Patents

Literature

63results about How to "Automatic take out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

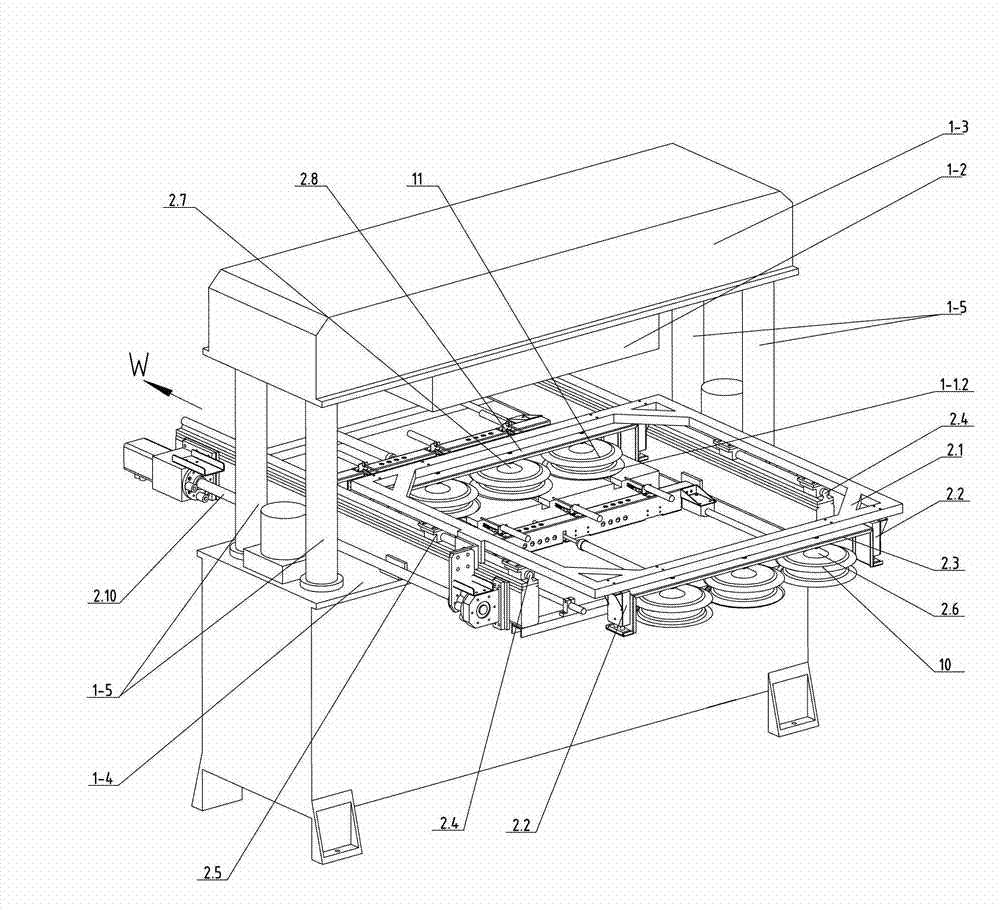

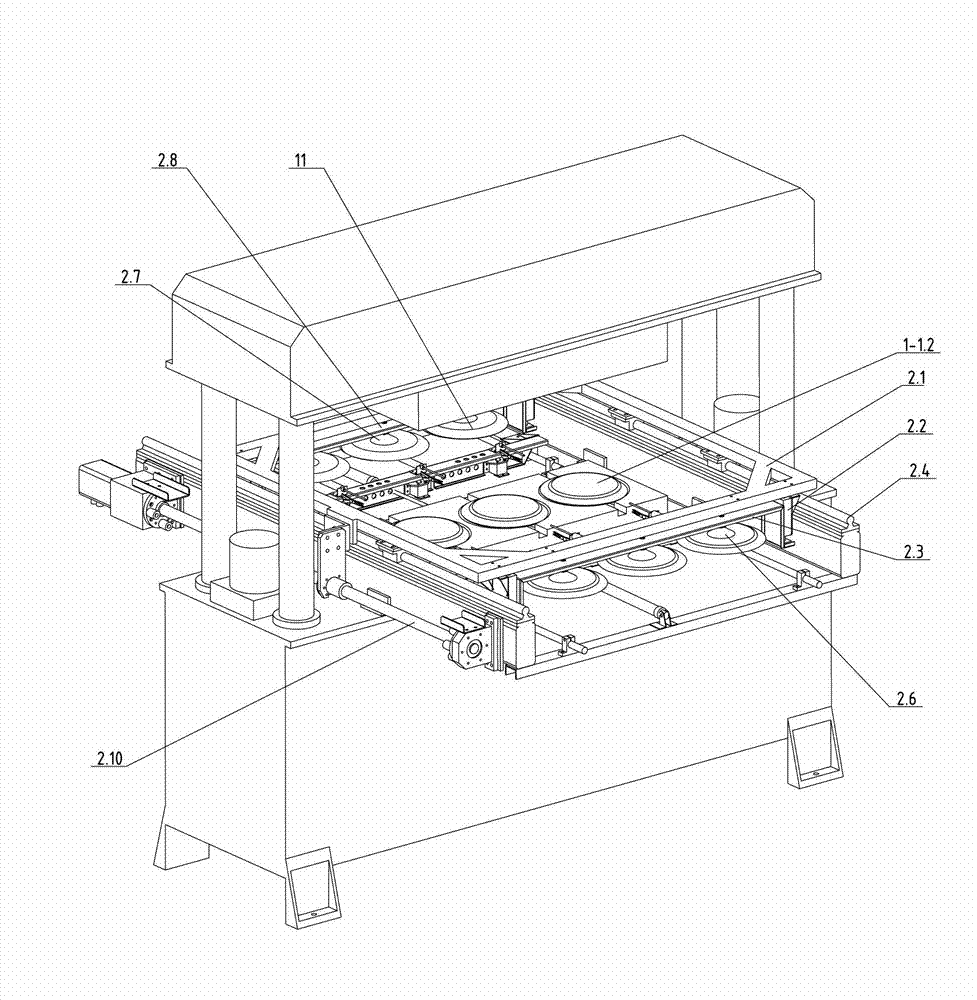

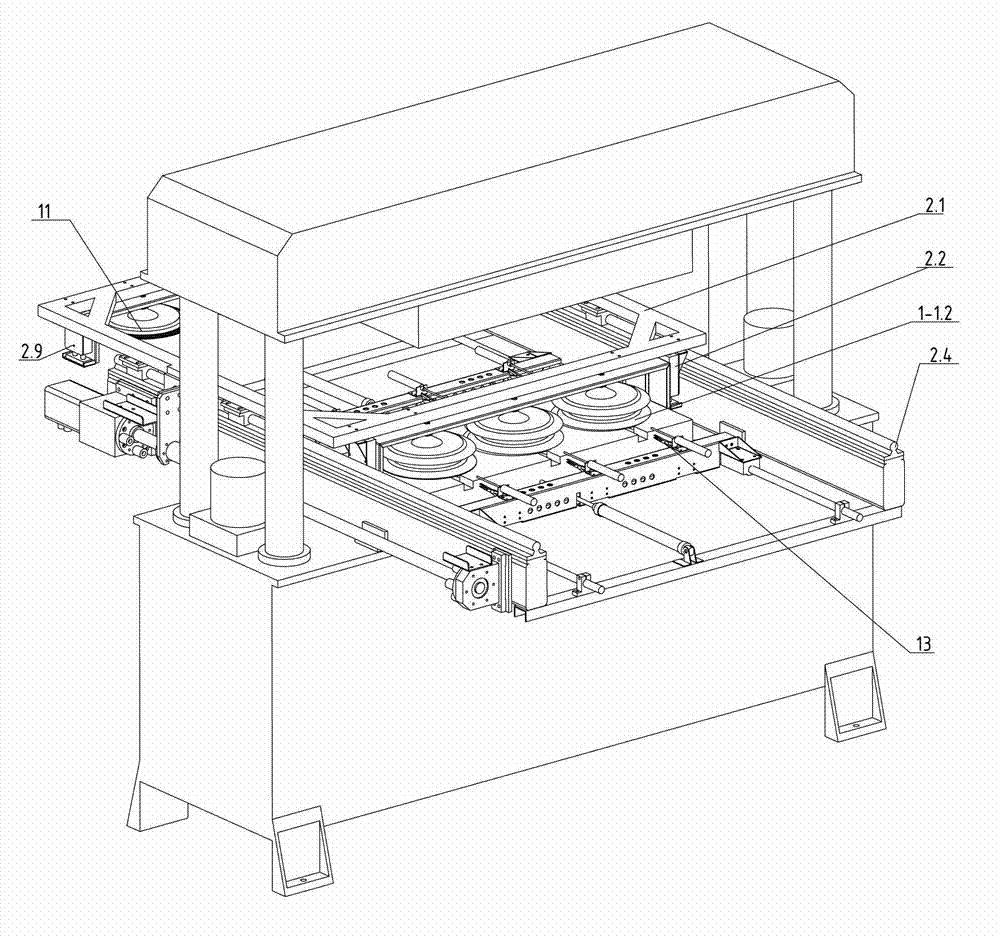

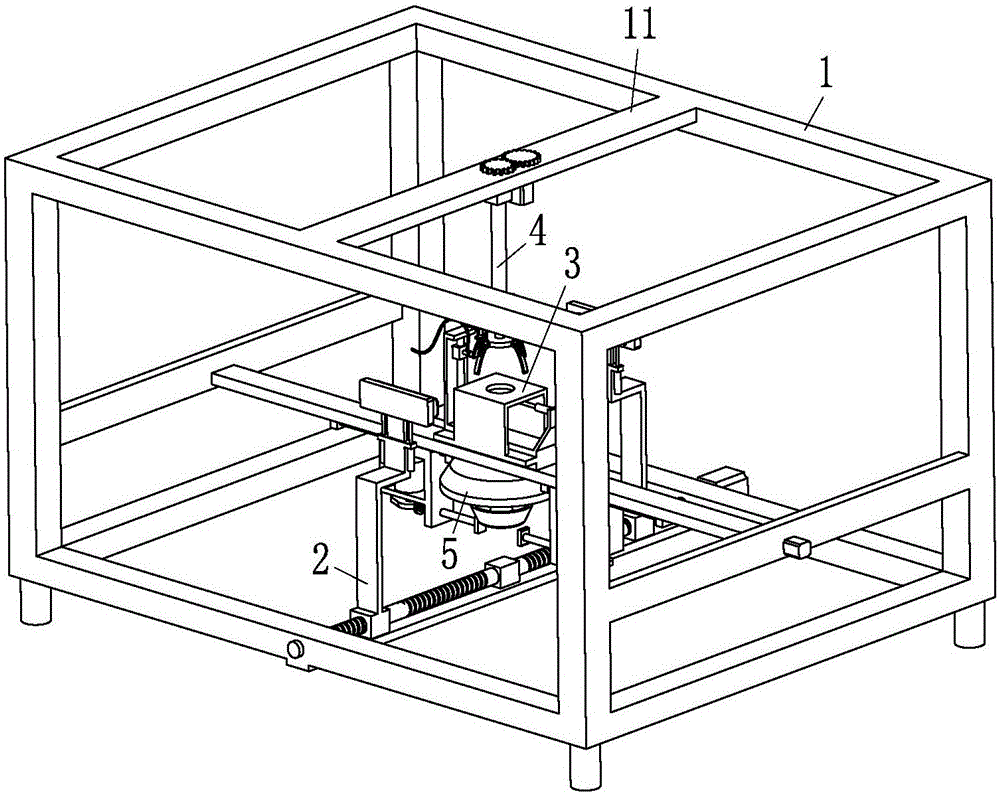

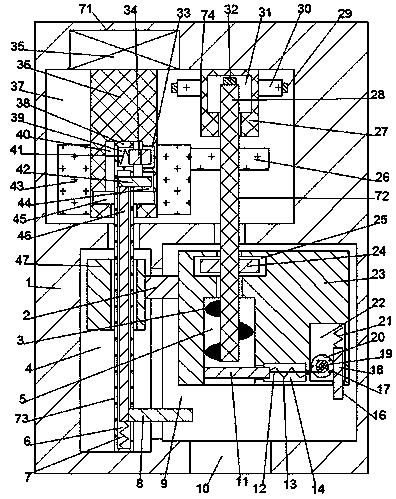

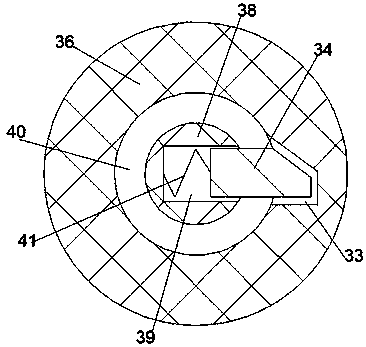

Automatic edge cutting method for plant fiber molding product and automatic edge cutting machine

ActiveCN103042639AAccurate cutting edge positioningHigh speedMetal working apparatusFiberEngineering

