to use and high in utilization rate, and the labor intensity is lowered.

Owner:准格尔旗昶旭煤炭有限责任公司

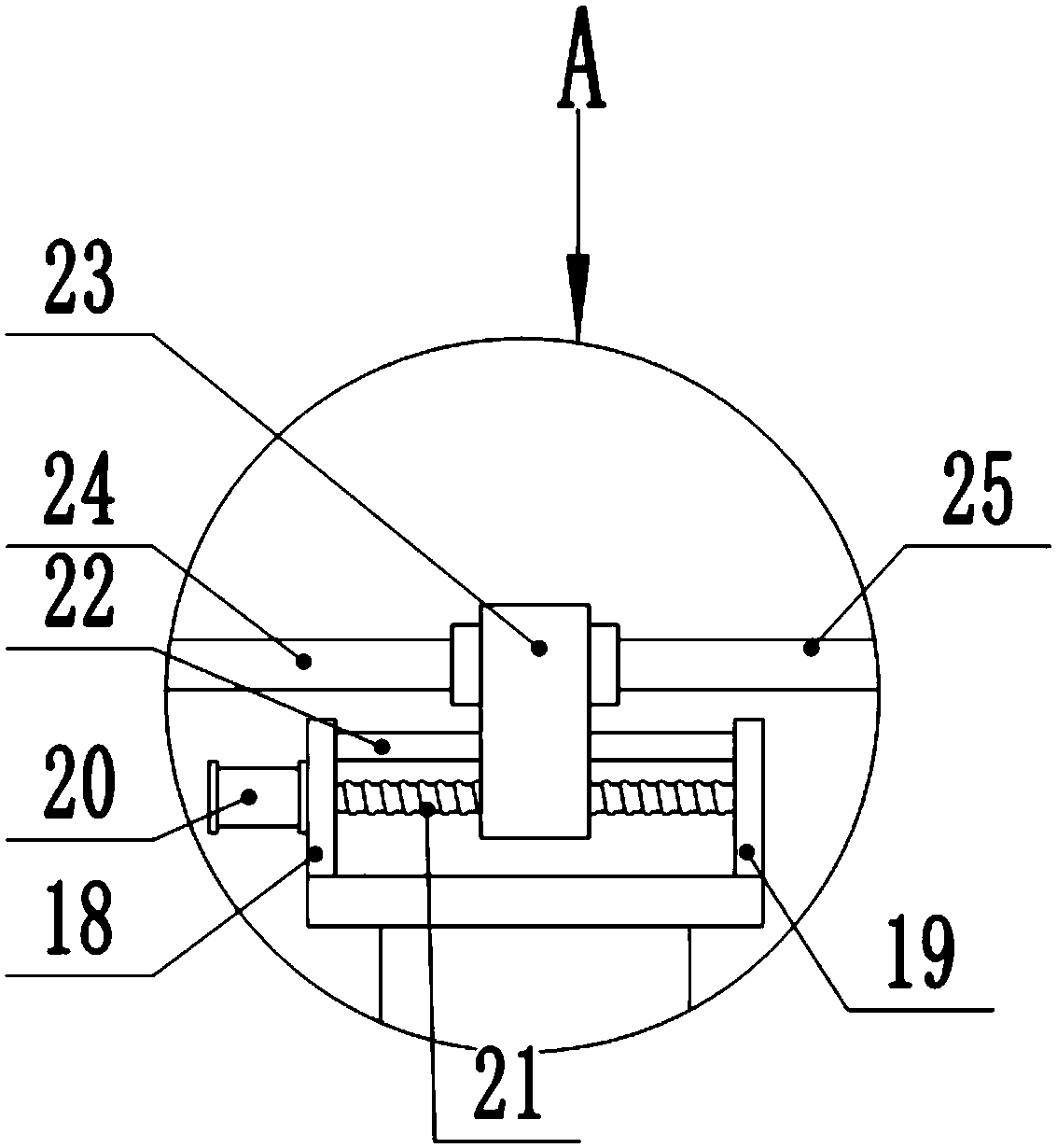

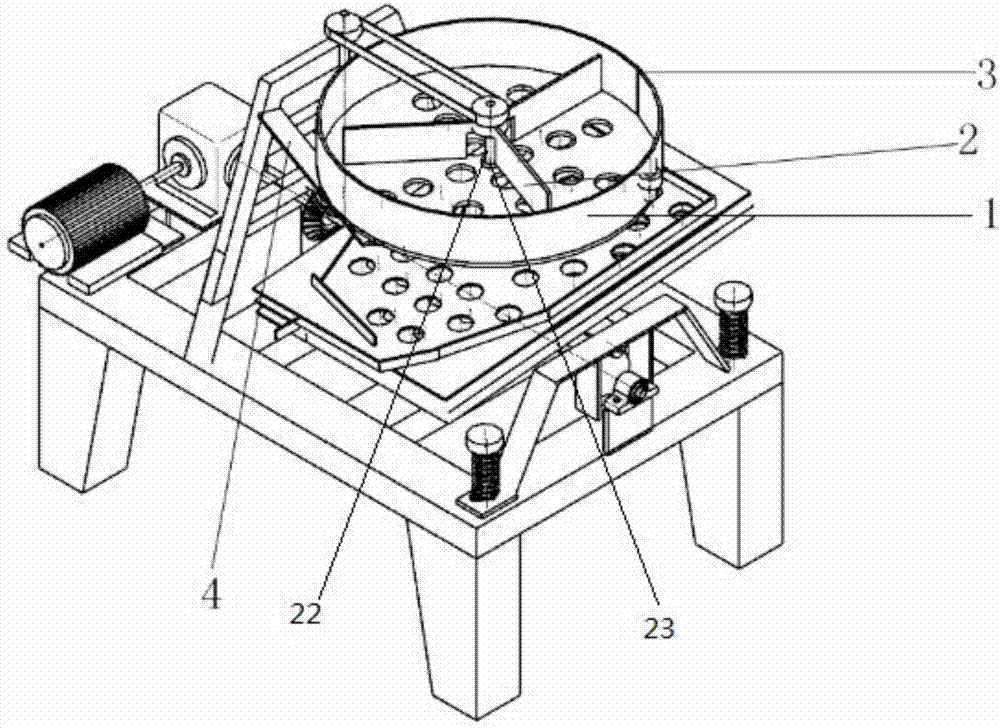

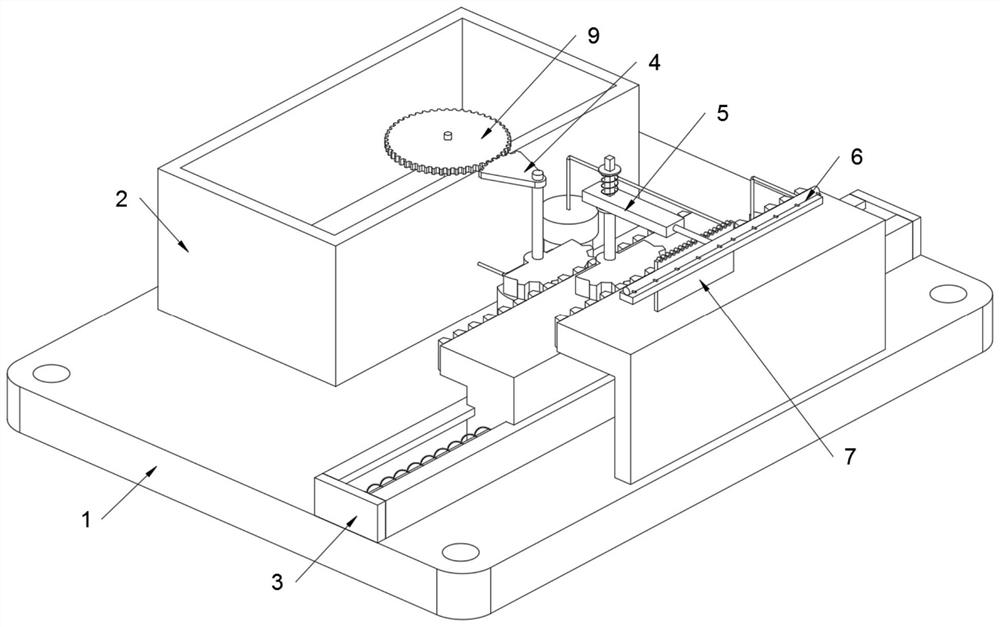

Screw rod transmission type double-station multi-dimensional screening device for Maojian tea

InactiveCN108499839AImprove screening efficiencyRealize automatic sortingSievingScreeningThree stageEngineering

The invention discloses a screw rod transmission type double-station multi-dimensional screening device for Maojian tea. The device comprises a base, a support table, a first screening box, a second screening box, a first-stage screening groove, a second-stage screening groove and a third-stage screening groove; a plurality of groups of electromagnets are arranged on the upper surface of the base,a plurality of groups of magnets are arranged on the lower side of the supporting table, and the magnets correspond to the electromagnets; and the first screening box and the second screening box arearranged on first slide rails on the left side and the right side respectively in a sliding mode. According to the screw rod transmission type double-station multi-dimensional screening device for the Maojian tea, during tea screening, the tea slide left and right through the first screening box and the second screening box, so that the screening efficiency of the tea inside the first screen boxand inside the second screening box is greatly improved; and the tea with larger particles are left in the first-stage screening groove, the tea with smaller particles are left in the three-stage screening groove, impurities in the tea are discharged from an impurity outlet, so that automatic sorting of the tea is realized, manual sorting is not needed, and the working efficiency is greatly improved.

