Patents

Literature

172results about How to "Take out accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

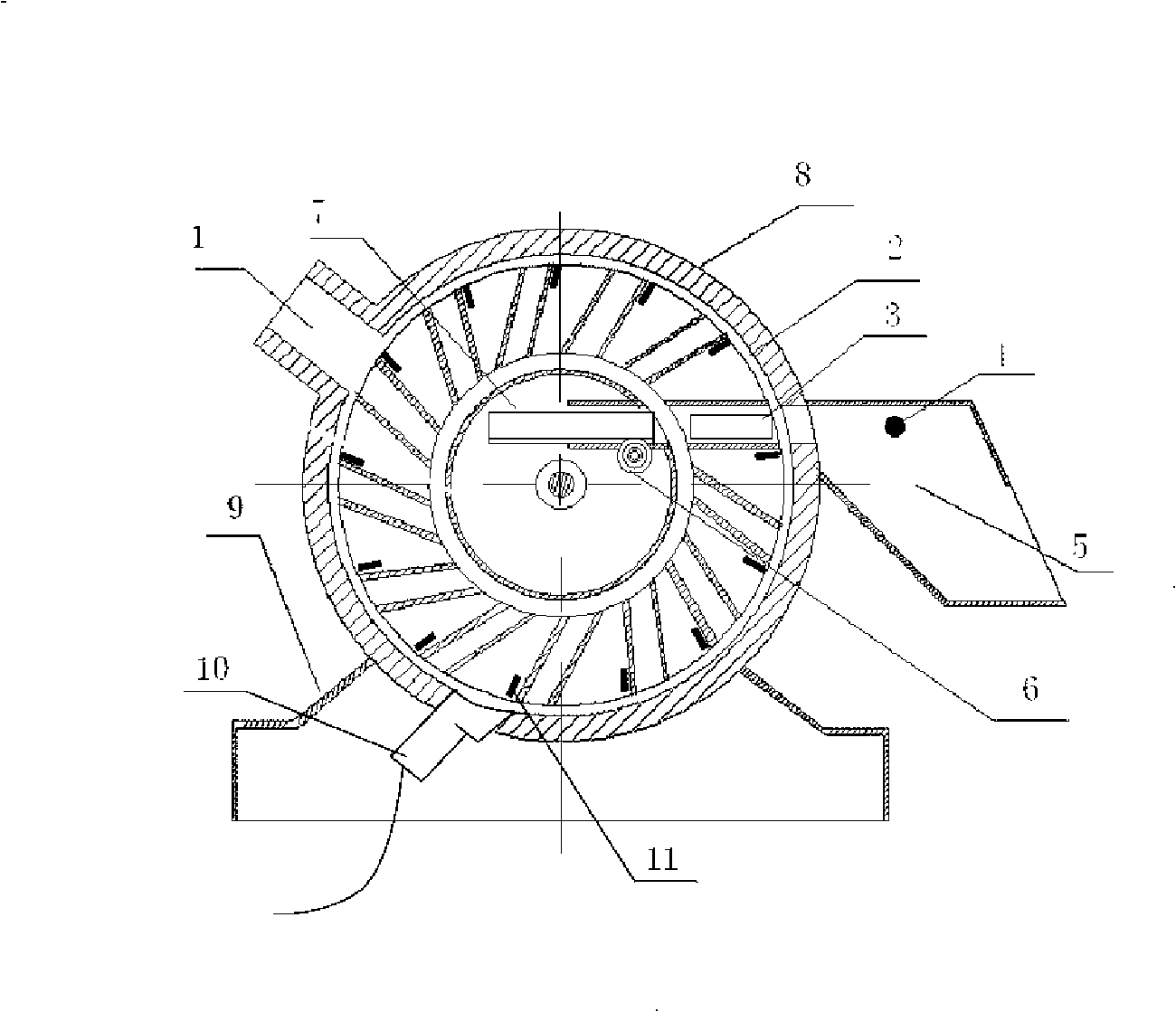

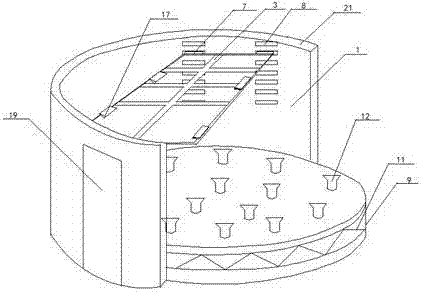

Coin separator

InactiveCN105321250APrevent card coin phenomenonImprove separation efficiencyCoin/paper handlersElectrical and Electronics engineeringPackaging machine

The invention relates to a coin separator which is capable of separating coins different in face value and rapidly and conveniently carrying out separation, countering and packaging on a large number of coins. The coin separator mainly comprises a cone-shaped tunnel, a chute, a coin separating track, a transmission belt, coin receiving boxes, electronic counters, coin packaging boxes and coin packaging machines. The cone-shaped tunnel of the coin separator is provided with a micro-vibrating device used for avoiding coin clamping. The coin separating track is set according to diameters of different coins and is capable of simply and rapidly separating different coins. The transmission belt is a power device for the coins on the coin separating track. When the coins pass through the coin receiving boxes, the counters counts the coins. The coin packaging machines are capable of circularly packaging the coins under a non-stop condition. By adopting the coin separator, the work efficiency is greatly improved, and the integral operation of coin separating and packaging is realized.

Owner:SOUTHWEST PETROLEUM UNIV

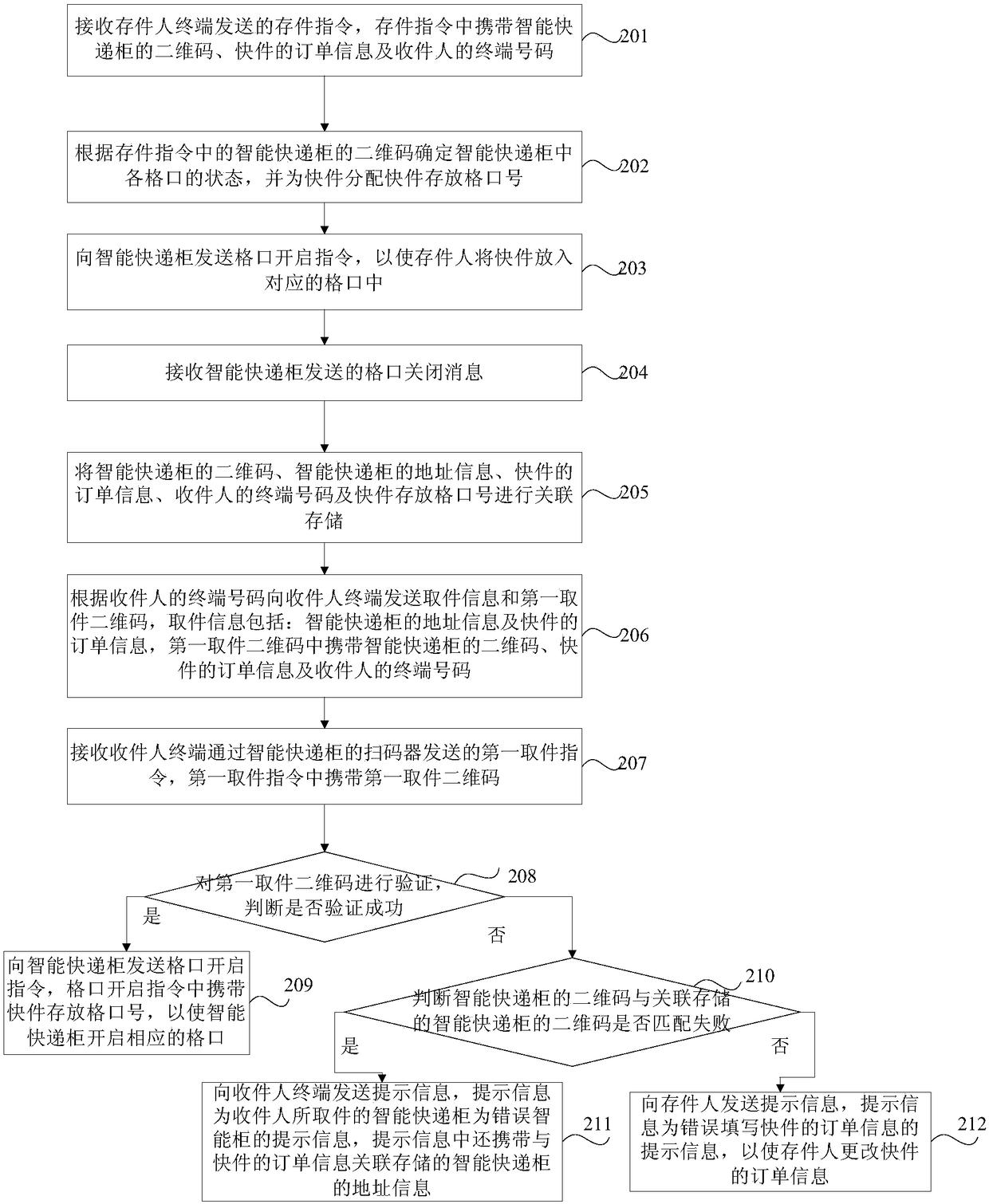

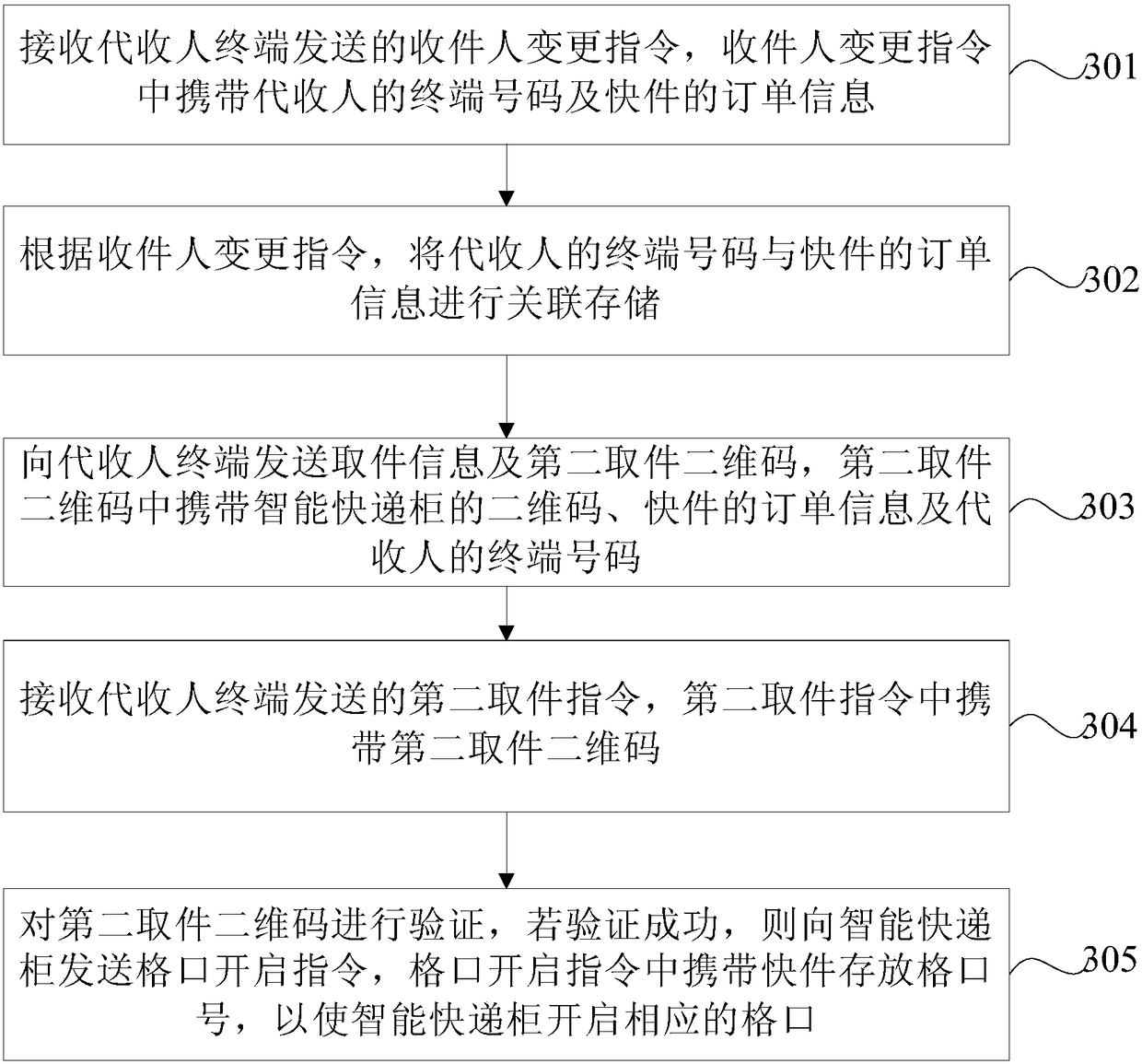

An express item processing method and device based on intelligent express delivery cabinets

ActiveCN108269363ATake out accuratelyImprove securityApparatus for meter-controlled dispensingIndividual entry/exit registersComputer scienceStorage cell

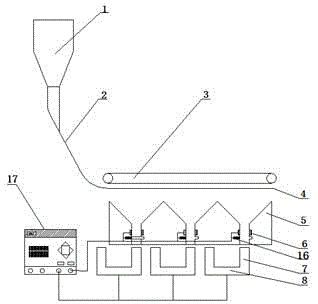

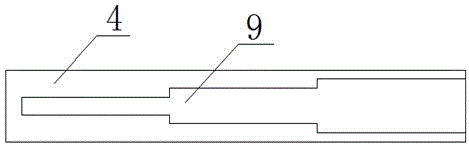

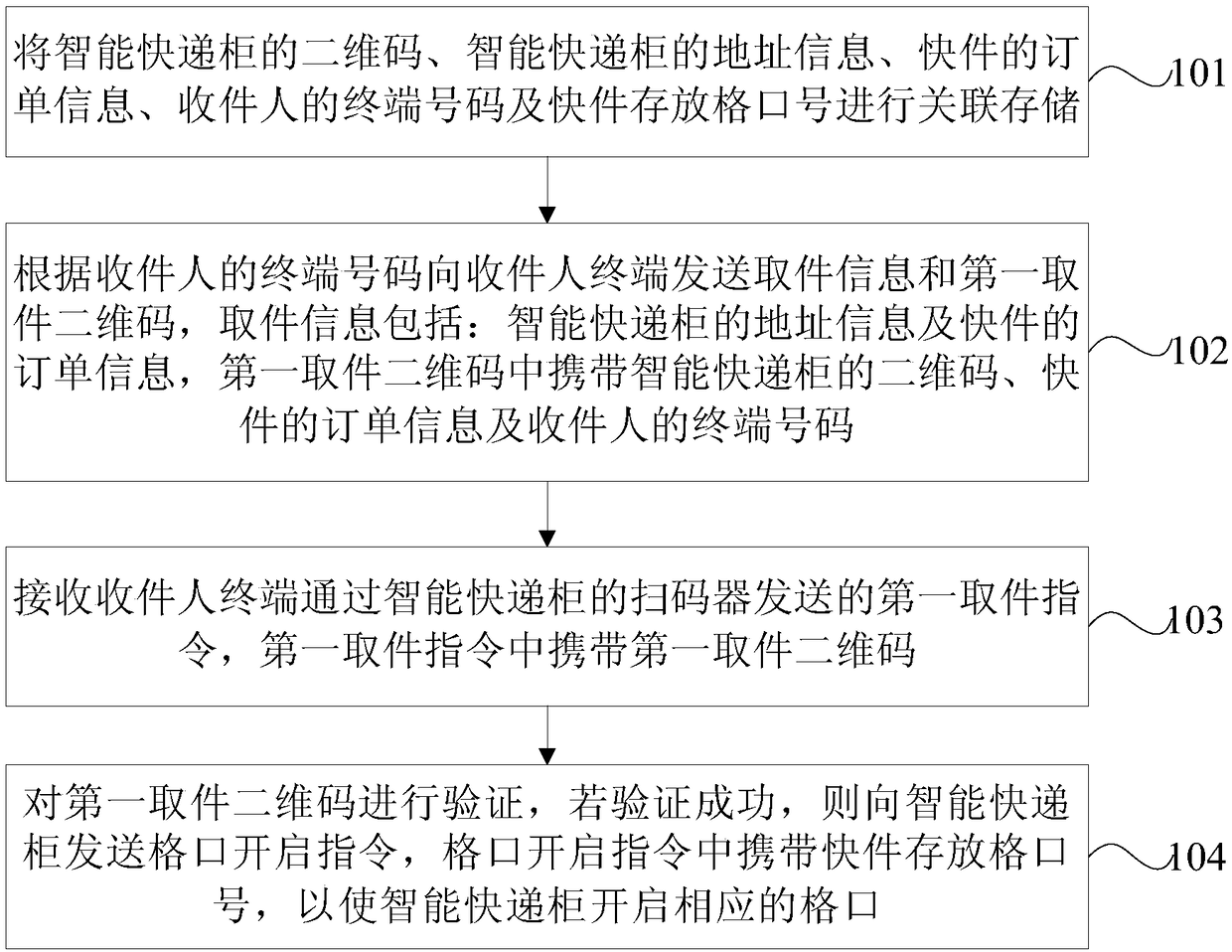

The invention provides an express item processing method and device based on intelligent express delivery cabinets. The method comprises the steps of: storing two-dimensional codes of intelligent express delivery cabinets, address information of the intelligent express delivery cabinets, order information of express items, terminal numbers of recipients and express item storage cell numbers in a correlated manner; sending item fetching information and first item fetching two-dimensional codes to the terminals of recipients according to the terminal numbers of the recipients, wherein the item fetching information includes the address information the intelligent express delivery cabinets and the order information of the express items and the first item fetching two-dimensional codes carry the two-dimensional codes of the intelligent express delivery cabinets, the order information of the express items and the terminal numbers of the recipients; receiving first item fetching instructionssent by the terminals of the recipients through code scanners of the intelligent express delivery cabinets, wherein the first item fetching instructions carry the first item fetching two-dimensional codes; verifying the first item fetching two-dimensional codes and sending cell opening instructions to the intelligent express delivery cabinets if the codes pass the verification, wherein the cell opening instructions carry the express item storage cell numbers so that the intelligent express delivery cabinets can open corresponding cells.