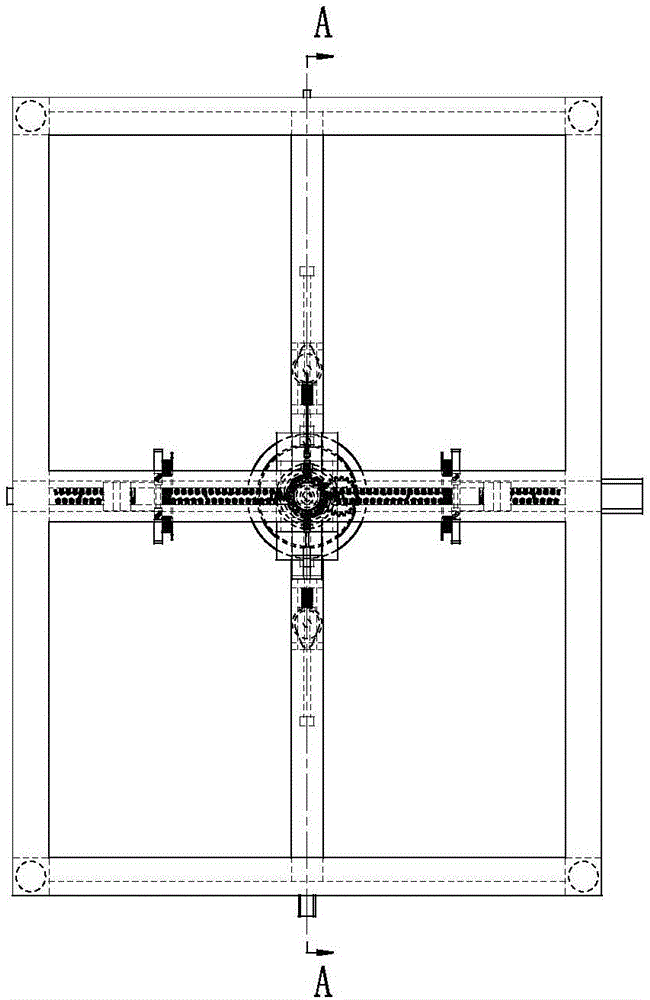

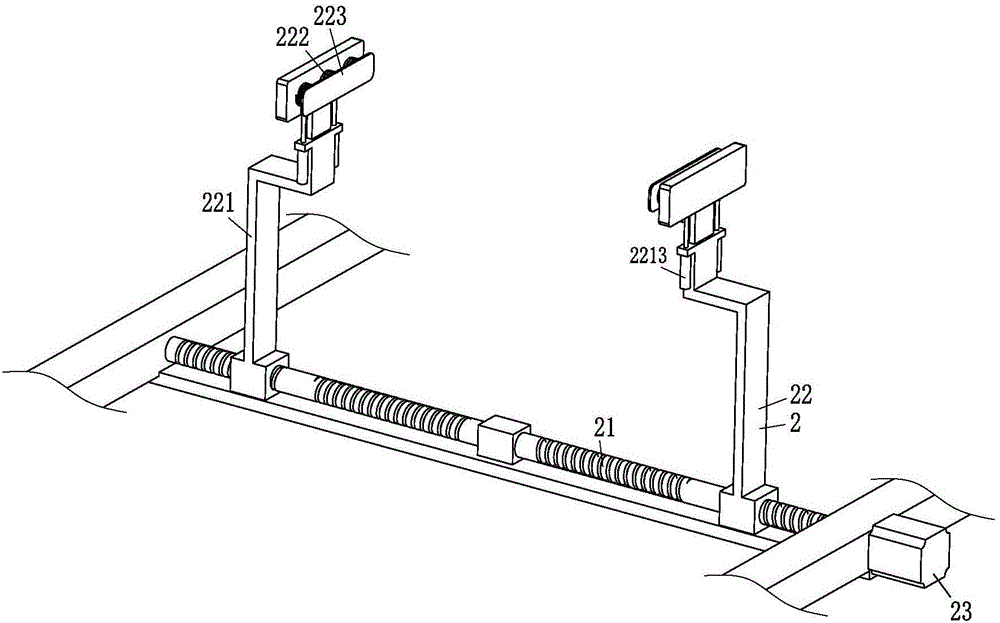

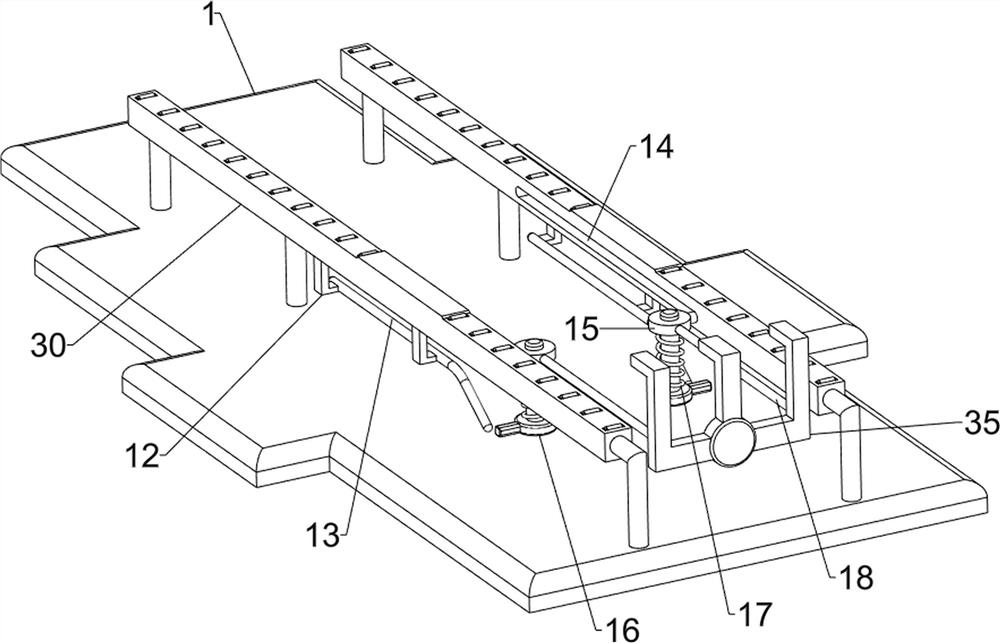

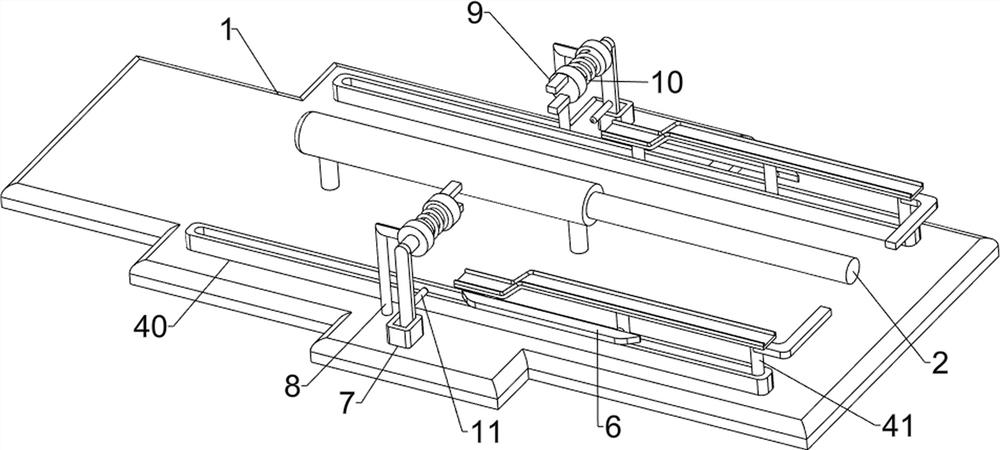

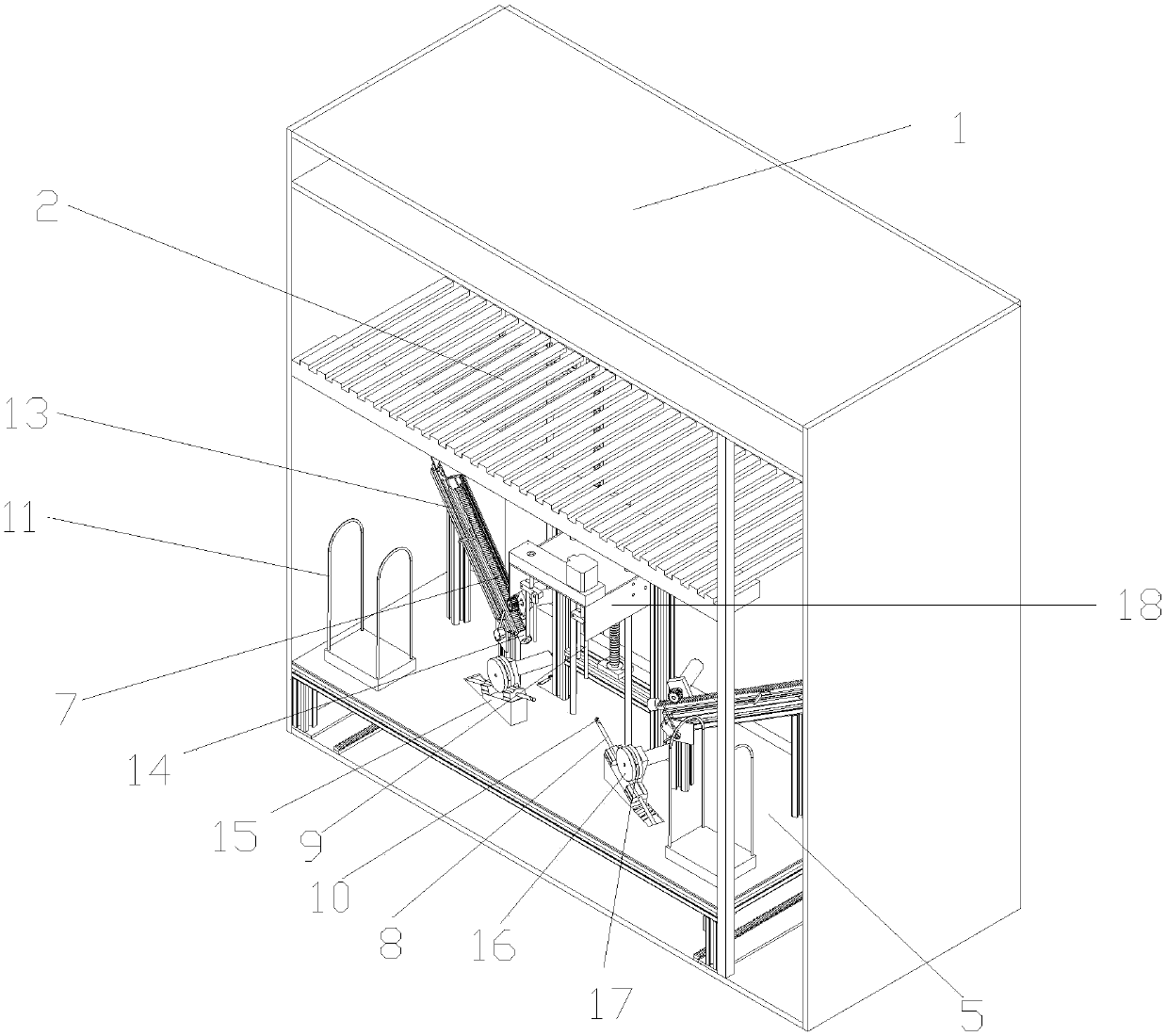

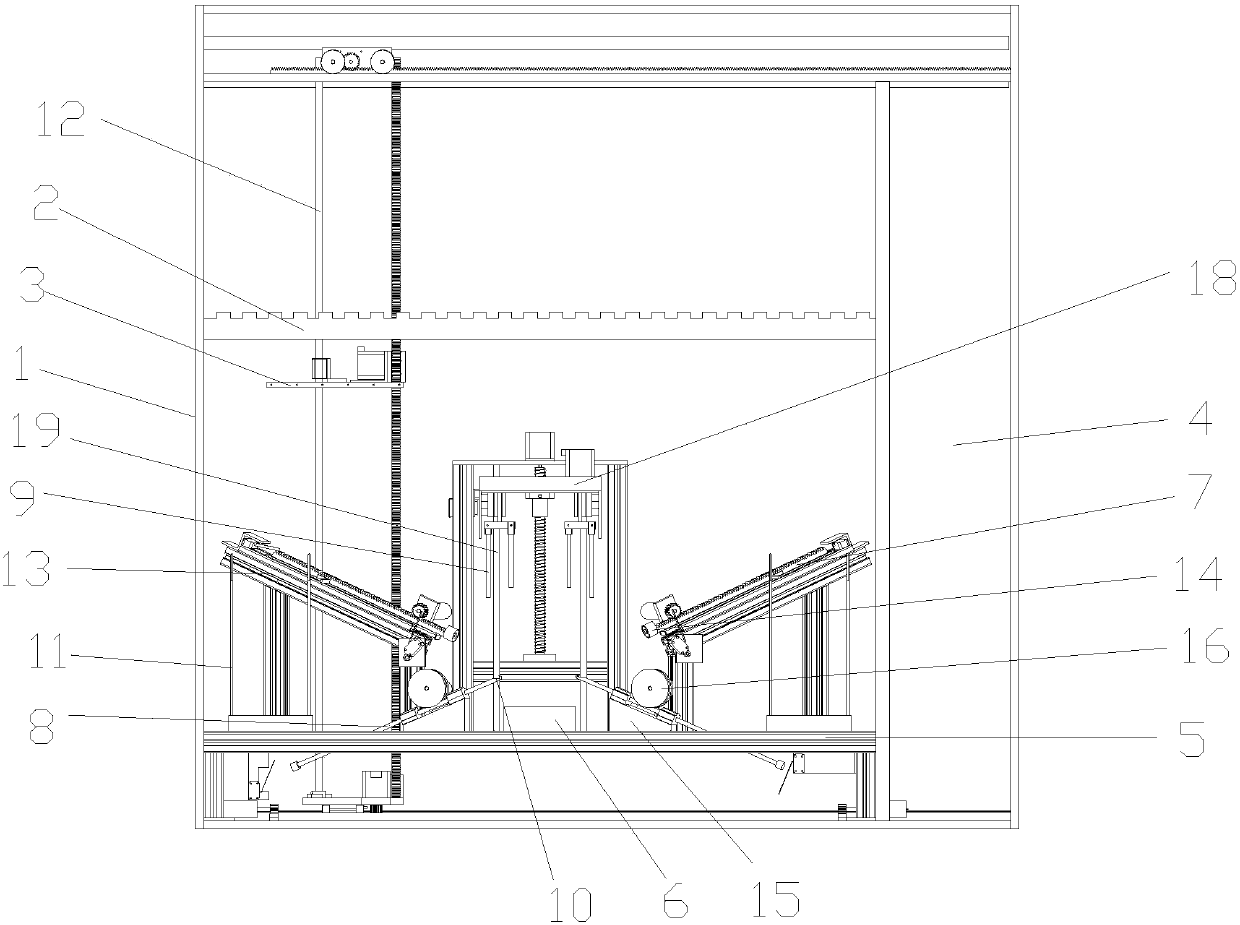

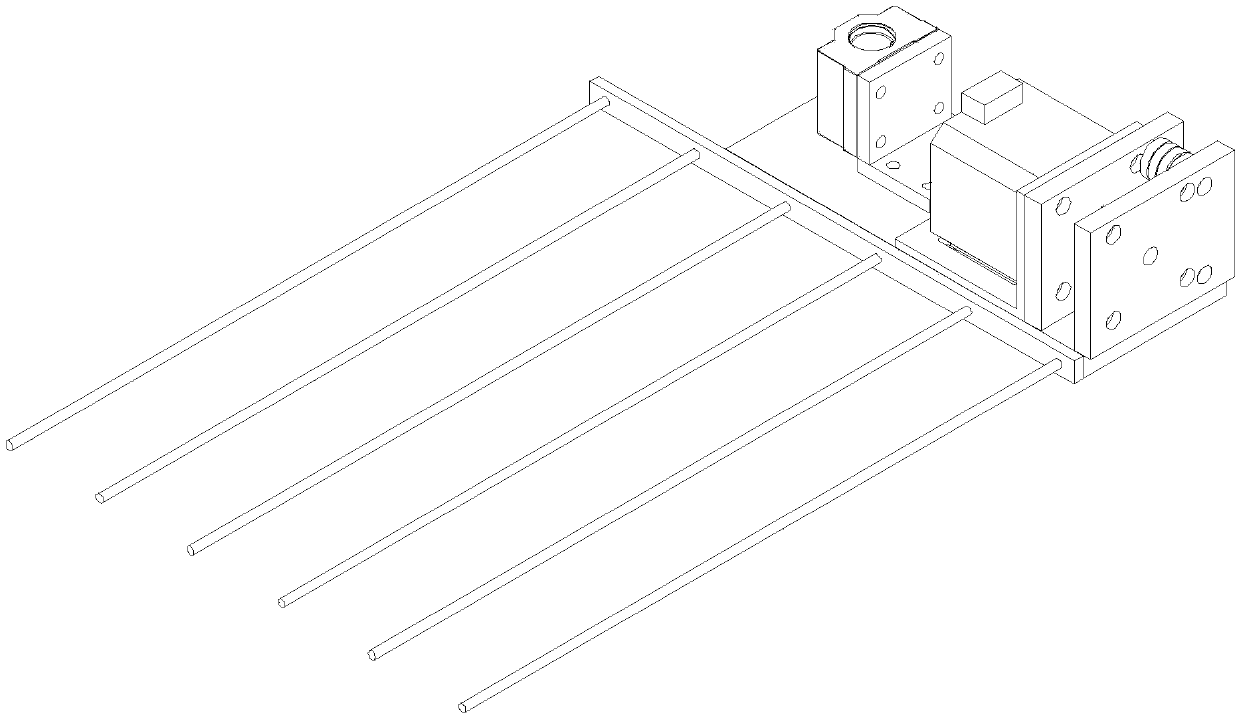

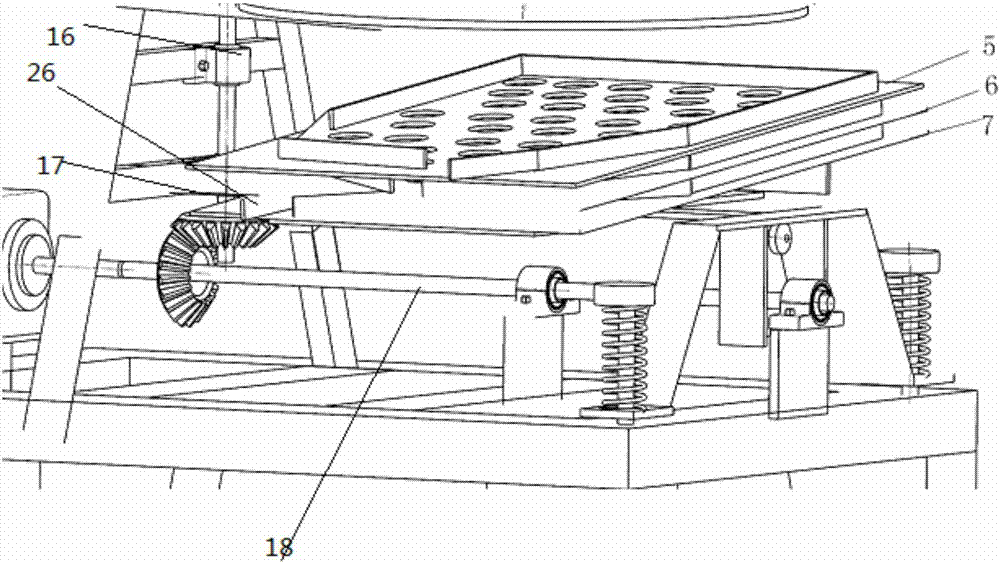

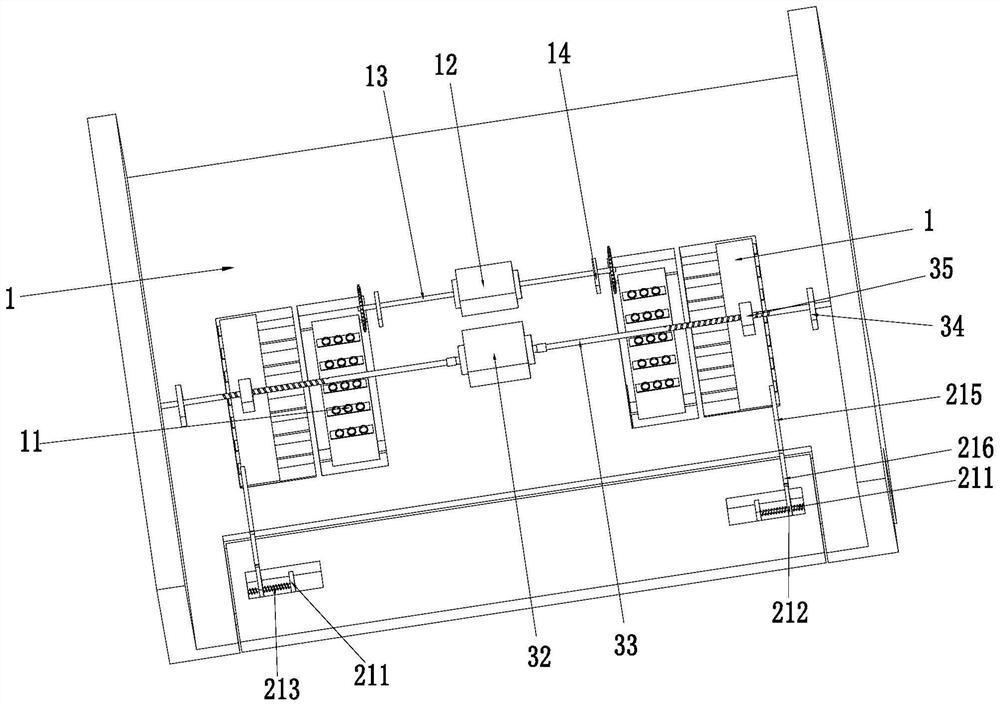

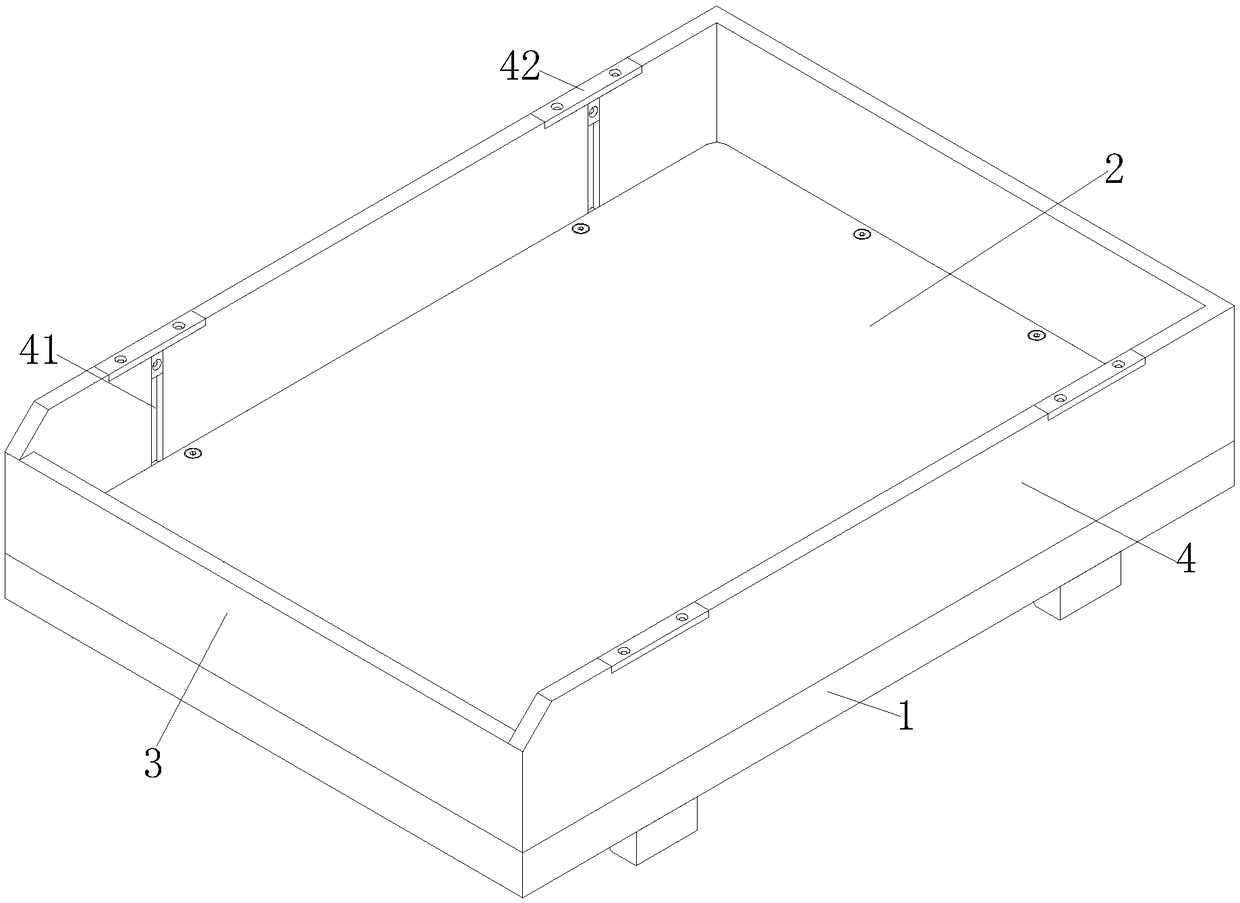

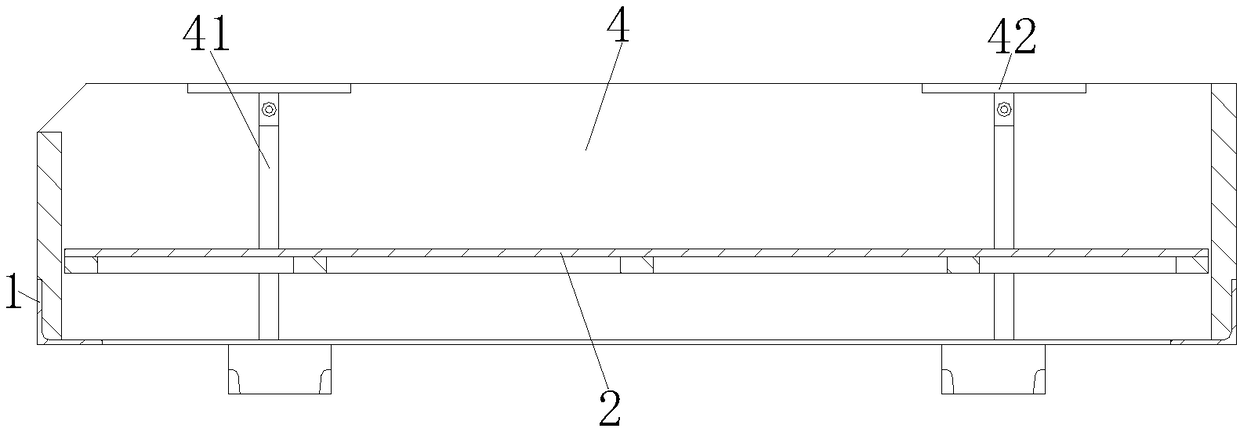

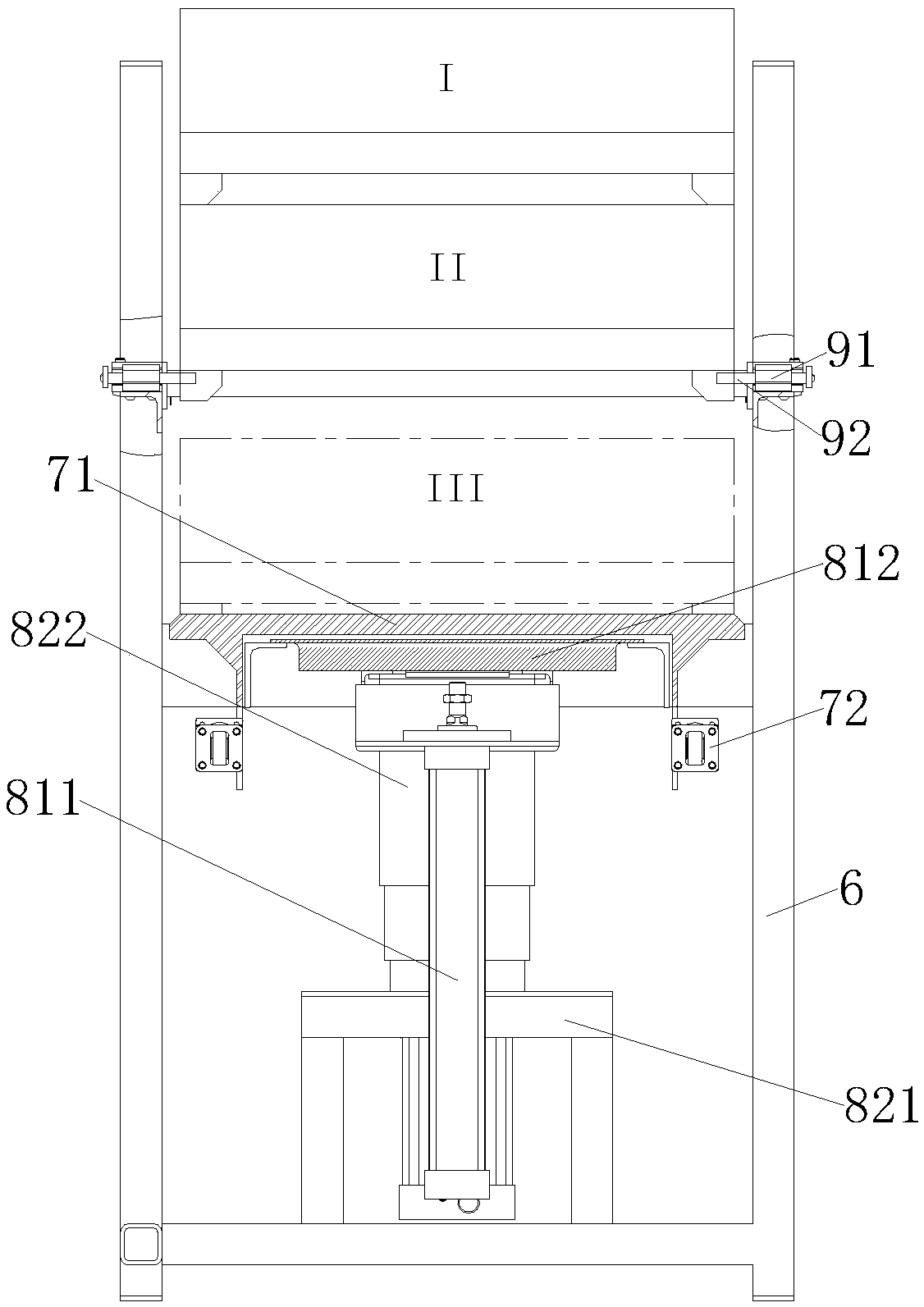

The invention relates to an automatic edge cutting method for a plant fiber molding product and an automatic edge cutting machine. The purposes are that the method has the characteristic of automatic and accurate location, and the automatic cutting machine has the characteristic of stable work. The technical scheme includes that the automatic edge cutting method for the plant fiber molding product proceeds as follows: 1), sucking the product with edges to be cut; 2), driving away waste edges from an edge cutting position; 3), positioning the product to be cut and a product with cut edges respectively; 4), cutting out deckle edges; 5), enabling a front row and a rear row of sucking disk sets to reach the corresponding positions respectively; and 6), sucking the product with edges to be cut and the product with cut edges; repeating from the step 2) to the step 6), and proceeding the circulation over and over again. The automatic edge cutting machine for the plant fiber molding product comprises an edge cutting and die assembly mechanism, wherein the edge cutting and die assembly mechanism comprises an upper edge cutting mold, a lower edge cutting mold, an upper installation plate, a lower installation plate and a power mechanism. The automatic edge cutting machine for the plant fiber molding product is characterized in that a product transferring mechanism and a waste edge moving out mechanism are also arranged on the automatic edge cutting machine.

Owner:EURASIA EP MACHINERY +1

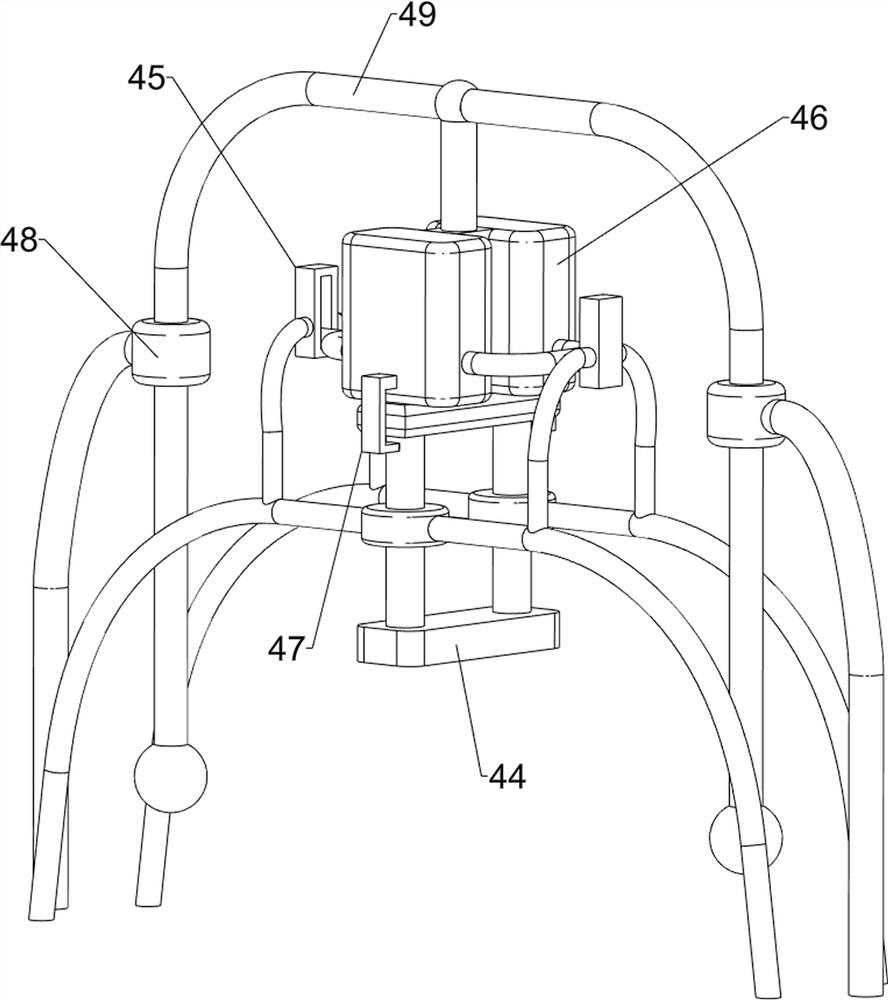

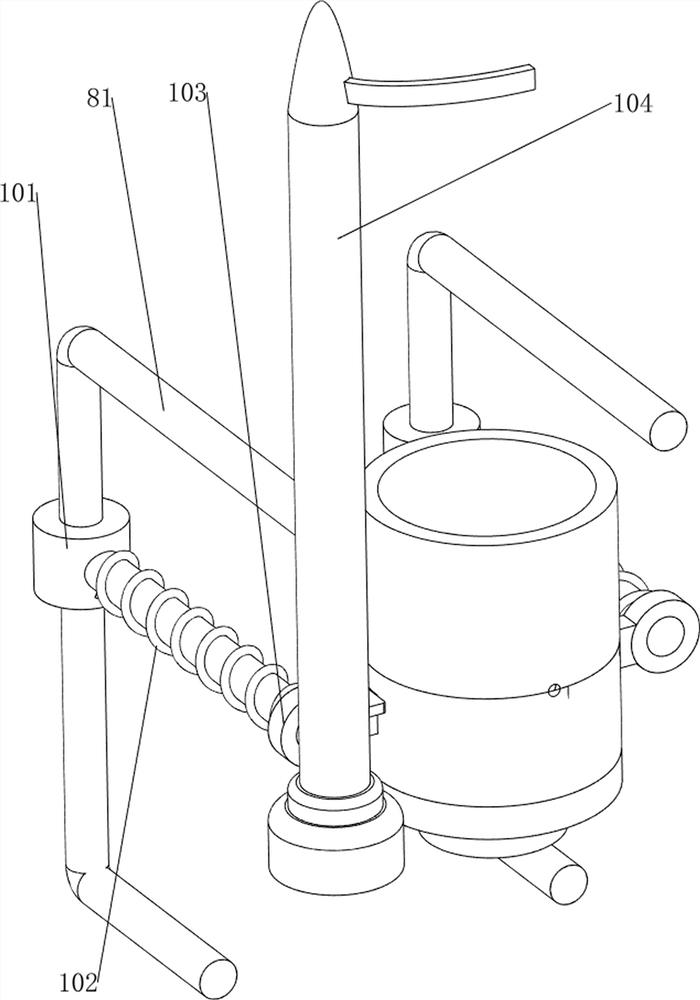

Robot for intelligently taking pomegranate pulp

ActiveCN106473162AAutomatic take outMeet the needs of large quantitiesFruit stoningAgricultural engineeringAgricultural machinery

The invention relates to the field of agricultural machinery, in particular to a robot for intelligently taking pomegranate pulp. The robot comprises a machine frame, a left and right clamping device, a cutting device, an upper clamping device and a fruit thumping device, wherein the left and right clamping device comprises a clamping screw, a pair of clamping units and a left and right clamping motor; the cutting device comprises a cutting support plate, a cutting and spinning motor, a placing plate, a pomegranate bottom removing device and a pomegranate side cutting device; the upper clamping device comprises an upper clamping motor, a first clamping wheel gear, a second clamping wheel gear, an upper clamping base, an upper clamping cylinder and a clamping jaw; the fruit thumping device comprises a fruit placing tray and a pair of fruit thumping units. According to the robot for intelligently taking pomegranate pulp, a portion which is several centimeters below the flower falling place of the pomegranate can be automatically cut open, pomegranate pericarp can be automatically cut into six sections, knocking on the surface skin of the pomegranate can be automatically conducted, thus the purpose of automatically taking out the pulp in the pomegranate can be achieved, manual operations are not needed, requirements of the markets on the pomegranate on a large scale can be satisfied, and thus the robot has strong practicability.