Owner:张春分

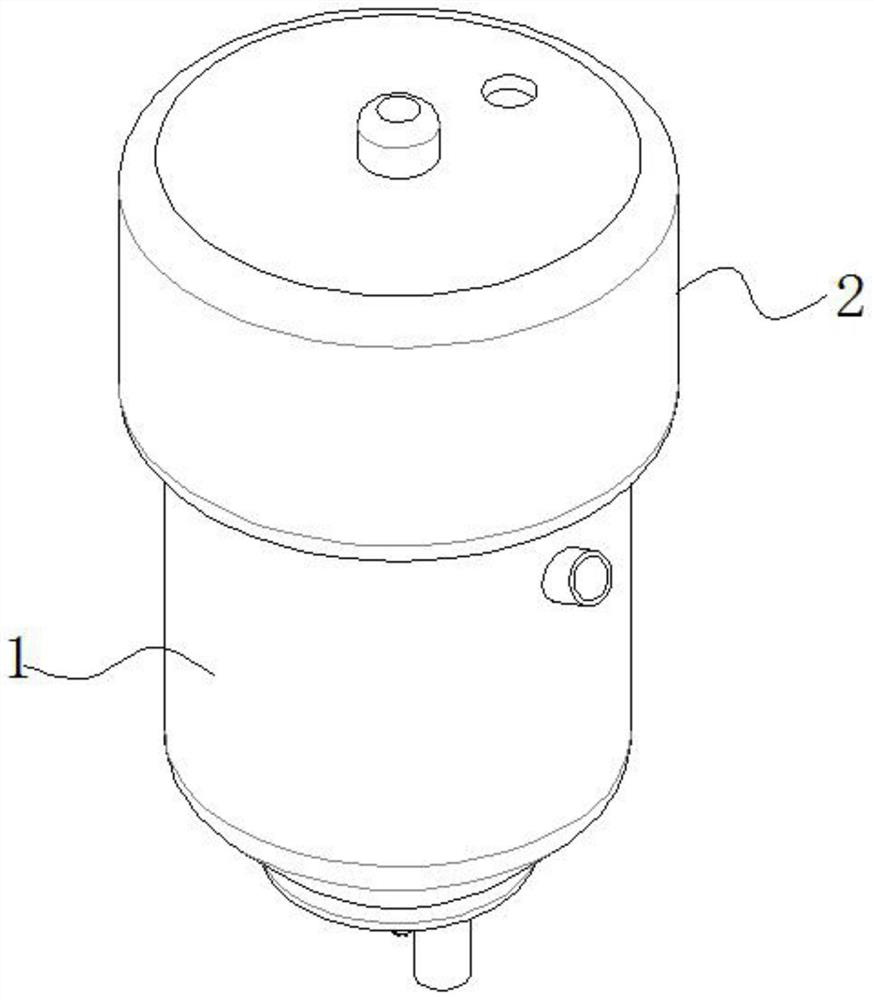

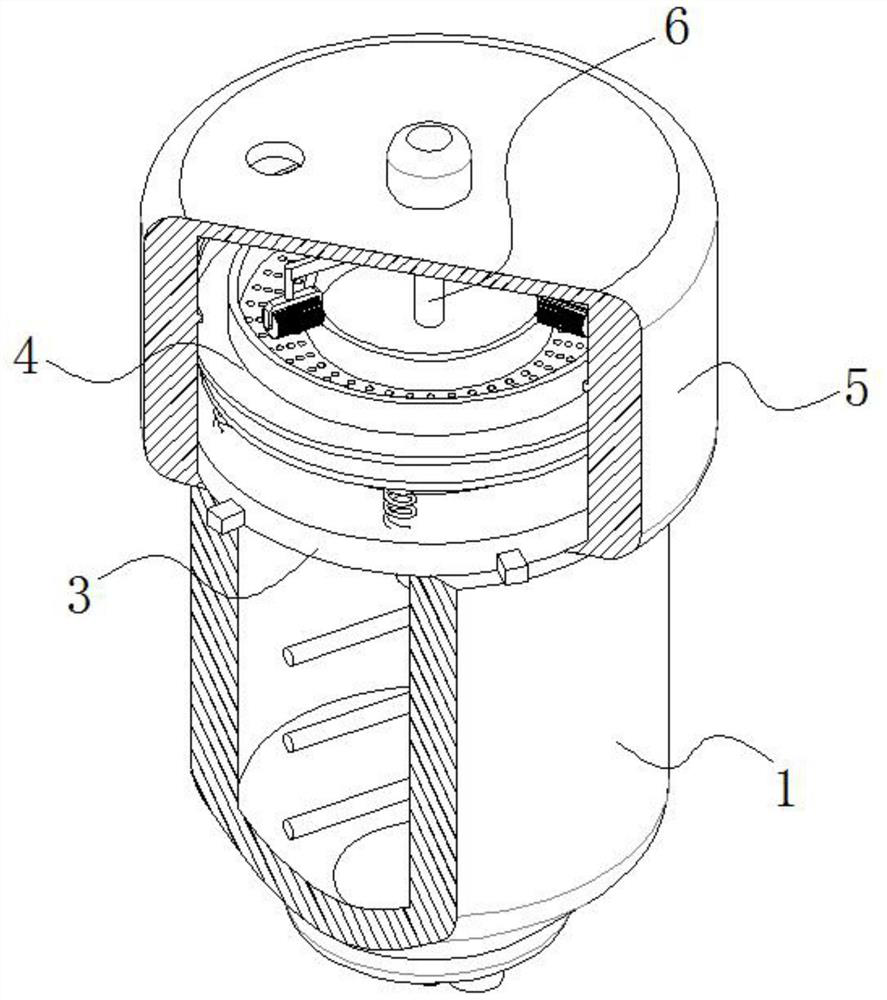

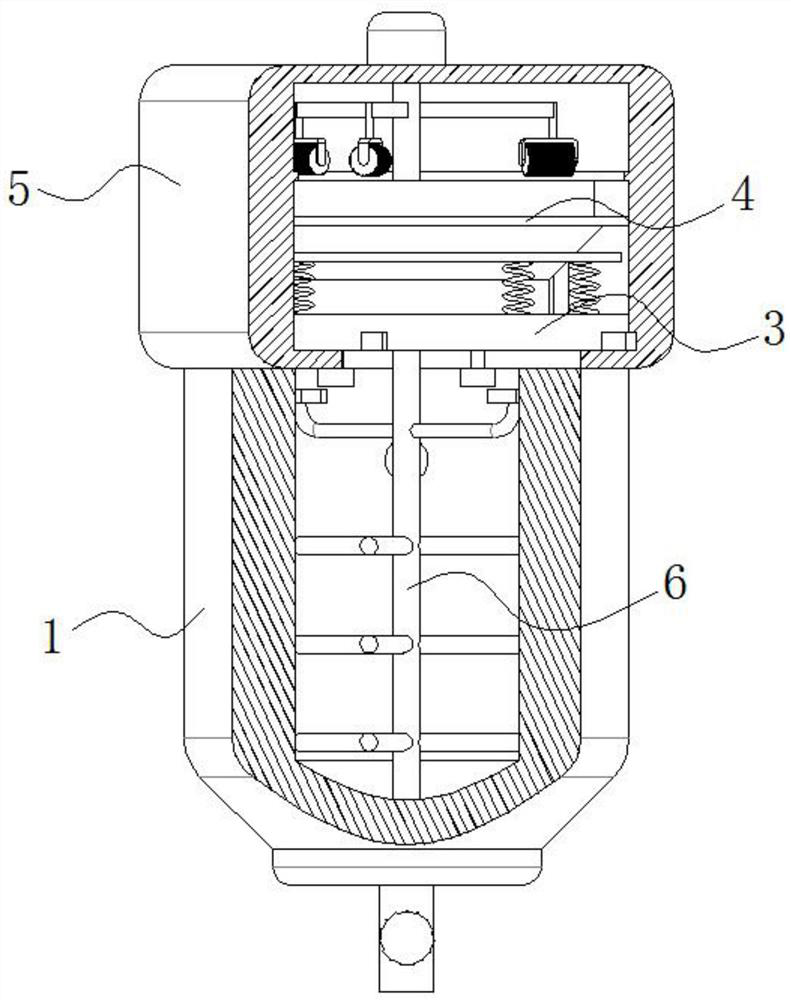

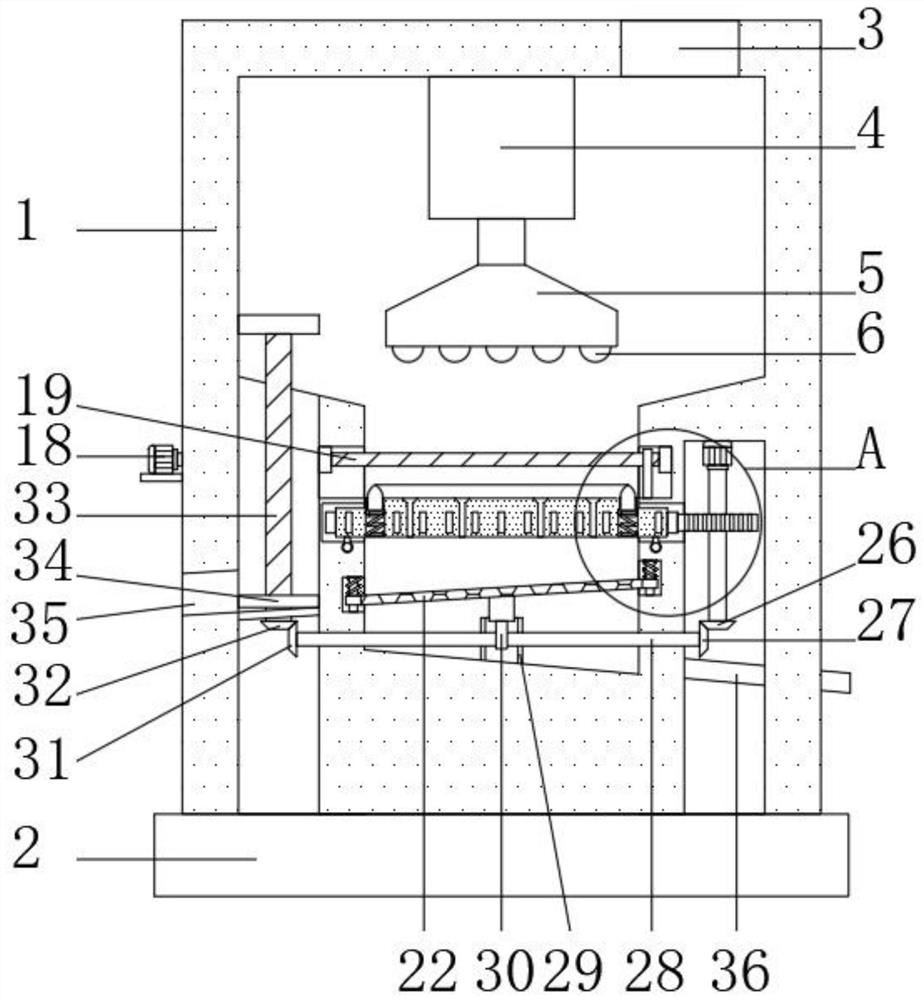

Sewage treatment device and treatment method thereof

ActiveCN110917699AEasy to handleRealize filtration and purificationMoving filtering element filtersElectric machineryEngineering

The invention discloses a sewage treatment device comprising a filter cartridge shell. A water inlet pipe and a water outlet pipe are connected on the filter cartridge shell. A driving motor is mounted at the top of the filter cartridge shell; stirring blades are mounted in the filter cartridge shell; the stirring blades are connected with the driving motor; a cylindrical filter screen is arrangedin the filter cartridge shell; the cylindrical filter screen is in clearance fit with the inner wall of the filter cartridge shell, the bottom of the cylindrical filter screen is coupled with the filter cartridge shell, driving blades are fixed at the bottom of the cylindrical filter screen, two adsorption discs are fixedly arranged in the filter cartridge shell, the two adsorption discs are respectively in sliding contact with the inner side surface and the outer side surface of the cylindrical filter screen, and the adsorption discs are connected with a negative pressure suction pipe. The sewage treatment device can overcome the defects in the prior art and is compact in structure and convenient to transport and is suitable for preliminary treatment of sewage under various temporary sudden working conditions.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