Owner:NEW FOUNDER HLDG DEV LLC +1

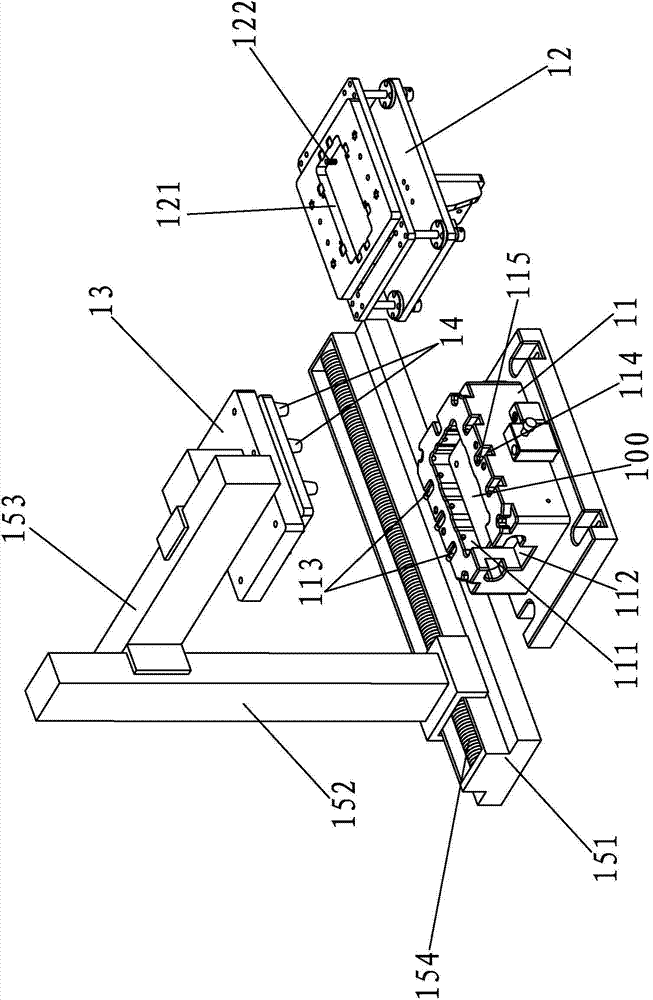

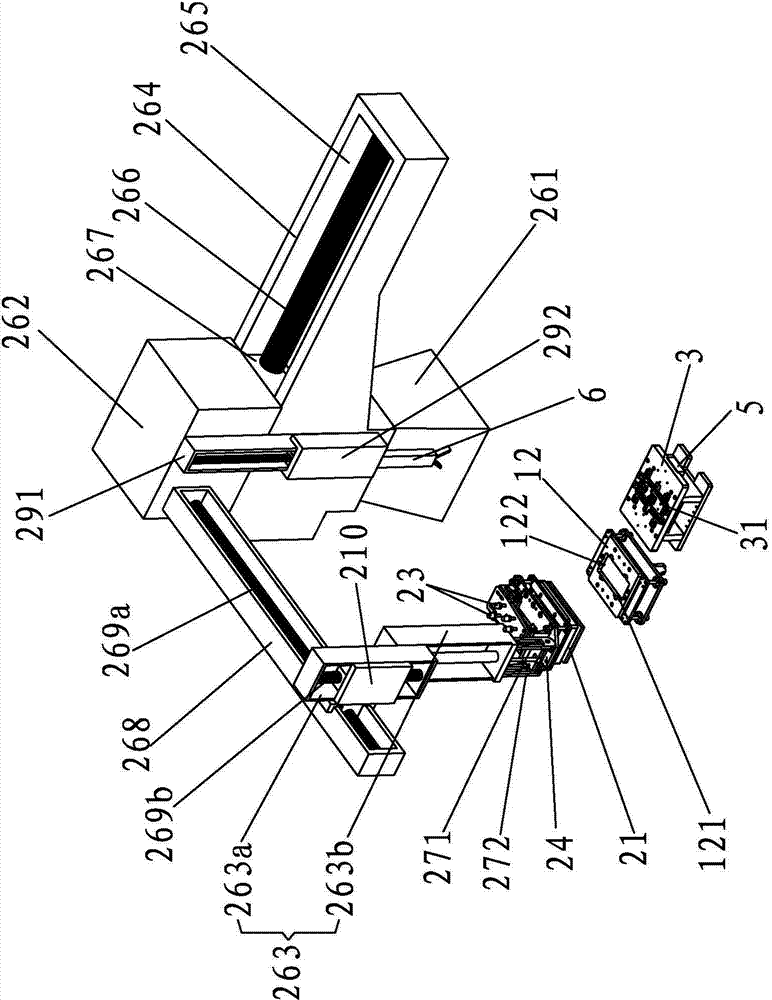

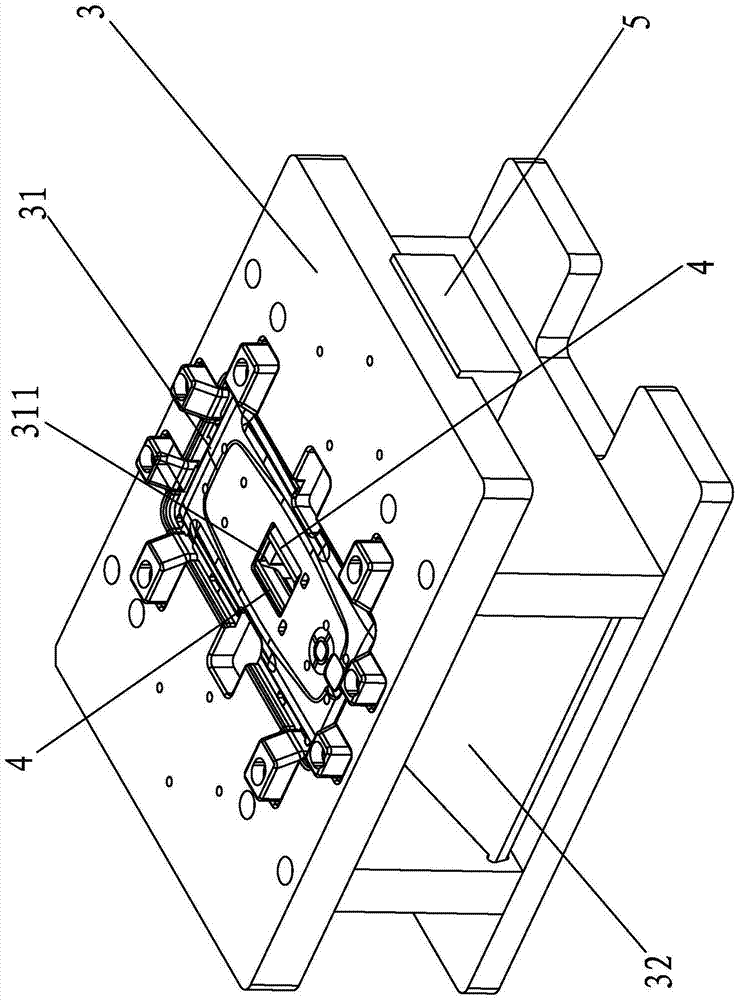

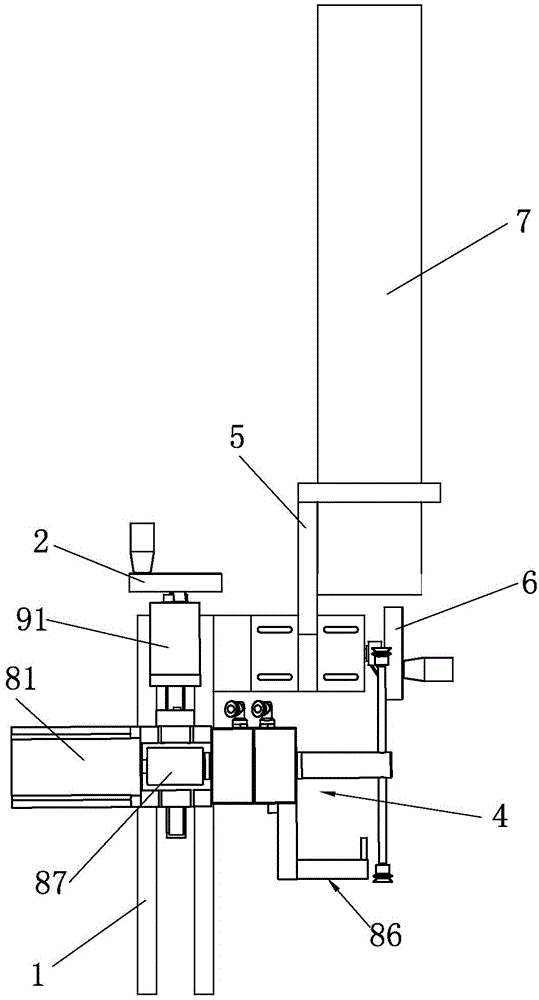

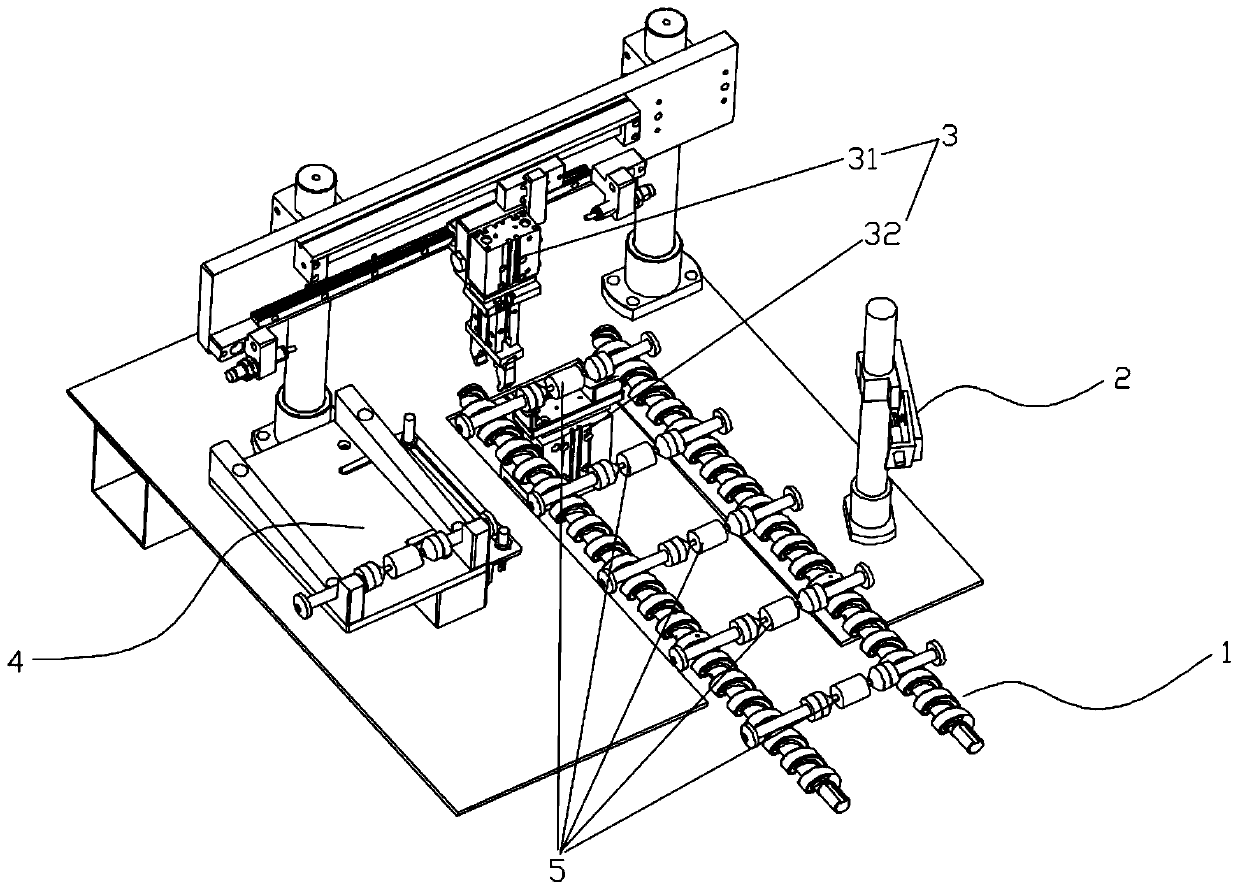

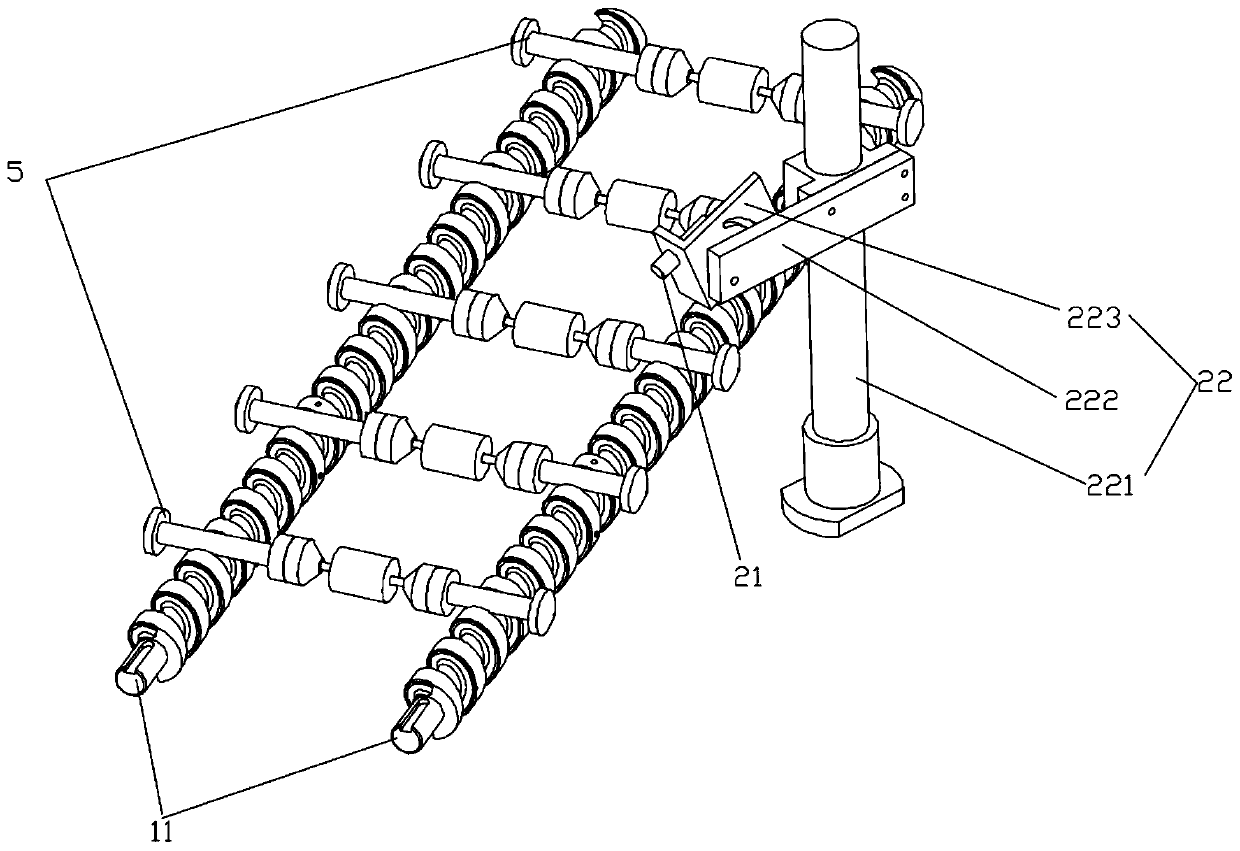

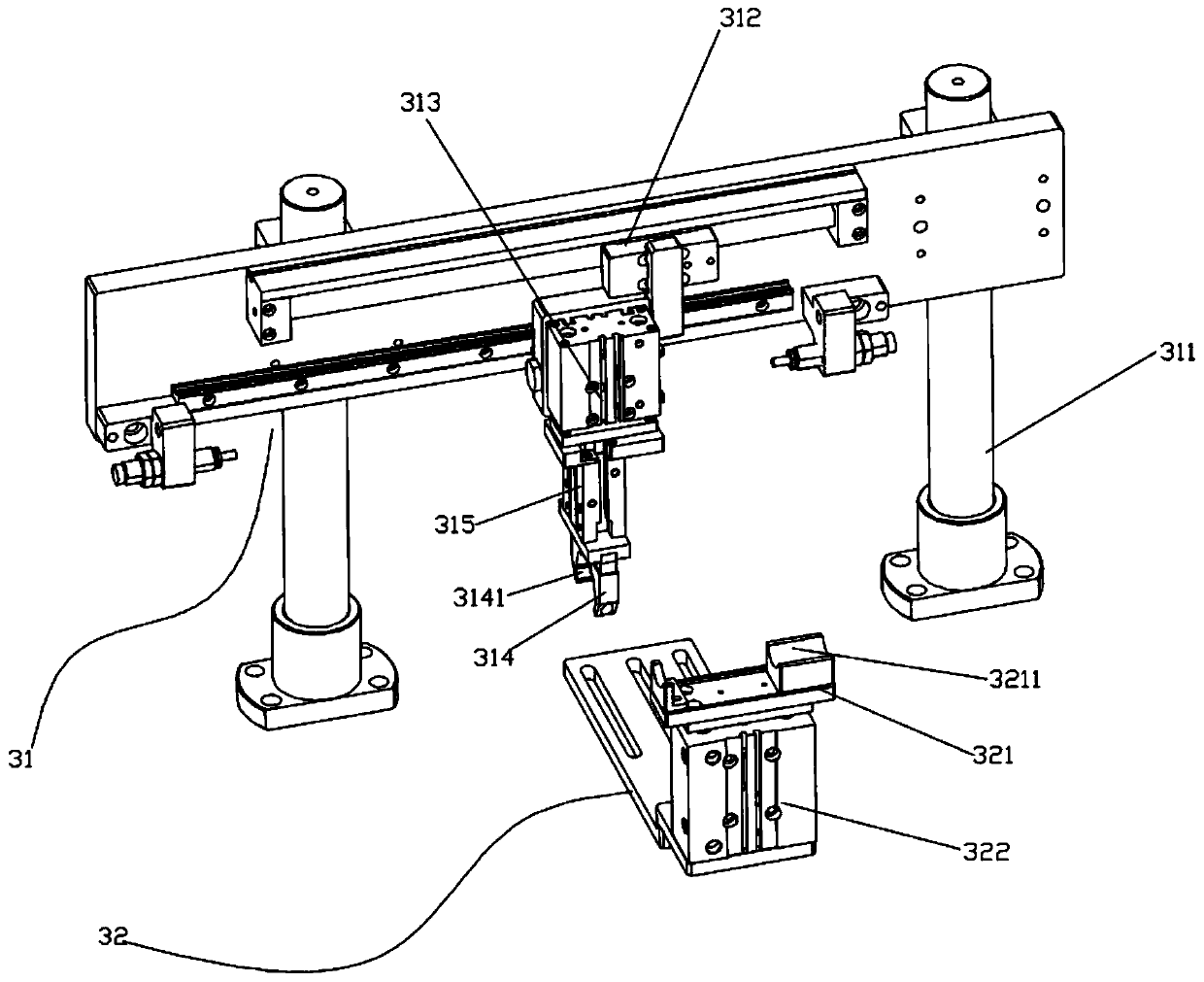

Automatic system for IML injection molding

The invention discloses an automatic system for IML injection molding. The automatic system comprises a sheet storage mechanism, a sheet transfer mechanism and an orifice cutting seat, wherein the sheet storage mechanism comprises a sheet storage and taking seat for storage of a stack of film sheets, a sheet storage and placement seat for placement of the single film sheet and a sheet suction seat for sucking away the film sheets in the sheet storage and taking seat and placing the film sheets in the sheet storage and placement seat; the sheet transfer mechanism comprises a sheet transfer seat for sucking the film sheets in the sheet storage and taking seat, placing the film sheets in an injection mold, and sucking IML decorating parts in the injection mold out of the injection mold; the orifice cutting seat comprises a positioning placement groove for placement of the IML decorating parts, blades used for cutting off orifices of the IML decorating parts, and a waste conveying channel. Compared with the prior art, the automatic system has the advantages as follows: full-automatic consecutive operation is adopted, and unmanned production is achieved, so that the whole working efficiency is improved greatly, the advantages of precision in taking out and high safety system are achieved, that the cutting surfaces of the IML decorating parts are relatively smooth is ensured, and appearance quality is not influenced.

Owner:通达(石狮)科技有限公司

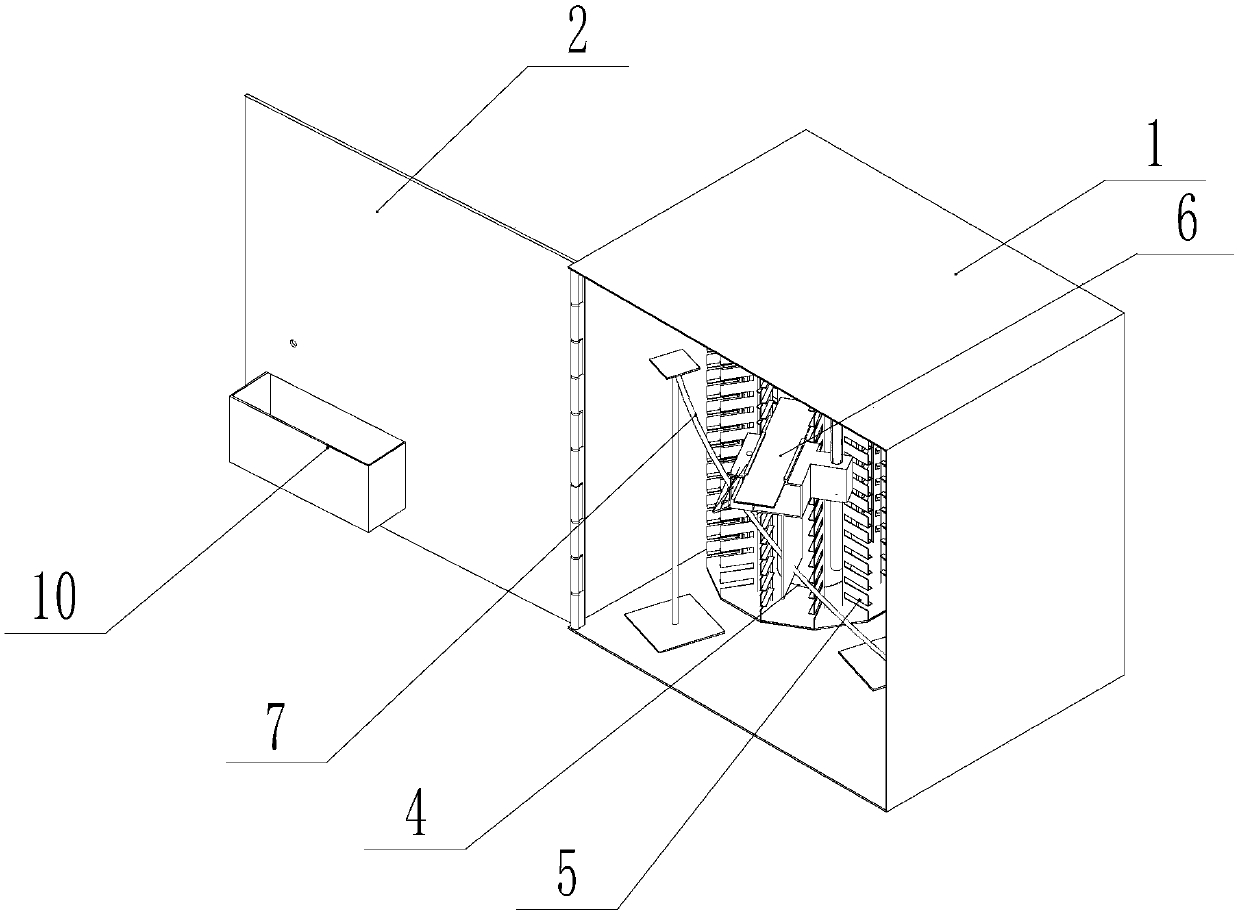

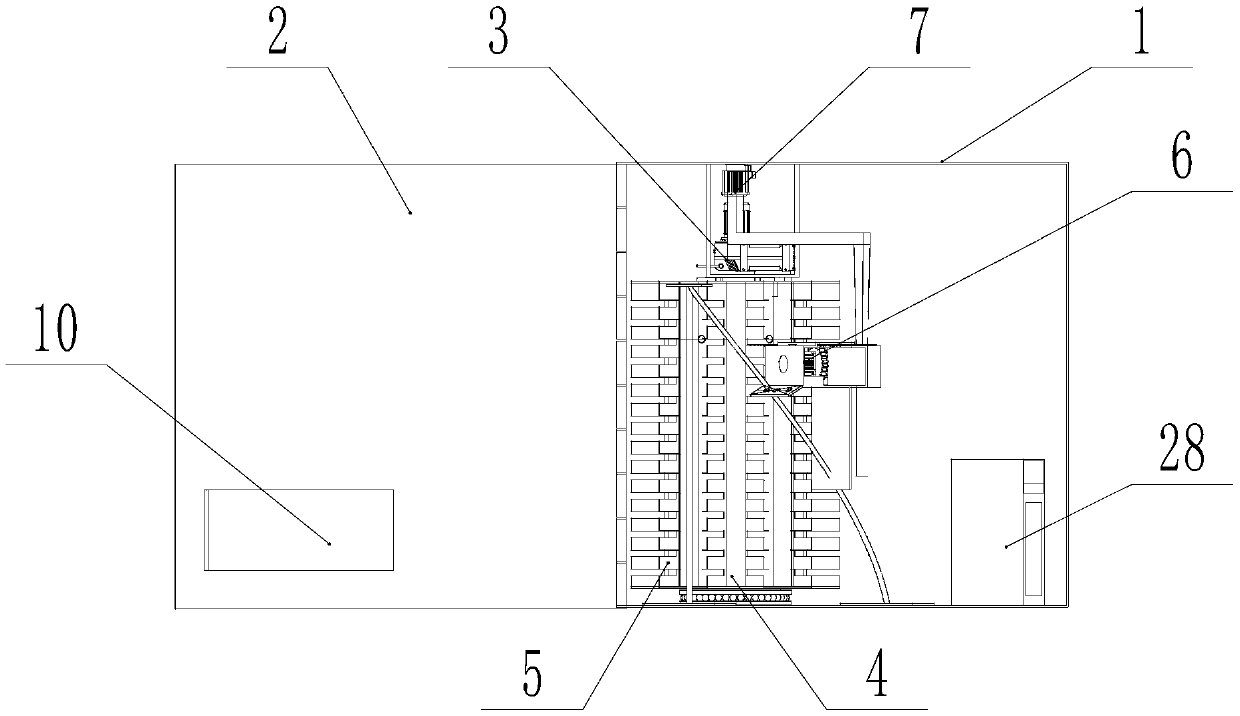

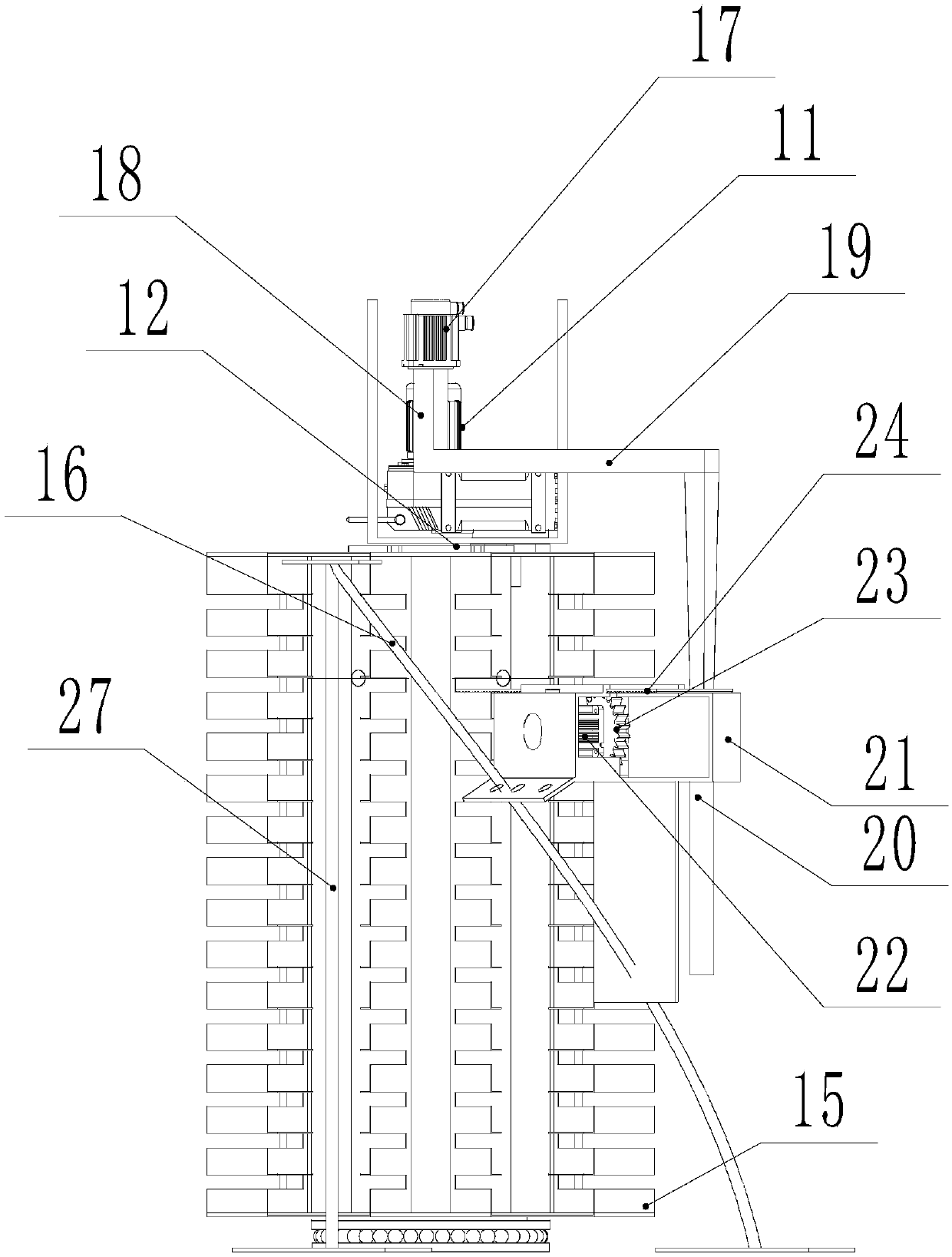

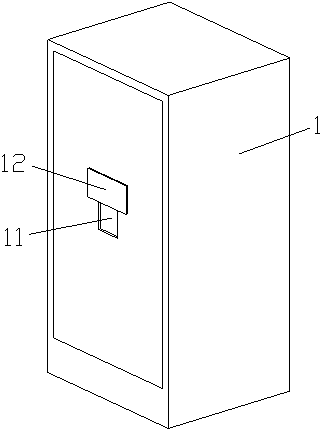

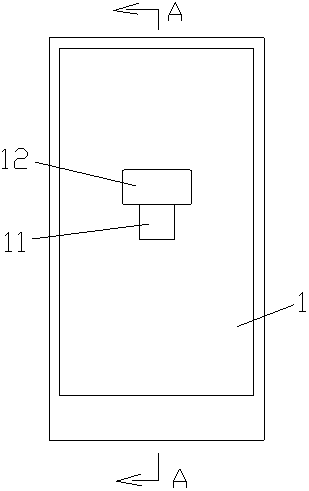

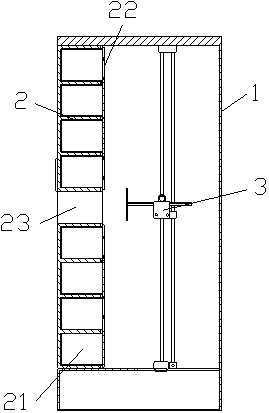

Clothing management coding system, clothing processing method, and integrated wardrobe applying clothing processing method

ActiveCN108055317AOrganizedImplement integrated managementWardrobesComputer controlProcess engineeringComputer science

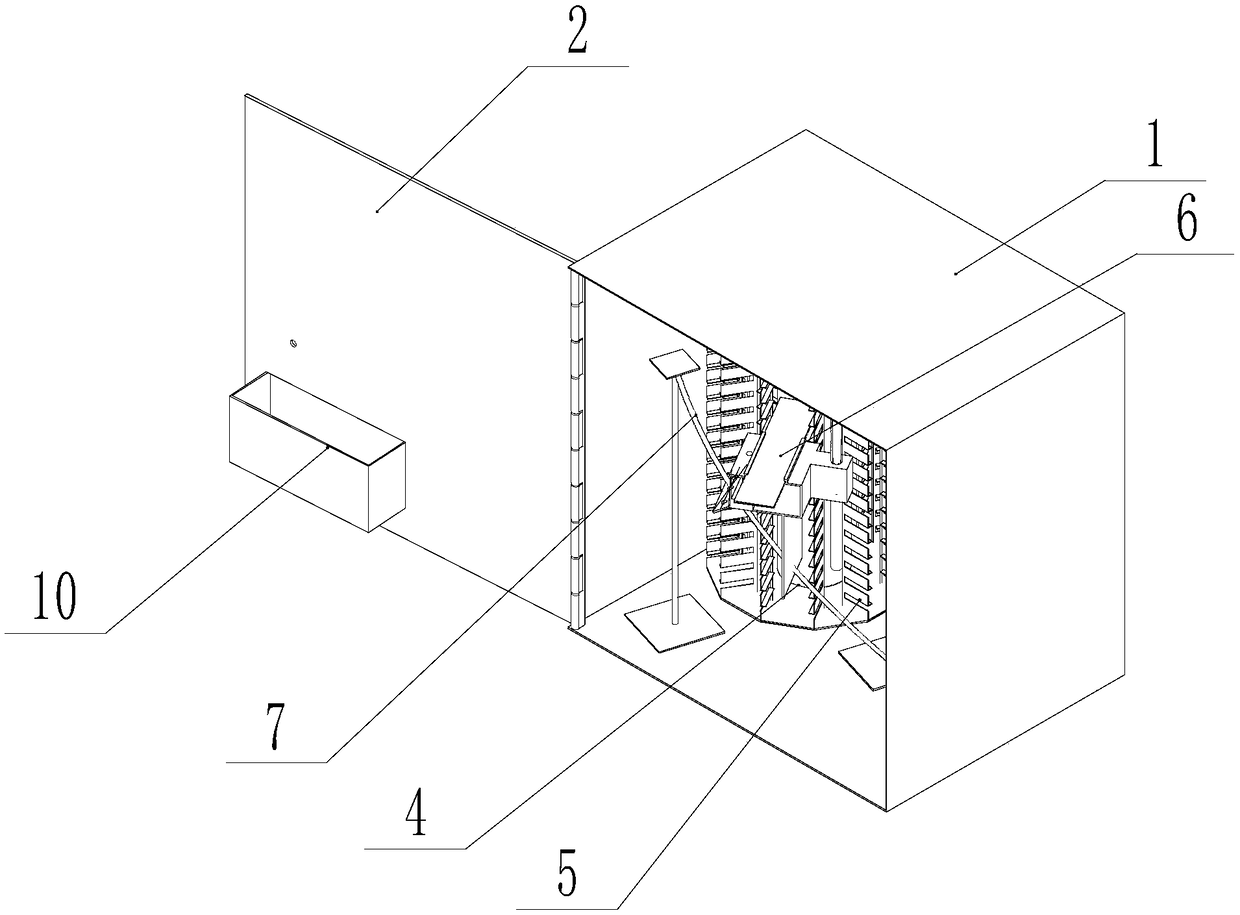

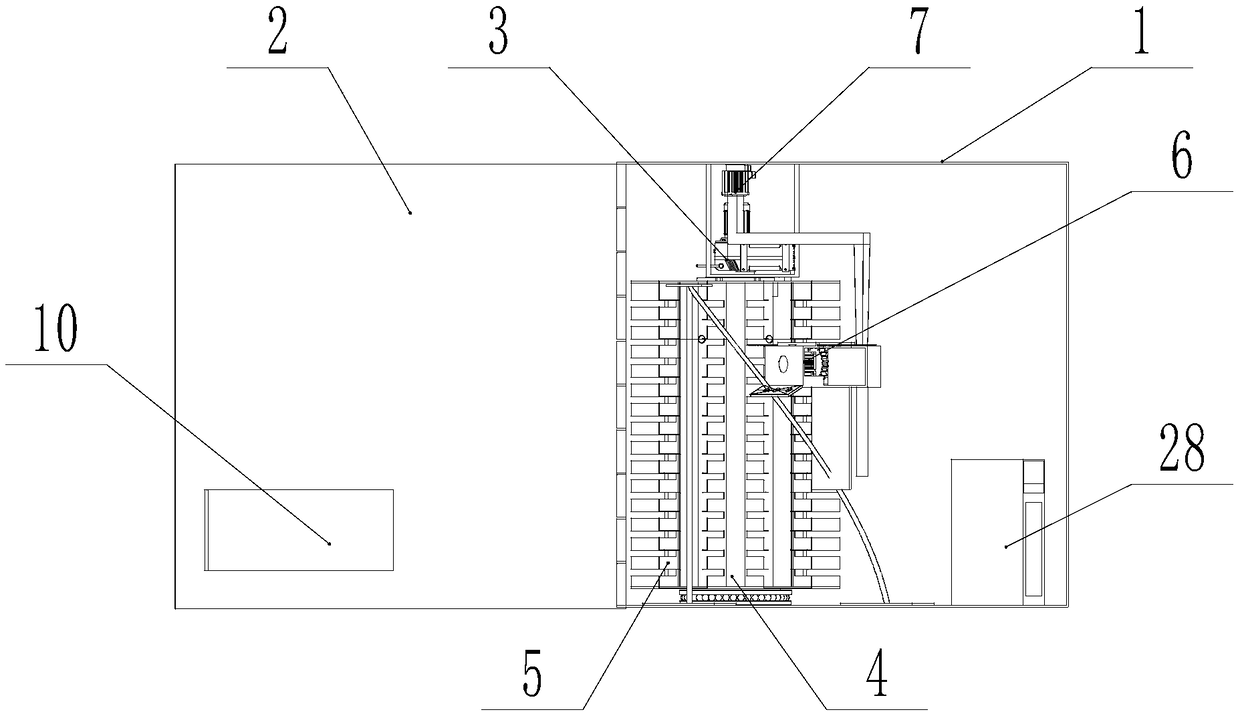

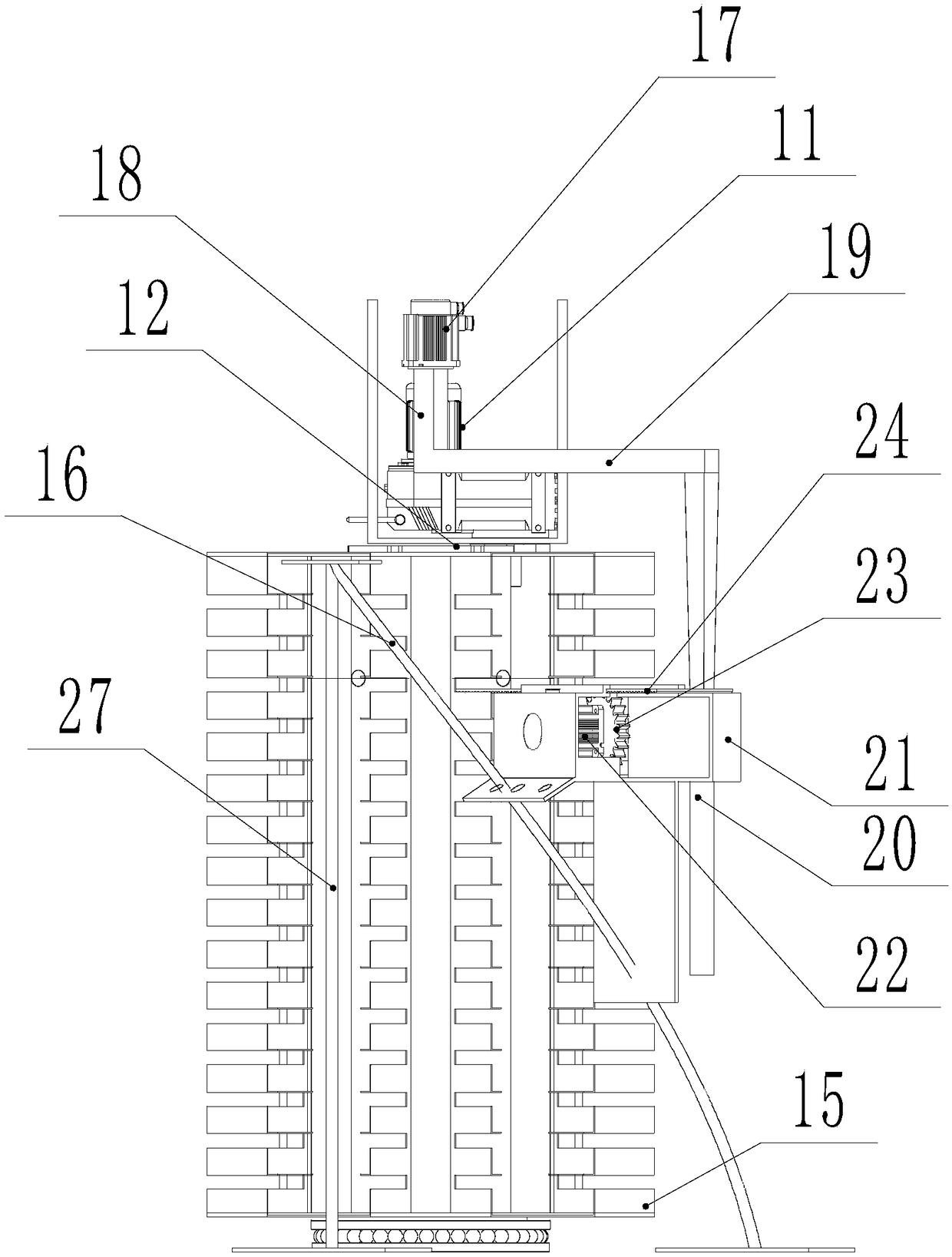

The invention discloses a clothing management coding system, a clothing processing method, and an integrated wardrobe applying the clothing processing method, related to the field of automatic control. The clothing management coding system disclosed by the invention comprises clothing identity signs, clothing hanger identity signs, transport frame position codes, and chamber storage position codes; the intelligent clothing processing method comprises a clothing calibration step, a clothing input step, a clothing transport step, a clothing transfer processing step, and a clothing taking out step; the multi-function integrated wardrobe comprises a clothing identity sign generation device, coded clothing hangers, a clothing transport device, chambers, a first recognition device, a second recognition device and a central processor; and a multi-function integrated wardrobe management system comprises a mobile terminal, a cloud server and the multi-function integrated wardrobe. The clothingmanagement coding system, the clothing processing method, and the integrated wardrobe applying the clothing processing method jointly realize the intelligent storage and taking out of the clothing; the functions are complete; and the practicability is good.