Owner:宿州市徽腾知识产权咨询有限公司

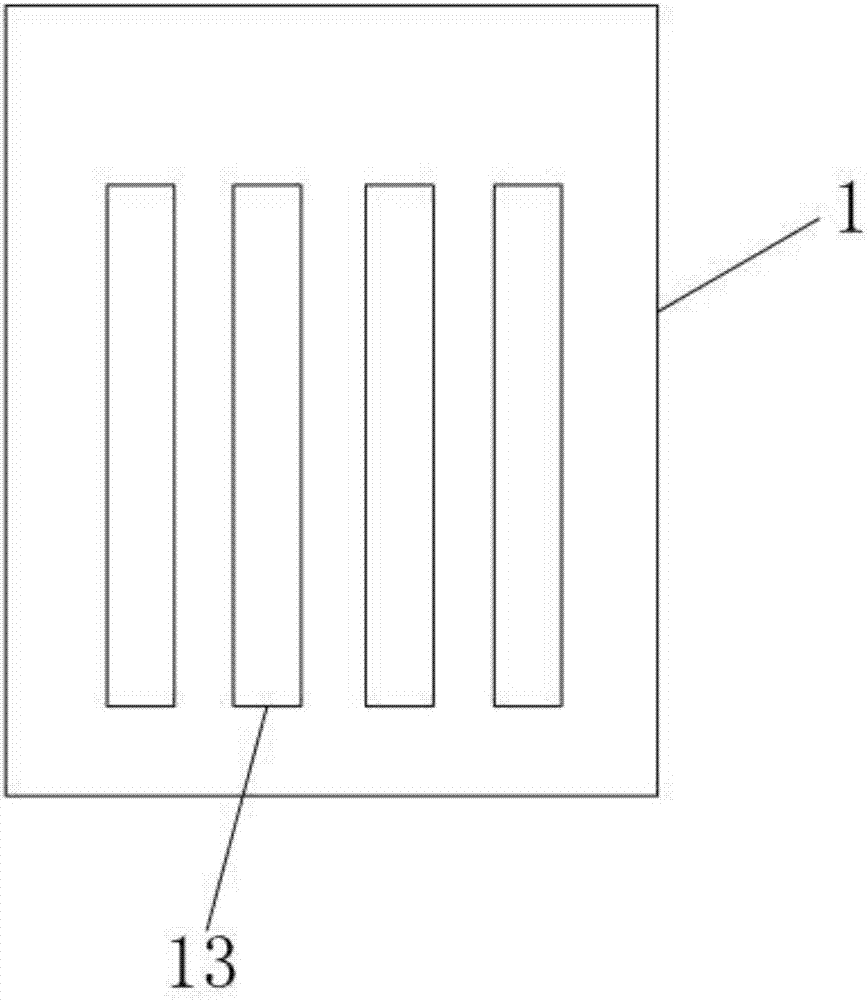

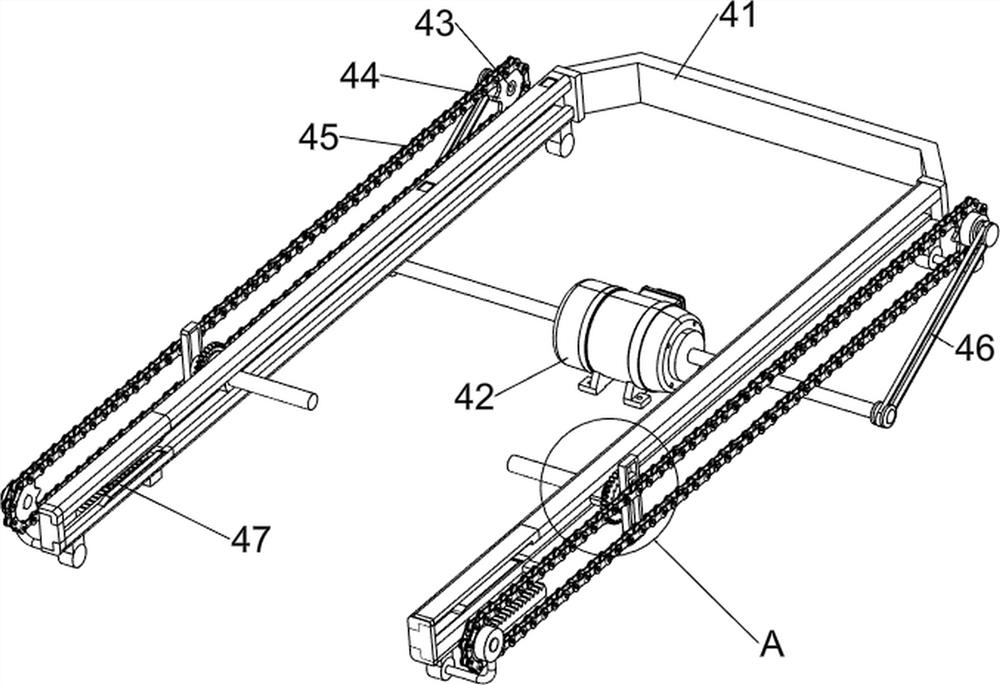

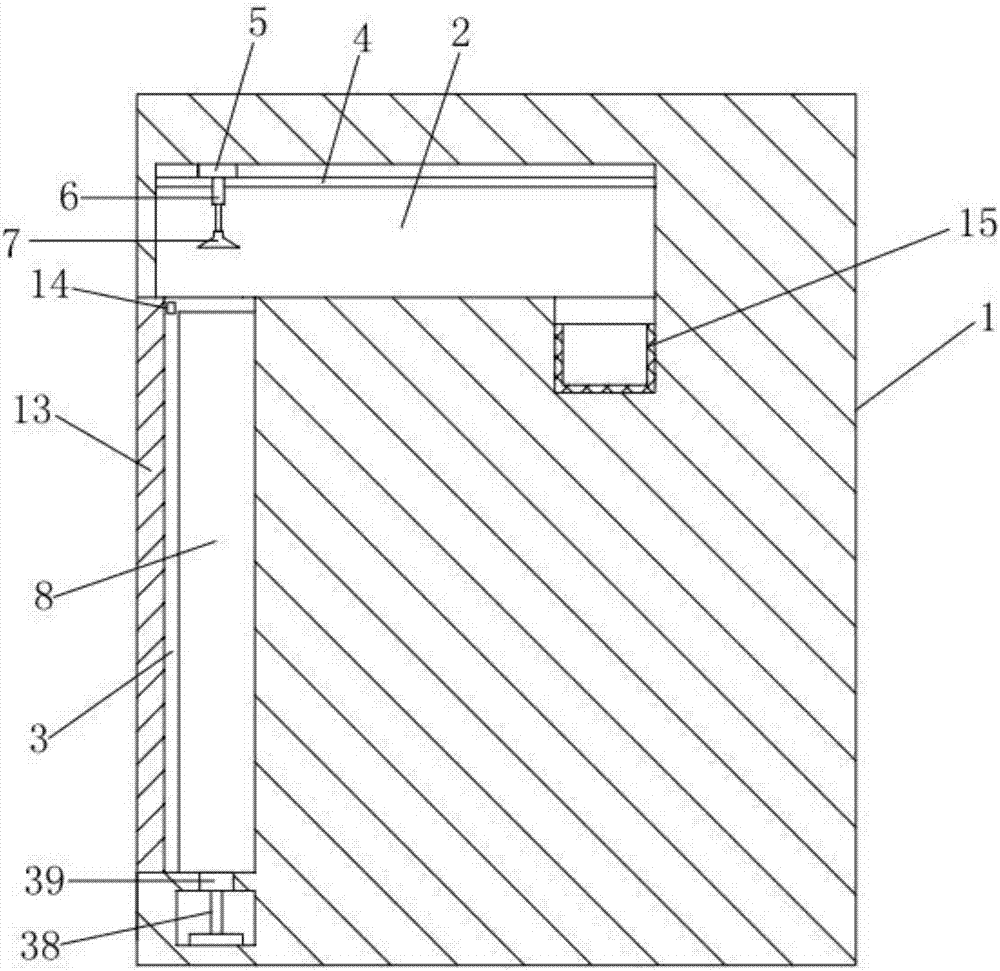

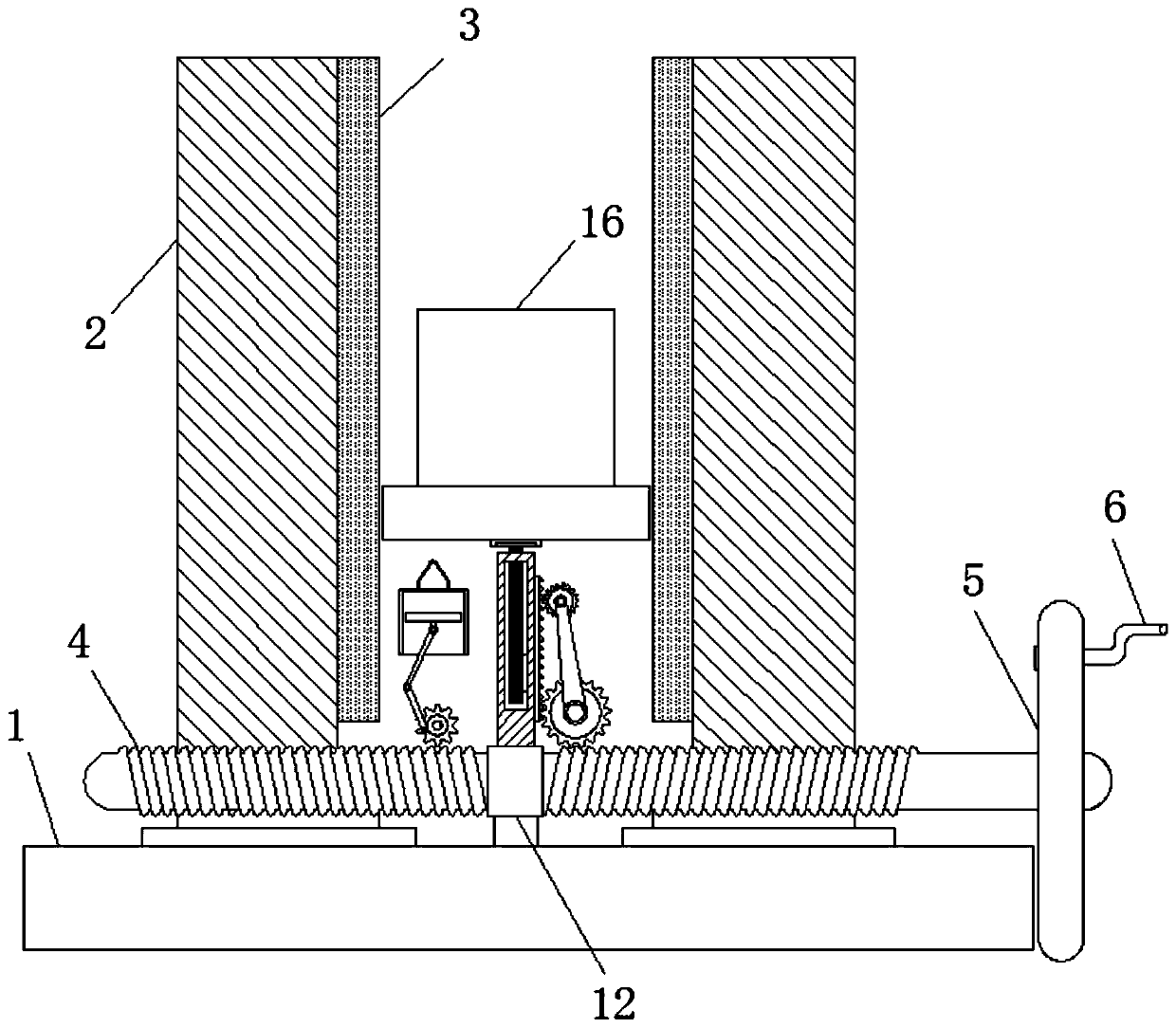

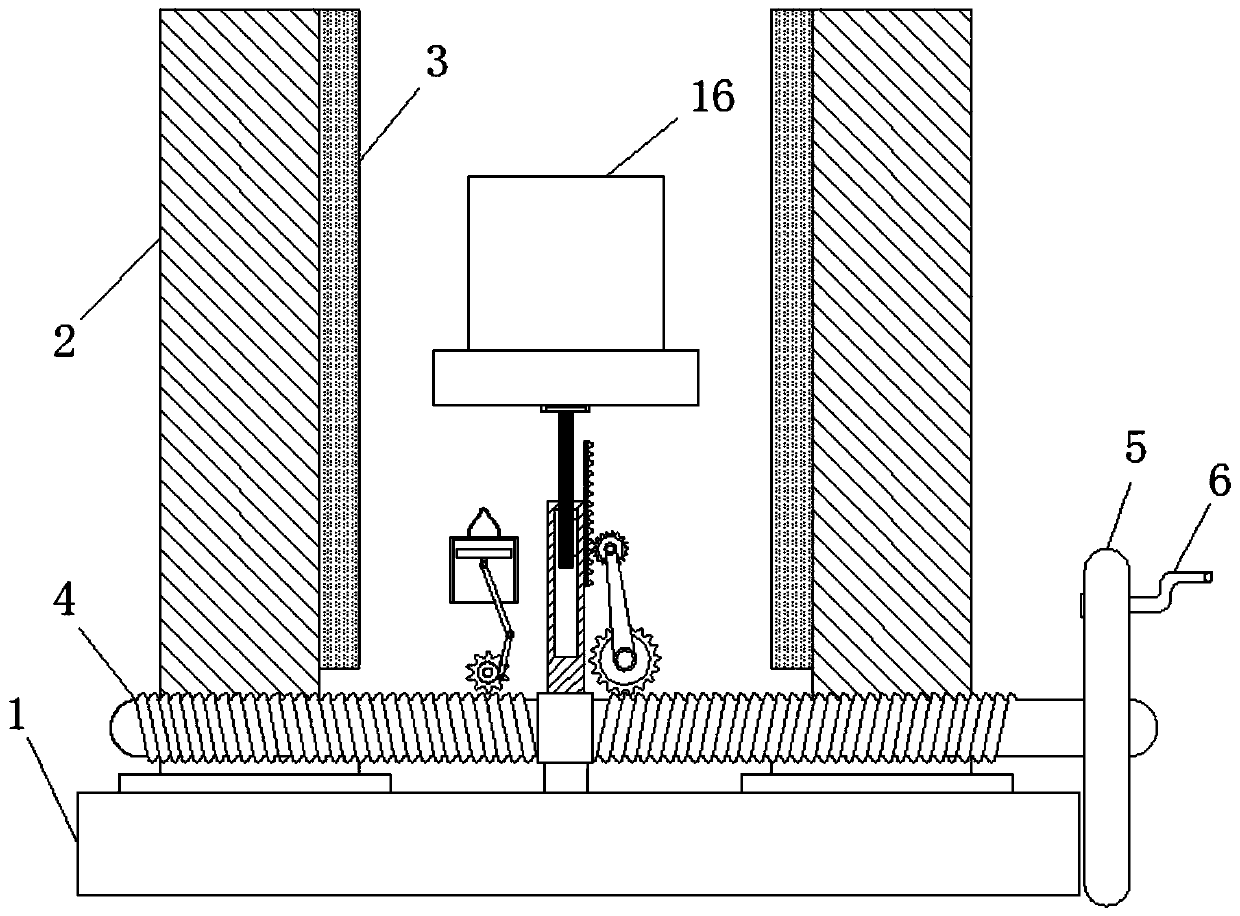

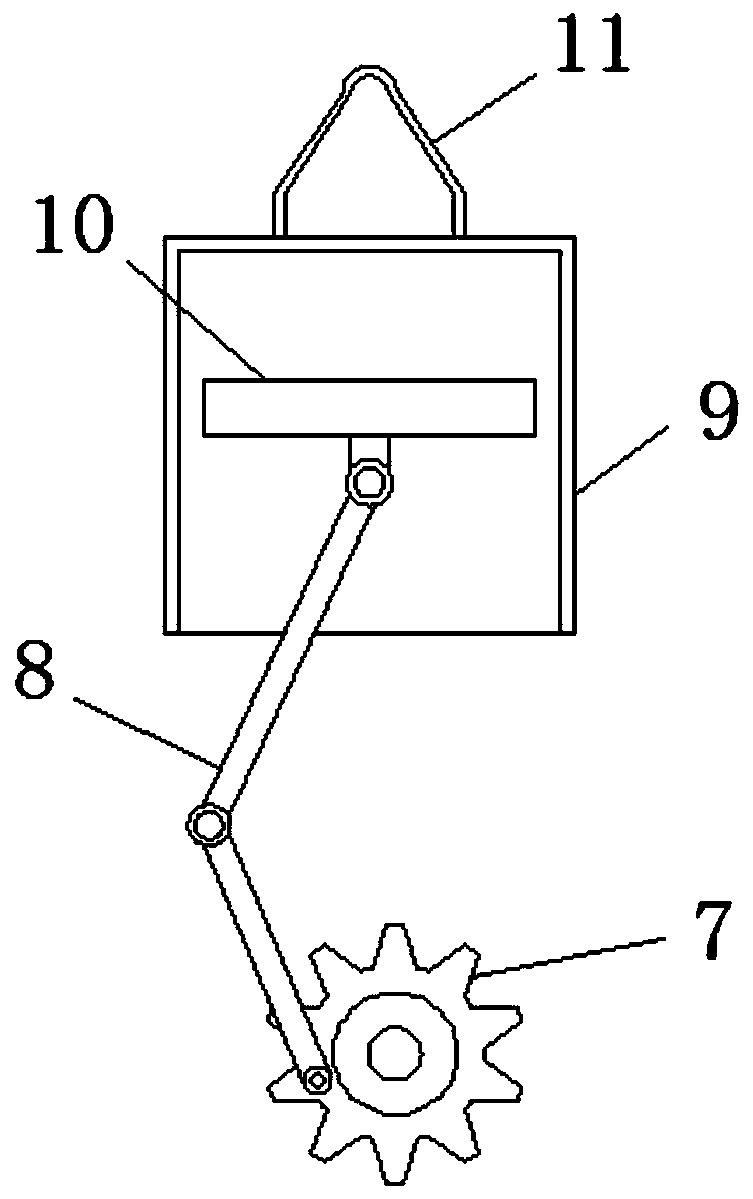

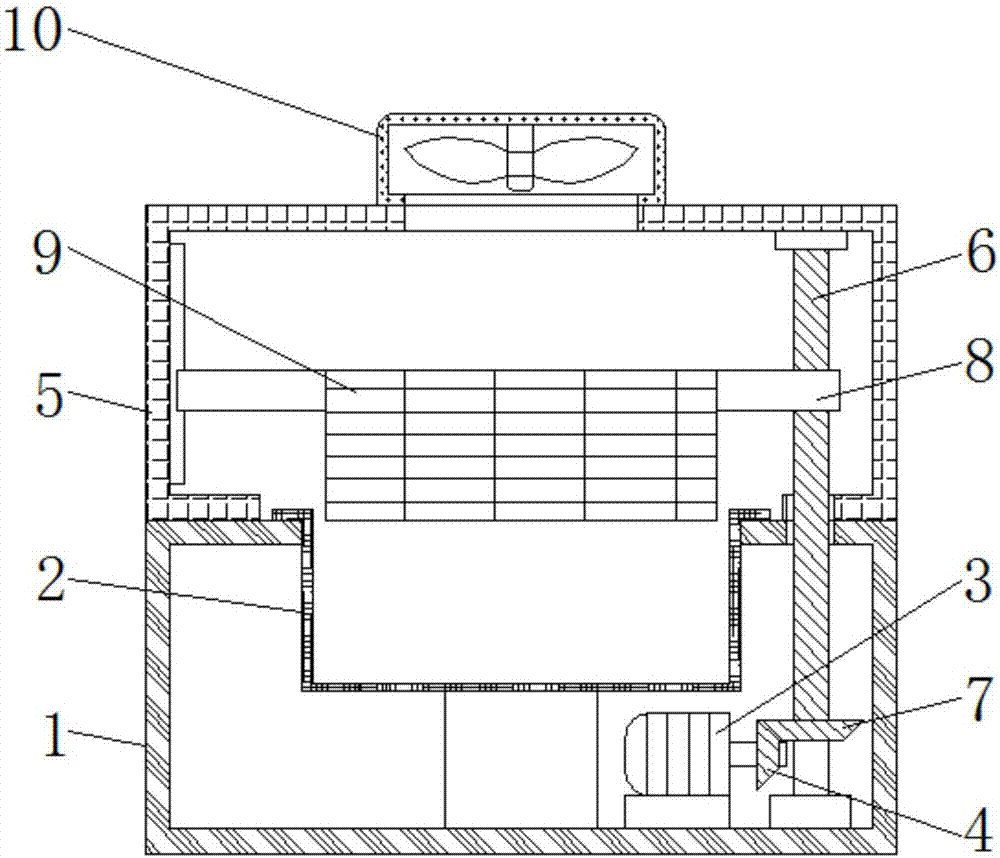

Special quality detection equipment for building bricks

PendingCN111982658AThe test result is accurateAutomatic pushMaterial strength using tensile/compressive forcesConveyor partsStructural engineeringMechanical engineering

The invention relates to quality detection equipment, and in particular, relates to special quality detection equipment for building bricks. Provided is the special quality detection equipment for thebuilding bricks, the bricks can be automatically and accurately pushed to the position below a detection mechanism, bearing detection is carried out on the bricks, and the detected bricks are automatically taken out. The special quality detection equipment for the building bricks comprises a base, an electric push rod, pushing mechanisms, a detection mechanism and blanking frames; the electric push rod is arranged in the middle of the top of the base. The pushing mechanisms are arranged on the two sides of the top of the base, and are connected with a telescopic rod of the electric push rod;the detection mechanism is arranged on the middle side of the top of the base, and the detection mechanism is connected with the pushing mechanisms; the blanking frames are evenly arranged on the leftside of the top of the base and connected with the pushing mechanisms. According to the special quality detection equipment for the building bricks, the effects that bricks needing to be detected canbe accurately pushed to the position below the transmission frame, the bearing capacity of the bricks is detected, and the detected bricks are pushed to the blanking frames automatically can be achieved.

Owner:邢海龙

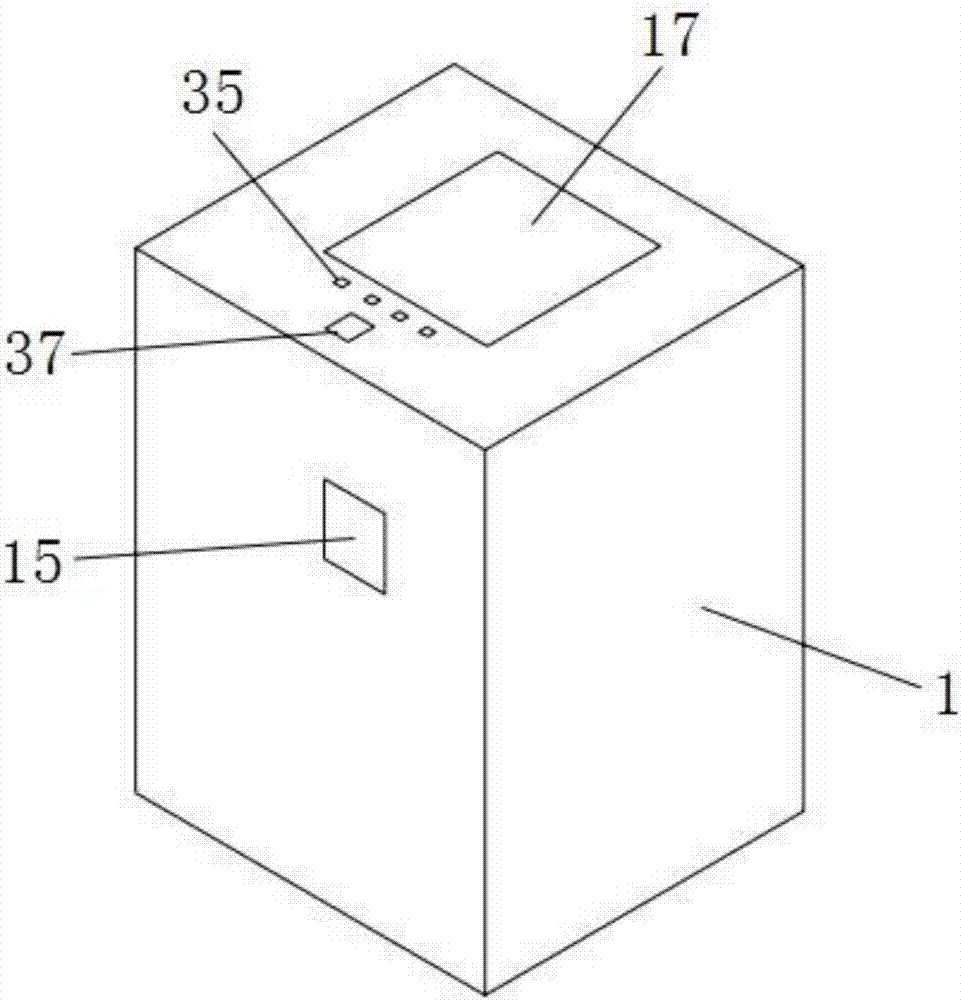

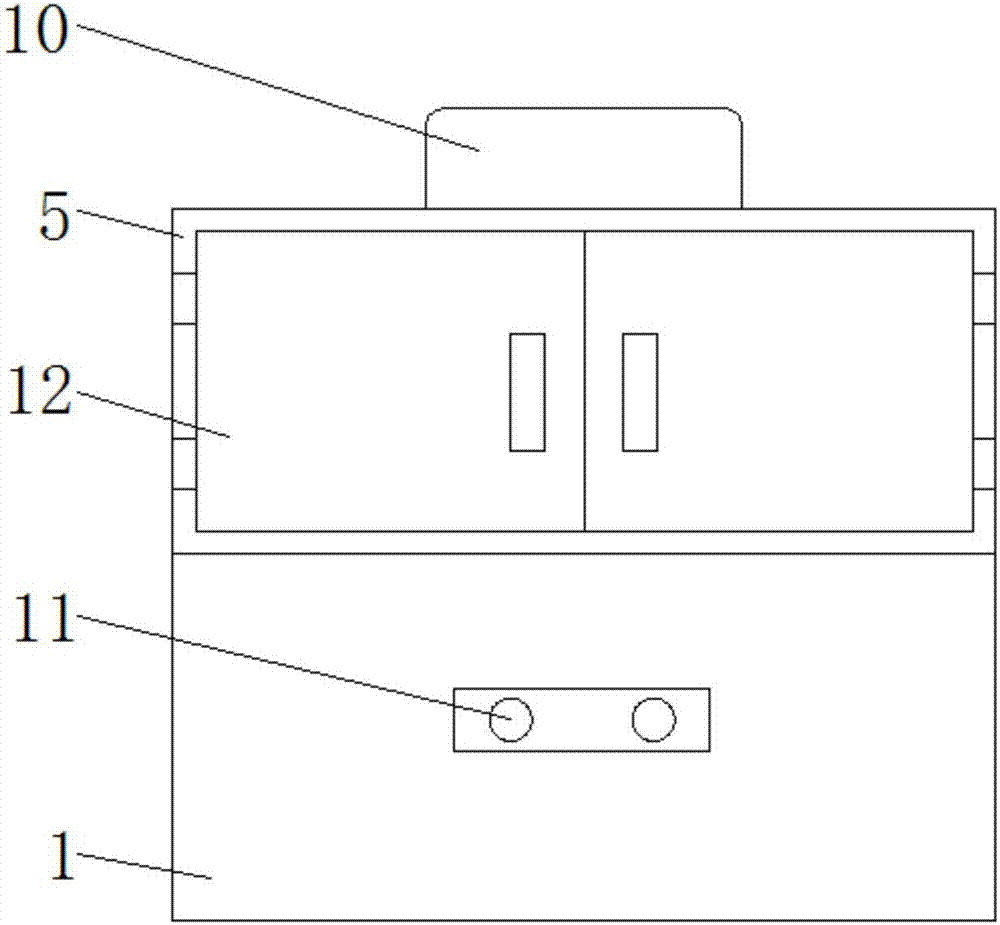

Intelligent medicine box capable of prompting users to take medicine and working method thereof

ActiveCN107296755AAvoid Medication ErrorsAutomatic take outPharmaceutical containersMedical packagingKey pressingElectricity

The invention discloses an intelligent medicine box capable of prompting users to take medicine and a working method thereof. The medicine box comprises a medicine box body. A controller, a touch screen, a key set, a voice output module and a wireless communication module are arranged on the medicine box body. The controller is electrically connected with the touch screen, the key set, the voice output module and the wireless communication module. The users can be prompted to take medicine within medicine taking time.

Owner:杭州欣卓科技有限公司

Automatic loving shoe cabinet and shoe-wearing method thereof

An automatic loving shoe cabinet comprises a shell. A shoe conveyer, a shoelace tying device and sock-wearing assistant devices are arranged in the shell, wherein the shoe conveyer comprises a transverse shoe cabinet partition plate and a movable shoe support which is arranged on the rear portion of the shoe cabinet partition plate; the shoelace tying device is located below the shoe cabinet partition plate and comprises a working table; the sock-wearing assistant devices are located on the left side and the right side at the front end of the working table, and sock-wearing racks used for putting socks on the feet are arranged on the sock-wearing assistant devices respectively. The automatic loving shoe cabinet is simple and compact in structure, by arranging the shoe conveyer, the shoelace tying device and the sock-wearing assistant devices on the automatic loving shoe cabinet, the automatic loving shoe cabinet mainly has the functions that the shoes which a user wants to wear can beautomatically taken out of the shoe cabinet through the shoe conveyer; due to the arrangement of the sock-wearing assistant devices, it can be achieved the user easily wears the socks without hands; by means of the shoelace tying device, it can be achieved that shoelaces are automatically tied or untied; by means of the automatic loving shoe cabinet, the problem that a person who inconveniently wears shoes quickly wears the shoes is effectively solved, the use effect is good, and the shoe cabinet is safe and convenient to use and suitable for popularization.

Owner:浙江机电职业技术学院

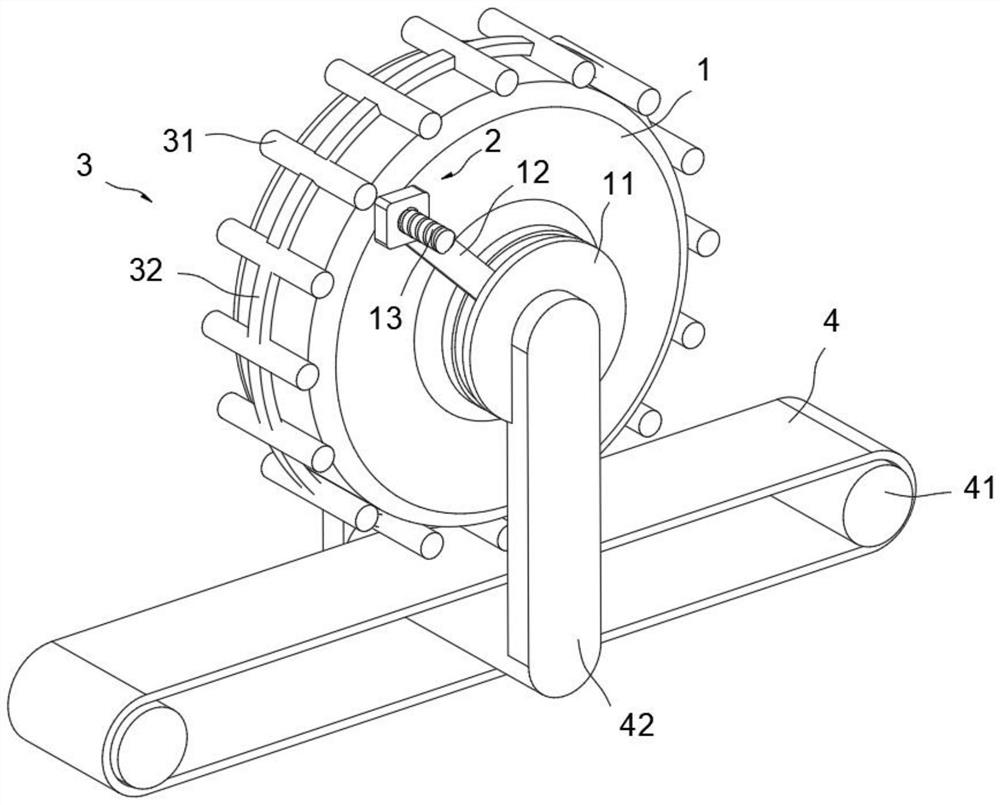

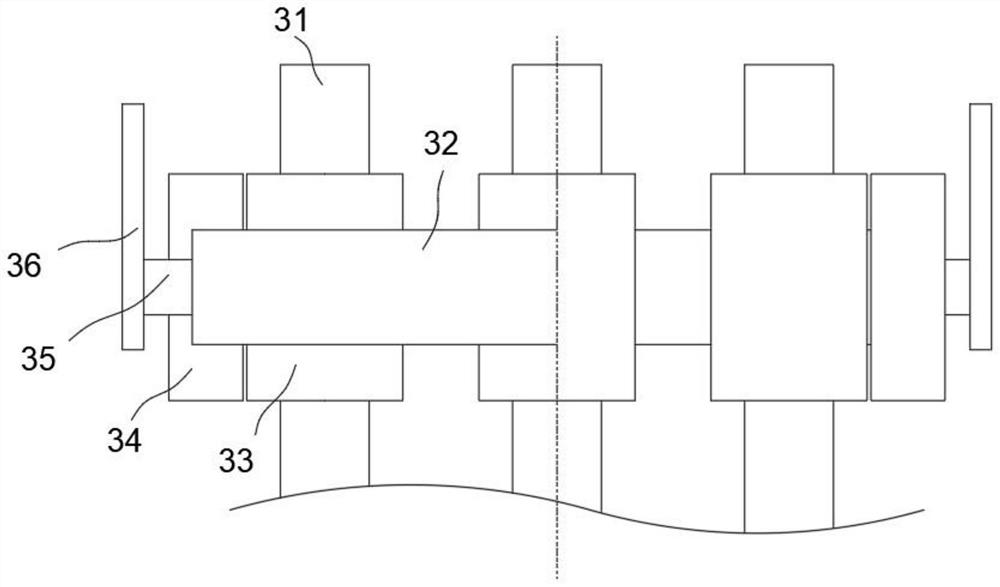

Money classification and coin sorting device

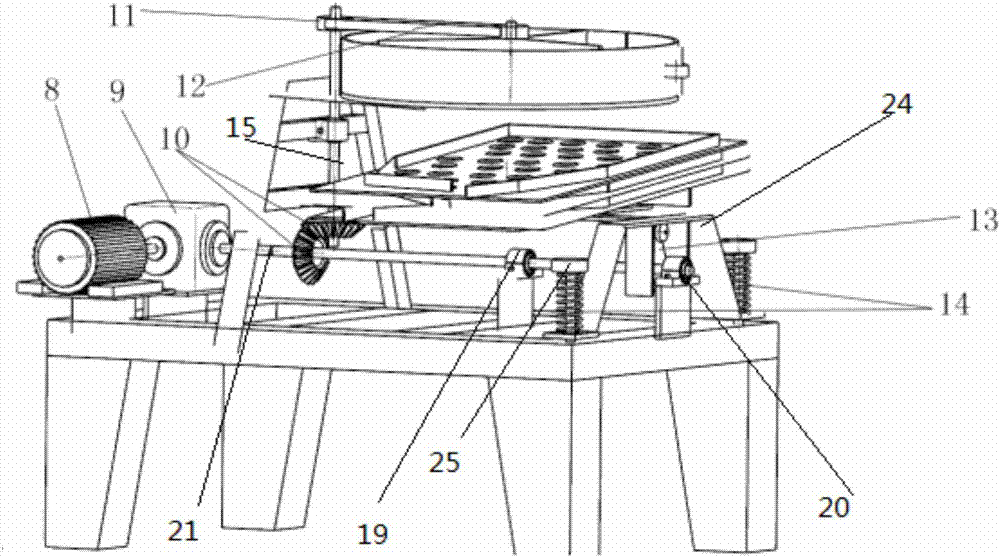

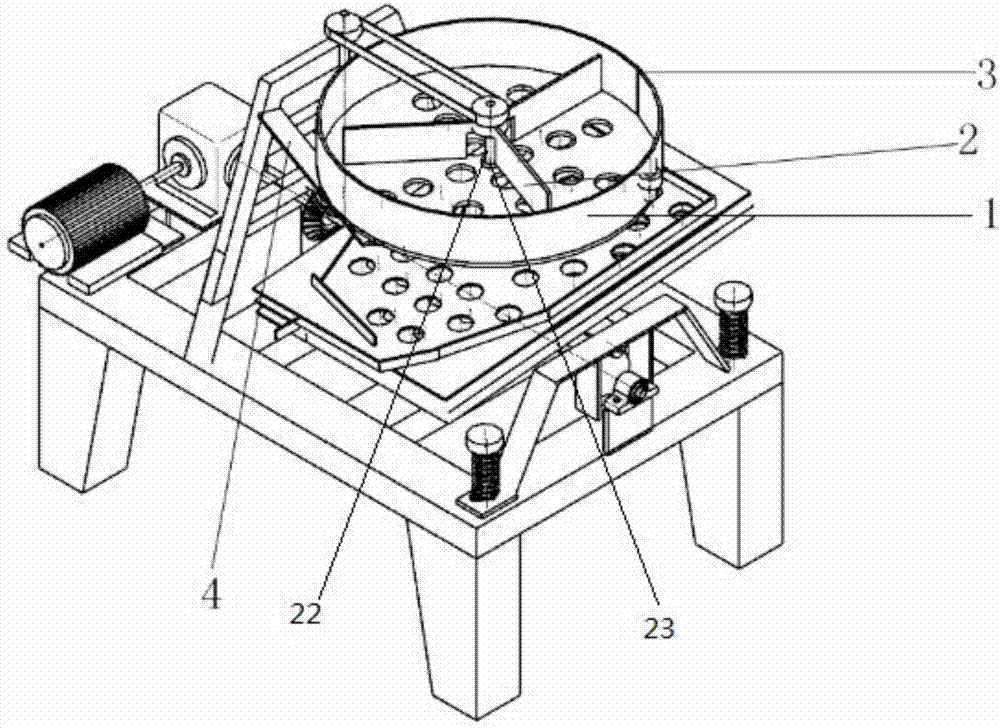

InactiveCN107067538AAutomatic take outImplement classificationCoin/currency accepting devicesEngineeringReducer

The invention provides a money classification and coin sorting device which comprises a rotating scraper coin and banknote separation mechanism, a three-layer screen plate coin sorting mechanism, and a power transmission mechanism. The output of power is realized through the cooperation of a motor and a speed reducer. The transmission of the power is realized through the vertical engagement of two straight tooth bevel gears, coins and banknotes can be classified, and coins of different denominations such as one yuan, five jiao and one jiao are classified and sorted. The device is a pure mechanical device, all components are mechanically connected, and the operation is safe and reliable.