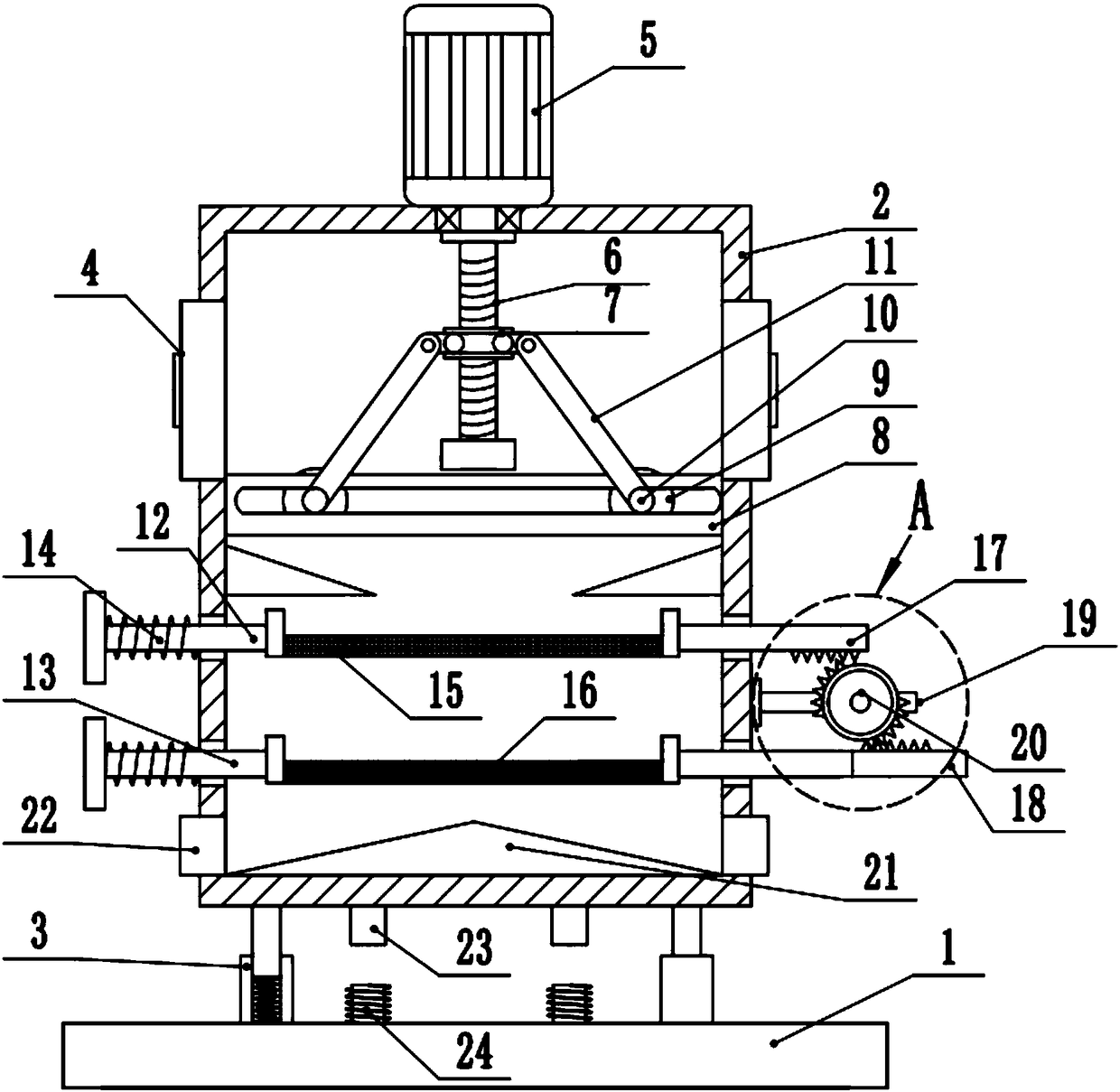

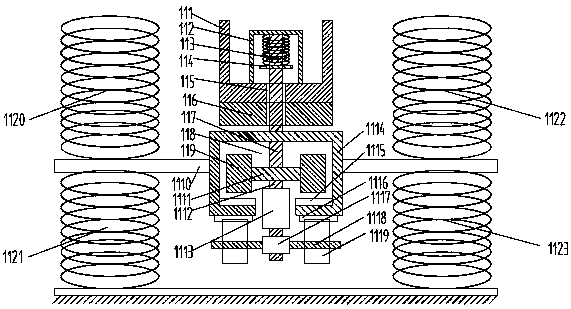

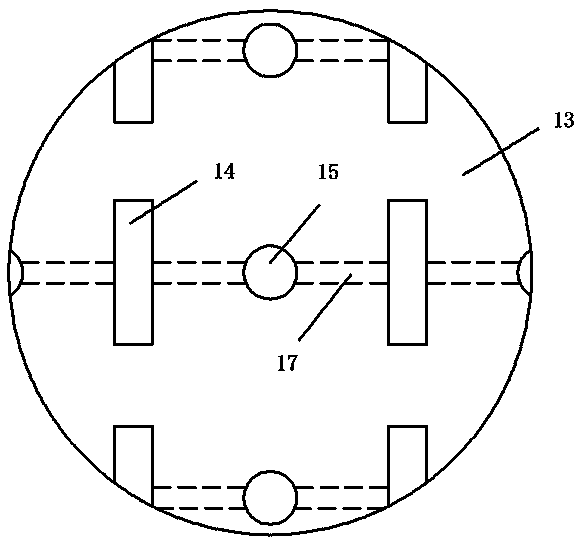

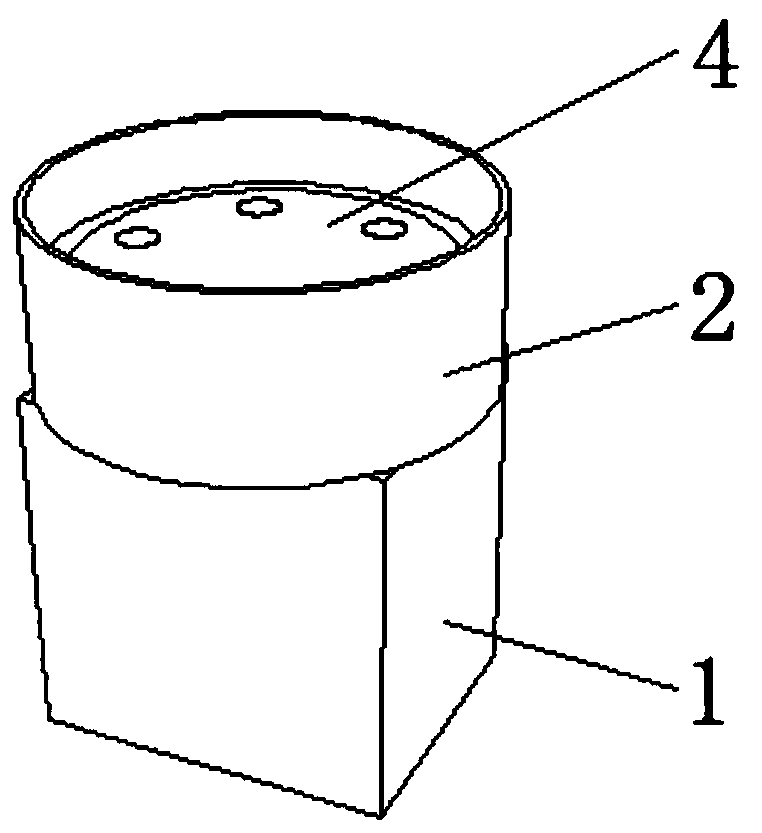

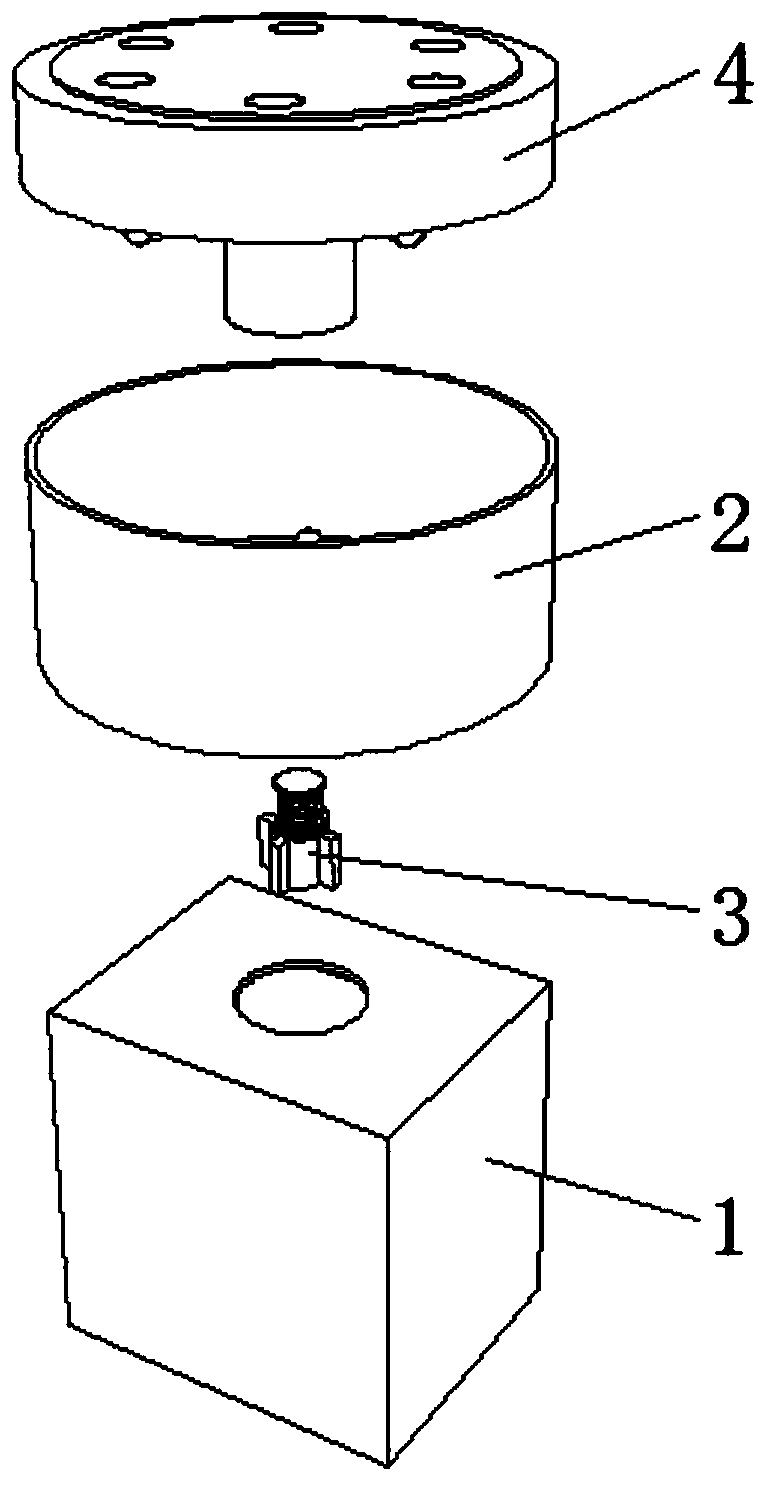

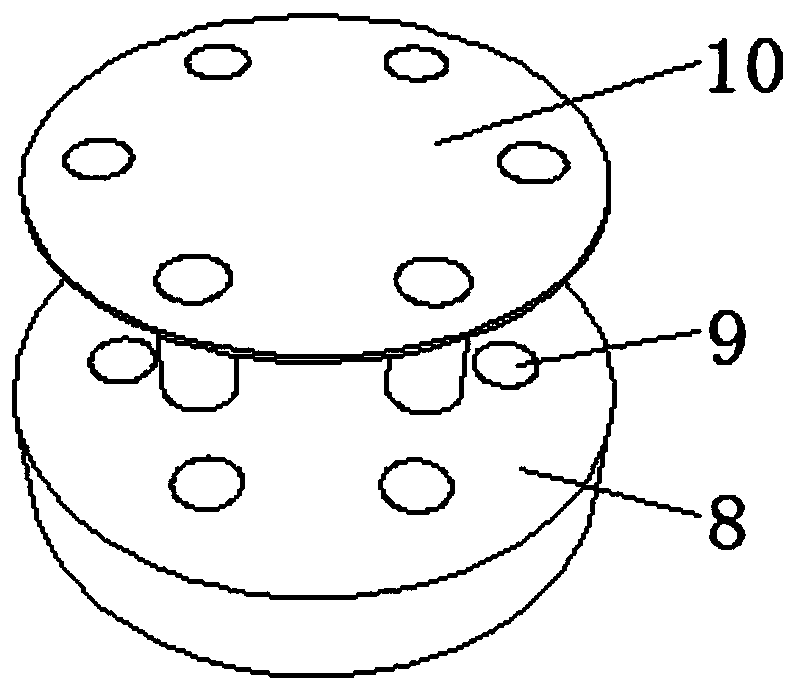

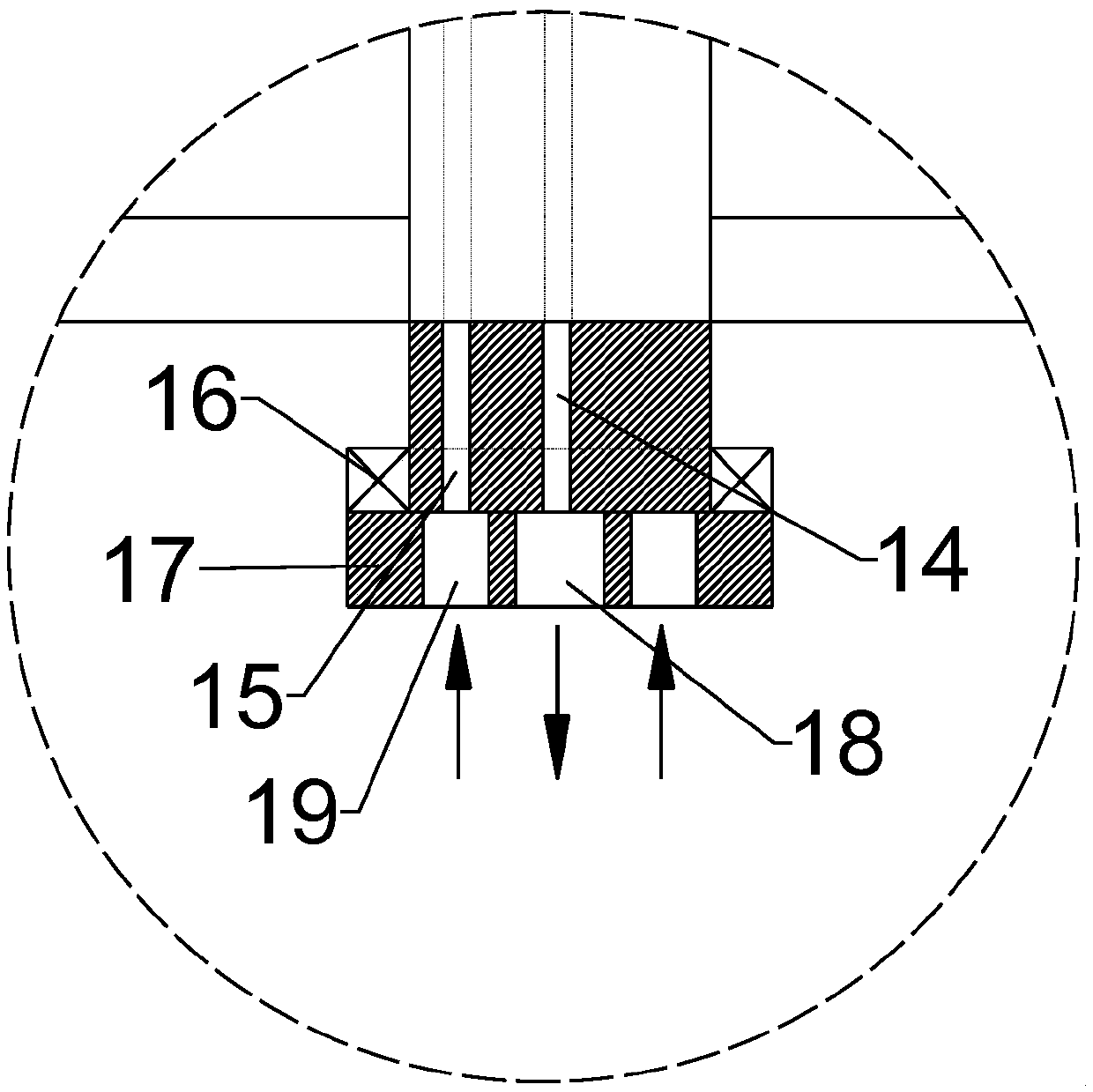

Blood oscillation mixing device for blood detection

InactiveCN111346556AVibration up and downFull shockShaking/oscillating/vibrating mixersTransportation and packagingMedical equipmentMechanical engineering

The invention discloses a blood oscillation mixing device for blood detection. The device comprises a base, wherein the top of the base is fixedly connected with a fixed seat; the base is movably connected with a rotating seat in the fixed seat through a connecting piece; the fixed seat comprises a bottom plate; six stop blocks are fixedly connected to the top of the bottom plate. The outer wall of the bottom plate is fixedly connected with a surrounding plate; the rotating seat comprises a rotary disc; six mounting grooves are formed in the top wall of the rotary disc; rubber pads are embedded in the six mounting grooves and are positioned at the top of the rotary disc; six protruding blocks are fixedly connected to the bottom of the rotary disc. A stand column is fixedly connected to themiddle of the rotary disc; and the bottom of the stand column is provided with a clamping groove. The blood oscillation mixing device for blood detection relates to the technical field of medical equipment, through the arrangement of the fixed seat and the rotating seat, the sufficient oscillation of blood is ensured, the mixing of the blood and an anticoagulant is ensured, the workload of medical personnel is reduced, and the working efficiency is improved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Anti-sticking wall type mixer for processing grain and fruit comprehensive oatmeal and using method thereof

InactiveCN111437752AFirmly connectedEasy accessRotary stirring mixersTransportation and packagingProcess engineeringMechanical engineering

The invention relates to the technical field of oatmeal processing, and discloses an anti-sticking wall type mixer for processing grain and fruit comprehensive oatmeal and a using method thereof. Theanti-sticking wall type mixer comprises a machine shell. A transmission mechanism is arranged in the machine shell, the transmission mechanism is connected with a stirring mechanism, the lower portionof the transmission mechanism is connected with a discharging mechanism, the discharging mechanism is located below the transmission mechanism, the stirring mechanism is located in the machine shell,and the discharging mechanism is located below the machine shell; the end part of the stirring mechanism is connected with a scraping mechanism; the scraping mechanism is attached to the inner wall of the machine shell. Grain and fruit comprehensive oatmeal raw materials can conveniently enter the machine shell through the arranged feeding hopper, driving is achieved through the arranged transmission mechanism, the transmission mechanism drives the stirring mechanism to rotate circumferentially in the machine shell and the stirring mechanism can rotate, and thus the grain and fruit comprehensive oatmeal raw materials can be fully stirred.

Owner:ANHUI YANZHIFANG FOOD

Money classification and coin sorting device

InactiveCN107067538AAutomatic take outImplement classificationCoin/currency accepting devicesEngineeringReducer

The invention provides a money classification and coin sorting device which comprises a rotating scraper coin and banknote separation mechanism, a three-layer screen plate coin sorting mechanism, and a power transmission mechanism. The output of power is realized through the cooperation of a motor and a speed reducer. The transmission of the power is realized through the vertical engagement of two straight tooth bevel gears, coins and banknotes can be classified, and coins of different denominations such as one yuan, five jiao and one jiao are classified and sorted. The device is a pure mechanical device, all components are mechanically connected, and the operation is safe and reliable.