Owner:XIAN UNIV OF SCI & TECH

Aluminum profile tool cleaning device

Owner:WUJIANG DONGFANG ALUMINUM

Method for extracting foreign materials from liquid crystal panel

InactiveCN103698907ASmall range of activitiesSimple methodNon-linear opticsForeign matterMaterials science

The invention discloses a method for extracting foreign materials from a liquid crystal panel, relates to the technical field of display and is invented for solving the problems of difficulty in sampling and inaccuracy of sampling of foreign materials in the liquid crystal panel. The method for extracting the foreign materials from the liquid crystal panel comprises the following steps of determining and marking positions where the foreign materials are located in the liquid crystal panel; cooling the liquid crystal panel to enable viscosity of liquid crystal molecules to be increased; extracting the foreign materials. The method is used for extracting the foreign materials from the liquid crystal panel and analyzing the foreign materials and is used for reducing poorness of the liquid crystal panel, which is caused by the foreign materials.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

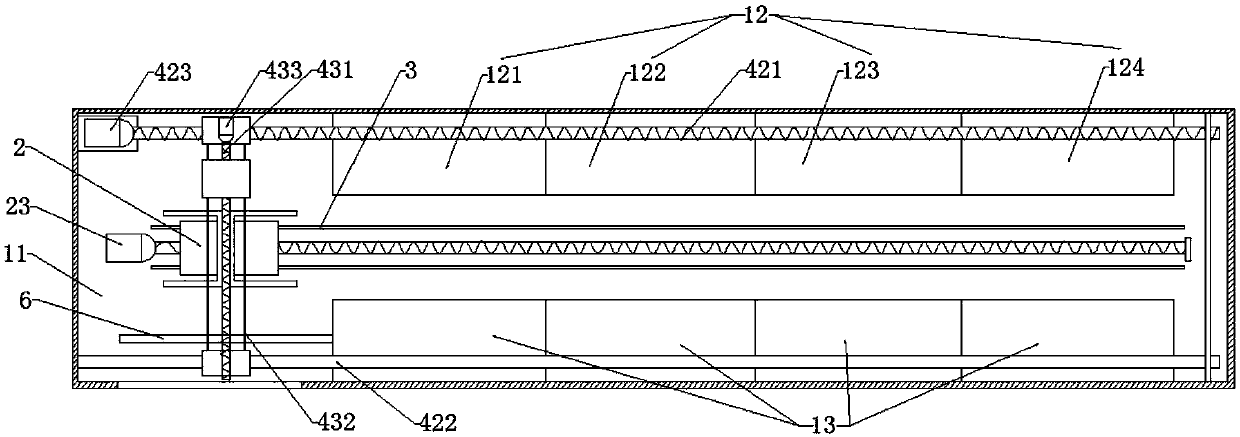

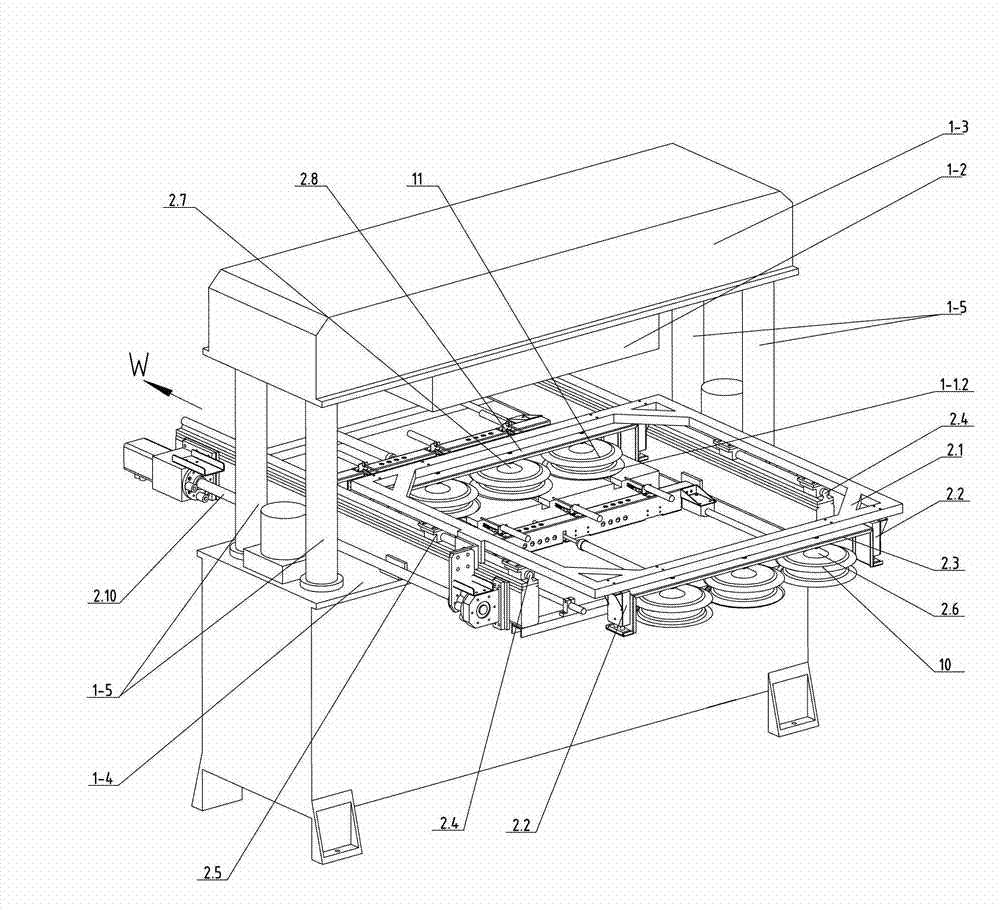

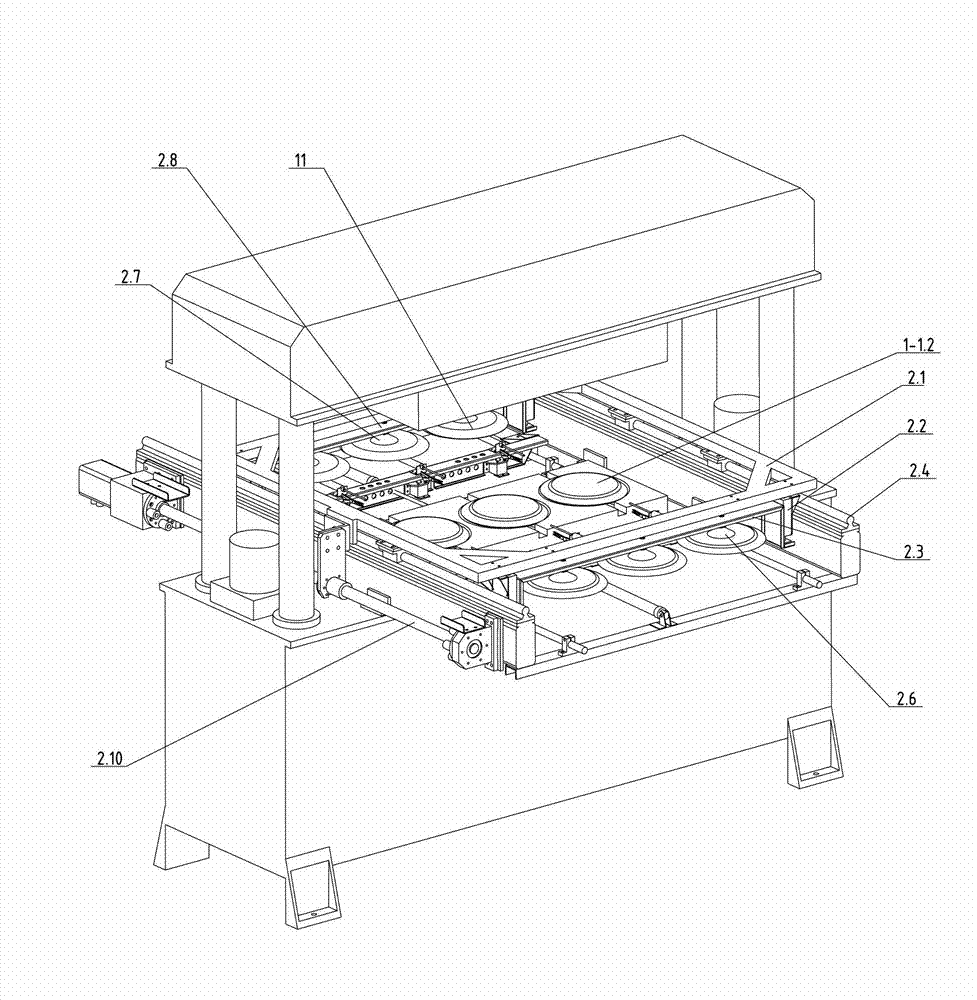

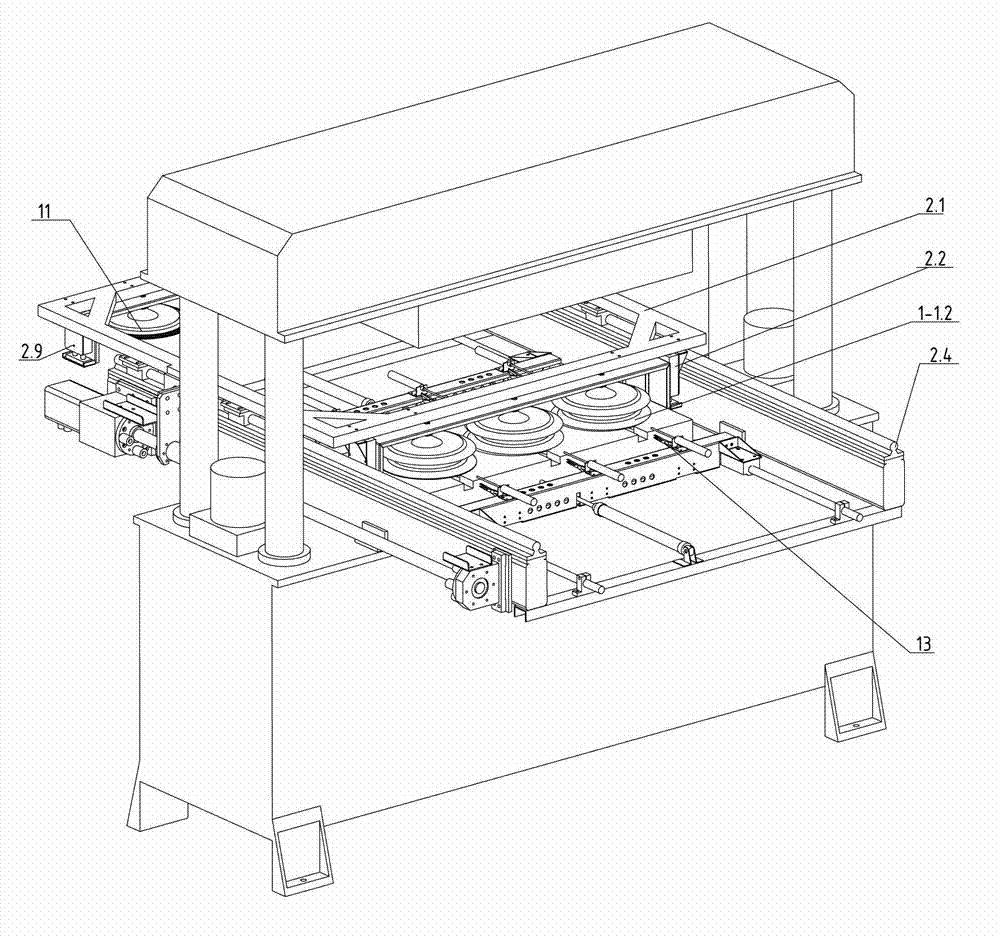

Automatic edge cutting method for plant fiber molding product and automatic edge cutting machine

ActiveCN103042639AAccurate cutting edge positioningHigh speedMetal working apparatusFiberEngineering

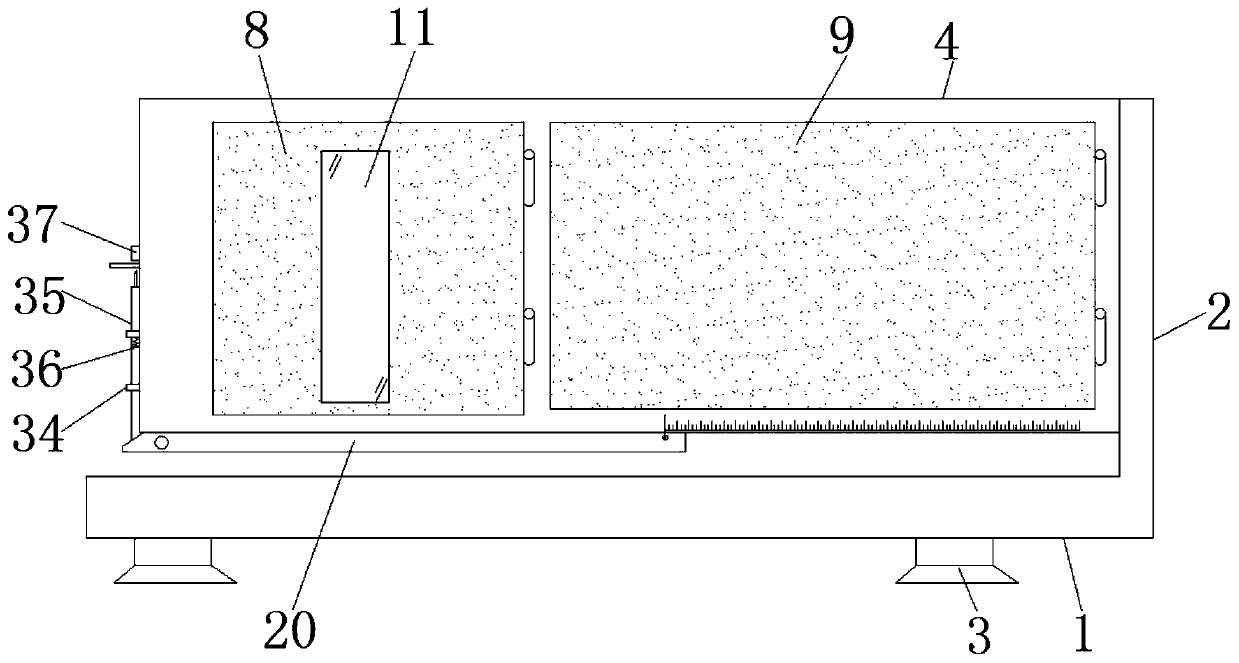

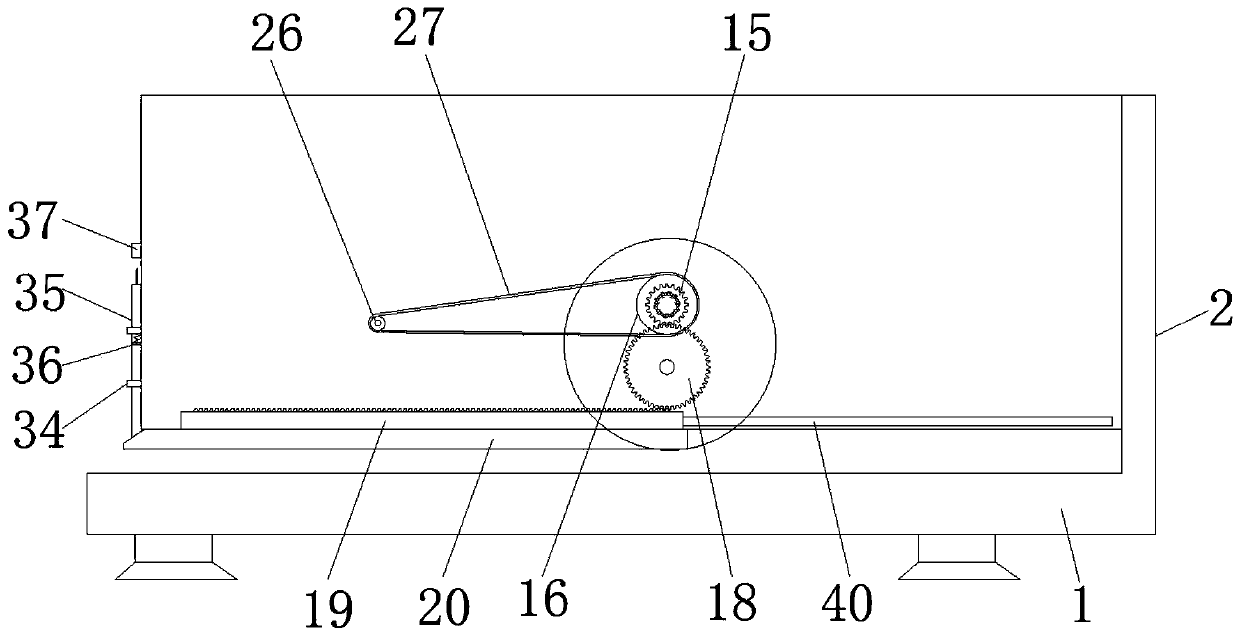

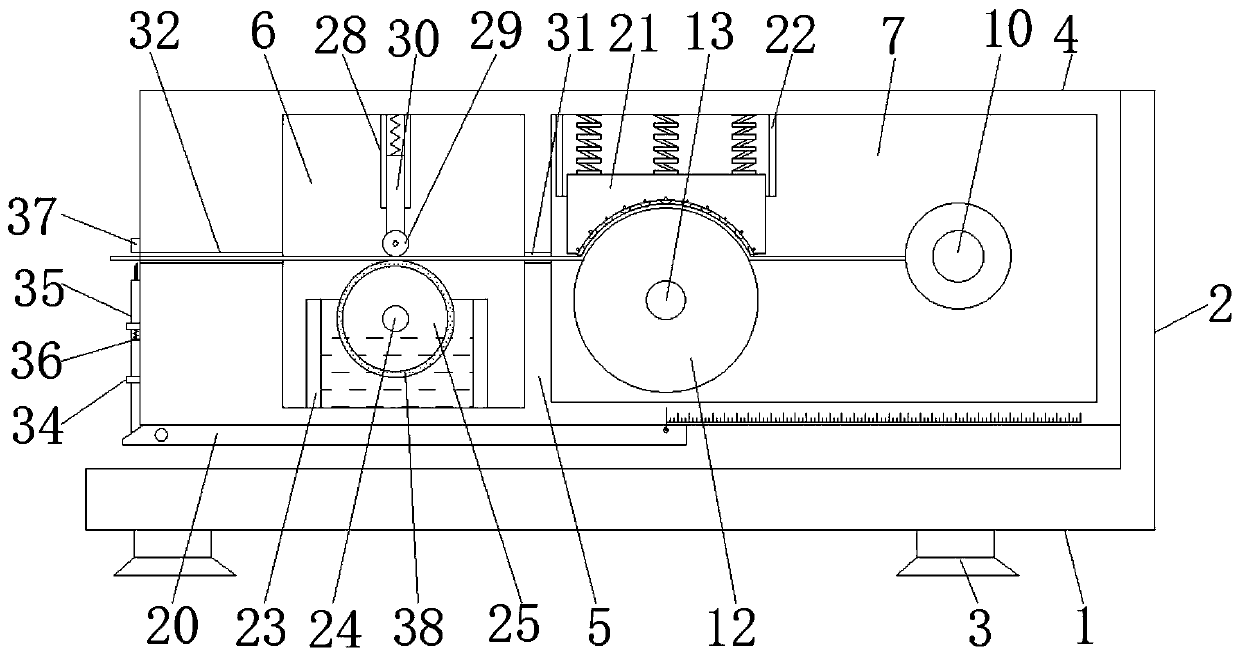

The invention relates to an automatic edge cutting method for a plant fiber molding product and an automatic edge cutting machine. The purposes are that the method has the characteristic of automatic and accurate location, and the automatic cutting machine has the characteristic of stable work. The technical scheme includes that the automatic edge cutting method for the plant fiber molding product proceeds as follows: 1), sucking the product with edges to be cut; 2), driving away waste edges from an edge cutting position; 3), positioning the product to be cut and a product with cut edges respectively; 4), cutting out deckle edges; 5), enabling a front row and a rear row of sucking disk sets to reach the corresponding positions respectively; and 6), sucking the product with edges to be cut and the product with cut edges; repeating from the step 2) to the step 6), and proceeding the circulation over and over again. The automatic edge cutting machine for the plant fiber molding product comprises an edge cutting and die assembly mechanism, wherein the edge cutting and die assembly mechanism comprises an upper edge cutting mold, a lower edge cutting mold, an upper installation plate, a lower installation plate and a power mechanism. The automatic edge cutting machine for the plant fiber molding product is characterized in that a product transferring mechanism and a waste edge moving out mechanism are also arranged on the automatic edge cutting machine.

Owner:EURASIA EP MACHINERY +1

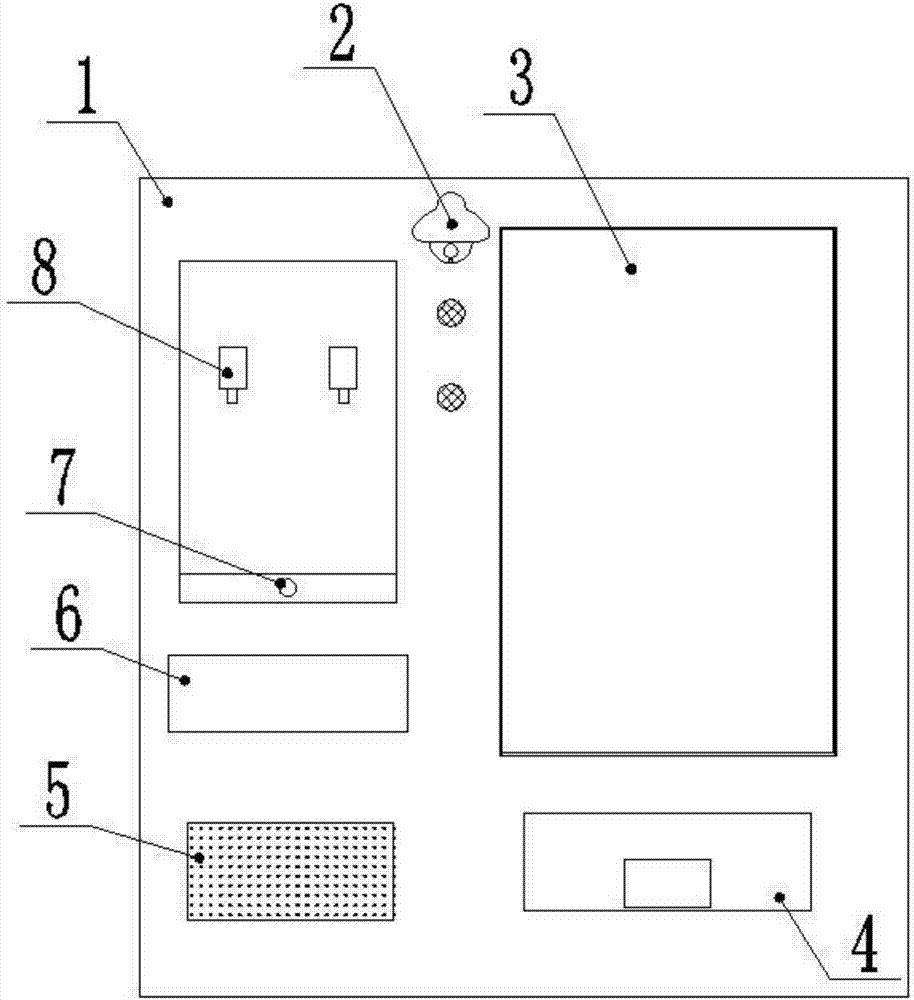

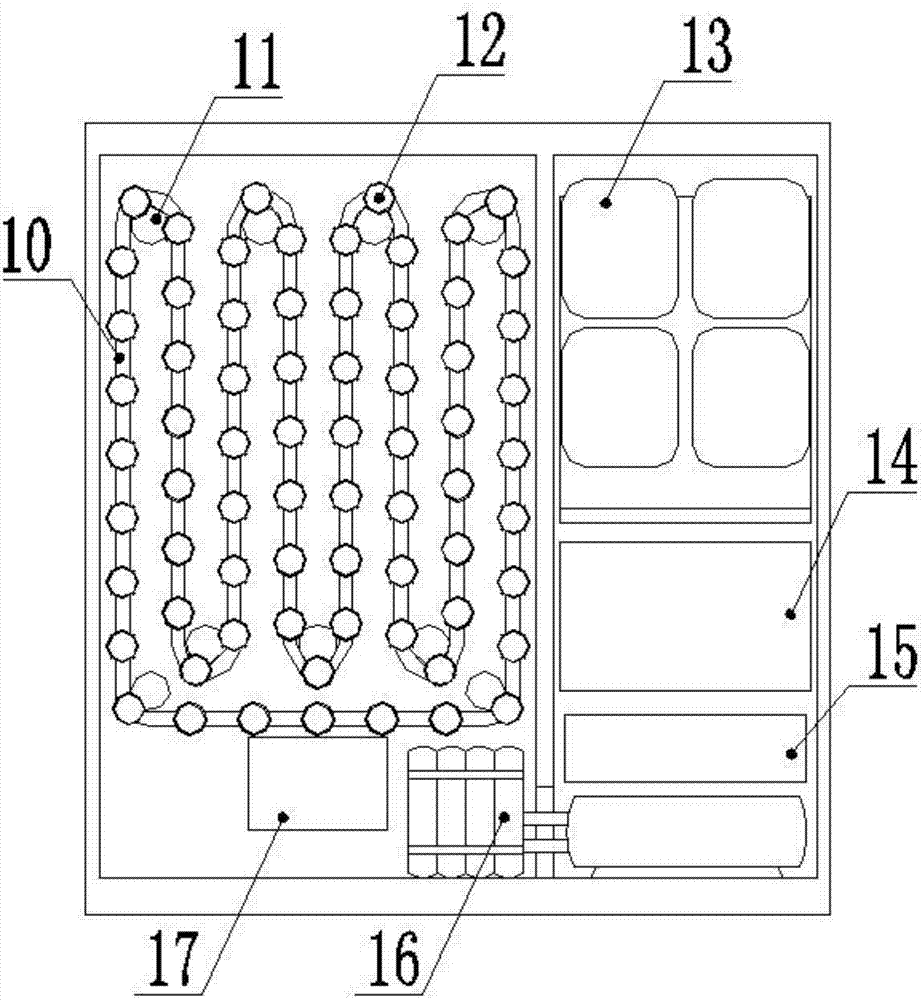

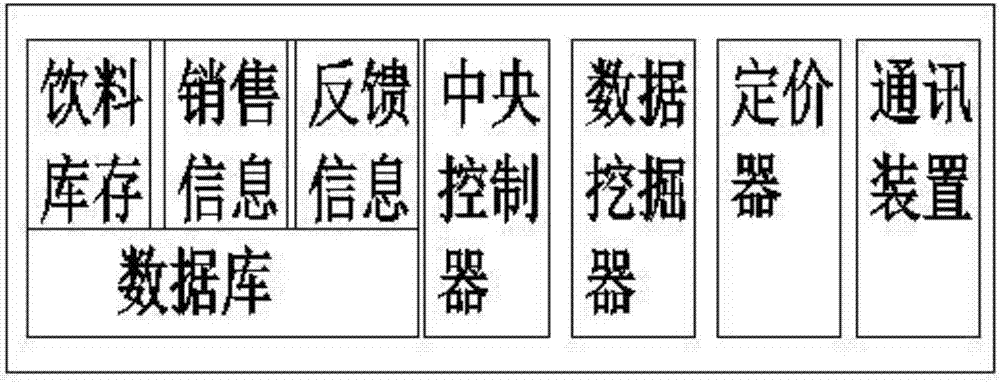

Vending machine based on data mining commodity stock and dynamic pricing

ActiveCN107316389ALess varietyAvoid Layered StackingApparatus for dispensing fluids/granular materialsPaymentControl system

The invention discloses a vending machine based on data mining commodity stock and dynamic pricing. The vending machine comprises a beverage cabinet which is provided with a self-service beverage blending area and a finished beverage product area, the self-service beverage blending area is provided with a beverage outlet head, an infrared sensor, a payment device, a cooling and exhaust window, a monitoring system is arranged on the beverage cabinet, the finished beverage product area is provided with a display screen and a beverage outlet area, and a chain drive warehouse, a discharging warehouse, a raw material barrel, a currency storage cabinet, a control system box and a refrigerating system are arranged at the back of the beverage cabinet. Accordingly, a circular closed chain drive warehouse is adopted for containing beverages, more varieties and a large number of the beverages are contained, tastes and formulas of the beverages can be understood, the varieties and the number of the beverages on the shelves are determined automatically through a data miner and a database, data of the data miner and data of the internet are received through a pricing device, the phenomenon that the price affects beverage sales is avoided, and by integrating the vending machine and a beverage blending device into a whole, the consumer demands of different consumers are met.