Owner:GUANGXI UNIV

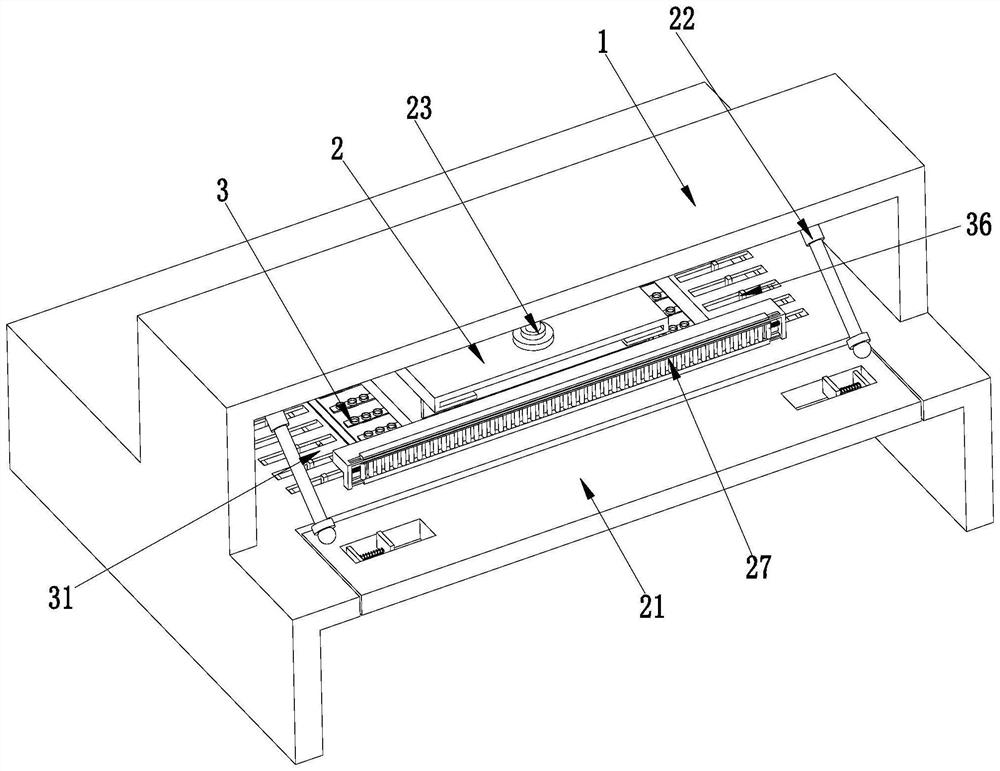

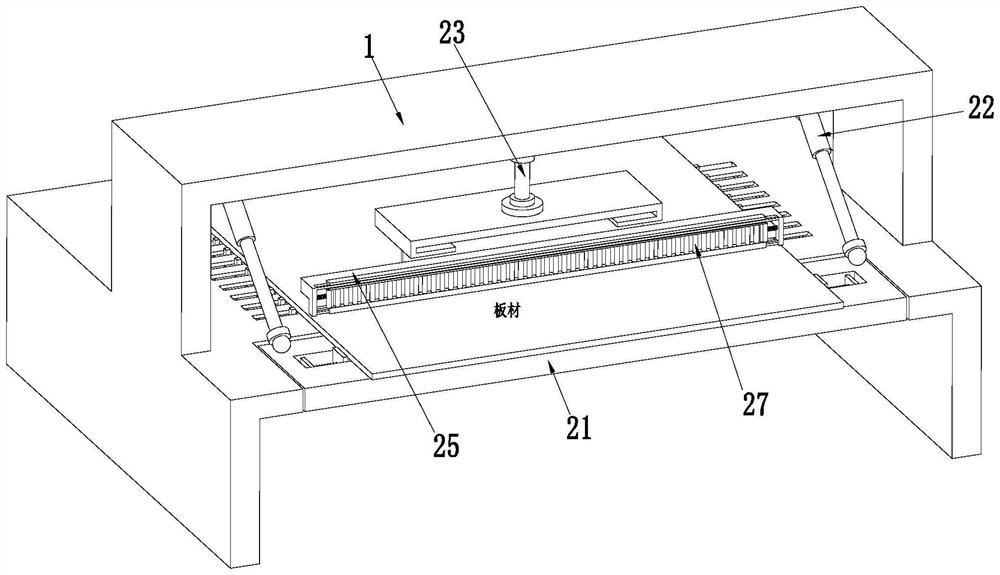

Power distribution cabinet body plate hydraulic bending machine

ActiveCN114130868ANo surface wrinklingMeet assembly requirementsClassical mechanicsStructural engineering

The invention relates to a power distribution cabinet body plate hydraulic bending machine which comprises a mounting rack, the mounting rack is provided with an execution turnover mechanism used for bending plates, and the mounting rack is provided with a position correction mechanism used for adjusting the positions of the plates. In the bending process of an existing power distribution cabinet body plate, the following problems exist: firstly, the position of the plate needs to be manually adjusted, errors exist when the plate is manually placed on bending equipment to adjust the position of the plate, the plate is prone to being bent in an inclined state, the errors are large after the plate is bent, and the bending efficiency is high; and secondly, the thickness of the plate near the bending position is easy to change due to extrusion at the bending position in the bending operation of the plate, so that the overall attractiveness of the cabinet body is influenced and the cabinet body cannot be normally assembled due to the position of the thickness of the plate when the cabinet body is assembled.

Owner:ANHUI FUYANG QIAOXING ELECTRICAL EQUIP CO LTD

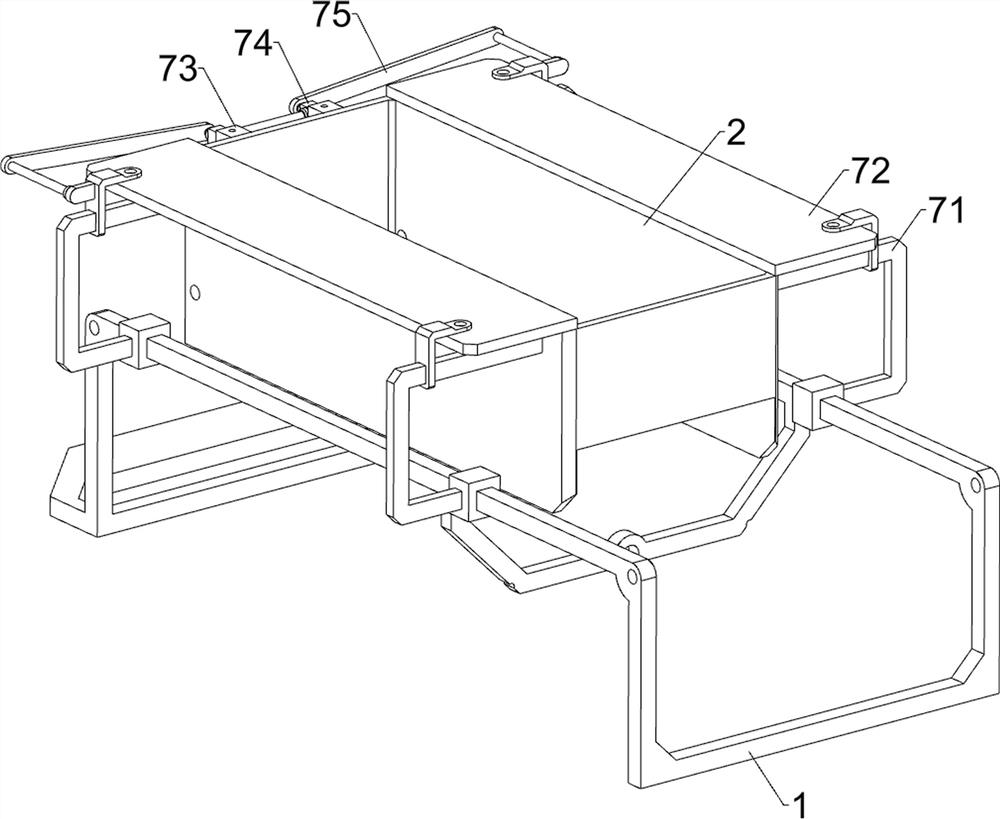

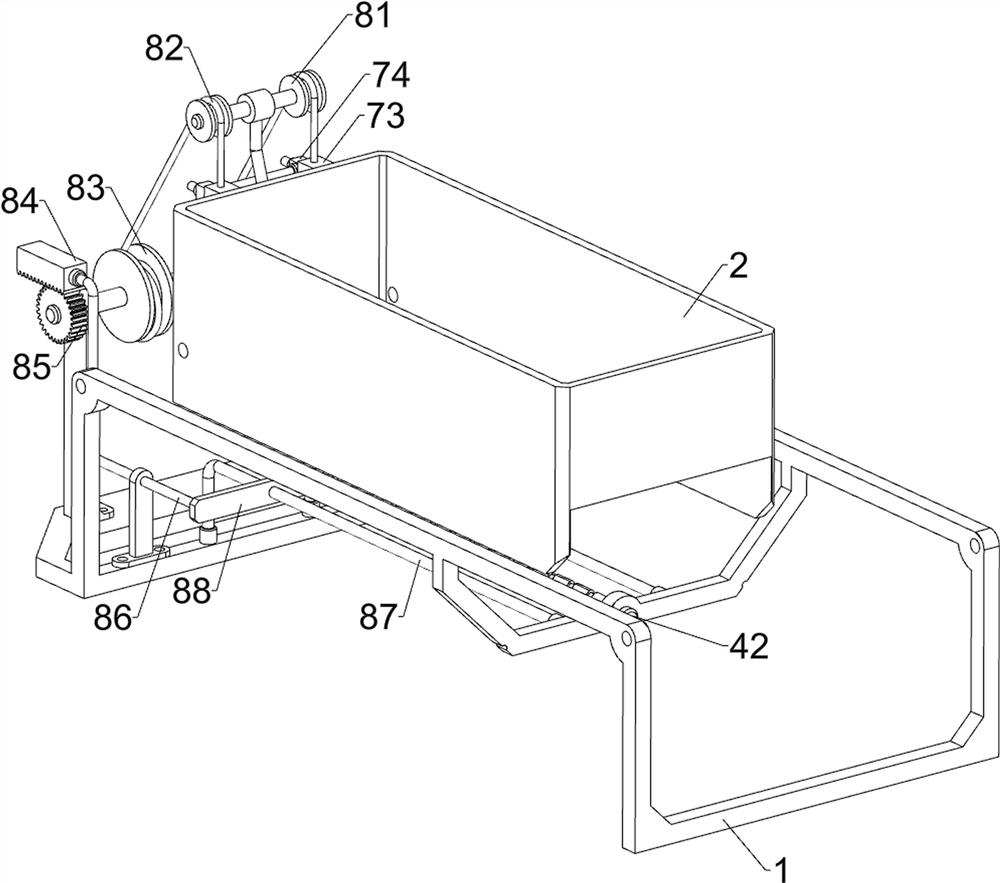

Turnover box and transfer device of turnover box

PendingCN109230576AImprove stabilityImprove securityConveyorsStacking articlesElectrical and Electronics engineeringEngineering

Owner:博侃电气(合肥)有限公司

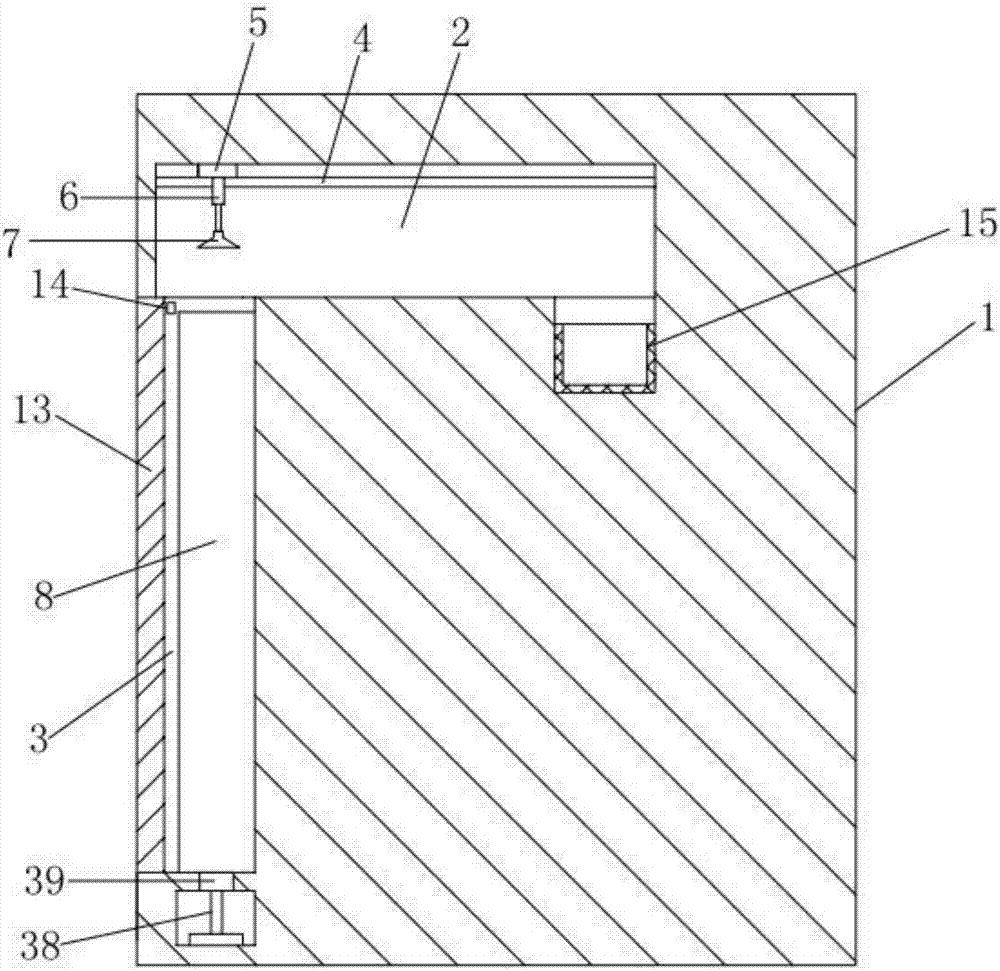

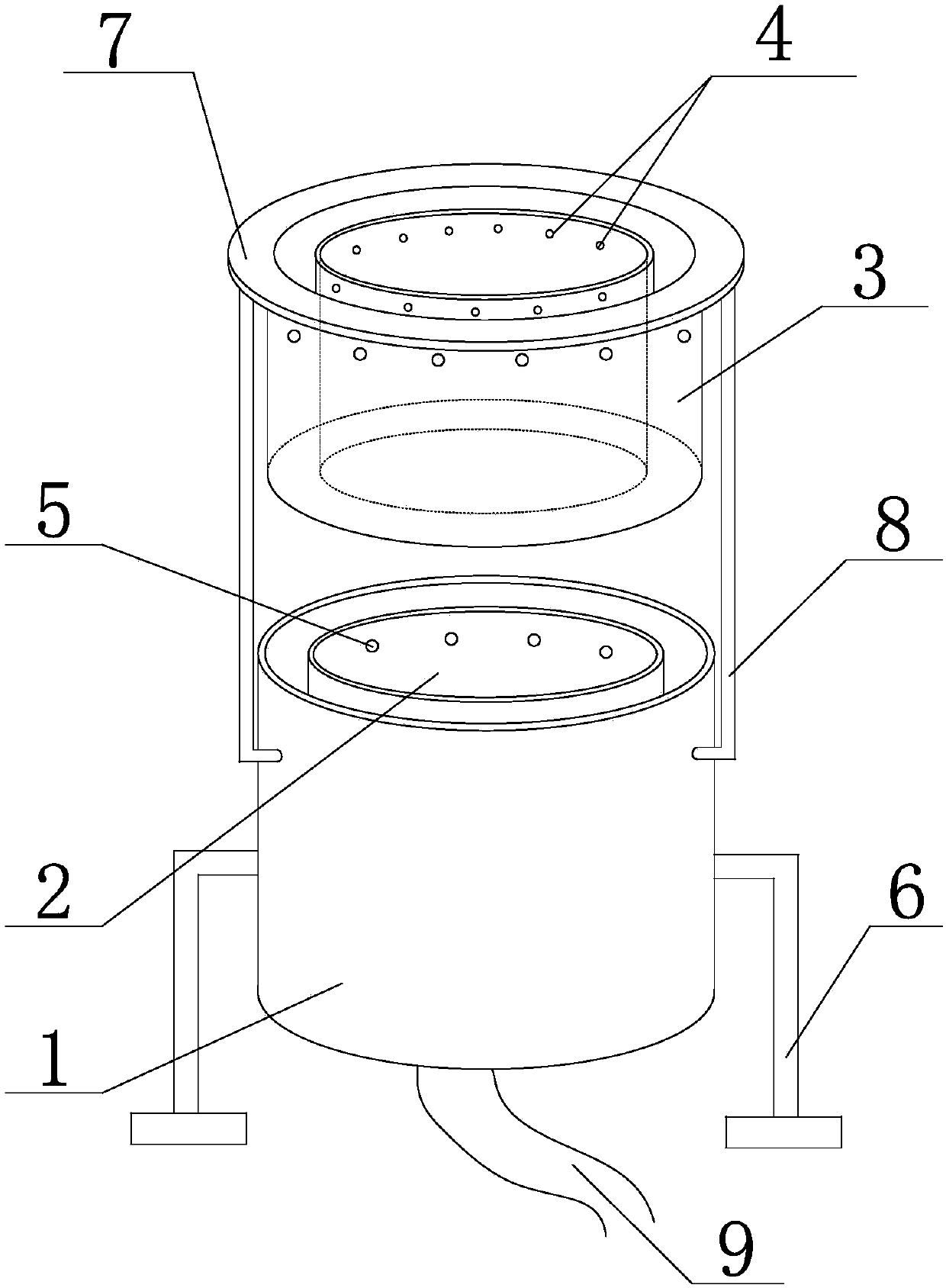

Traditional Chinese medicinal material cooking device for improving safety

ActiveCN108670830AEnsure safetyEasy loading and unloadingPharmaceutical product form changeDomestic articlesEngineeringCooling pipe

The invention discloses a traditional Chinese medicinal material cooking device for improving safety. The traditional Chinese medicinal material cooking device comprises a cooking pot, an isolation cylinder is sleeved with the cooking pot, the device further comprises a hollow annular and cylindrical medicinal material placing cylinder, the size of the medicinal material placing cylinder is matched with that of a cooking cavity, and water inlet holes are uniformly formed in the inner wall and the outer wall of the medicinal material placing cylinder; an annular rotation plate is arranged on the bottom surface in the cooking cavity, water injection holes are formed in the side wall of the isolation cylinder, and a sealing lid is arranged above the cooking pot; supports are connected to thetwo sides of the side walls below the cooking pot, a drainage pipe is connected to the bottom of the isolation cylinder, and a cooling pipe sleeves a junction of the drainage pipe and the isolation cylinder. By means of the traditional Chinese medicinal material cooking device, the medicinal material cooking pot can very conveniently feed and discharge traditional Chinese medicinal materials, andthe production efficiency is improved; meanwhile, the safety of production personnel is guaranteed, accidents like scalding are prevented, the cooking pot can be inclined at the same time, and manualoperation is not needed, so that feeding and discharging are more convenient and safer.

Owner:四川西蜀九锦现代中药有限公司

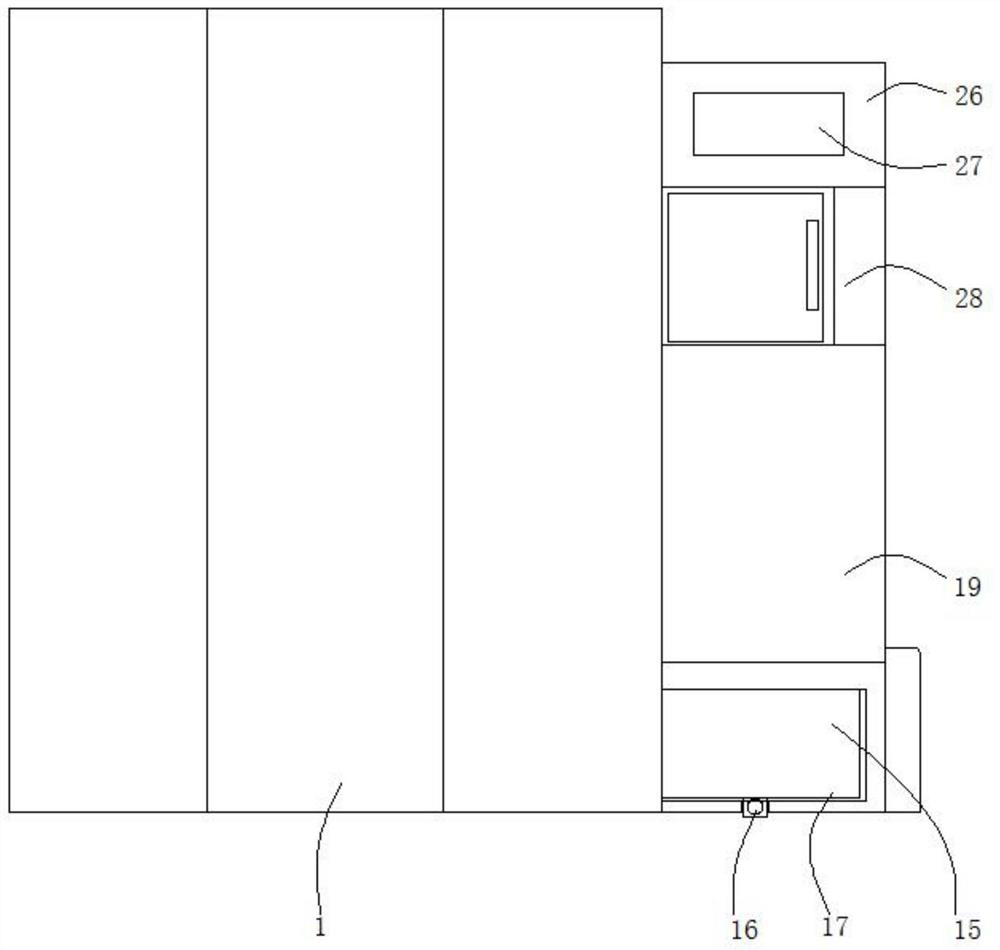

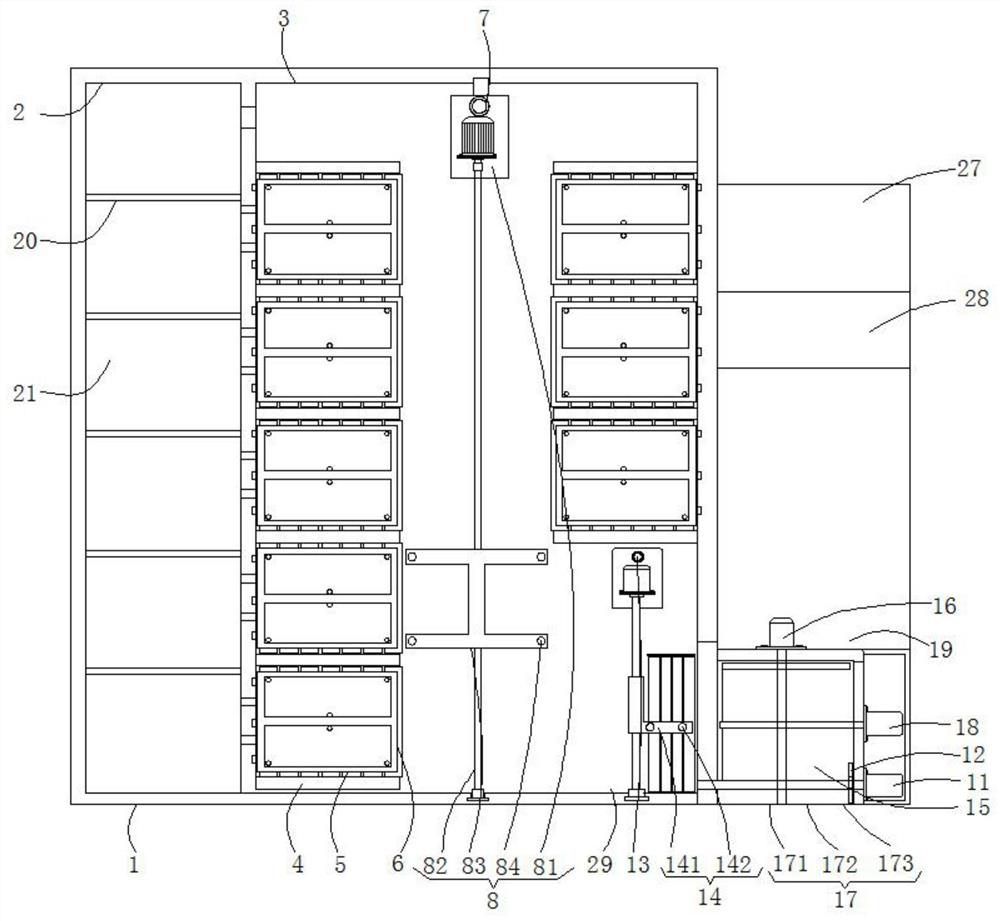

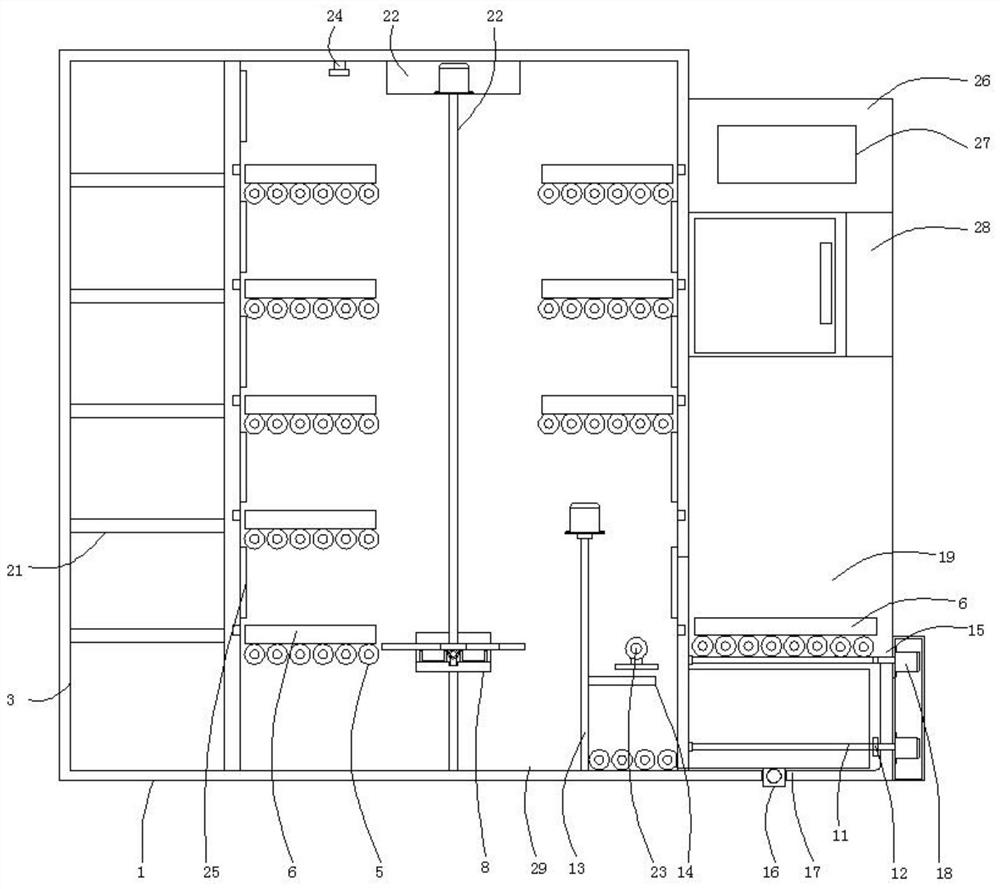

Multifunctional intelligent shoe cabinet and control method thereof

ActiveCN111772354AKeep warmComfortable to wearWardrobesLavatory sanitoryStructural engineeringMechanical engineering

The invention discloses a multifunctional intelligent shoe cabinet comprising a cabinet body; the interior of the cabinet body is divided into a season changing storage area and a common storage areathrough a baffle. A plurality of first partition plates are arranged on one side of the baffle and located in the common storage area. A containing cavity is formed between every two adjacent first partition plates, a plurality of supporting plate rolling wheels are arranged between the two sides of the inner wall of each containing cavity, shoe storage trays are arranged at the tops of the supporting plate rolling wheels, a lifting assembly is arranged on one side of the interior of the common storage area, and a lifting sliding table is connected to the lifting assembly in a transmission mode. The invention relates to the technical field of shoe cabinet. According to the multifunctional intelligent shoe cabinet and a control method thereof, a conveying assembly is arranged to be matchedwith supporting assemblies, bearing assemblies and pushing assemblies so that shoes can be automatically placed and taken out; and different placing cavities and the plurality of supporting assembliesare arranged, so that shoes of different users can be placed in a classified manner, the shoes can be correspondingly placed on the supporting assemblies, and the shoes can be placed more neatly andorderly.