Owner:GUANGXI UNIV

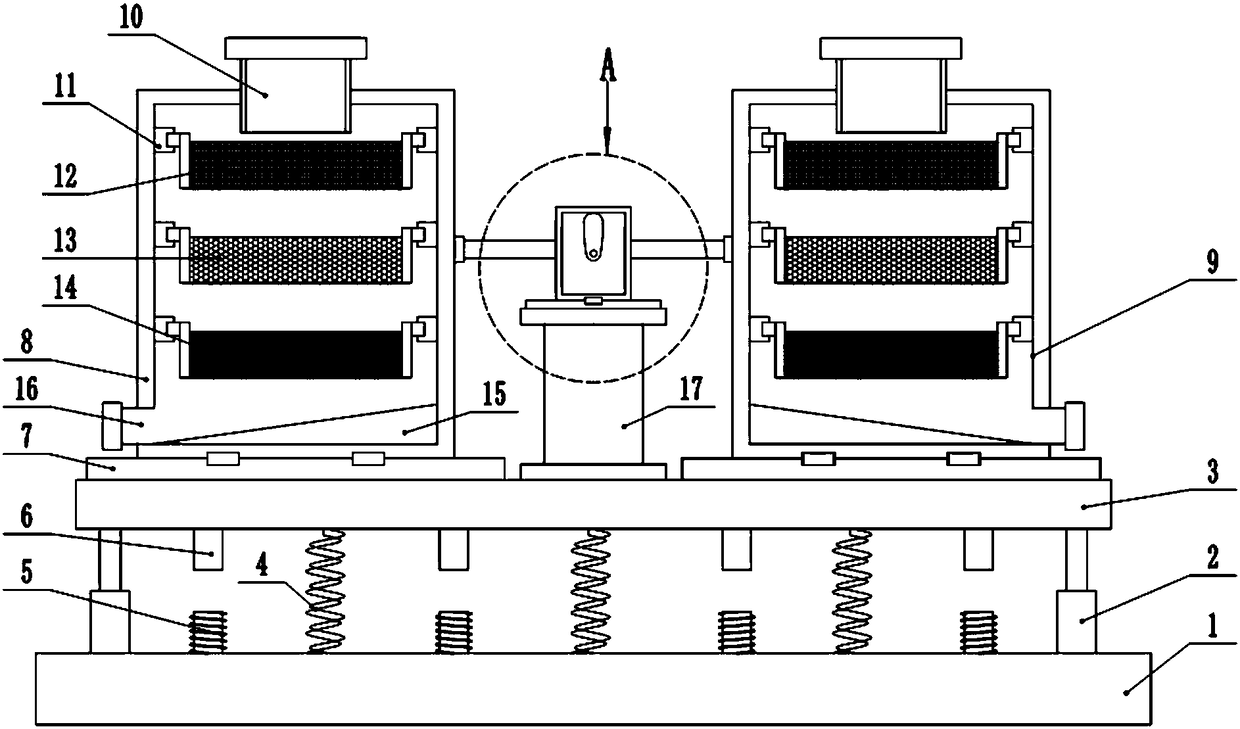

Vibrating screen for flour processing

The invention discloses a vibrating screen for flour processing, and belongs to the field of cat litter boxes. In the vibrating screen for flour processing, a feeding hopper and a screening box are arranged to be of an integrally-formed structure, and the problem that flour is scattered out of the box in the vibration process to cause waste can be effectively prevented; Vibration devices comprising installation frames, fan-shaped eccentric blocks and fixing plates are symmetrically arranged on the two sides of the screening box, when the fan-shaped eccentric blocks are rotated, the whole installation frames are driven to vibrate up and down, therefore, flour stuck to screen net wires is shaken down, screen hole blockage is prevented, the screening effect is better, the production efficiency is improved, and energy consumption of tons of flour is reduced. Since a first spring, a second spring and a third spring are arranged, vibration noise can be reduced, and damage to the ground foundation structure is reduced.

Owner:ZHENGZHOU JINCHENG CHENGXIN SCREEN EQUIP CO LTD

Magnetic drive based medicine feeder for medical care department

InactiveCN113397984AImprove work efficiencyImprove melt mixingRotary stirring mixersOral administration deviceMedical staffEngineering

The invention discloses a magnetic drive based medicine feeder for the medical care department, and relates to the technical field of medical care. The medicine feeder comprises a medicine melting bin, and further comprises a grinding and screening mechanism; the bottom of the grinding and screening mechanism is fixedly connected with the top of the medicine melting bin; the grinding and screening mechanism is composed of a vibration screening assembly, a grinding supporting assembly and a mounting assembly; the vibration screening assembly is in sliding fit with the mounting assembly; the grinding supporting assembly is elastically connected with the vibration screening assembly; a stirring and grinding assembly is rotationally connected to the center of the bottom in the medicine melting bin; a stirring part of the stirring and grinding assembly is located in the medicine melting bin; and a grinding part of the stirring and grinding assembly is located above the grinding supporting assembly. By arranging the medicine melting bin and the grinding and screening mechanism, the integration of dual functions of tablet grinding and medicine powder melting and stirring is achieved; and tablets directly fall into the medicine melting bin after being ground into powder to be subjected to medicine liquid stirring processing, so that the nursing working efficiency of a medical staff is greatly improved.

Owner:张宇

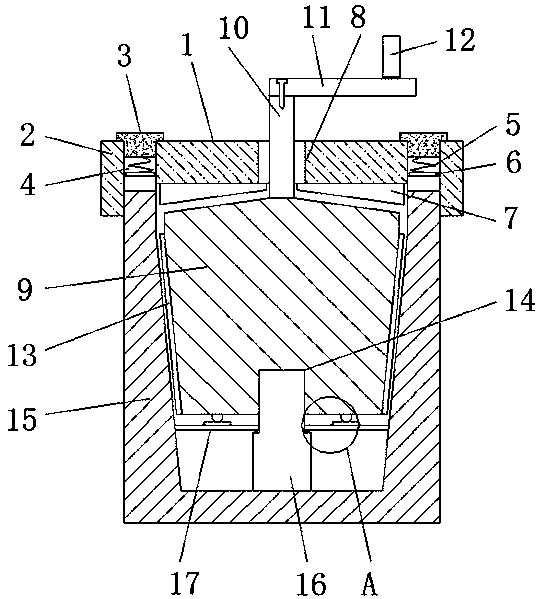

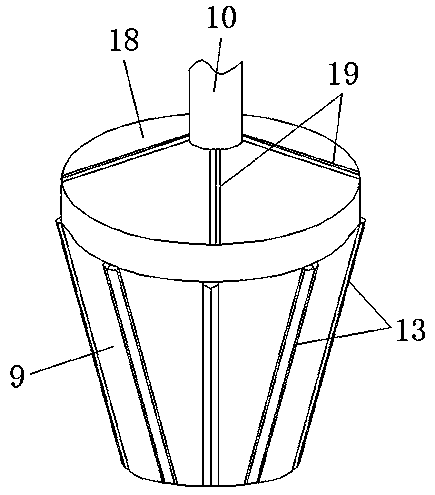

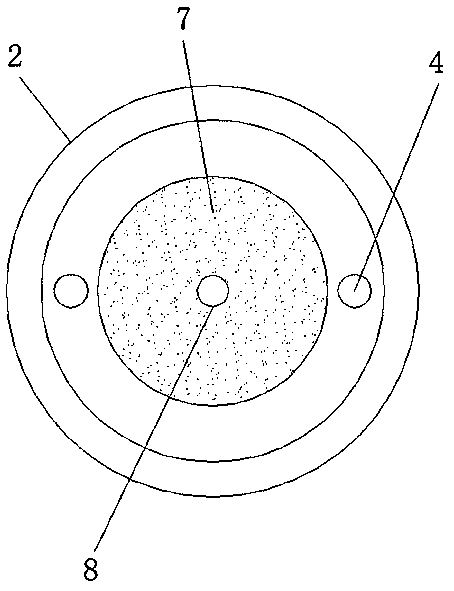

Traditional Chinese medicine processing grinding device

ActiveCN110142105AImprove grinding effectImprove grinding qualitySievingScreeningEngineeringScrew thread

The invention discloses a traditional Chinese medicine processing grinding device. A grinding device body, a connection rod, a rotating rod and a holding handle are included; the top of the grinding device body is provided with a protective cover which is provided with a compressing hole, and the compressing hole is connected with a tight jacking rotary knob; meanwhile, the lower end of the tightjacking rotary knob is in screw connection with a connection block through a spring; the protective cover is connected with a connection column on a grinding barrel through the compressing hole, and the middle portion of the protective cover is provided with a sliding hole; a grinding block is fixed to the lower end face of the protective cover through a screw; the lower end face of a grinding body is provided with a connection groove, and the grinding body is connected with a positioning column through the connection groove; the upper portion of the positioning column is provided with a boss,and the upper portion of the boss is connected with a screen plate through an elastic piece; and an external thread is machined outside the grinding barrel. The traditional Chinese medicine processing grinding device can be used for performing secondary grinding on Chinese herbal medicine, then the grinding effect of the Chinese herbal medicine is improved, and the grinding quality of the Chineseherbal medicine is improved.

Owner:安徽华善堂中药饮片有限公司

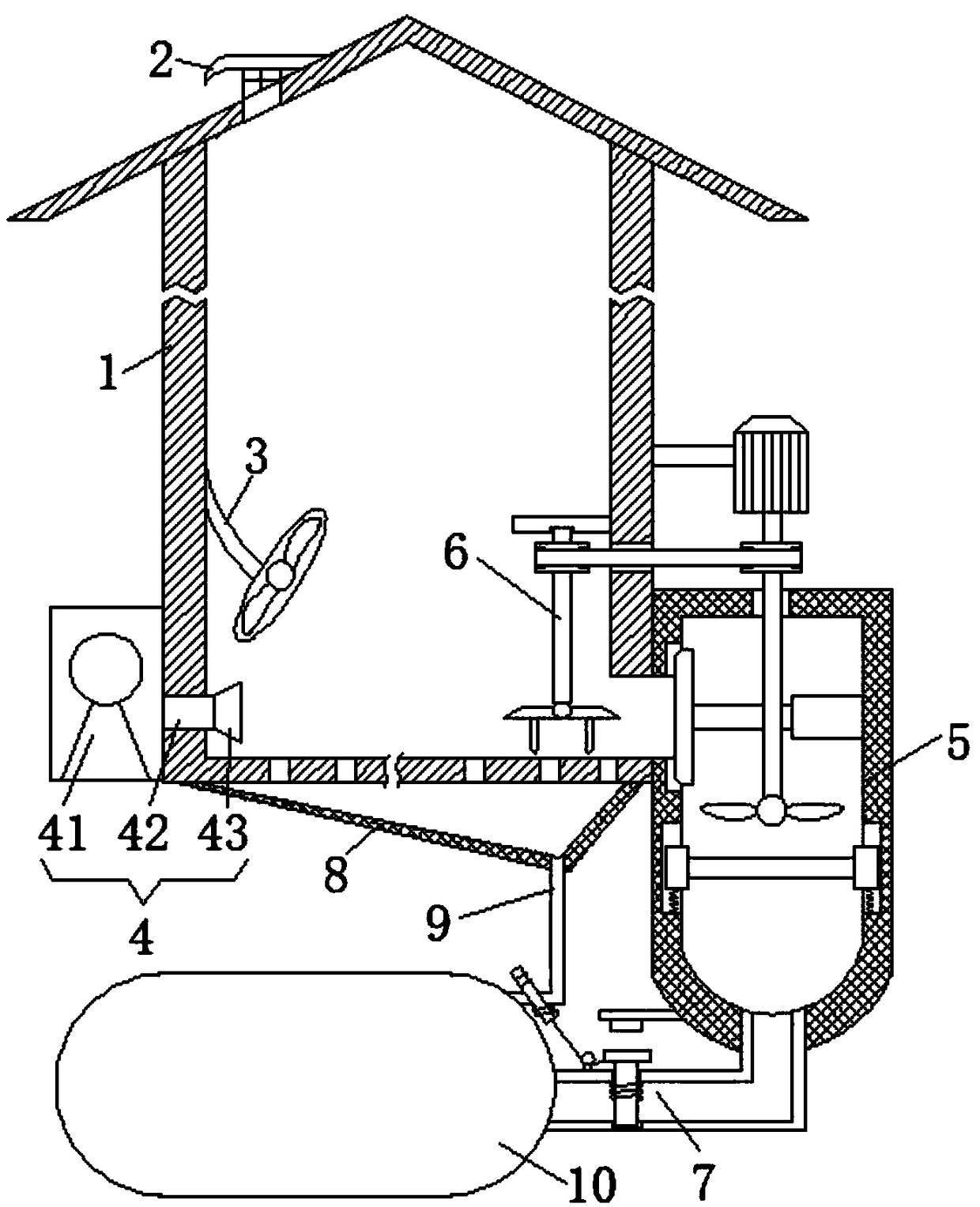

Manure cleaning system of chick room

ActiveCN109197658AChicken manure in timeEasy to moveTransportation and packagingMixer accessoriesBiogasFeces

The invention provides a manure cleaning system of a chick room. The chick room is included, a stirring device is arranged in the outer sidewall of the chick room, a shearing device is arranged in theinner sidewall of the chick room, and water outlets are formed in the lower end of the chick room. Via the system, disadvantages in the prior art are overcome, design is reasonable, the structure iscompact, chick manure is cleaned directly by a cleaning device in the chick room, a drying device is arranged to dry the wet chick room, the shearing device is arranged to shear large manure to avoidthe large manure from block second and first through holes, the stirring device is arranged to mix the chick manure with water uniformly, so that a mixture can be fermented more rapidly after enteringa biogas tank, and due to cooperation of the above devices, the chick room can be cleaned and dried, and the chick manure can be utilized timely and fully.