Owner:秦皇岛维拓科技有限公司

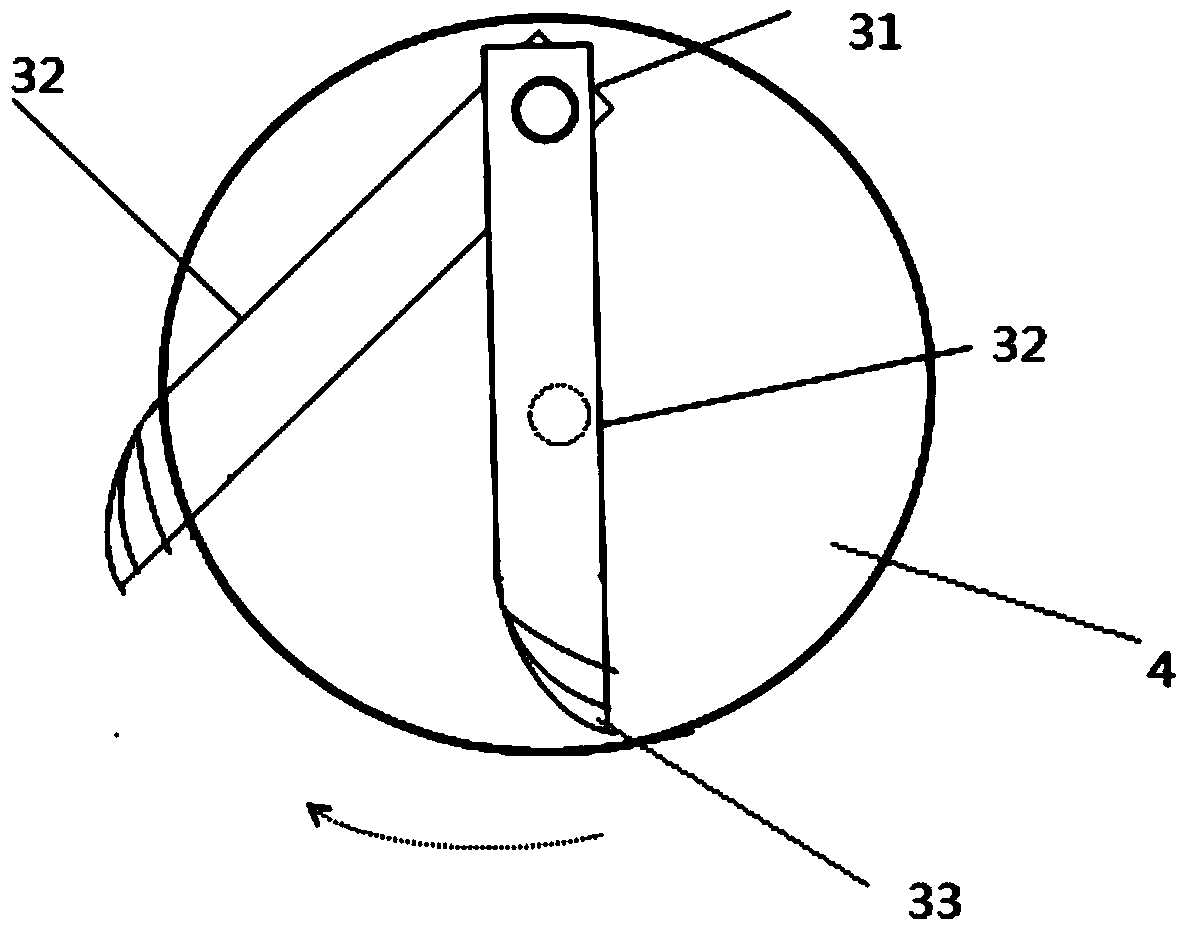

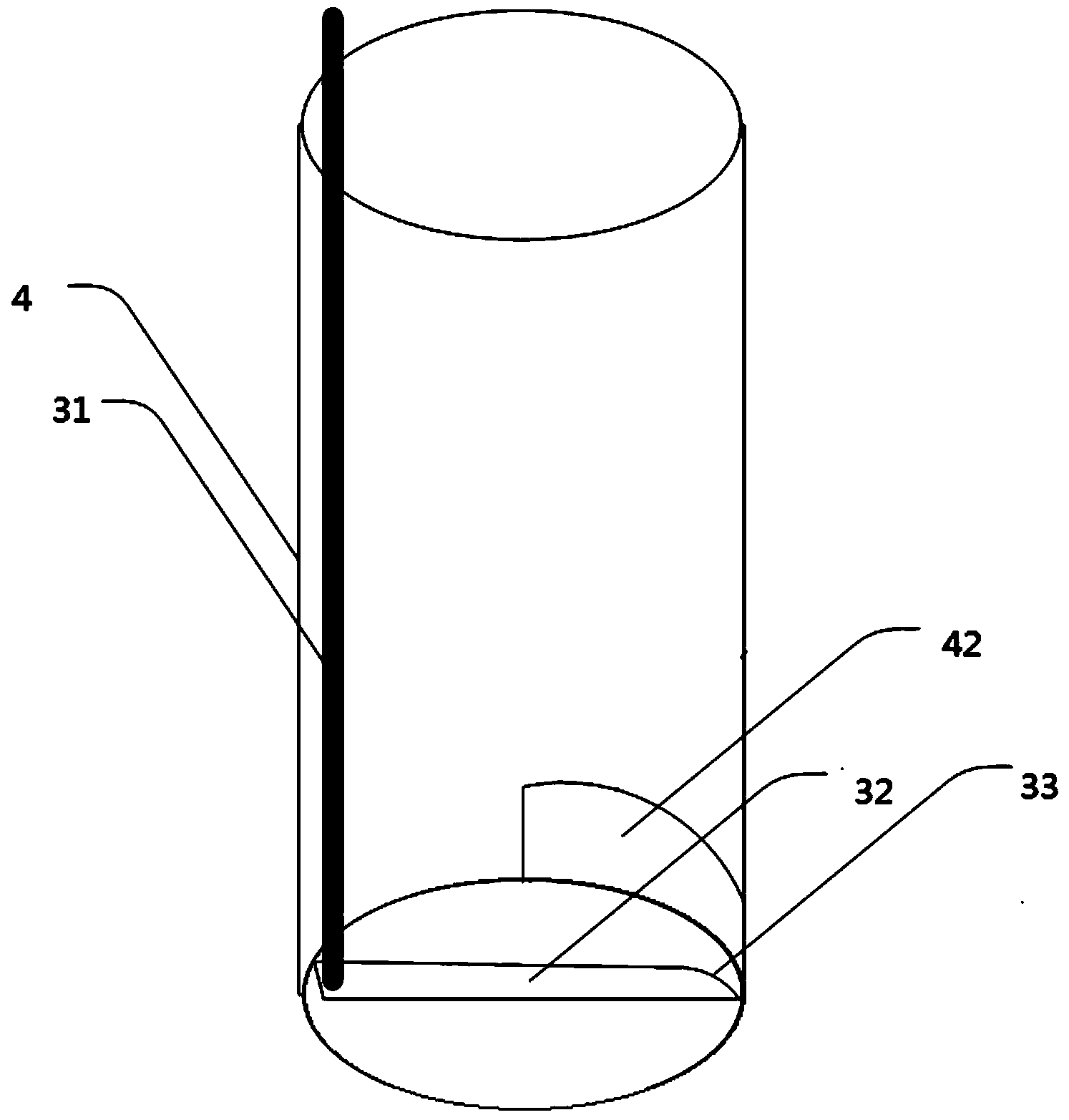

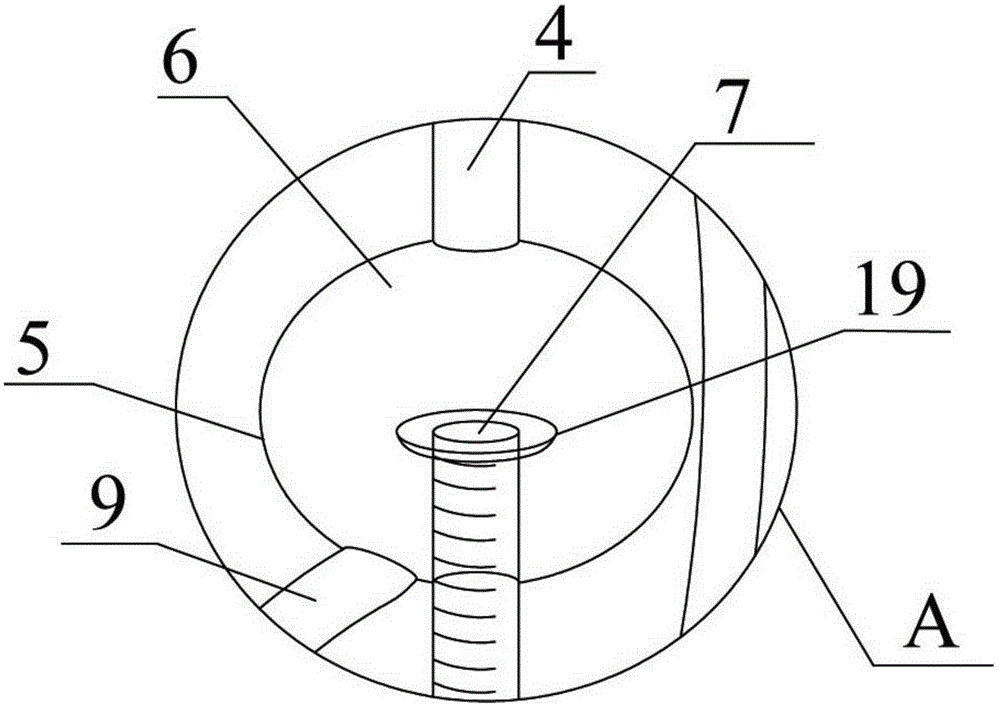

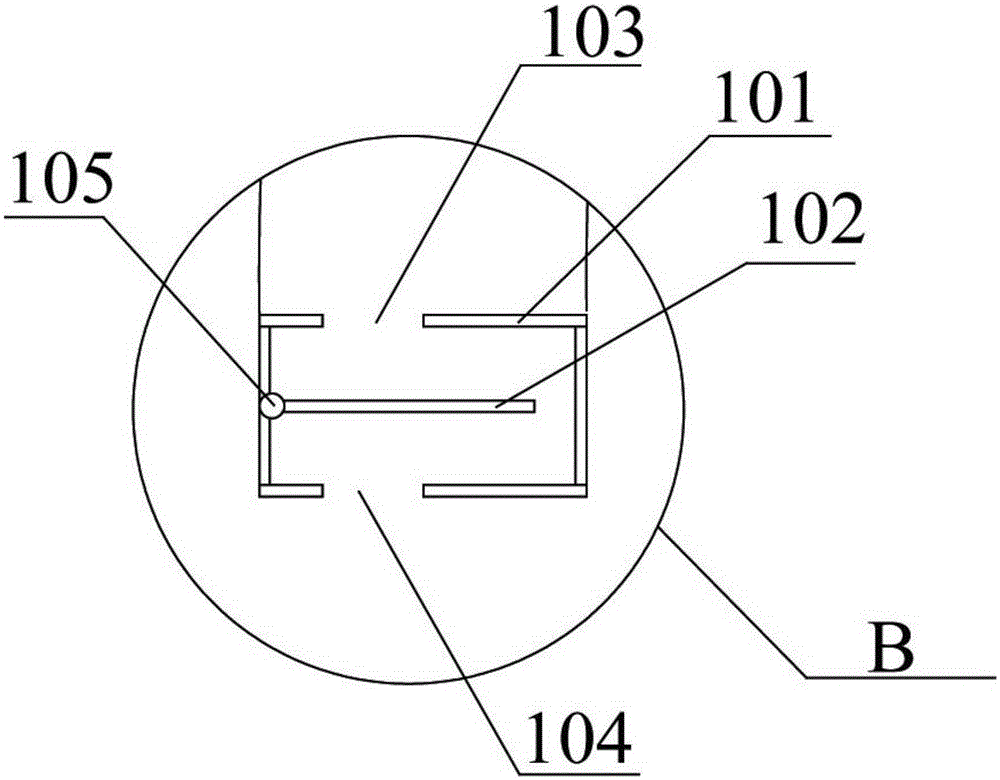

Automatic light disk set disk taking device

ActiveCN104299628ATake out accuratelyApparatus modification to store record carriersRecord information storageEngineeringInfrared emitter

The invention belongs to the technical field of data storage, and provides an automatic light disk set disk taking device. The automatic light disk set disk taking device comprises a supporting plate and a displacement driving assembly driving the supporting plate to move. The supporting plate is provided with a rotating motor. The rotating motor comprises a lower rotating shaft. A lower rotating sheet is horizontally installed at one end of the lower rotating shaft. A blade is arranged at the top end of the rotating sheet. A main rod and a side rod are installed on the bottom face of the supporting plate. A first infrared emitter is installed at the tail end of the main rod. A first light sensitive tube is installed at the tail end of the side rod. The first infrared emitter and the first light sensitive tube are arranged in pairs. The lower rotating sheet is provided with a starting position and a screwing-out position. At the starting position, the lower rotating sheet and the blade are located inside a light disk hole. At the screwing-out position, the blade is located between two light disks of a light disk set. The automatic light disk set disk taking device is simple in structure, the infrared emitter and the light sensitive tube are used for performing positioning, and a stack of light disks at any position can be automatically grabbed from the stacked light disk set.

