Iron ore screening device for converter

A screening device, iron ore technology, applied in the direction of separating solids from solids with airflow, filtering, solid separation, etc., can solve problems such as filter blockage, unhealthy operators, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

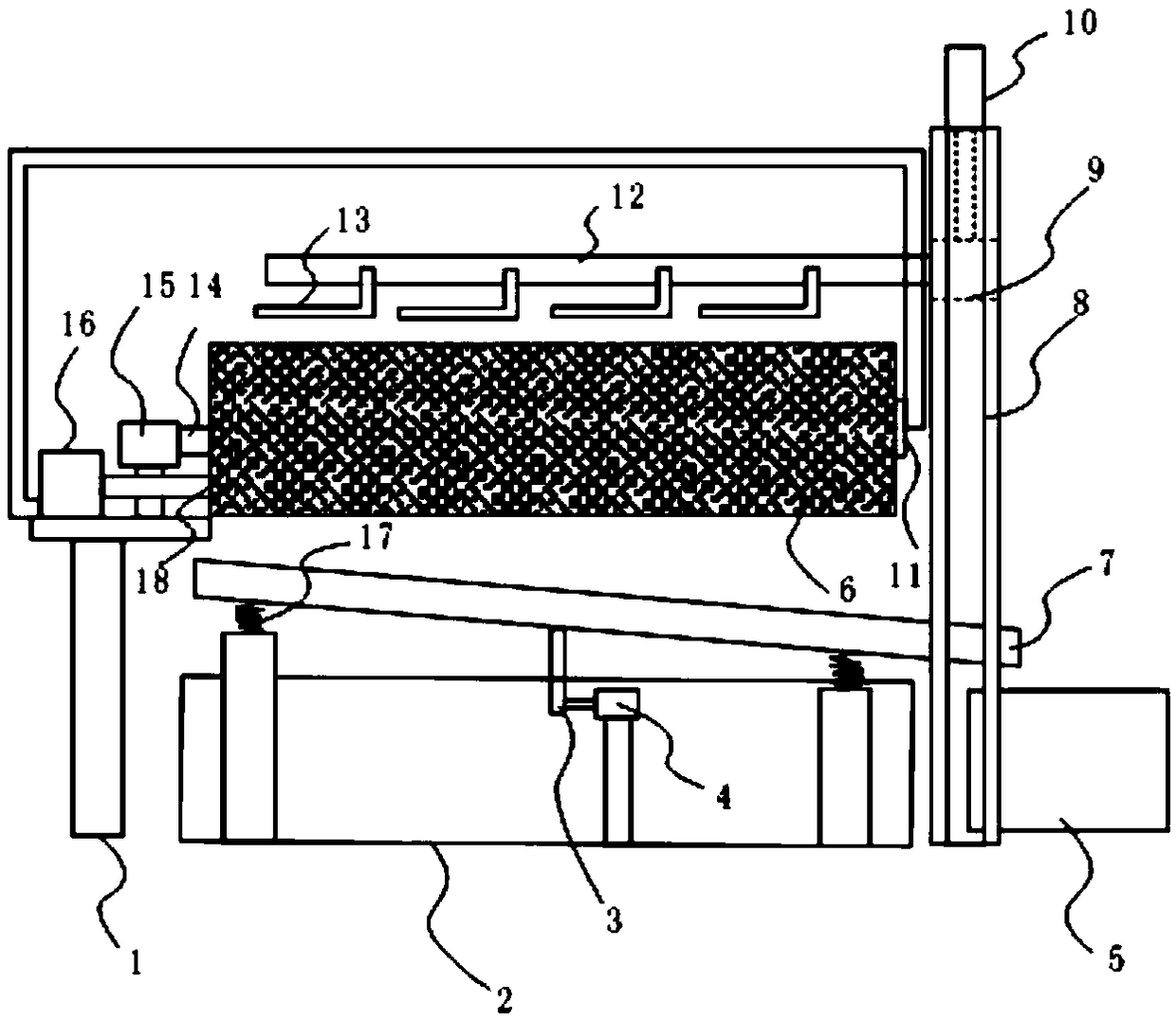

[0014] An iron ore screening device for a converter, which includes a frame 1, a hopper, a vibrating device, a screening device and a crusher 16, and the screening device includes a trommel 6 and a rotating shaft 14 passing through the center of the trommel, The rotating shaft is driven by a rotating shaft motor 15 fixedly installed on the frame, and one end of the trommel is provided with a trommel inlet 11, and the other end is provided with a trommel outlet 18, and the trommel outlet is connected to the trommel outlet. The feed port of the crusher is connected through a pipeline, the discharge port of the crusher is connected with the feed port of the drum screen through a pipe, and a filter screen 7 is arranged under the drum screen, and the filter screen is fixedly installed with the frame and extends along the drum screen. Downwardly inclined, there are two feed troughs, which are respectively the small particle size feed tank 2 located at the bottom of the filter screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com