Owner:安徽标王农牧股份有限公司

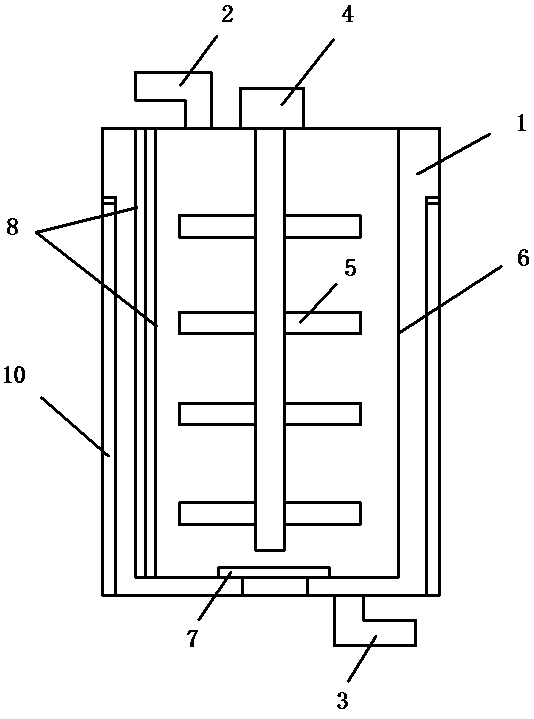

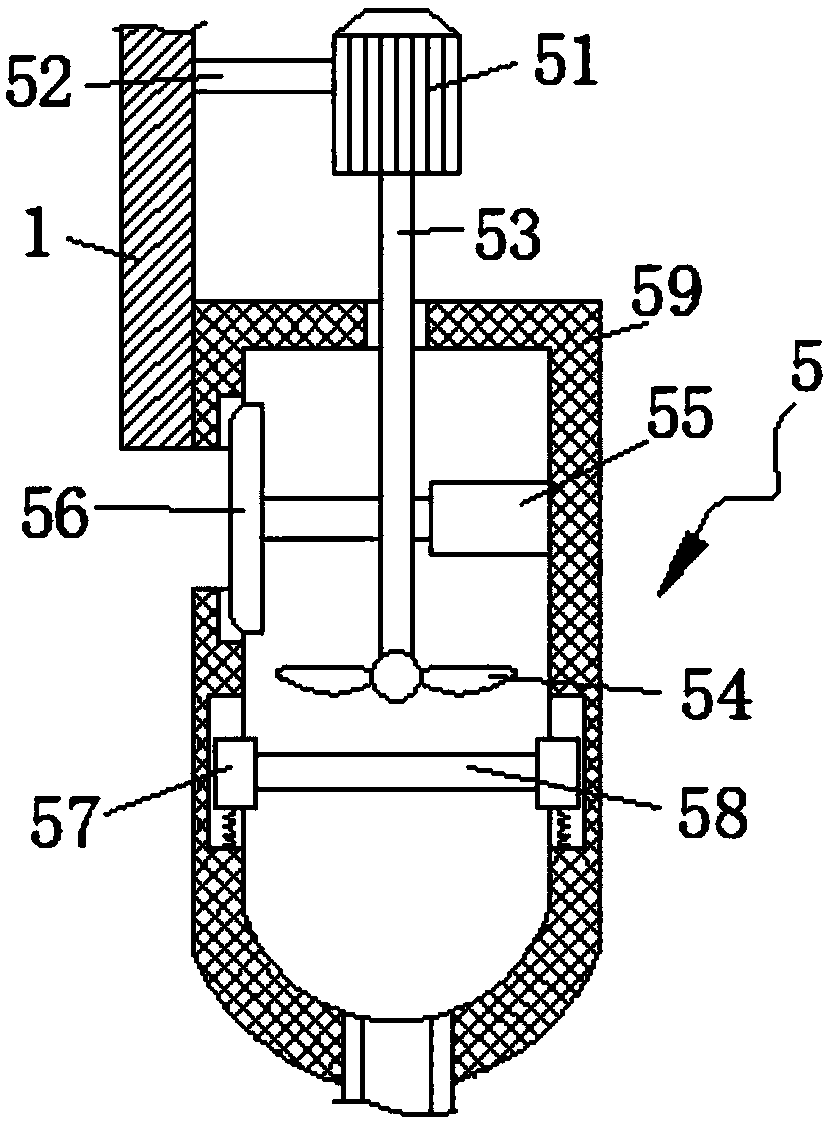

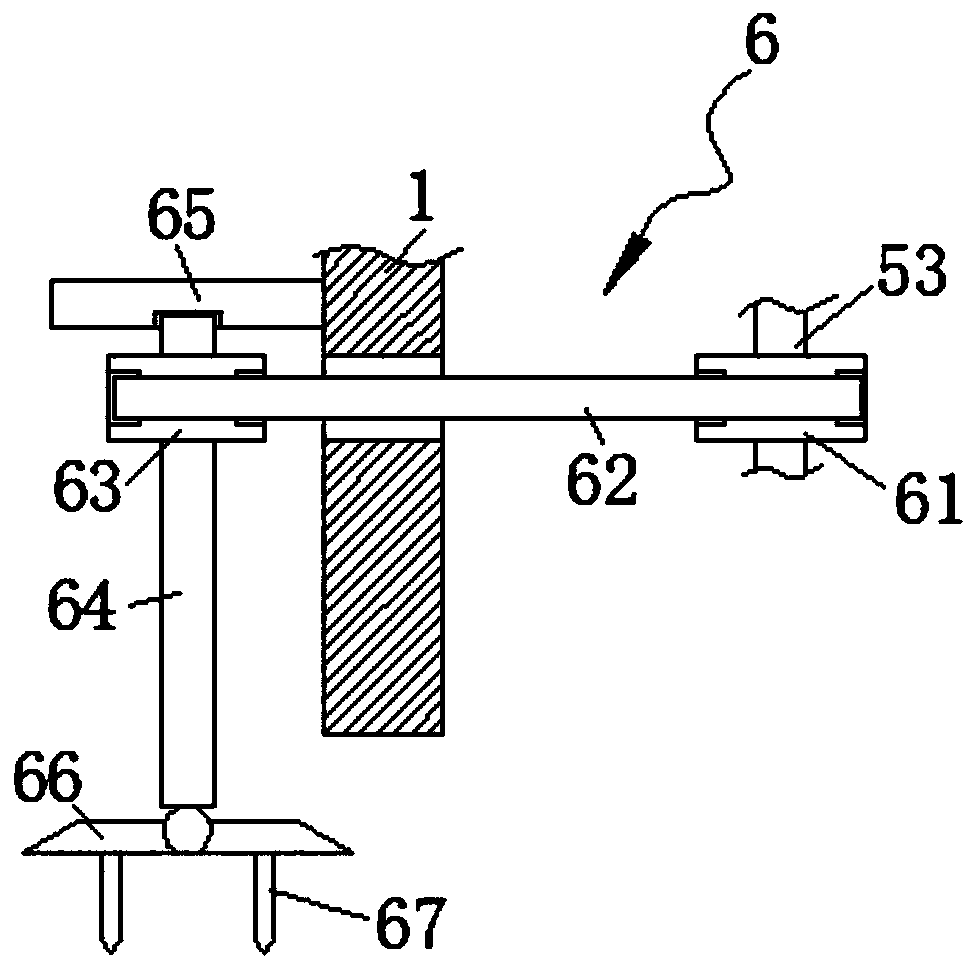

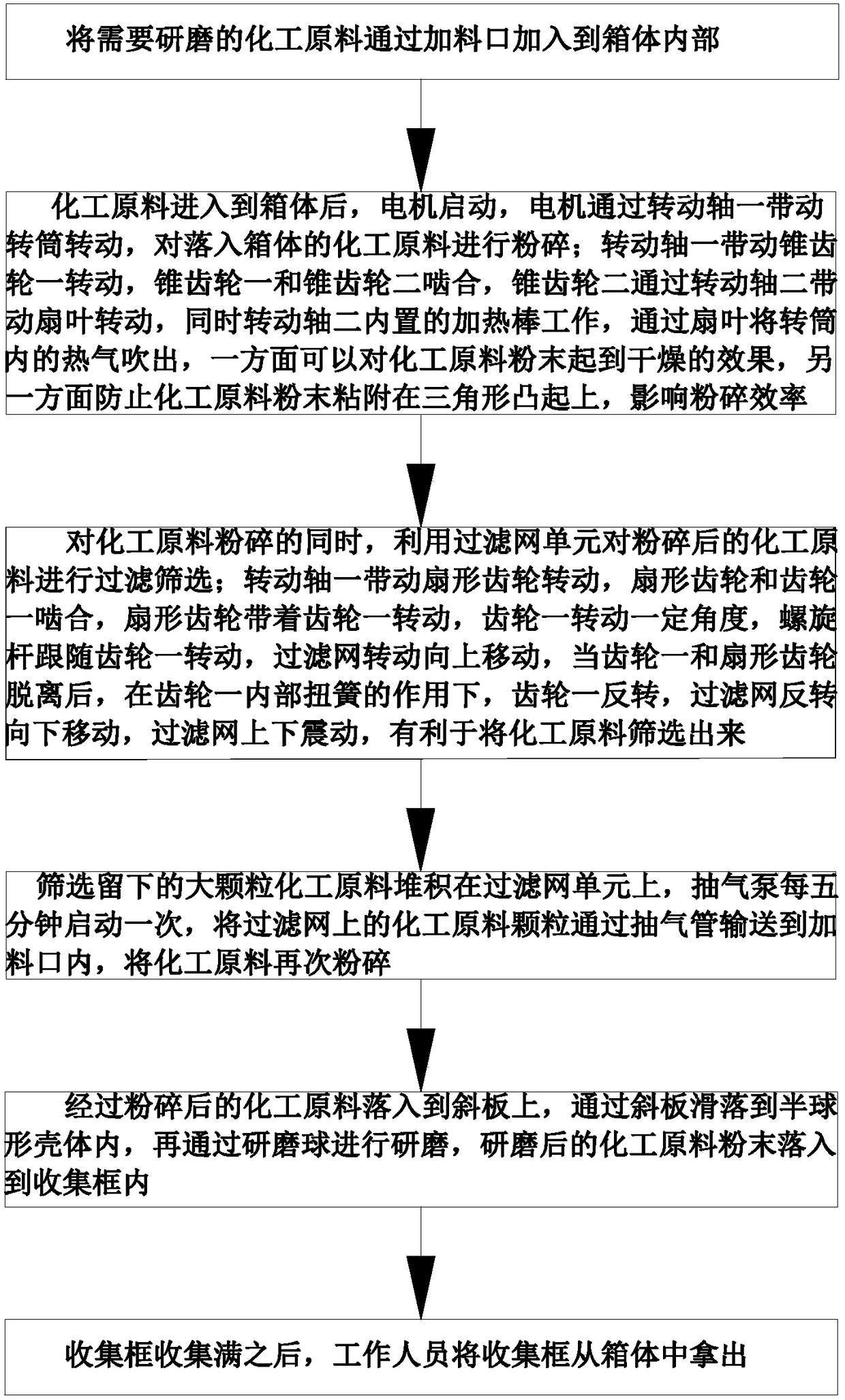

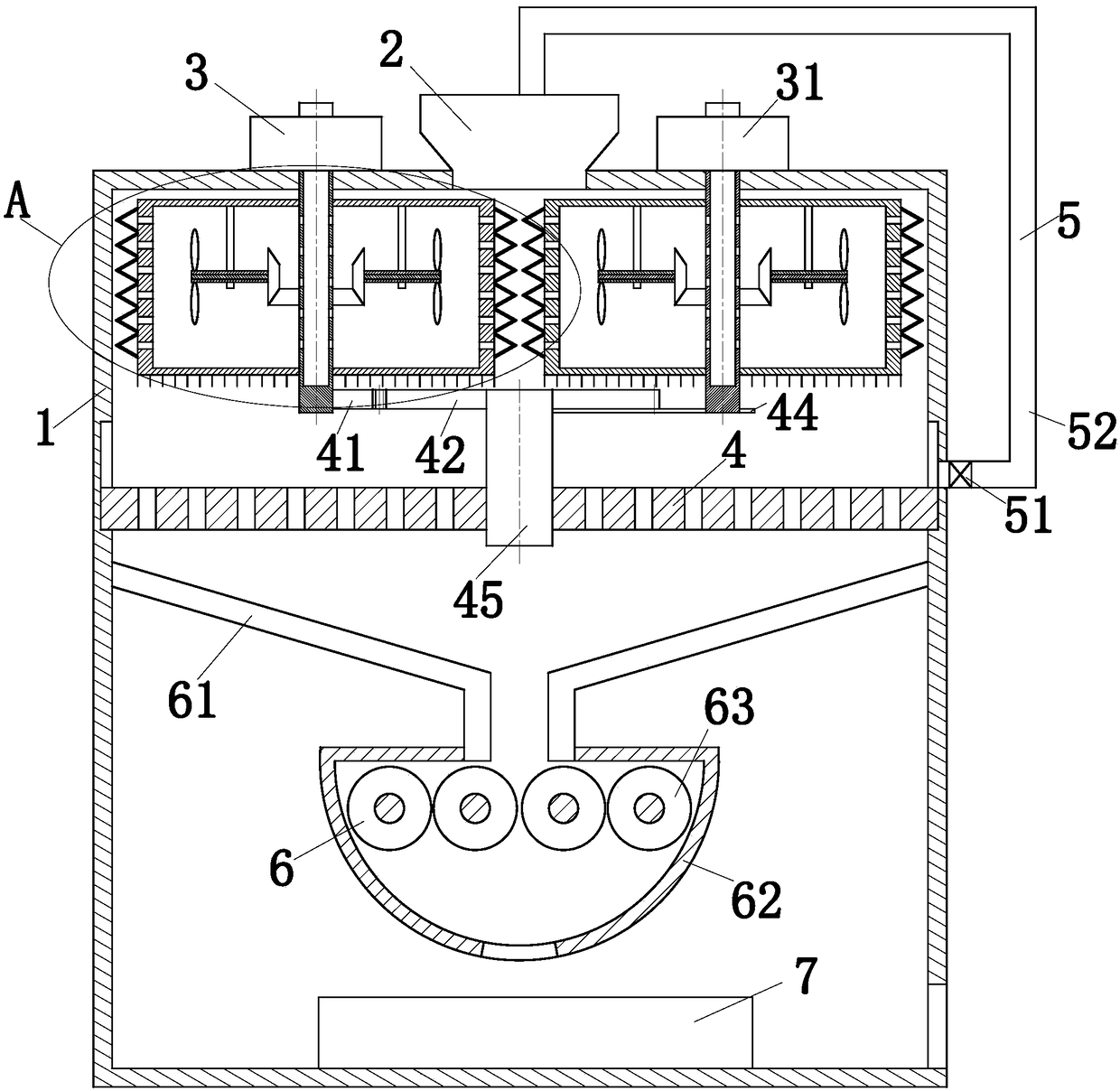

Refined production method for chemical raw materials

ActiveCN108355764AEasy to operateIncrease the fineness of grindingSievingScreeningFinenessEngineering