Owner:WUHAN OPSTOR TECH LTD

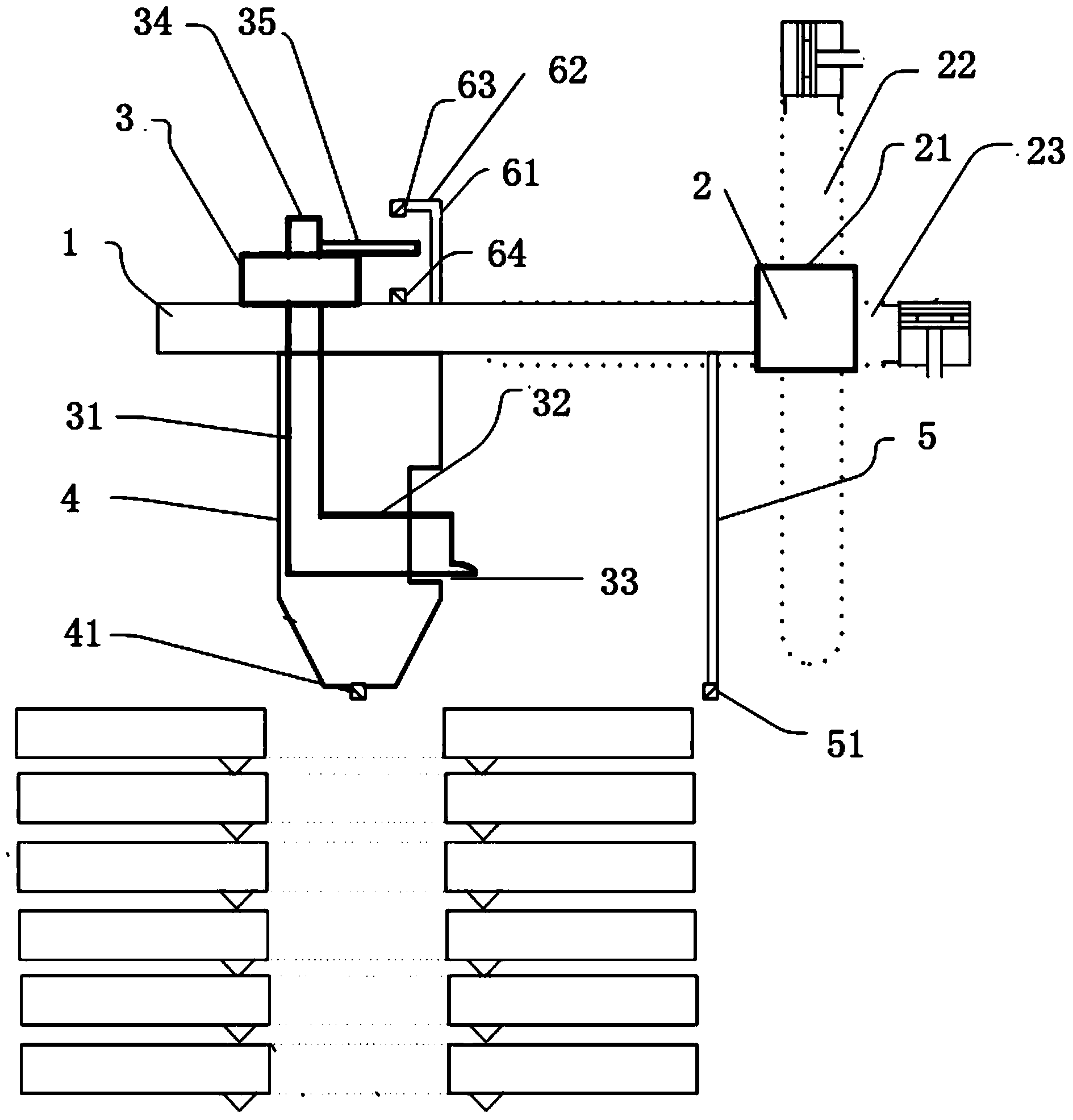

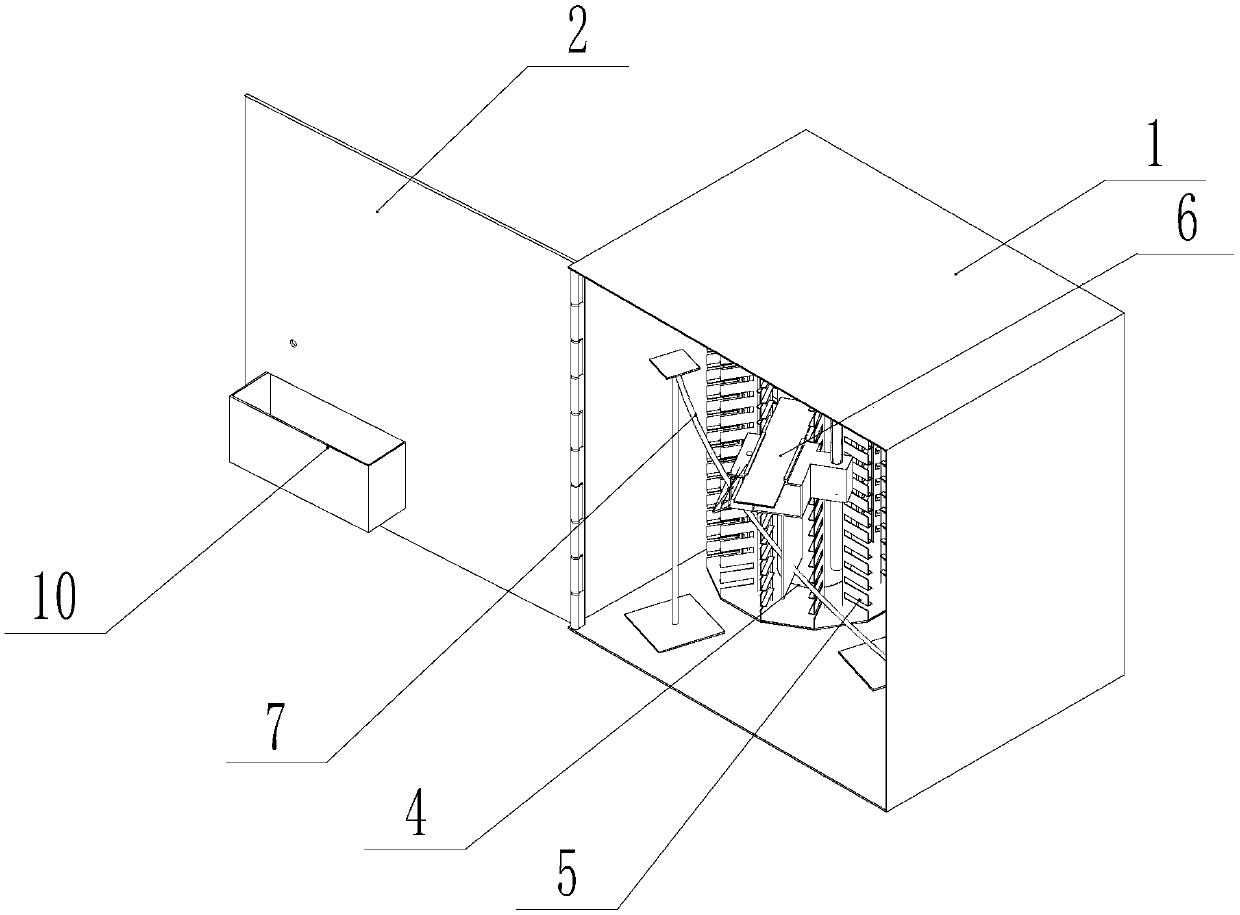

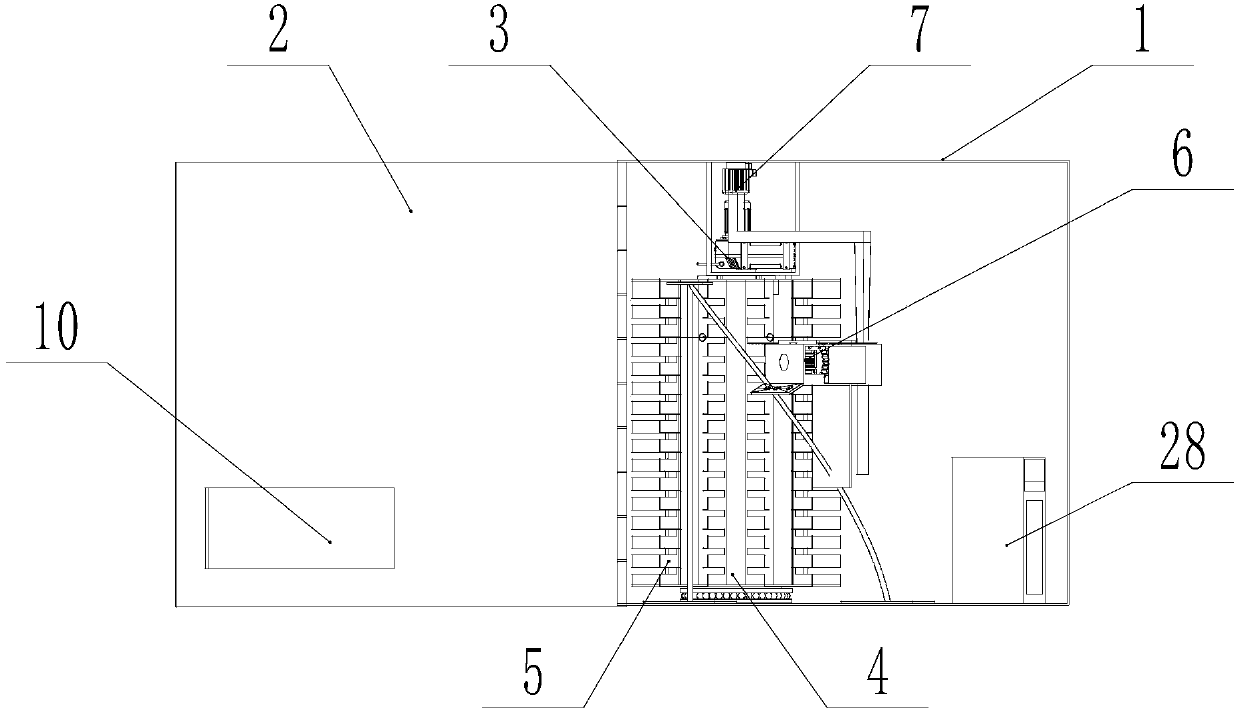

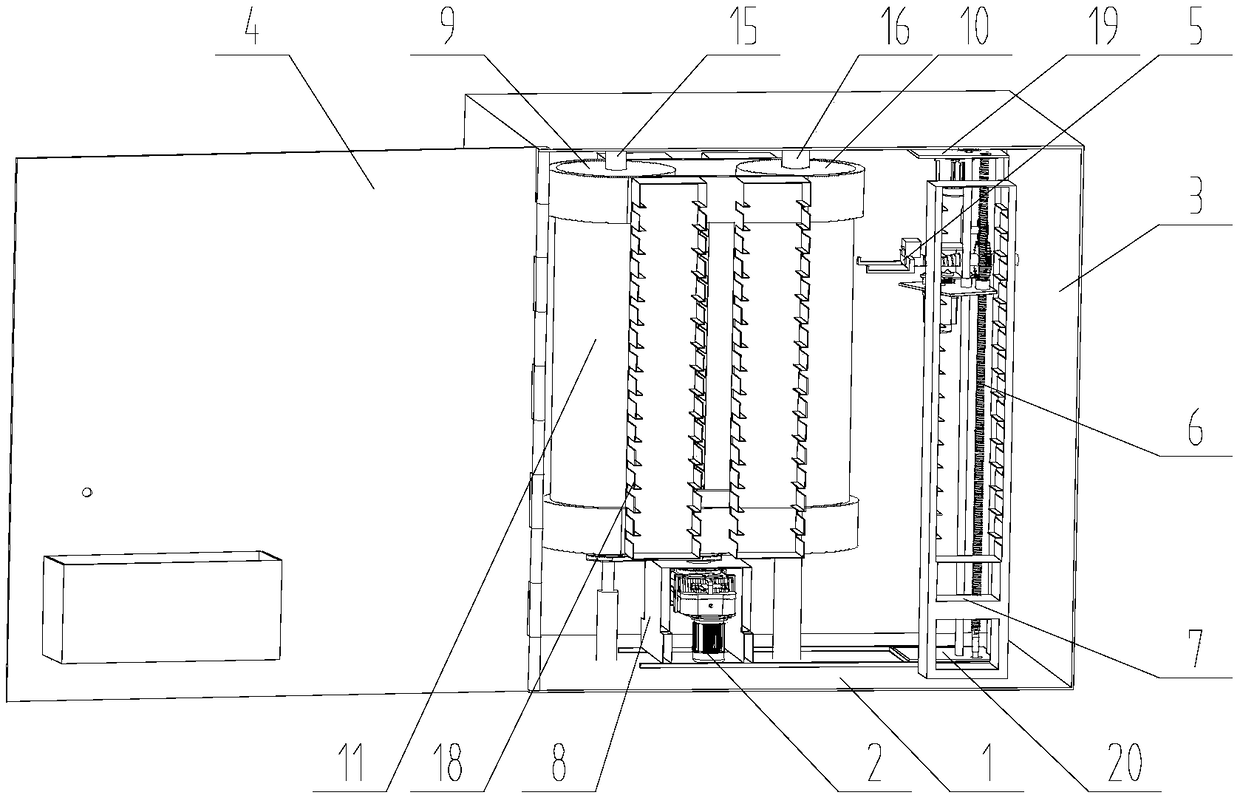

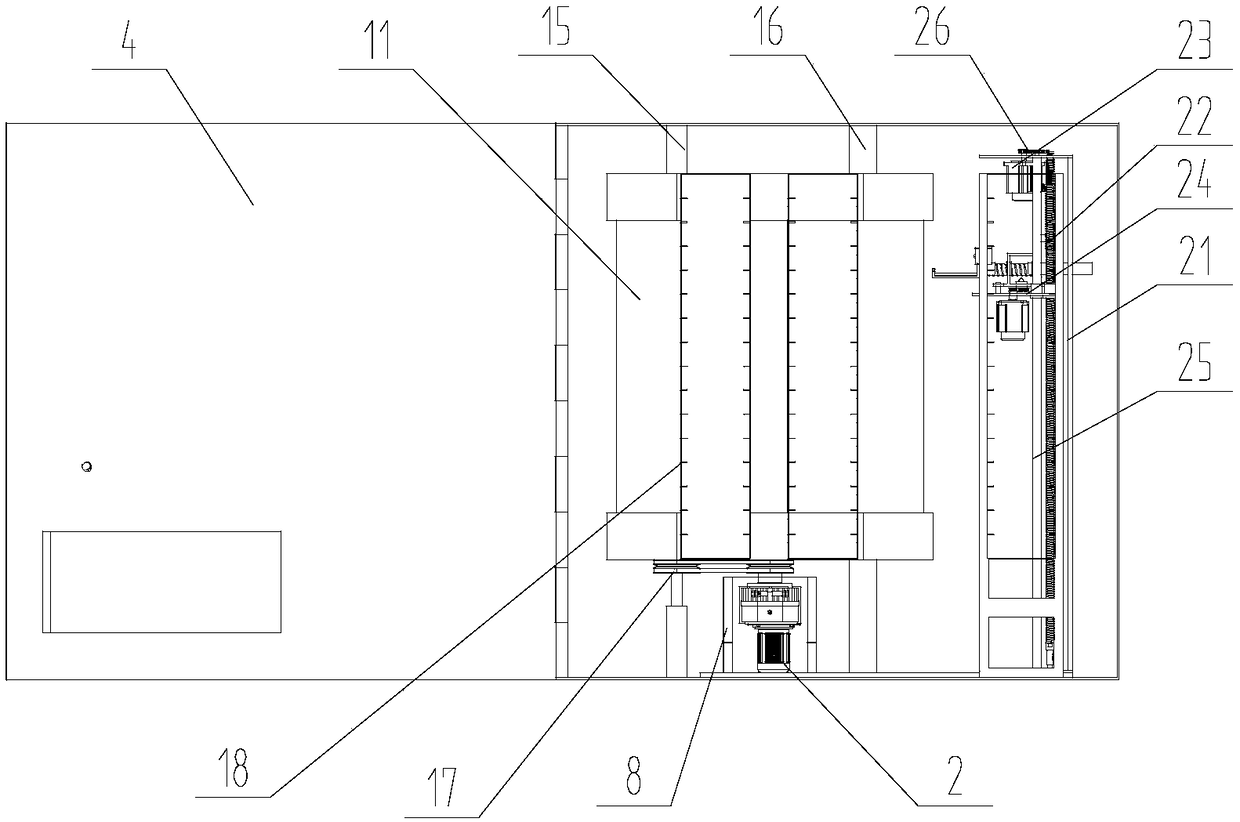

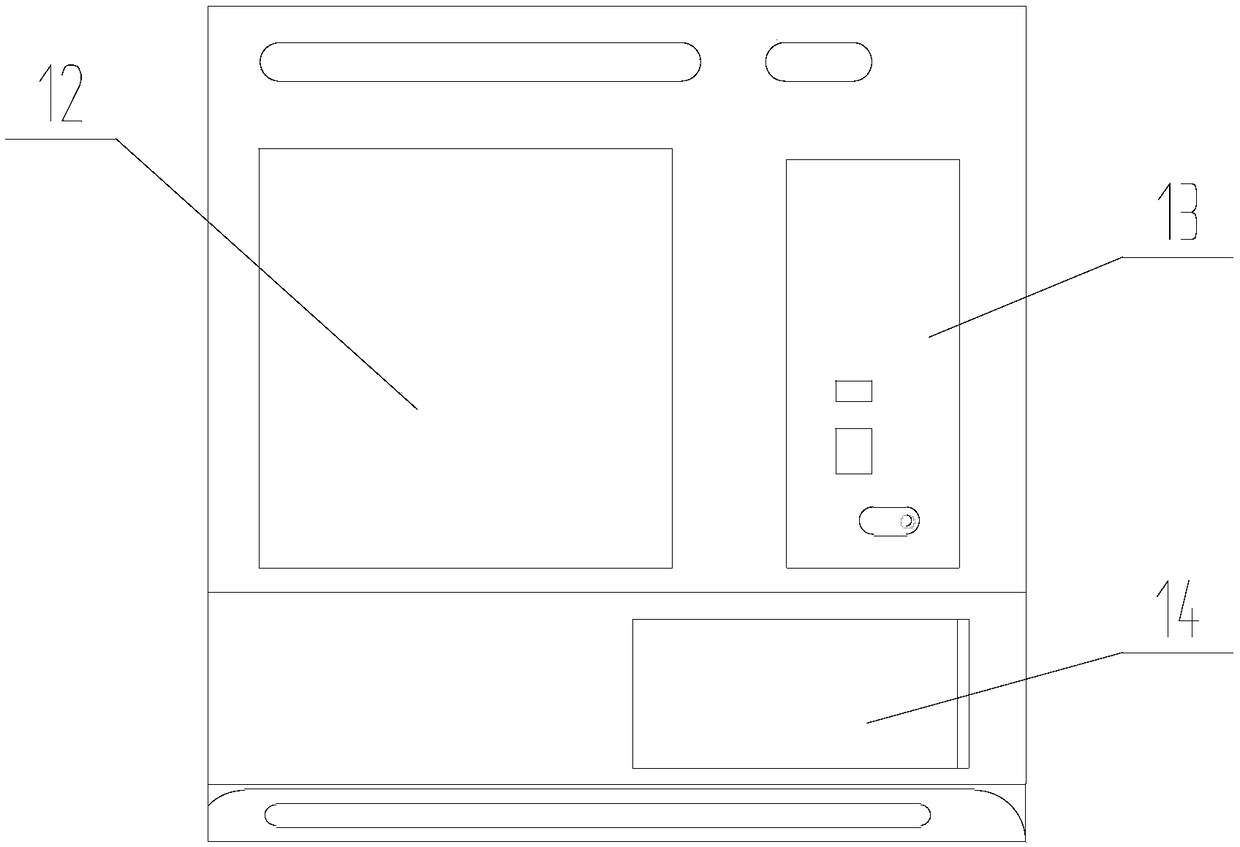

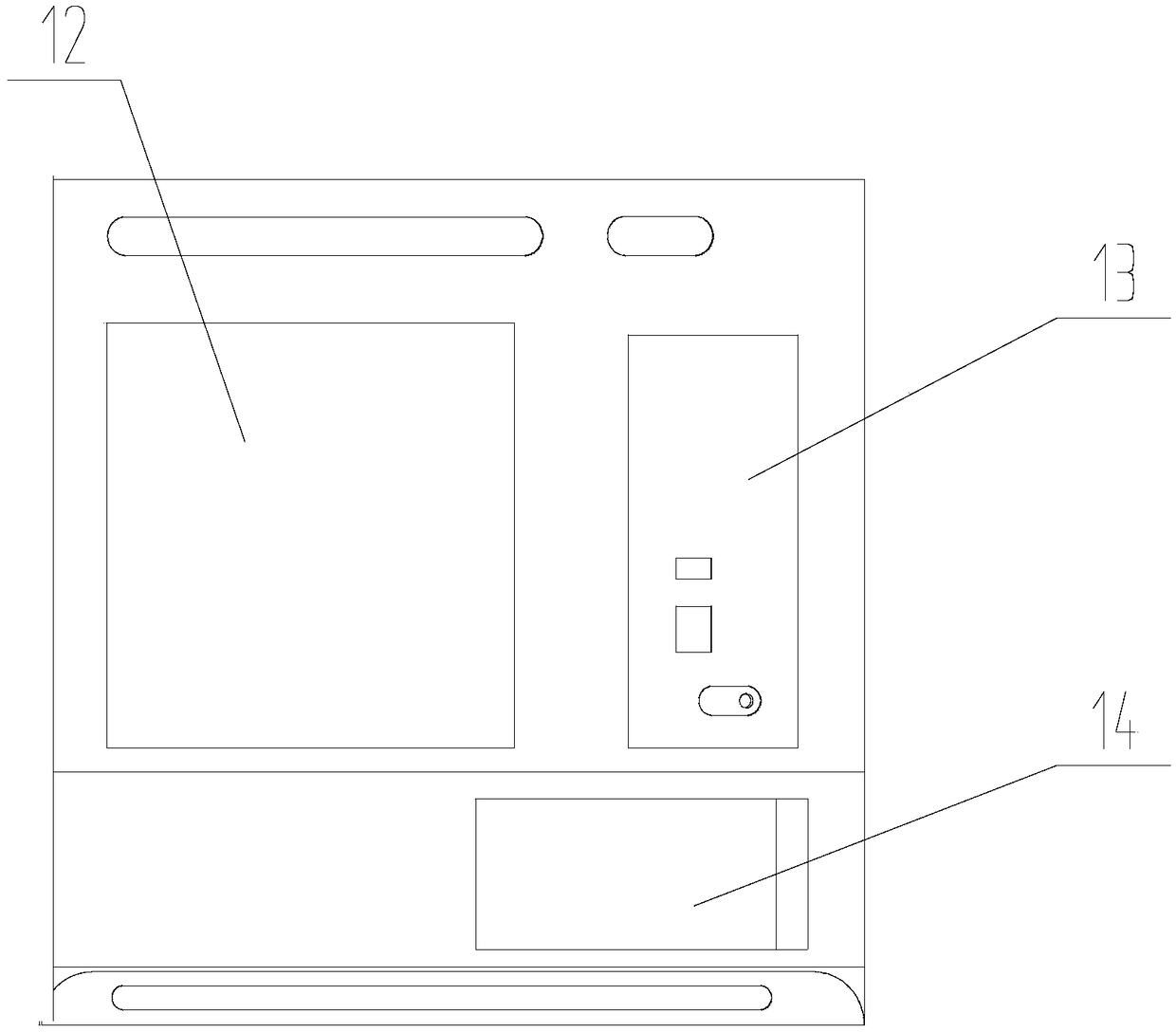

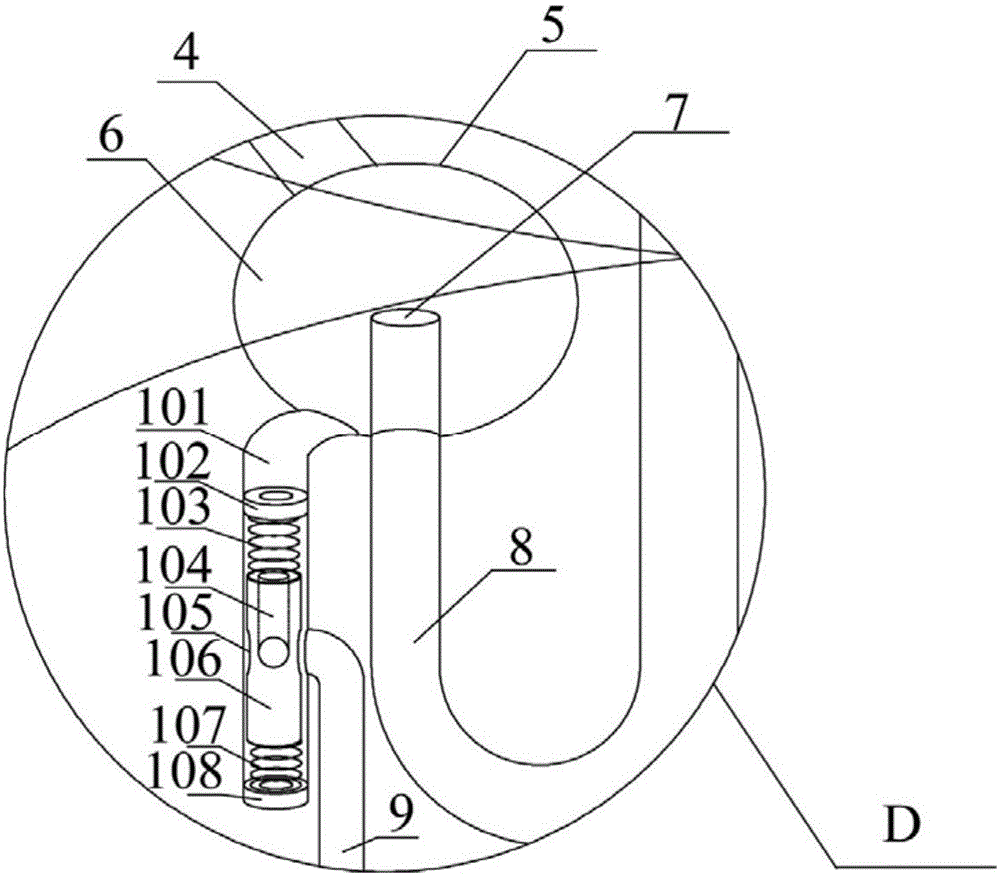

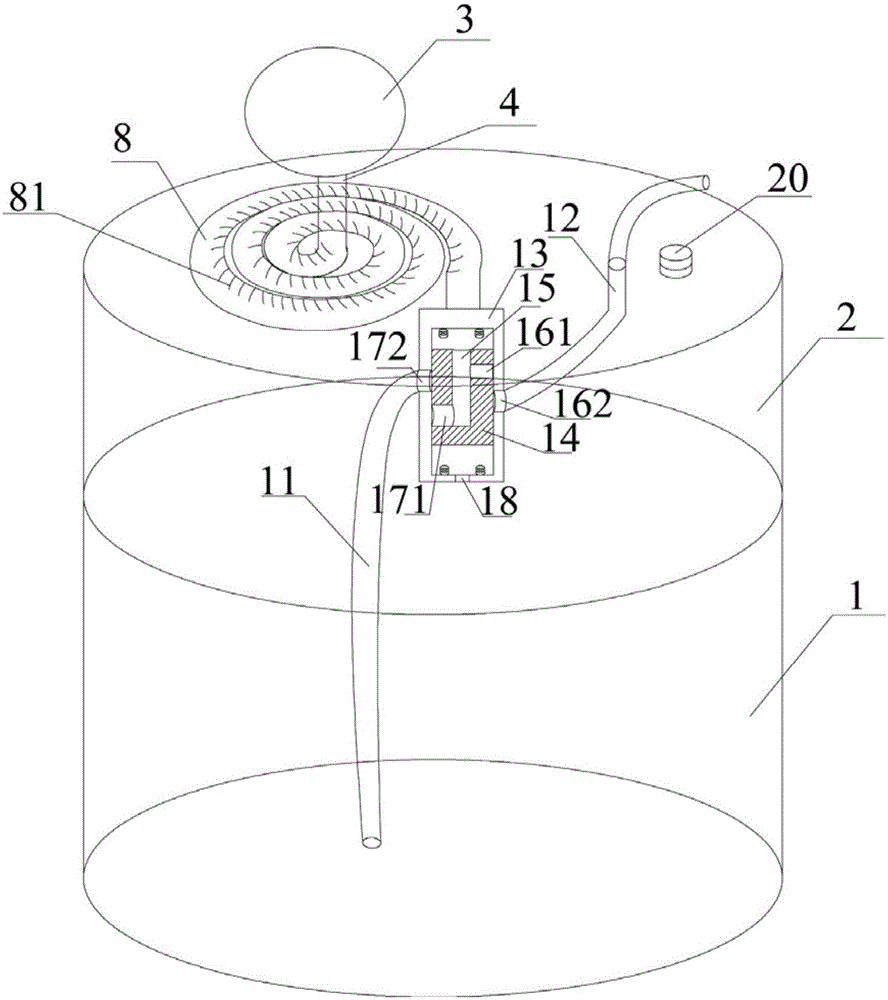

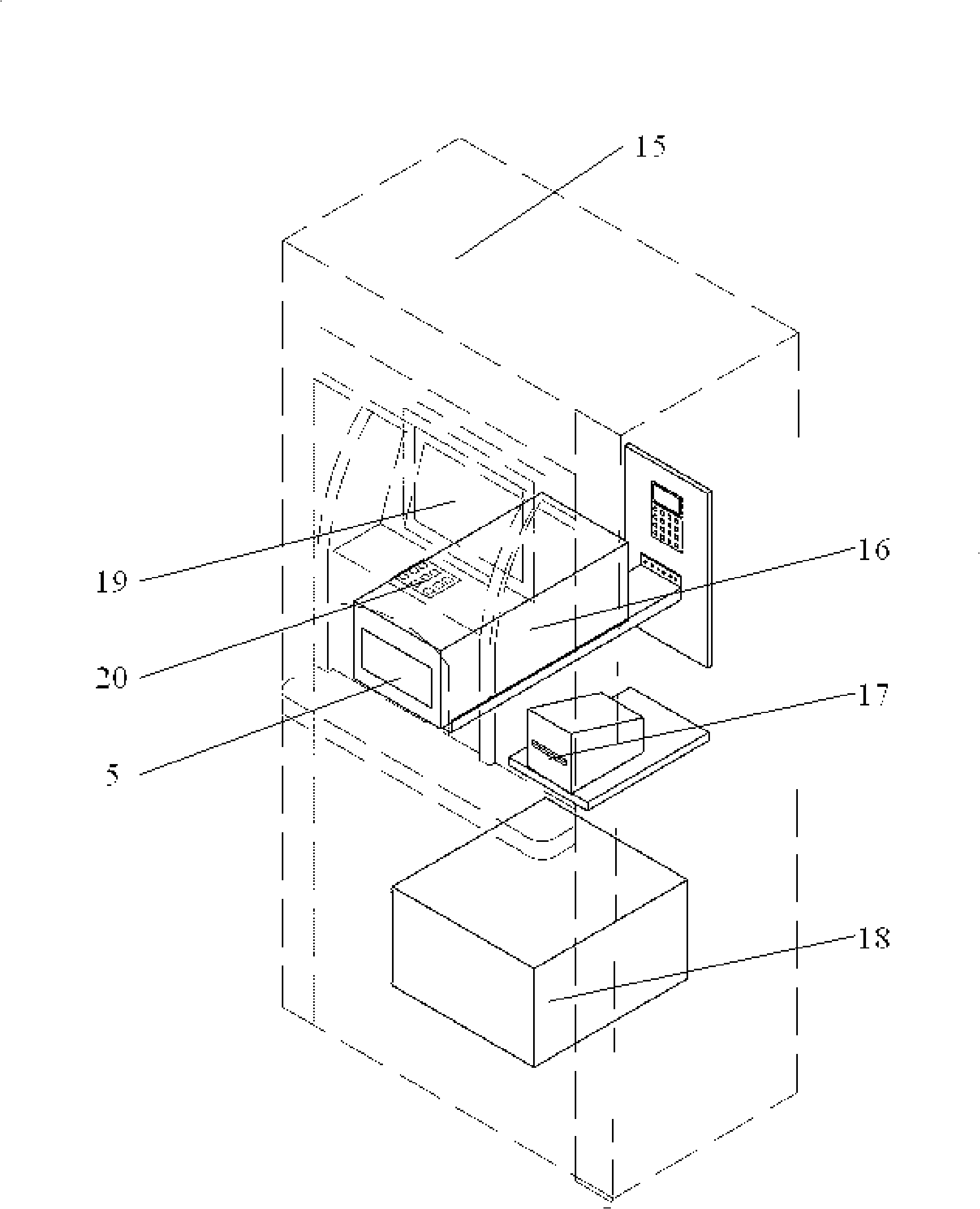

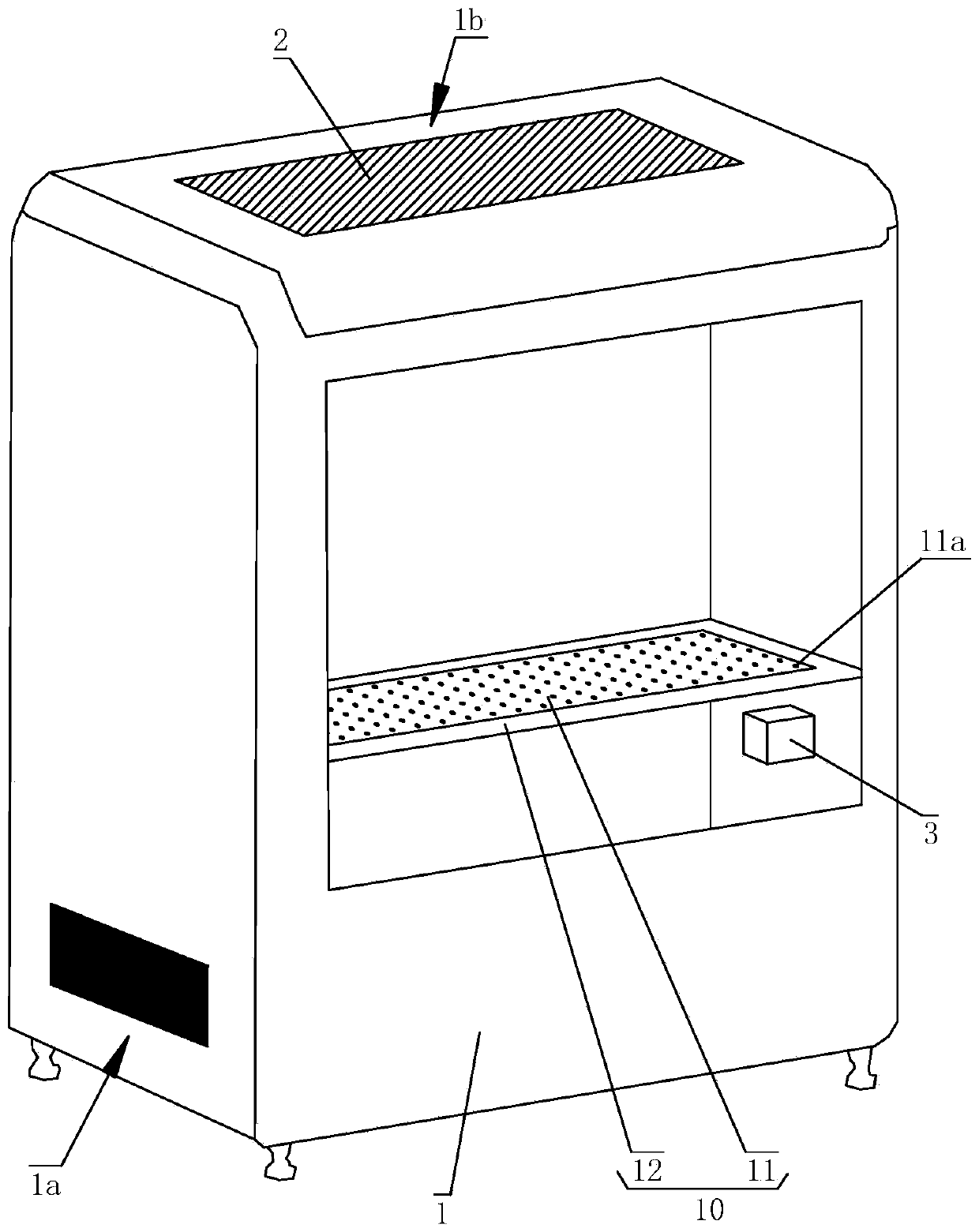

Vending system with overdue reminding rotary material-taking type storage type bento

ActiveCN109493512AEasy to take outTake out accuratelyCoin-freed apparatus detailsApparatus for meter-controlled dispensingHeating timeComputer terminal

The invention discloses a vending system with overdue reminding rotary material-taking type storage type bento, which comprises a user handheld terminal, a vending machine and a cloud server, whereinthe user handheld terminal is provided with a bento selling APP, the vending machine is provided with a code scanning mechanism, the user handheld terminal is connected with the cloud server through anetwork, and the vending machine is connected with the cloud server through GPRS. The vending machine comprises a shell, a door, a rotary driving device, an upright column, a storage bin, a material-taking device and a material-taking driving device, wherein the rotary driving device comprises a rotary motor and a grooved wheel mechanism, the material-taking device comprises an arc-shaped liftingtrack and the material-taking device. The vending system with overdue reminding rotary material-taking type storage type bento can make the user order the food in the vending machine on the APP. After the vending machine receives the order of the user, the food reserved by the user can be processed before the pick-up time reserved by the user. The user can directly take the processed food when taking the meal without waiting for heating time.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Initial positioning device, container and method

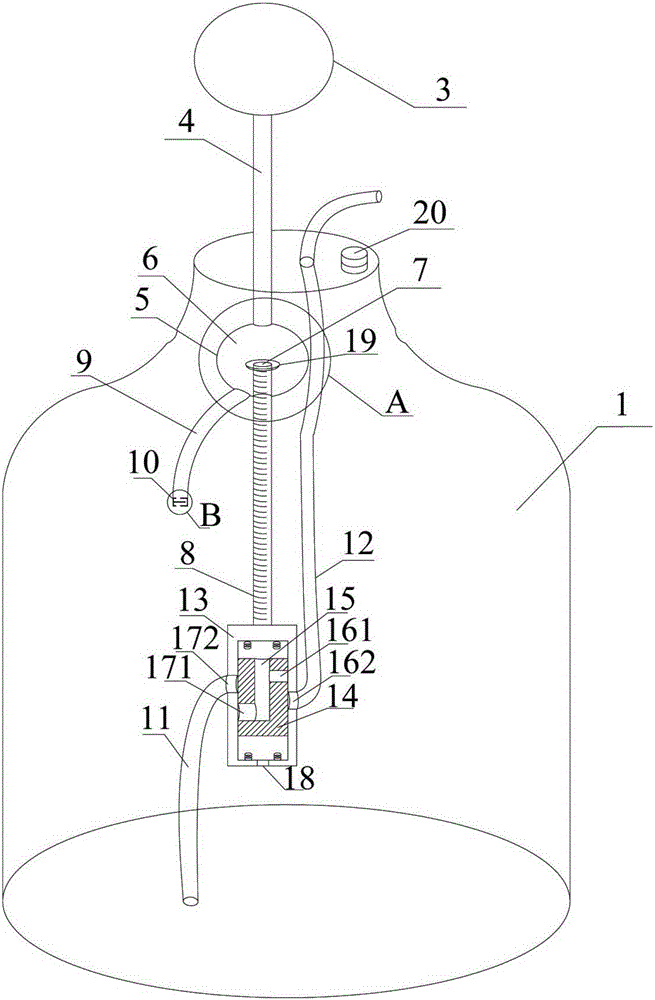

ActiveCN105236025ASimple structureEasy to take outDispensing apparatusContainer/bottle contructionEngineeringMechanical engineering

The invention provides an initial positioning device, container and method. The container comprises a container body, a variable pressure assembly, a metering channel and a discharging channel; when the pressure of the variable pressure assembly is decreased, objects contained in the container body enter the metering channel; when the pressure of the variable pressure assembly is increased, the objects contained in the metering channel flow outwards through the discharging channel. The container further comprises the initial positioning device. The initial positioning device comprises a backflow cavity, a backflow channel and an assembly capable of closing the backflow channel. The backflow cavity is communicated with the variable pressure assembly and the initial end of the metering channel. The initial end of the metering channel is higher than the bottom of the backflow cavity. The backflow channel is communicated with the bottom of the backflow cavity and the container body. The container is simple in structure, convenient to use and accurate in metering.

Owner:BEIJING RED SEA TECH

Restocking method for food vending machine

ActiveCN109615779AEasy replenishmentTake it accuratelyCoin-freed apparatus detailsApparatus for dispensing discrete articlesFood vending machinesEngineering

The invention discloses a restocking method for a food vending machine, which is used for carrying out restocking for the vending machine. The method comprises the steps of: designing a unique two-dimensional code for each food placing cavity; in each time the vending machine needs restocking, a staff reading the two-dimensional code on the food placing cavity where a meal box to be placed by using a camera in the vending machine to acquire the position information of the storage cavity; then reading the two-dimensional code of the box meals to be placed to acquire food information; the vending machine binding the food information of the meal box to be placed in the current food placing cavity, sending the information to the cloud server; and the cloud server storing the information in a database and updating original food information and inventory of the food placing cavity. According to the restocking method for the food vending machine, by means of twice code scanning of the staff,each box meal stored in the vending machine corresponds to an accurate food placing cavity position, so that it is easy for the staff to replenish, and utilization rate of the storage cabinet is improved.

Owner:ZHEJIANG UNIV OF TECH

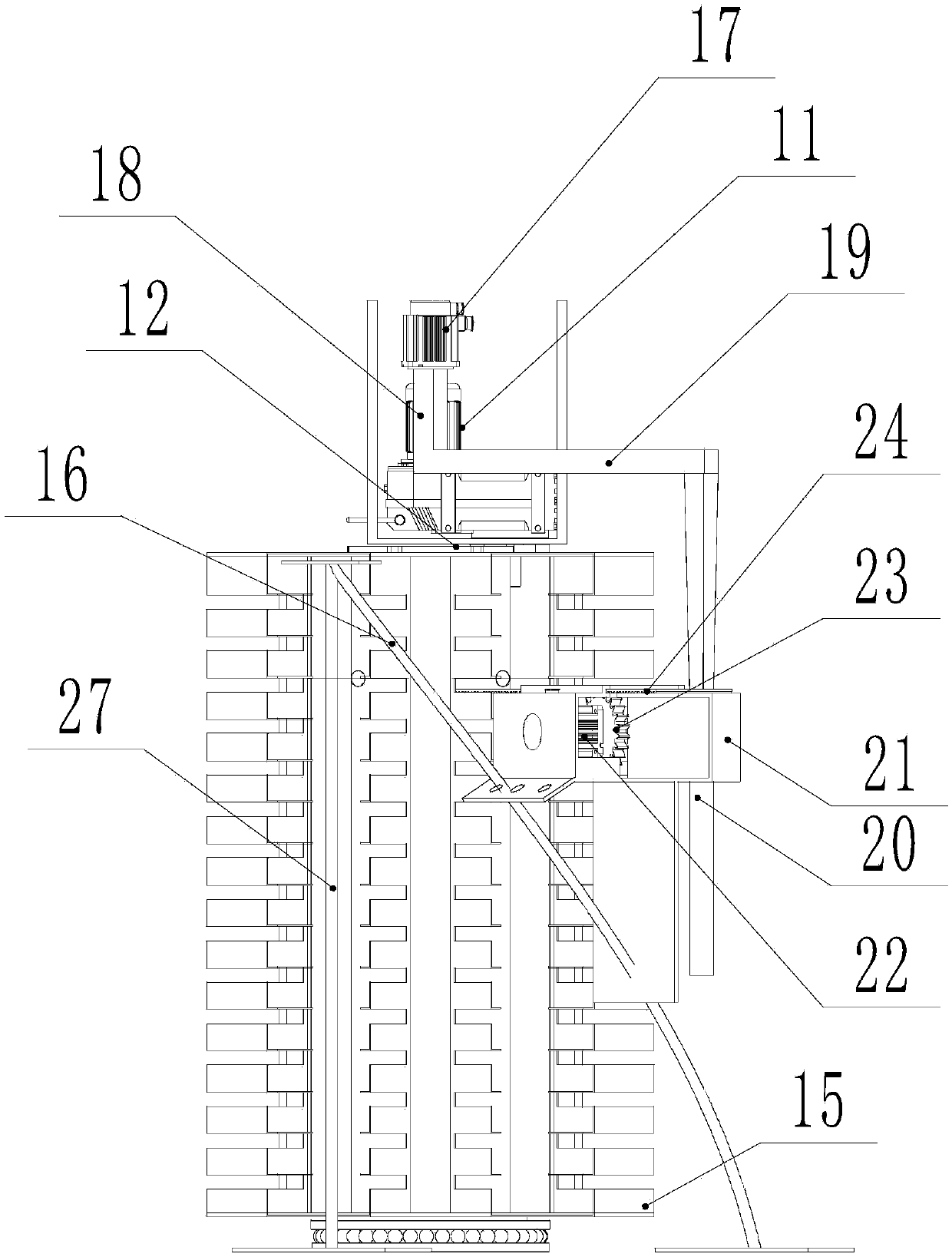

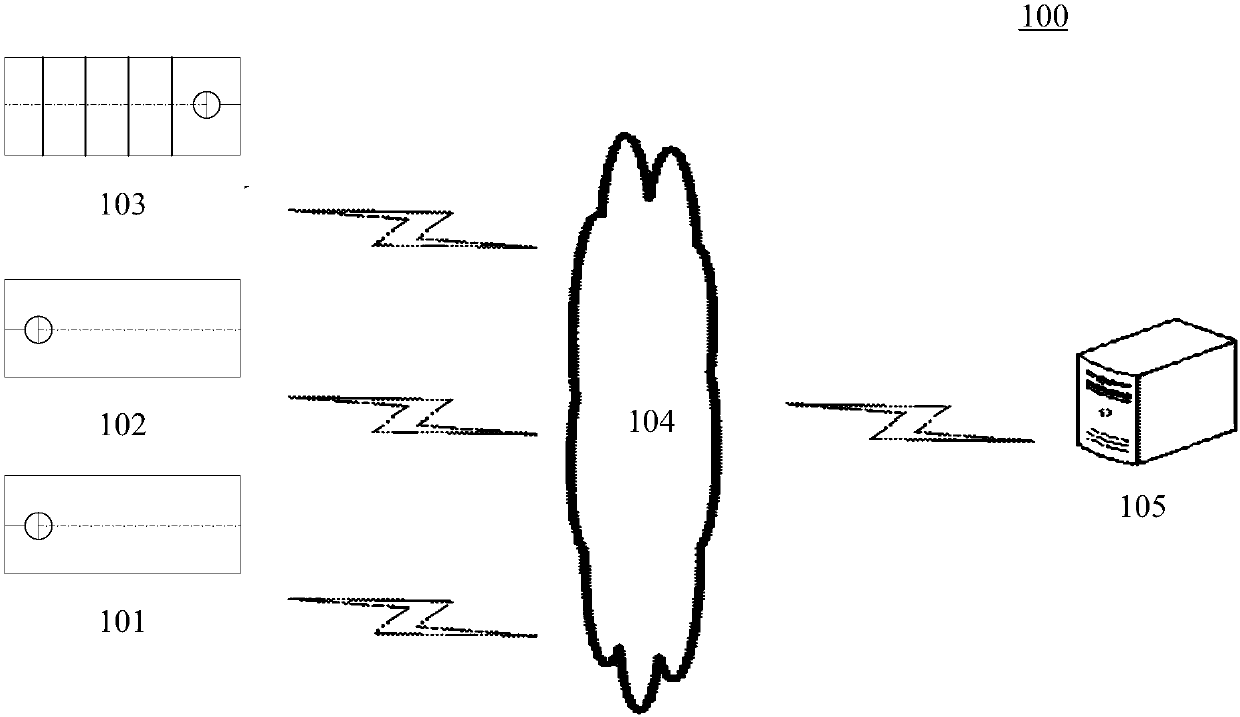

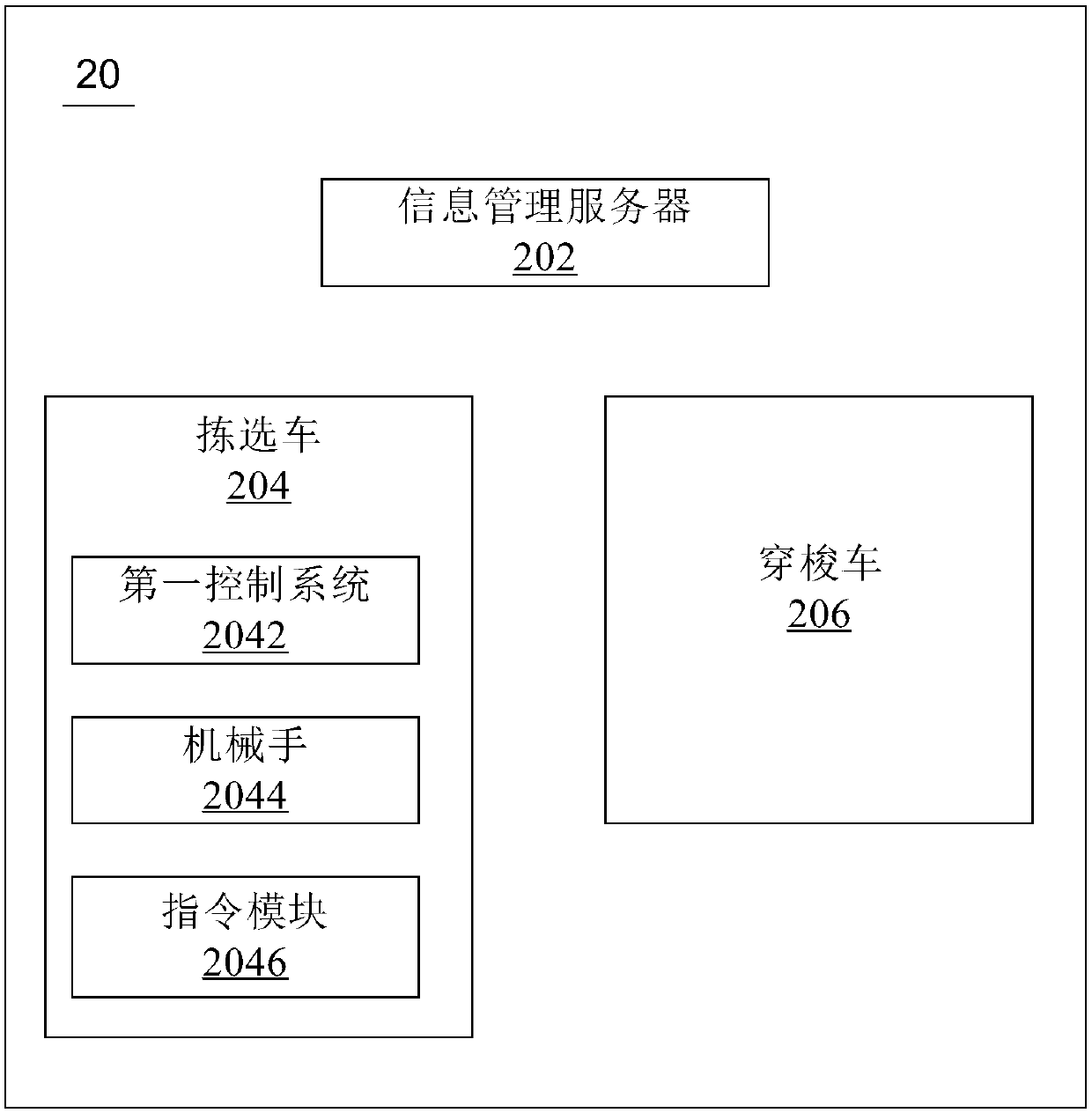

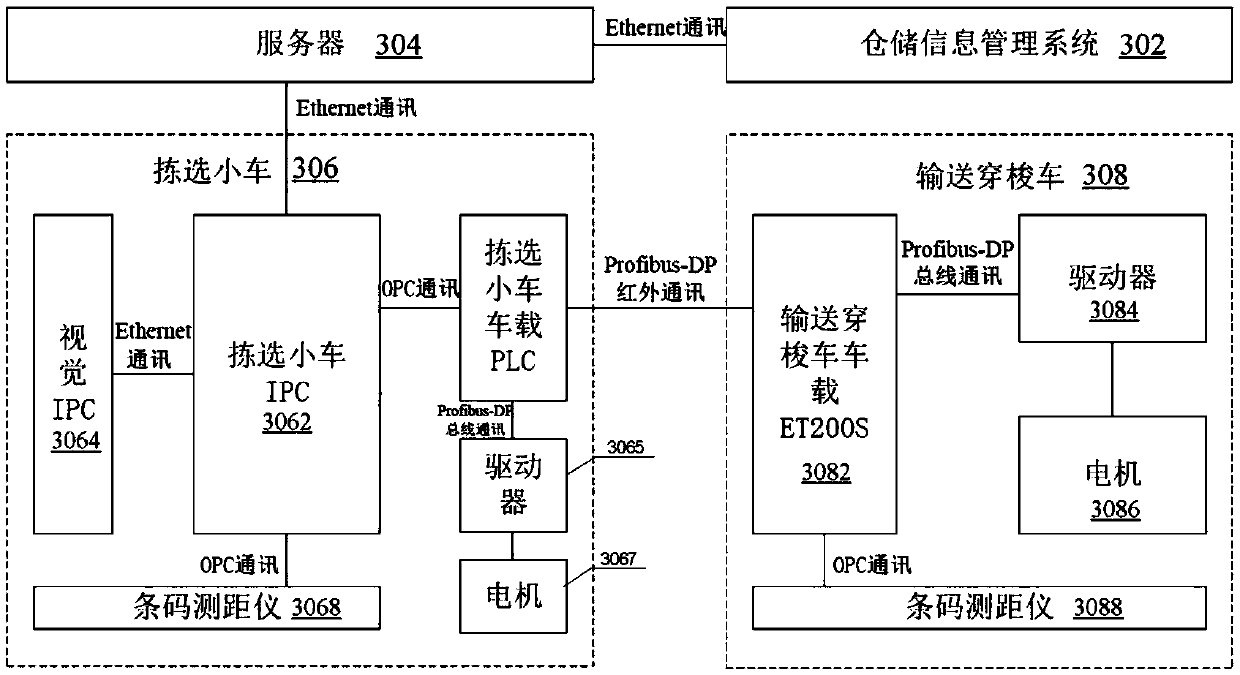

System, method and device for storage cargo sorting, sorting vehicle and shuttle vehicle

PendingCN109867077ATake out accuratelyProvide speedLogisticsStorage devicesTask completionRelevant information

The invention discloses a system, method and device for storage cargo sorting, a sorting vehicle and a shuttle vehicle. The system for storage cargo sorting includes an information management server used for receiving a cargo sorting task and updating an inventory of corresponding cargoes according to task completion information, the sorting vehicle used for sorting the corresponding cargoes according to relevant information of the cargo sorting task and generating an unloading command after cargo sorting is completed, and the shuttle vehicle used for transferring the cargoes on the sorting vehicle to a station according to the unloading command and generating task completing information after the cargoes are transferred to the station; and the relevant information includes the item name,the cargo picking quantity, the item position, the material size and the inventory quantity. By means of the system, method and device for storage cargo sorting, the sorting vehicle and the shuttle vehicle, items in the quantity required in each sorting task package can be accurately taken out, the inventory quantity is automatically modified, and the cargo sorting speed and accuracy can be greatly provided.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

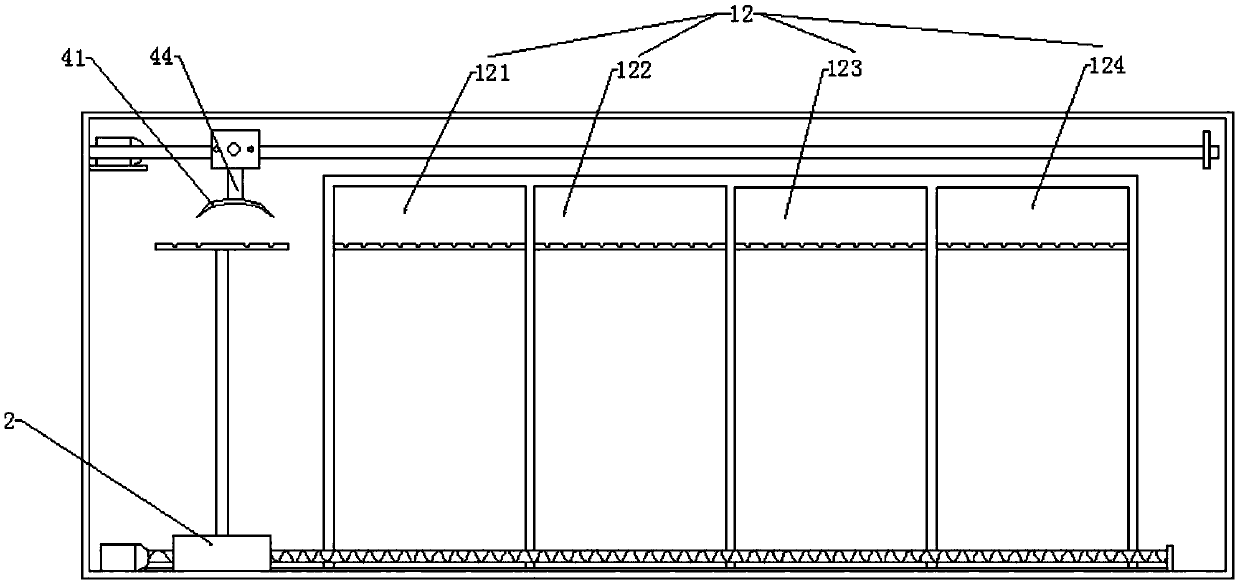

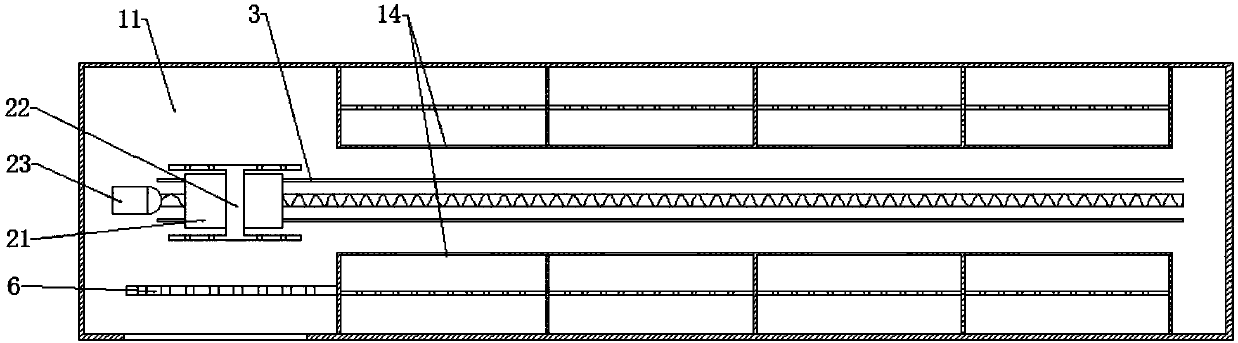

Runway type storage style boxed meal vending system

InactiveCN109035573ATake out accuratelyImprove efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesHeating timeHand held

The invention discloses a runway type storage style boxed meal vending system, comprising a user hand-held terminal provided with a boxed meal selling mobile phone APP, a vending machine and a cloud server, wherein a code scanning mechanism is arranged on the vending machine, the user hand-held terminal is connected with the cloud server through a network, and the vending machine is connected withthe cloud server through GPRS; and the storage style vending machine disclosed by the invention enables a user to order the food in the vending machine through an ordering manner on the mobile phoneAPP. After the vending machine receives an order of the user, the food ordered by the user can be processed before the scheduled meal taking time; and the user can directly take the processed food when taking the meal without waiting for a heating time.