Owner:张盘

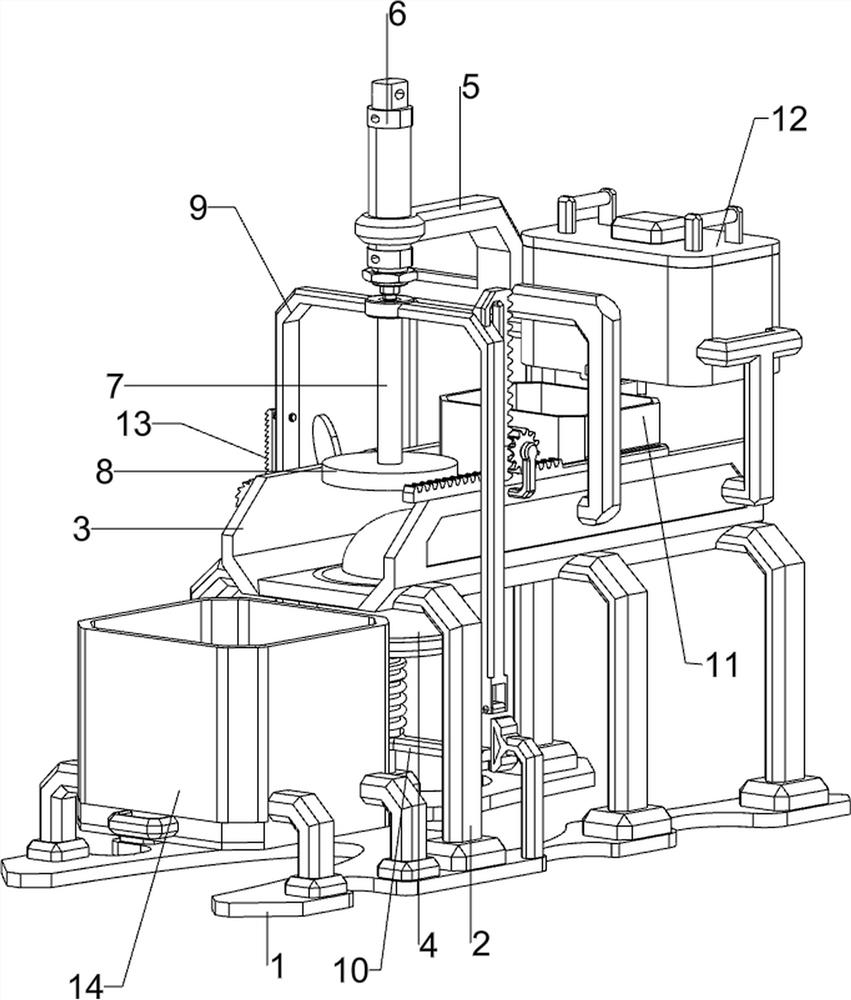

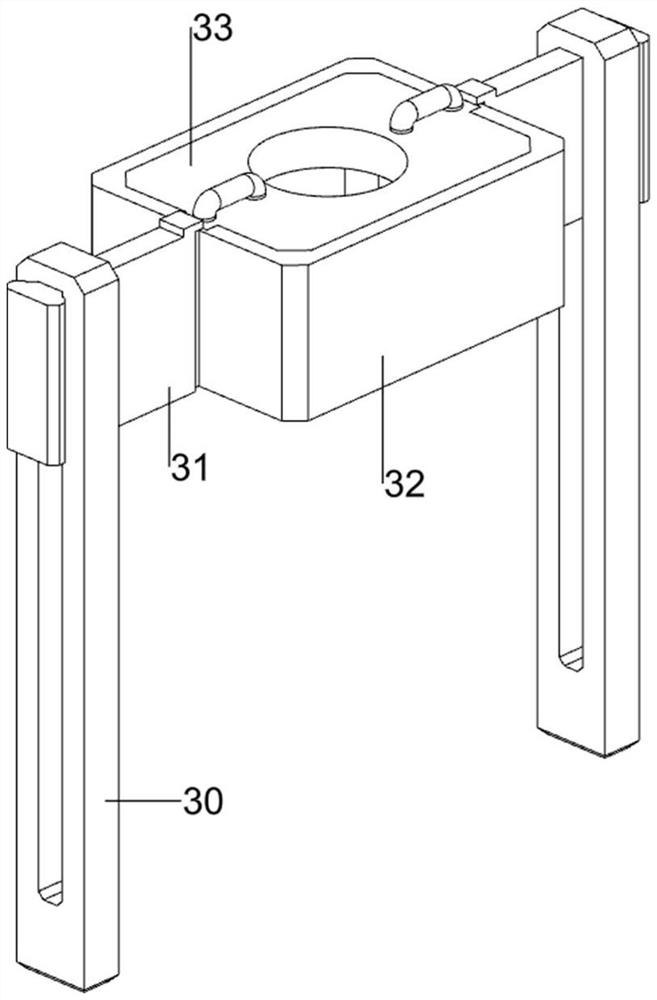

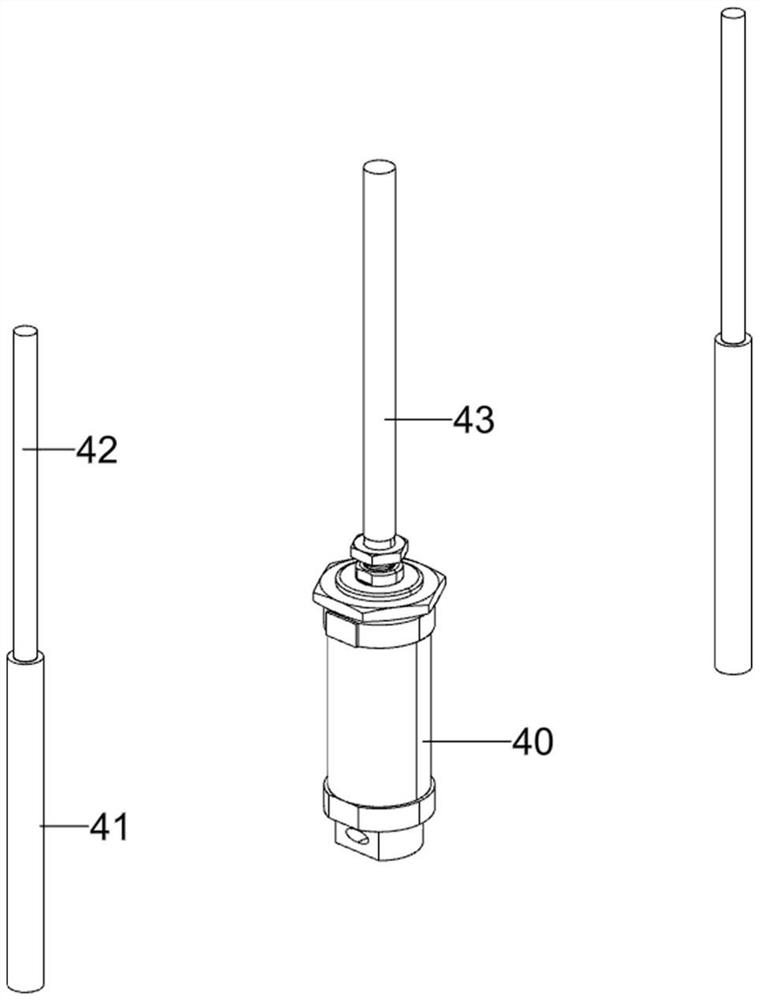

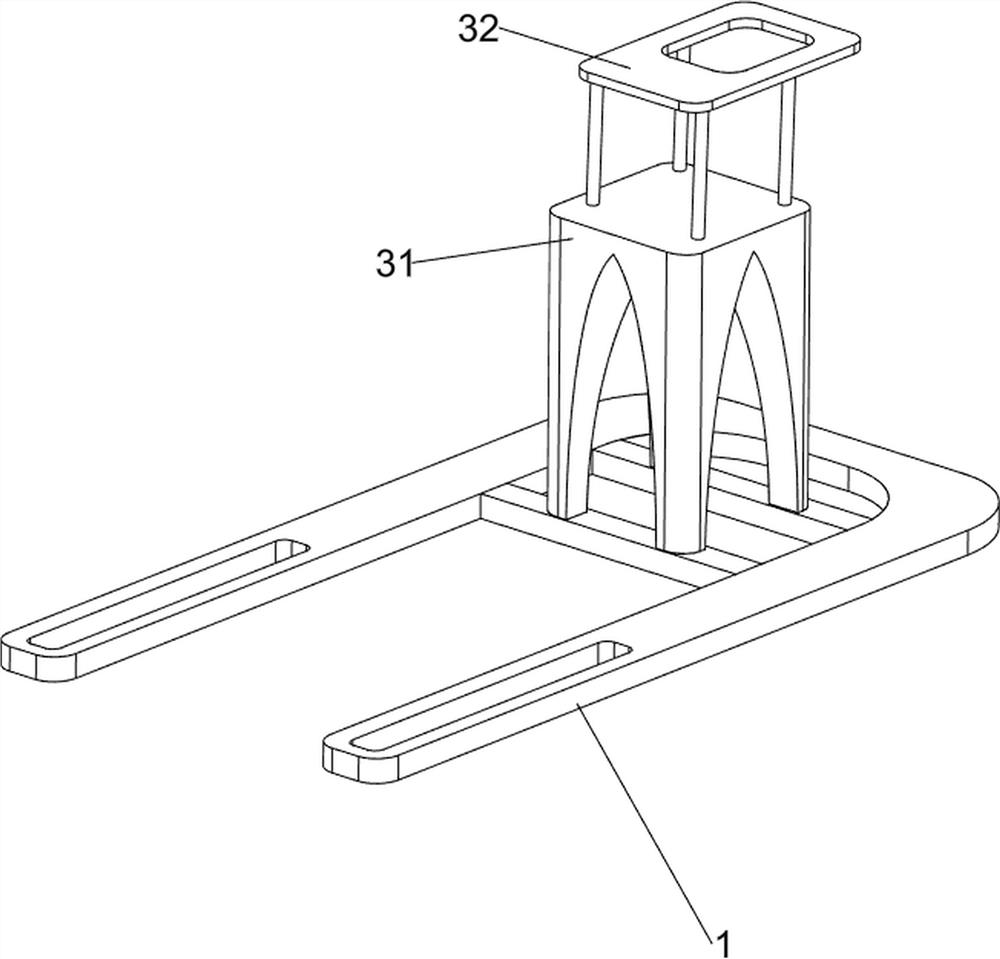

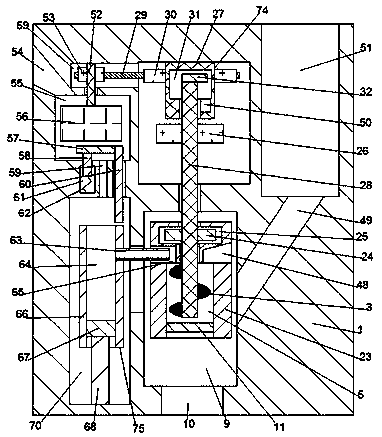

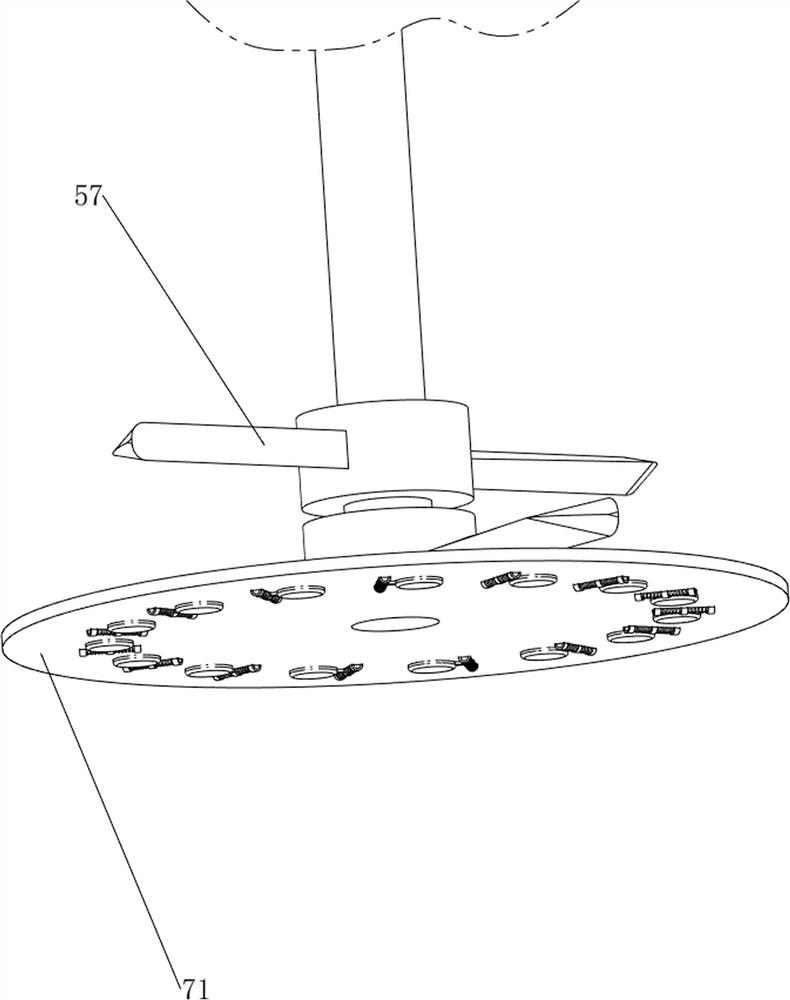

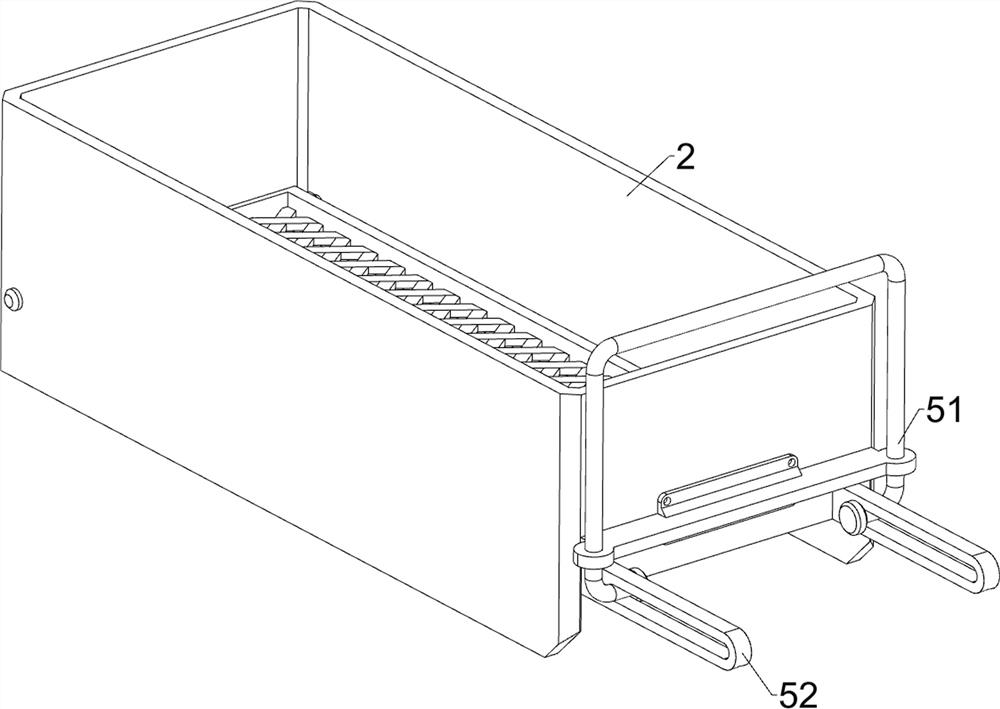

Compression molding equipment for tea cakes

PendingCN113016894ARealize automatic extrusionAutomatic take outPre-extraction tea treatmentFood shapingCompression moldingEngineering

The invention relates to forming equipment, in particular to compression molding equipment for tea cakes. The technical problem is to provide the compression molding equipment for tea cakes which can realize automatic compression and does not need trimming. According to the technical scheme, the compression molding equipment for tea cakes comprises a bottom plate, first supporting legs, a placing frame, a forming mold, a fixing rod, an air cylinder, a first connecting rod, a downward pressing block and an upward pulling mechanism, the first supporting legs are evenly arranged on the two sides of the right portion of the bottom plate, the placing frame is connected between the first supporting legs, and a molding die is arranged on one side of the containing frame. The fixing rod is arranged in the middle of the placing frame, the cylinder is arranged on the fixing rod, the first connecting rod is arranged at the bottom of the cylinder, the downward pressing block is arranged at the bottom of the first connecting rod, and the first connecting rod is provided with the upward pulling mechanism. By cooperation of the upward pulling mechanism and an auxiliary material discharging mechanism, tea leaves can be automatically extruded into cakes, and meanwhile tea cakes can be automatically taken out.

Owner:文纯

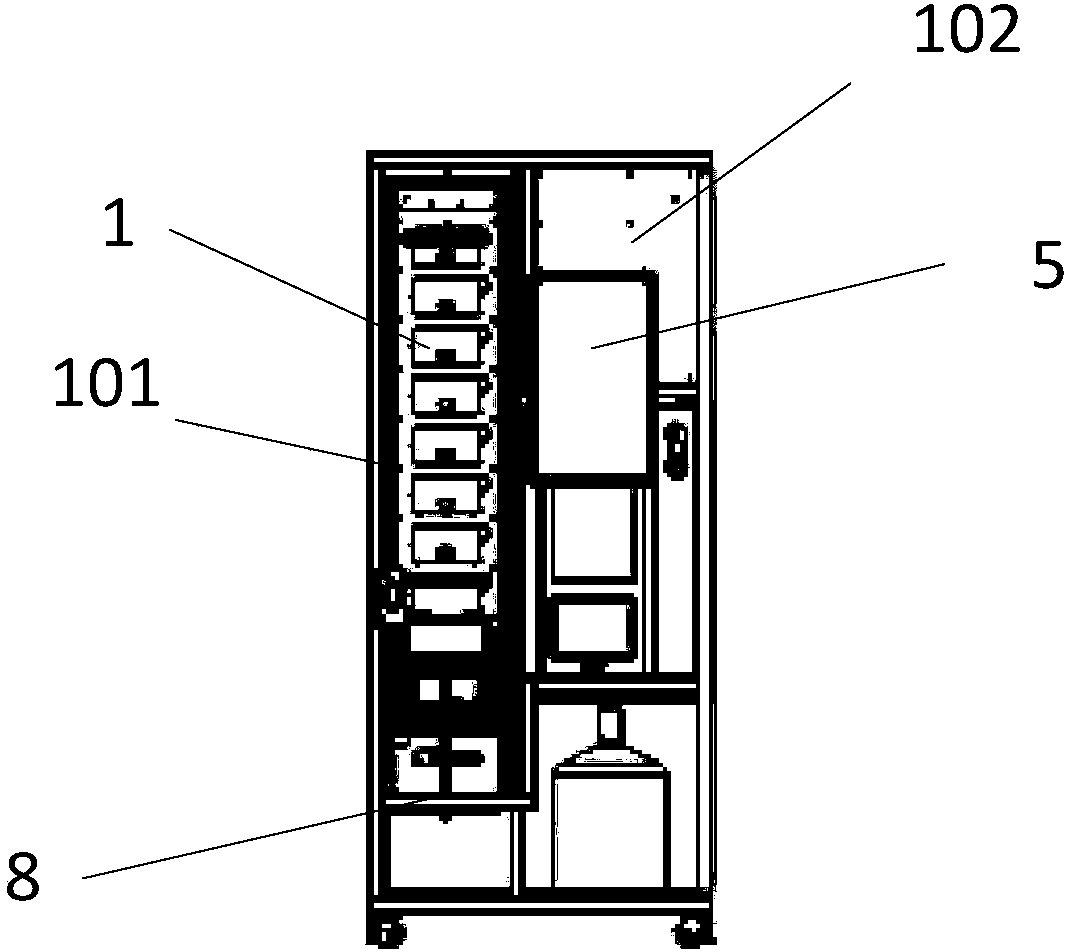

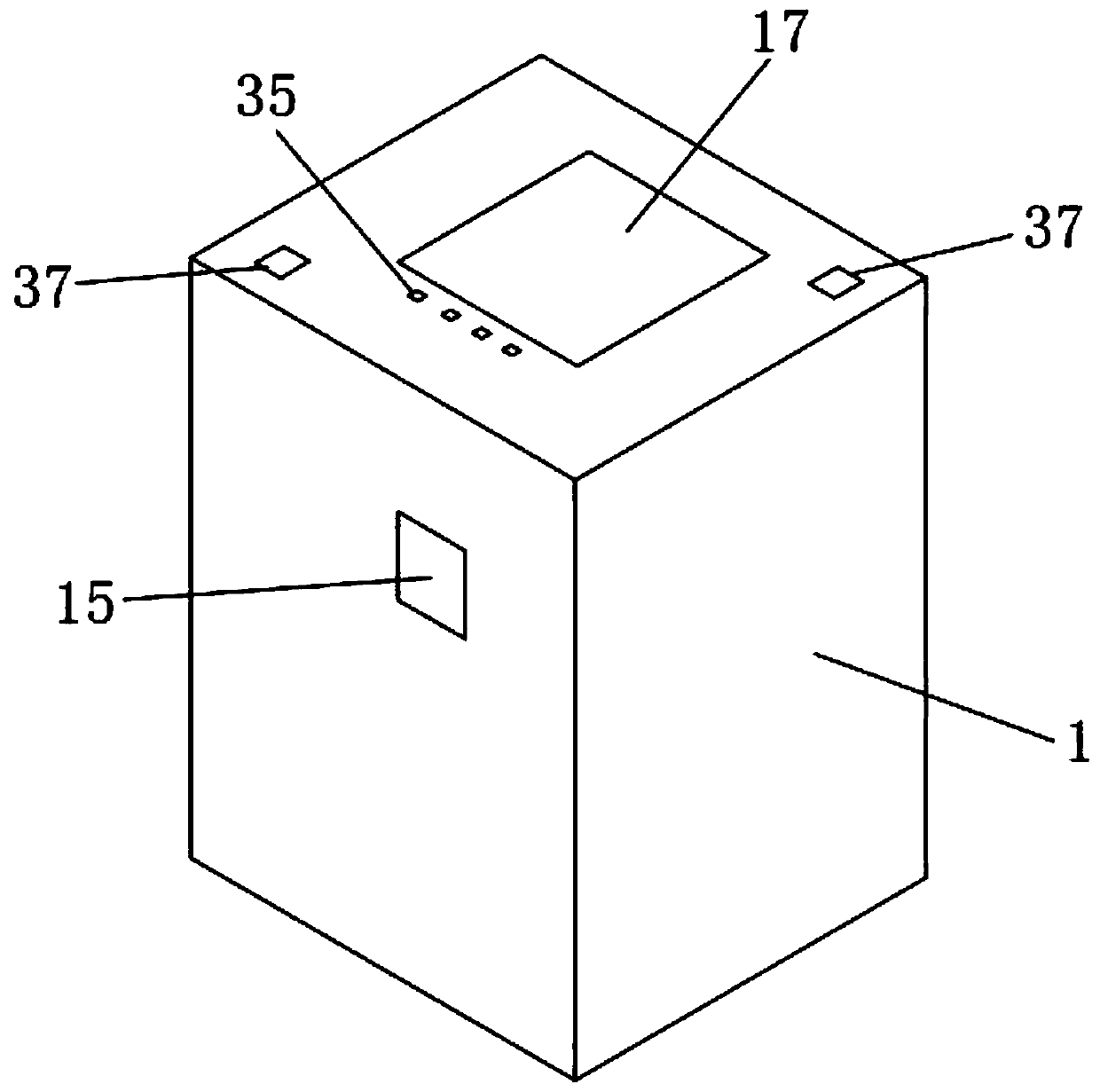

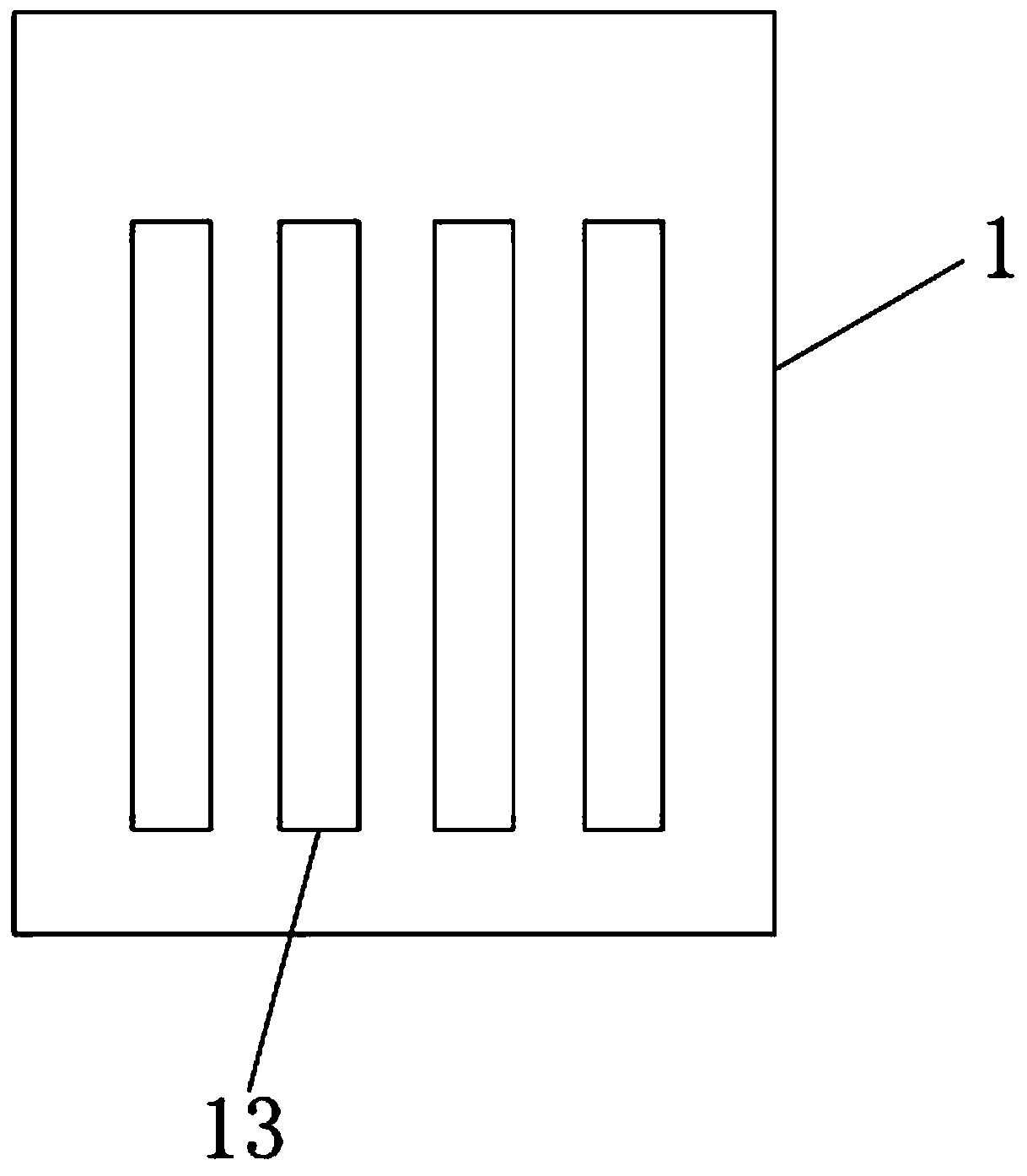

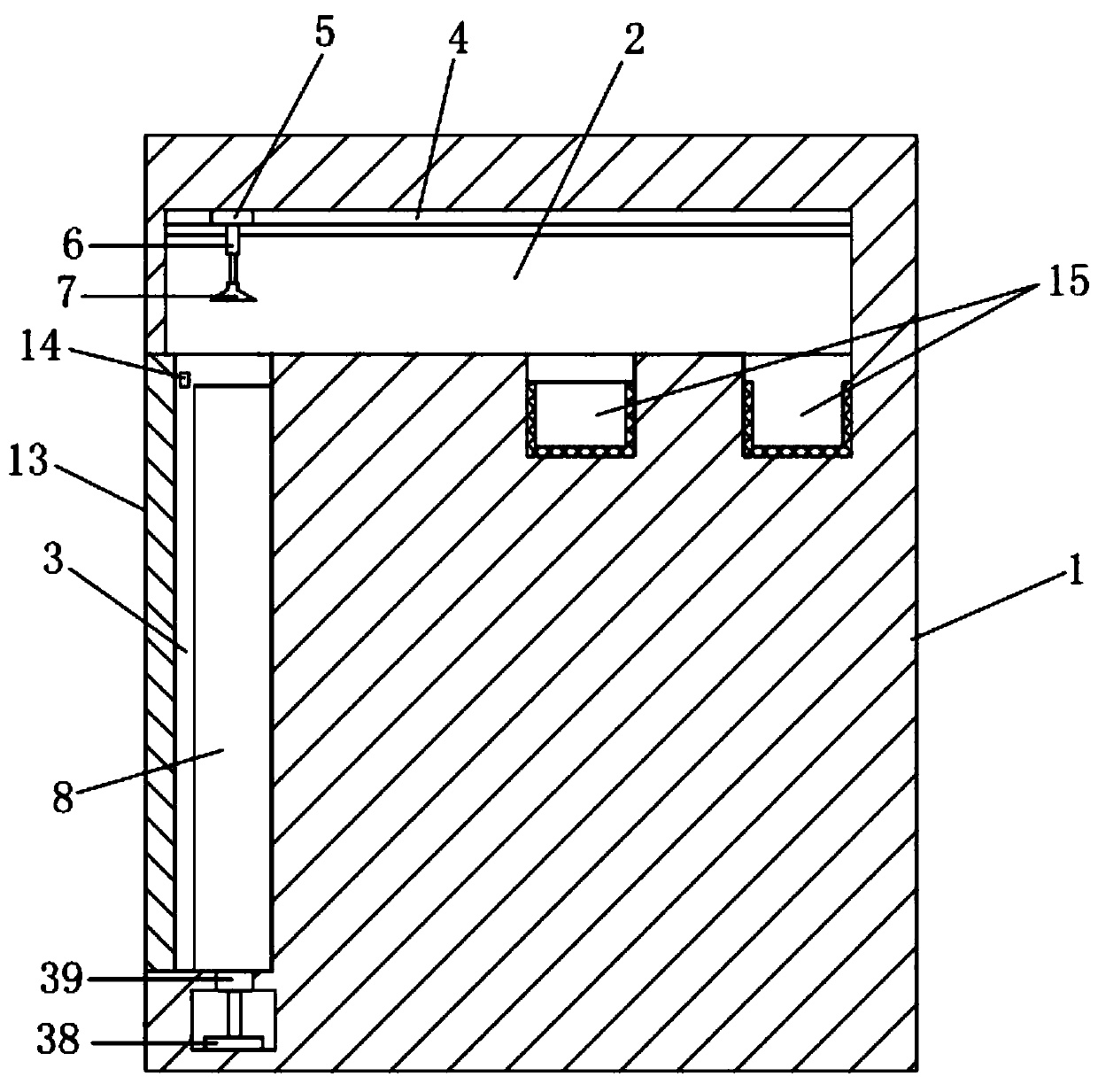

Liftable sealed storage instrument storage cabinet

InactiveCN112722535AAchieve dehumidification and moisture-proof effectTo achieve the effect of shockproofShock-sensitive articlesContainers preventing decayStructural engineeringMechanical engineering