The invention belongs to the technical field of chemical engineering, and particularly relates to a refined production method for chemical raw materials. The method adopts a chemical raw material grinder. The chemical raw material grinder comprises a box body, a feeding port, a smashing unit, a filter net unit, a circulating unit, a grinding unit and a collection basket, wherein the box body is cylindrical; the feeding port is mounted at the top of the box body; the smashing unit is used for smashing the chemical raw materials; the filter net unit is used for screening and filtering the smashed chemical raw materials; the circulating unit is used for conveying relatively large granular chemical raw materials on the filter net unit to the feeding port for resmashing; the grinding unit is used for grinding the smashed chemical raw materials into powder; the collection basket is located below the grinding unit; and the collection basket is used for loading the ground chemical raw materialpowder. The refined production method disclosed by the invention is mainly used for smashing and grinding block-shaped chemical raw materials. According to the method, the chemical raw materials areinitially smashed in advance and then are ground, so that the grinding efficiency is improved, and the grinding fineness is increased at the same time.

Owner:上海福美泰生物科技有限公司

Visceral system specimen storage device

InactiveCN109566603ALow replenishment and replacement costsAvoid squeezing each otherDead animal preservationUrinary systemCentrifugal pump

The invention discloses a visceral system specimen storage device. The visceral system specimen storage device comprises a reproductive system specimen storage device, a urinary system specimen storage device, a respiratory system specimen storage device, a digestive system specimen storage device, a liquid storage container, a centrifugal pump and a device body. The reproductive system specimen storage device, the urinary system specimen storage device, the respiratory system specimen storage device and the digestive system specimen storage device are sequentially mounted on a stepped mounting platform of the device body in a stepped manner. The visceral system specimen storage device has the advantages that the amount of a formalin solution volatilized into a specimen room or a laboratory when a specimen is taken out or put in during the teaching process of the visceral system is decreased, shedding or entangling of internal tissues of the specimen due to resistance and buoyancy of the formalin solution when the specimen is taken out or put in is reduced, and the replenishing and replacing cost of the formalin solution is low.

Owner:LUOHE MEDICAL COLLEGE

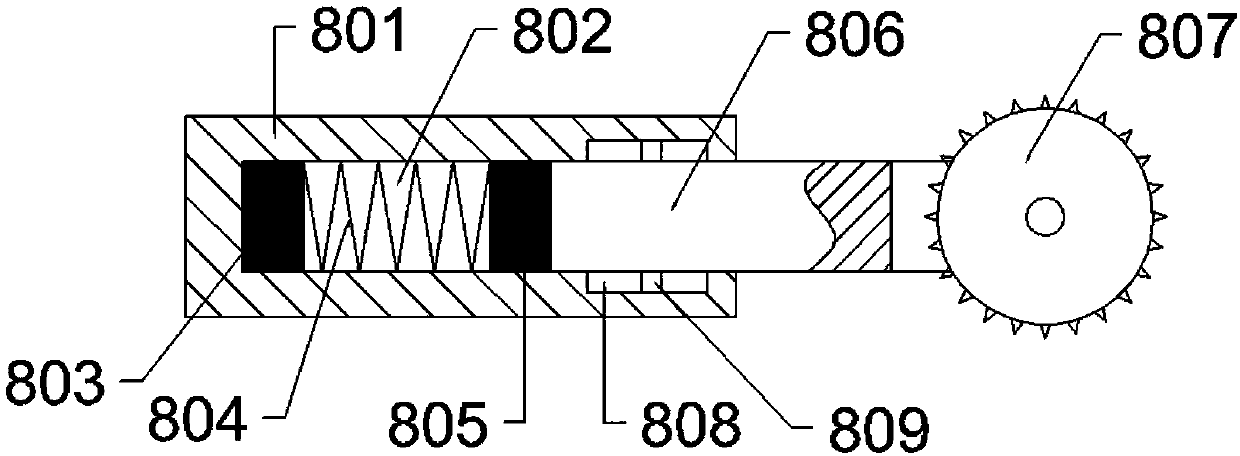

In-use bolt corrosion condition detection device

ActiveCN112525810ARealize cyclic hammeringRealize up and down reciprocating vibrationWeather/light/corrosion resistanceFilament handlingClassical mechanicsElectric machinery

The invention discloses an in-use bolt corrosion condition detection device. The device comprises a protection shell, a moving block, a moving plate, a screw rod, a detection device box body and a wrapping post, the protection shell is internally provided with the detection device box body, and the two sides of the surface of the detection device box body are rotationally connected with rotating discs; third driving motors are in transmission connection with one sides of the two rotating discs correspondingly, the surfaces of the two rotating discs are fixedly connected with one ends of connecting rods correspondingly, the other ends of the two connecting rods are fixedly connected with connecting blocks correspondingly, a vibration pipe is arranged between the two rotating discs, and a second reset spring is fixedly connected to the bottom end of the vibration pipe; and the bottom end of the second reset spring is fixedly connected to the upper surface of a supporting plate. The rotating discs can rotate through operation of a third driving motor, and the connecting rods and the connecting blocks on the surfaces of the rotating discs can rotate together through rotation of the rotating discs.

Owner:杭州塔桅检测技术有限公司

Novel chemical reaction kettle with efficient stirring structure

InactiveCN113019302AEfficient mixingImprove mixing efficiencyShaking/oscillating/vibrating mixersTransportation and packagingChemical reactionGear wheel

The invention relates to the technical field of chemical reaction kettles, and discloses a novel chemical reaction kettle with an efficient stirring structure; the novel chemical reaction kettle comprises a bottom plate, and support rods are fixedly mounted on the left and right sides of the top of the bottom plate. According to the novel chemical reaction kettle with the efficient stirring structure, a driving motor, a driving gear, driven gears, a connecting rod, a transmission rack, a rotating shaft, a transmission gear, a connecting disc, a fixed gear ring, a stirring shaft and a driving gear are arranged, the driving motor is started, the driving gear rotates, and the two driven gears are driven to rotate at the same speed in the same direction; the connecting rod is driven to continuously move left and right, so that the transmission gear can positively and negatively rotate, and the rotation time of the positively and negatively rotate is the same; the rotating shaft and the connecting disc rotate, so that the fixed gear ring is meshed with the driving gear to rotate, and stirring blades on the outer surfaces of the rotating shaft and the stirring shaft positively and negatively rotate to efficiently stir raw materials; the problem of low stirring efficiency is solved.

Owner:董爱民

Agricultural production equipment with quick removal function of pod shells

The invention provides agricultural production equipment with the quick removal function of pod shells. The agricultural production equipment comprises a housing, a feed cover is arranged on the upperside of the housing in a covering manner, the opening of the feed cover is set to the left, a pot shell separating device is arranged in the feed cover and includes a first rotating shaft and a second rotating shaft, the second rotating shaft is located under the first rotating shaft, and both the first rotating shaft and the second rotating shaft are erected on the front and rear side walls of the feed cover. The agricultural production equipment has the advantages that separation rods on the first rotating shaft and the second rotating shaft are interlaced so that the pod shells with rapeseed are detached from rapeseed rods to facilitate subsequent shelling; a gear drives a rack meshed with the same to move to the left, the rack drives an upper removal plate to move to the left lower side through a connector, and a second removal protrusion arranged on the lower side of the upper removal plate is matched with a first removal protrusion arranged on the upper side of a lower removal plate to have the pot shells kneaded to have the rapeseed in the pot shells removed.

Owner:诸暨市众创机械设备厂

Dust suppression device based on building construction site

ActiveCN111804091ARealize reciprocating displacementRealize swing sprayingUsing liquid separation agentSpraying apparatusWater storageGear wheel

The invention provides a dust suppression device based on a building construction site, and relates to the technical field of building construction. The problem that linkage type reciprocating shaking, left-right swinging and vibration cannot be realized at the same time through structural improvement so as to improve the spraying dust suppression efficiency and the problem that cleaning of the water suction faucet cannot be achieved in the swing spraying process through structural improvement are solved. The dust suppression device based on the building construction site comprises a base. A water storage barrel is installed on the base, a water suction faucet is installed on the water storage barrel, and a cleaning structure is further installed on the water storage barrel. The rotating shaft A is rotationally connected to a sliding seat, and an incomplete gear C is mounted on the rotating shaft A; and the incomplete gear C is meshed with a tooth row A, and the rotating shaft A is still in a swinging state when the rotating shaft A reciprocates left and right along with the sliding seat.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

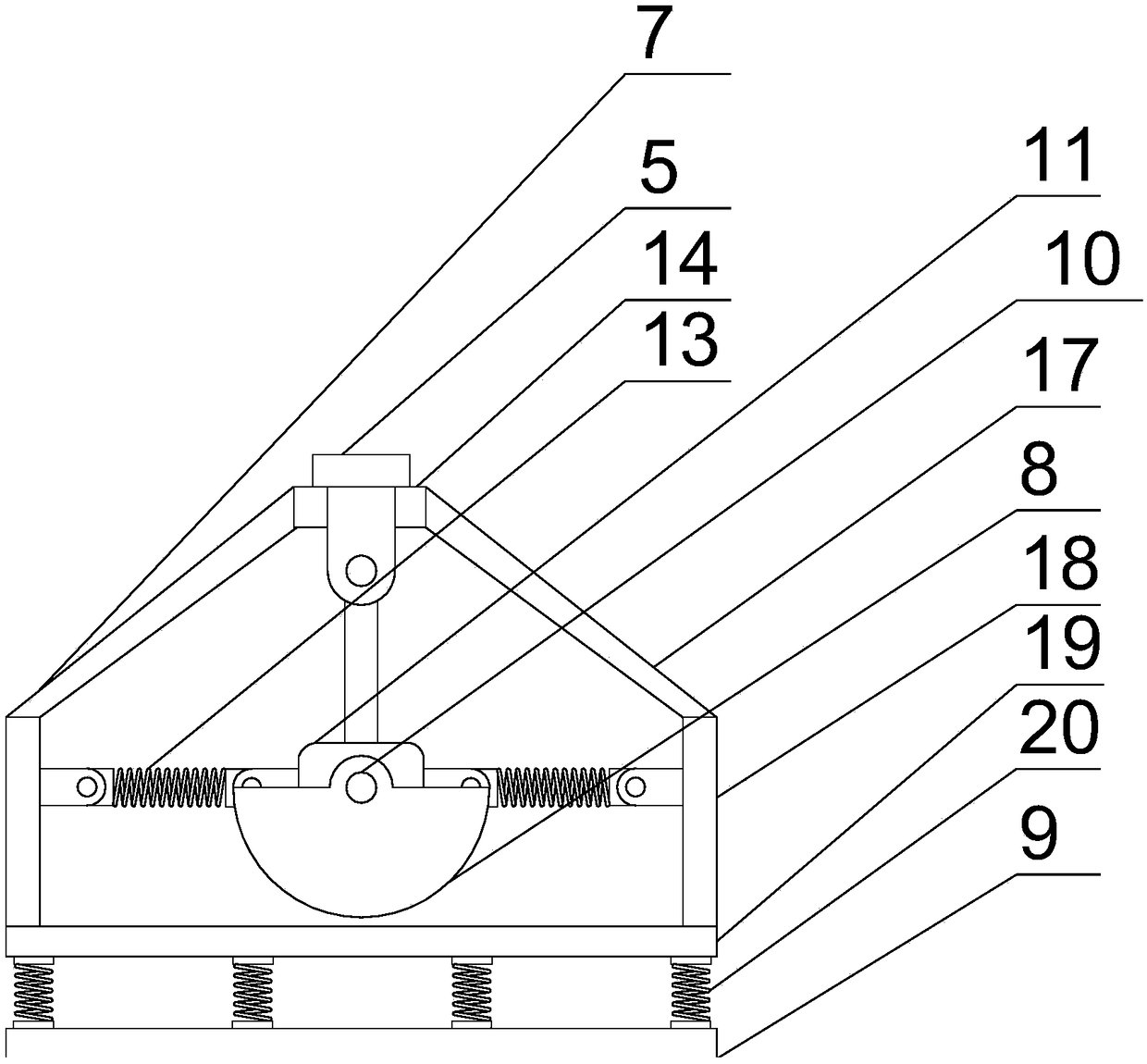

Steel sand separation device of automatic sanding machine

PendingCN108787448AVibration up and downImplement automatic filteringSievingScreeningEngineeringMechanical engineering

The invention discloses a steel sand separation device of an automatic sanding machine, and relates to the technical field of sanding machine equipment. The device comprises a telescopic bracket, a vibration table, a driving mechanism, a vibration mechanism, a pushing mechanism and loading mechanism; a through hole is formed in the vibration table; the bottom of the vibration table is fixedly connected with the top of the telescopic bracket; the pushing mechanism is connected with the vibration table; the driving mechanism is connected with the inner side surface of the telescopic bracket; thevibration mechanism is connected with the driving mechanism and the vibration table; and the loading mechanism is connected with the outer side surface of the telescopic bracket. According to the device, automatic screening of residual steel sand in workpieces is realized, so that the working efficiency is enhanced and the labor intensity of workers is reduced at the same time; and through the design of a loading platform, the practicability of the whole device is further enhanced.