Owner:ZHEJIANG UNIV OF TECH

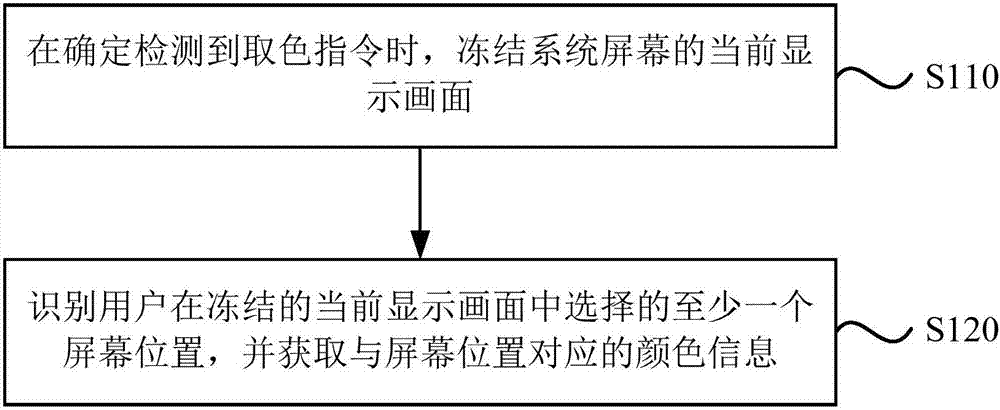

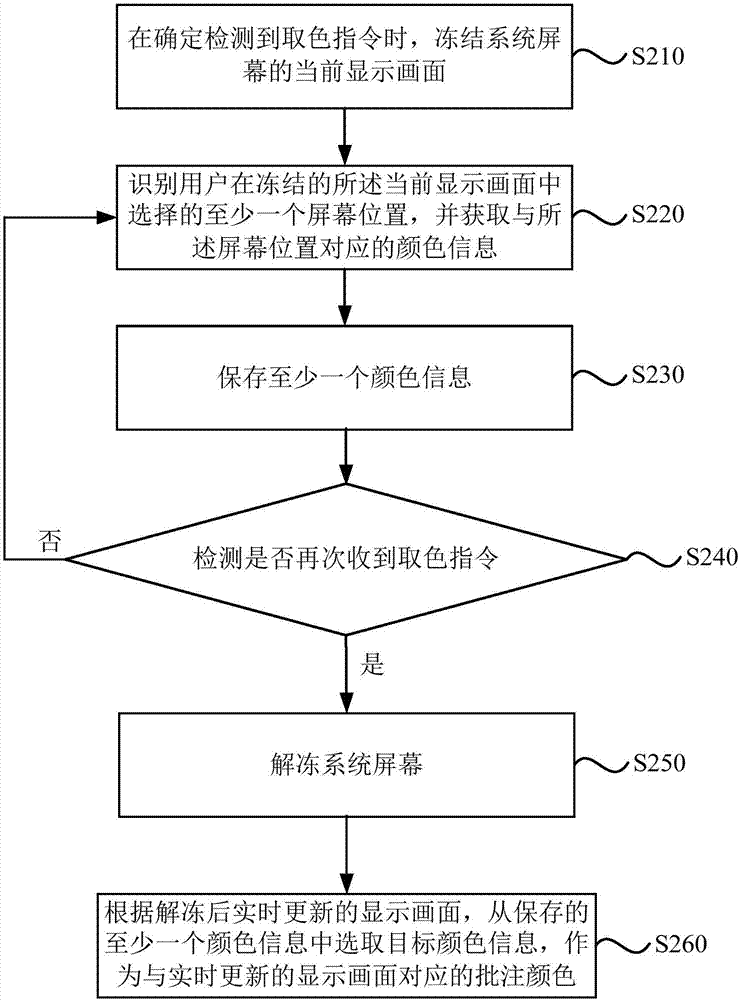

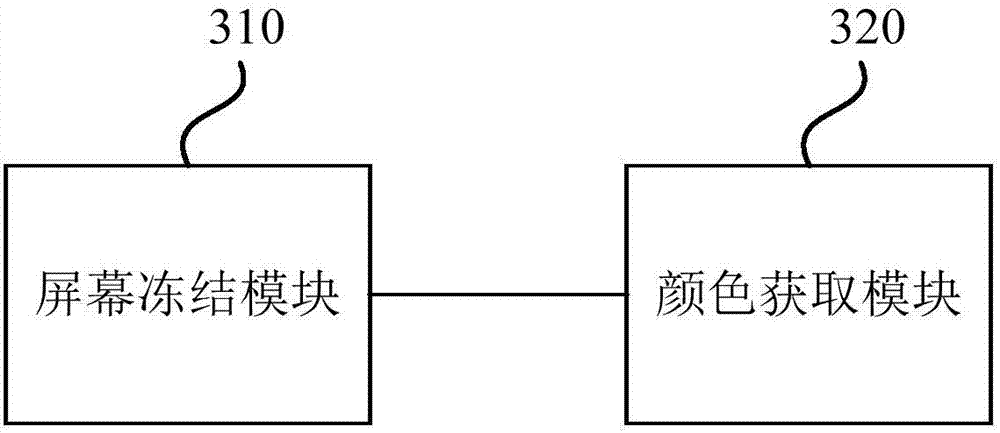

Color taking method and device, equipment and storage medium

ActiveCN107193458AImprove experienceTake out in real timeInput/output processes for data processingComputer graphics (images)

The embodiment of the invention discloses a color taking method and device, equipment and a storage medium. The method comprises the following steps that: when a color taking instruction determines to be detected, freezing the current display picture of a system screen; and identifying at least one screen position selected by a user in the frozen current display picture, and obtaining color information corresponding to the screen position. Through the technical scheme of the invention, colors required by the user can be quickly, conveniently and accurately taken in time, and user experience is improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

Boxed meal vending system with external chute from which materials are taken through direct pushing for goods acquisition based on time

ActiveCN109410462AEasy accessAccurate acquisitionCoin-freed apparatus detailsDigital data protectionNetwork connectionComputer terminal

The invention discloses a boxed meal vending system with external chute from which materials are taken through direct pushing for goods acquisition based on time. The vending system includes users' handheld terminals provided with a boxed meal vending mobile phone APP, an automatic vending machine and a cloud server. A code scanning mechanism is arranged on the automatic vending machine, the users' handheld terminals are linked with the cloud server through a network, and the automatic vending machine is linked with the cloud server through GPRS; the automatic vending machine consists of a boxbody, a box door, a roller driving device, a first roller arranged vertically, a second roller arranged vertically, a first synchronous belt sleeving the upper ends of the first and second rollers, asecond synchronous belt sleeving the lower ends of the first and second rollers, a material taking device, a heating device, a material taking drive device and a boxed meal storage cavity. A date judgment module is arranged in the automatic vending machine, the capacity of the automatic vending machine is large, boxed meals can be placed freely, and convenience is provided for operation of merchants.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

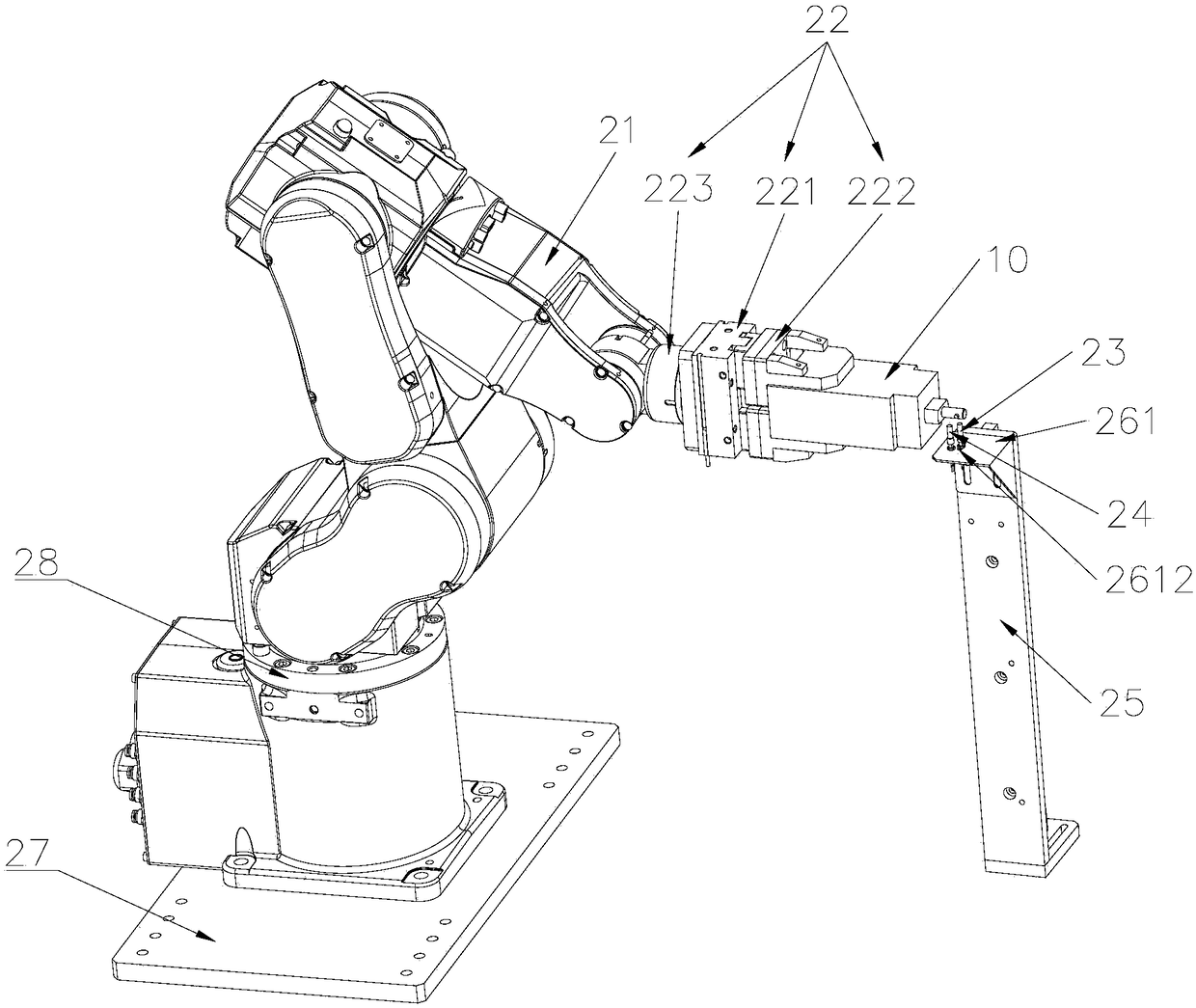

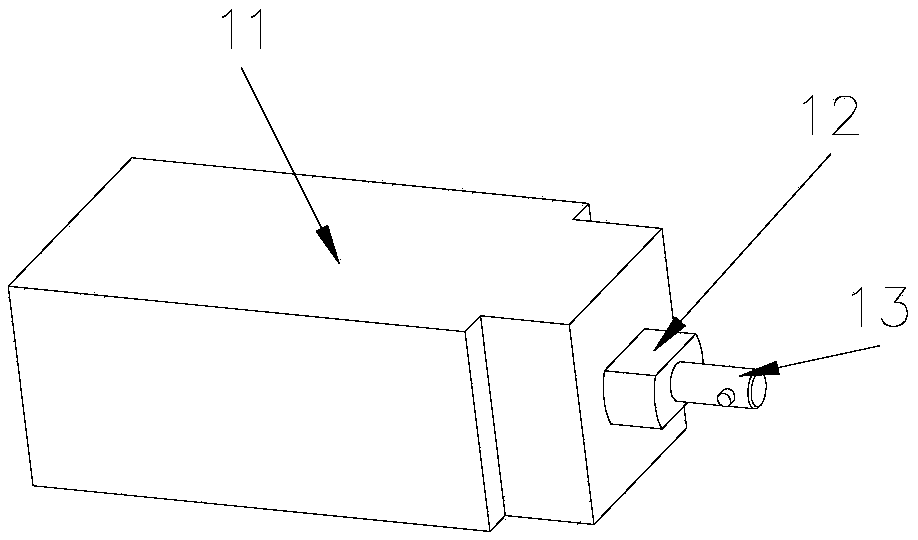

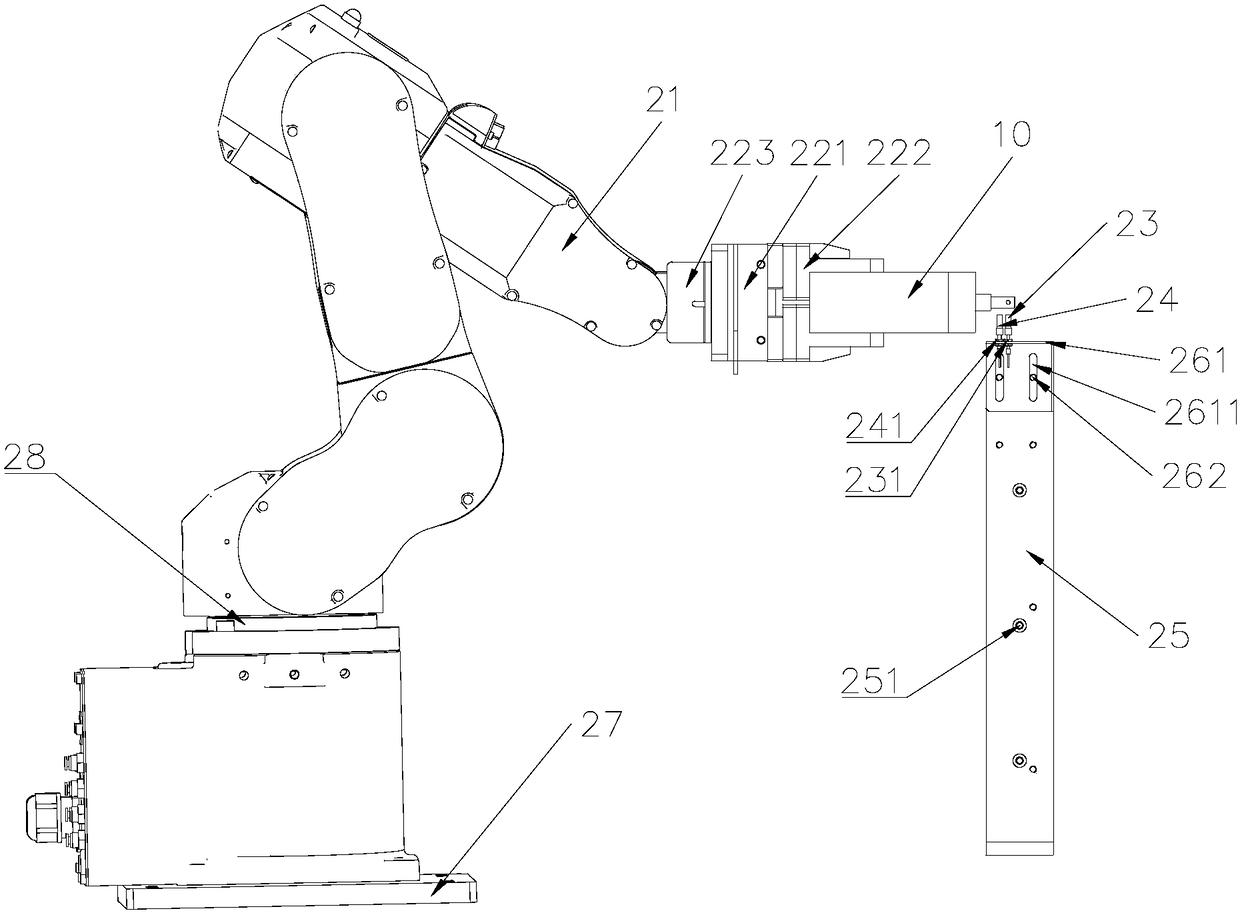

Fool-proof detection device, system and method for disconnecting switch

ActiveCN108445380ATake out accuratelyRealize position adjustmentCircuit interrupters testingManipulatorAutomation

The invention relates to the field of automation equipment, and in particular to a fool-proof detection device for a disconnecting switch. The device comprises a mechanical arm and a clamping assemblymounted on the mechanical arm, and also comprises a first sensor for detecting a cylindrical pin and a second sensor for detecting a fixed seat. The clamping assembly clamps the disconnecting switch,and the mechanical arm drives the clamping assembly to move to a set position. When the first sensor does not sense a sensing signal, the mechanical arm drives the clamping assembly to advance untilthe first sensor senses the sensing signal. If the second sensor does not sense the sensing signal at this time, the correct information is fed back. The two sensors are used for respectively detecting the cylindrical pin and the fixed seat of the disconnecting switch, thereby achieving the foo-proof detection of the disconnecting switch. The device can accurately take out a wrong disconnecting switch, so as to avoid the subsequent wrong marking.

Owner:HANS LASER TECH IND GRP CO LTD

Surgical suture fixing box for operating room nursing

InactiveCN110584731AMobile will notKeep moistSuture equipmentsSurgical needlesLiquid storage tankOperating theatres

The invention discloses a surgical suture fixing box for operating room nursing. The fixing box comprises a base and a shell; a partition plate is vertically fixed in the shell; the partition plate divides the interior of the shell into a left cavity and a right cavity from left to right; a winding roller and a pay-off reel are sequentially fixed to the right cavity from right to left; one end ofa first fixing shaft horizontally extends out of the side wall of the shell and is fixedly provided with a first gear and a first belt wheel; the first gear is fixed to a first fixing shaft through aone-way bearing; a second fixing shaft is fixed to the outer side wall of the shell; a second gear matched with the first gear is fixed on the second fixing shaft; a liquid storage tank is fixed on the bottom end face of the left cavity; a third fixing shaft is fixed into the liquid storage tank through a bearing; and the third fixing shaft is sleeved with a wetting roller. The fixing box is reasonable in structure, medical staff can accurately and quickly take out surgical sutures with the required length from the surgical suture fixing box when preparing the surgical sutures, the working efficiency is improved, and the surgical sutures can be wetted when being taken out so as to guaranteed that the surgical sutures are always kept wet in the wound suturing process.

Owner:李荣荣

Container and cover

The invention provides a container. The container comprises a container body and a cover and further comprises a variable-pressure part, a metering channel, a liquid taking channel and a flow-out channel. The head of the metering channel is communicated with the variable-pressure part. The tail of the metering channel is communicated with the flow-out channel and the liquid taking channel. A valve is arranged between the metering channel and the flow-out channel; and the valve is opened when the variable-pressure part is pressurized, and the valve is closed when the variable-pressure part is depressurized. A valve is arranged between the metering channel and the liquid taking channel or in the liquid taking channel; and the valve is opened when the variable-pressure part is depressurized, and the valve is closed when the variable-pressure part is pressurized. The metering channel, the liquid taking channel and the flow-out channel are fixed to the cover. The container is simple in structure, convenient to use and accurate in metering.

Owner:BEIJING RED SEA TECH

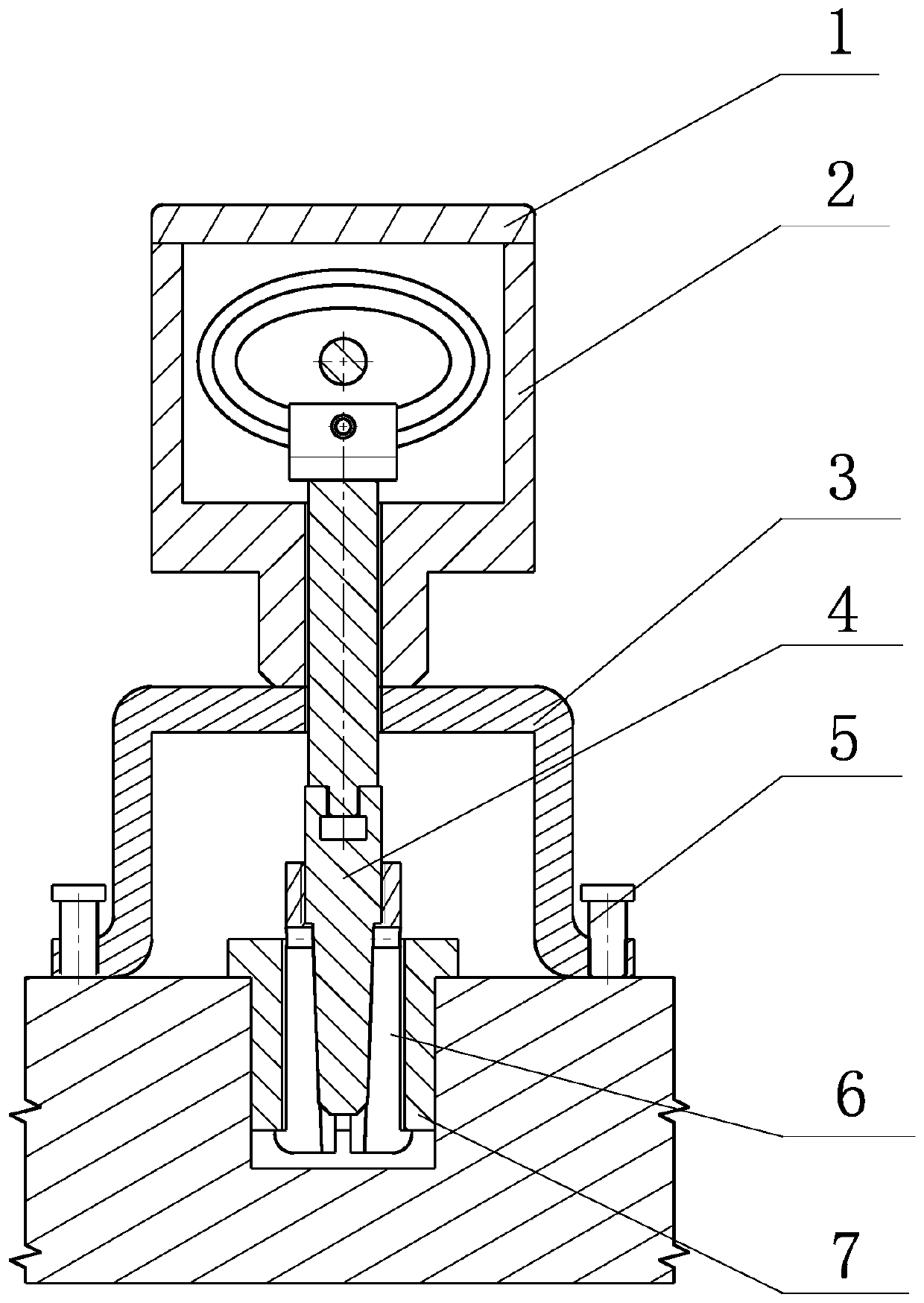

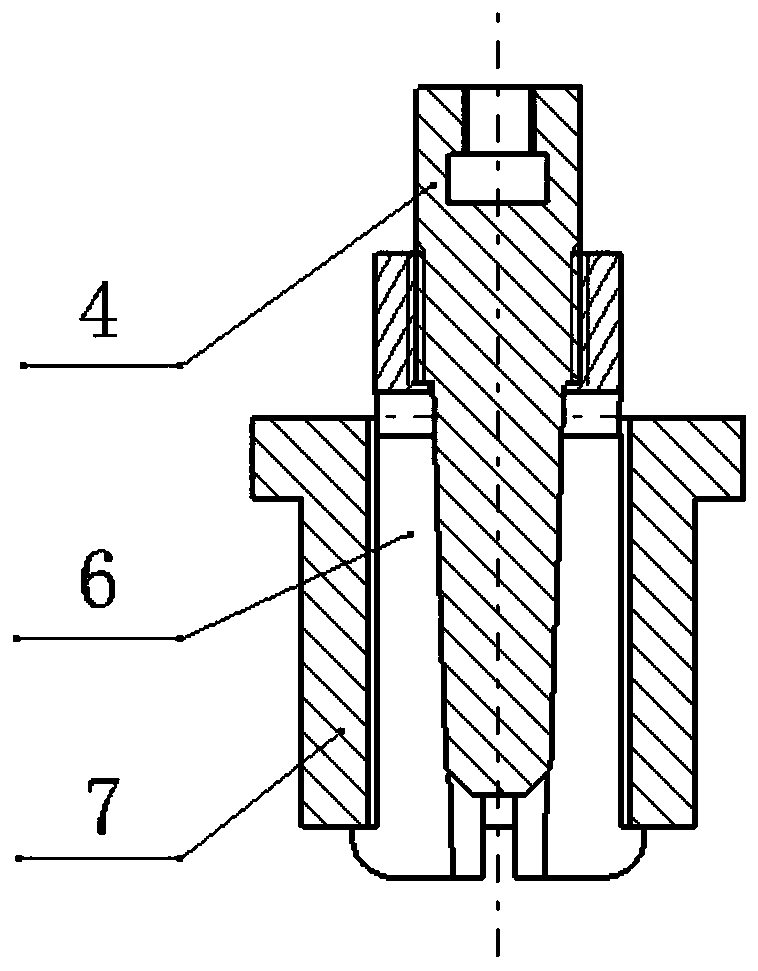

Method for pulling out embedded bushing

InactiveCN111360751APrevent deformation or damageSimple structureMetal-working hand toolsRotational axisClassical mechanics

The invention discloses a method for pulling out an embedded bushing, and aims to overcome the defect that the bushing is difficult to detach in the bushing pulling-out process. According to the technical scheme, the method comprises the following steps that a pull-up rod, a brim opening pressure bearing seat, an elastic expansion sleeve and a cam rotating shaft are prepared, wherein the pull-up rod is inserted into an upper sleeve power cabin, the brim opening pressure bearing seat is capable of being fixed to the working face of a workpiece bushing, the elastic expansion sleeve is capable ofbeing inserted into the bottom end face of a workpiece hole along the inner wall of the workpiece bushing and is provided with symmetrical opening grooves and end bottom hook rings, the cam rotatingshaft transversely penetrates through the cavity of the upper sleeve power cabin to be assembled; and the elastic expansion sleeve is inserted into the inner diameter of the workpiece bushing after being contracted in the radial direction. The pull-up rod is connected with a conical guide expansion rod, by utilizing the brim opening pressure bearing seat, an expansion pulling head of the conical guide expansion rod with a large upper part and a small lower part in taper falls into the elastic expansion sleeve inserted into the hole wall of the workpiece bushing through a supporting sleeve, thepull-up rod is driven by the cam rotating shaft, and a cam upwards and outwards pulls a pull head of the conical guide opening rod in a self-locking state with the inner wall of the elastic expansionsleeve through an elliptical ring, and the elastic expansion sleeve for fastening expansion of the inner hole wall of the workpiece bushing retreats the workpiece bushing inserted into the workpiecehole along with the elastic hook ring through an annular elastic hook ring clamped in the end direction and the expansion pulling head tightly pressing the inner wall of the bushing by virtue of axialcomponent force generated by the taper.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