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

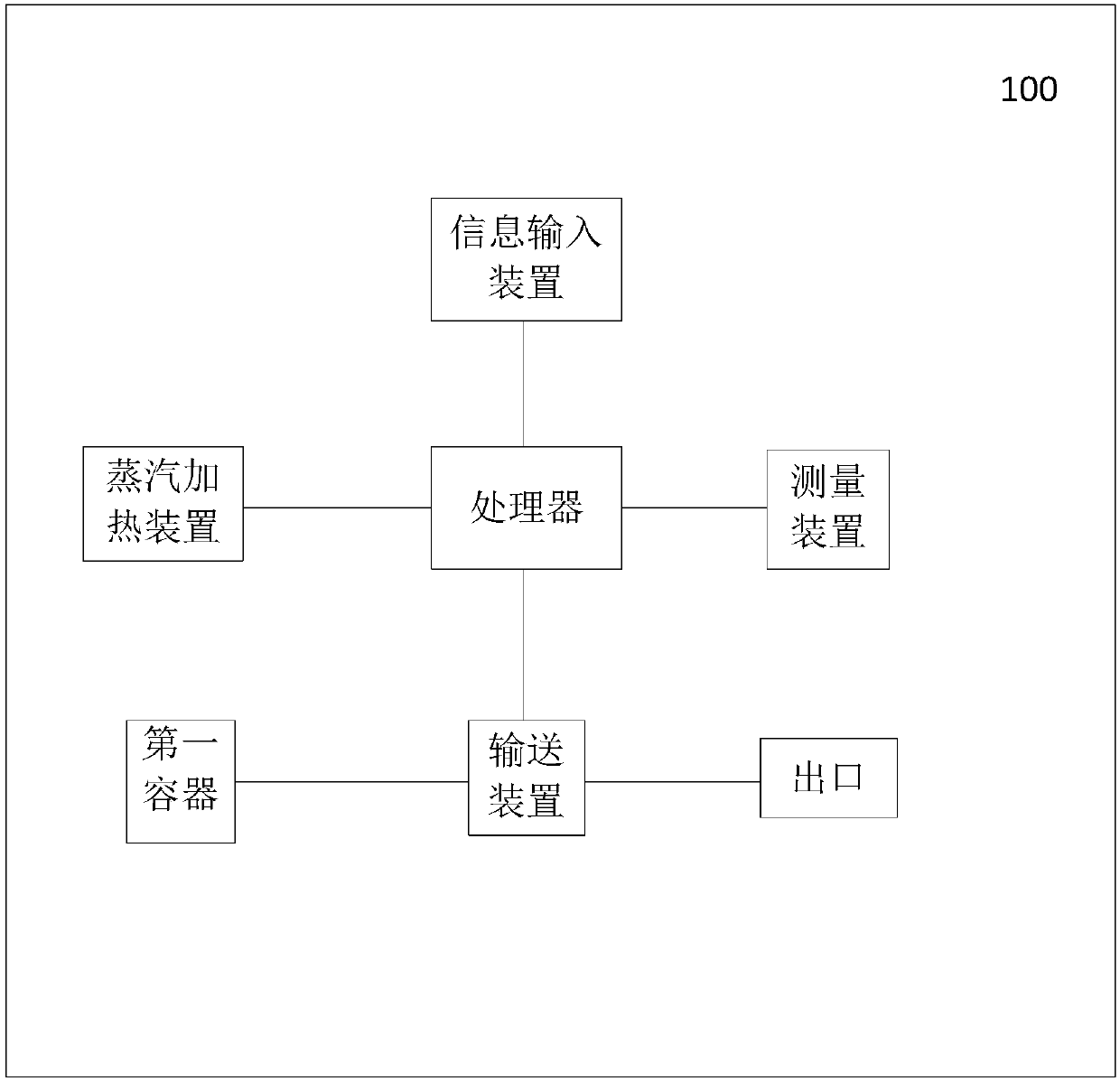

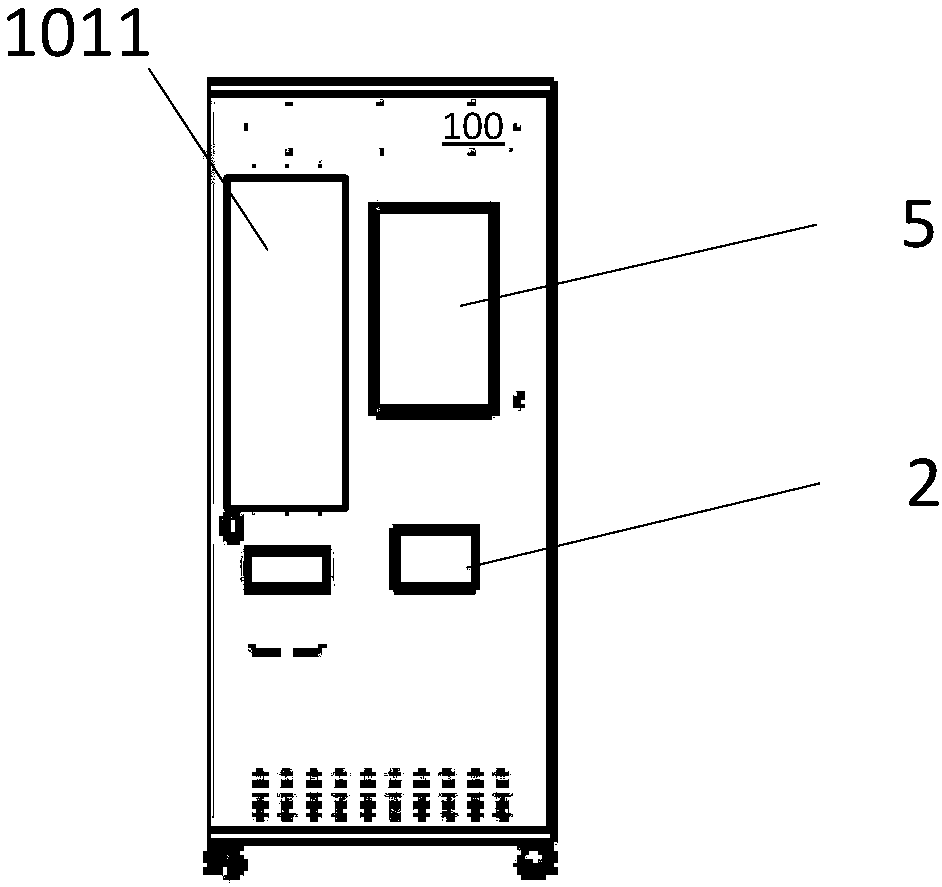

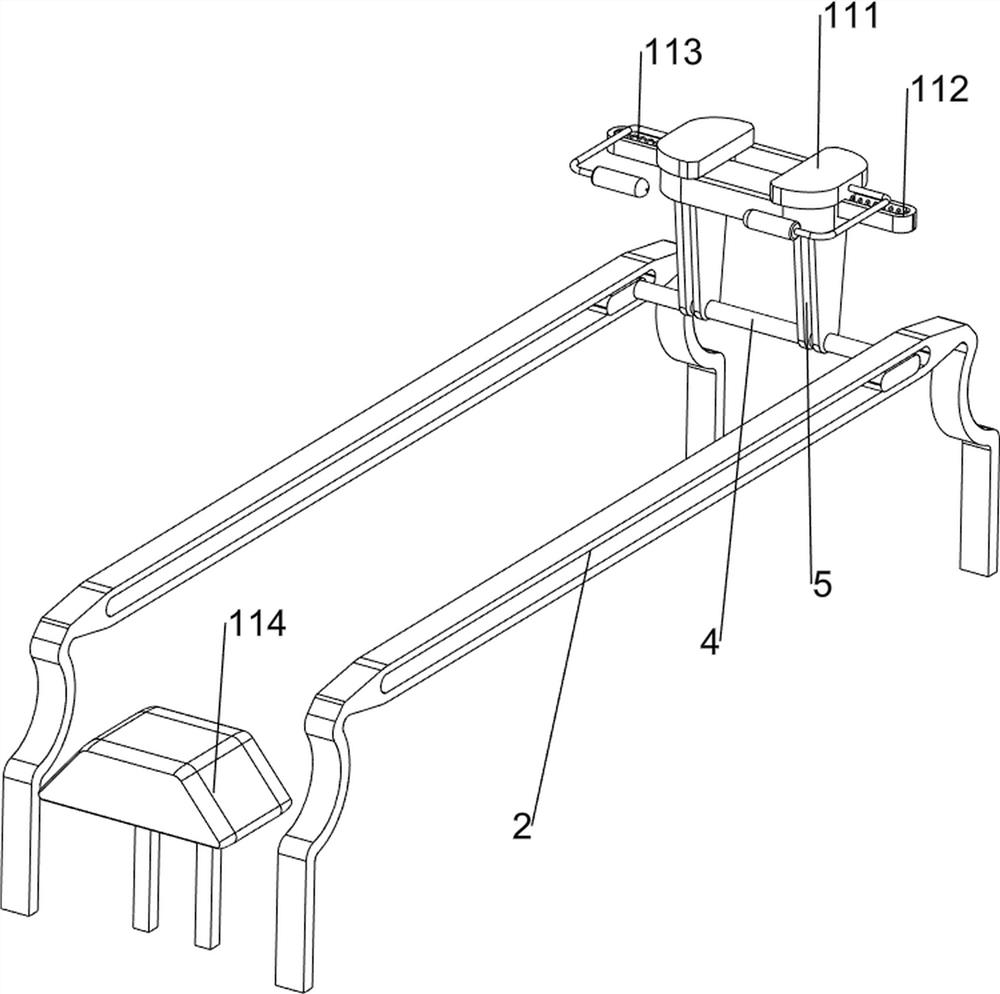

Steam-heated food vending machine

PendingCN107833387AAutomatic take outAccurate outputCoin-freed apparatus detailsApparatus for meter-controlled dispensingFood vending machinesProcess engineering

The invention relates to the field of the retail industry, in particular to a steam-heated food vending machine. The steam-heated food vending machine comprises an equipment cabinet, a first cavity, afirst container, an outlet, a first measuring device, a conveying device, an information inputting device, a steam heating device and a processor, wherein the first cavity is arranged in the equipment cabinet; the first container is arranged in the first cavity; first to-be-sold food in the first container is discharged from the outlet; the first measuring device is connected with the first container and generates a measurement result; the conveying device is arranged in the equipment cabinet, and is used for conveying the first to-be-sold food to the outlet from the first container; the steam heating device is arranged in the first cavity and is used for heating the first to-be-sold food in the container through steam; and the processor is connected with the first measurement device, theconveying device, the steam heating device and the information inputting device. By the steam-heated food vending machine, the corresponding number of food can be automatically discharged according to demands of a user, the purchasing efficiency is improved, the time is saved, and meanwhile, the circumstance that steamed stuffed buns are lost is prevented.

Owner:北京七十五度科技有限公司

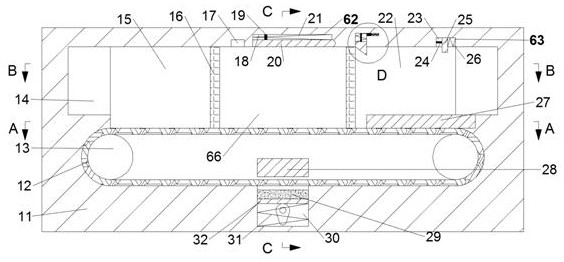

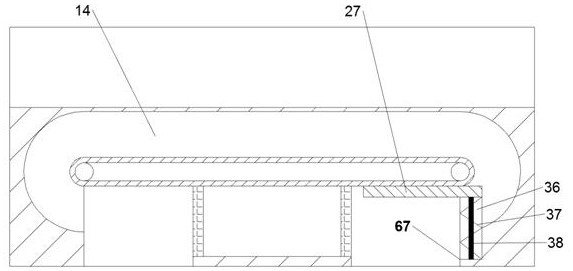

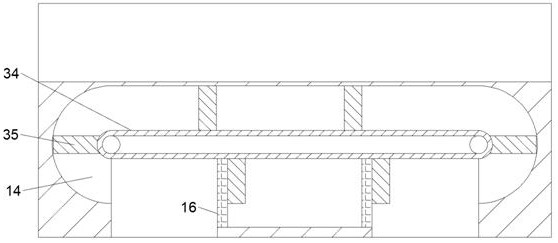

Security inspection device capable of cleaning conveying belt and preventing goods from being toppled

InactiveCN111891635AAutomatic take outAvoid pollutionConveyorsCleaningStructural engineeringMechanical engineering

The invention discloses a security inspection device capable of cleaning a conveying belt and preventing goods from being toppled. The security inspection device comprises a box body. An inlet and anoutlet with forward openings are formed in the box body. The interior of the right inner wall of the inlet is provided with a detection cavity communicating with the inlet and the outlet, and two light shielding curtains are fixedly connected to the upper inner wall of the detection cavity. A rotating cavity communicating with the inlet is formed in the rear inner wall of the inlet, and a rotatingbelt is rotationally connected to the lower inner wall of the rotating cavity. Six rotating plates are fixedly connected to the rotating belt, and two conveying shafts are rotationally connected in the box body. The security inspection device is simple in structure and convenient to use, the conveying belt can be automatically cleaned, subsequent goods can be prevented from being polluted by theconveying belt, in addition, the goods can be prevented from being toppled, labor waste is reduced, and the goods can also be automatically taken out; and in addition, the device can be used for marking the dangerous goods, subsequent finding and checking are facilitated, and time and labor are saved.

Owner:WENZHOU SHANHENG LOCKS CO LTD

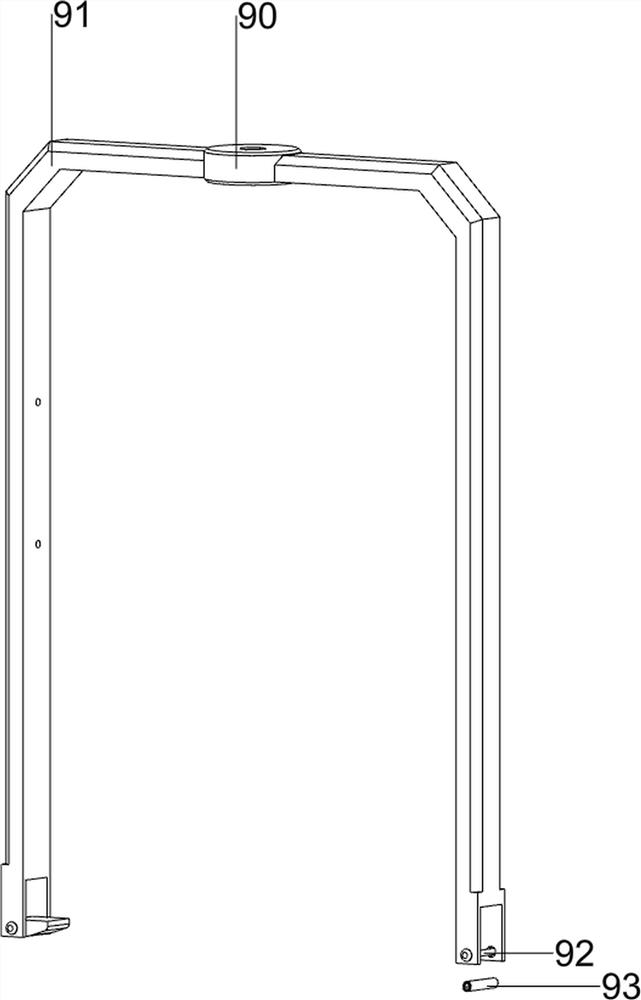

Overturning type painting equipment for PCB for electrical protection

The invention relates to painting equipment, in particular to overturning type painting equipment for a PCB for electrical protection. The overturning type painting equipment for the PCB for electrical protection is high in efficiency and is sanitary. The overturning type painting equipment for the PCB for electrical protection comprises a base, two supporting frames arranged on the base, a bearing mechanism arranged on the base and a moving mechanism arranged on the supporting frames, and the bearing mechanism cooperates with the moving mechanism. Through the design of the moving mechanism and a clamping mechanism, the PCB can be automatically overturned, a worker does not need to overturn the PCB manually, and thus the worker can paint the PCB more easily. Through the design of a feeding mechanism and a paint spraying mechanism, the PCB can be automatically fed and sprayed with paint, the worker does not need to put the PCB into the equipment and spray the PCB with paint manually, and thus the worker can operate the equipment more conveniently.

Owner:深圳市兴晟捷电子有限公司

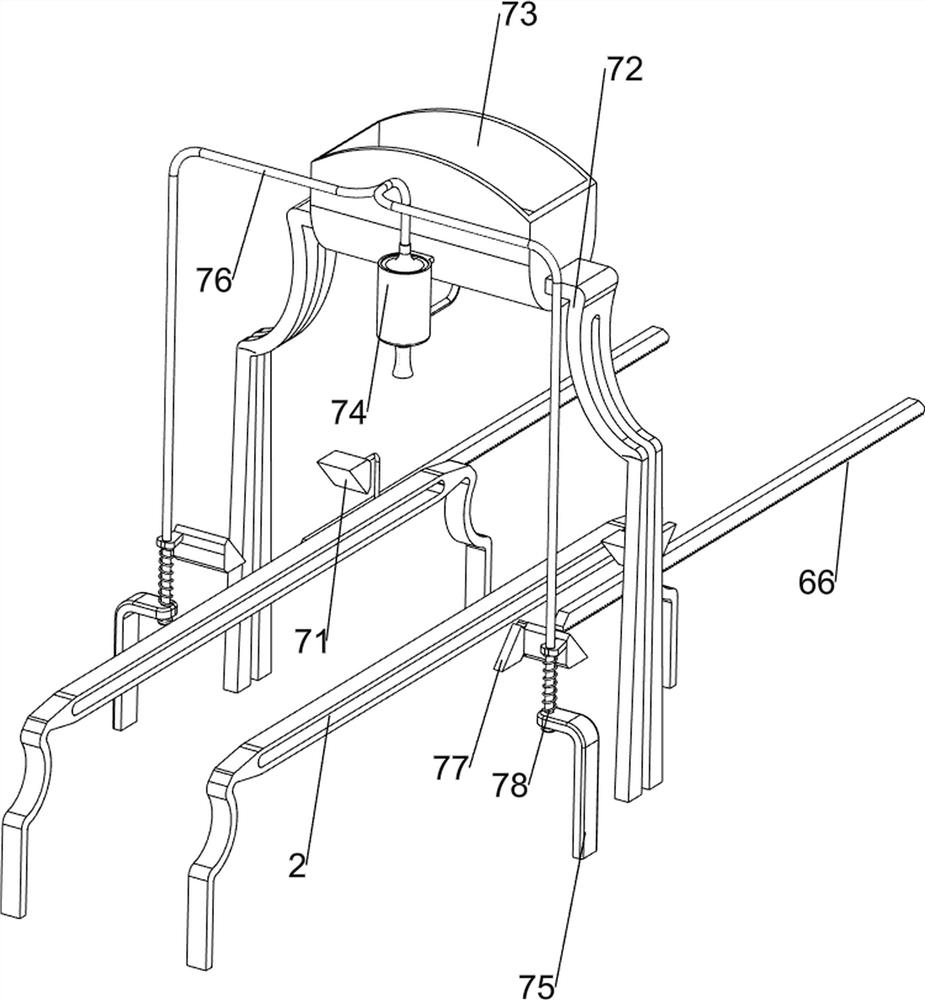

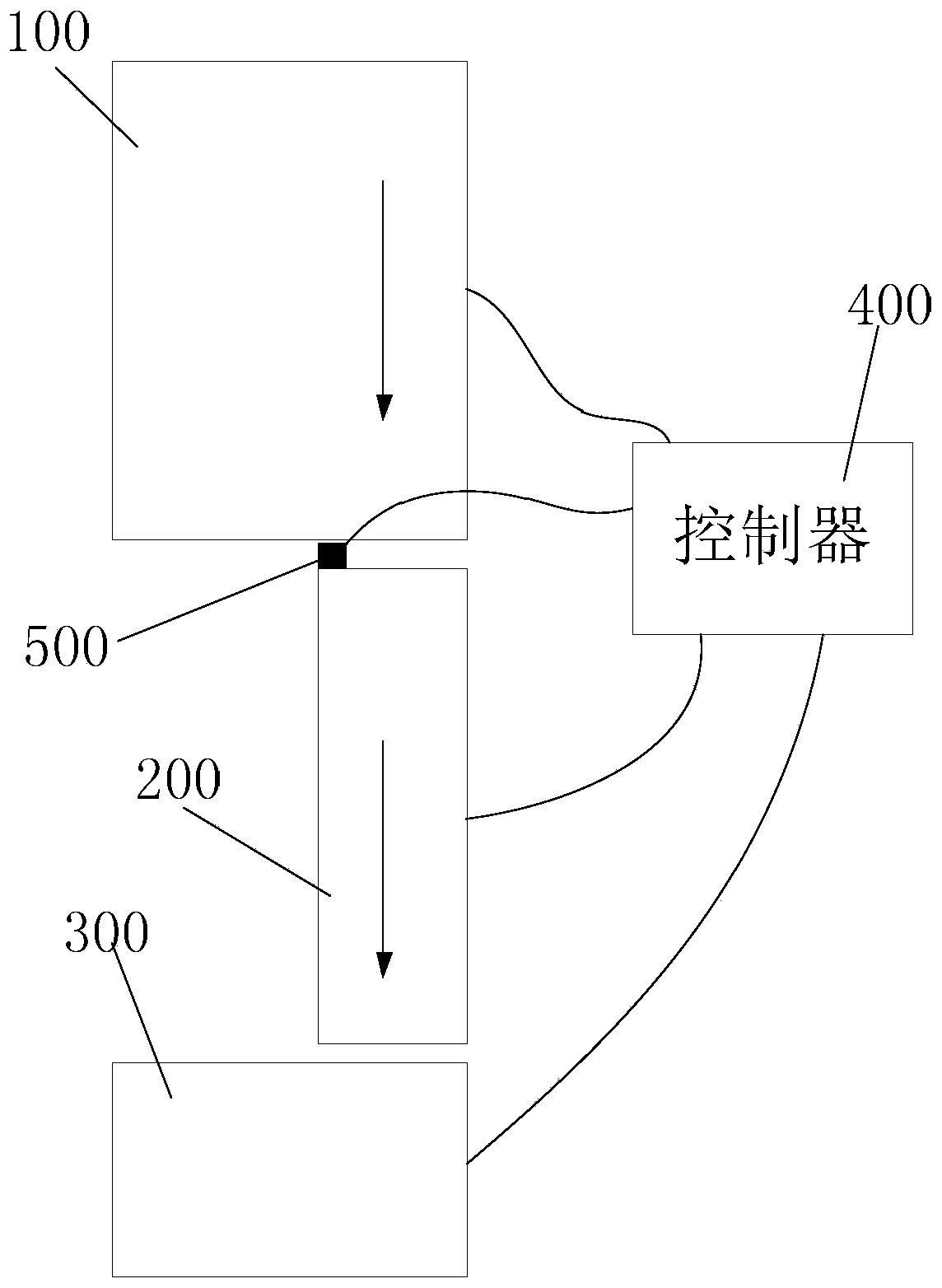

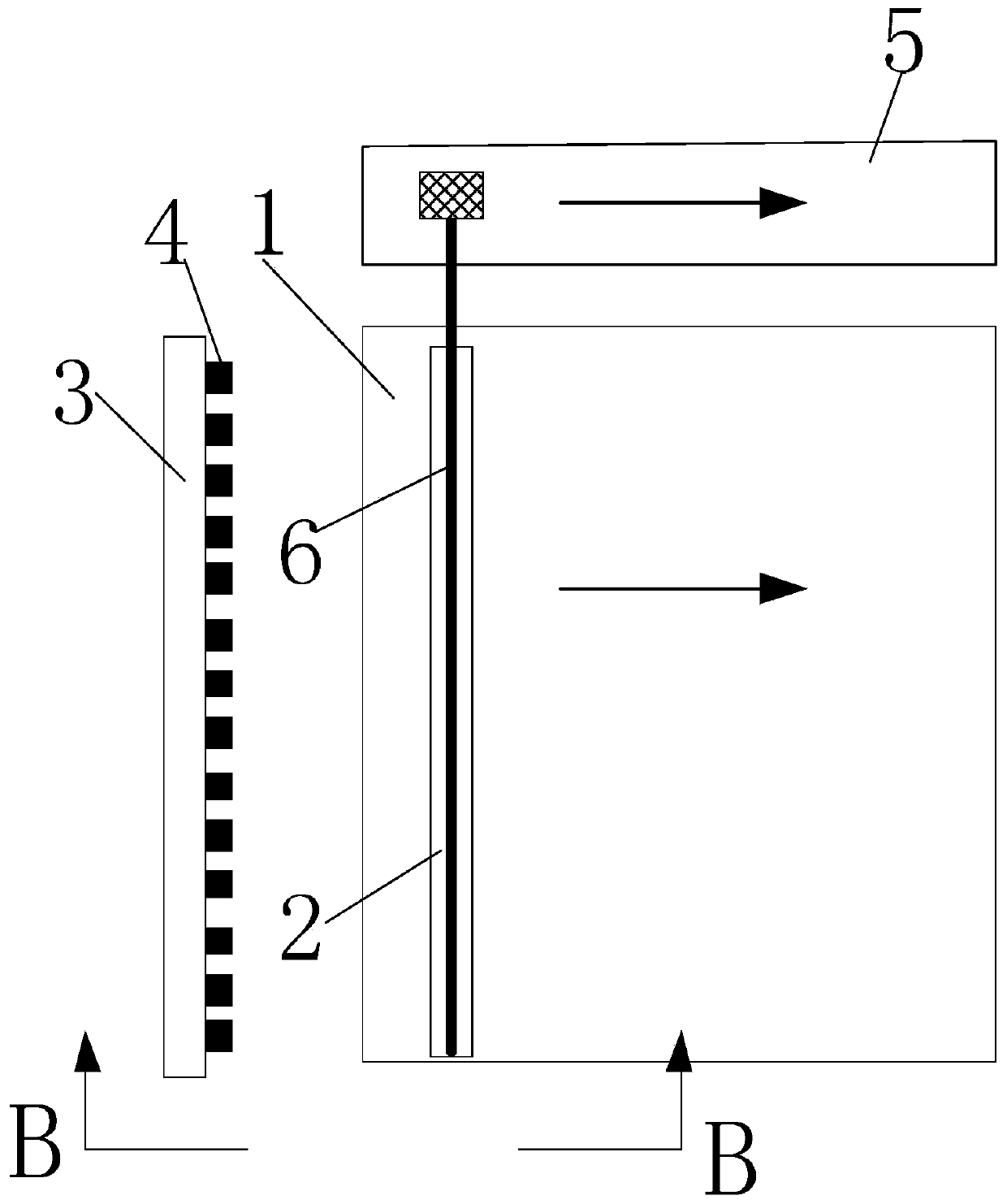

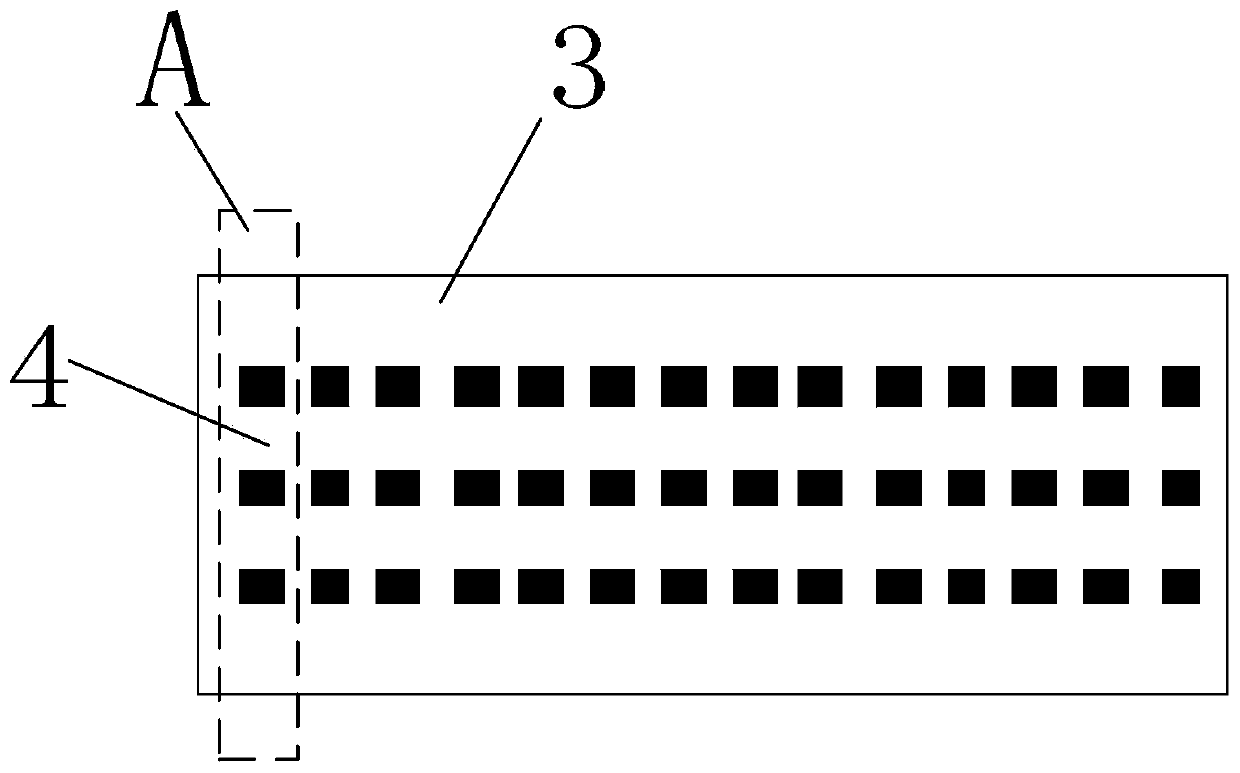

Intelligent medicine box and working method thereof

ActiveCN107298256AAvoid Medication ErrorsAutomatic take outSmall article dispensingUser needsEmergency medicine

The invention discloses an intelligent medicine box and a working method thereof. The medicine box includes a shell body, the shell body is internally provided with a plurality of medicine supplying mechanisms, and each medicine supplying mechanism comprises a cavity arranged crosswise in a horizontal direction, wherein the left end of the bottom of each cavity is provided with a groove, and the top portion of each cavity is provided with a guiding rail in a horizontal direction and a mobile mechanism capable of moving along the guiding rail; the bottom of each mobile mechanism is provided with a lifting device, and the lifting end of each lifting device is provided with a vacuum chuck, and each groove is internally provided with a medicine placing pipe which comprises a column where a medicine placing hole running though the column in an axial direction is formed; the upper end of each groove is provided with a sensor for detecting whether or not the top portions of the medicine placing holes contain pills, the shell body is further provided with a medicine outputting mechanism, and the bottom of each cavity is provided with a through hole communicated with an electric drawer; moreover, the shell body is also provided with a controller, a touch screen and an air extracting and exhausting mechanism. By using the intelligent medicine box, a user does not need to separately place pills to be taken each time for taking pills in advance, and the intelligent medicine box can automatically output the corresponding pills when the user needs to take pills.