Owner:芜湖聚鑫涂装有限公司

Edible oil processing device

PendingCN113021985APromote productionAchieve the effect of smashing peanutsCocoaFatty-oils/fats productionEdible oilMechanical engineering

The invention discloses an edible oil processing device comprising a shell and a base. The shell is fixedly connected to the upper side of the base, a feeding port is formed in the upper side of the shell, a pressure lever is fixedly connected to the inner top of the shell, an extrusion plate is fixedly connected to the lower side of an output shaft of the pressure lever, and a plurality of protrusions are arranged on the lower side of the extrusion plate. An annular groove is symmetrically formed in the inner side of the shell, a circular plate is connected to the inner side of the annular groove in a rotating mode, a plurality of through holes are formed in the circular plates, a rotating assembly is arranged in the annular groove, a guiding assembly is arranged between the annular groove and the circular plate, a scraping assembly is arranged inside the shell, and a material guiding assembly is arranged inside the shell. A filtering assembly is arranged inside the shell. The edible oil processing device is reasonable in design, peanut particles screened by a screening plate and on the upper layer of the circular plate are collected by arranging the material guiding assembly, then the peanut particles are transferred to the circular plate through a material guiding plate, secondary grinding is facilitated, and the conversion rate of peanut oil can be higher.

Owner:廖杨辉

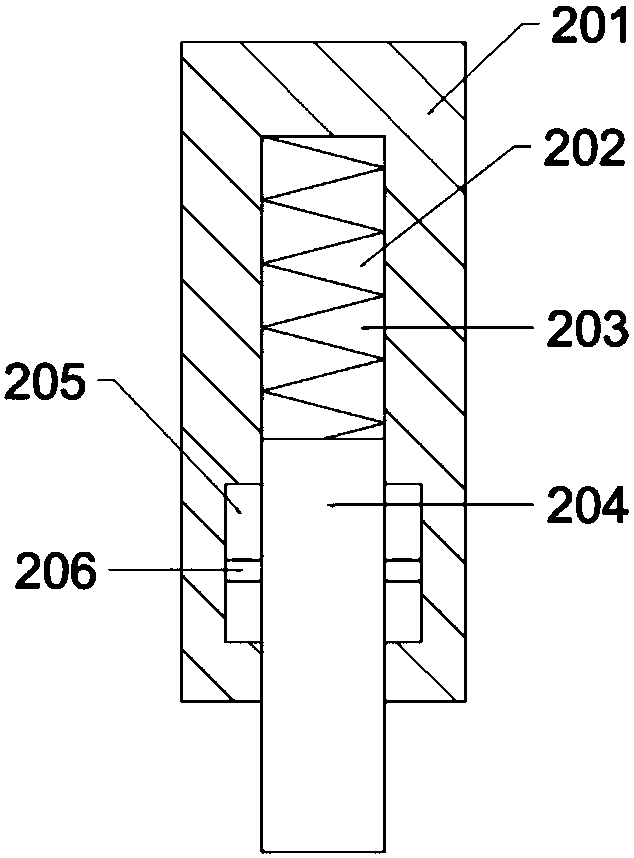

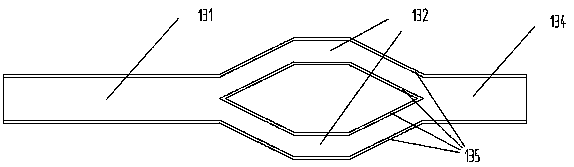

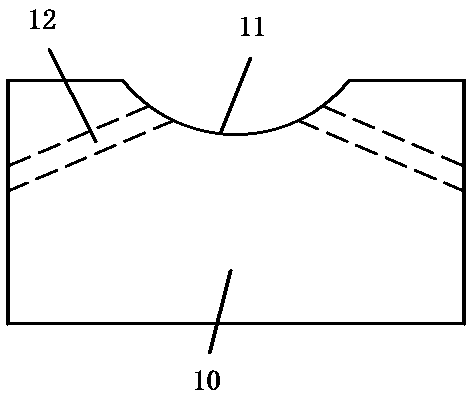

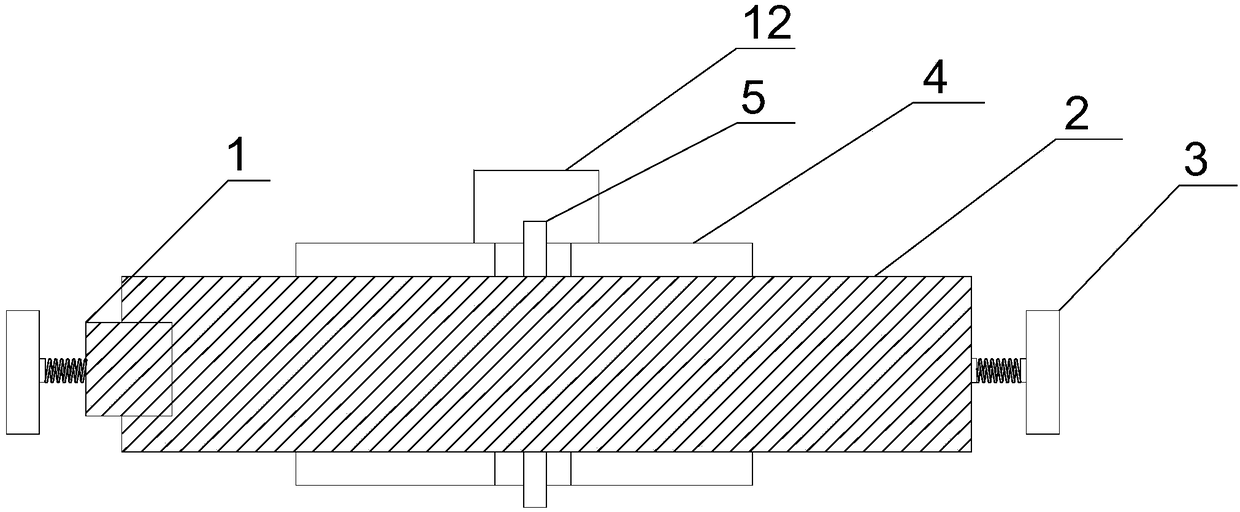

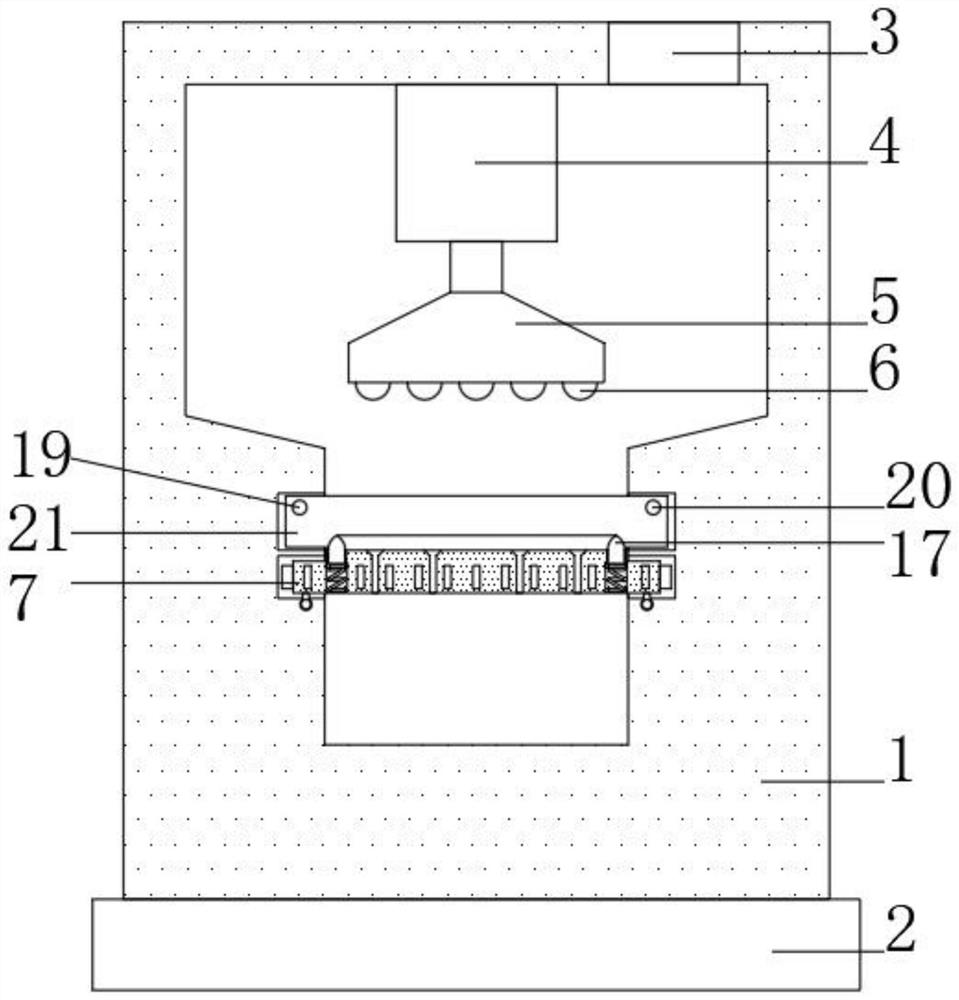

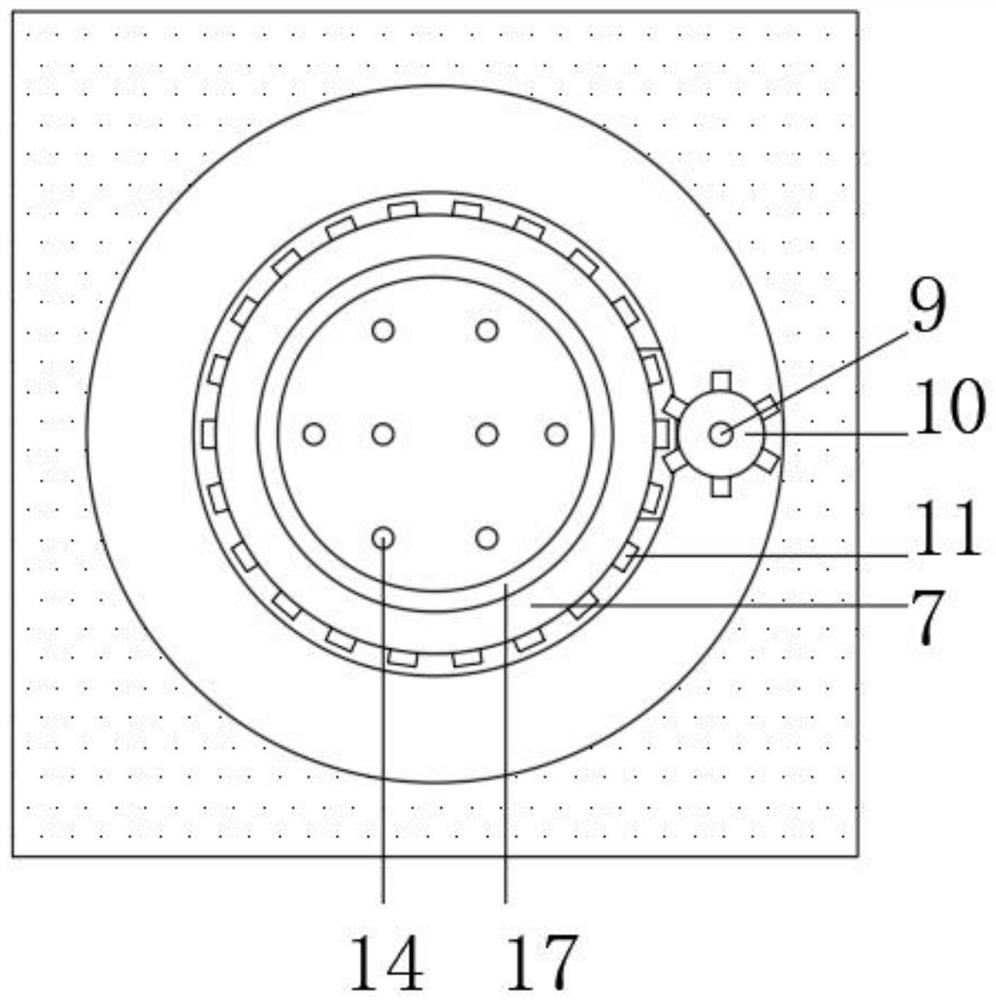

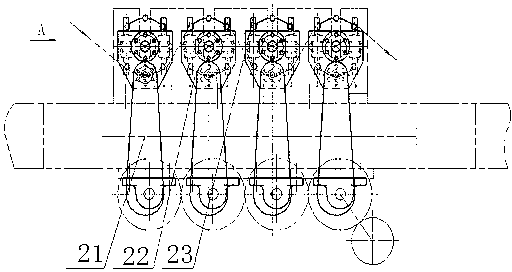

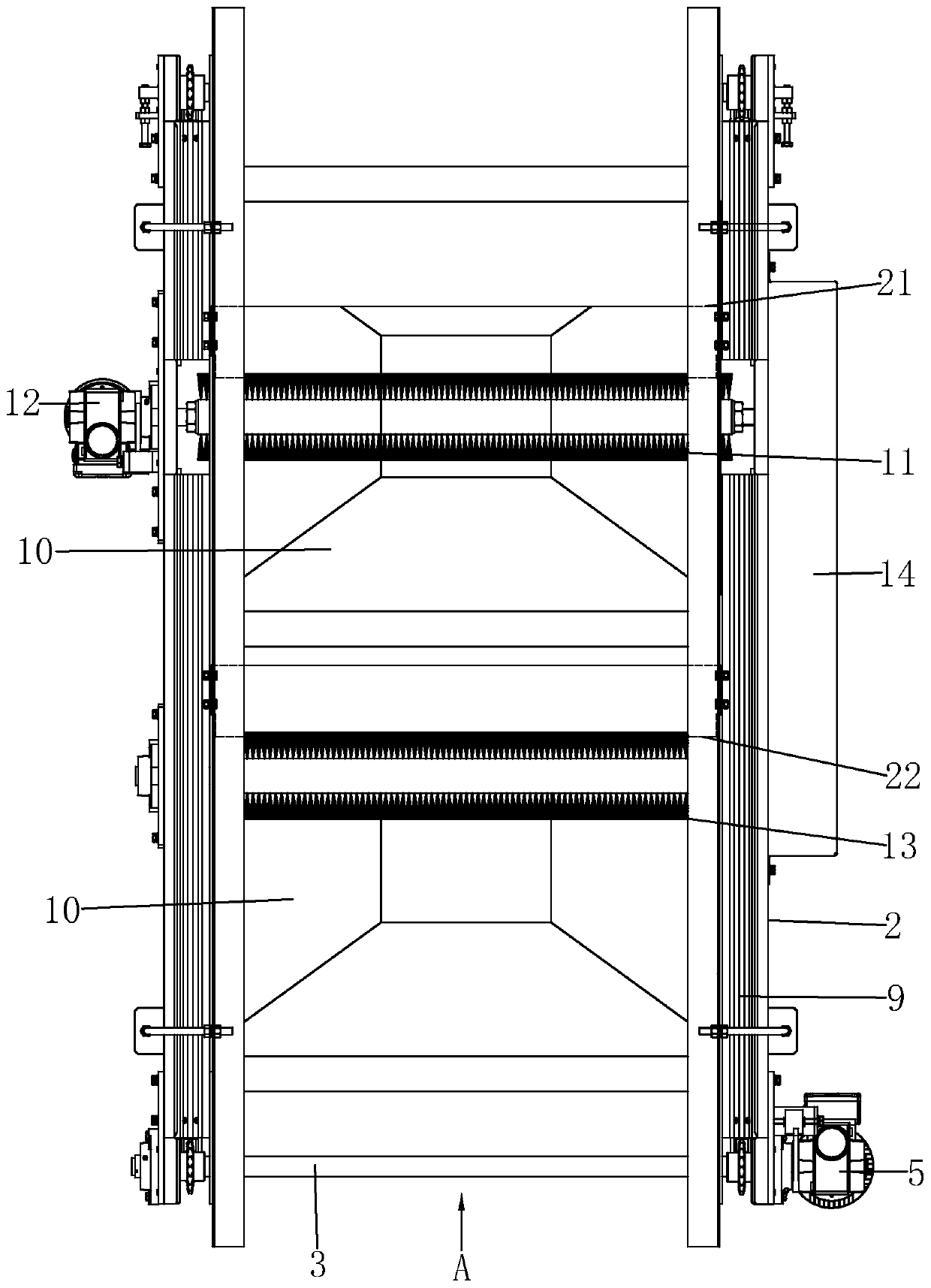

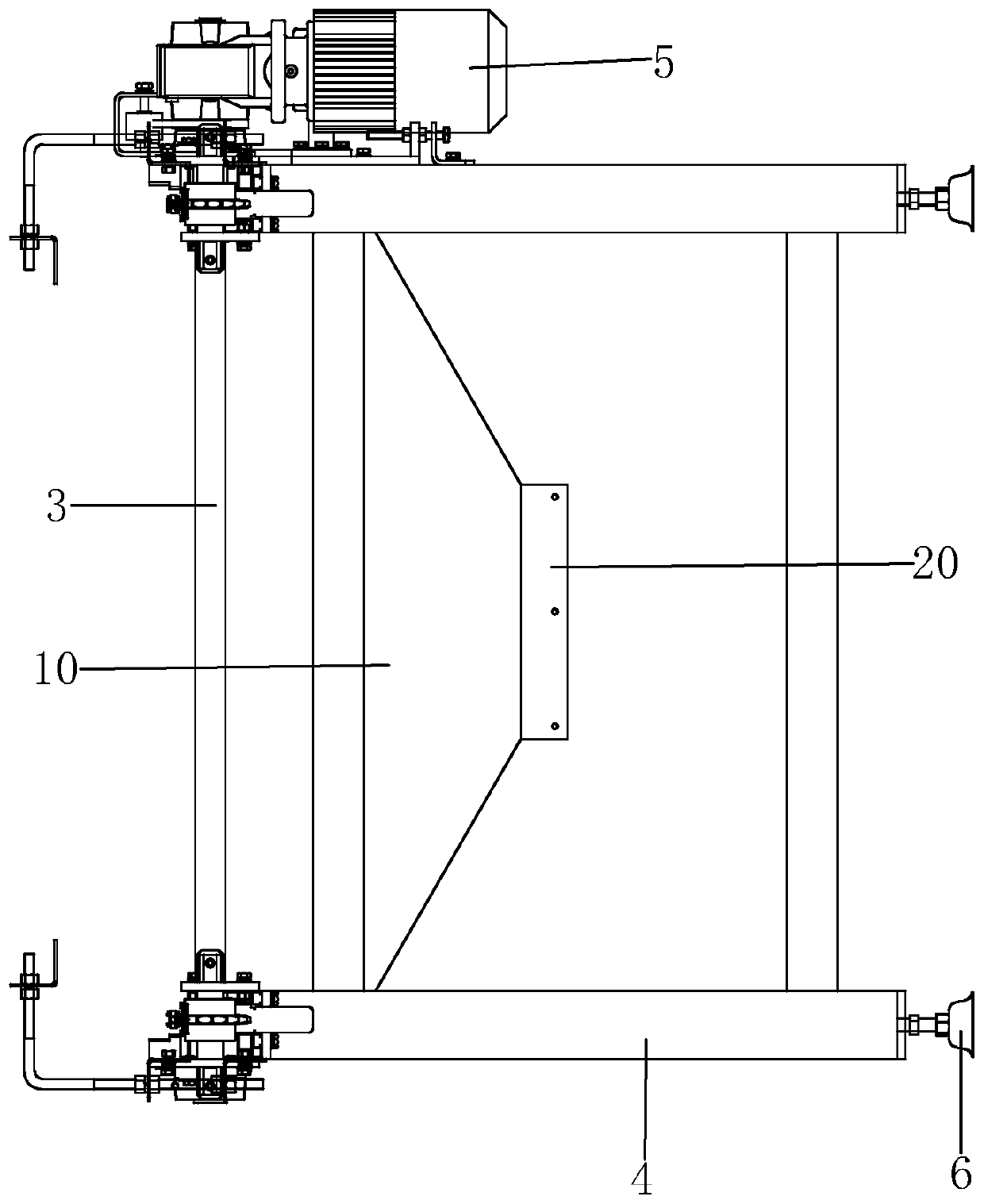

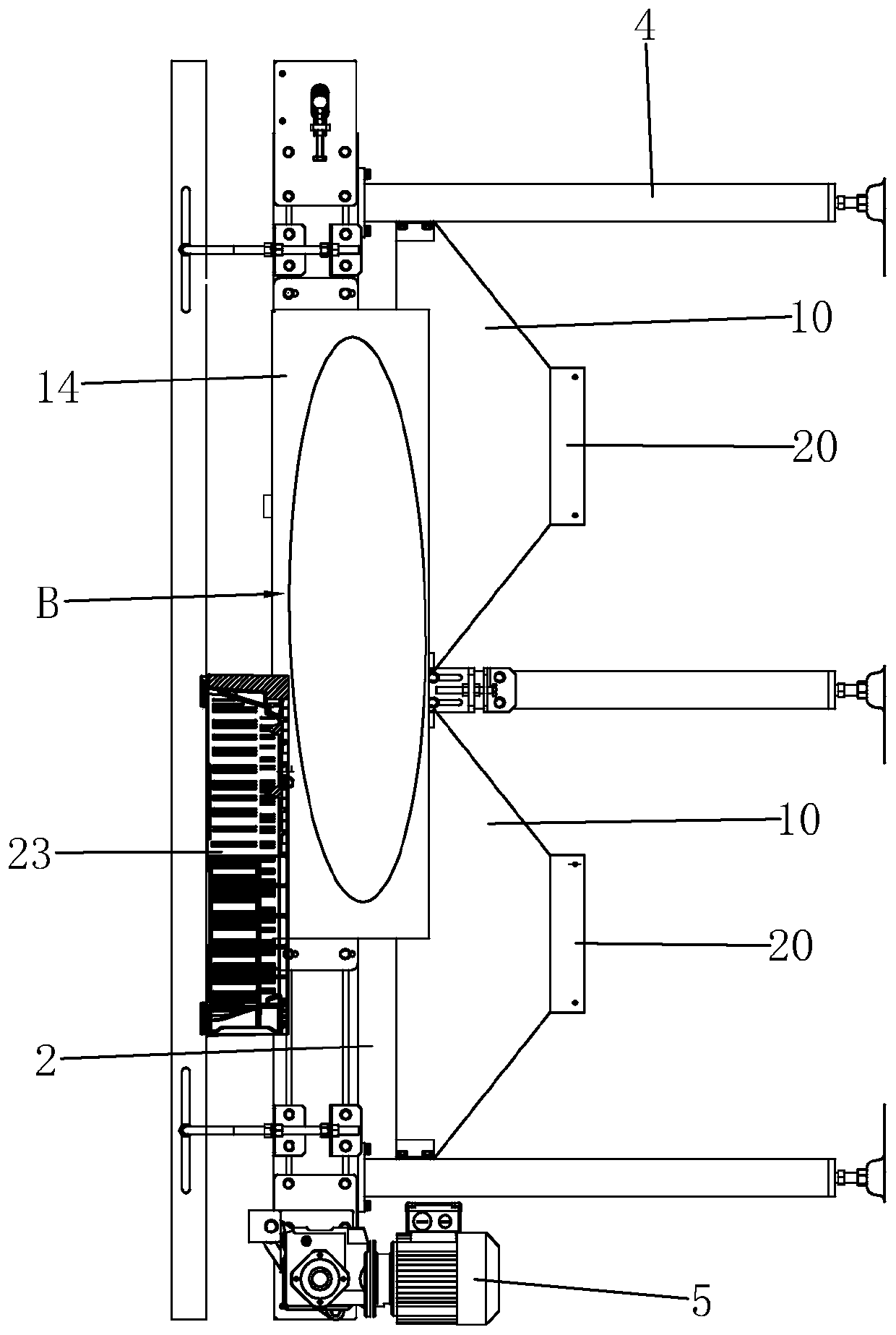

Up-down vibration flattening device

ActiveCN102517691BGuaranteed flattening effectNovel structureTextile/flexible product manufactureFibre chemical featuresMoving partsCarbon filaments