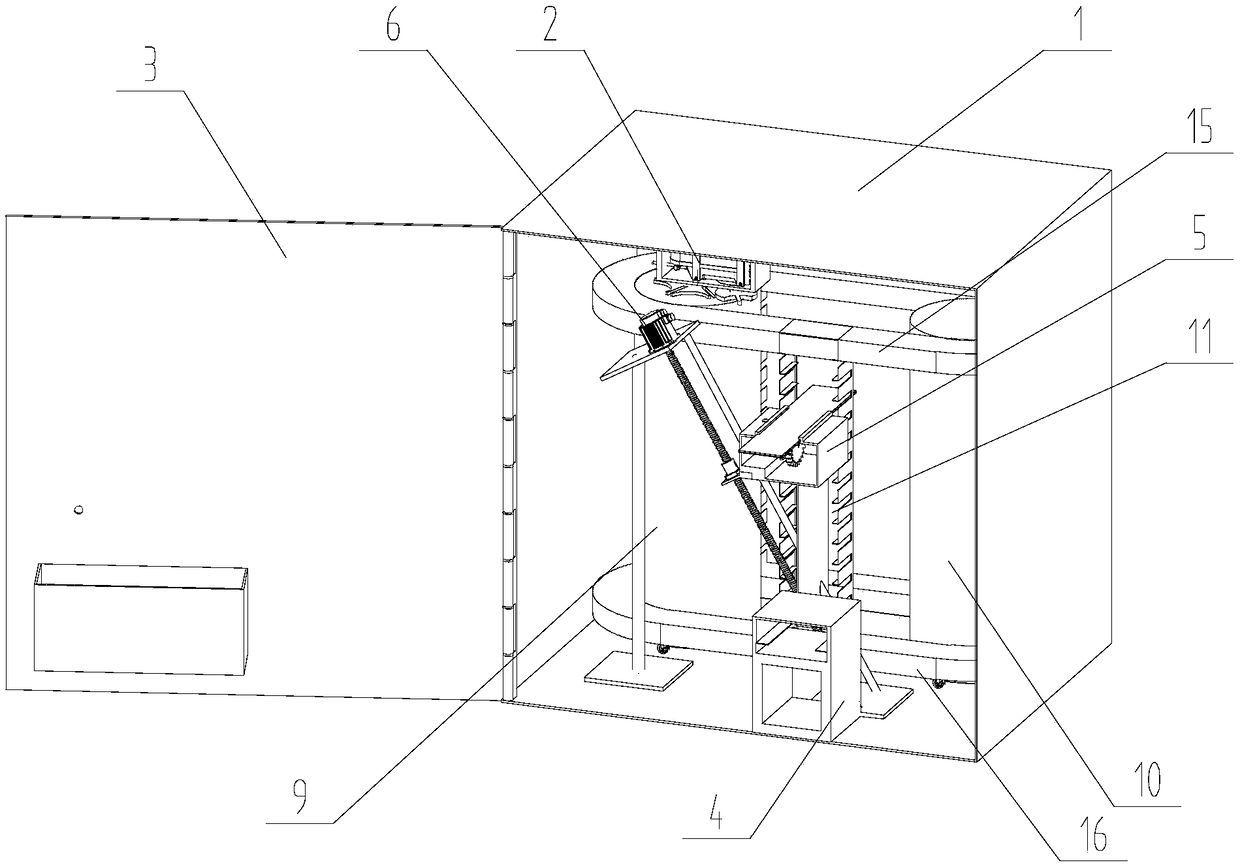

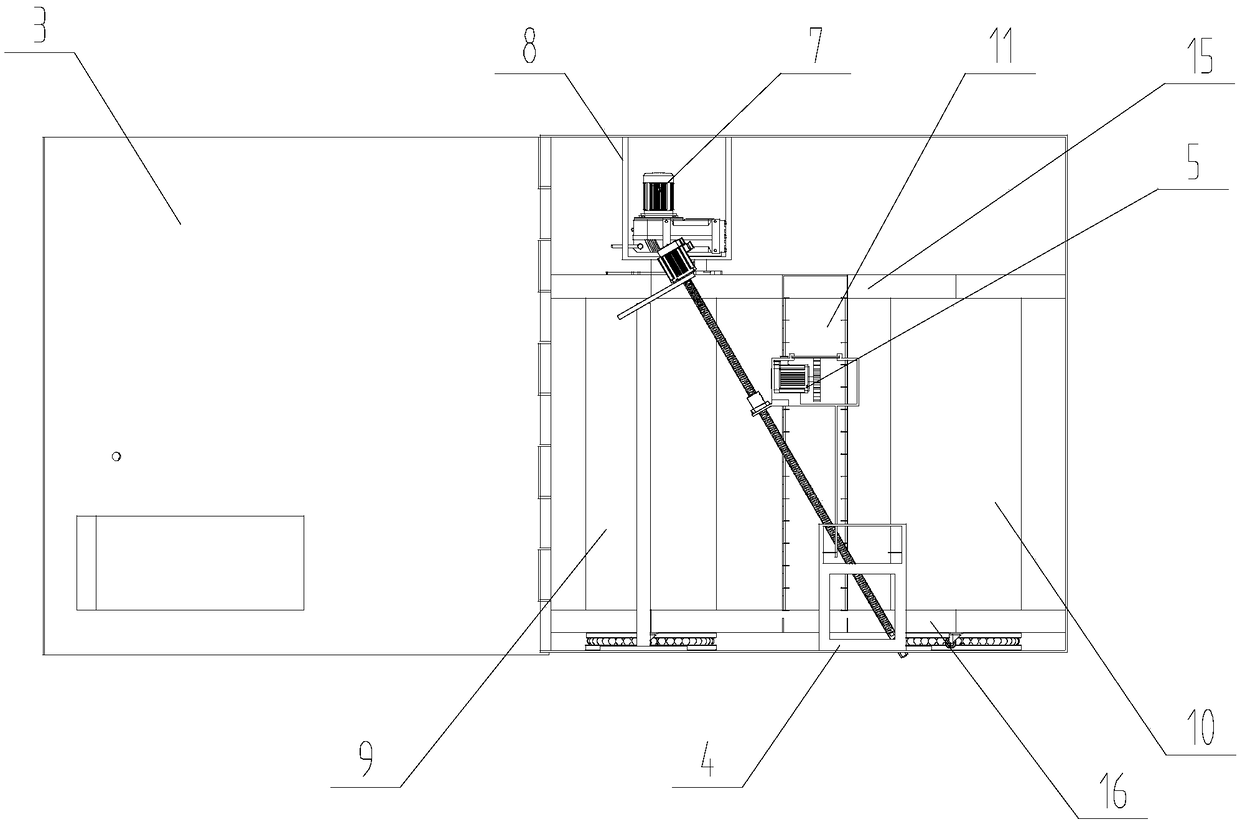

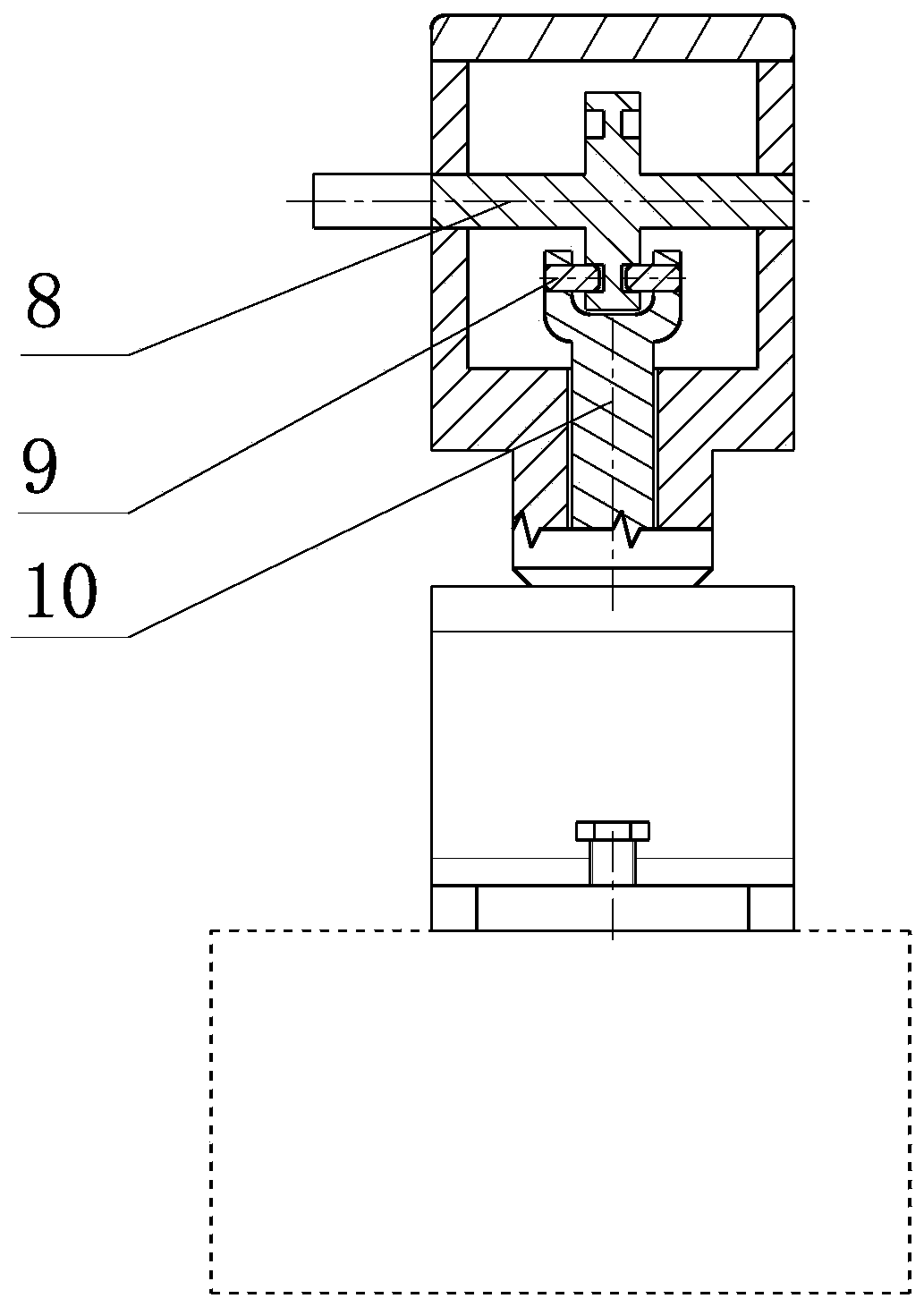

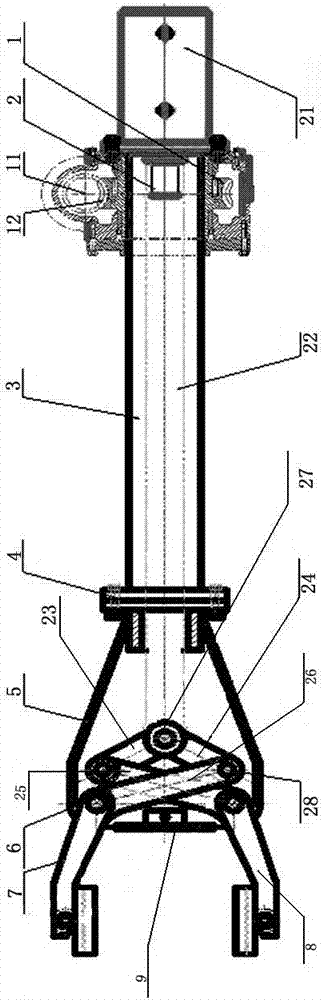

Tong head rotating device for forging charging and taking machine

PendingCN107470536ASimple structureReduce production costs and failure ratesForging/hammering/pressing machinesPhysicsEngineering

The invention discloses a tong head rotating device for a forging charging and taking machine. The tong head rotating device comprises a rotating assembly used for controlling a tong head to rotate, the end of a clamping assembly used for controlling a pair of clamping arms to move is connected to one end of the rotating assembly, the center of the rotating assembly is connected with one end of a hollow shaft, the other end of the hollow shaft is connected with one end of a tong head shell through a flange plate, the other end of the tong head shell is connected with one end of each clamping arm through one of clamping arm pin shafts taking the hollow shaft as the symmetric axis, the clamping arms take the hollow shaft as the symmetric axis, and the other end of each clamping arm is hung in the air; and the clamping assembly penetrates through a central through hole of the hollow shaft to the inner side of the tong head shell and is connected with one end of each clamping arm through the corresponding clamping arm pin shaft. The tong head rotating device is used on the forging charging and taking machine and has the purposes that the tong head does plus and minus 360-degree rotation around the axis of the hollow shaft and then stops at a needed station, so that heated workpieces are taken out of the machine more quickly and more accurately from different directions.

Owner:SHANXI CHENHUI FORGING EQUIP MFG CO LTD

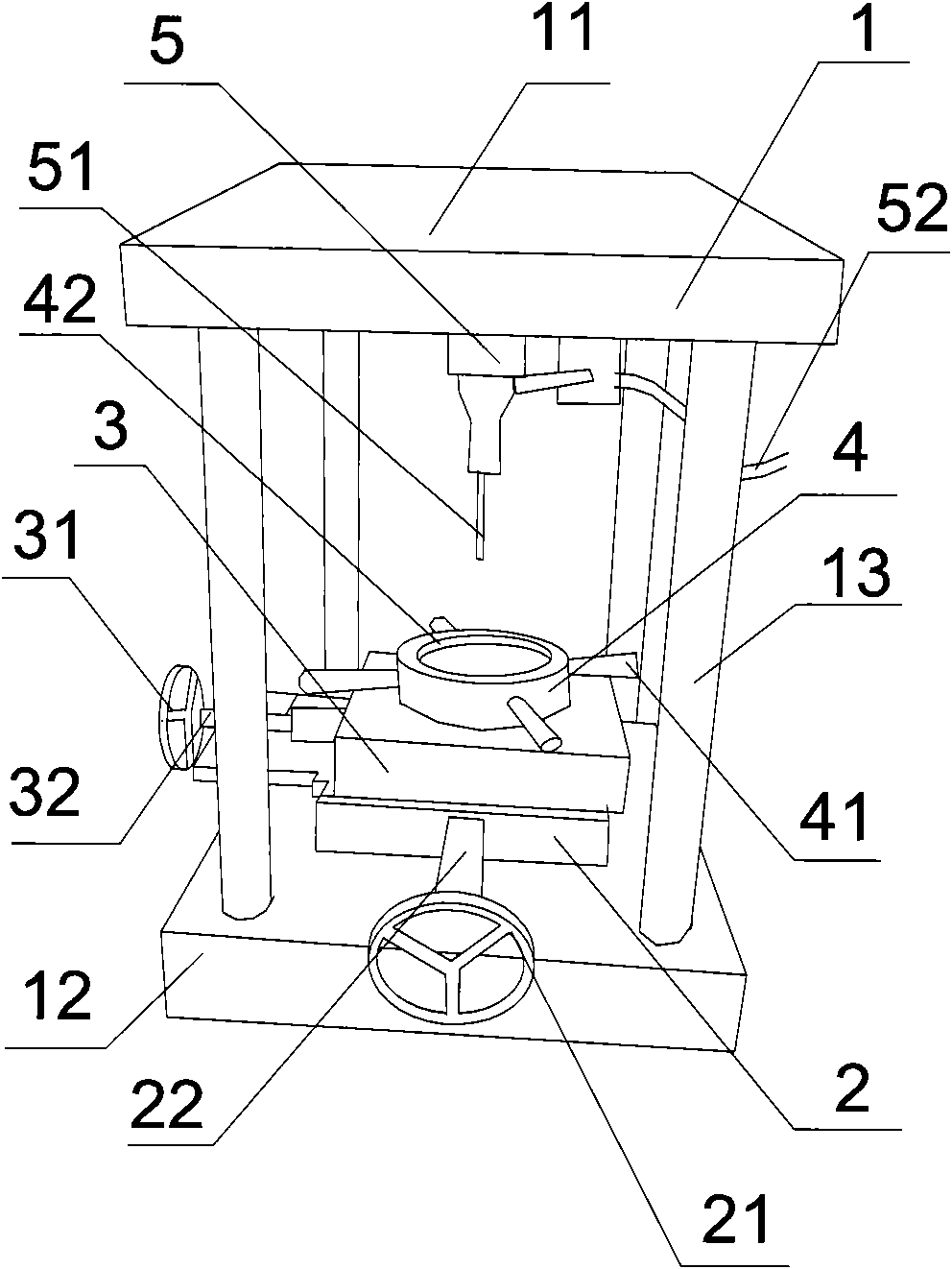

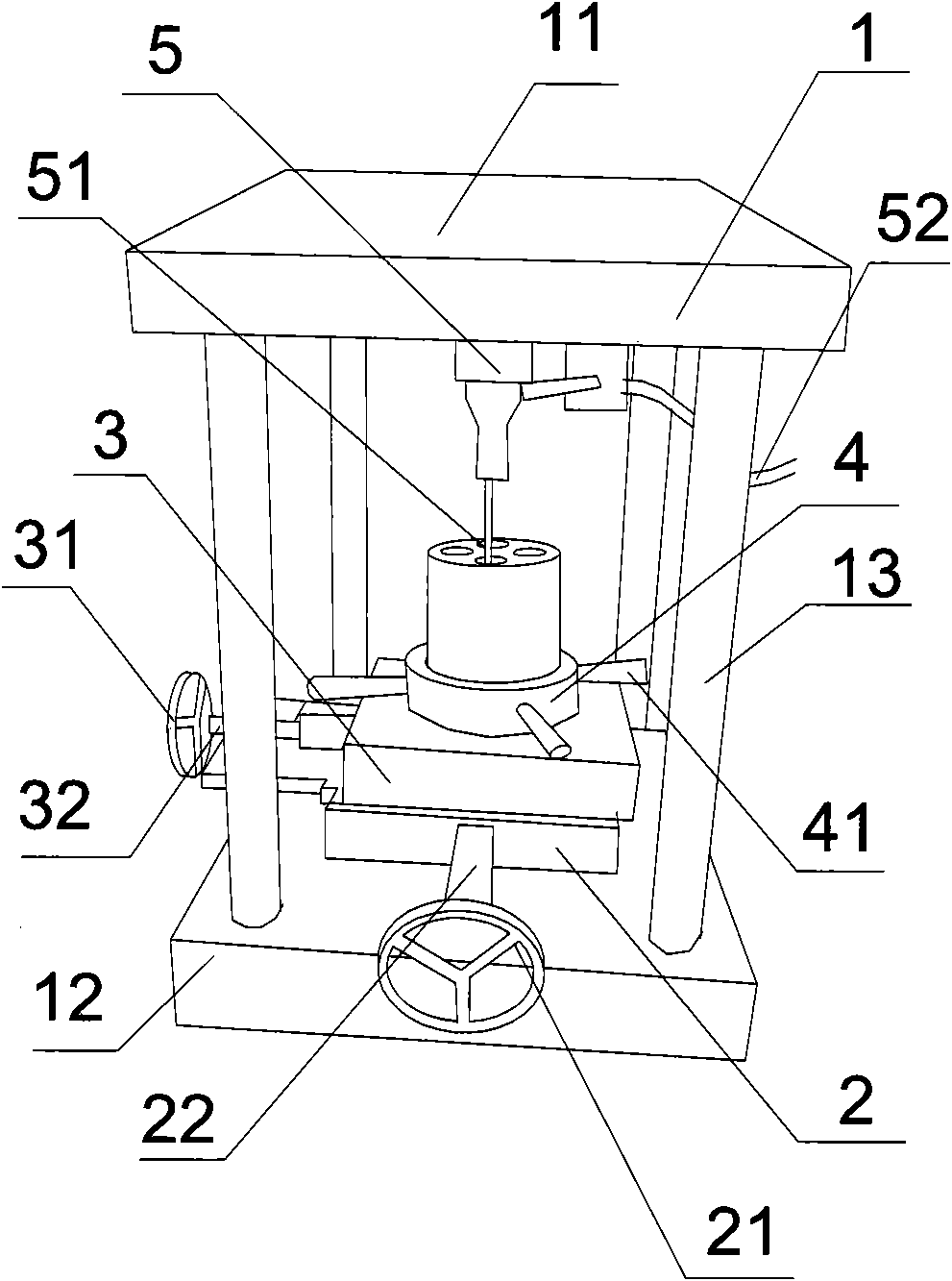

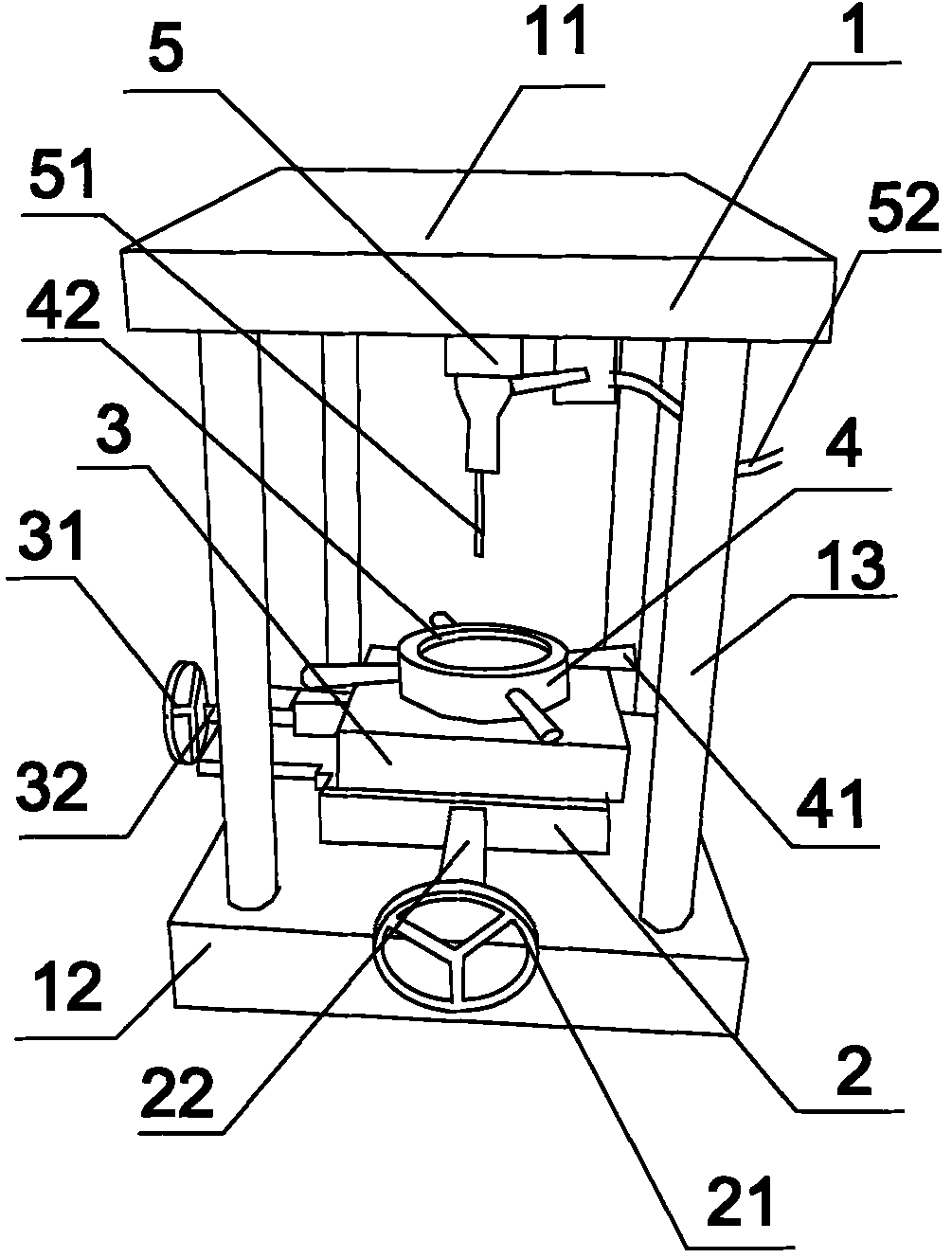

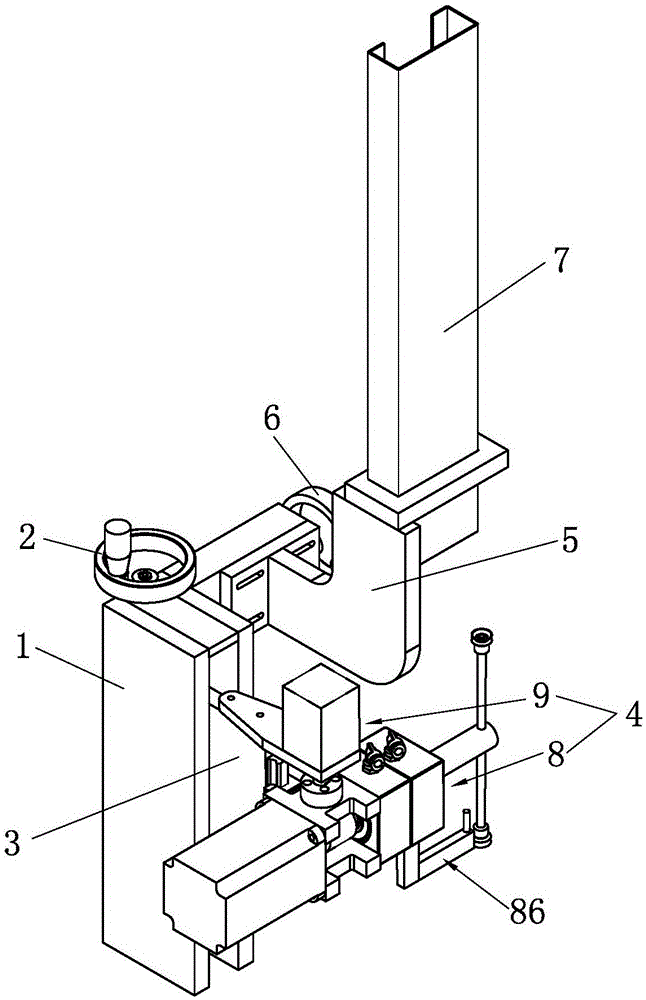

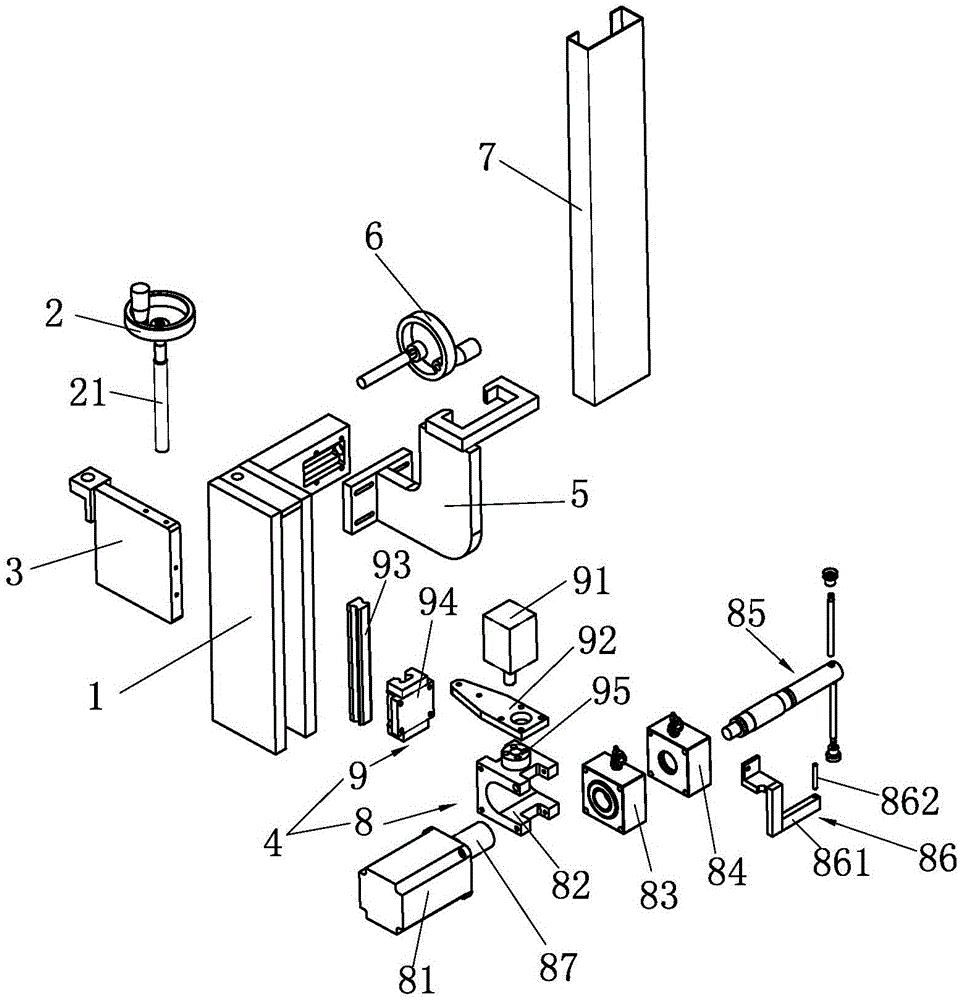

Automatic sub-packaging device

The invention provides an automatic sub-packaging device. The automatic sub-packaging device comprises a first support, a first hand wheel, a first connecting plate, a sub-packaging mechanical arm, a second support, a second hand wheel and a storage tank. The first hand wheel is arranged at the top end of the first support. A threaded rod at the lower end of the first hand wheel is in threaded connection with one side of the first connecting plate. The first connecting plate is arranged in the first support. The other side of the first connecting plate stretches out of the first support. The first connecting plate is fixedly connected with the sub-packaging mechanical arm. The sub-packaging mechanical arm comprises a sub-packaging mechanism and a reciprocating mechanism. The bottom end of the second support is connected to the top end of the first support. The top of the first support is further provided with the second hand wheel. The top end of the second support is provided with the storage tank. According to the automatic sub-packaging device, adhesive bandage strips to be packaged can be quickly, accurately and automatically arranged and sub-packaged; the packaging production efficiency can be greatly improved, and the packaging production percent of pass can be greatly increased; the labor intensity of workers can be effectively relieved.

Owner:QUANZHOU HUASHUO IND

Rotor temperature detection and abnormal rotor rejection device

The invention relates to the technical field of rotor electrostatic coating, in particular to a rotor temperature detection and abnormal rotor rejection device. The device comprises a conveying mechanism used for conveying a rotor to pass through an electrostatic coating high-temperature zone and a normal-temperature zone, a temperature detection mechanism arranged in the electrostatic coating high-temperature zone and used for detecting the temperature of the rotor on the conveying mechanism, an rejection mechanism arranged in the normal-temperature zone and used for removing a rotor with abnormal temperature from the conveying mechanism, and a controller. The temperature detection mechanism is in signal connection with the controller so as to judge whether the temperature of the rotor isabnormal or not through the controller and calibrate the rotor with abnormal temperature, and the controller is in signal connection with the rejection mechanism so as to control the rejection mechanism to remove the calibrated rotor with abnormal temperature from the conveying mechanism. The rotor temperature detection and abnormal rotor rejection device can detect the electrostatic coating temperature of rotors, judge whether the electrostatic coating temperature of the rotors is abnormal or not, and reject the rotors with abnormal coating temperature.

Owner:广东省机械研究所有限公司

Method and device for automatically drawing a large mount of money

InactiveCN101315719AMake up for slow withdrawalsTake out accuratelyComplete banking machinesEmbedded systemCard reader

The invention provides a method and a device for large-denomination money automatic drawing; the method comprises the following steps: money is put into an intelligent paying device according to a certain amount; a magnetic card is inserted by a reader, passwords are input and identification is decided; then a multimedia display device displays all the amount which can be drawn according to instructions of a control system; then the amount which needs to be drawn is input by the operation of a keyboard; according to instructions of the control system, a storage unit with equivalent money which corresponds to the input amount is turned to the exit of the money; the control system compares the money which is paid practically with the amount of the money which is input till the money which is paid practically is consistent with the amount of the money which is input. The invention can draw large-denomination money fast and accurately.

Owner:BEIJING RINRONG TECH

A method for adjusting and optimizing goods between vending machine stations

ActiveCN109685239AReduce scrap rateLow costCoin-freed apparatus detailsForecastingOptimal decisionRejection rate

The invention discloses a method for adjusting and optimizing goods between vending machine stations, which comprises vending machines arranged at the vending stations, and comprises the following specific steps of: 1, setting parameters; 2, assuming an access sequence number; Step 3, determining an objective function; 4, determining constraint conditions of the objective function; 5, solving theobjective function; 6, obtaining an optimal decision variable according to an algorithm solving result in the step 5; According to the method, a replenisher can adjust the goods between the selling stations in the replenishment process according to the optimal path obtained by the optimization algorithm, and the optimization algorithm enables the replenisher to complete replenishment and goods adjustment along the shortest path; The goods adjustment scheme can reduce the food rejection rate and reduce the cost.

Owner:ZHEJIANG UNIV OF TECH

Automatic storing and taking refrigerator

PendingCN111380275AAvoid odorTake out accuratelyLighting and heating apparatusDomestic refrigeratorsCold airIcebox

The invention provides an automatic storing and taking refrigerator. The automatic storing and taking refrigerator comprises a box body, a storage part and a conveying device, wherein a storing and taking window is formed in a front plate of the box body; the storage part is arranged in the box body and is provided with a plurality of storage units for placing food materials internally; and the conveying device is arranged in the box body for conveying the food materials from the storing and taking window to the storage units or from the storage units to the storing and taking window. By meansof the storage units, the food materials are stored in different storage units favorably, so that tainting among the food materials by odor is avoided, it is convenient to record the storage positions and it is favorable to take out the stored food materials accurately. When it is needed to take the food materials, the conveying device is directly controlled to take the food materials in the corresponding storage units, so that the automatic storing and taking refrigerator is rapid and efficient. By arranging the conveying device, the food materials are stored and taken automatically, a condition that the food materials are hunt through manually is avoided, it is only needed to open the storing and taking window to store or take the food materials, and cold air leakage in a large area asa door body is opened is avoided.

