Initial positioning device, container and method

An initial positioning, container technology, applied in containers, rigid containers, dispensing devices, etc., can solve problems such as damage to transformer components, contamination of liquids, and the widespread application of containers that hinder the self-metering function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

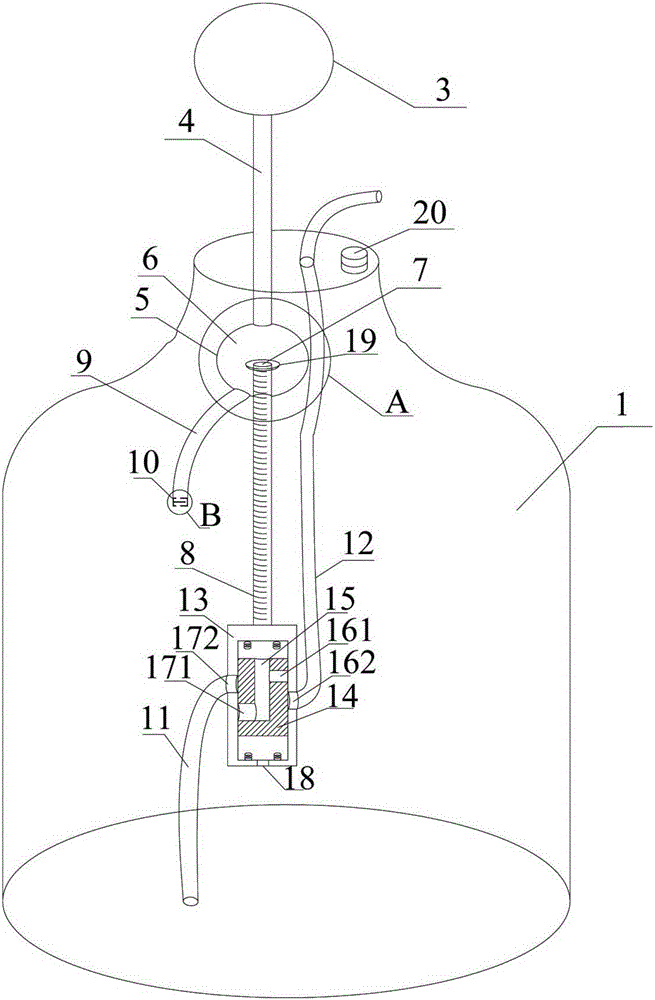

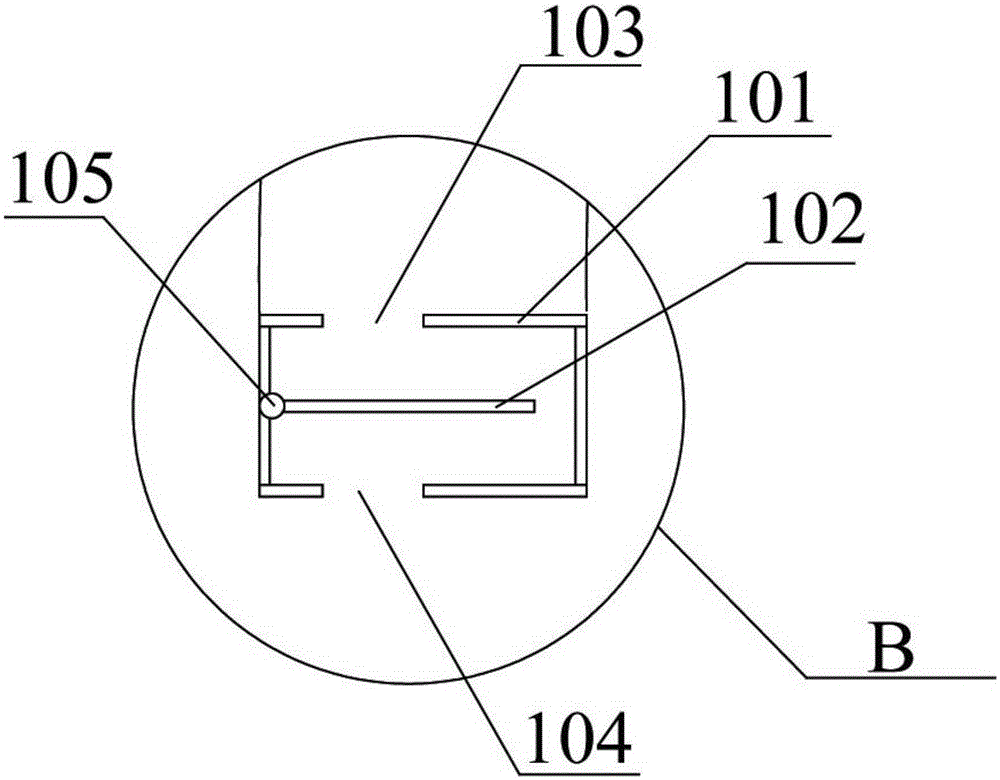

[0054] Such as figure 1 , figure 2 and image 3 Shown is a container using the initial positioning system of the present invention according to Embodiment 1. The container includes a container main body 1 with a filling opening on the top of the container main body 1, and the filling opening is sealed with a check valve 20 after filling the contents. The one-way valve 20 only allows gas to enter the interior of the container body 1 . Openings of the outflow channel 12 and the pressure changing channel 4 are reserved on the top of the container body 1 .