The invention discloses an up-down vibration flattening device which mainly consists of a transmission part (1), a moving part (2) and a vibration roller part (3), wherein the transmission part (1) is mounted at the bottom of a frame body of the flattening device; the moving part (2) is mounted on the frame body; the vibration roller part (3) is arranged at the upper part of the frame body and connected with the moving part (2); the vibration roller part (3) consists of four groups of vibration rollers; and every two adjacent groups of vibration rollers move relatively up and down in the axial direction under the effect of an eccentric wheel of the moving part (2). The up-down vibration flattening device disclosed by the invention has a novel, compact and reasonable structure; the transmission part adopts a variable-frequency motor which directly drives a rotation shaft with the eccentric wheel to rotate to realize up-down vibration, and can realize online adjustment of the vibration frequency according to the production process; the moving part adopts a precise linear guide rail to ensure vibration stability; and the vibration roller adopts a rachis structure so that the carbon filament is in linear contact and the carbon filament flattening effect is ensured.

Owner:大连橡胶塑料机械有限公司

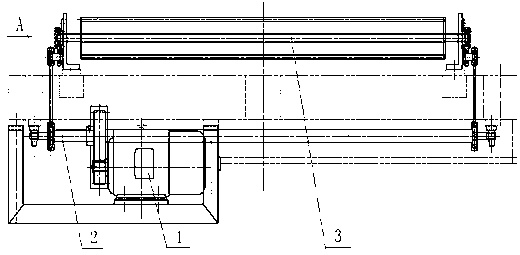

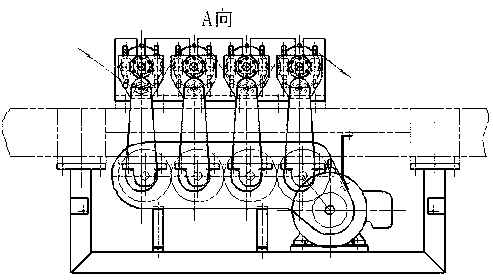

Frame bottom cocoon harvesting machine

The invention discloses a frame bottom cocoon harvesting machine which comprises a conveying mechanism; the conveying mechanism is provided with a material receiving funnel, a driving brush roller anda speed reducing motor; the driving brush roller is arranged above the material receiving funnel; and the speed reducing motor is connected with the driving brush roller. The frame bottom cocoon harvesting machine is novel in structure and good in cocoon harvesting effect, is automatic and efficient, saves manpower and can realize continuous cocoon harvesting work.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com