Owner:杭州欣卓科技有限公司

Steel pipe cutting system based on wall thickness measuring results

ActiveCN110682162ATake advantage ofAvoid scrappingMeasurement/indication equipmentsPipeMechanical engineering

The invention provides a steel pipe cutting system based on wall thickness measuring results. The system comprises a wall thickness measuring device, a conveying platform, a cutting device and a controller, wherein the wall thickness measuring device is used for measuring the wall thickness of all sections of a steel pipe, sending the measuring results to the controller, and conveying the steel pipe subjected to wall thickness measuring to the conveying platform, an infrared position sensor is arranged at an inlet of the conveying platform, when the steel pipe is detected to be conveyed to theinlet of the conveying platform through the infrared position sensor, the infrared position sensor sends an arrival signal to the controller, the conveying platform conveys the steel pipe subjected to the wall thickness measuring to the cutting device, after receiving the arrival signal, the controller determines the section, currently conveyed into the cutting device, of the steel pipe accordingto the conveying speed of the conveying platform, and if the wall thickness of the section is not qualified, the cutting device is controlled to cut the section. According to the system, the steel pipe can be prevented from being totally scrapped due to the fact that a certain section is unqualified, so that the steel pipe which can be scrapped can be fully utilized.

Owner:聊城市艾智信息科技有限公司

Pneumatic type low-temperature storage device

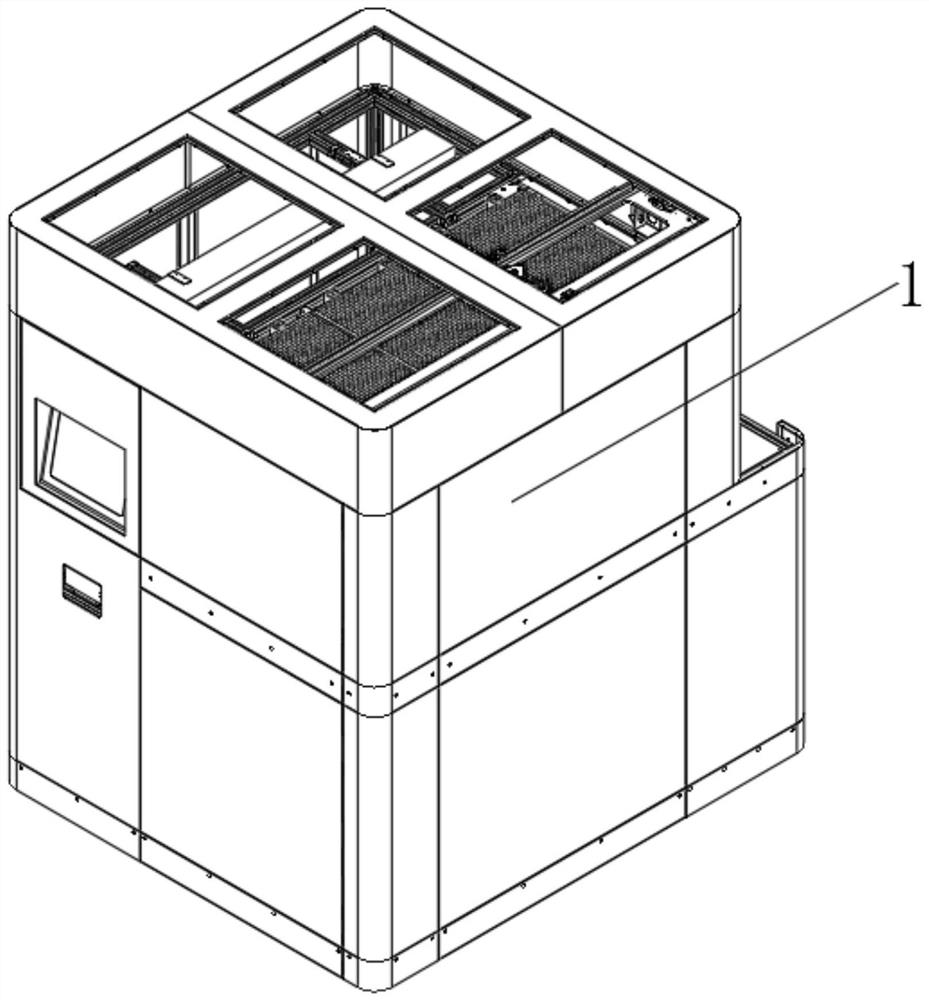

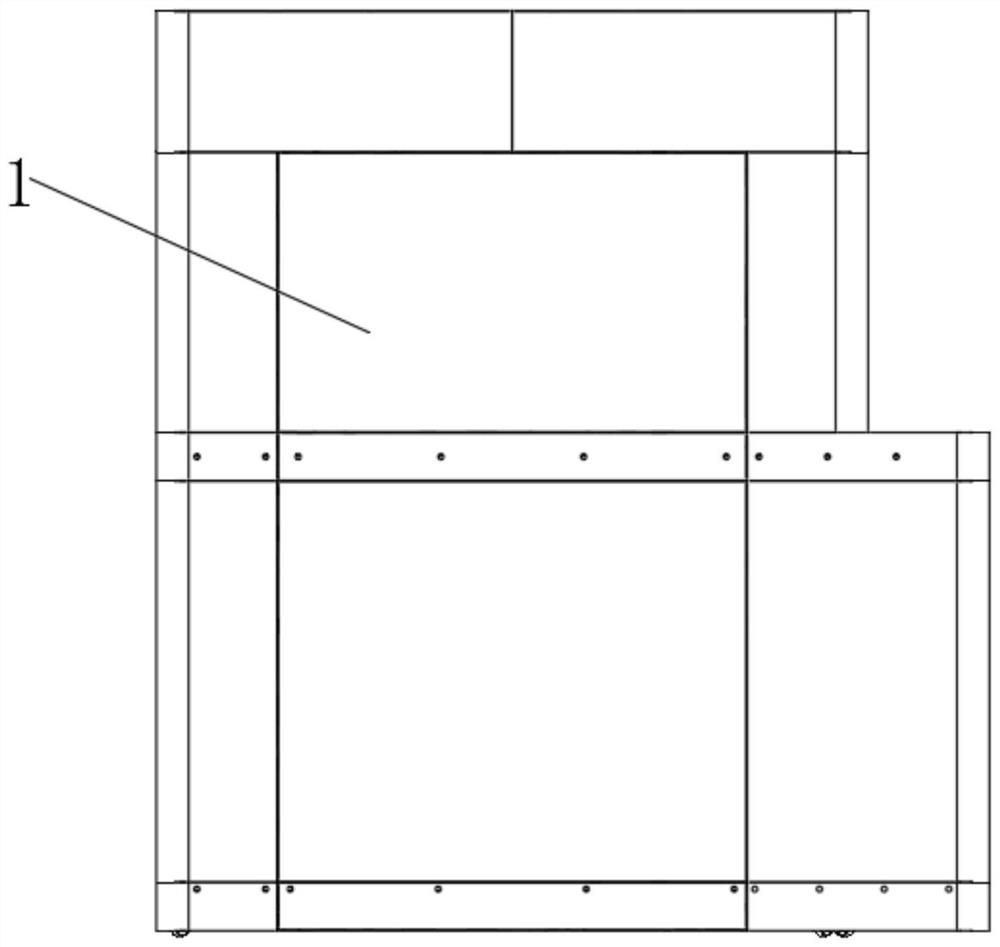

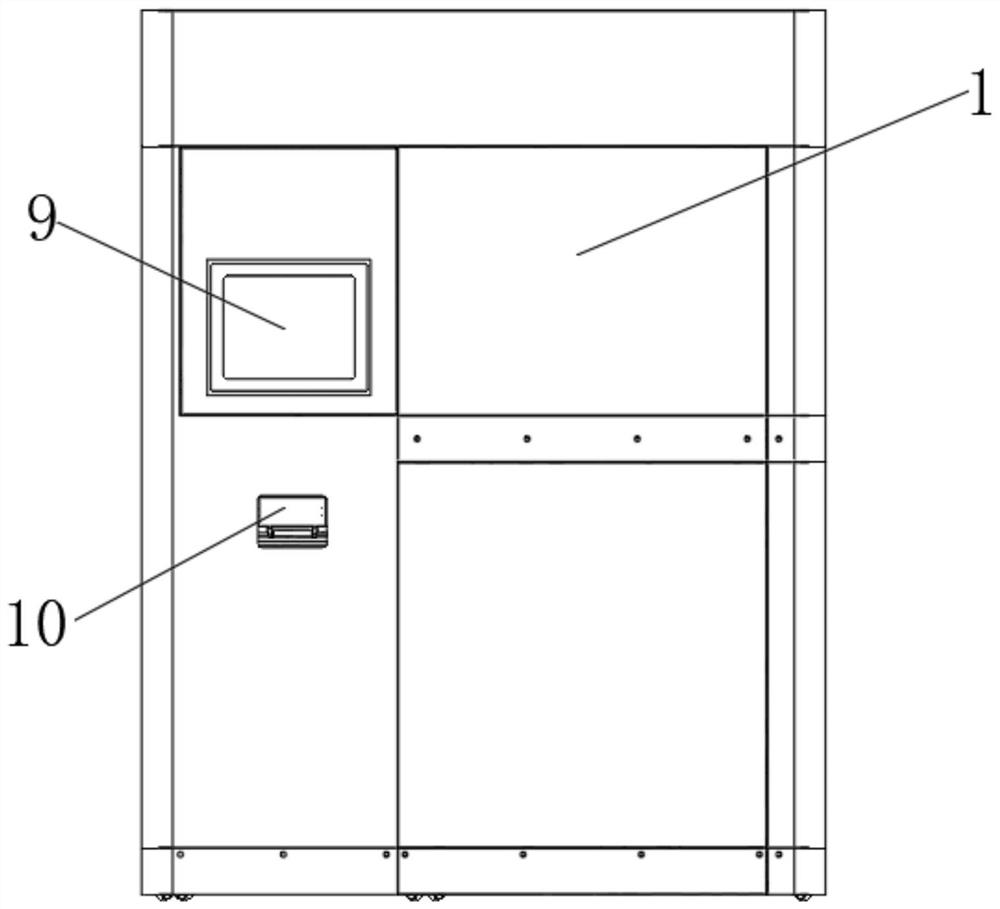

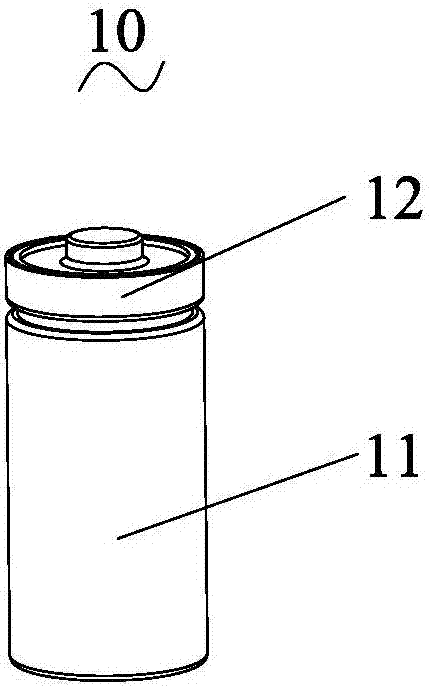

PendingCN114403134AEnsure health and safetyGuarantee the safety of lifeDead animal preservationSensing by electromagnetic radiationElectronics coolingComputer module

The invention belongs to the technical field of biotechnology regeneration, and particularly relates to a pneumatic low-temperature memory which comprises a shell, a low-temperature module, a carrier plate platform, a program cooling module, an electronic cooling module, a low-temperature area mechanical motion module and a software and computer module. The top of the frame is fixedly connected with a refrigeration heat preservation box, the low-temperature module comprises a refrigerating machine fixedly connected with the frame, the refrigerating machine is located at the bottom of the frame, the carrier plate platform comprises a carrier plate bin fixedly connected with the frame, the carrier plate bin is located on one side of the middle of the frame, and the top of the frame is fixedly connected with a movable platform. The moving platform comprises an X-axis sliding mechanism and a Y-axis sliding mechanism which are fixedly connected with the frame. A pneumatic transmission mode is adopted, the principle of atmospheric pressure is utilized, and the effect of solving various problems existing in equipment such as a traditional low-temperature refrigerator or a liquid nitrogen tank at present is achieved.

Owner:岑锦(上海)科技有限公司

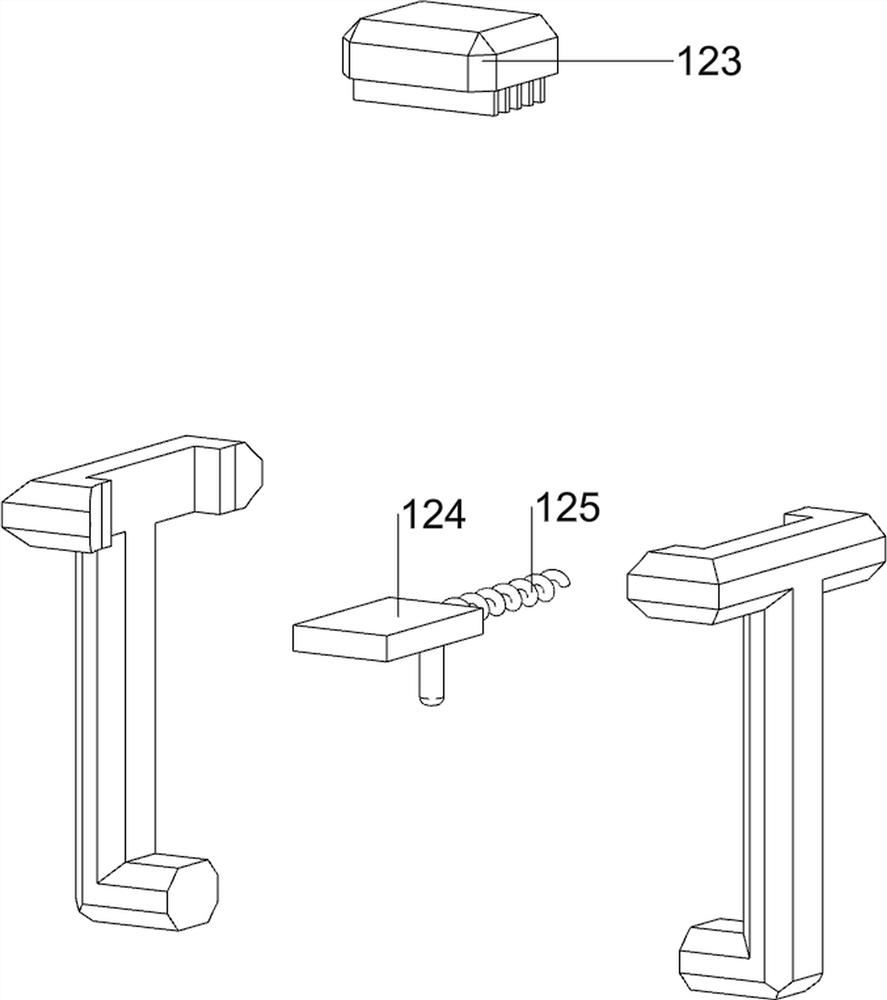

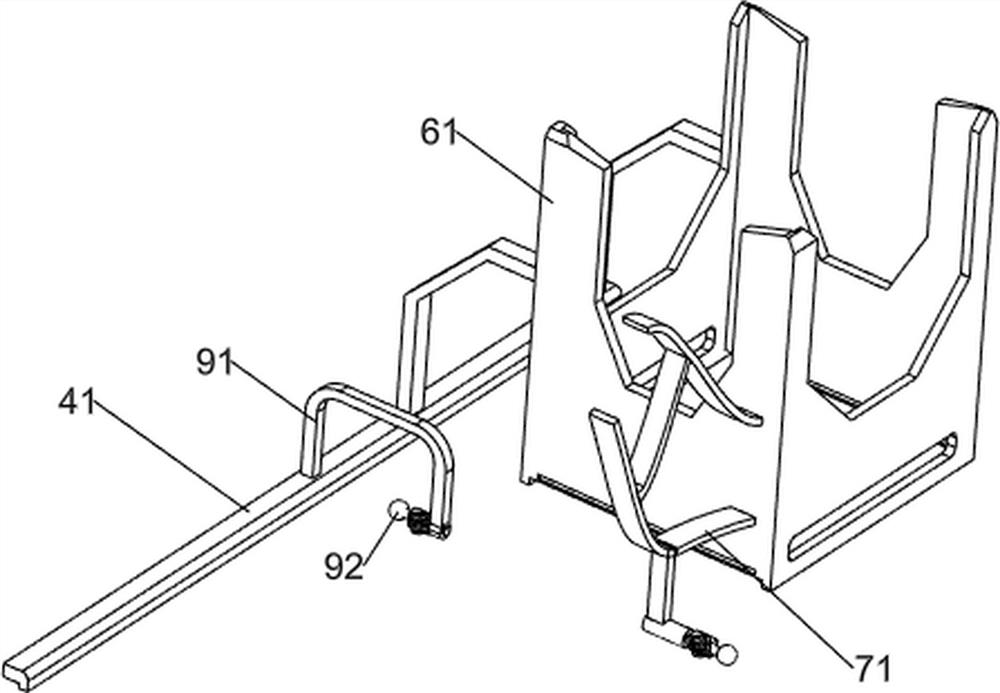

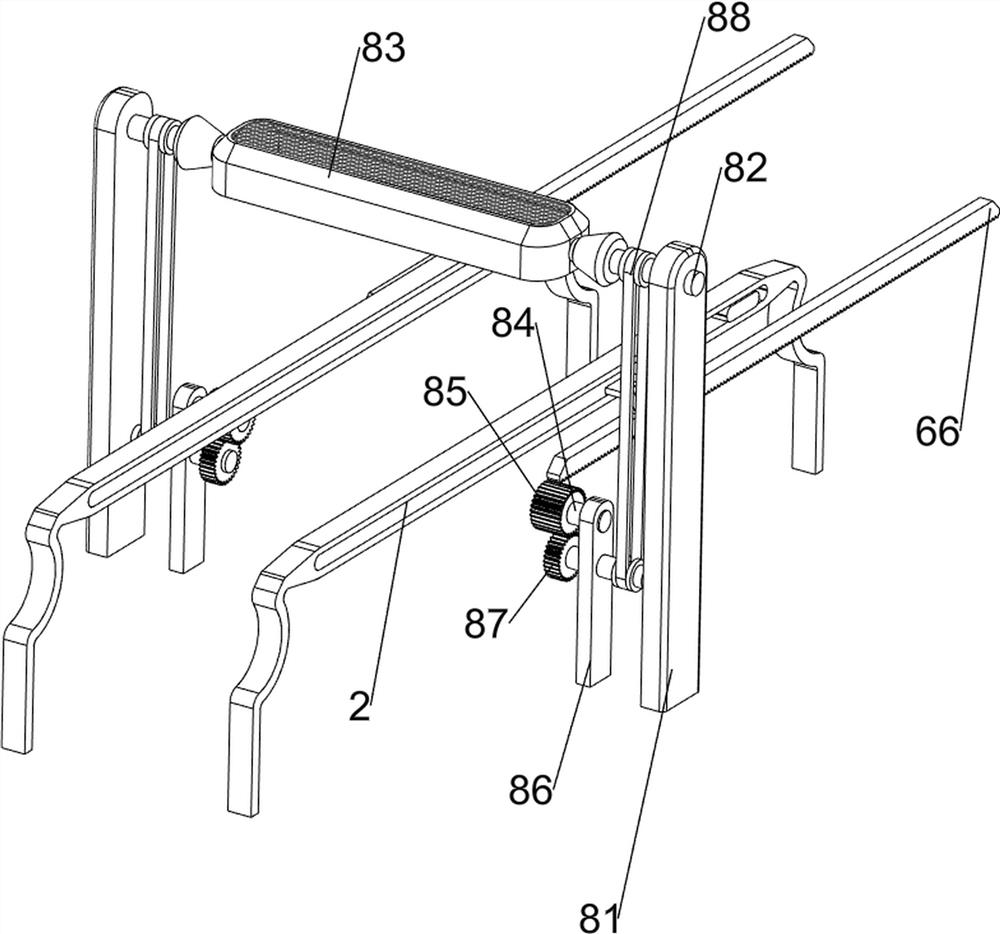

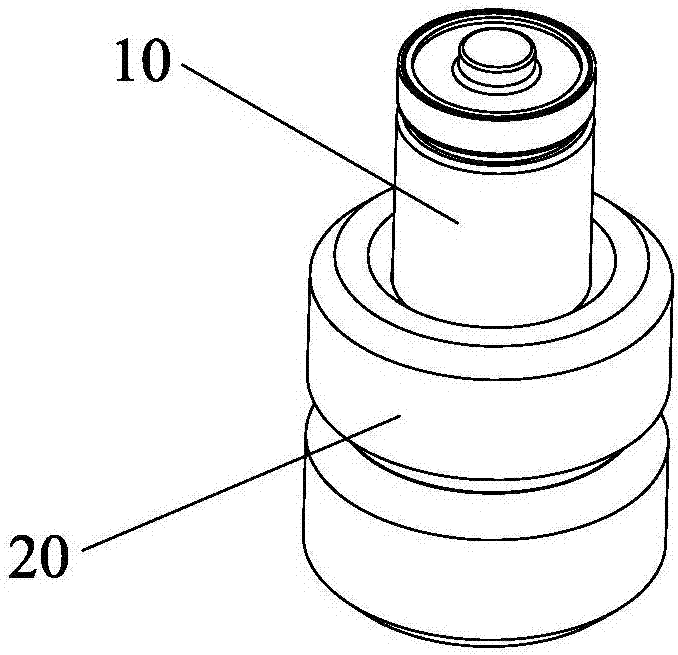

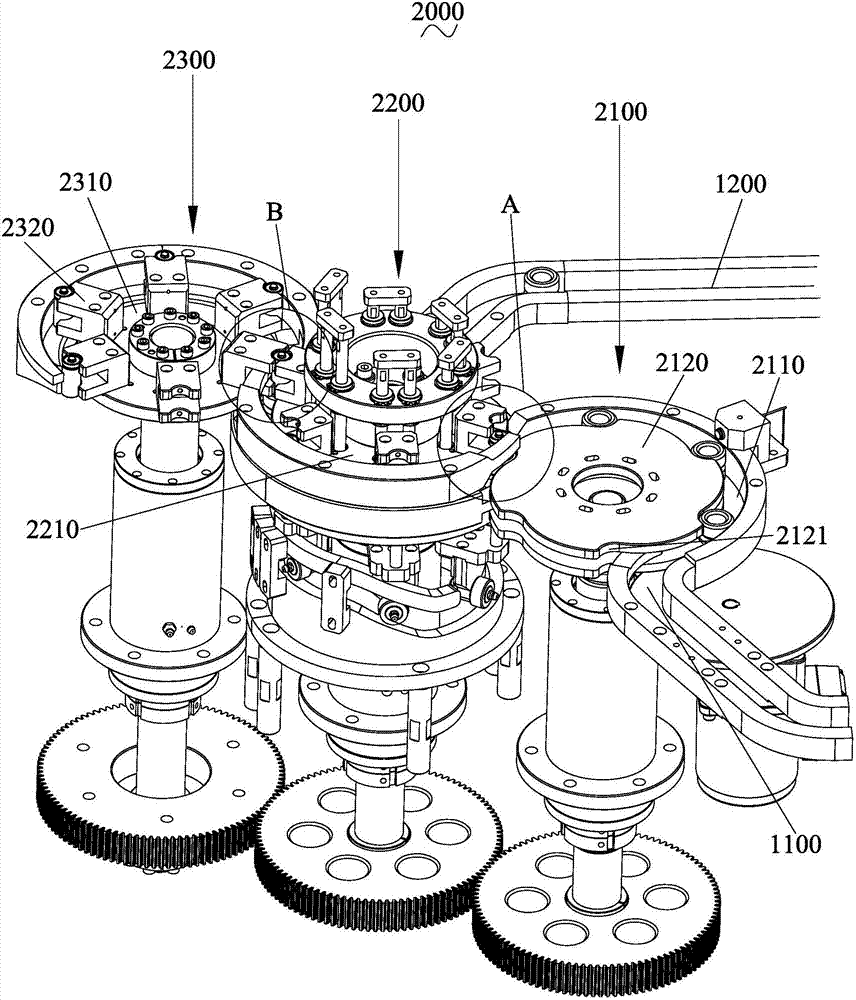

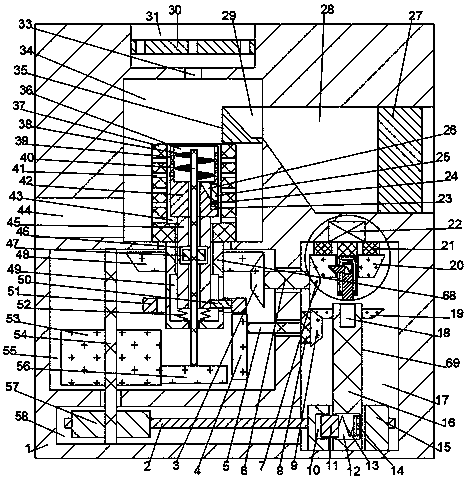

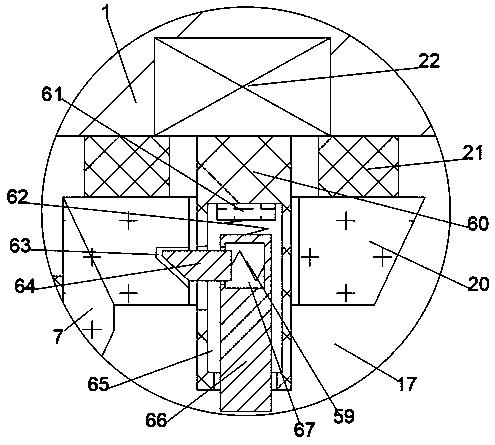

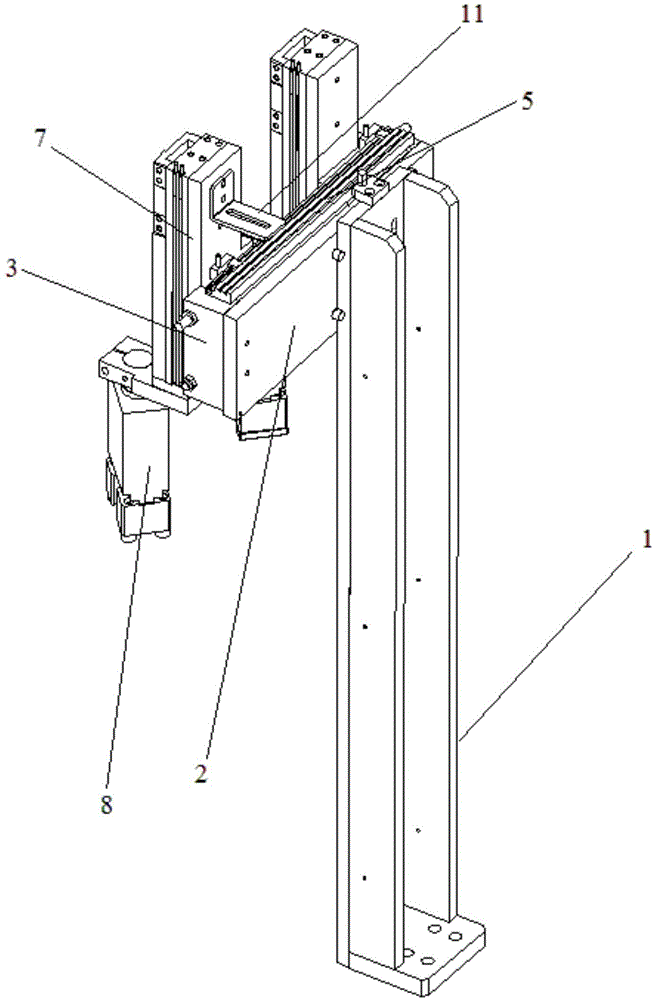

Battery core and jig separation mechanism

ActiveCN106910931AAutomatic take outPrimary cell manufactureAssembling battery machinesEngineeringCam

The invention discloses a battery core and jig separation mechanism which comprises a first material rotating device, a second material rotating device and a third material rotating device, wherein the first material rotating device is provided with an arc-shaped material rotating channel; the second material rotating device is provided with a circular material rotating channel; the first material rotating device comprises a battery core jig loading turntable; a battery core and jig cutting groove is formed in the edge of the battery core jig loading turntable; the second material rotating device comprises a battery core and jig separation cam, a battery core and jig separation turntable, a battery core ejection rod and a battery core fixing block; the third material rotating device comprises a battery core loading turntable and a battery core clamping block; the battery core clamping block is fixedly mounted at the edge of the battery core loading turntable; the structure of the battery core clamping block is identical with that of the battery core fixing block; the battery core fixing block and the battery core clamping block are respectively rotated through the battery core and jig separation cam and the battery core loading turntable to form tangent fit. The battery core and jig separation mechanism disclosed by the invention can automatically take a cylindrical battery core out of a jig to make a preparation for pressing of the battery core in the next working procedure.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

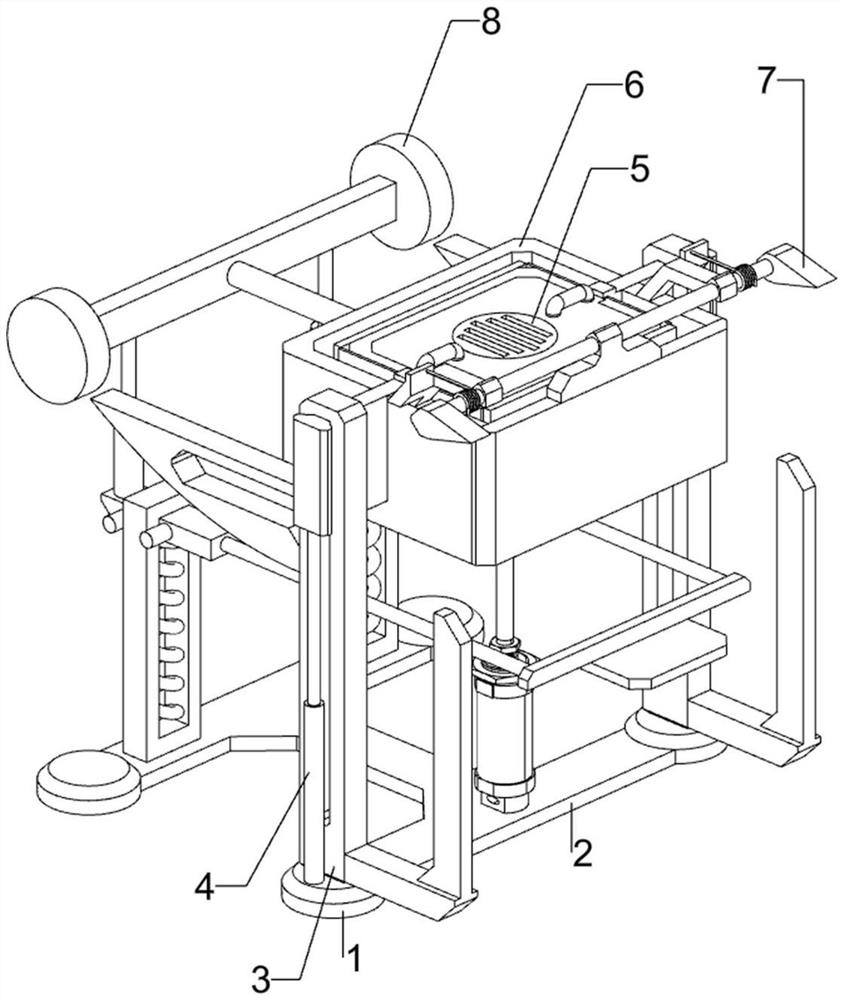

Industrial dehydrator with sewage disposal device based on mechanical principle and use method thereof

InactiveCN109110950AAutomatic take outSimple organizationWater/sewage treatment by centrifugal separationSpecific water treatment objectivesEngineeringSewage

The invention discloses an industrial dehydrator with a sewage disposal device based on the mechanical principle and a use method thereof. The industrial dehydrator comprises a working block; a working space is formed in the working block; a draining pipeline is arranged on the lower side of a left end wall of the working space; a right end wall of the draining pipeline is connected with the working space while a left end is connected with an outside space; a filtering space is formed in an upper end wall of the working space; an upper end wall of the filtering space is connected with the outside space; a sewage pipeline is arranged in a lower end wall of the filtering space; the upper end wall of the sewage pipeline is connected with the filtering space while the lower end wall is connected with the working space; a driving space is formed in the lower end wall of the working space. The industrial dehydrator disclosed by the invention has a simple structure and convenience in operation and is capable of filtering the sewage and then dehydrating; the dehydrating wastes can be automatically taken out, so that the running of the dehydrator can be prevented from being influenced by the waste accumulation; the wastes in the dehydrator need not be manually treated, so that the working efficiency is increased; the industrial dehydrator has ultrahigh practicability.