Owner:QINGDAO HAIER SPECIAL ICEBOX

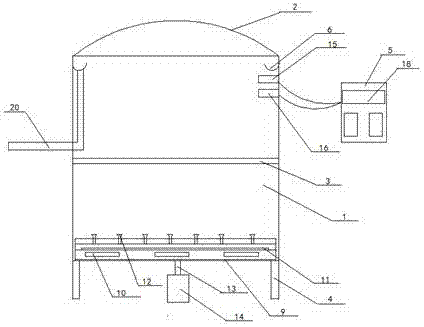

Novel cocoon silk product drying device

InactiveCN107462009AReasonable contact areaIncrease contact areaDrying gas arrangementsDrying solid materialsInsulation layerPulp and paper industry

The invention discloses a novel cocoon silk product drying device. The novel cocoon silk product drying device comprises a drying box body, an end cover mounted on the top of the drying box body, a support, a supporting frame used for carrying cocoon silk products, a drying system, a motor and a controller. The end cover is semi-circular. The edge of the bottom of the end cover is provided with a water accumulation tank. The water accumulation tank communicates with the outside through a pipeline to discharge steam water in the water accumulation tank to a designated position. The supporting frame is a frame type supporting frame. The end of the supporting frame is provided with supporting blocks. Each end of the supporting frame is provided with two supporting blocks. The inner sidewall of the drying box body is provided with supporting grooves matched with the supporting blocks. The drying system comprises a supporting seat, draught fans arranged in the supporting seat, an electric heating wire and air outlets formed in the upper surface of the supporting seat. The air outlets are tapered air outlets. The bottom of the supporting seat is connected with the motor through a rotary shaft. The inner sidewall of the drying box body is further provided with a temperature sensor and a humidity sensor. The outer sidewall of the drying box body is further provided with a heat insulation layer. The novel cocoon silk product drying device is novel in structure, reasonable in design and capable of increasing the yield of cocoon silk products, and has high practical value.

Owner:SUQIAN JIUJIU WIRE

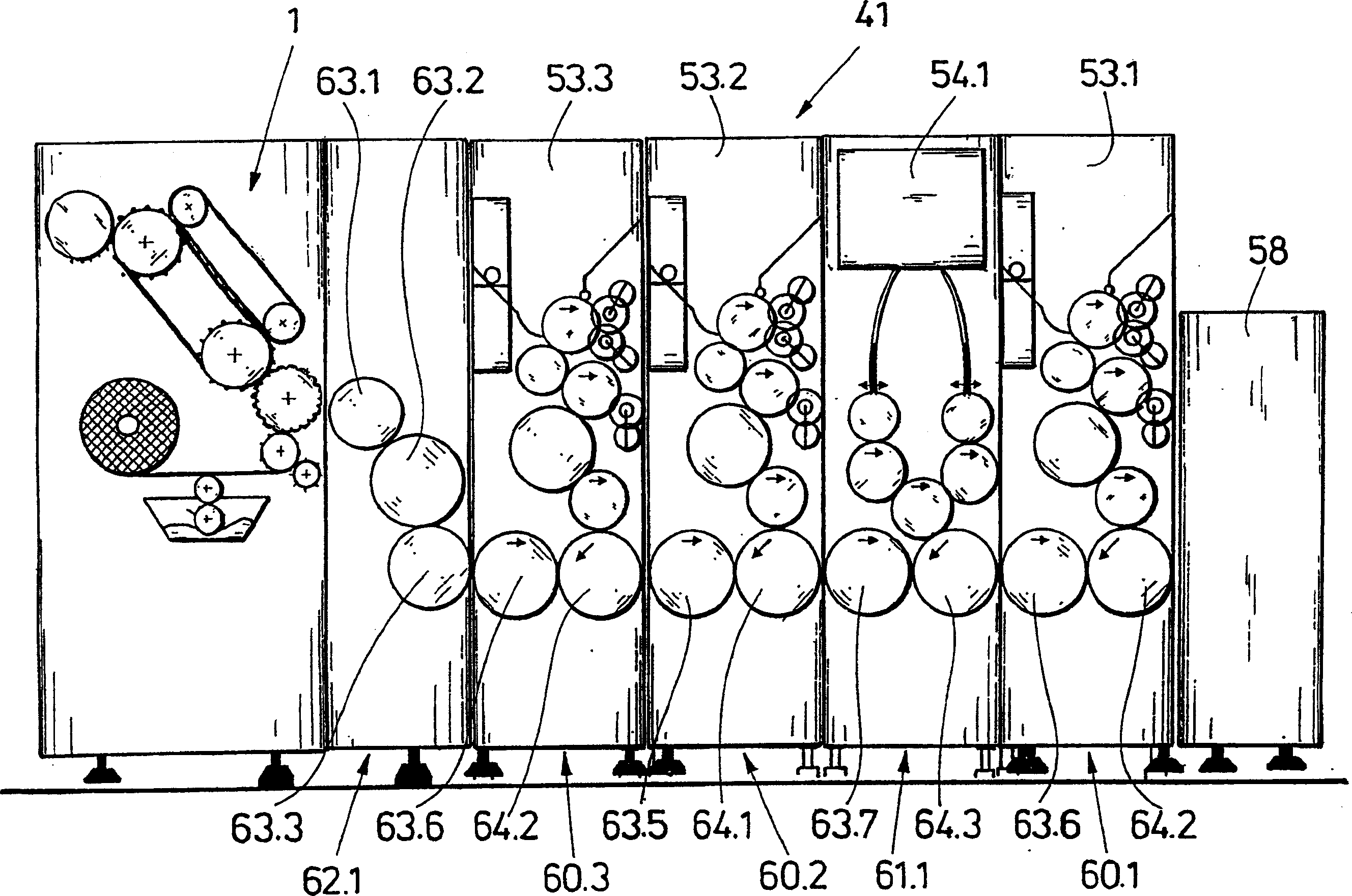

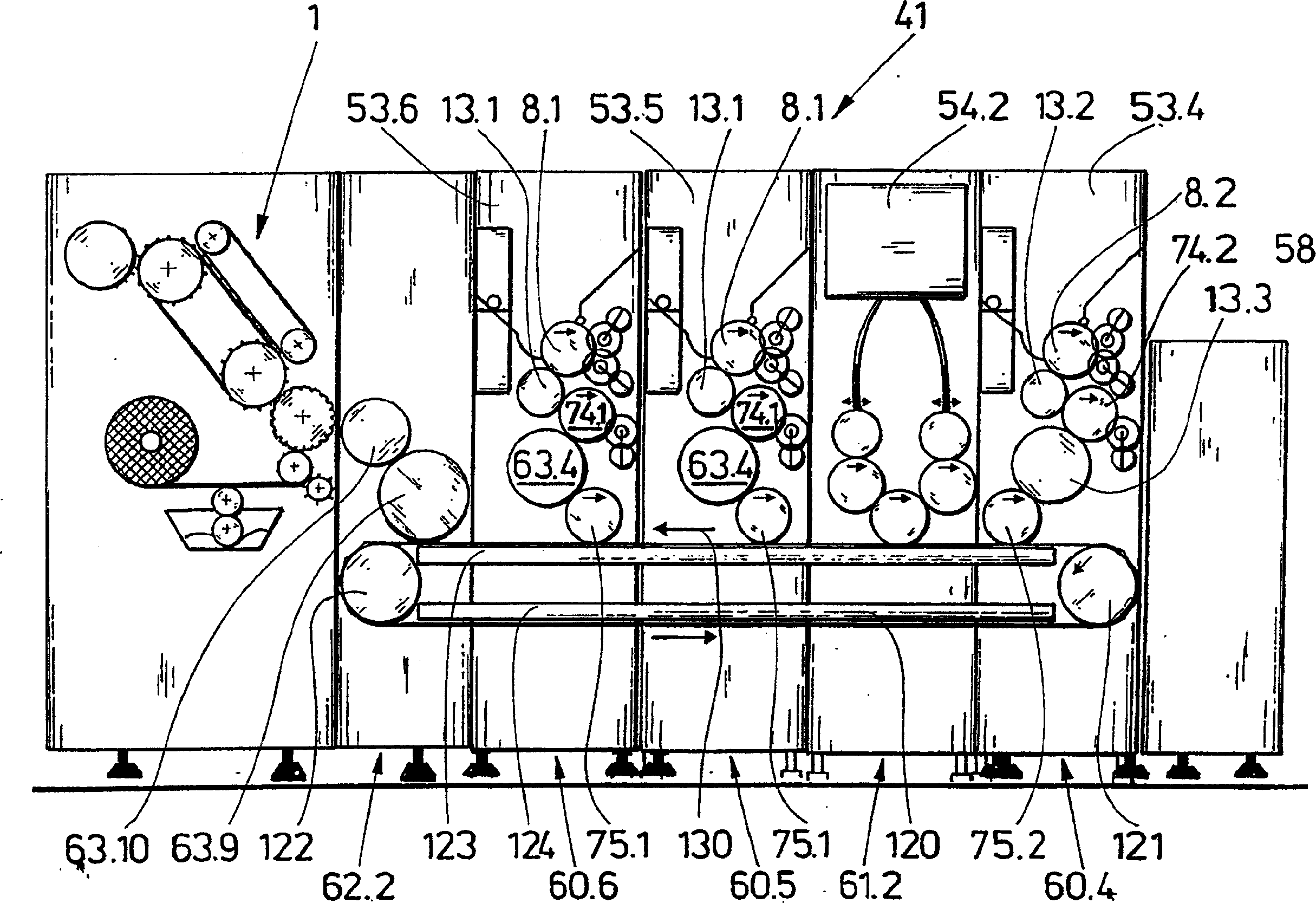

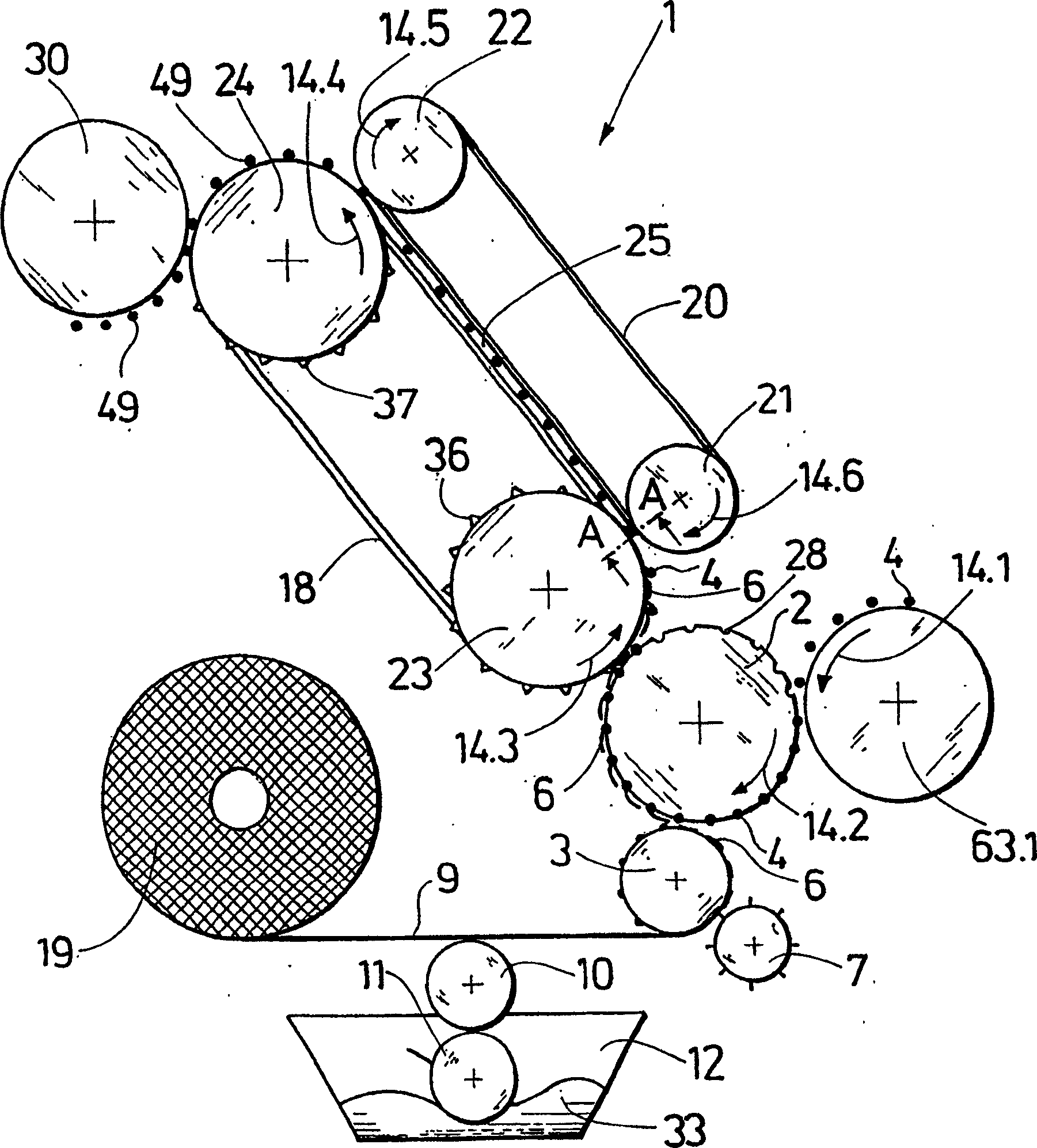

Device for wrapping groups of filter segments with a wrapping material for producing multi-segment filters of the tobacco industry and multi-segment filter production device

InactiveCN1582121AClear starting positionSimple and reliable playCigarette manufactureTobacco smoke filtersEngineeringMulti segment

The invention relates to a device for wrapping groups (4) of filter segments (5.1-5.7, 83, 87) with a wrapping material (9) for producing multi-segment filters (49) of the tobacco industry, comprising a rolling channel (25) for wrapping by rolling the groups (4) with the wrapping material (9). The invention further relates to a multi-segment filter production device. According to the invention, the rolling channel (25) is formed by adjacent ends of at least one first and at least one second tape (18, 20). The inventive multi-segment filter production device comprises one of the above-mentioned devices for wrapping groups of filter segments (5.1-5.7, 83, 87) with a wrapping material and a transfer device (62.1, 62.2) for transferring groups (4) of filter segments (5.1-5.7, 83, 87) from a filter segment group combination device (41).

Owner:HAUNI MASCHINENBAU AG

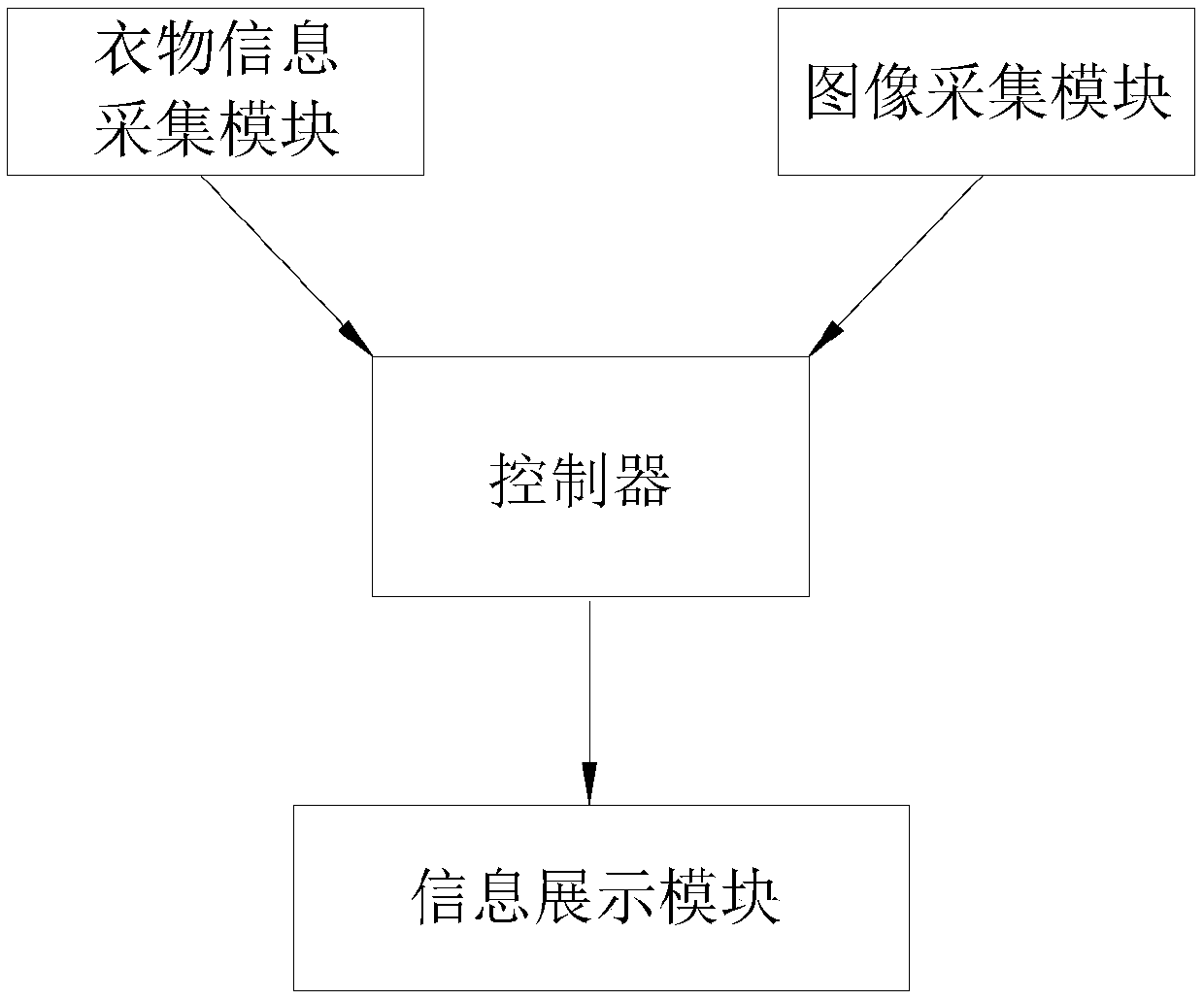

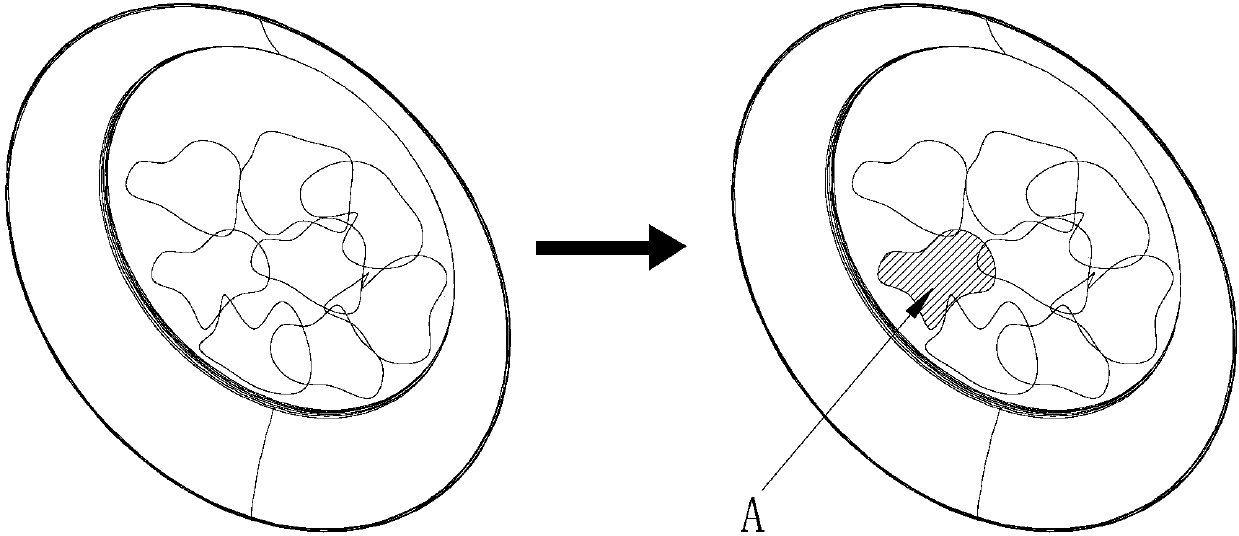

Washing machine clothing identification reminding system and reminding method

ActiveCN109594300AEasy to take outTake out accuratelyOther washing machinesControl devices for washing apparatusComputer moduleEngineering

The invention discloses a washing machine clothing identification reminding system and reminding method. The system comprises a controller, a clothing information collecting module and a clothing position indicating unit connected with the controller, wherein the clothing information collecting module collects clothing information and transmits the clothing information to the controller; the controller processes and analyses the clothing information and determines the clothing position; the clothing position indicating unit receives the clothing position information sent by the controller, andindicates the position of the clothing in the washing machine. The system further comprises an image acquiring module; an image acquired by the image acquiring module is transmitted to the controller, processed and analyzed by the controller, the position of the clothing in the image is obtained according to the clothing information collected by the clothing information collecting module, and theposition is marked and sent to the clothing position indicating unit. The system facilitates a user to accurately take out clothes which are not suitable for shuffling or misplacement from the washing machine, so that the probability of accidentally taking the clothes is reduced, the washing efficiency is relatively improved, and the user experience is enhanced.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

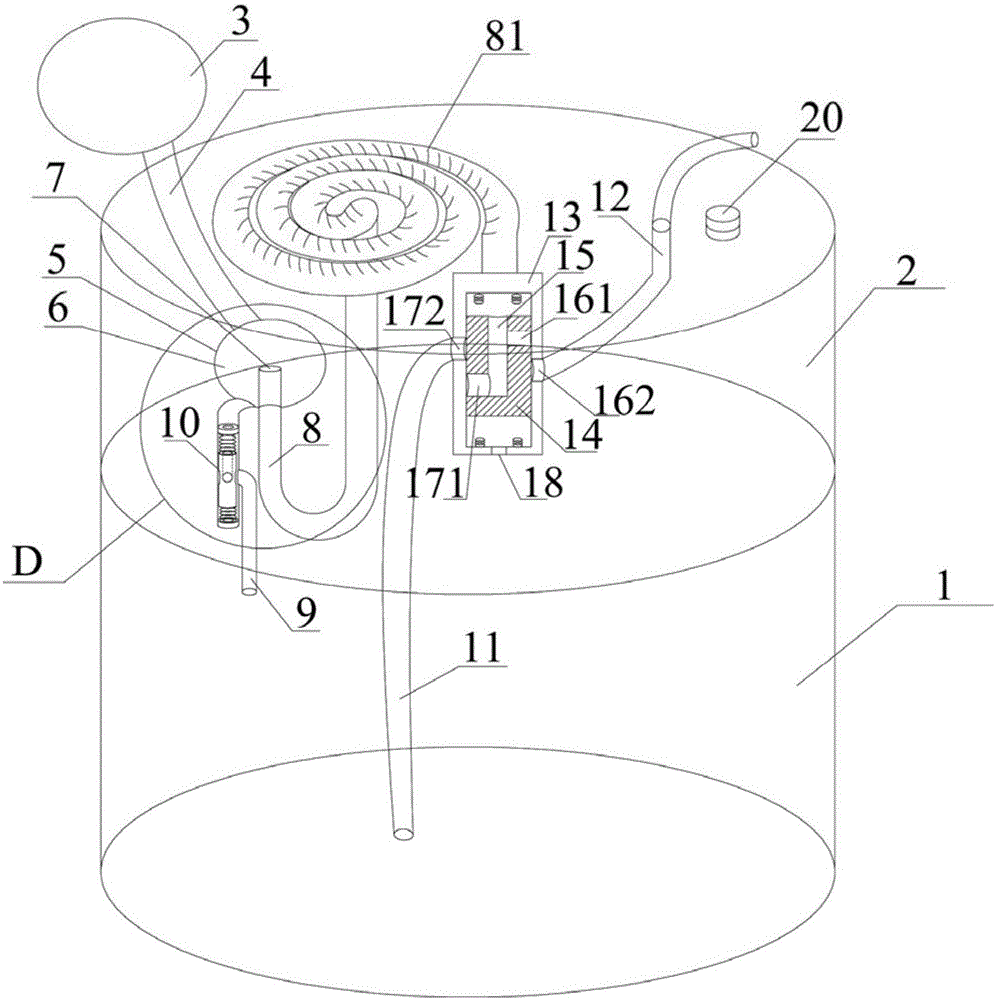

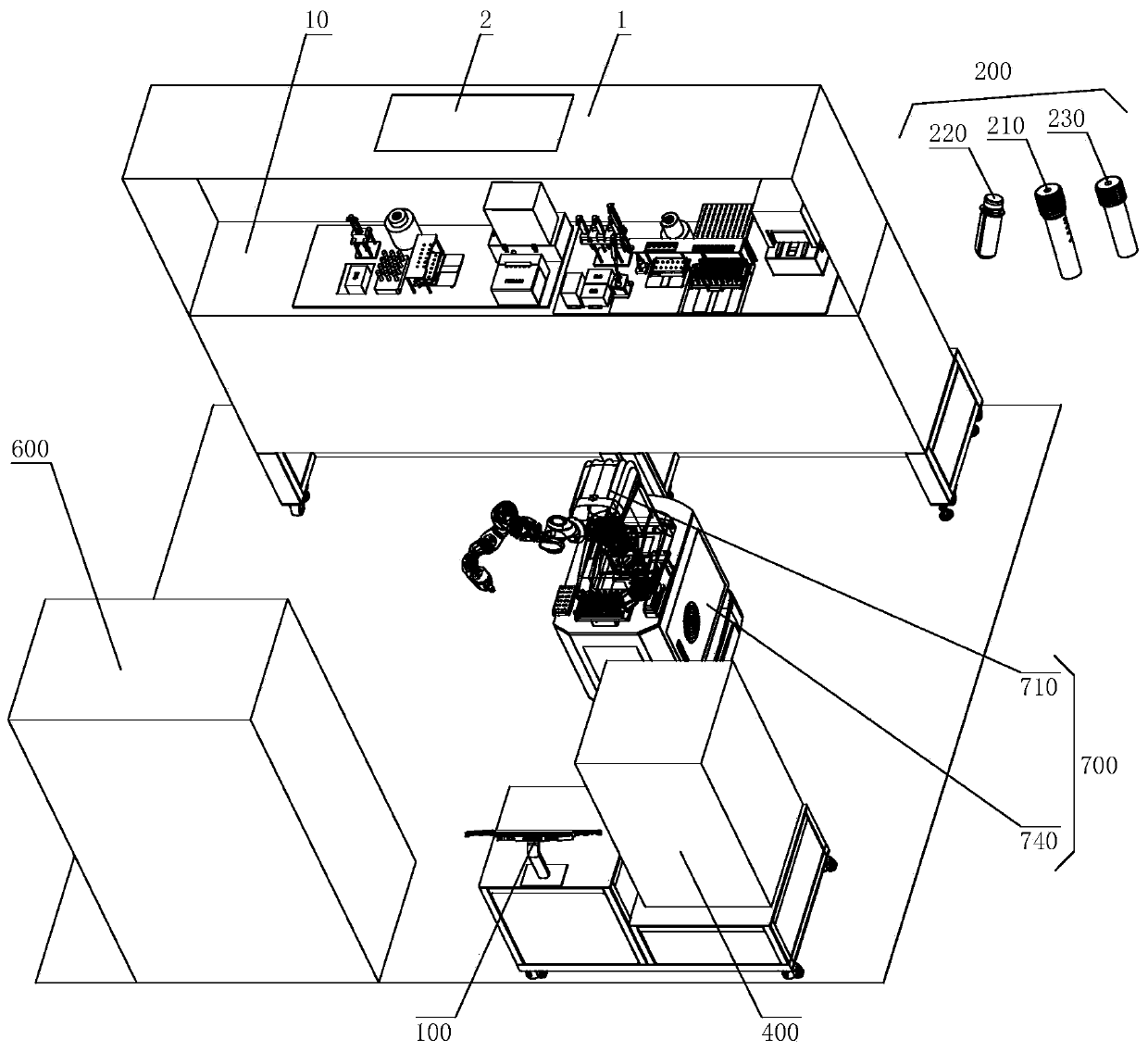

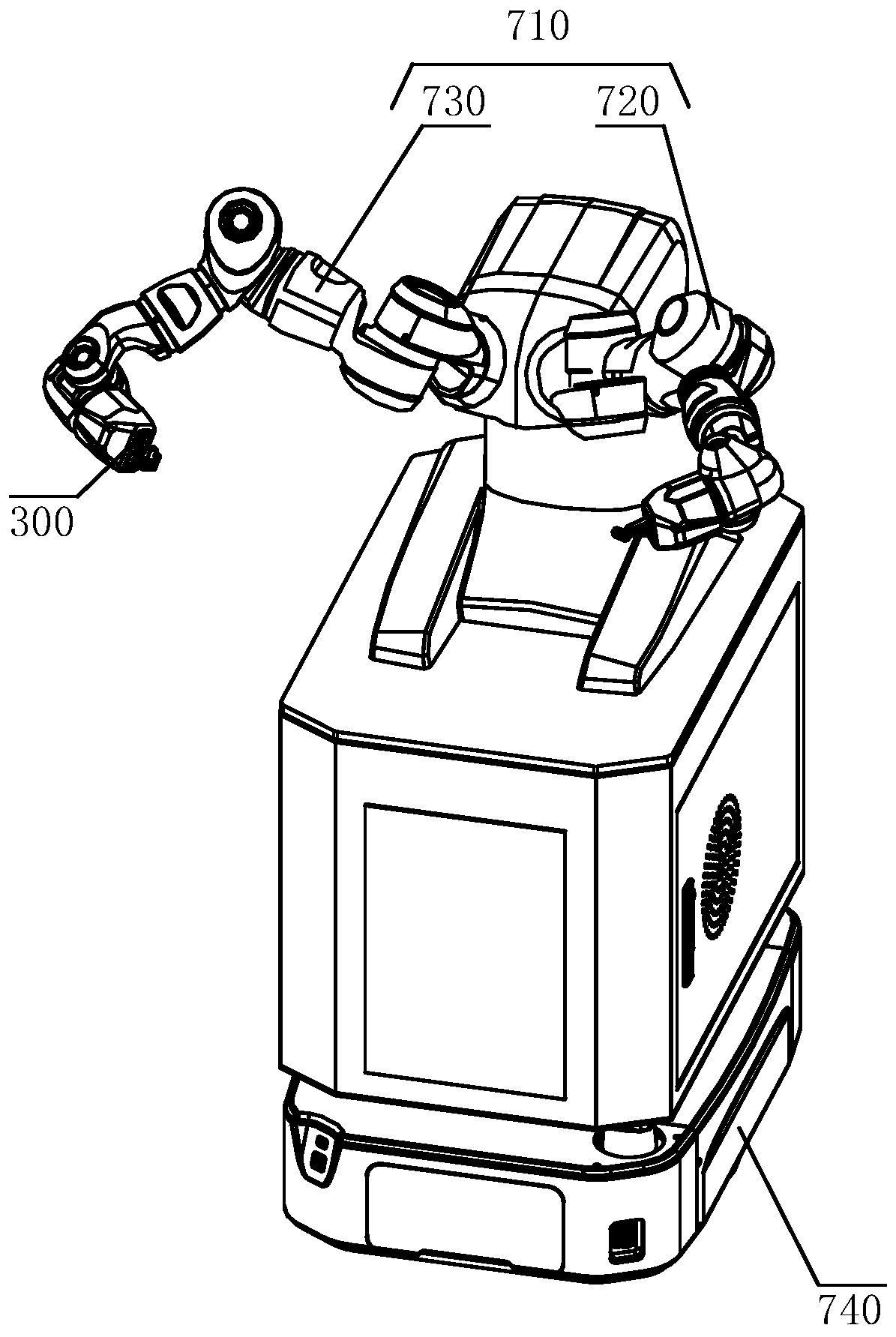

Gene detection system

PendingCN111575172ASave human resourcesReduce testing costsBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyHazardous substance

The invention relates to the technical field of gene detection, and discloses a gene detection system. The gene detection system comprises a control unit, a reagent consumable unit, a label identification unit, a constant-temperature storage unit, a cabinet body, an efficient filtering unit, a gene detection device and a turnover unit; the cabinet body is provided with an air inlet and an air outlet, wherein an operating table for placing operating instruments is arranged in the cabinet body; and the air outlet of the cabinet body is filled with the efficient filtering unit. According to the gene detection system, a pipetting assembly and other devices are integrated on the operation table in the cabinet body, the steps of liquid moving and taking and the like are carried out on the operation table, and harmful substances generated in the experiment process are filtered out through the efficient filtering unit, so that reagents can be prevented from being polluted by pollutants in theenvironment, and pollution of reagents related to biological hazards to the environment can also be avoided.

Owner:上海宏滩生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com