[0055] The pressure changing component is a component capable of pressurizing and depressurizing the return chamber 6 , including the air bag 3 and the pressure changing channel 4 . The pressure changing channel 4 passes through the top of the container body 1 and communicates with the return cavity 6 surrounded by the shell 5 . The initial end 7 of the metering channel 8 extends into the interior of the return chamber 6...

Embodiment 2

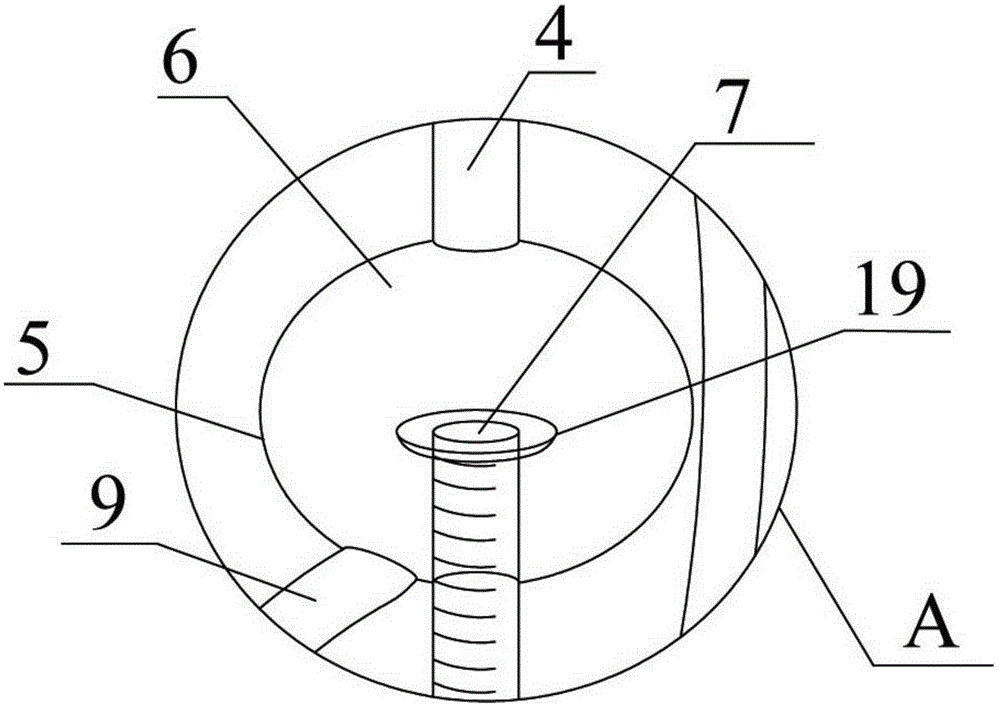

[0072] Such as Figure 4 , Figure 5 Shown is a kind of container according to embodiment 2. The container includes a container main body 1, a pressure changing component composed of an air bag 3 and a pressure changing channel 4, a recovery chamber 6 surrounded by a cavity wall 5, a metering channel 8 located above the container main body 1, side walls and bottom, and an outflow channel 12 , including the return channel 9 of two reverse series one-way valves and other components.

[0073] Specifically, the return chamber 6 communicates with the pressure-transforming passage 4, the return passage 9, and the metering passage 8. The initial end 7 of the metering passage 8 extends into the return chamber 6, and a spherical device 19 is suspended above it. When the content enters the return cavity 6 from the initial end of the metering channel 8, the spherical device 19 can amplify the signal of the content entering the return cavity 6, which is convenient for the operator to ob...

Embodiment 3

[0084] Such as Figure 6 and Figure 7 Shown is a container using the initial positioning system of the present invention according to Embodiment 3. The container as a whole includes a container main body 1 and a top cover 2 , and the upper part of the container main body 1 is the top cover 2 . The container body 1 holds most of the contents. Other components including pressure changing parts, initial positioning device, metering channel 8, liquid taking channel 11, outflow channel 12 valves, etc. are all installed on the top cover. The top cover 2 also has a one-way valve 20, and the one-way valve 20 only allows liquid and gas to enter the interior of the container body 1.

[0085] The pressure changing component is a component capable of pressurizing and depressurizing the return chamber 6 , including the air bag 3 and the pressure changing channel 4 . The air bag 3 is located above the top cover 2 and is fixed on the top cover 2 through the pressure changing channel 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com