Owner:张振寰

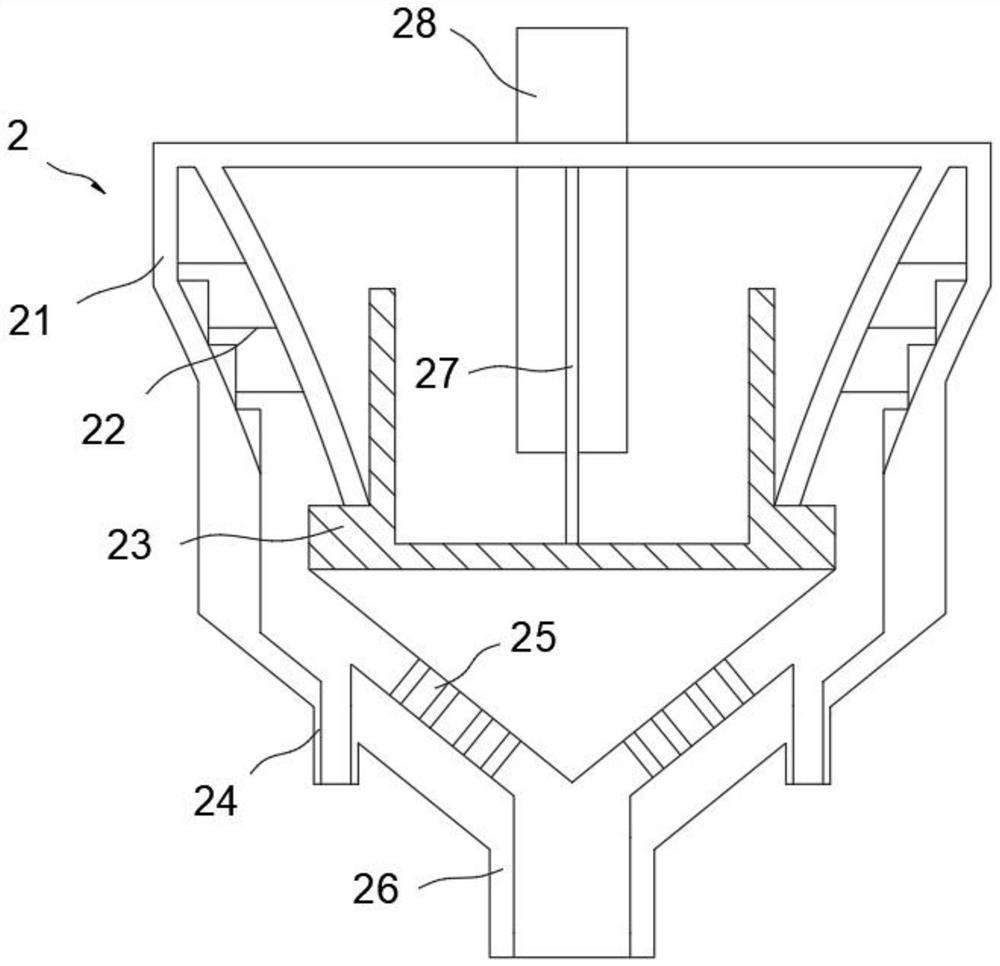

Method for mixing and stirring by utilizing stirring device of clay and other materials

The invention discloses a method for mixing and stirring by utilizing a stirring device of clay and other materials. The stirring device of clay and other materials comprises a working block; a working space is formed in the working block; a driving mechanism is arranged in the upper end of the working space; a rotating space is formed in a driving shaft; a lifting mechanism is arranged in the rotating space; a mixing mechanism is arranged on the upper end of a stirring mechanism. During the working process, clay and water are mixed and stirred for reducing the adhesion of clay, so that the clay can be conveniently added and the coagulation and adhesion of clay during the adding process can be reduced; the mixture of clay and water and gaseous and solid materials are slowly and uniformly added, so that the clay can be more uniformly stirred with other materials in the manner of adding materials while stirring and the stirring efficiency can be increased; after stirring is finished, thestirred clay mixture can be automatically taken out and the degree of automation is high.

Owner:陈柏海

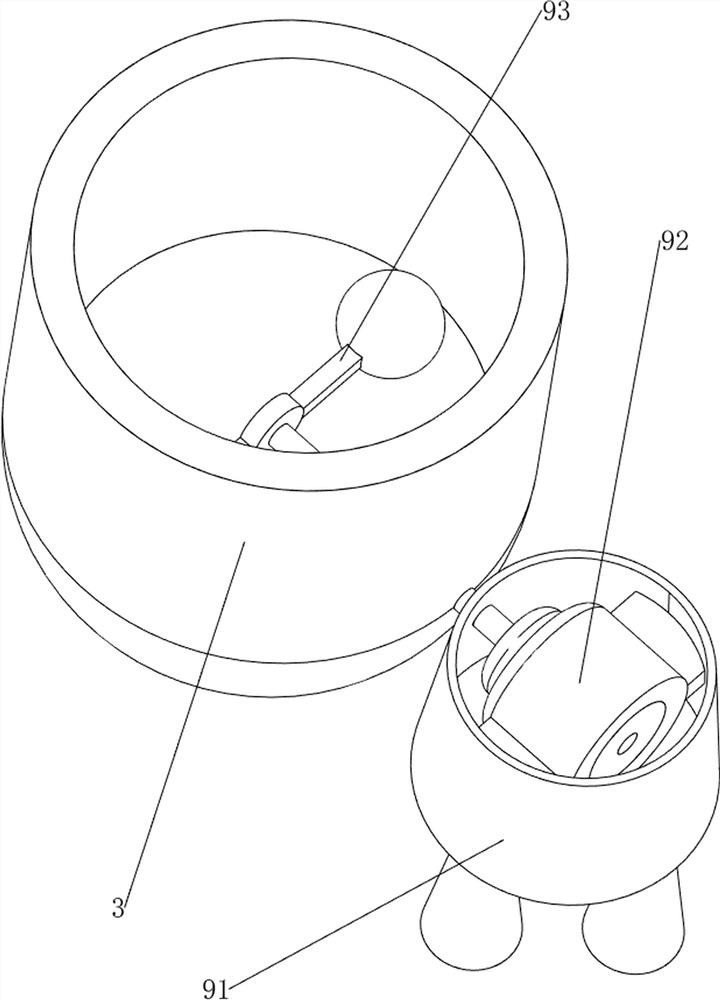

Household chili sauce making machine

ActiveCN113367599AAchieve the effect of automatically cutting peppersEasy to operateClimate change adaptationKitchen equipmentChilli con carneEngineering

The invention relates to a making machine, in particular to a household chilli sauce making machine. The household chilli sauce making machine provided by the invention can automatically cut and stir-fry chilli and improve the making efficiency of the chilli sauce. The household chilli sauce making machine comprises a base, a heating ring, a finished product frame, a baffle, a rotary cutting mechanism, a discharging mechanism, a sorting mechanism and the like, the heating ring is arranged on the base, the finished product frame is placed on the heating ring, the baffle is arranged on the rear side of the base, the rotary cutting mechanism is arranged on the front side of the upper portion of the baffle, and the discharging mechanism is arranged in the middle of the baffle. A sorting mechanism is arranged in the middle of the inner side of the rotary cutting mechanism. Through the arrangement of the rotary cutting mechanism, people start the rotary cutting mechanism to cut the chilies, so that the effect of automatically cutting the chilies is achieved, and people do not need to cut the chilies to hurt hands.

Owner:成都六汇鑫邦农业科技有限公司

Environment-friendly fly ash treatment equipment for coal chemical industry production

InactiveCN113369126AAvoid pollutionReduce the burden onSievingScreeningProcess engineeringEnvironmental engineering

The invention relates to treatment equipment, in particular to environment-friendly fly ash treatment equipment for coal chemical industry production. The technical problem to be solved by the invention is to provide the environment-friendly fly ash treatment equipment for coal chemical industry production, which not only facilitates collection and removal of fly ash, but also can prevent fly ash from flying up. The environment-friendly fly ash treatment equipment for coal chemical industry production comprises a machine frame, a frame, first springs, a driving assembly, a screening assembly and a stop assembly, wherein the frame is mounted on the machine frame in a sliding manner; the first springs are mounted on the left and right sides of the front parts of the machine frame and the frame; the driving assembly is mounted between the machine frame and the frame; the screening assembly is mounted on the frame; and the stop assembly is mounted on the machine frame. The equipment is provided with a covering assembly, so that a cover plate of the equipment can cover the frame, and the fky ash can be effectively prevented from polluting the air when screened materials are shaken.

Owner:邹丽婷

Device capable of automatically taking out blank piece and cleaning interior of cavity after air cylinder casting is completed

InactiveCN111408705AAutomatic take outTo achieve the effect of cleaning the cavityHollow article cleaningCircular discGear wheel

The invention relates to the technical field of air cylinder casting, and discloses a device capable of automatically taking out a blank piece and cleaning the interior of a cavity after air cylindercasting is completed. The device comprises a fixed base, film closing plates are movably installed at the left end and the right end of the top of the fixed base, and heat preservation materials are fixedly installed on the opposite faces of the two film closing plates; and the upper end of the fixed base is rotationally connected with a threaded rod, the right end of the threaded rod is rotationally connected with a rotating disc, and a rotating handle is fixedly installed at the upper end of the rotating disc. According to the device, the rotating handle is manually rotated to drive the rotating disc to rotate and drive the threaded rod to rotate, so that the film closing plates are driven to move left and right, a gear set is matched to drive a movable toothed plate to move, the movabletoothed plate drives a movable plate to move, and a casting table can be conveyed out of a casting cavity, so that the effect of automatically taking out the blank piece is achieved, and meanwhile, the effect of cleaning the casting cavity is achieved through cooperation with an air outlet cylinder.

Owner:朱洁怡

Device for attaching oil on surface of machining part

InactiveCN107297301AAutomatic take outSave time at workLiquid surface applicatorsCoatingsMachine partsGear wheel

The invention discloses a device for attaching oil to the surface of machined parts, which comprises a case, the bottom of the inner wall of the case is fixedly connected with an oil tank through a support block, the top of the oil tank runs through the case and extends to the top of the case, the The bottom of the inner wall of the case and one side of the support block are fixedly connected with a motor through a connecting block, the outer surface of the output shaft of the motor is covered with a first bevel gear, and the top of the case is fixedly connected with an auxiliary oil tank. The invention belongs to the technical field of mechanical processing equipment. The surface oil attachment device for mechanical processing parts does not need the processing personnel to manually take out the oiled parts from the oil attachment tank, which greatly saves the working time of the processing personnel and reduces the processing time. The work burden of the personnel is realized by operating the control switch, so that the mechanical parts that have been treated with oil can be automatically taken out, thereby improving the work efficiency of the processing personnel.

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

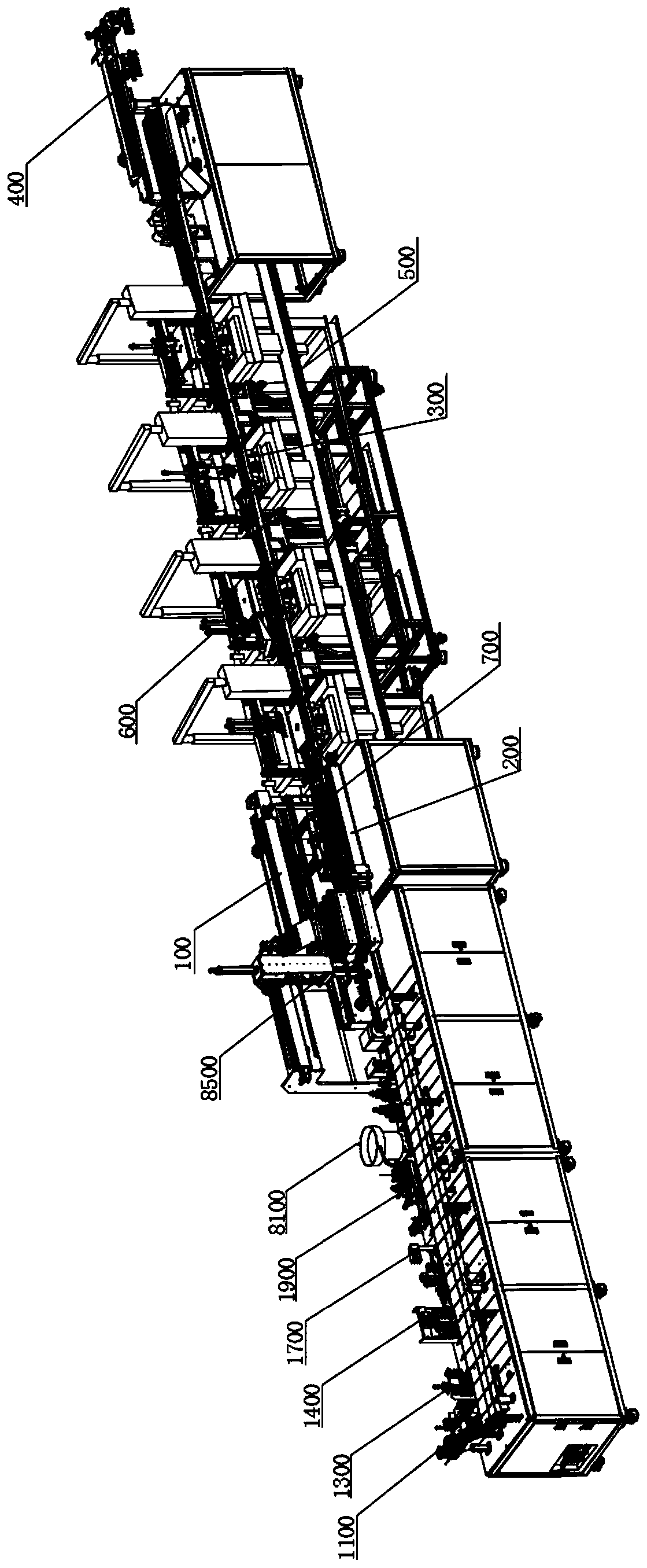

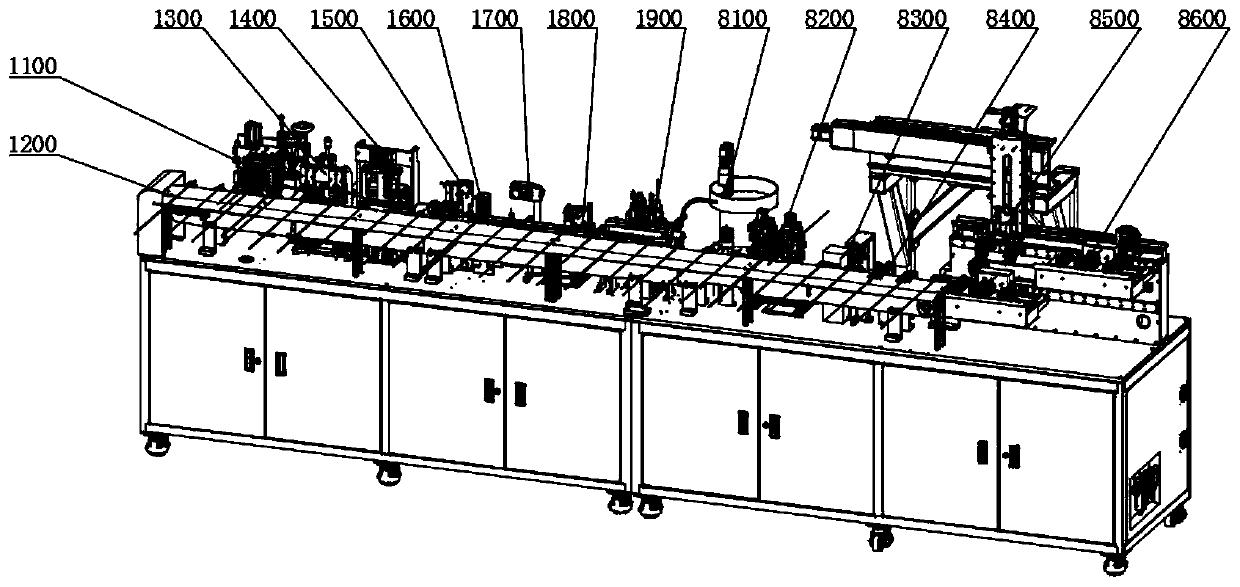

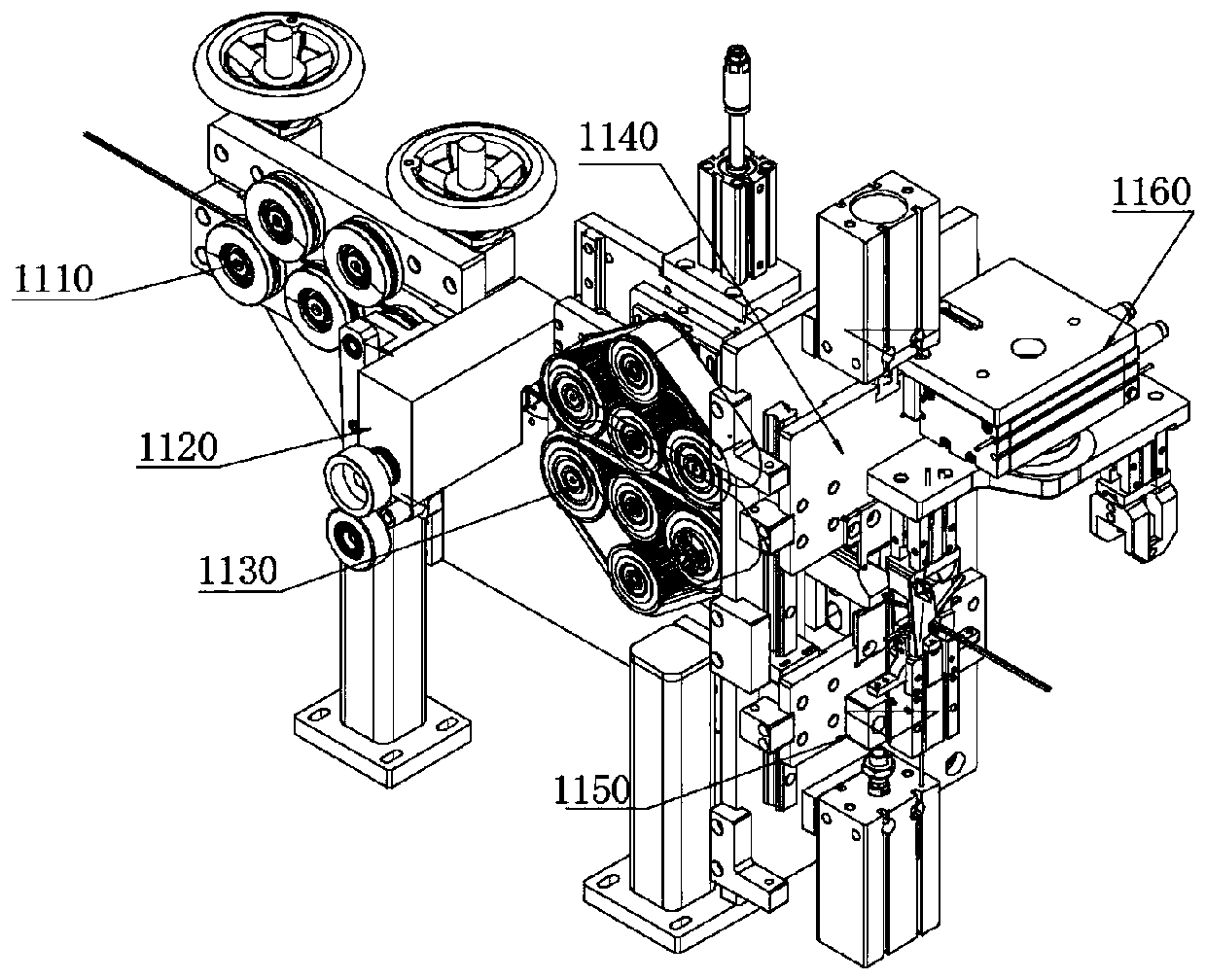

Automatic wire production equipment

The invention discloses automatic wire production equipment. The automatic wire production equipment comprises a front wire machining section and a rear wire machining region. The front wire machiningsection comprises a wire automatic transfer mechanism, a fixed-length cutting mechanism, a skin stripping mechanism, a core wire stripping mechanism, a wire twisting mechanism, a wire separating mechanism, a flux adding device, a tin soaking mechanism, a welding MICRO mechanism, a welding detection device, a double-head electric testing mechanism, an SR end trimming mechanism, a wire fetching pre-positioning mechanism, a mechanical hand transfer mechanism and a distance-variable up-and-down staggered connecting mechanism. The rear wire machining section comprises a wire loading mechanism, a jig die strip pushing mechanism, a jig die strip and wire lower die entering mechanism, a wire fetching mechanism, a jig die strip backflow mechanism, a water fetching opening mechanism and a jig die strip. The design is reasonable, a wire not subjected to injection molding is automatically inserted into a die strip, the die strip and the wire are automatically put in a lower die, injection moldingcan be conveniently completed, meanwhile, the wire obtained after injection molding can be automatically taken out, and the production efficiency of wire production and the quality of the wire are improved.

Owner:深圳市美思晟科技有限公司

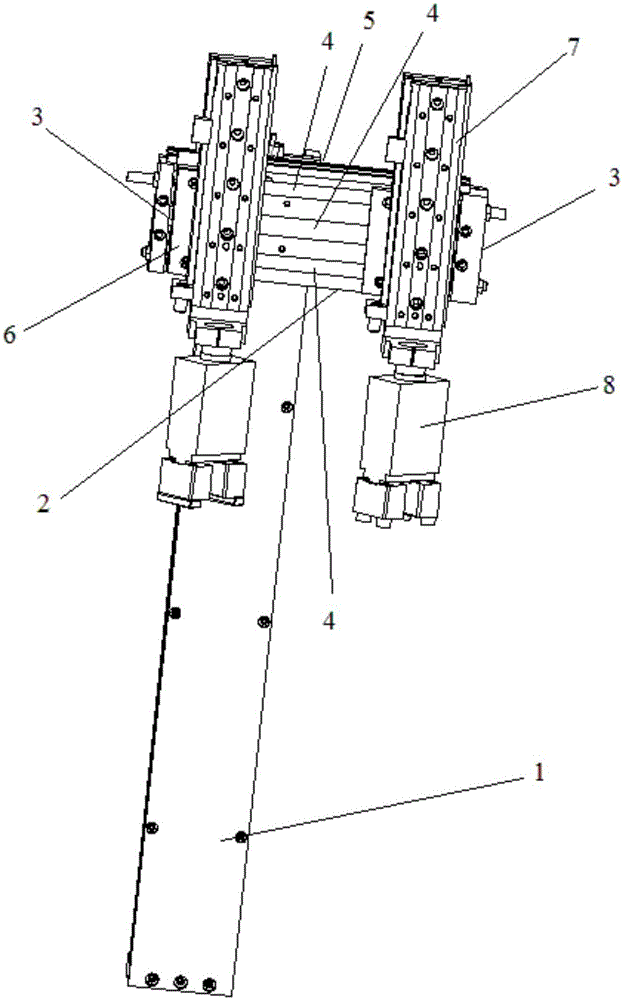

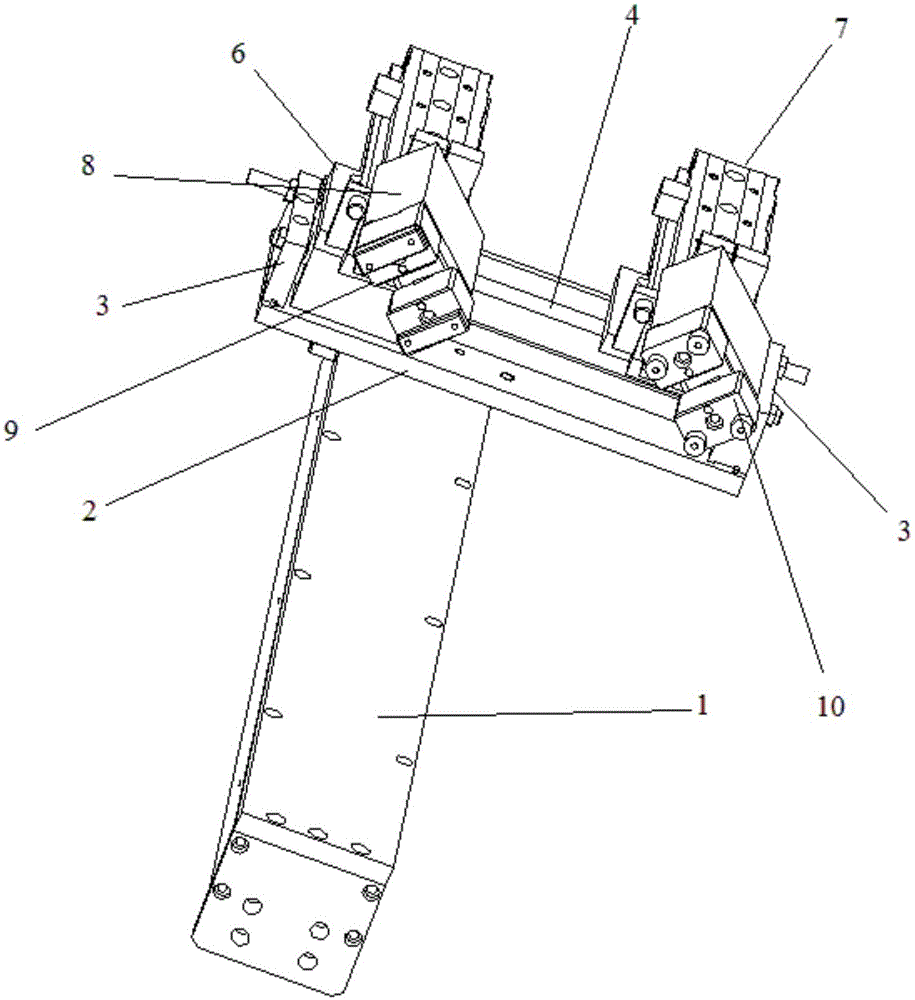

Defective product taking out mechanism

InactiveCN105082176AAutomatic take outImprove efficiencyProgramme-controlled manipulatorArmsEngineeringMechanical engineering

Owner:SUZHOU TINGYIHUA AUTOMATION EQUIP CO LTD

A medicine box capable of automatically dispensing medicine and its working method

Owner:湖北联扑科技集团有限公司

Wheat seeder tire leveling device for wet and rotten fields

The invention discloses a wheat seeder tire flattening device for wet and rotten fields. The device comprises a tire, and is characterized in that one side of the tire protrudes outwards to form a protruding edge, one side of the protruding edge is provided with a sliding groove, the inner wall of the sliding groove is slidably connected with a driving plate block, and the top of the tire is provided with an anti-skid device; and the anti-skid device comprises a hoop sleeve, anti-skid rollers are evenly inserted into the hoop sleeve, a detaching rod is inserted into one side of the driving plate block in a threaded manner, the detaching rod is matched with the anti-skid rollers, a rotary air cylinder is connected to the middle of the drive plate block, and the rotary air cylinder is connected with the middle of the protruding edge. A plurality of supply rollers are arranged in the protruding edge, one end of each supply roller is flexible and is in a U-shaped bent shape, one end of each anti-skid roller and one end of each supply roller are both made of magnetic materials, the polarity of the supply rollers is opposite to that of the anti-skid rollers, and the device has the beneficial effects that soil is convenient to take out, and automatic vacancy filling can be achieved.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com